Parametric Analysis of Rammed Earth Walls in the Context of the Thermal Protection of Environmentally Friendly Buildings

Abstract

1. Introduction

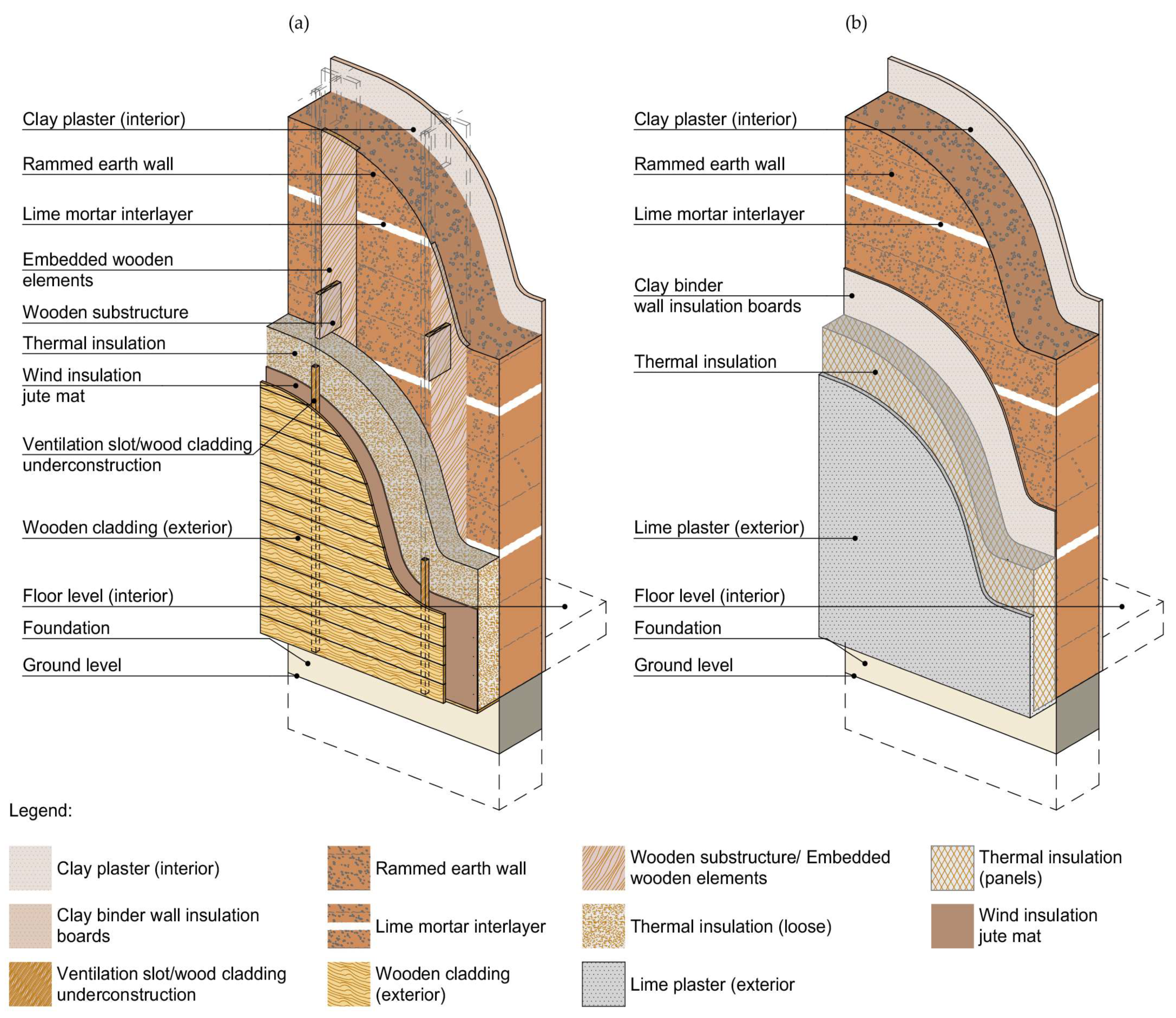

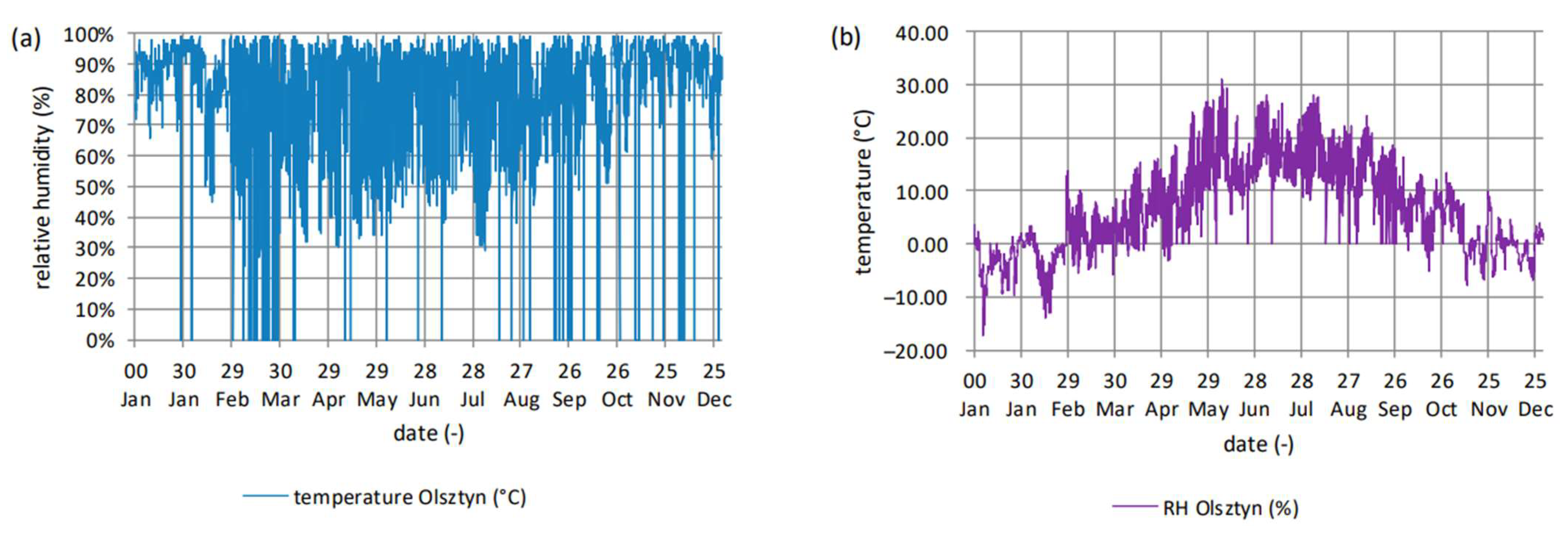

