Safety Equipment Planning Through Experimental Analysis of Hydrogen Leakage and Ventilation in Enclosed Spaces

Abstract

1. Introduction

2. Experimental Setup and Method

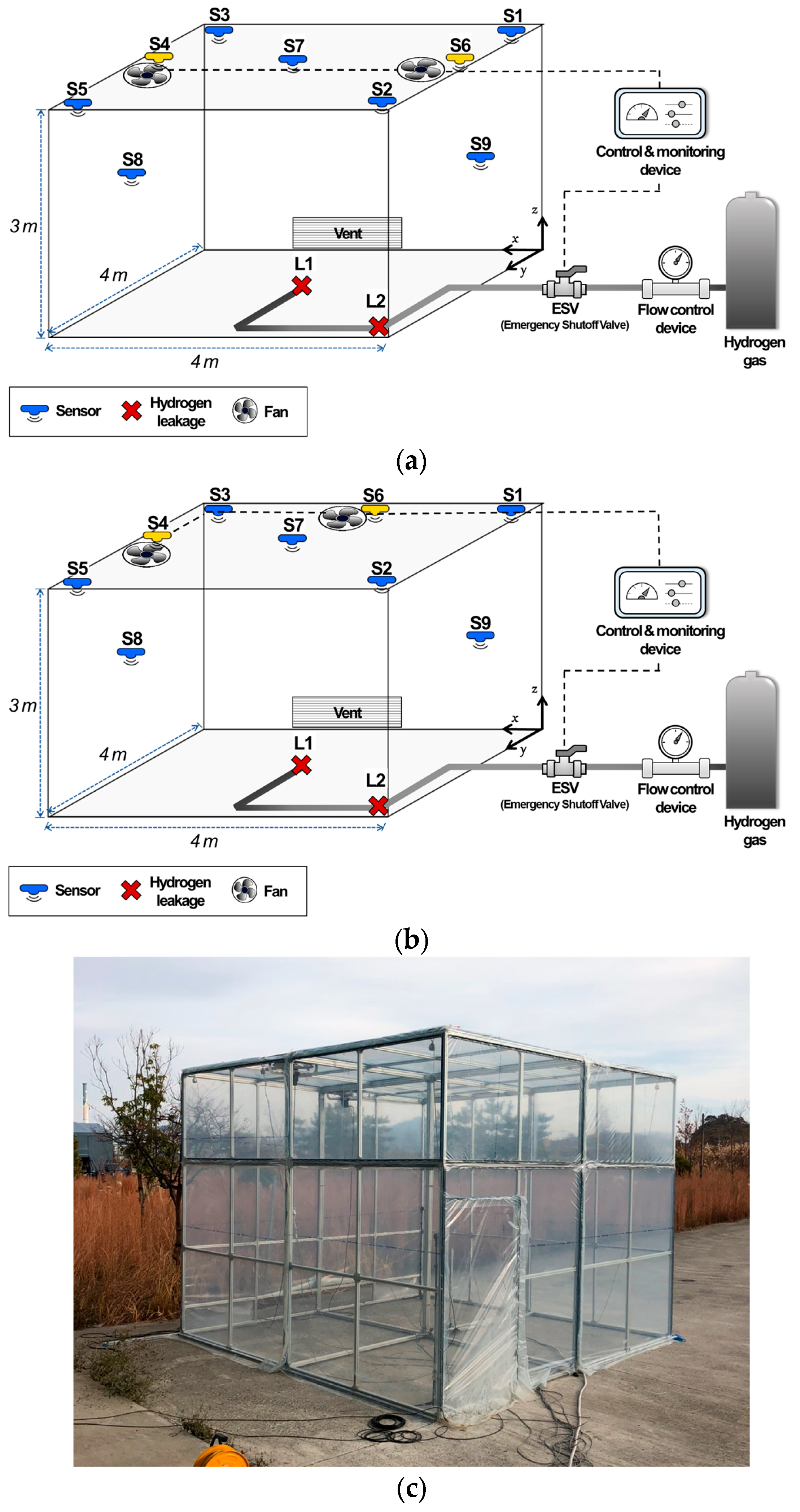

2.1. Experimental Setup

- W: mass flow rate of leaking hydrogen [kg/s]

- Cd: discharge coefficient

- Aleak: cross-sectional area of leak nozzle [m2]

- Pcon: internal pressure of hydrogen container [Pa]

- : polytropic index of adiabatic expansion

- : molar mass of hydrogen [kg/kmol]

- Z: compressibility factor

- R: gas constant [8314 J/kmol K]

- T: temperature [K]

