1. Introduction

Agricultural machinery plays a pivotal role in modern crop production, with its efficiency and reliability directly dependent on the accurate characterization of agricultural materials. The design of operating procedures, structural components, and control systems for such machinery requires comprehensive data on the physical and mechanical properties of the materials they handle—particularly seeds, which are critical for seeding precision and crop establishment [

1]. Among these properties, geometric dimensions, weight, moisture content, and tribological characteristics (e.g., friction angles) are fundamental as they govern seed flowability, handling behavior, and interactions with machine components. For small-seeded vegetables, which are widely cultivated in tropical regions such as Hainan, China, understanding these properties is especially crucial due to their unique challenges in seeding (e.g., uneven distribution, blockages) and the lack of targeted data for local varieties.

Existing research has highlighted the significance of the physical properties of seeds in agricultural engineering. Studies on crop seeds such as corn, rice, and flax have demonstrated that triaxial dimensions inform the design of seed meter holes [

2], while thousand-grain weight and moisture content influence seeding rate calibration and storage stability [

3]. Tribological properties, including sliding friction angles and natural repose angles, are equally critical: they determine the optimal inclination of seed boxes, material selection for guide plates, and the prevention of seed aggregation during conveying [

4,

5]. Meanwhile, discrete element method (DEM) simulations, enabled by software such as Engineering Discrete Element Method (EDEM 2021), have emerged as a powerful tool to validate experimental results and predict granular behavior, reducing the need for extensive physical prototyping [

6,

7].

However, despite advancements in characterizing agricultural materials, research gaps remain. Most studies focus on major crops or temperate-region varieties, with limited systematic investigation into small-seeded vegetables specific to tropical areas like Hainan. Local varieties such as flowering Chinese cabbage, Chinese cabbage, lettuce, and leaf lettuce—each with multiple cultivars—exhibit distinct morphological and mechanical traits that may differ from their temperate counterparts, yet their properties are not well-documented. This lack of data hinders the development of region-specific agricultural machinery, such as seed rope braiding machines, which require precise parameterization to ensure reliable performance.

Against this backdrop, the present study aims to address this gap by systematically investigating the material properties of 16 small-seeded vegetable varieties commonly grown in Hainan. Specifically, we measured key physical parameters (triaxial dimensions, thousand-grain weight, moisture content) and tribological properties (sliding friction angles on different materials, natural repose angles). We validated these measurements using DEM simulations and assessed seed germinability to support subsequent field applications.

The significance of this work lies in its provision of region-specific, comprehensive data for optimizing agricultural machinery design—particularly for seed-handling components. The closer they are to a sphere, the better their fluidity, making it easier to separate and count them during the sowing process, thus facilitating single-seed sowing. This study contributes to the advancement of precision seeding technology in tropical vegetable production by identifying differences in properties between near-spherical (flowering Chinese cabbage, Chinese cabbage) and long–flat (lettuce, leaf lettuce) seeds, determining optimal contact materials (e.g., plastic plates for minimal friction), confirming the reliability of DEM simulations, and selecting high-germinability varieties.

In summary, this research bridges the gap between material characterization and machinery innovation, offering actionable insights for engineers and agronomists alike. It is also of great significance for sustainable seeding in agriculture.

2. Materials and Methods

This study used several small vegetable seeds commonly grown in Hainan, including flowering Chinese cabbage (

Brassica campestris L. ssp.

Chinensis var.

utilis Tsen et Lee), Chinese cabbage (

Brassica rapa L. ssp.

pekinensis, AA), lettuce (

Lactuca sativa), and leaf lettuce (

Lactuca sativa L.). Four varieties were selected for each leafy vegetable, totaling 16 varieties: Hong Kong flowering Chinese cabbage, Huifeng No.2 pointed-leaf flowering Chinese cabbage, Lüxiu four-season pointed-leaf oil-green flowering Chinese cabbage, Zhenbao flowering Chinese cabbage, Lifeng No.3 Chinese cabbage, Express Train No.5 Chinese cabbage, Zaohuangjing Chinese cabbage, Huangjing Chinese cabbage No.1, Danish four-season lettuce, Xindali No.2 lettuce, Huayu heading lettuce, Italian year-round bolting-resistant lettuce, spotless super fragrant leaf lettuce, Qingxiang sweet and crisp leaf lettuce king, four-season sweet pointed leaf lettuce, and fast-growing sweet red leaf lettuce (

Table 1 and

Figure 1).

Equipment used to measure the basic physical parameters of seeds included a digital vernier caliper (Deli, Ningbo, China; accuracy 0.01 mm), an electronic balance (LICHEN, Shanghai, China; accuracy 0.001 g), a constant-temperature oven (Shangyi, Shanghai, China.), and aluminum boxes. The vernier caliper was used to measure the triaxial dimensions of the seeds, the electronic balance (LICHEN, Shanghai, China; accuracy 0.001 g) for measuring 1000-grain weight, and the oven and aluminum boxes for determining seed moisture content.

Equipment for measuring the tribological properties of seeds included a self-made sliding friction angle tester, G-clamps, stirring rods, glass funnels, iron tripods, glass Petri dishes, aluminum profiles, and stainless steel, acrylic, and plastic plates. The injection method was selected to measure the angle of repose of the seeds, and a testing device to measure the natural angle of repose was designed and built according to test requirements. The basic parameters of the main self-developed equipment are shown in

Table 2.

The main self-developed equipment is shown in

Figure 2.

3. Results

3.1. Determination of Basic Physical Parameters of Vegetable Seeds

The physical parameters of seeds are crucial at every stage of the sowing process. Therefore, studying the properties of bulk seed materials can provide important data support for the design and research of seeders and related components.

3.1.1. Geometric Properties of Vegetable Seeds

The triaxial dimensions of vegetable seeds can represent their shape and size, making them key data for designing the hole size of seed meters, affecting the filling and flow performance of seeds in the seed meter, and also serving as a reference for designing the air chamber and structure of seed boxes.

In the test design, 100 seeds were randomly selected from each vegetable variety, and their length, width, and thickness were measured and recorded using a digital vernier caliper (Deli, Ningbo, China; accuracy 0.01 mm). Statistical data were calculated and analyzed using SPSS 22 software.