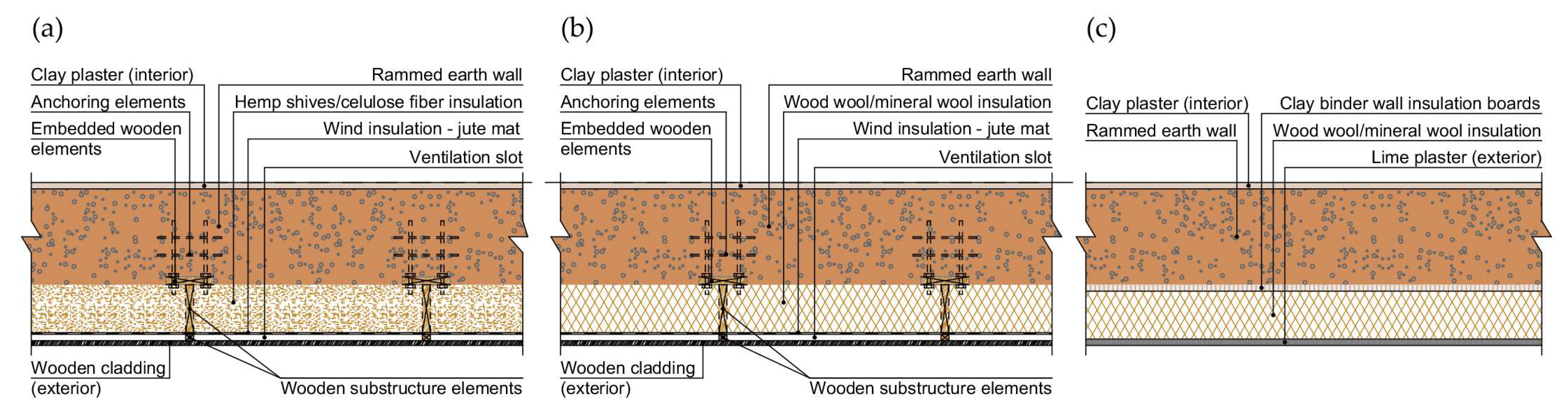

2. Materials and Methods

3. Results

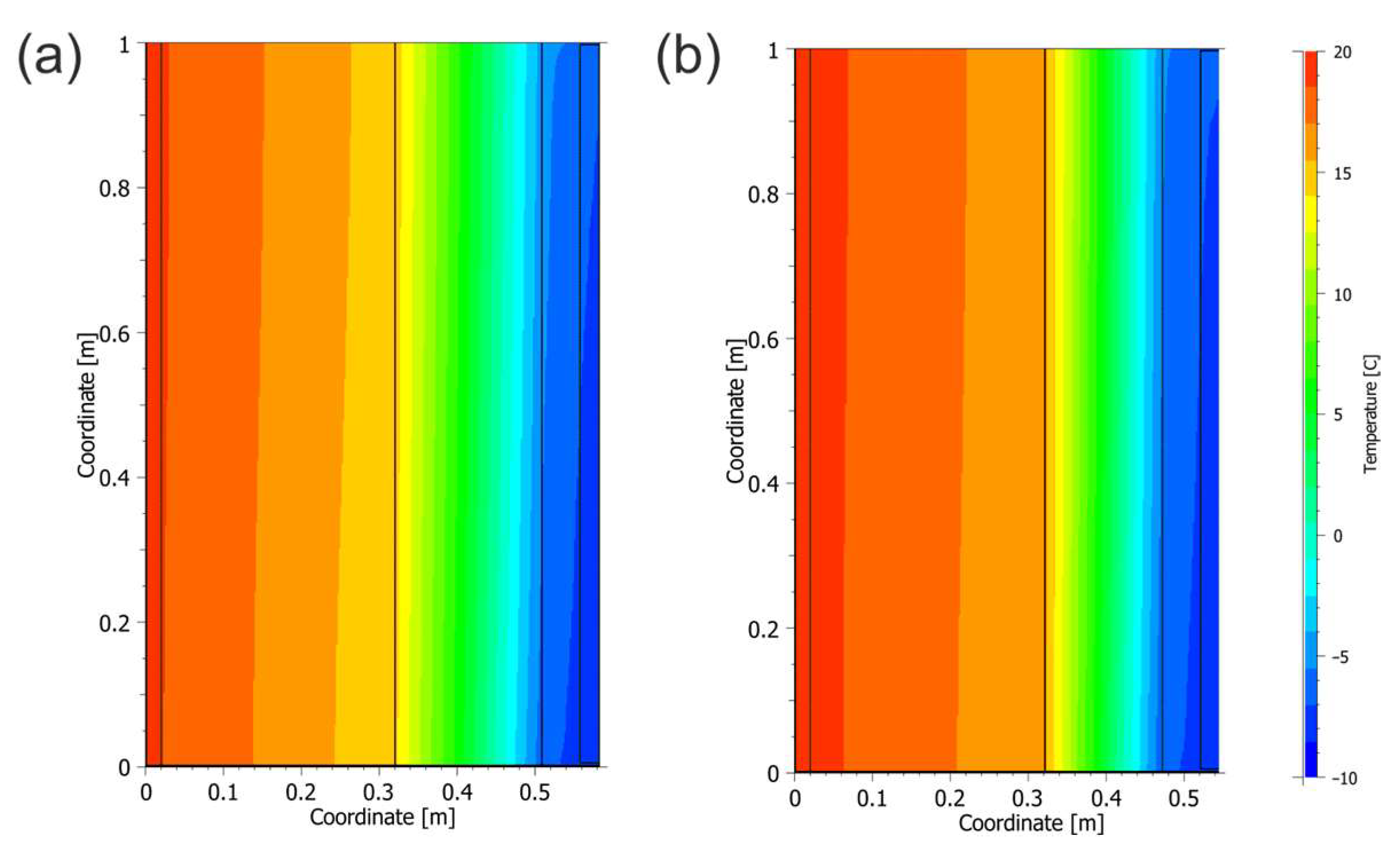