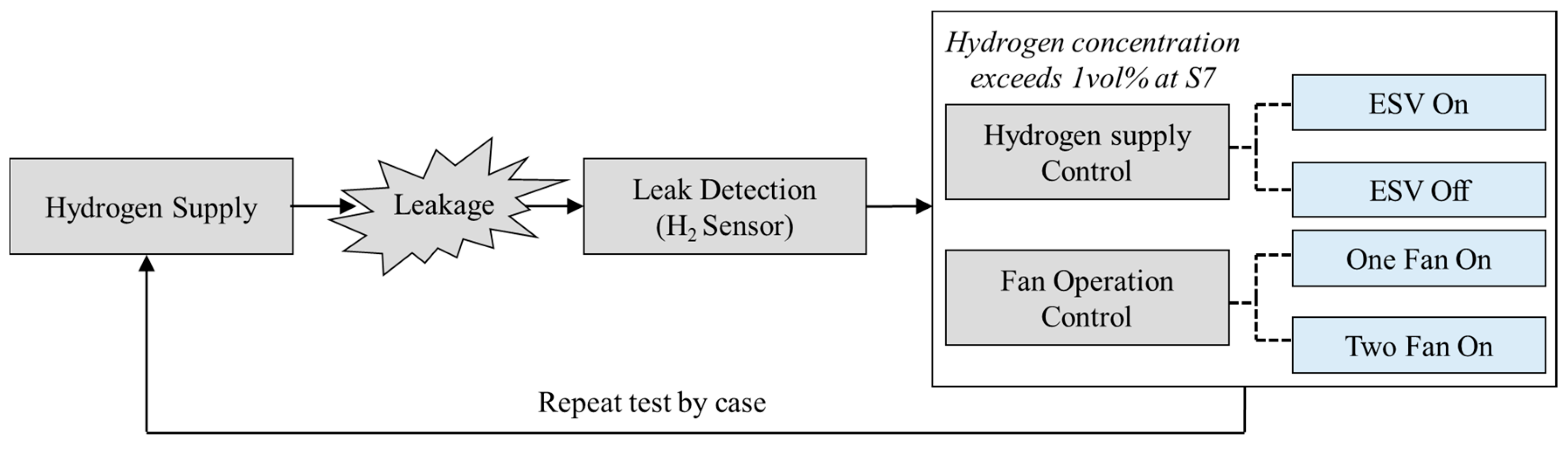

2.2. Experimental Method

3. Analysis of Experimental Results

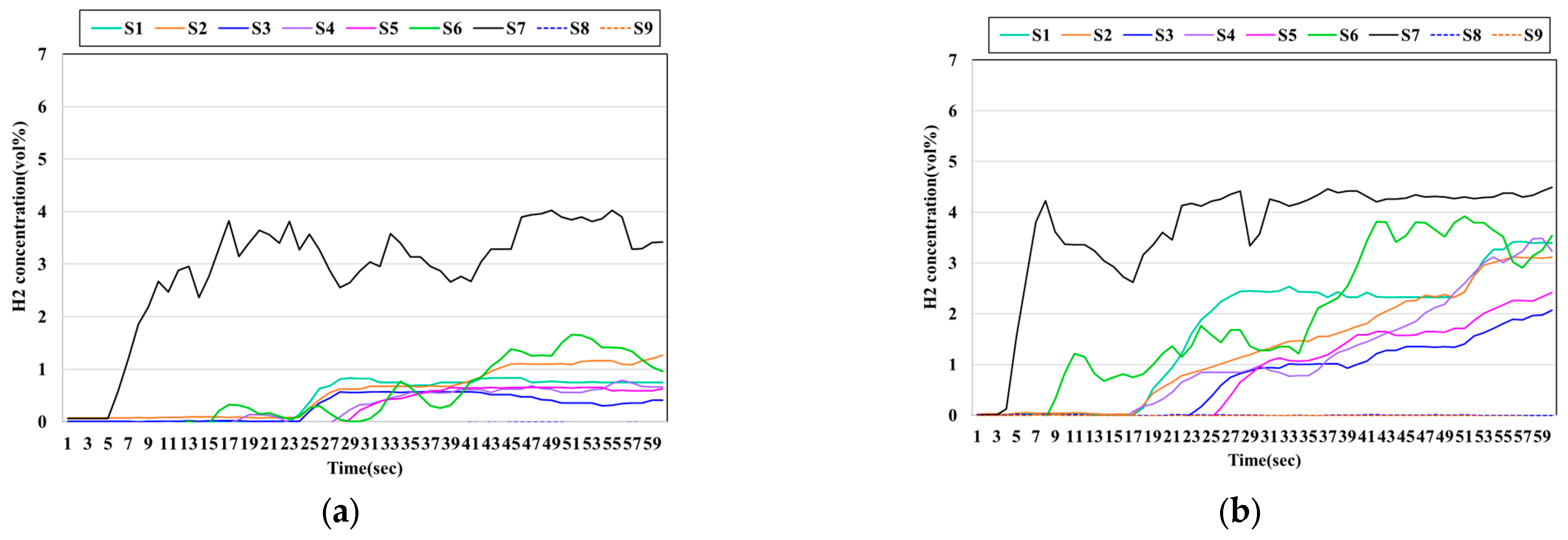

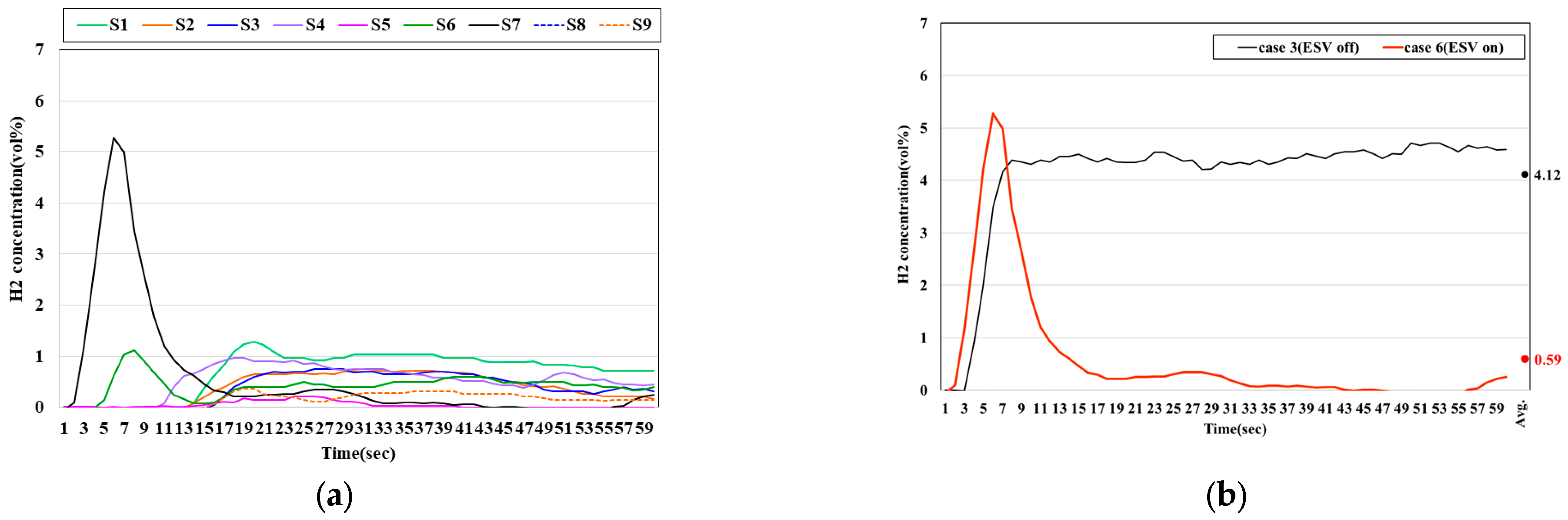

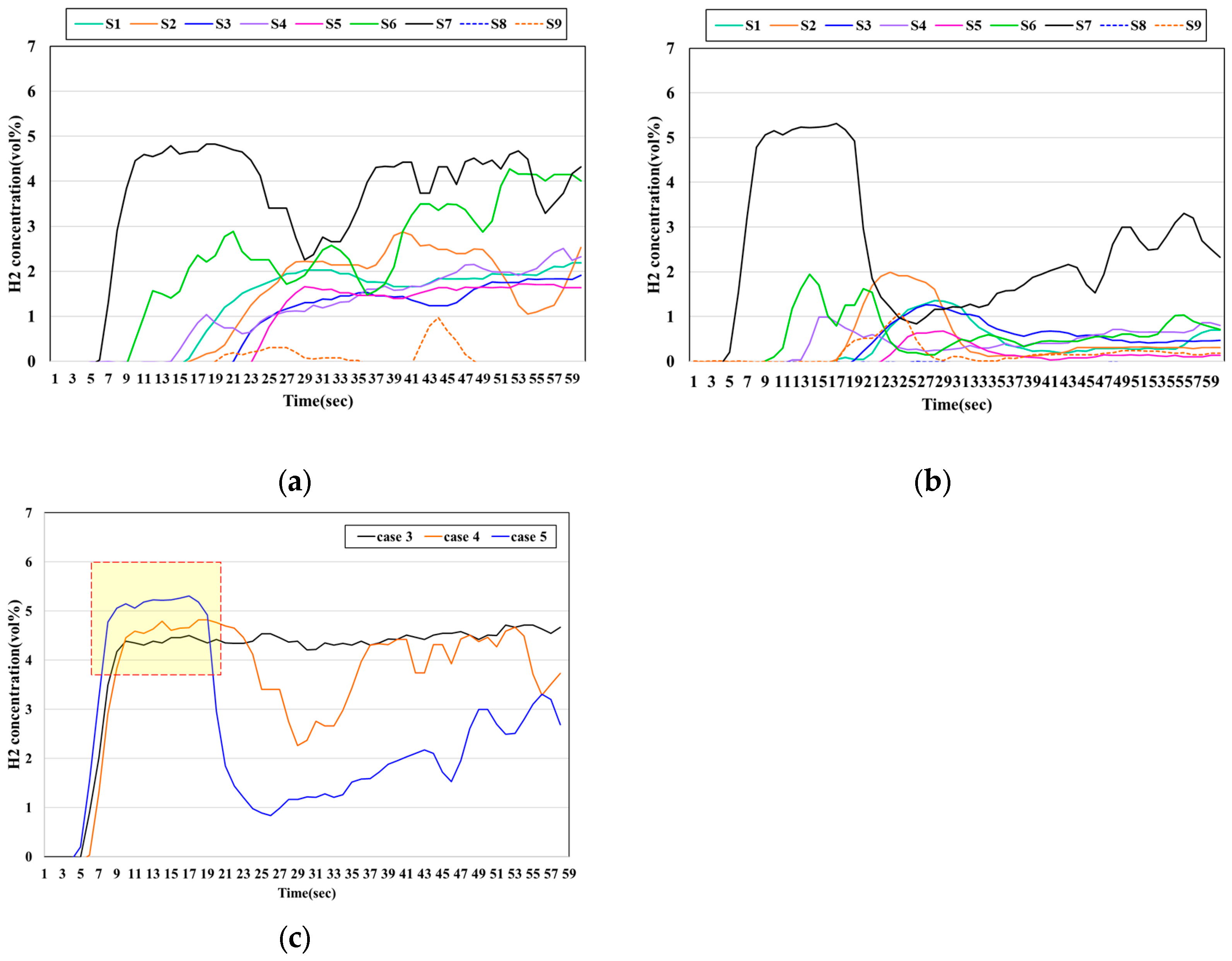

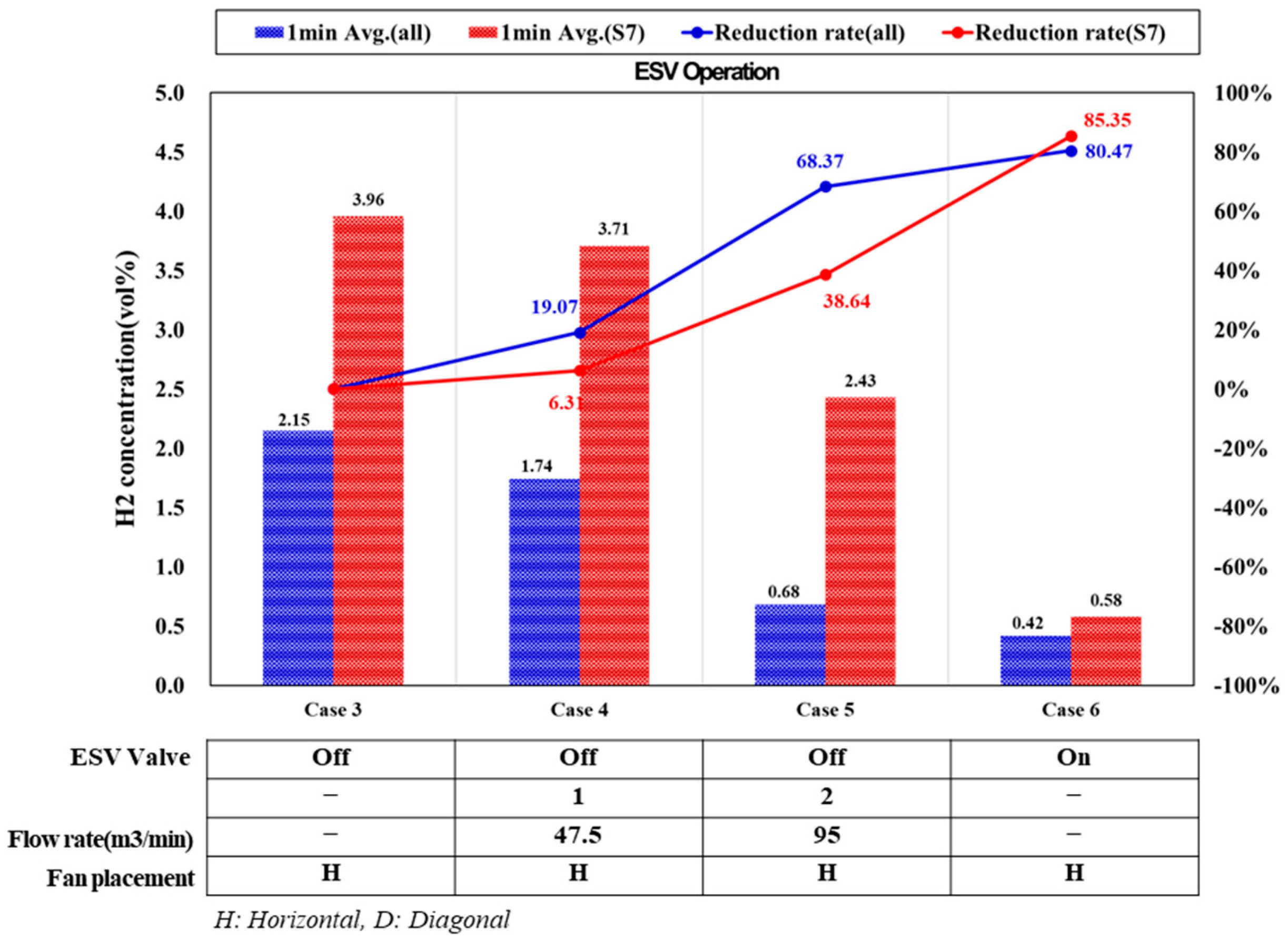

3.1. Evaluation of Indoor Characteristics According to ESV Operation

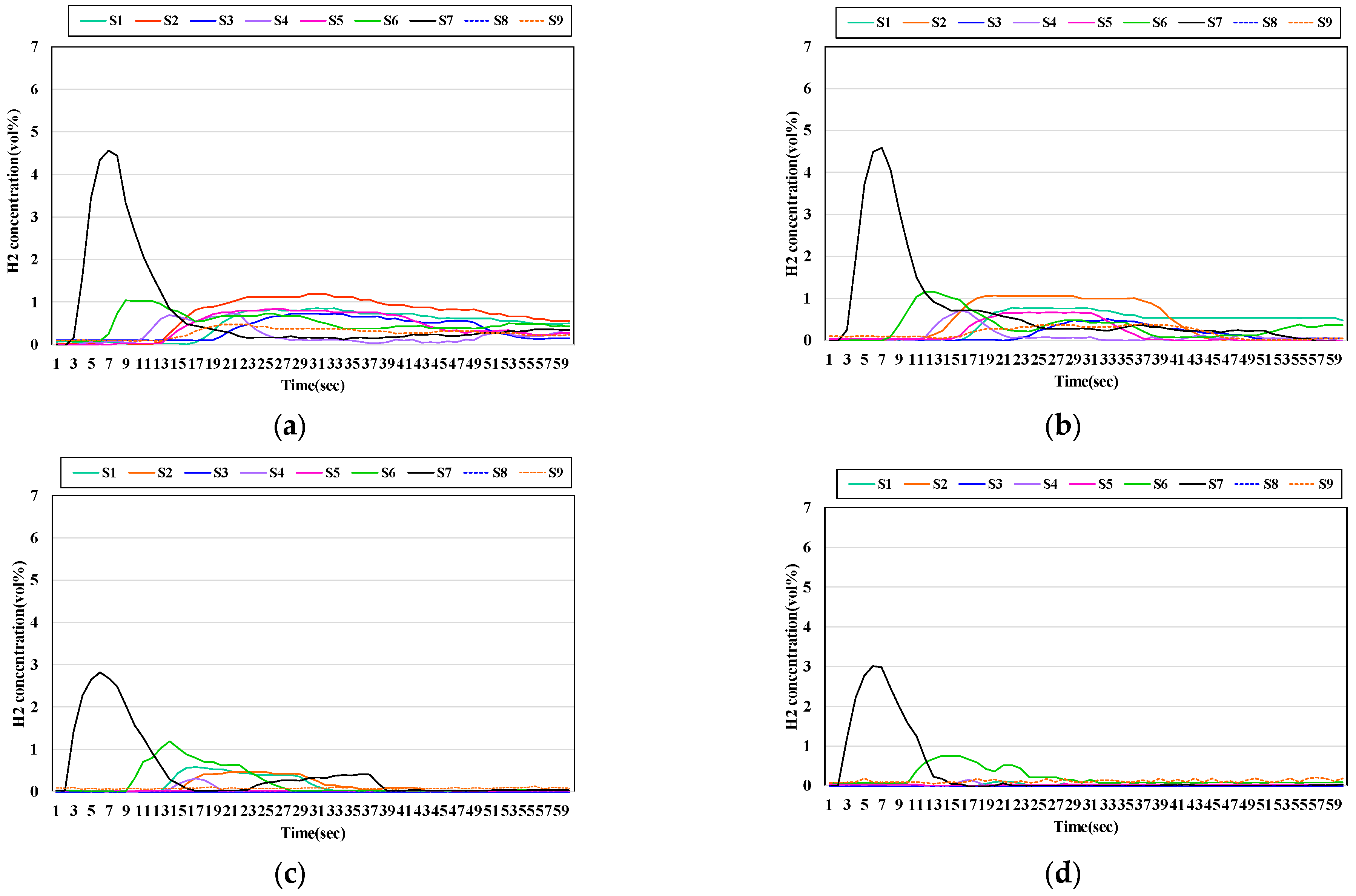

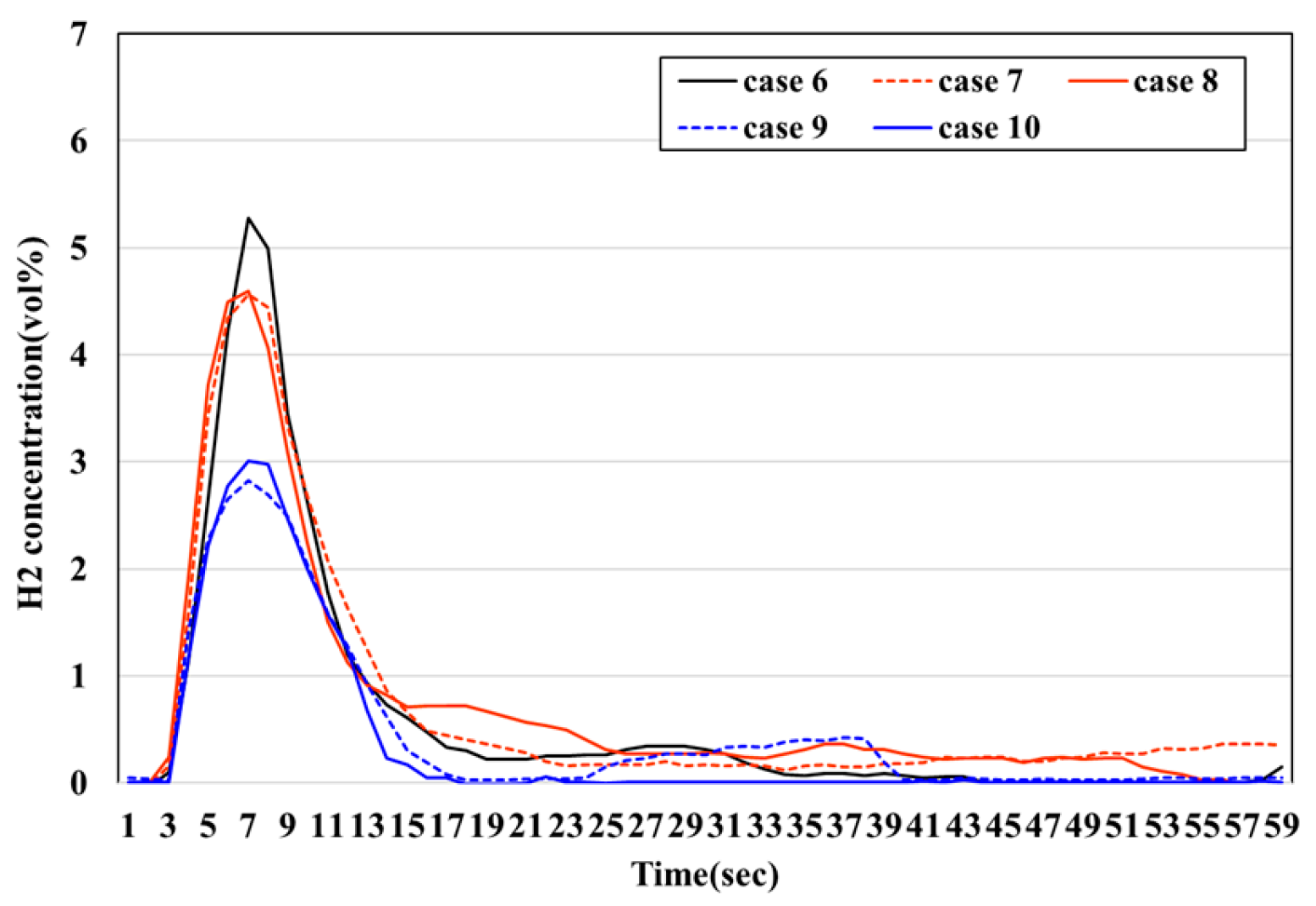

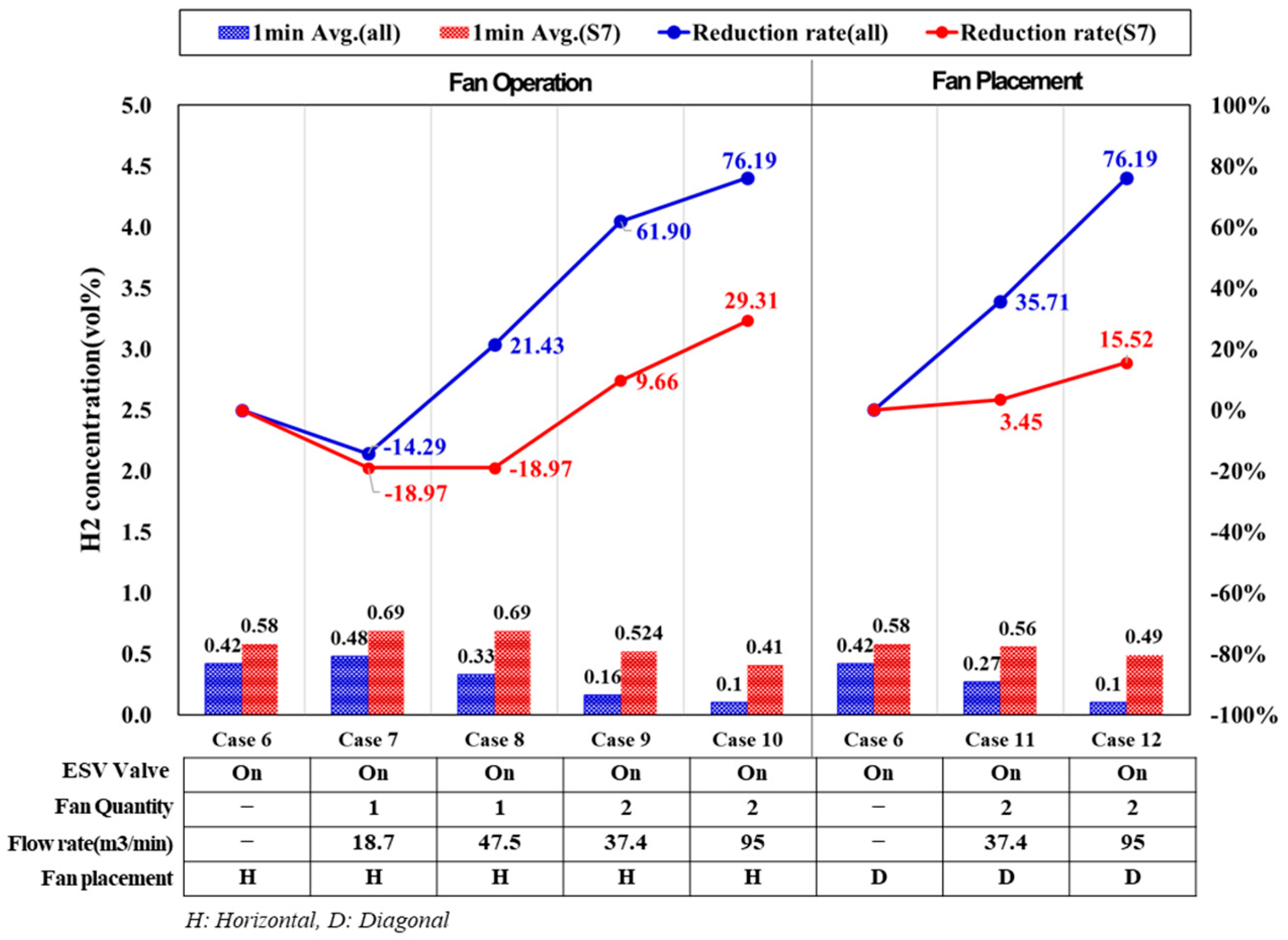

3.2. Evaluation of Indoor Characteristics According to Ventilation Fan Operation

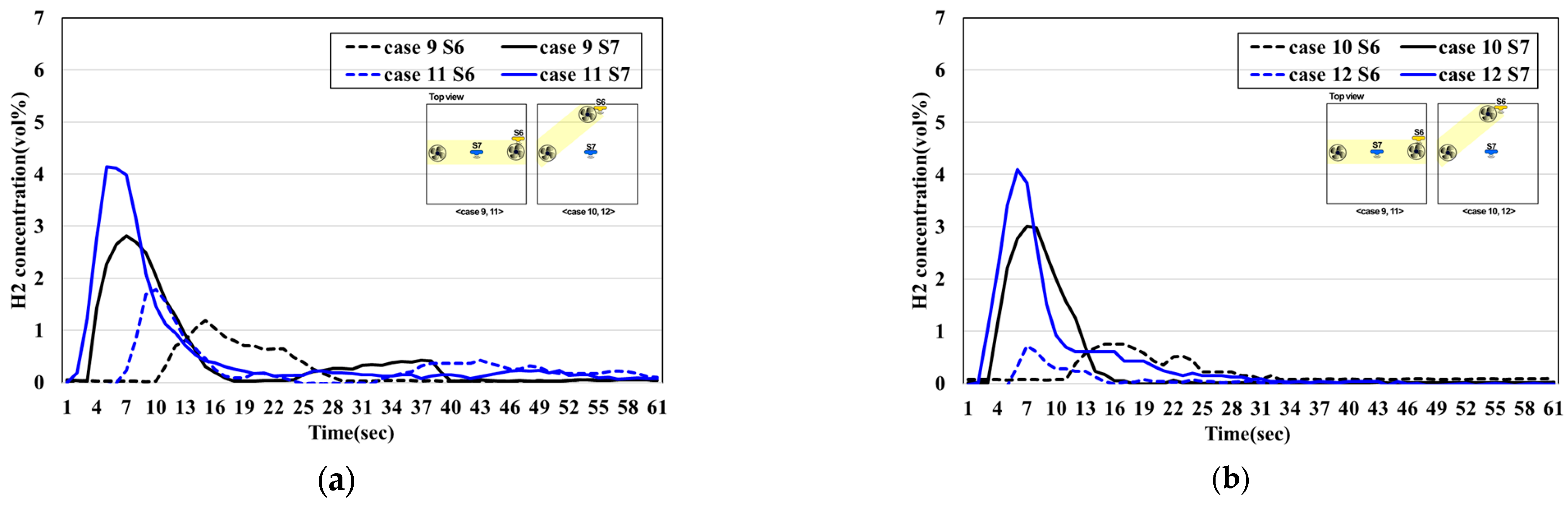

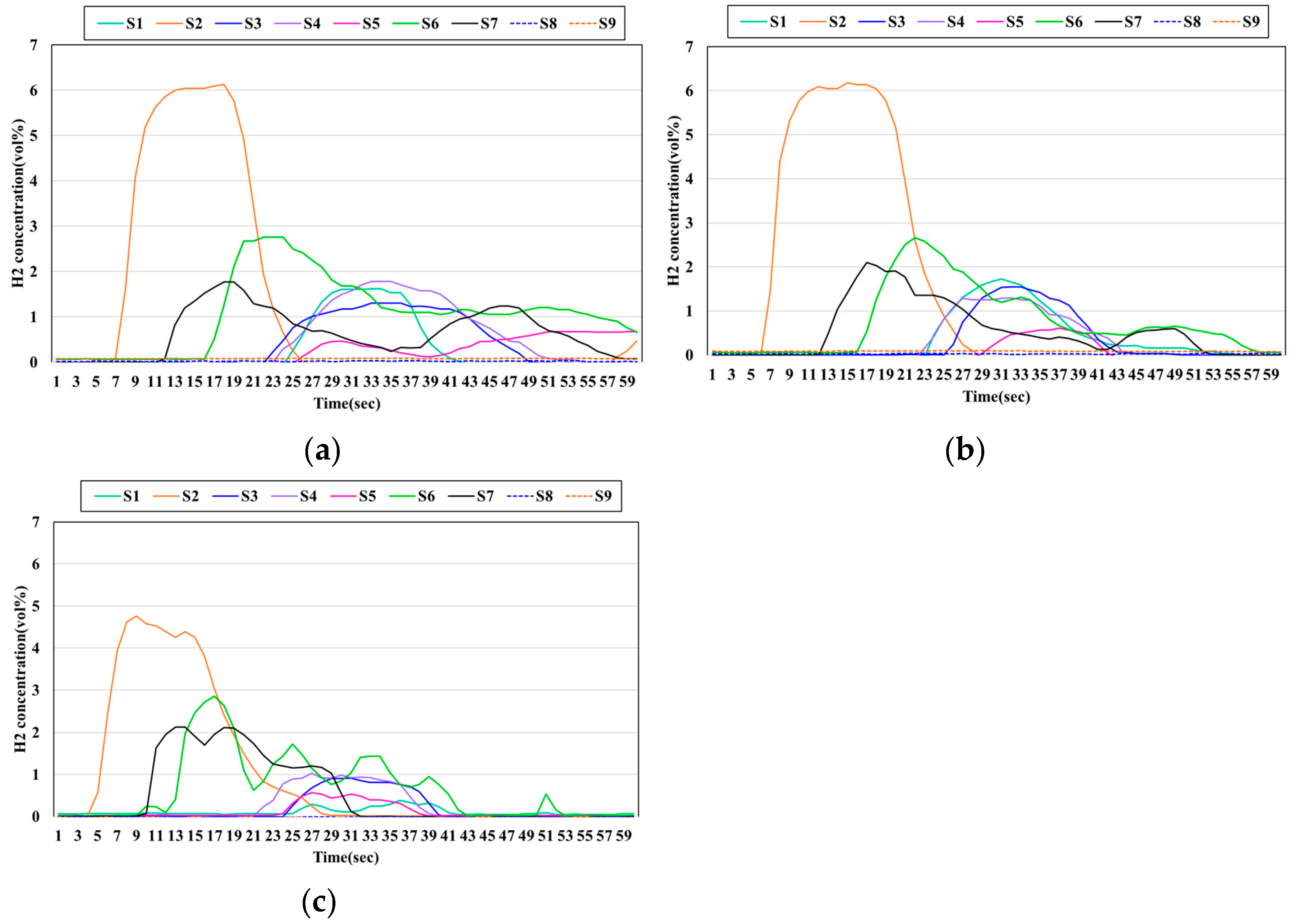

3.3. Evaluation of Indoor Characteristics Based on Hydrogen Leak Location Change

4. Conclusions

- Hydrogen sensors should be installed in the upper central part of the room and at the upper sections of the joints where leaks are likely to occur.