The statistical results of the seed triaxial dimension measurements are shown in

Figure 3. Overall, the triaxial dimensions of flowering Chinese cabbage and Chinese cabbage seeds are similar, and both close to spherical; the triaxial dimensions of lettuce and leaf lettuce seeds are also similar, with long length, moderate width, and small thickness, and both showing a long and flat shape. Among the nearly spherical seeds, flowering Chinese cabbage seeds have a higher roundness than Chinese cabbage seeds, while the four varieties of Chinese cabbage seeds show significant differences in length, width, and thickness, with irregular and less rounded shapes. Among the long and flat seeds, there are slight differences in size ratios between different varieties of lettuce and leaf lettuce seeds; for example, the total length of Xindali No.2 lettuce and four-season sweet pointed leaf lettuce exceeds 4 mm, which is significantly longer than that of other varieties.

3.1.2. Thousand-Grain Weight of Vegetable Seeds

The 1000-grain weight of seeds can provide a reference for the seeding rate of seeders and is an important basis for designing the size of seed boxes. For each variety, three groups of seeds were randomly selected, with 1000 seeds in each group. Measurements were taken using an electronic balance (LICHEN, Shanghai, China; accuracy 0.001 g) with an accuracy of 0.001 g, and the average value was calculated according to Formula (1).

The calculation results of seed 1000-grain weight are shown in

Table 3. The 1000-grain weight of flowering Chinese cabbage seeds ranges from 2.35 g to 2.53 g, that of Chinese cabbage seeds from 2.27 g to 3.06 g, that of lettuce seeds approximately from 1.05 g to 1.29 g, and that of leaf lettuce seeds from approximately 1.00 g to 1.13 g. From the data range, the 1000-grain weight of nearly spherical seeds is significantly larger than that of long and flat seeds. Among the nearly spherical seeds, the 1000-grain weight of Chinese cabbage seeds is slightly larger than that of flowering Chinese cabbage seeds, with Lifeng No.3 Chinese cabbage seeds having the largest 1000-grain weight of 3.06 g, which is significantly different from other Chinese cabbage varieties. The differences in 1000-grain weight among long and flat lettuce and leaf lettuce varieties are small.

3.1.3. Moisture Content of Vegetable Seeds

The moisture content of seeds affects their processing, packaging, and storage, and is also a key factor affecting rates of seed germination and emergence. Determining seed moisture content is of great significance for seed-related tests.

In line with the “Rules for Agricultural Seed Testing—Moisture Determination” (GB/T3543.6-1995 [

8]), the low-temperature constant drying method was used in the test. Since the particle size of the test seeds is less than 5 mm, 5 g of seeds were randomly weighed from each variety, ground into a powder, and placed in an aluminum box. The weight of the sample box with its lid and the sample was recorded. The oven was set to a constant temperature of 103 °C, and the seeds were dried at a constant temperature for 8 h before being weighed again until the weight no longer changed. The final weight of the sample box with its lid and the dried sample was recorded, and the moisture content was calculated according to Formula (2).

The moisture content of seeds is expressed using wet-based moisture content

Mw, calculated as follows:

where

M1—mass of the sample box with its lid;

M2—mass of the sample box with its lid and the sample before drying; and

M3—mass of the sample box with its lid and the sample after drying.

The statistical results of seed moisture content are shown in

Table 4. The moisture content of most seeds used in the test ranges from 7% to 9%. The seeds with the highest and lowest moisture contents are both lettuce seeds: the highest is Huayu heading lettuce, with a moisture content of 8.63%, and the lowest is Danish four-season lettuce, with a moisture content of 6.47%.

3.2. Determination of Tribological Properties of Vegetable Seeds

Tribological properties are an important research direction for understanding the physical properties of seeds. Studying these properties helps improve seed performance and serves as a basis for designing agricultural machinery and components such as seed meters and seeders. Tests measured the sliding friction angle and natural repose angle of small vegetable seeds. Based on the appearance of the test varieties, they were divided into two categories: nearly spherical seeds (flowering Chinese cabbage and Chinese cabbage) and long and flat seeds (lettuce and leaf lettuce).

3.2.1. Sliding Friction Angle of Vegetable Seeds

The sliding friction angle represents the tribological relationship between bulk materials and contact solids when they slide relative to each other. It is an important parameter for judging the scattering performance of seeds in seed boxes, providing a basis for force analysis during seeding, and is of great reference significance for the structural design and material selection of seed meter boxes and seed guide tubes.

A self-developed sliding friction angle measuring instrument was used in the test. The test factors included 16 different seed varieties and three different contact materials: stainless steel plates, acrylic plates, and PVC plastic plates. An amount of 10 g of seeds was weighed for each variety. During the test, the seeds were placed on the bottom plate of the tester, and the handle was shaken slowly to tilt the plate. When more than 90% of the seeds began to slide, the angle between the bottom plate and the horizontal plane was measured as the sliding friction angle. Since the bottom plate of the self-made sliding friction angle measuring instrument is fixed as a stainless steel plate, G-clamps were used to fix the acrylic plate and PVC plastic plate during their measurement, and seeds of different varieties were measured and recorded in sequence. The surface of the PVC plastic board is smooth, and the flowability of the seed group is better. The seed group is not easily arched and lifted, so compared to other materials, the angle of inclination on the side of the plastic seed box does not need to be very large, which can accommodate more seeds. The measurement results of the sliding friction angle are shown in

Table 5.

Table 6 shows the results of one-way ANOVA for the sliding friction angle of vegetable seeds. The results show that except for the sliding friction angle between Chinese cabbage seeds and acrylic, where the significance

p > 0.05 (no significant difference), the significance

p of the sliding friction angle between all other seeds and the three contact materials is <0.05. Therefore, there are significant differences in the sliding friction angle with the same contact material among most of the seed varieties.

A comparison chart of the sliding friction angles of different varieties of seeds is shown in

Figure 4. One-way ANOVA was performed on different varieties of the same vegetable with the three contact materials, and the statistical results indicate significant differences in the sliding friction angles between different vegetable varieties and the same contact material. It can be intuitively seen from the chart that the sliding friction angle between acrylic and seeds of nine varieties is relatively large, making it less suitable for use as a seed box guide plate. Compared with stainless steel plates and PVC plastic plates, 11 varieties of seeds have a larger sliding friction angle with stainless steel plates, while only 5 varieties have a larger sliding friction angle with PVC plastic plates.

In the design and production of seeding machinery, seeds with a larger sliding friction coefficient require a larger inclination angle for the seed box guide plate, and the angle of the hole position when the seed meter discharges seeds also increases accordingly. To ensure the adaptability and rationality of seeding, the sliding friction coefficient should be minimized during design and selection. Therefore, in the subsequent use of seed rope braiding machines, PVC plastic plates should be used for the pneumatic seed box guide plates, which conform to the tribological properties of most seeds, can better control seed discharge, and ensure the accuracy of seed rope braiding.

