Evaluating the Use of Rice Husk Ash for Soil Stabilisation to Enhance Sustainable Rural Transport Systems in Low-Income Countries

Abstract

1. Introduction

2. Rice Husk Ash as a Supplementary Cementitious Material

| Composition | Content (%) Arabani & Tahami (2017) [44] | Content (%) Zareei et al. (2017) [28] | Content (%) Anjum et al. (2025) [45] | Content (%) Valenzuela et al. (2025) [46] | Content (%) Shehata et al. (2024) [47] |

|---|---|---|---|---|---|

| SiO2 | 91.42 | 86.73 | 86.80 | 76.23 | 91.10 |

| CaO | 1.03 | 0.39 | 1.87 | 2.20 | 0.57 |

| K2O | 2.596 | 0.01 | - | 2.25 | 2.40 |

| Na2O | 1.12 | 9.76 | - | 0.67 | - |

| Al2O3 | 0.114 | 0.04 | 0.23 | 9.89 | 0.03 |

| MgO | 0.821 | 0.08 | 0.30 | 0.77 | - |

| SO3 | 0.572 | 1.32 | - | 0.27 | - |

| Fe2O3 | 0.197 | 0.61 | 0.10 | - | 0.05 |

| Others | 0.021 | - | 4.47 | 1.22 | 5.85 |

| Loss of ignition (LOI) | 2.109 | 0.54 | - | - | 4–6 |

3. Materials and Methods

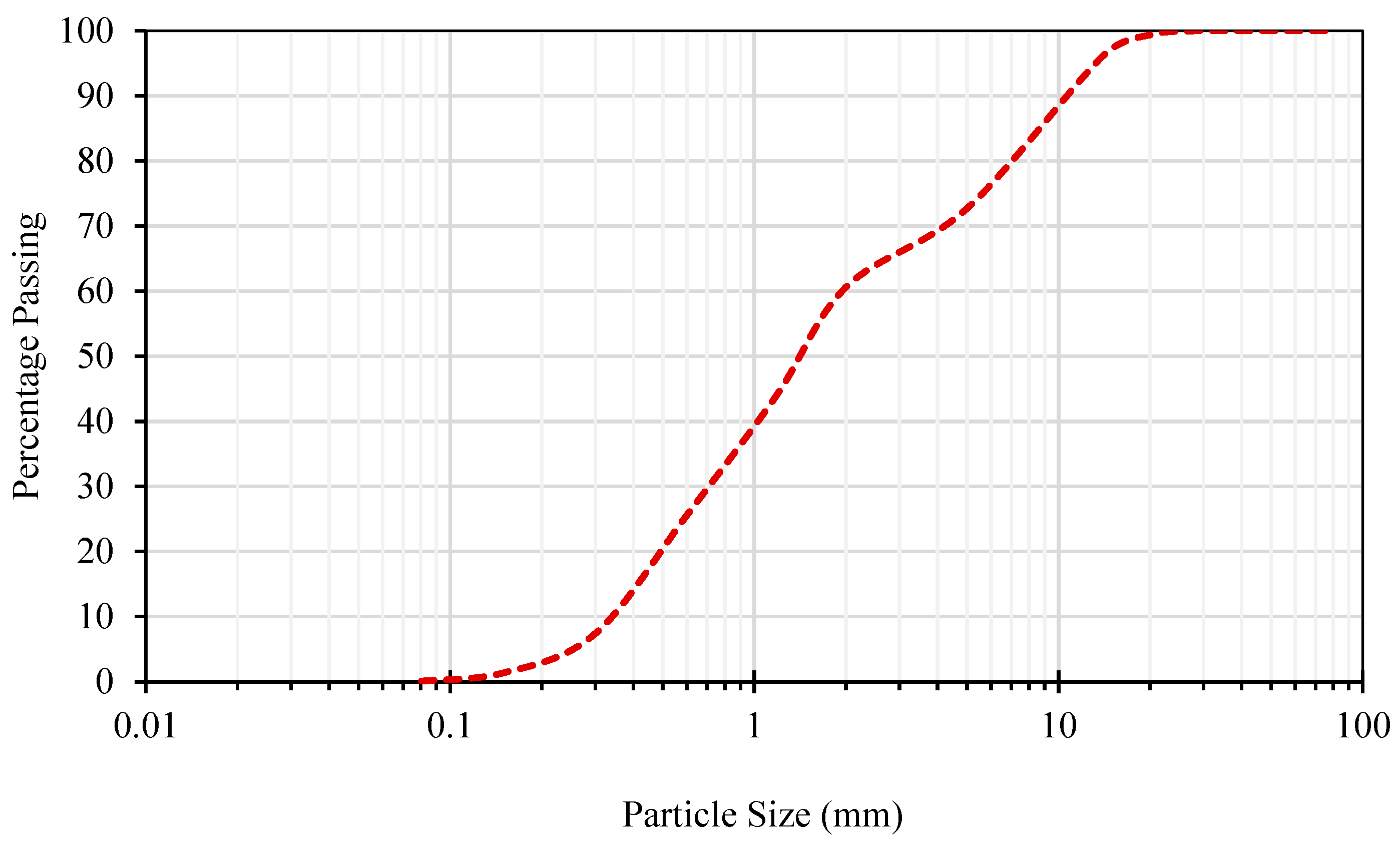

3.1. Sieve Analysis

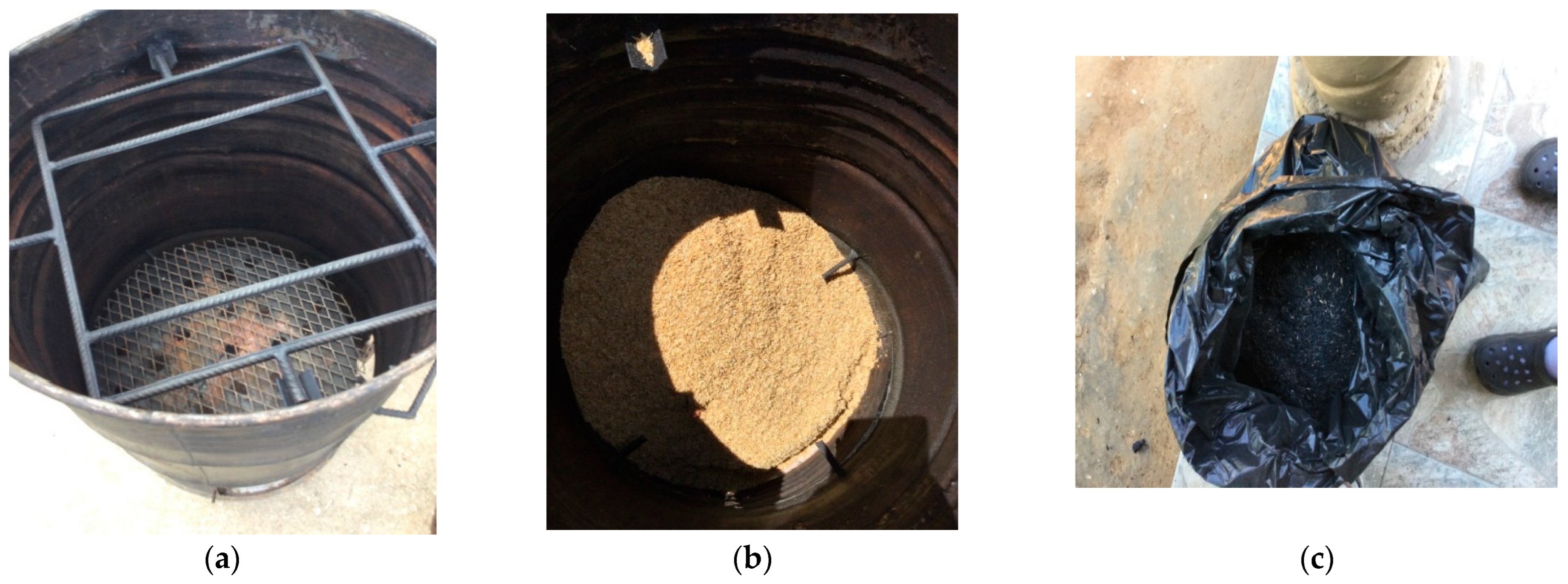