- Among the safety equipment for hydrogen handling facilities, an ESV alone can control over 80% of the initial internal hydrogen concentration, making it the most crucial equipment in safety equipment planning.

- When planning the placement of internal ventilation fans, at least two fans should be installed, and a horizontal arrangement is more effective in reducing hydrogen concentration.

- For effective ventilation, increasing the number of ventilation fans, rather than simply increasing the ventilation flow rate, is more effective in reducing zones of hydrogen stagnation and lowering the average hydrogen concentration.

- Both the shut-off valve and the ventilation fans must be activated in the event of hydrogen leakage. However, if the shut-off valve fails to operate owing to an error, relying on the ventilation fans alone has limitations in reducing the internal hydrogen levels. Therefore, precautions must be taken to prevent shut-off valve malfunctions, and additional safety measures must be considered.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ESV | Emergency shut-off valves |

| COP21 | 2015 Paris Climate Conference |

| UNFCCC | United Nations Framework Convention on Climate Change |

| DIPPR | Design Institute for Physical Property |

| MSDS | Material Safety Data Sheet |

| LFL | Lower flammability limit |

References

- Li, Q.; Li, Q.; Wang, F.; Xu, N.; Wang, Y.; Bai, B. Settling behavior and mechanism analysis of kaolinite as a fracture proppant of hydrocarbon reservoirs in CO2 fracturing fluid. Colloids Surf. A Physicochem. Eng. Asp. 2025, 724, 137463. [Google Scholar] [CrossRef]