3.2.2. Natural Repose Angle of Vegetable Seeds

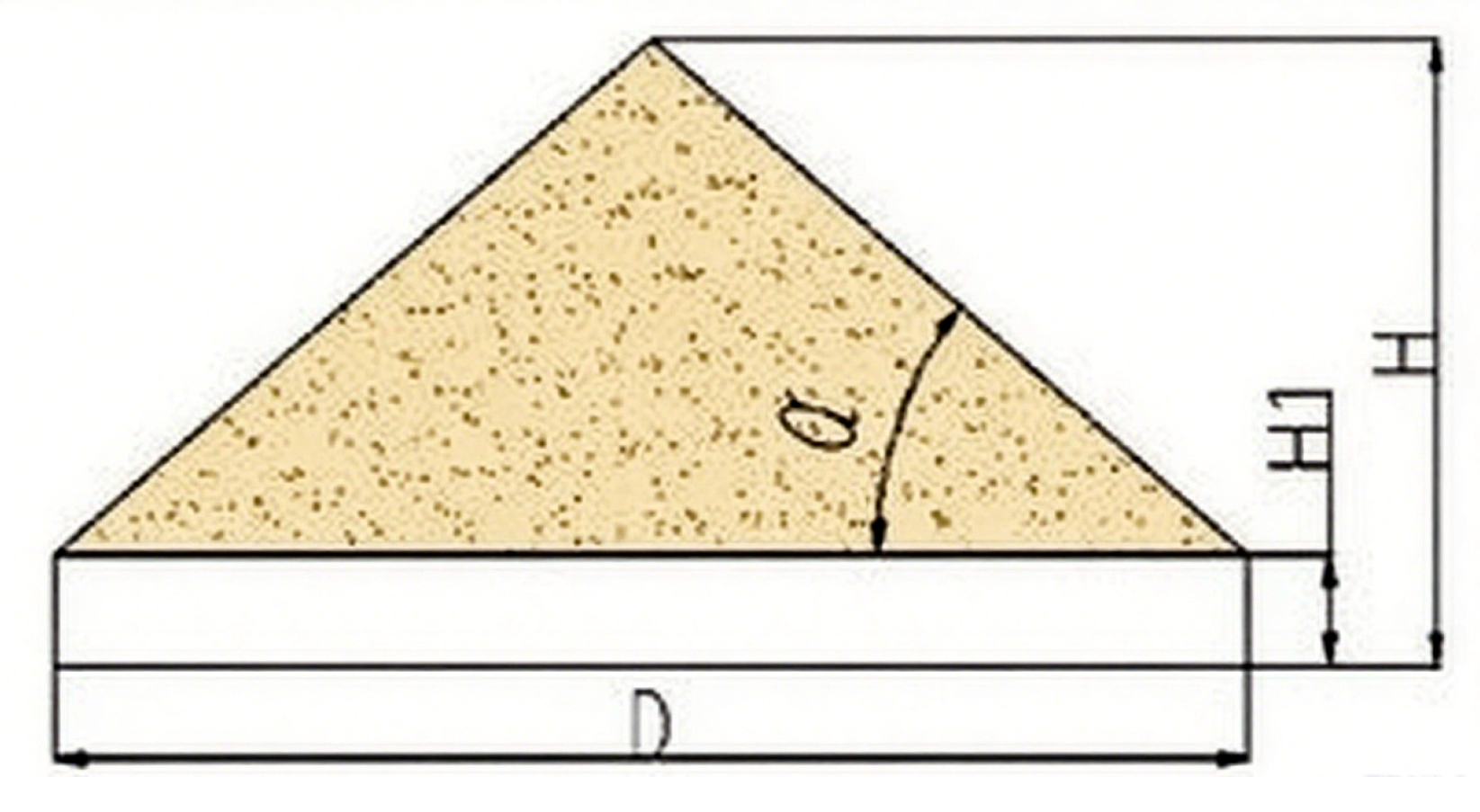

For agricultural bulk materials, the natural repose angle refers to the angle between the generatrix of the cone formed by the material continuously falling from a certain height onto a plane and the bottom plane. In each measurement, a glass Petri dish was used as the substrate to ensure a smooth and uniform base, minimizing the influence of substrate effects on the seed pile morphology. It reflects the friction characteristics and scattering performance of bulk materials: the larger the repose angle, the greater the internal friction of the material and the lower the scattering performance. The measurement of the repose angle can provide a basis for the shape design and selection of seed boxes. In this study, the injection method was selected to measure each variety, and the parameters and schematic diagram of the injection method are shown in

Figure 5.

To prevent the significant electrostatic adsorption of plastic from affecting the results, a glass funnel was used in the test. The glass funnel was fixed on a bracket at a certain height, the funnel outlet was blocked, 100 g of seeds was poured into the funnel, and the surface was leveled. Then, the blockage at the bottom outlet was removed, allowing the seeds to continuously fall from the top of the funnel onto the horizontal surface of a large-diameter glass Petri dish below the funnel, naturally forming a conical pile. The base angle of the cone is the repose angle α. By fixing the bottom diameter D and boundary height H1 of the Petri dish, only the height H of the seed pile needs to be measured to calculate the repose angle α using Formula (3).

The natural repose angle data of each variety of seeds measured in the test are shown in

Table 7.

Figure 6 is a comparison chart of the natural repose angles of four types of leafy vegetable seeds. Overall, the natural repose angles of nearly spherical flowering Chinese cabbage and Chinese cabbage seeds are much smaller than those of long and flat lettuce and leaf lettuce seeds, indicating that lettuce and leaf lettuce seeds have greater internal friction but poorer scattering performance than flowering Chinese cabbage and Chinese cabbage seeds.

3.3. Discrete Element Simulation of Tribological Properties of Vegetable Seeds

3.3.1. Discrete Element Method and EDEM 2021 Software

The discrete element method (DEM) is a numerical simulation technology used to study and simulate the mechanical behavior and dynamic characteristics of granular materials (such as rocks, sand, and grains) [

9,

10,

11]. This method simulates the interaction between particles and their influence on overall behavior by calculating parameters such as the position, velocity, and force of each particle. EDEM 2021 is the world’s first general CAE software based on the advanced discrete element method (DEM). This software can simulate the dynamic movement of thousands or even millions of particles and support custom particle shapes, making it suitable for simulating and analyzing the behavior of granular materials in industrial production processes. By setting simulation parameters, running simulations, and analyzing results, it can provide strong support for designing and optimizing product equipment and production processes.