3.2. RHA Preparation

3.3. Sample Preparation

3.4. Experimental Procedure

4. Results

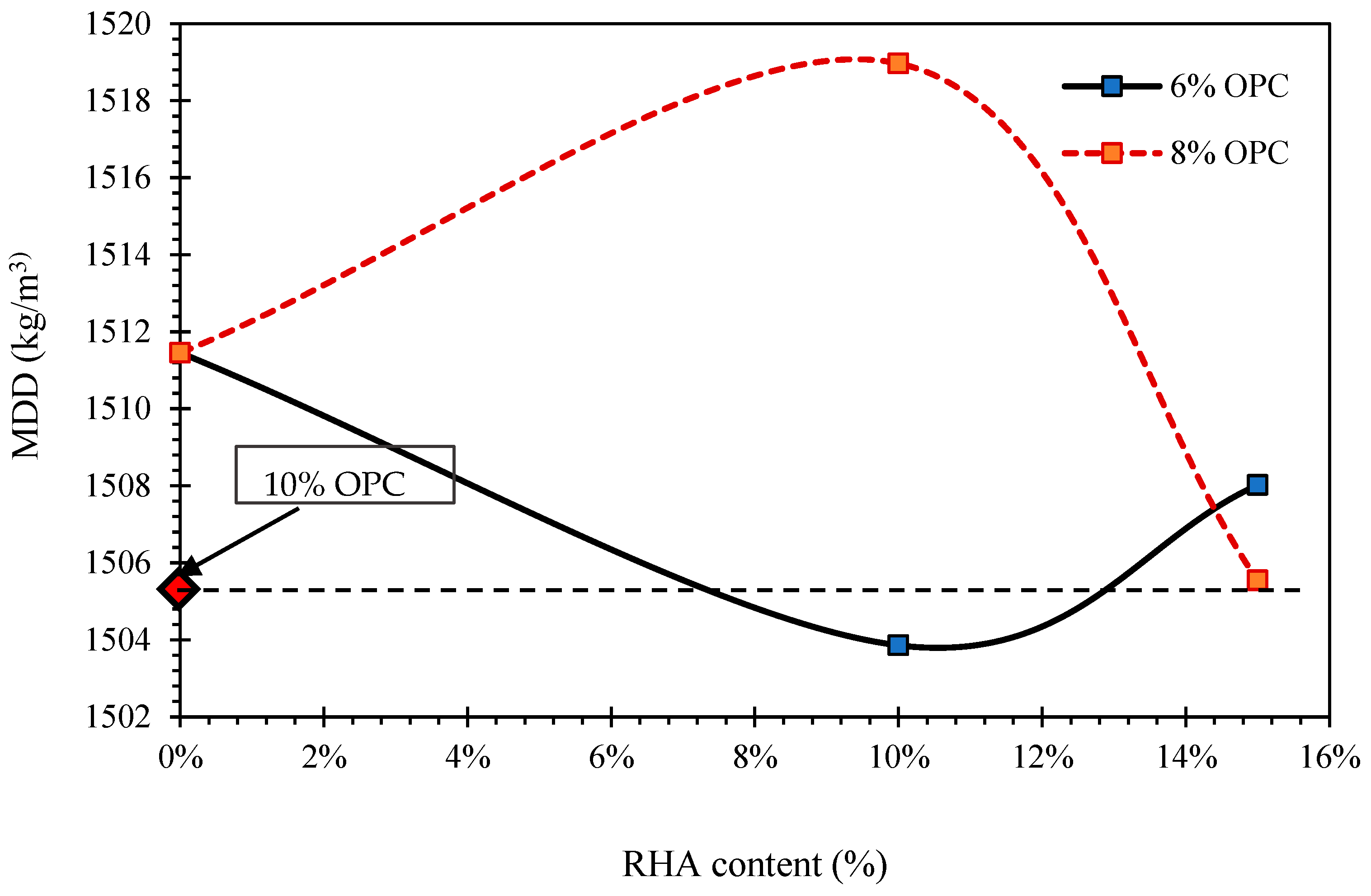

4.1. Maximum Dry Density

4.2. Optimum Moisture Content

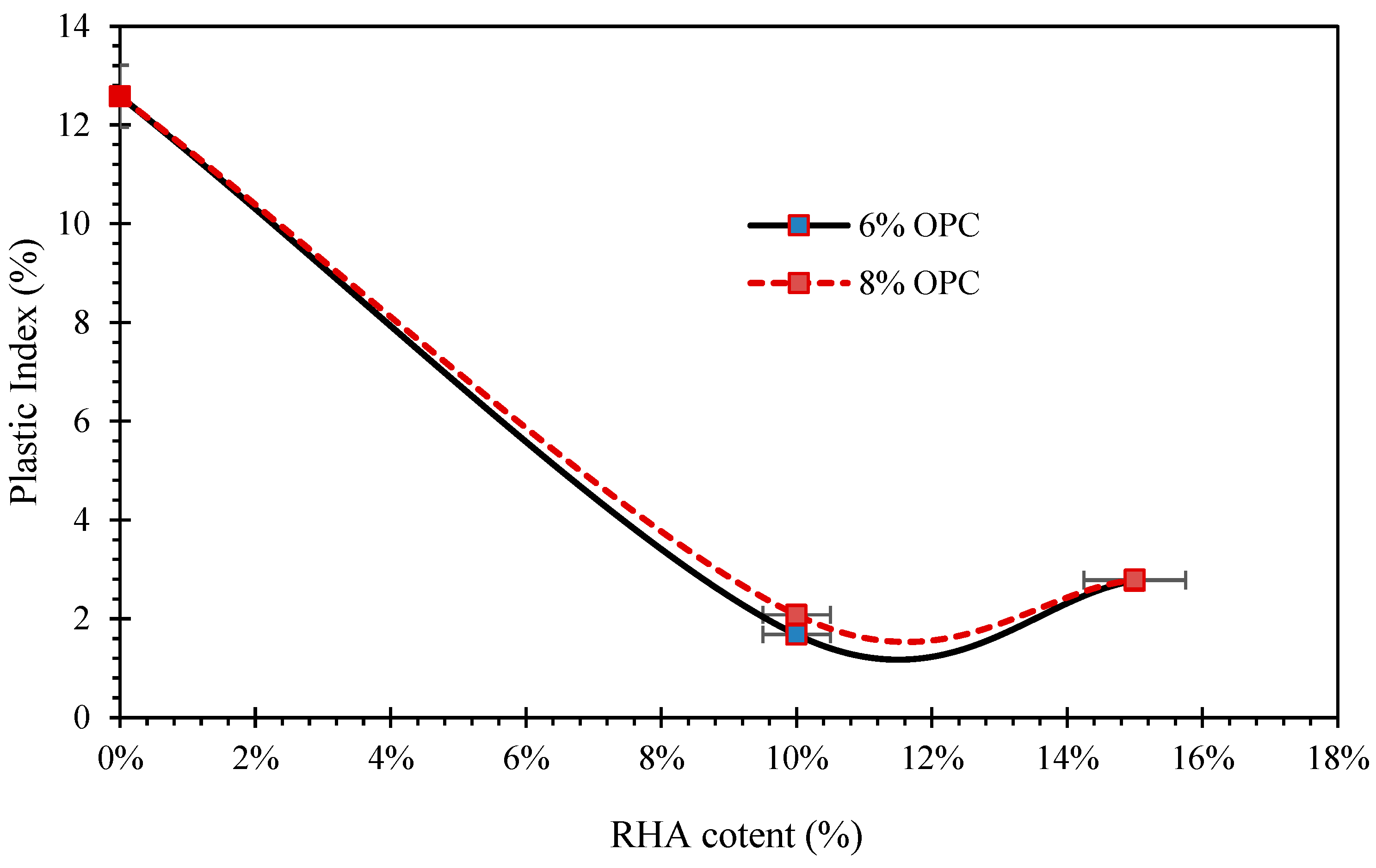

4.3. Soil Plasticity

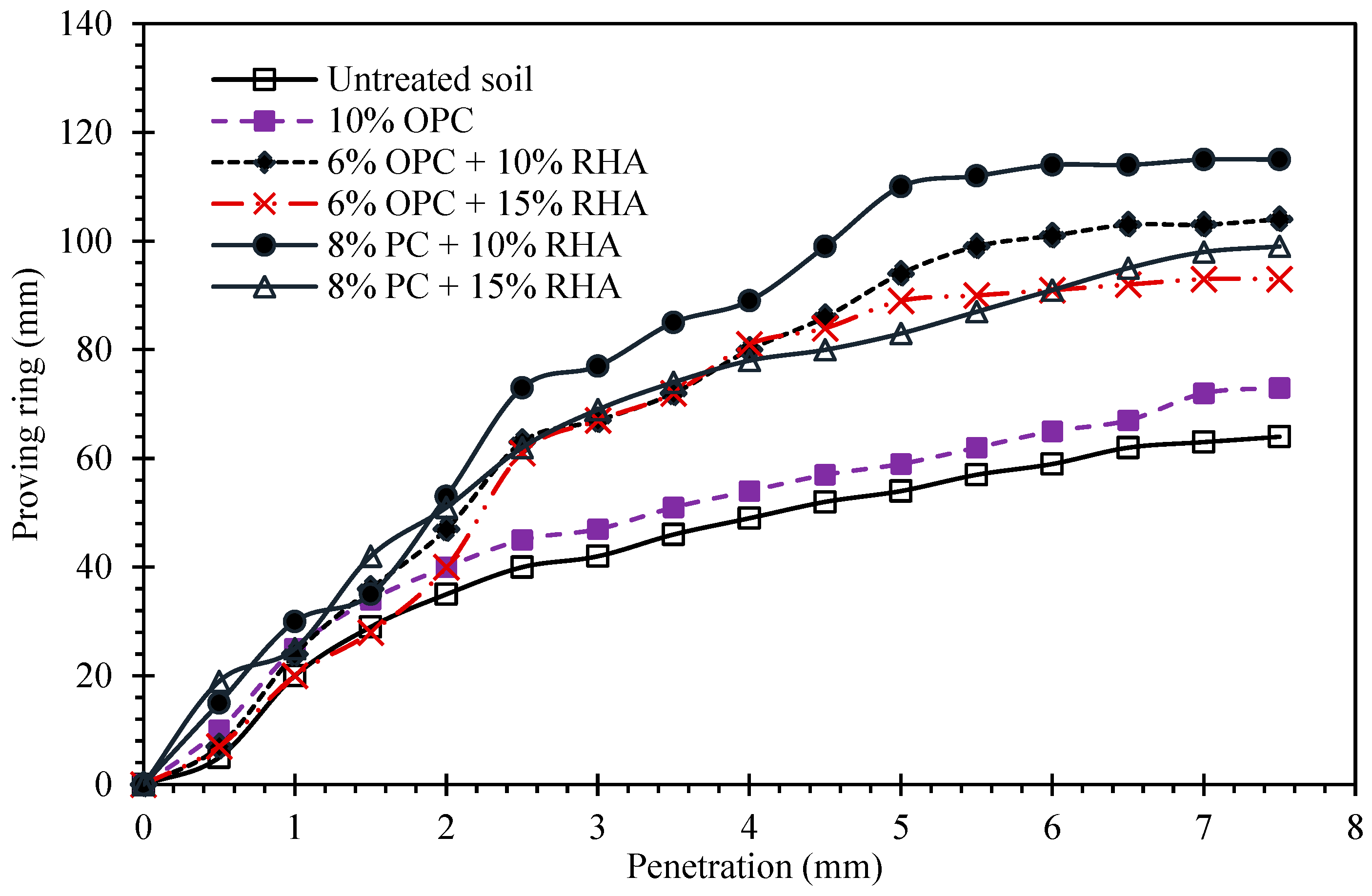

4.4. California Bearing Ratio

5. Discussion

6. Conclusions

- The untreated soil was a well-graded, slightly silty, gravelly sand with a maximum dry density of 1511.5 kg/m3 and an optimum moisture content of 19.6%. When treated with 8% OPC and 10% RHA, the MDD slightly increased to 1519 kg/m3, while the OMC rose to 25%, indicating the higher water demand of the porous RHA particles and potential to contain more infiltrated water before the failure of road foundations and embankments.

- The addition of OPC and RHA reduced the soil plasticity significantly, demonstrating that higher percentages of RHA tend to reduce the soil’s plasticity index. The reduction in the soil’s plasticity with increased RHA content implies