- Li, Q.; Han, Y.; Liu, X.; Wang, Y.; Zhang, Y. Hydrate as a By-Product in CO2 Leakage during the Long-Term Sub-Seabed Sequestration and Its Role in Preventing Further Leakage. Environ. Sci. Pollut. Res. 2022, 29, 77737–77754. [Google Scholar] [CrossRef] [PubMed]

- Falkner, R. The Paris Agreement and the new logic of international climate politics. Int. Aff. 2016, 92, 1107–1125. [Google Scholar] [CrossRef]

- UNFCCC. The Paris Agreement; United Nations: New York, NY, USA, 2016. [Google Scholar]

- Ball, M.; Wietschel, M. The future of hydrogen–opportunities and challenges. Int. J. Hydrogen Energy 2009, 34, 615–627. [Google Scholar] [CrossRef]

- Evro, S.; Oni, B.A.; Tomomewo, O.S. Carbon neutrality and hydrogen energy systems. Int. J. Hydrogen Energy 2024, 78, 1449–1467. [Google Scholar] [CrossRef]

- Solomon, B.D.; Banerjee, A. A global survey of hydrogen energy research, development and policy. Energy Policy 2006, 34, 781–792. [Google Scholar] [CrossRef]

- Cleaves, H.J. Hydrogen. In Encyclopedia of Astrobiology; Gargaud, M., Ed.; Springer: Berlin/Heidelberg, Germany, 2023; pp. 1374–1375. [Google Scholar] [CrossRef]

- Ren, J.T.; Chen, L.; Wang, H.Y.; Tian, W.W.; Yuan, Z.Y. Water electrolysis for hydrogen production: From hybrid systems to self-powered/catalyzed devices. Energy Environ. Sci. 2024, 17, 49–113. [Google Scholar] [CrossRef]

- Nowotny, J.; Veziroglu, T.N. Impact of hydrogen on the environment. Int. J. Hydrogen Energy 2011, 36, 13218–13224. [Google Scholar] [CrossRef]

- Mckinsey Company. Hydrogen Insights. 2022. Available online: https://hydrogencouncil.com/wp-content/uploads/2022/09/Hydrogen-Insights-2022-2.pdf (accessed on 5 February 2025).