Shi L et al. used DEM to study the influence of irregular corn on the performance of high-grouting-rate seed testing devices [

12,

13]. Zeng Y conducted a numerical simulation of the discharge of a three-dimensional conical silo using the discrete element method, quantitatively analyzed the velocity fluctuations and total force fluctuations in the initial stage of discharge, and studied the relationship between velocity fluctuations and the disappearance of contact forces [

14]. Zeng Y also used the discrete element method to numerically simulate the movement of spherical particles in a horizontal rice mill under different static friction coefficients (i.e., the friction coefficient between particles and the screen wall and between particles), clarifying the influence of rice surface roughness on the milling process and its mechanism [

15]. Ji, Y.J. et al. explores how particle friction properties influence horizontal rice milling, analyzing their impact on rice movement, breakage, whitening, efficiency, quality, and energy consumption through experiments and simulations like the discrete element method [

16]. It offers theoretical and practical insights for optimizing mill design, process parameters, and rice processing performance, with value for understanding grain processing dynamics and improving milling equipment. Wang, M. et al. compared the test results of the repose angle with the simulation results based on the seeding and filling process of EDEM 2021, and analyzed the velocity and force of particles during seeding using EDEM 2021, providing a theoretical basis for optimizing the structure and parameters of sugarcane billet machines [

17]. Zhang, W.X. used a combination of physical and discrete element simulation tests to calibrate various parameters of American ginseng seeds, determined the optimal combination of simulation parameters, and provided a basis for the design and performance optimization of subsequent American ginseng seed metering devices [

18].

3.3.2. Establishment of Vegetable Seed Particle Models

Based on the measurement results of the triaxial dimensions of the test seeds, flowering Chinese cabbage and Chinese cabbage seeds were classified as spherical particles, and spherical particle models were directly established in EDEM 2021 software. For lettuce and leaf lettuce seeds, 3D geometric models of long and flat seeds were first created in SolidWorks 2022 software and then imported into EDEM 2021 software as the boundary of particle models, with multiple particles selected for shape filling. The two particle models are shown in

Figure 7.

3.3.3. Simulation and Result Analysis of Sliding Friction Angle

A basic model of the sliding friction angle measuring instrument was established using SolidWorks software. After establishing the seed particle model, it was imported into EDEM 2021 software in STL format. The material parameters were set for the three materials selected for the bottom plate of the instrument, namely the stainless steel, acrylic, and plastic plates, including the coefficient of restitution, the static friction coefficient, and the rolling friction coefficient [

12,

19]. The main simulation parameters are shown in

Table 8.

The process of determining the sliding friction angle of vegetable seeds using simulation was carried out as follows: First, a cubic virtual particle factory was established at an appropriate position on the right side of the bottom plate of the instrument model to generate seed particles in an orderly manner [

20,

21,

22,

23,

24]. Then, the movement trajectory of the plate was added. To measure the sliding friction angle, a rotation speed of 9 deg/s was applied to the right side of the movable bottom plate to slowly raise it. After establishing the particle factory and the movement of the bottom plate, the simulation was run, allowing the seed particles to slide downward from the right plate under the action of gravitational acceleration. The simulation model and process of seed sliding friction angle determination are shown in

Figure 8.

The simulation results of Lüxiu four-season pointed-leaf oil-green flowering Chinese cabbage seeds were post-processed, and the angle between the bottom plate and the base was measured, as shown in

Figure 9. The measured sliding friction angle of the seeds was 16.24°, while the actual measurement result was 17.33°, the range of error variation is less than 7%. The EDEM 2021 simulation results and the actual measurement results of the seed sliding friction angle were mutually verified.

3.3.4. Simulation and Result Analysis of Natural Repose Angle

Particle–particle and particle–surface interactions are core factors influencing the simulation of angles of repose. Sliding and rolling friction between particles determines the resistance to their relative movement: higher friction coefficients make particles less likely to slide or roll, leading to steeper angles when piled up. Additionally, the interlocking effect of particle shapes (such as the uneven structures of non-spherical particles) further enhances this resistance, improving the stability of the pile. Meanwhile, the frictional interaction between particles and container surfaces is also crucial: higher particle–wall friction restricts the sliding of particles along the wall, causing particles at the edges to pile up more steeply and increasing the overall angle of repose; conversely, lower wall friction allows particles to spread more easily, resulting in a smaller angle. These interactions collectively balance the downward movement tendency of particles caused by gravity and the resistance generated by friction. Discrepancies between the parameter settings and reality (such as inaccurate friction coefficients or excessive simplification of shapes) will directly lead to differences between the simulated angle of repose and the measured value.

A basic model of the natural repose angle measuring instrument was established using SolidWorks software. After establishing the seed particle model, it was imported into EDEM 2021 software in STL format. The material parameters of the contact materials, namely the glass funnel and glass Petri dish, were set, including the coefficient of restitution, static friction coefficient, and rolling friction coefficient. The main simulation parameters are shown in

Table 9.

The process of determining the natural repose angle of vegetable seeds using a simulation is as follows: First, a conical virtual particle factory with a size not exceeding the inner diameter of the funnel is established at an appropriate position above the glass funnel. Then, a plane is added at the funnel outlet to ensure that particles were completely generated inside the funnel. Then, a translation trajectory and speed are added to the blocking plane at the outlet. After all seeds are generated, the plane is quickly moved away, allowing the seeds to fall through the funnel tube under the action of gravitational acceleration and accumulate in the glass Petri dish at the bottom. The simulation model and the process of determining the natural repose angle of small vegetable seeds are shown in

Figure 10.

The simulation results of Lüxiu four-season pointed-leaf oil-green flowering Chinese cabbage seeds were post-processed, and the angle between the seed pile and the bottom surface of the Petri dish was measured, as shown in

Figure 11. The measured natural repose angle of the seeds was 23.76°, while the actual measurement result was 26.62°,the range of error variation is less than 10%. The natural repose angle results obtained for the seeds through EDEM 2021 simulation and actual measurement were mutually verified.

The natural angle of repose is a useful foundational criterion for designing hoppers and preventing blockages in seeding equipment, providing a baseline for hopper wall inclination—typically, walls are angled steeper than the repose angle to ensure gravity-driven flow, which works well for free-flowing, uniform particles like dry, spherical seeds. However, its reliability is limited by context and material-specific factors: it is highly sensitive to particle size distribution, shape, moisture content, and other properties, and real-world changes (such as seeds absorbing moisture or containing debris) can make it inaccurate in reflecting flow resistance. Additionally, the dynamic conditions of seeding equipment (vibration, impact, varying feed rates) alter actual flow behavior, which static repose angles cannot fully capture. Thus, it must be combined with dynamic flow tests, measurements of internal friction/cohesion, and considerations of operational variables to reliably guide design.