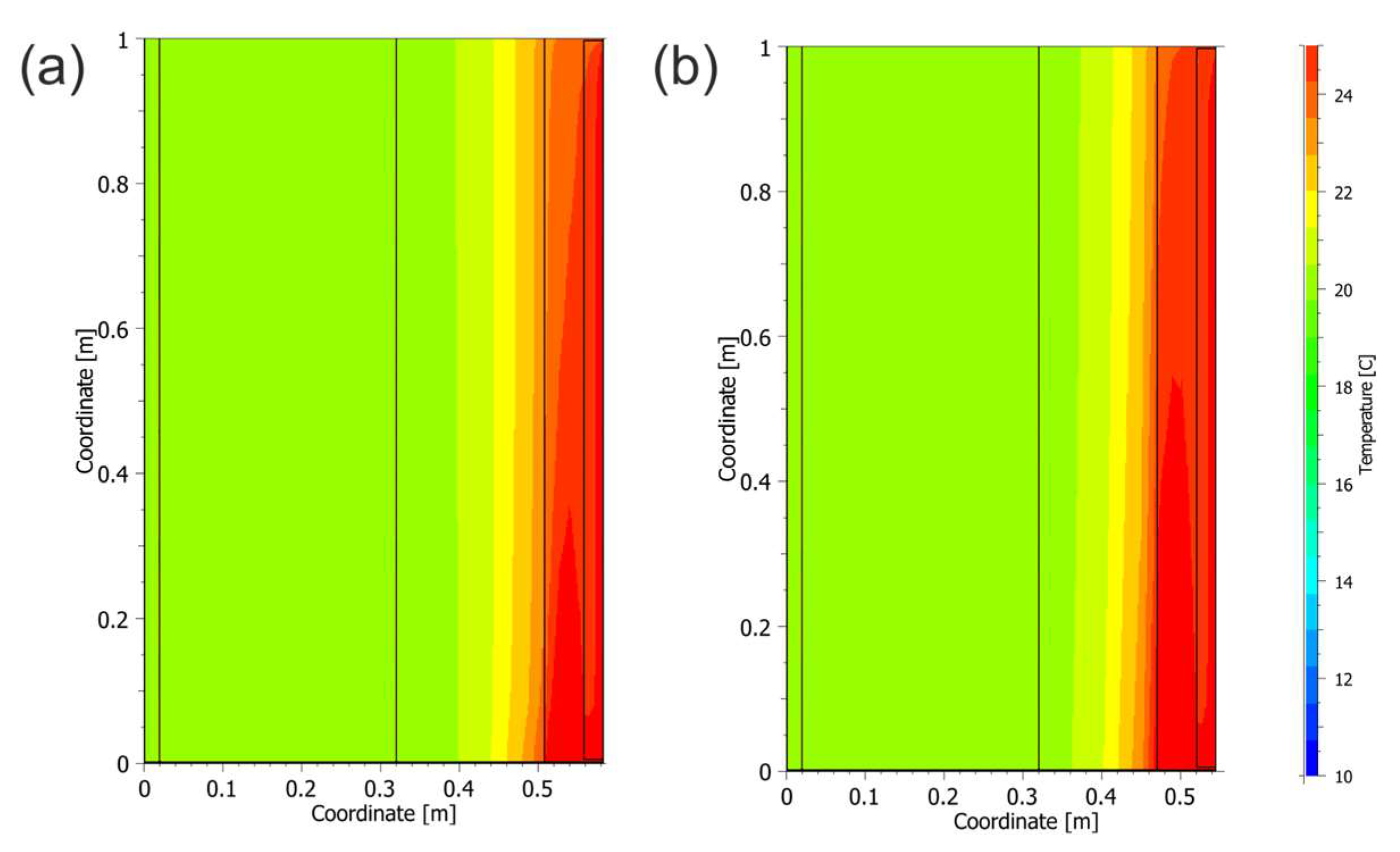

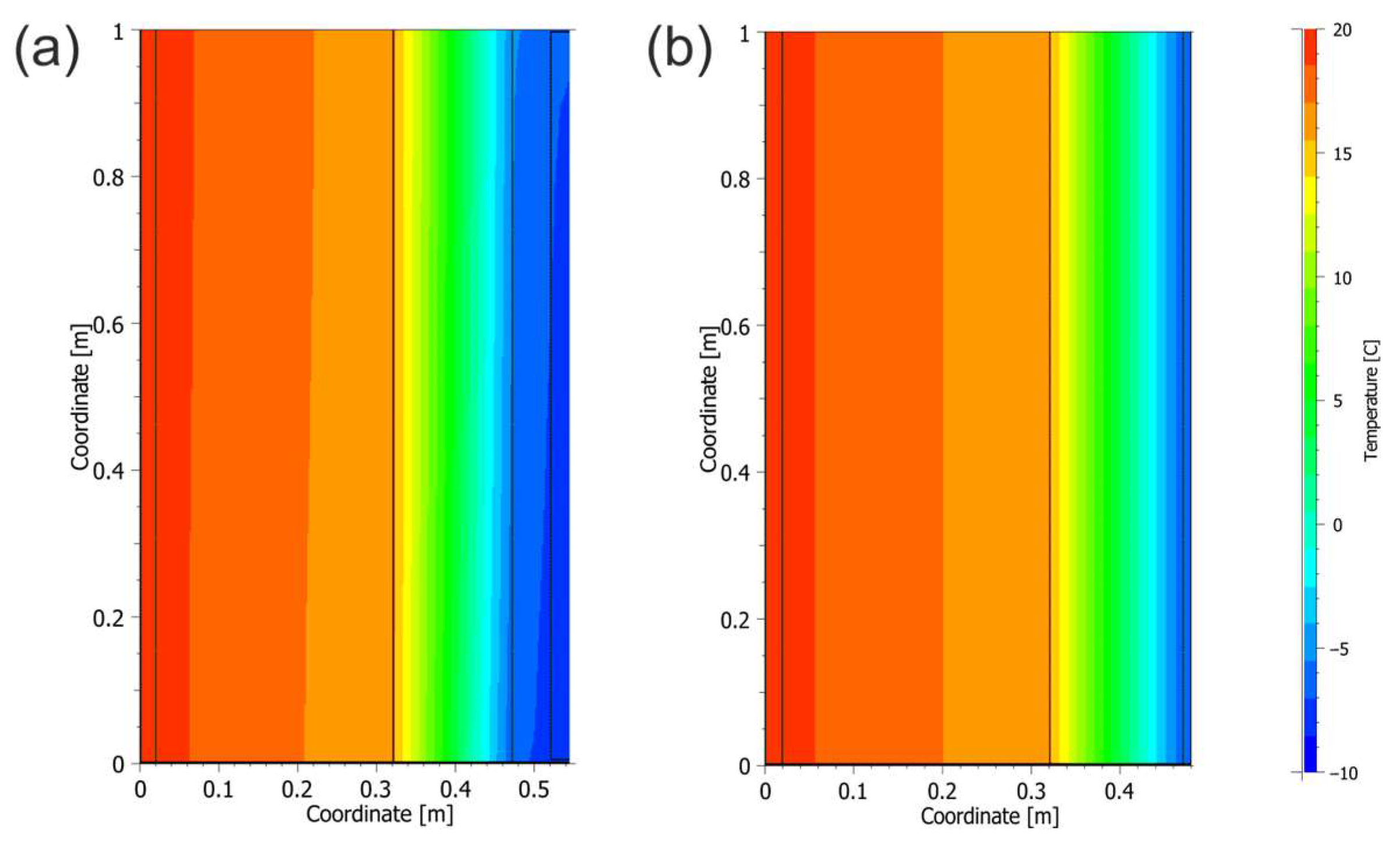

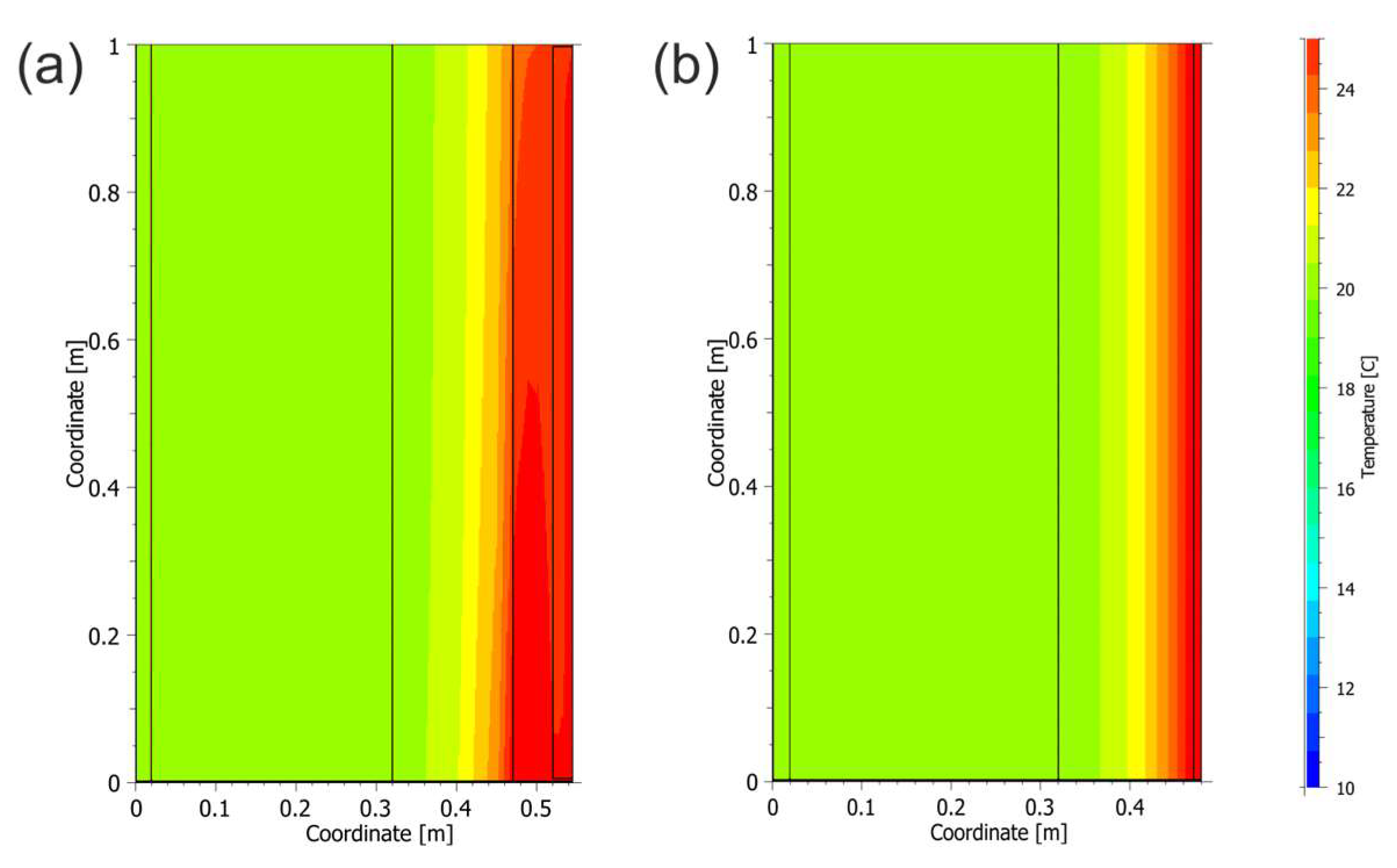