- Ball, M.; Weeda, M. The hydrogen economy–vision or reality? Int. J. Hydrogen Energy 2015, 40, 7903–7919. [Google Scholar] [CrossRef]

- Hugo, A.; Rutter, P.; Pistikopoulos, S.; Amorelli, A.; Zoia, G. Hydrogen infrastructure strategic planning using multi-objective optimization. Int. J. Hydrogen Energy 2005, 30, 1523–1534. [Google Scholar] [CrossRef]

- IEA. Global Hydrogen Review 2023. 2023. Available online: https://iea.blob.core.windows.net/assets/ecdfc3bb-d212-4a4c-9ff7-6ce5b1e19cef/GlobalHydrogenReview2023.pdf (accessed on 9 February 2025).

- Korea Energy Economics Institute (KEEI). Overseas Case Studies on Hydrogen Supply to Revitalize the Hydrogen Economy. 2020. Available online: https://www.keei.re.kr/pdfOpen.es?bid=0001&list_no=82008&seq=1 (accessed on 5 February 2025).

- US Department of Energy (DOE). National Zero-Emission Freight Corridor Strategy. 2024. Available online: https://driveelectric.gov/files/zef-corridor-strategy.pdf (accessed on 5 February 2025).

- Kim, H.; Eom, M.; Kim, B.I. Development of strategic hydrogen refueling station deployment plan for Korea. Int. J. Hydrogen Energy 2020, 45, 19900–19911. [Google Scholar] [CrossRef]

- Stangarone, T. South Korean efforts to transition to a hydrogen economy. Clean Technol. Environ. Policy 2021, 23, 509–516. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://www.aiche.org/dippr (accessed on 24 January 2025).

- Available online: https://msds.kosha.or.kr/MSDSInfo/ (accessed on 24 January 2025).

- Najjar, Y.S.H. Hydrogen safety: The road toward green technology. Int. J. Hydrogen Energy 2013, 38, 10716–10728. [Google Scholar] [CrossRef]

- Veziroğlu, T.N.; Şahi, S. 21st century’s energy: Hydrogen energy system. Energy Convers. Manag. 2008, 49, 1820–1831. [Google Scholar] [CrossRef]

- Xiao, H.; Duan, Q.; Sun, J. Premixed flame propagation in hydrogen explosions. Renew. Sustain. Energy Rev. 2018, 81, 1988–2001. [Google Scholar] [CrossRef]

- Ryu, B.R.; Duong, P.A.; Kim, J.B.; Choi, S.Y.; Shin, J.W.; Jung, J.; Kang, H. The effect of ventilation on the hazards of hydrogen release in enclosed areas of hydrogen-fueled ship. J. Mar. Sci. Eng. 2023, 11, 1639. [Google Scholar] [CrossRef]

- Patel, P.; Baalisampang, T.; Arzaghi, E.; Garaniya, V.; Abbassi, R.; Salehi, F. Computational analysis of the hydrogen dispersion in semi-confined spaces. Process Saf. Environ. Prot. 2023, 176, 475–488. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Q.; Hou, X.; Li, Y.; Miao, Y.; Li, K.; Zhang, L. Effect of the position and the area of the vent on the hydrogen dispersion in a naturally ventilated cubiod space with one vent on the side wall. Int. J. Hydrogen Energy 2022, 47, 9071–9081. [Google Scholar] [CrossRef]

- Genovese, M.; Blekhman, D.; Fragiacomo, P. An exploration of safety measures in hydrogen refueling stations: Delving into hydrogen equipment and technical performance. Hydrogen 2024, 5, 102–122. [Google Scholar] [CrossRef]

- ISO 19880-1:2020; Gaseous Hydrogen—Fuelling Stations—Part 1: General Requirements. ISO: Geneva, Switzerland, 2020.

- NFPA 2; Hydrogen Technologies Code. National Fire Protection Association: Boston, MA, USA, 2023.

- NFPA 853; Standard for the Installation of Stationary Fuel Cell Power Systems. National Fire Protection Association: Boston, MA, USA, 2025.

- KGS FU671; Facility/Technical/Inspection Code for Use of Hydrogen Gases. KGS: Eumseong-gun, Republic of Korea, 2021.

- KOSHA GUIDE P-30-2021; Technical Guidelines on Safety of Hydrogen Charging Stations. KOSHA: Ulsan, Republic of Korea, 2021.

- Ji, H.W.; Lee, H.; Hwang, I.; Jang, H. Safe ventilation methods against leaks in hydrogen fuel cell rooms in homes. Energies 2022, 15, 5434. [Google Scholar] [CrossRef]

- Tanaka, T.; Azuma, T.; Evans, J.A.; Cronin, P.M.; Johnson, D.M.; Cleaver, R.P. Experimental study on hydrogen explosions in a full-scale hydrogen filling station model. Int. J. Hydrogen Energy 2007, 32, 2162–2170. [Google Scholar] [CrossRef]

- KSG GC101; High-Pressure Gas Safety Control Standards. KSG: Eumseong-gun, Republic of Korea, 2018. Available online: https://cyber.kgs.or.kr/kgscode.codeSearch.view.ex.do?onEngYn=F&pblcRlmCd=&pblcMdclCd=&pblcCd=GC101_220830&stDayY=2008&stDayM=01&etDayY=2025&etDayM=08 (accessed on 24 January 2025).