that the treatment could be effective in reducing the cohesion between soil particles and hence improving drainage properties of the soils, which is an important parameter for the soils in road construction.

- The California bearing ratio (CBR) value, which was 7.43% for untreated soil, improved markedly in treated samples, with the 8% OPC + 10% RHA mixture demonstrating the highest resistance at both 2.5 mm and 5 mm penetration tests. This positive improvement in CBR values could be the most important effect of the RHA to the soils used in road construction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CBR | California bearing ratio |

| CRN | Core road network |

| RHA | Rice Hush Ash |

| OPC | Ordinary Portland Cement |

| OMC | Optimum moisture content |

| MDD | Maximum dry density |

| SSA | Sub-Saharan Africa |

References

- Kaiser, N.; Barstow, C.K. Rural transportation infrastructure in low- and middle-income countries: A review of impacts, implications, and interventions. Sustainability 2022, 14, 2149. [Google Scholar] [CrossRef]

- Torbaghan, M.E.; Ngezahayo, E.; Avis, W.; Luiu, C.; Burrow, M.; Paterson, J. Social Equity and Social Accessibility—A PIARC Special Project; World Road Association (PIARC): Paris, France, 2023. [Google Scholar]

- Ngezahayo, E.; Torbaghan, M.E.; Luiu, C.; Avis, W.; Obuolloh, E.O. Assessing social equity and accessibility of transport systems for people with disability in Kenya. In Proceedings of the 27th World Road Congress 2023, Prague, Czech Republic, 2–6 October 2023. [Google Scholar]

- Mokitimi, M.M.; Vanderschuren, M. Significance of non-motorised transport interventions in South Africa: A rural and local municipality focus. Transp. Res. Procedia 2017, 25, 4798–4821. [Google Scholar] [CrossRef]

- United Nations Department of Economic and Social Affairs. Goal 11: Sustainable Cities and Communities, SDGs 2030; United Nations: New York, NY, USA, 2024. [Google Scholar]

- Mazlumolhosseini, A. Relationships between Social and Economic Development and Access to Rural Roads in Developing Countries. Transp. Res. Rec. 1990, 1274, 179–194. [Google Scholar]

- Sieber, N.; Allen, H. Impacts of rural roads on poverty and equity. Transport and Communications Bulletin for Asia and the Pacific: Sustainable Rural Access (UN ESCAP, ST/ESCAP/SER.E/86) 2016, 86, 23–40. [Google Scholar]

- Road Development Agency. Zambia Road Maintenance Strategy: 2014–2024; RDA: Lusaka, Zambia, 2014. [Google Scholar]

- Road Development Agency. Road Development Agency 2022 Annual Report; RDA: Lusaka, Zambia, 2022. [Google Scholar]

- Cao, D.; He, Z.; Liu, Q. Study on the Stabilization Method and Performance for Local Material and its Application in Rural Road. In Proceedings of the International Conference of Chinese Transportation Professionals, Nanjing, China, 14–17 August 2011; pp. 3182–3192. [Google Scholar] [CrossRef]

- Nik Daud, N.N.; Jalil, F.N.A.; Celik, S.; Albayrak, Z.N.K. The important aspects of subgrade stabilization for road construction. IOP Conf. Ser. Mater. Sci. Eng. 2019, 512, 012005. [Google Scholar] [CrossRef]