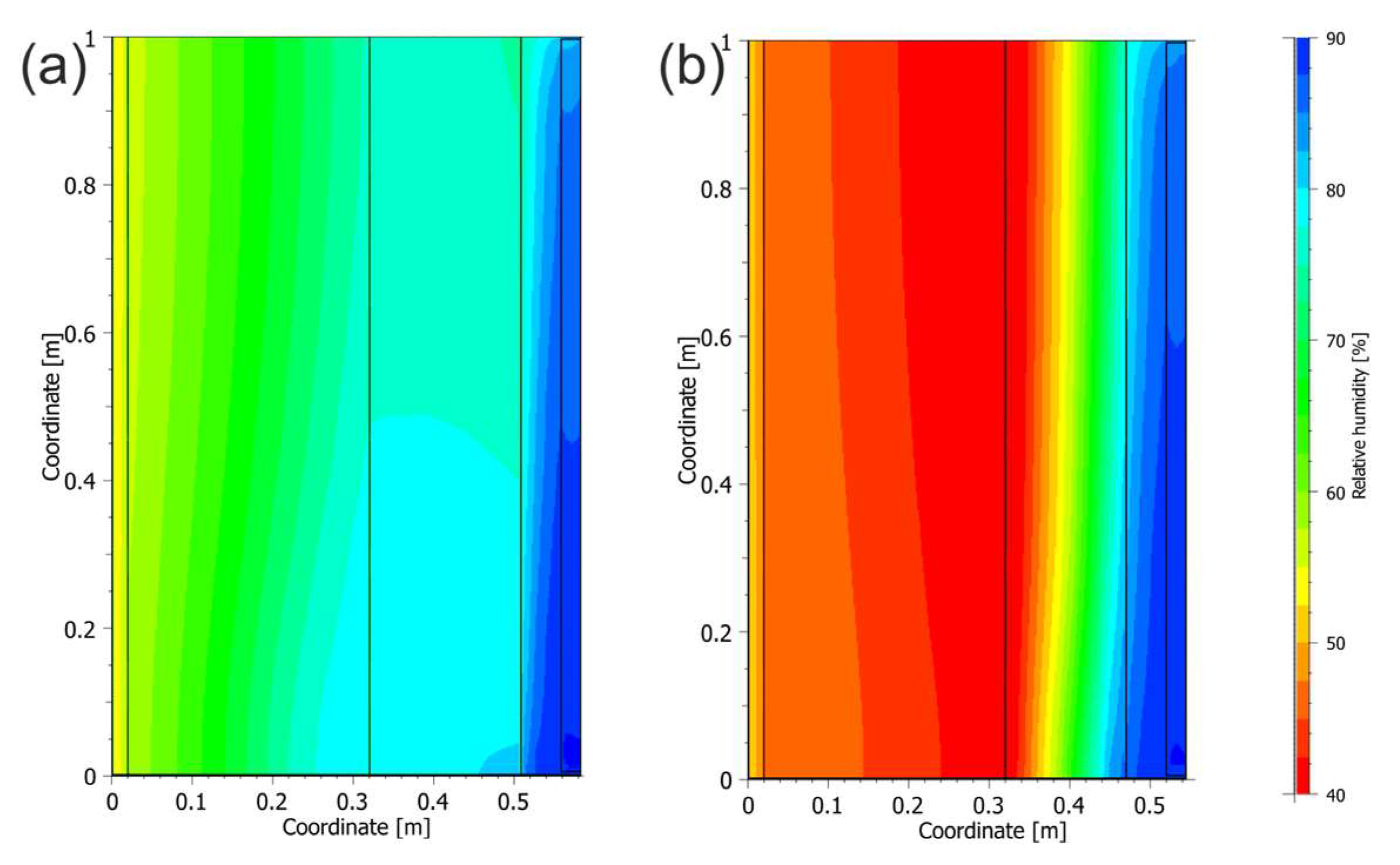

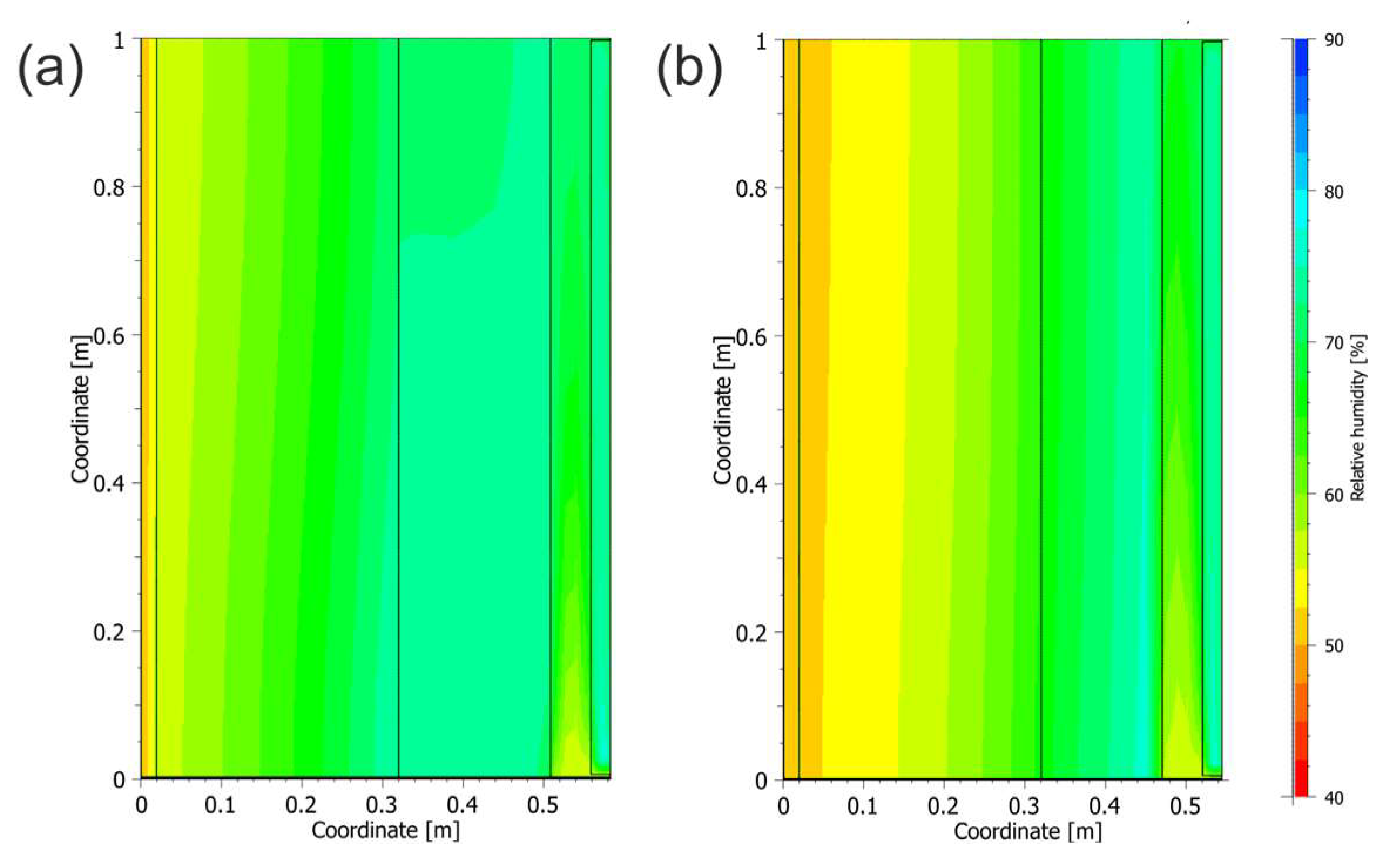

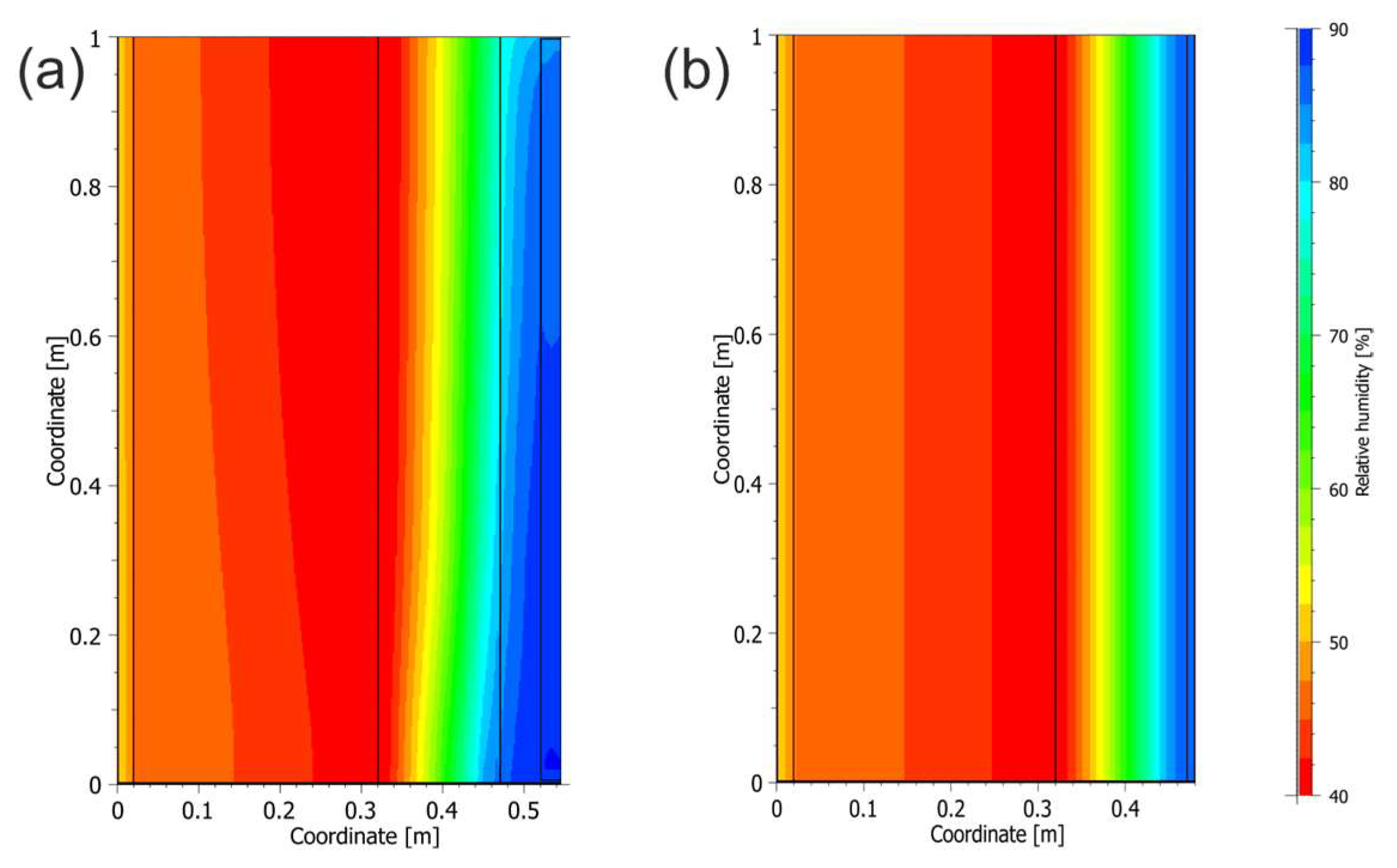