- Swain, M.R.; Filoso, P.; Grilliot, E.S.; Swain, M.N. Hydrogen leakage into simple geometric enclosures. Int. J. Hydrogen Energy 2003, 28, 229–248. [Google Scholar] [CrossRef]

- Vudumu, S.K.; Koylu, U.O. Detailed simulations of the transient hydrogen mixing, leakage and flammability in air in simple geometries. Int. J. Hydrogen Energy 2009, 34, 2824–2833. [Google Scholar] [CrossRef]

- Sakamoto, J.; Sato, R.; Nakayama, J.; Kasai, N.; Shibutani, T.; Miyake, A. Leakage-type-based analysis of accidents involving hydrogen fueling stations in Japan and USA. Int. J. Hydrogen Energy 2016, 41, 21564–21570. [Google Scholar] [CrossRef]

- Kim, H.L.; Kang, S.K.; Huh, Y.S. Accidents Analysis of Domestic and Overseas Refueling Stations and Assessment of Dangerous Distance by Gas leak. J. Energy Eng. 2017, 26, 7–13. [Google Scholar]

- Matsuura, K. Effects of the geometrical configuration of a ventilation system on leaking hydrogen dispersion and accumulation. Int. J. Hydrogen Energy 2009, 34, 9869–9878. [Google Scholar] [CrossRef]

- Hajji, Y.; Bouteraa, M.; Bournot, P.; Bououdina, M. Assessment of an accidental hydrogen leak from a vehicle tank in a confined space. Int. J. Hydrogen Energy 2022, 47, 28710–28720. [Google Scholar] [CrossRef]

- Hou, X.; Lan, H.; Zhao, Z.; Li, J.; Hu, C.; Li, Y. Effect of obstacle location on hydrogen dispersion in a hydrogen fuel cell bus with natural and mechanical ventilation. Process Saf. Environ. Prot. 2023, 171, 995–1008. [Google Scholar] [CrossRef]

- Hwang, D.J.; Kil, B.L.; Park, S.K.; Kim, M.H. Numerical study on the location of exhaust outlet for effective ventilation in the event of hydrogen gas leakage in a hydrogen tank storeroom. J. Korean Soc. Mar. Eng. 2017, 41, 619–625. [Google Scholar] [CrossRef]

- Lee, C.Y.; Cho, D.H. Numerical study on the effect of area changes in air inlets and vent ports on the ventilation of leaking hydrogen. J. Korean Soc. Mar. Environ. Saf. 2022, 28, 385–393. [Google Scholar] [CrossRef]

| Emergency Shutoff Valve (ESV) | Hydrogen Detection | Ventilation | |

|---|---|---|---|

| ISO 19880-1 [28] | Mandatory | Mandatory (when hydrogen concentration exceeds 1%) |

|

| NFPA 2 [29] | Mandatory | Mandatory (when hydrogen concentration exceeds 1%) |

|

| NFPA 853 [30] | Mandatory | Mandatory (when hydrogen concentration exceeds 1%) |

|

| KGS FU671 [31] | Mandatory | Mandatory (when hydrogen concentration exceeds 1%) |

|

| KOSHA GUIDE P-30-2021 [32] | Mandatory | Mandatory (when hydrogen concentration exceeds 1%) |

|

| Leakage Types | Accident Cases by Country | Causes of Leakage | ||

|---|---|---|---|---|

| Korea | Japan | U.S. | ||

| Damage to Equipment and Piping | 1 | 3 | 4 | Design error |

| Flange, Valve, and Seal Issues | 1 (33%) | 14 (74%) | 6 (46%) | Improper Sealing |

| Human Error and External Influences | 1 | 2 | 3 | Human Error |

| Sum of accident cases | 3 | 19 | 13 | |

| Sensor and Leakage Locations | Installation Location (1) | |||||

|---|---|---|---|---|---|---|

| X-Axis | Y-Axis | Z-Axis | ||||

| #1 | #2 | #1 | #2 | #1 | #2 | |

| S1 | 2 m | 2 m | 2 m | 2 m | 3 m | 3 m |

| S2 | 2 m | 2 m | −2 m | −2 m | 3 m | 3 m |

| S3 | −2 m | −2 m | 2 m | −2 m | 3 m | 3 m |

| S4 | −2 m | −2 m | −2 m | −2 m | 3 m | 3 m |

| S5 | −2 m | −2 m | −2 m | −2 m | 3 m | 3 m |

| S6 | 2 m | 0 | 0 | 2 m | 3 m | 3 m |

| S7 | 0 | 0 | 0 | 0 | 3 m | 3 m |

| S8 | −2 m | −2 m | 0 | 0 | 1.5 m | 1.5 m |

| S9 | 2 m | 2 m | 0 | 0 | 1.5 m | 1.5 m |

| L1 | 0 | 0 | 0 | 0 | 0.1 m | 0.1 m |

| L2 | 2 m | 2 m | −2 m | −2 m | 0.1 m | 0.1 m |

| Case | LPM (Leak Flow Rate) | Leak Location | ESV On/Off | Fan Operation | |||

|---|---|---|---|---|---|---|---|

| On/Off | Quantity (Units) | Flow Rate (m3/min) | Fan Placement | ||||

| Case 1 | 100 | L1 | Off | Off | - | - | - |

| Case 2 | 200 | Off | Off | - | - | - | |

| Case 3 | 300 | Off | Off | - | - | - | |

| Case 4 | Off | On | 1 | 47.5 | - | ||

| Case 5 | Off | On | 2 | 95 | Horizontal | ||

| Case 6 | On | Off | - | - | - | ||

| Case 7 | On | On | 1 | 18.7 | - | ||

| Case 8 | On | On | 1 | 47.5 | - | ||

| Case 9 | On | On | 2 | 37.4 | Horizontal | ||

| Case 10 | On | On | 2 | 95 | |||

| Case 11 | On | On | 2 | 37.4 | Diagonal | ||

| Case 12 | On | On | 2 | 95 | |||

| Case 13 | L2 | On | Off | - | - | ||

| Case 14 | On | On | 1 | 47.5 | - | ||

| Case 15 | On | On | 2 | 95 | Horizontal | ||

| Case | Case 3 | Case 6 |

|---|---|---|

| Mean hydrogen concentration ± Standard deviation | 4.12 ± 1.11 | 0.59 ± 1.20 |

| Case | Case 6 | Case 7 | Case 8 | Case 9 | Case 10 |

|---|---|---|---|---|---|

| Mean hydrogen concentration ± Standard deviation | 0.59 ± 1.20 | 0.70 ± 1.13 | 0.70 ± 1.10 | 0.45 ± 0.77 | 0.35 ± 0.81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, H.-L.; Seo, H.-S.; Shin, H.-C.; Hwang, I.-J. Safety Equipment Planning Through Experimental Analysis of Hydrogen Leakage and Ventilation in Enclosed Spaces. Sustainability 2025, 17, 7070. https://doi.org/10.3390/su17157070

Jang H-L, Seo H-S, Shin H-C, Hwang I-J. Safety Equipment Planning Through Experimental Analysis of Hydrogen Leakage and Ventilation in Enclosed Spaces. Sustainability. 2025; 17(15):7070. https://doi.org/10.3390/su17157070

Chicago/Turabian StyleJang, Hee-La, Hyeon-Seok Seo, Hong-Cheol Shin, and In-Ju Hwang. 2025. "Safety Equipment Planning Through Experimental Analysis of Hydrogen Leakage and Ventilation in Enclosed Spaces" Sustainability 17, no. 15: 7070. https://doi.org/10.3390/su17157070

APA StyleJang, H.-L., Seo, H.-S., Shin, H.-C., & Hwang, I.-J. (2025). Safety Equipment Planning Through Experimental Analysis of Hydrogen Leakage and Ventilation in Enclosed Spaces. Sustainability, 17(15), 7070. https://doi.org/10.3390/su17157070