- Wu, Y.; Satvati, S.; Li, C.; Ashlock, J.C.; Cetin, B.; Ceylan, H. Mechanistic Performance Evaluation of Chemically and Mechanically Stabilized Granular Roadways. In Proceedings of the Geo-Congress 2020, Minneapolis, MN, USA, 25–28 February 2020. [Google Scholar] [CrossRef]

- Ngezahayo, E.; Michael, P.N.B.; Ghataora, G.S. Rainfall induced erosion of soils used in earth roads. E3S Web Conf. 2019, 92, 17006. [Google Scholar] [CrossRef]

- Ngezahayo, E.; Burrow, M.P.N.; Ghataora, G.S. The Advances in Understanding Erodibility of Soils in Unpaved Roads. Int. J. Civ. Infrastruct. 2019, 2, 18–29. [Google Scholar] [CrossRef]

- Abe, E.O.; Adetoro, E.A. Assessment of Performance Properties of Stabilized Lateritic Soil for Road Construction in Ekiti State. Int. J. Adv. Eng. Res. Sci. 2017, 4, 33–39. [Google Scholar] [CrossRef]

- Khozin, V.; Khokhryakov, O.; Nizamov, R. A carbon footprint of low water demand cements and cement-based concrete. IOP Conf. Ser. Mater. Sci. Eng. 2020, 890, 012105. [Google Scholar] [CrossRef]

- Boesch, M.E.; Hellweg, S. Identifying Improvement Potentials in Cement Production with Life Cycle Assessment. Environ. Sci. Technol. 2010, 44, 9143–9149. [Google Scholar] [CrossRef]

- Bhat, D.A.K.; Marathe, S.; Ashmitha, N.M. Stabilization of Locally Available Soil using CNSA and Glass Industry Waste. Int. J. Recent Technol. Eng. 2019, 8, 4244–4249. [Google Scholar] [CrossRef]

- Our World in Data. Per Capita CO2 Emissions. Global Carbon Budget. 2023. Available online: https://ourworldindata.org/grapher/co-emissions-per-capita (accessed on 15 April 2025).

- United Nations Climate Change. Paris Agreement. The Paris Agreement | UNFCCC. 2015. United Nations Climate Change. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement (accessed on 18 April 2025).

- Schmidt, W.; Commeh, M.; Olonade, K.; Schiewer, G.L.; Dodoo-Arhin, D.; Dauda, R.; Fataei, S.; Tawiah, A.T.; Mohamed, F.; Thiedeitz, M.; et al. Sustainable circular value chains: From rural waste to feasible urban construction materials solutions. Dev. Built Environ. 2021, 6, 100047. [Google Scholar] [CrossRef]

- Schmidt, W.; Cunningham, P.R.; Shaba, A.F.; Olonade, K.; Ndawula, J.; Tawiah, A.T.; Marangu, J.M.; Tlhatlha, P.; Obeng, E. Informal Sector Inclusion in Sustainable Concrete Construction in Africa. In Smart & Sustainable Infrastructure: Building a Greener Tomorrow; Springer Nature: Berlin, Germany, 2024; Volume 1, pp. 506–520. [Google Scholar]

- Msinjili, N.S.; Schmidt, W.; Mota, B.; Leinitz, S.; Kühne, H.C.; Rogge, A. The effect of superplasticizers on rheology and early hydration kinetics of rice husk ash-blended cementitious systems. Constr. Build. Mater. 2017, 150, 511–519. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Fairbairn, E.M.R. Effect of calcination temperature on the pozzolanic activity of sugar cane bagasse ash. Constr. Build. Mater. 2009, 23, 3301–3303. [Google Scholar] [CrossRef]

- Msinjili, N.S.; Schmidt, W. Valorisation of Industrial By-products for Sustainable Cement and Concrete Construction-Improvement on solid waste management. In Proceedings of the 2nd KEYS Symposium on Knowledge Exchange for Young Scientists, Accra, Ghana, 6–10 June 2016. [Google Scholar]

- Shakouri, M.; Exstrom, C.L.; Ramanathan, S.; Suraneni, P. Hydration, strength, and durability of cementitious materials incorporating untreated corn cob ash. Constr. Build. Mater. 2020, 243, 118171. [Google Scholar] [CrossRef]

- Koteswara, R.D.; Pranav, P.R.T.; Anusha, M. Stabilization of Expansive Soil with Rice Husk Ash. Lime and Gypsum—An Experimental Study. Int. J. Eng. Sci. Technol. 2011, 3, 8076–8085. [Google Scholar]

- Zareei, S.A.; Ameri, F.; Dorostkar, F.; Ahmadi, M. Rice husk ash as a partial replacement of cement in high strength concrete containing micro silica: Evaluating durability and mechanical properties. Case Stud. Constr. Mater. 2017, 7, 73–81. [Google Scholar] [CrossRef]

- Tulashie, S.K.; Mensah, D.; Ebo, P.; Ansah, J.K. Production of Portland Pozzolana Cement from Rice Husk Ash. SSRN Electron. J. 2020, 16, 101048. [Google Scholar] [CrossRef]