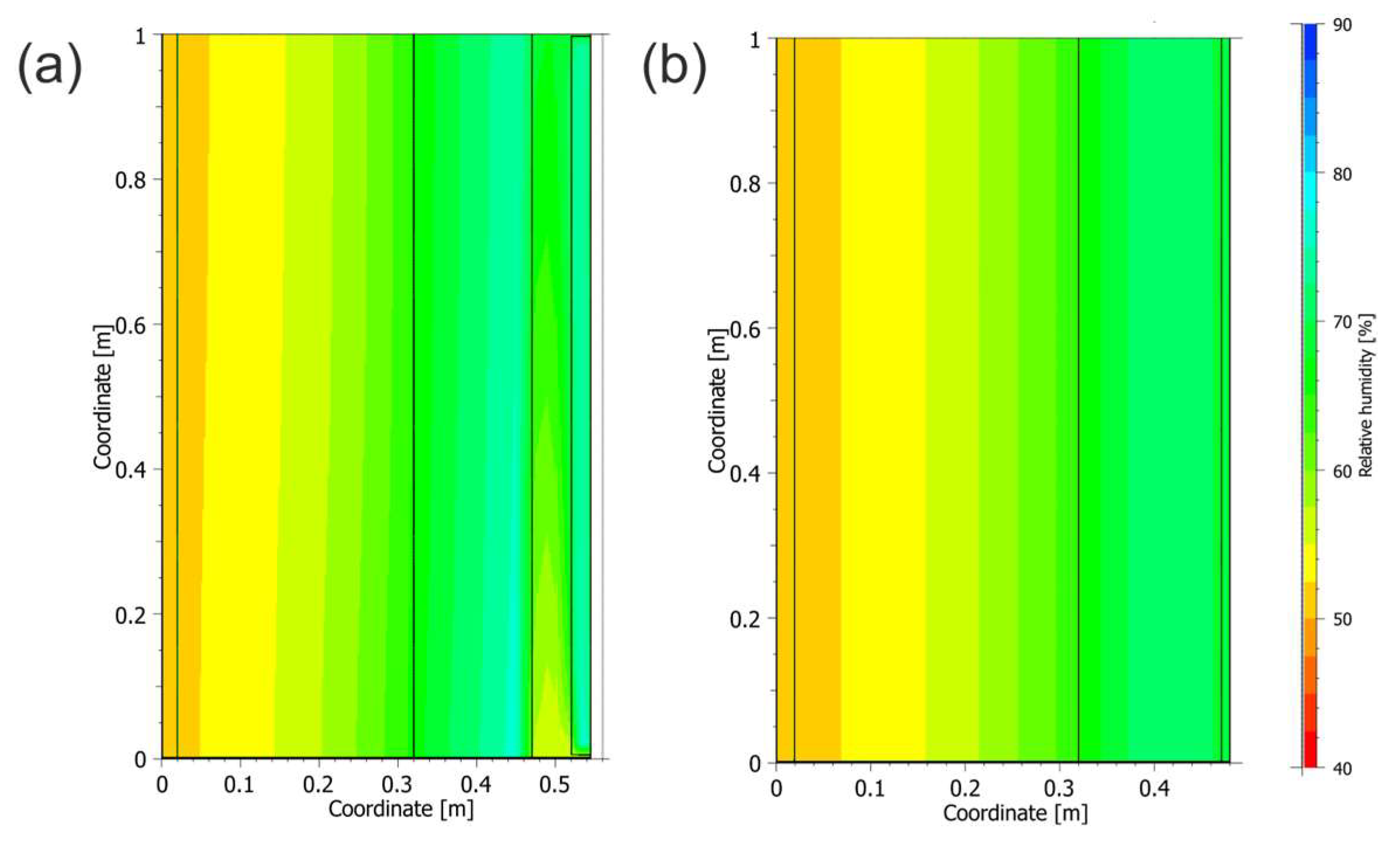

3.1. Temperature Distribution and Relative Humidity

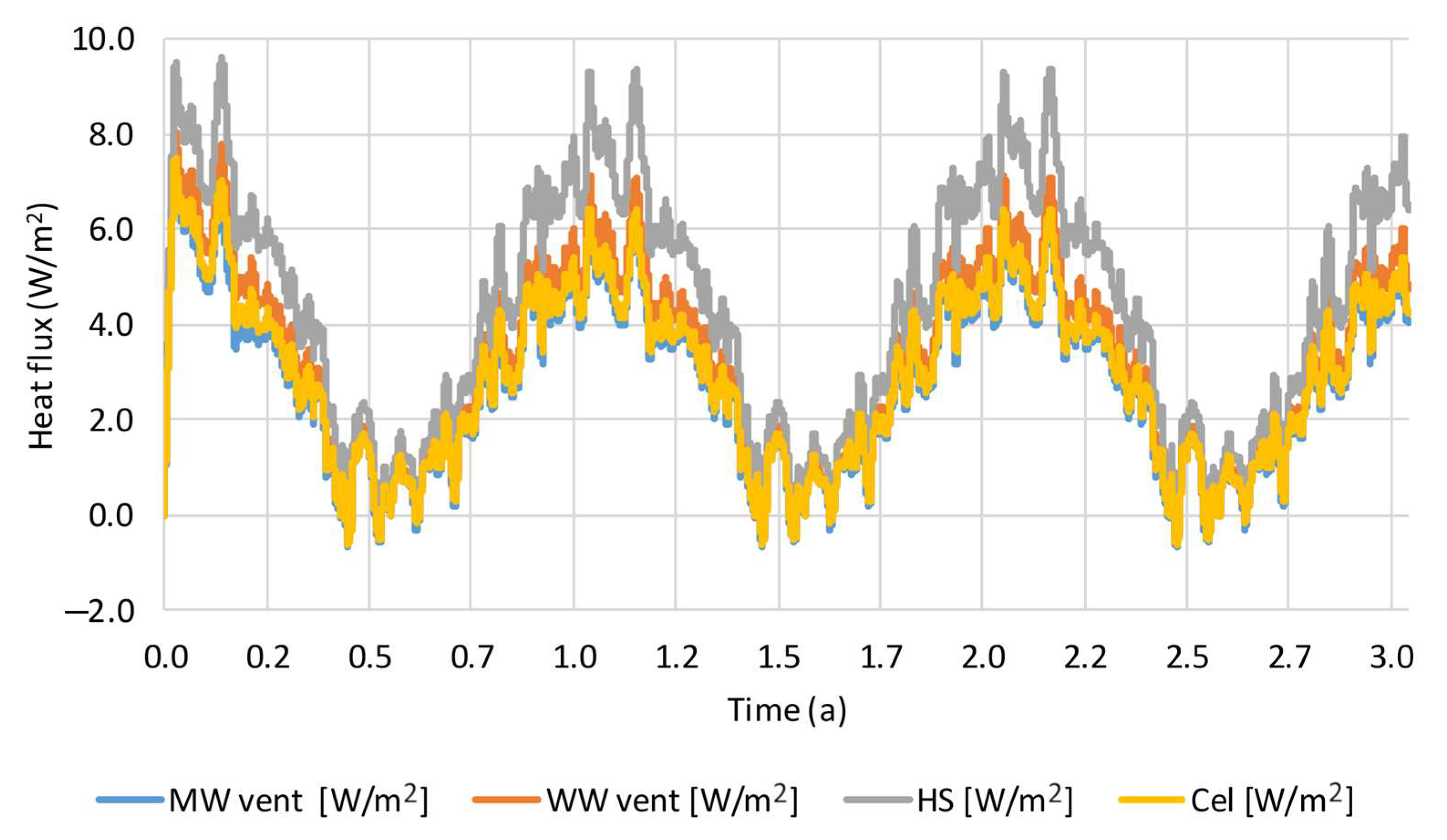