3.4. Test of Vegetable Seed Germinability

Test Materials and Methods

The test materials comprised four of each variety of flowering Chinese cabbage, Chinese cabbage, lettuce, and leaf lettuce seeds and one of each type of pelleted flowering Chinese cabbage, Chinese cabbage, lettuce, and leaf lettuce seed. A total of 50 seeds were randomly selected from each variety of vegetables, while only 10 pelleted vegetable seeds were selected due to their large particle size. The seeds were first disinfected with 75% absolute ethanol, rinsed repeatedly with distilled water 5–6 times until clean, and then placed in a cool and dry place for later use.

Petri dishes (85 mm in diameter) were cleaned, lined with two layers of filter paper, and moistened with distilled water. A total of 50 seeds were neatly placed in each Petri dish, while only 10 pelleted seeds were placed in each due to their large volume. A constant-temperature incubator was used for cultivation, with the temperature set to 20 °C. The number of germinated seeds was counted daily from 18:00 to 19:00, and the water level in the Petri dishes was checked, with distilled water added as appropriate. Seed germination was considered to occur when the radicle broke through the seed coat, and the test was considered complete when no seeds germinated for three consecutive days (

Figure 12).

The following are the indices to be determined: Germination potential (%) = (Total number of normally germinated seeds on the 3rd day/Number of tested seeds) × 100%; Germination rate (%) = (Total number of normally germinated seeds/Number of tested seeds) × 100%; Germination speed (%) = (Number of germinated seeds per day / Number of tested seeds) × 100%. Observations during the test showed that the particle size of pelleted seeds increased; their coating materials did not decompose easily without soil decomposition, and only when in contact with water at the bottom, making it difficult for water to reach the seeds. None of the pelleted seeds germinated after 7 days, so no relevant calculations were performed temporarily.

The limitations of pelleted seeds in germination include: the coating may form physical barriers, affecting embryo breakthrough and water absorption; poor air permeability can easily lead to oxygen deficiency; and sensitivity to temperature and humidity—under high or low temperatures, it may exacerbate difficulties in water and oxygen uptake or cause premature coating decomposition, resulting in uneven germination and low germination rates.

The results of seed germination potential and germination rate are shown in

Table 10. Among the selected vegetable seeds, the highest germination rate was 98% for Hong Kong flowering Chinese cabbage, Zhenbao flowering Chinese cabbage, and Lifeng No.3 Chinese cabbage; following this, the germination rates all exceeded 90% for Lüxiu four-season pointed-leaf oil-green flowering Chinese cabbage, Huangjing Chinese cabbage No.1, and four-season sweet pointed leaf lettuce. Danish four-season lettuce and Italian year-round bolting-resistant lettuce had the lowest germination rates, with neither exceeding 50%. The germination rates of the remaining varieties ranged from 60% to 90%. To reduce errors caused by large differences in seed germination rates in subsequent tests, seeds with a germination rate exceeding 90% are most suitable.

A visual comparison chart of the germination speed of different seeds is shown in

Figure 13. It can be seen that Lifeng No.3 Chinese cabbage, Zaohuangjing Chinese cabbage, Zhenbao flowering Chinese cabbage, and Hong Kong flowering Chinese cabbage have the fastest germination speeds, reaching the highest on the first day of the germination test. However, due to their high germination rates, the germination speeds of these four varieties began to drop rapidly from the second day of the test and gradually approached zero. From the chart, it can be seen that the germination speeds of several long and flat lettuce and leaf lettuce seeds began to increase in the middle and late stages of the test.

4. Discussion

The present study systematically investigated the physical and tribological properties of 16 small-seeded vegetable varieties from Hainan, aiming to provide foundational data for agricultural machinery design, particularly direct-seeding systems. The results can be contextualized within the existing literature and practical agricultural engineering frameworks, while their implications and future research directions merit further exploration.

From the perspective of physical properties, the distinct differences between near-spherical seeds (flowering Chinese cabbage, Chinese cabbage) and long–flat seeds (lettuce, leaf lettuce) align with prior observations on granular material behavior. Near-spherical seeds exhibited more uniform triaxial dimensions and higher 1000-grain weights (2.27–3.06 g) compared to long–flat seeds (1.00–1.29 g), consistent with studies by Zhang, W. et al., who reported that particle shape directly influences bulk density and flowability. The moisture content of most seeds (6.47–8.63%) falls within the typical range for stored vegetable seeds, suggesting these seeds are physiologically stable for processing and sowing—critical for maintaining germination consistency, as noted in seed storage research [

18].

Tribological properties, including sliding friction angles and natural repose angles, provide key insights for seeding machinery design. The finding that plastic plates minimized sliding friction (compared to stainless steel and acrylic) supports the hypothesis that low-friction materials enhance seed flowability, aligning with Shi Linrong et al.’s work on flax seeds, where contact material properties significantly affected friction behavior [

12,

13]. This outcome validates the practicality of plastic as a preferred material for seed box guides, reducing resistance during seed discharge and improving seeding precision—an essential consideration for optimizing seed rope braiding mechanisms.

Natural repose angles were larger for long–flat seeds (30.30–32.71°) than for near-spherical seeds (26.15–28.73°), indicating poorer scattering performance due to higher internal friction. This observation is consistent with research on granular material discharge, where larger repose angles correlate with reduced flowability, necessitating steeper inclinations in seed box design to prevent blockages. Such findings reinforce the role of repose angles as a critical parameter for shaping storage and conveying components in agricultural machinery.

The validation of discrete element method (DEM) simulations via EDEM 2021 software strengthens the reliability of numerical modeling in predicting seed behavior. The close agreement between simulated and measured sliding friction angles (e.g., 16.24° vs. 17.33° for Lüxiu flowering Chinese cabbage) mirrors the results presented by Wang, M. et al., who demonstrated that DEM effectively replicates granular dynamics in seeding processes [

17]. This confirms that DEM is a cost-effective tool for pre-optimizing machinery structures, reducing the need for extensive physical prototyping—particularly valuable for refining seed meter and guide plate designs.