- Hao, T.; Liu, Q.; Leng, F.G.; Qiao, T.L. Research progress of rice husk ash in solidified soil. E3S Web Conf. 2021, 293, 02018. [Google Scholar] [CrossRef]

- Sadiqul Hasan, N.S.; Sobuz, H.R.; Khan, M.H.; Mim, N.J.; Meraz, M.; Datta, S.D.; Rana, J.; Saha, A.; Akid, A.S.M.; Mehedi, T.; et al. Integration of Rice Husk Ash as Supplementary Cementitious Material in the Production of Sustainable High-Strength Concrete. Materials 2022, 15, 8171. [Google Scholar] [CrossRef]

- Msinjili, N.S.; Schmidt, W.; Rogge, A.; Kühne, H.C. Performance of rice husk ash blended cementitious systems with added superplasticizers. Cem. Concr. Compos. 2017, 83, 202–208. [Google Scholar] [CrossRef]

- Sun, H.; Li, Z.; Bai, J.; Memon, S.A.; Dong, B.; Fang, Y.; Xu, W.; Xing, F. Properties of Chemically Combusted Calcium Carbide Residue and Its Influence on Cement Properties. Materials 2015, 8, 638–651. [Google Scholar] [CrossRef] [PubMed]

- Das, S.K.; Adediran, A.; Kaze, C.R.; Mustakim, S.M.; Leklou, N. Production, characteristics, and utilization of rice husk ash in alkali activated materials: An overview of fresh and hardened state properties. Constr. Build. Mater. 2022, 345, 128341. [Google Scholar] [CrossRef]

- Sandhu, R.K.; Siddique, R. Properties of sustainable self-compacting concrete made with rice husk ash. Eur. J. Environ. Civ. Eng. 2022, 26, 6670–6694. [Google Scholar] [CrossRef]

- Bayapureddy, Y.; Muniraj, K.; Mutukuru, M.R.G. Sugarcane bagasse ash as supplementary cementitious material in cement composites: Strength. durability, and microstructural analysis. J. Korean Ceram. Soc. 2020, 57, 513–519. [Google Scholar] [CrossRef]

- Jiang, X.; Luo, X.; Ma, F.; Huang, Z. Analysis of Strength Development and Soil-Water Characteristics of Rice Husk Ash-Lime Stabilized Soft Soil. Materials. Materials 2019, 12, 3873. [Google Scholar] [CrossRef]

- Nair, D.G.; Fraaij, A.L.A.; Klaassen, A.A.K.; Kentgens, A.P.M. A structural investigation relating to the pozzolanic activity of rice husk ashes. Cem. Concr. Res. 2008, 38, 861–869. [Google Scholar] [CrossRef]

- Farooque, K.N.; Zaman, M.; Halim, E.; Islam, S.; Hossain, M.; Mollah, Y.A.; Mahmood, A.J. Characterization and Utilization of Rice Husk Ash (RHA) from Rice Mill of Bangladesh. Bangladesh J. Sci. Ind. Res. 2009, 44, 157–162. [Google Scholar] [CrossRef]

- Endale, S.A.; Taffese, W.Z.; Vo, D.-H.; Yehualaw, M.D. Rice Husk Ash in Concrete. Sustainability 2022, 5, 137. [Google Scholar] [CrossRef]

- Pushpakumara, B.H.J.; Mendis, W.S.W. Suitability of Rice Husk Ash (RHA) with lime as a soil stabilizer in geotechnical applications. Int. J. Geo-Eng. 2022, 13, 4. [Google Scholar] [CrossRef]

- Roy, A. Soil Stabilization using Rice Husk Ash and Cement. Int. J. Civ. Eng. Res. 2014, 5, 49–54. [Google Scholar]

- Yan, K.; Lan, H.; Li, Q.; Ge, D.; Li, Y. Optimum utilization of recycled aggregate and rice husk ash stabilized base material. Constr. Build. Mater. 2022, 348, 128627. [Google Scholar] [CrossRef]

- Arabani, M.; Tahami, S.A. Assessment of mechanical properties of rice husk ash modified asphalt mixture. Constr. Build. Mater. 2017, 149, 350–358. [Google Scholar] [CrossRef]

- Anjum, S.; Sharma, A.; Onyelowe, K.C.; Alsabhan, A.H.; Alam, S.; Singh, K.; Tiwary, A.K.; Sharma, S.; Qadri, J. Sustainable subgrade improvement with calcium carbide residue and rice husk ash. Sci. Rep. 2025, 15, 14351. [Google Scholar] [CrossRef]

- Valenzuela, M.; Tuninetti, V.; Ciudad, G.; Miranda, A.; Oñate, A. Designing sustainable cement free compositions with rice husk ash to improve mechanical performance in next generation ecoblocks. Sci. Rep. 2025, 15, 14920. [Google Scholar] [CrossRef] [PubMed]