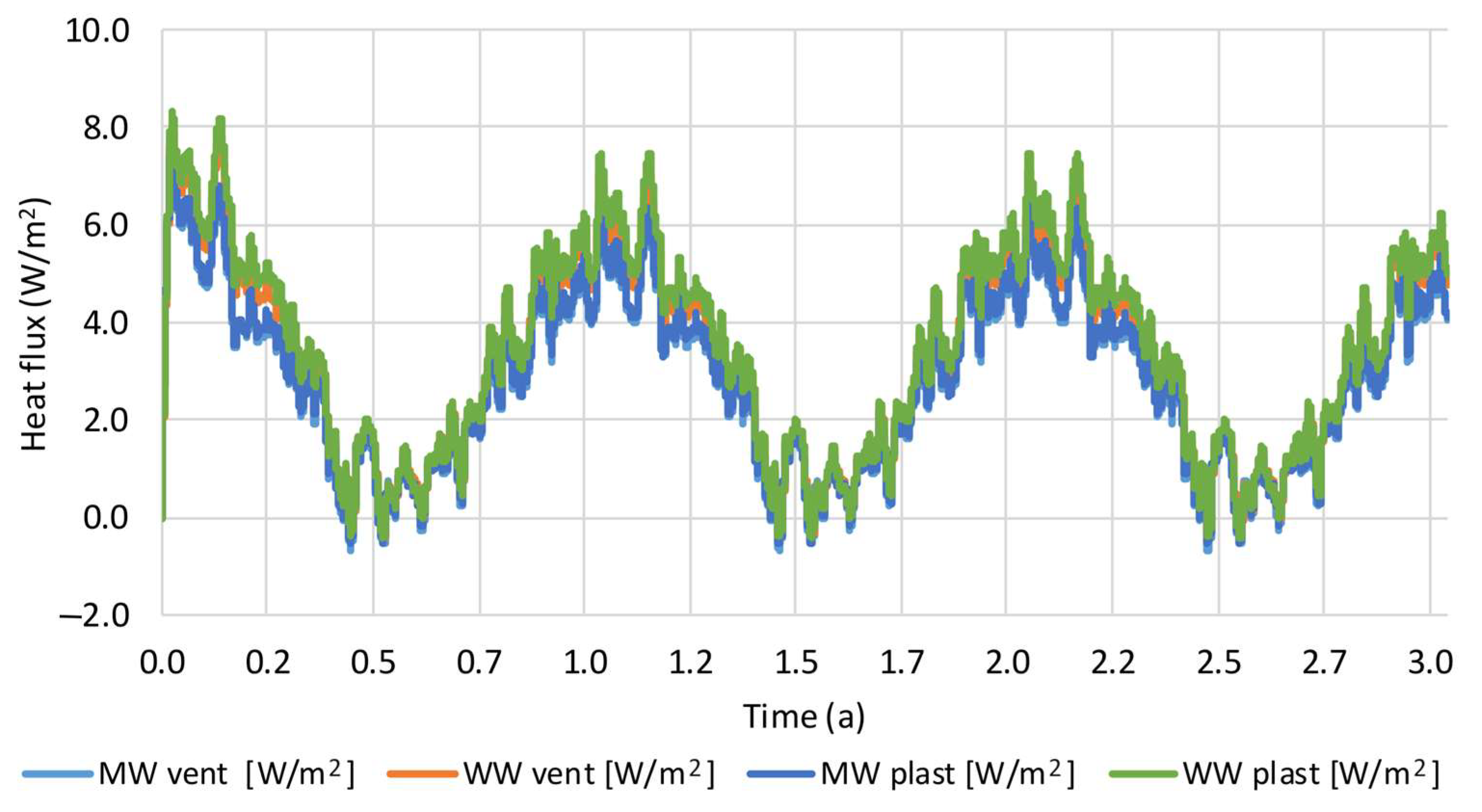

3.2. Heat Flux

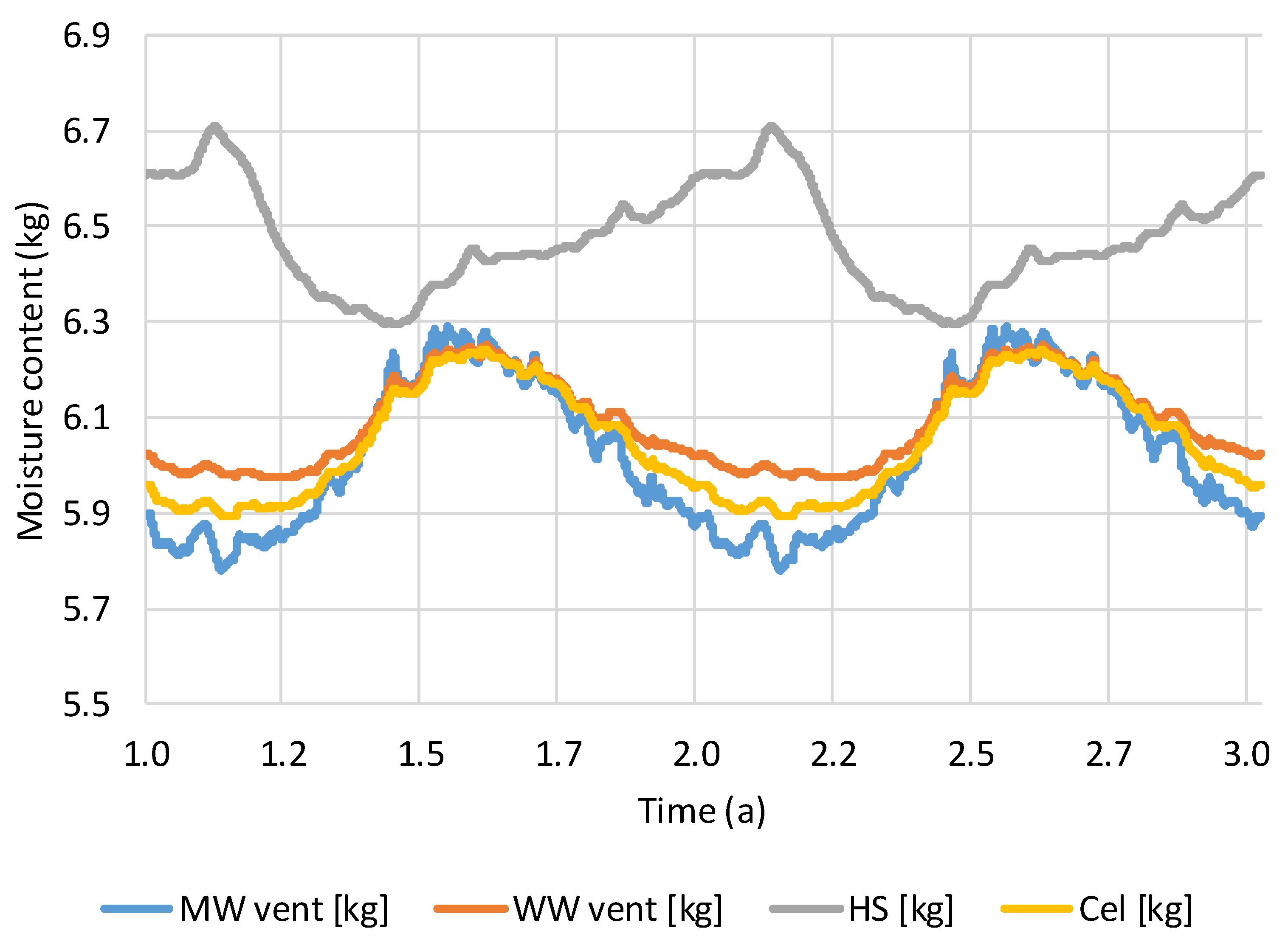