Regarding germinability, the high germination rates (≥90%) of near-spherical seeds (e.g., Hong Kong flowering Chinese cabbage, Lifeng No.3 Chinese cabbage) and their rapid germination speeds highlight their suitability for consistent crop establishment, supporting their preference in subsequent field trials. In contrast, the failure of pelleted seeds to germinate underscores a practical challenge: the coating material’s poor water permeability under controlled conditions. This aligns with studies on seed pelleting, which emphasize that coating formulations must balance mechanical protection with access to moisture—especially critical for small-seeded crops.

The broader implications of this work are multifaceted. For the design of agricultural machinery, the identified optimal materials (e.g., plastic plates for low friction) and geometric parameters (e.g., triaxial dimensions for seed meter hole sizing) directly inform the customization of seed rope braiding machines, enhancing seeding accuracy and reducing material waste. For crop production, the germinability data guide variety selection, ensuring higher emergence rates and yield stability.

The limitations of the current study include the focus on 16 varieties under static laboratory conditions, which may restrict generalizability to other regions or dynamic seeding environments (e.g., vibration-induced seed flow). Future research could extend to (1) incorporating more diverse vegetable species and environmental variables (e.g., temperature, humidity) to broaden applicability; (2) investigating dynamic tribological behavior during seed discharge to simulate real-world machinery operation; (3) optimizing pelleting materials to improve water permeability for small seeds; and (4) integrating DEM with field trials to validate long-term machinery performance.

In summary, this study bridges physical property characterization, tribological analysis, and germinability testing, offering a holistic dataset for advancing small-seeded vegetable cultivation and machinery innovation. Its findings resonate with existing agricultural engineering principles while identifying actionable gaps for future exploration.

5. Conclusions

This study systematically characterized 16 small-seeded vegetable varieties from Hainan, yielding key insights into their physical, tribological, and germinability traits:

Physical Properties: Near-spherical seeds (flowering Chinese cabbage, Chinese cabbage) have larger 1000-grain weights (2.27–3.06 g) and more uniform triaxial dimensions compared to long–flat seeds (lettuce, leaf lettuce: 1.00–1.29 g), with moisture contents predominantly ranging from 6.47% to 8.63%.

Tribological Properties: Sliding friction angles vary with contact materials, with plastic plates minimizing friction (optimal for seed guides). Natural repose angles are larger for long–flat seeds (30.30–32.71°) than near-spherical seeds (26.15–28.73°), indicating poorer flowability.

DEM Validation: Simulations accurately replicated experimental tribological data, confirming the utility of EDEM 2021 for pre-optimizing seeding machinery.

Germinability: High-germination-rate seeds (≥90%), such as Hong Kong flowering Chinese cabbage and Lifeng No. 3 Chinese cabbage, are recommended for practical applications, while pelleted seed formulations require refinement.

These findings provide a scientific basis for designing efficient precision seeding equipment, particularly seed rope braiding machines, and guide future agricultural material research.

Author Contributions

Conceptualization, B.W.; methodology, J.D.; software, J.D.; validation, J.D.; formal analysis, J.D.; investigation, J.D.; resources, B.W.; data curation, X.S.; writing—original draft preparation, J.D.; writing—review and editing, J.D.; visualization, X.S.; project administration, B.W.; funding acquisition, B.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Nanhai nova project in Hainan Province, grant number NHXXRCXM202308, and the 2024 Sanya Science and Technology “Starry Sky” Project, grant number 2024KJFX020, and National Undergraduate Innovation Training Program, grant number: 202510589008.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Acknowledgments

We would like to thank the Innovation and Utilization team of tropical meloncrop genetic germplasm, Hainan University.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ma, Y.H. Agricultural Materials Science; Chemical Industry Press: Beijing, China, 2015. [Google Scholar]

- Shi, L.R.; Ma, Z.T.; Zhao, W.Y.; Yang, X.P.; Sun, B.G.; Zhang, J.P. Calibration of simulation parameters of flaxed seeds using discrete element method and verification of seed-metering test. Trans. Chin. Soc. Agric. Eng. 2019, 35, 25–33. [Google Scholar] [CrossRef]

- GB/T 3543.6-1995; Rules for Agricultural Seed Testing—Determination of Moisture Content. General Administration of Market Regulation of China: Beijing, China, 1995.

- Jun, G.; Yue, Y.; Memon, M.S.; Chuang, T.; Linyu, W.; Pei, T. Design and simulation for seeding performance of high-speed inclined corn metering device based on discrete element method (DEM). Sci. Rep. 2022, 12, 19415. [Google Scholar] [CrossRef]

- Gao, X.; Cui, T.; Zhou, Z.; Yu, Y.; Xu, Y.; Zhang, D.; Song, W. DEM study of particle motion in novel high-speed seed metering device. Adv. Powder Technol. 2021, 32, 1438–1449. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, T.; Wang, X. Characterization of Seed Physical Properties and Their Influence on Seeding Uniformity Using DEM. Appl. Sci. 2021, 11, 8765. [Google Scholar]

- González-Montellano, C.; Fuentes, J.; Ayuga-Téllez, E.; Ayuga, F. Determination of the mechanical properties of maize grains and olives required for use in DEM simulations. J. Food Eng. 2012, 111, 553–562. [Google Scholar] [CrossRef]

- GB/T3543.6-1995; Rules for Agricultural Seed Testing—Moisture Determination. China Standards Press: Beijing, China, 1983.

- Chen, S.; Li, X.; Wang, H. Tribological Behavior of Rice Seeds and Its Impact on Seed Handling Machinery Design. Sustainability 2022, 14, 14321. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, Y.; Liu, Z. DEM Simulation-Based Optimization of Seed Metering Device for Small-Seeded Vegetables. Appl. Sci. 2021, 11, 6789. [Google Scholar] [CrossRef]

- Shi, J.F.; Gao, Z.L.; Yang, J.; Ma, J.X. Simulation Research on Impact Load of Powder Weighing Based on EDEM. Mach. Des. Manuf. 2023, 3, 11–14. [Google Scholar]

- Shi, L.; Zhao, W.; Hua, C.; Rao, G.; Guo, J.; Wang, Z. Study on the Intercropping Mechanism and Seeding Improvement of the Cavity Planter with Vertical Insertion Using DEM-MBD Coupling Method. Agriculture 2022, 12, 1567. [Google Scholar] [CrossRef]

- Shi, L.R.; Zhao, W.Y.; Sun, W.; Yang, X.P.; Wang, G.P.; Xin, S.L. Analysis of the Metering Performance for Typical Shape Maize Seeds Using DEM. Int. J. Agric. Biol. Eng. 2023, 16, 26–35. [Google Scholar] [CrossRef]