- Shehata, A.A.A.; Owino, A.O.; Islam, M.Y.; Hossain, Z. Shear strength of soil by using rice husk ash waste for sustainable ground improvement. Discov. Sustain. 2024, 5, 64. [Google Scholar] [CrossRef]

- Ma, J.; Su, Y.; Liu, Y.; Tao, X. Strength and Microfabric of Expansive Soil Improved with Rice Husk Ash and Lime. Adv. Civ. Eng. 2020, 2020, 9646205. [Google Scholar] [CrossRef]

- Basha, E.A.; Hashim, R.; Mahmud, H.B.; Muntohar, A.S. Stabilization of residual soil with rice husk ash and cement. Constr. Build. Mater. 2005, 19, 448–453. [Google Scholar] [CrossRef]

- Rahman, M.A. A comparative study of the potentials of rice husk ash on cohesive and cohesionless soils. Build. Environ. 1987, 22, 331–337. [Google Scholar] [CrossRef]

- Rainaud, C.; Master, S.; Armstrong, R.A.; Robb, L.J. Geochronology and nature of the Palaeoproterozoic basement in the Central African Copperbelt (Zambia and the Democratic Republic of Congo), with regional implications. J. Afr. Earth Sci. 2005, 42, 1–31. [Google Scholar] [CrossRef]

- BS 1377-2:2022; Methods of Test for Soils for Civil Engineering Purposes—Part 2: General Requirements and Sample Preparation. British Standards Institute (BSI): London, UK, 1990.

- BS 5930:2015+A1:2020; Code of Practice for Ground Investigations. British Standards Institution (BSI): London, UK, 2020.

- BS 1377-4:1990; Methods of Test for Soils for Civil Engineering Purposes—Part 4: Compaction-Related Tests. British Standards Institution (BSI): London, UK, 1990.

- Verma, S.; Khanduri, V.S.; Mittal, A. Stabilization of colluvial soil using rice husk ash and micro silica powder. Mater. Today Proc. 2020, 32, 819–823. [Google Scholar] [CrossRef]

- Zha, F.; Du, Y.; Liu, S.; Cui, K. Behavior of expansive soils stabilized with fly ash. Nat. Hazards 2008, 47, 509–523. [Google Scholar] [CrossRef]

| BS test sieve (mm) | 14–20 | 2–5 | 0.0006–1.18 | 0.00015–0.0003 | <0.000075 |

|---|---|---|---|---|---|

| Cumulative percentage passing | 96.4 | 61.4 | 26.4 | 2.4 | 1.4 |

| Sample No. | Soil% | OPC% | RHA% |

|---|---|---|---|

| 1 | 100 | - | - |

| 2 | 90 | 10 | |

| 3 | 84 | 6 | 10 |

| 4 | 79 | 6 | 15 |

| 5 | 82 | 8 | 10 |

| 6 | 77 | 8 | 15 |

| Soil Property | Value |

|---|---|

| Gravel (%) | 30 |

| Sand (%) | 50 |

| Silt (%) | 20 |

| Liquid limit (%) | 30.3 |

| Plastic limit (%) | 17.72 |

| Plasticity Index (%) | 12.58 |

| Linear Shrinkage (%) | 4.29 |

| Specific Gravity | 4.9 |

| BS Classification | Well-graded, slightly silty, gravelly sand with low plasticity |

| Colour | Reddish-brown |

| Maximum Dry Density (kg/m3) | 1511.5 |

| Optimum Moisture Content (%) | 19.6 |

| Unsoaked CBR (%) | 7.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shaba, A.F.; Ngezahayo, E.; Masheka, G.; Sakuhuka, K.S. Evaluating the Use of Rice Husk Ash for Soil Stabilisation to Enhance Sustainable Rural Transport Systems in Low-Income Countries. Sustainability 2025, 17, 7022. https://doi.org/10.3390/su17157022

Shaba AF, Ngezahayo E, Masheka G, Sakuhuka KS. Evaluating the Use of Rice Husk Ash for Soil Stabilisation to Enhance Sustainable Rural Transport Systems in Low-Income Countries. Sustainability. 2025; 17(15):7022. https://doi.org/10.3390/su17157022

Chicago/Turabian StyleShaba, Ada Farai, Esdras Ngezahayo, Goodson Masheka, and Kajila Samuel Sakuhuka. 2025. "Evaluating the Use of Rice Husk Ash for Soil Stabilisation to Enhance Sustainable Rural Transport Systems in Low-Income Countries" Sustainability 17, no. 15: 7022. https://doi.org/10.3390/su17157022

APA StyleShaba, A. F., Ngezahayo, E., Masheka, G., & Sakuhuka, K. S. (2025). Evaluating the Use of Rice Husk Ash for Soil Stabilisation to Enhance Sustainable Rural Transport Systems in Low-Income Countries. Sustainability, 17(15), 7022. https://doi.org/10.3390/su17157022