- Zeng, Y.; Jia, F.G.; Zhang, Y.X.; Meng, X.Y.; Han, Y.L.; Wang, H. DEM Study to Determine the Relationship Between Particle Velocity Fluctuations and Contact Force Disappearance. Powder Technol. 2017, 313, 112–121. [Google Scholar] [CrossRef]

- Zeng, Y.; Jia, F.G.; Meng, X.Y.; Han, Y.L.; Xiao, Y.W. The Effects of Friction Characteristic of Particle on Milling Process in a Horizontal Rice Mill. Adv. Powder Technol. 2018, 29, 1280–1291. [Google Scholar] [CrossRef]

- Ji, Y.J.; Xue, H.D.; Li, C.H. Simulation Analysis of Seed Metering Procedure in Scoop Metering Device Based on Discrete Element Method. Appl. Mech. Mater. 2012, 157–158, 550–557. [Google Scholar] [CrossRef]

- Wang, M.; Liu, Q.; Ou, Y.; Zou, X. Numerical Simulation and Verification of Seed-Filling Performance of Single-Bud Billet Sugarcane Seed-Metering Device Based on EDEM. Agriculture 2022, 12, 983. [Google Scholar] [CrossRef]

- Zhang, W.X.; Wang, F.Y. Parameter Calibration of American Ginseng Seeds for Discrete Element Simulation. Int. J. Agric. Biol. Eng. 2022, 15, 16–22. [Google Scholar] [CrossRef]

- Xie, J.F.; Li, Y.H.; Zhang, Y. Calibration of Discrete Element Simulation Parameters for Fresh Lotus Seeds. J. South China Agric. Univ. 2023, 44, 18–25. [Google Scholar]

- Chen, Z.; Xue, D.; Guan, W.; Guo, J.; Liu, Z. Performance Optimization of a Spoon Precision Seed Metering Device Based on a Maize Seed Assembly Model and Discrete Element Method. Processes 2023, 11, 3076. [Google Scholar] [CrossRef]

- Guzman, L.J.; Chen, Y.; Landry, H. Discrete Element Modeling of Seed Metering as Affected by Roller Speed and Damping Coefficient. Trans. ASABE 2020, 63, 1113–1122. [Google Scholar] [CrossRef]

- Li, Z.D.; Chen, Y.X.; Gao, X.H. Numerical Simulation and Test of Airflow Distribution Seed Metering Device Based on EDEM-Fluent Coupling. J. South China Agric. Univ. 2017, 38, 110–116. [Google Scholar] [CrossRef]

- Lai, Q.; Hua, Z.; Xing, J.; Ma, W. Simulation and Verification for Seed-Filling Performance of Cell Wheel Precision Seed Metering Device Based on Discrete Element Method. MATEC Web Conf. 2018, 169, 01035. [Google Scholar] [CrossRef][Green Version]

- Liu, W.Z.; He, J.; Li, H.W. Calibration of Simulation Parameters for Lettuce Seeds Based on EDEM. Trans. Chin. Soc. Agric. Eng. 2023, 39, 932–940. [Google Scholar]

Figure 1.

(a) Rice (b) Leaf-used Lettuce (c) Lettuce (d) Chinese Cabbage (e) Flowering Chinese Cabbage (f) Celery.

Figure 1.

(a) Rice (b) Leaf-used Lettuce (c) Lettuce (d) Chinese Cabbage (e) Flowering Chinese Cabbage (f) Celery.

Figure 2.

(a) Sliding friction angle and (b) repose angle measuring instruments.

Figure 2.

(a) Sliding friction angle and (b) repose angle measuring instruments.

Figure 3.

Statistical results of seed triaxial size. “Average” represents the arithmetic mean of three-axis seed dimensions (length, width, thickness). Different lowercase letters above bars indicate significant differences between groups.

Figure 3.

Statistical results of seed triaxial size. “Average” represents the arithmetic mean of three-axis seed dimensions (length, width, thickness). Different lowercase letters above bars indicate significant differences between groups.

Figure 4.

Sliding friction angle of different seeds. Different lowercase letters above bars indicate significant differences between groups.

Figure 4.

Sliding friction angle of different seeds. Different lowercase letters above bars indicate significant differences between groups.

Figure 5.

Measurement method of repose angle.

Figure 5.

Measurement method of repose angle.

Figure 6.

Repose angles of different seeds. Different lowercase letters indicate significant differences between groups.

Figure 6.

Repose angles of different seeds. Different lowercase letters indicate significant differences between groups.

Figure 7.

(a) Spherical and (b) long–flat seed particle models.

Figure 7.

(a) Spherical and (b) long–flat seed particle models.

Figure 8.

Simulation process of sliding friction angle.

Figure 8.

Simulation process of sliding friction angle.

Figure 9.

Comparison of sliding friction angle test and simulation test post-processing.

Figure 9.

Comparison of sliding friction angle test and simulation test post-processing.

Figure 10.

Repose angle simulation process.

Figure 10.

Repose angle simulation process.

Figure 11.

Comparison of natural angle of repose test and simulation test post-processing. The red line represents the angle between the line connecting the top of the vertebra to the bottom of the vertebral angle endpoint and the horizontal line.

Figure 11.

Comparison of natural angle of repose test and simulation test post-processing. The red line represents the angle between the line connecting the top of the vertebra to the bottom of the vertebral angle endpoint and the horizontal line.

Figure 12.

Seed germinability test.

Figure 12.

Seed germinability test.

Figure 13.

Diagram of different seed germination rates. Letter designations refer to

Table 1.

Figure 13.

Diagram of different seed germination rates. Letter designations refer to

Table 1.

Table 1.

Vegetable cultivar labels.

Table 1.

Vegetable cultivar labels.

| Variety | Label | Variety | Label |

|---|

| Hong Kong flowering Chinese cabbage | A | Danish four-season lettuce | I |

| Huifeng No.2 pointed-leaf flowering Chinese cabbage | B | Xindali No.2 lettuce | J |

| Lüxiu four-season pointed-leaf oil-green flowering Chinese cabbage | C | Huayu heading lettuce | K |

| Zhenbao flowering Chinese cabbage | D | Italian year-round bolting-resistant lettuce | L |

| Lifeng No.3 Chinese cabbage | E | Spotless super fragrant leaf lettuce | M |

| Express Train No.5 Chinese cabbage | F | Qingxiang sweet and crisp leaf lettuce king | N |

| Zaohuangjing Chinese cabbage | G | Four-season sweet pointed leaf lettuce | O |

| Huangjing Chinese cabbage No.1 | H | Fast-growing sweet red leaf lettuce | P |

Table 2.

Basic parameters of self-developed equipment.

Table 2.

Basic parameters of self-developed equipment.

| Index | Sliding Friction Angle Measuring Instrument | Index | Natural Repose Angle Measuring Instrument |

|---|

| Bottom plate material | Stainless steel | Petri dish diameter | 120 mm |

| Bottom plate size | 400 mm × 200 mm | Funnel diameter | 100 mm |

| Column height | 485 mm | Funnel height | 75 mm |

| G-clamp clamping size | 50 mm | Funnel down tube outer diameter | 10 mm |

Table 3.

Statistical results of 1000-grain weight of seeds.

Table 3.

Statistical results of 1000-grain weight of seeds.

| Variety | 1000-Grain Weight (g) | Standard

Deviation | Variety | 1000-Grain Weight (g) | Standard

Deviation |

|---|

| A | 2.53 | 0.10 | I | 1.18 | 0.01 |

| B | 2.43 | 0.10 | J | 1.29 | 0.02 |

| C | 2.39 | 0.04 | K | 1.05 | 0.01 |

| D | 2.35 | 0.06 | L | 1.24 | 0.01 |

| E | 3.06 | 0.03 | M | 1.03 | 0.01 |

| F | 2.60 | 0.06 | N | 1.03 | 0.01 |

| G | 2.64 | 0.10 | O | 1.13 | 0.02 |

| H | 2.27 | 0.04 | | | |

Table 4.

The moisture content of seeds.

Table 4.

The moisture content of seeds.

| Variety | Seed Moisture Content (%) | Variety | Seed Moisture Content (%) |

|---|

| A | 6.92 | I | 6.47 |

| B | 6.78 | J | 8.17 |

| C | 7.84 | K | 8.63 |

| D | 7.25 | L | 7.45 |

| E | 7.76 | M | 7.44 |

| F | 7.87 | N | 7.93 |

| G | 7.12 | O | 7.73 |

| H | 8.56 | P | 7.95 |

Table 5.

Sliding friction angle between seeds and different materials (°).

Table 5.

Sliding friction angle between seeds and different materials (°).

| Seed Variety | Contact Material |

|---|

| Stainless Steel | Acrylic | Plastic |

|---|

| A | 25.47 | 48.21 | 24.99 |

| B | 17.92 | 32.73 | 20.25 |

| C | 17.33 | 24.91 | 21.01 |

| D | 23.97 | 32.08 | 18.98 |

| E | 21.71 | 26.93 | 17.54 |

| F | 21.21 | 20.34 | 21.69 |

| G | 25.36 | 21.97 | 23.38 |

| H | 28.67 | 24.36 | 23.11 |

| I | 29.86 | 31.79 | 28.92 |

| J | 28.93 | 31.58 | 29.11 |

| K | 30.21 | 32.62 | 30.41 |

| L | 32.76 | 32.30 | 29.97 |

| M | 32.10 | 29.90 | 27.96 |

| N | 33.62 | 29.78 | 28.63 |

| O | 33.33 | 31.08 | 30.09 |

| P | 31.67 | 28.10 | 27.82 |

Table 6.

Result of one-way ANOVA of sliding friction angle of vegetable seeds.

Table 6.

Result of one-way ANOVA of sliding friction angle of vegetable seeds.

| Vegetable Type | Stainless Steel | Acrylic | Plastic |

|---|

| F-Value | Significance | F-Value | Significance | F-Value | Significance |

|---|

| Flowering Chinese cabbage | 15.951 | 0.001 | 11.568 | 0.001 | 3.684 | 0.021 |

| Chinese cabbage | 5.343 | 0.004 | 2.181 | 0.107 | 7.809 | 0.001 |

| Lettuce | 79.496 | 0.001 | 5.892 | 0.002 | 25.439 | 0.001 |

| Leaf lettuce | 24.535 | 0.001 | 59.731 | 0.001 | 41.612 | 0.001 |

Table 7.

Repose angles of different seeds.

Table 7.

Repose angles of different seeds.

| Variety | Natural Repose Angle (°) | Variety | Natural Repose Angle (°) |

|---|

| A | 27.99 | I | 31.51 |

| B | 28.73 | J | 31.32 |

| C | 26.62 | K | 32.31 |

| D | 27.34 | L | 31.25 |

| E | 26.29 | M | 30.30 |

| F | 27.83 | N | 30.33 |

| G | 27.49 | O | 32.71 |

| H | 26.15 | P | 30.90 |

Table 8.

Simulation material parameters of sliding friction angle.

Table 8.

Simulation material parameters of sliding friction angle.

| Material | Density (g/cm3) | Poisson’s Ratio | Shear Modulus (Pa) |

|---|

| Spherical seeds | 0.068 | 0.25 | 1.1 × 107 |

| Long–flat seeds | 0.045 | 0.25 | 1.1 × 107 |

| 304 stainless steel | 7.93 | 0.25 | 1.9 × 1011 |

| Acrylic | 1.20 | 0.35 | 1.3 × 109 |

| Plastic (PP) | 0.90 | 0.42 | 4.0 × 109 |

Table 9.

Material parameters for repose angle simulation.

Table 9.

Material parameters for repose angle simulation.

| Material | Density (g/cm3) | Poisson’s Ratio | Shear Modulus (Pa) |

|---|

| Spherical seeds | 0.068 | 0.25 | 1.1 × 107 |

| Long–flat seeds | 0.045 | 0.25 | 1.1 × 107 |

| Glass | 2.50 | 0.20 | 2.62 × 1010 |

Table 10.

Germination potential and rate of seeds.

Table 10.

Germination potential and rate of seeds.

| Variety (Label) | Germination Potential (%) | GerminationRate (%) | Variety (Label) | Germination Potential (%) | Germination Rate (%) |

|---|

| A | 94.00 | 98.00 | I | 18.00 | 44.00 |

| B | 74.00 | 88.00 | J | 14.00 | 68.00 |

| C | 94.00 | 94.00 | K | 16.00 | 60.00 |

| D | 94.00 | 98.00 | L | 8.00 | 42.00 |

| E | 98.00 | 98.00 | M | 32.00 | 76.00 |

| F | 82.00 | 88.00 | N | 62.00 | 78.00 |

| G | 88.00 | 88.00 | O | 78.00 | 90.00 |

| H | 92.00 | 94.00 | P | 26.00 | 82.00 |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).