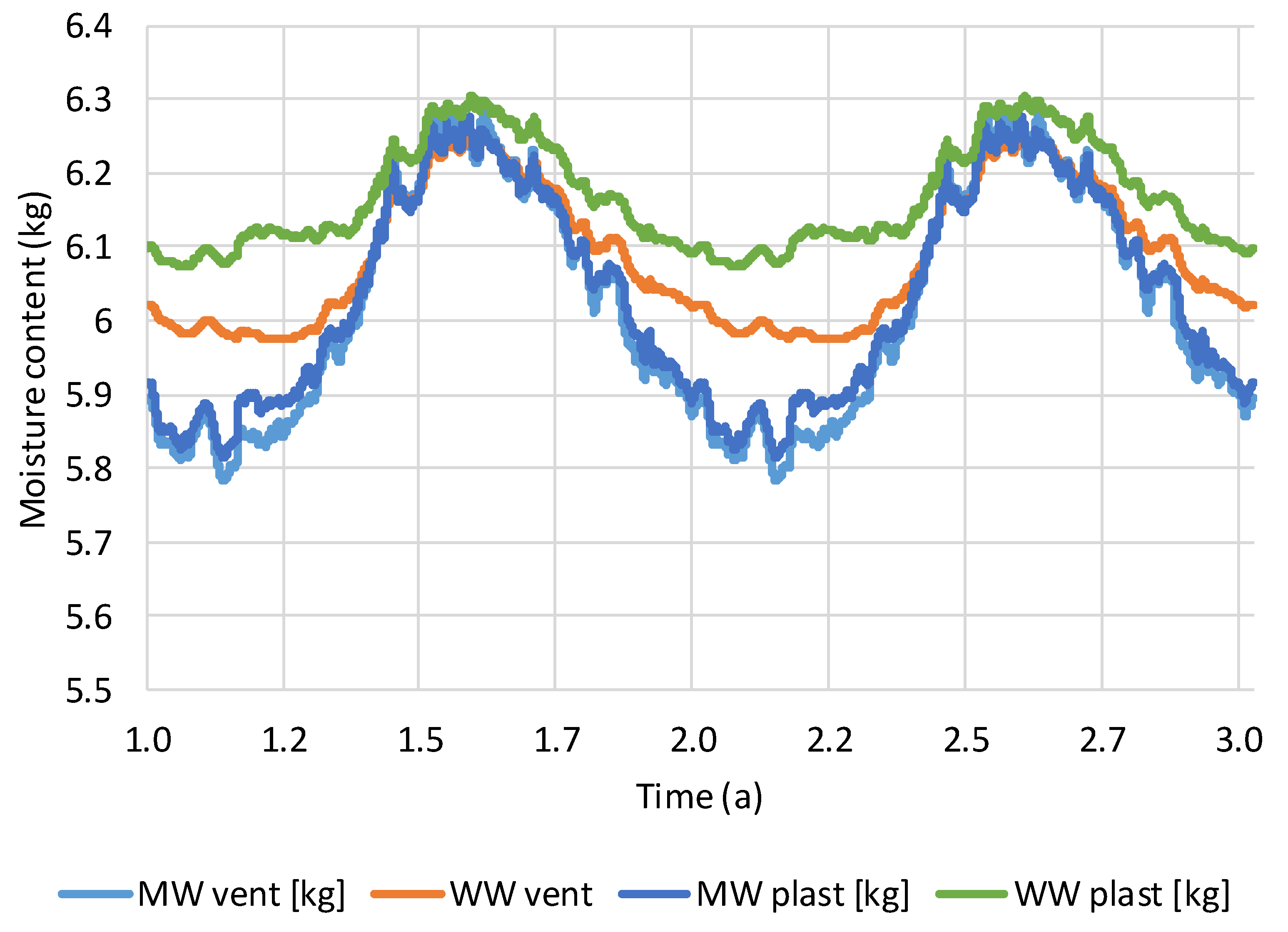

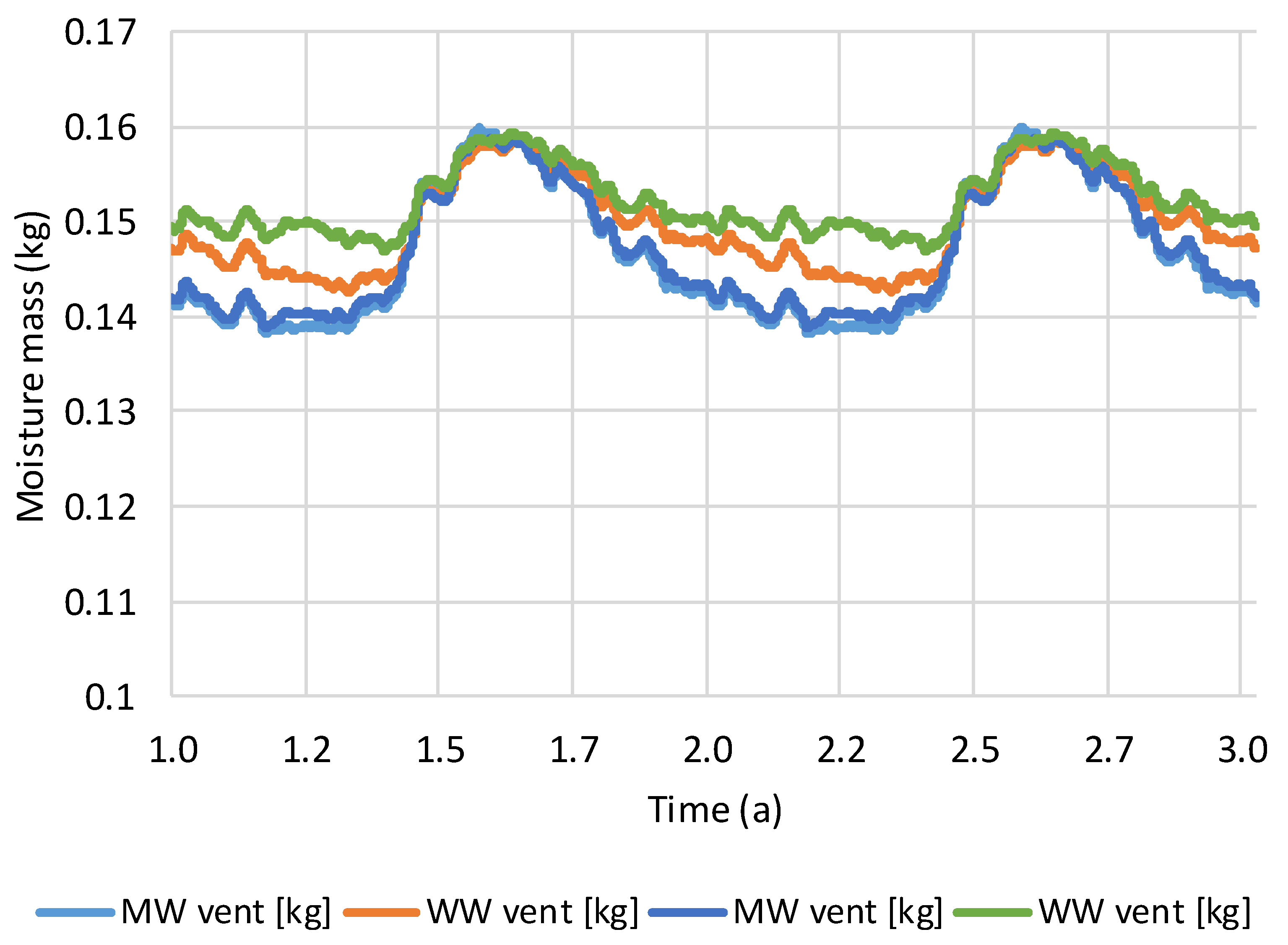

3.3. Moisture Content in the Rammed Earth Layer

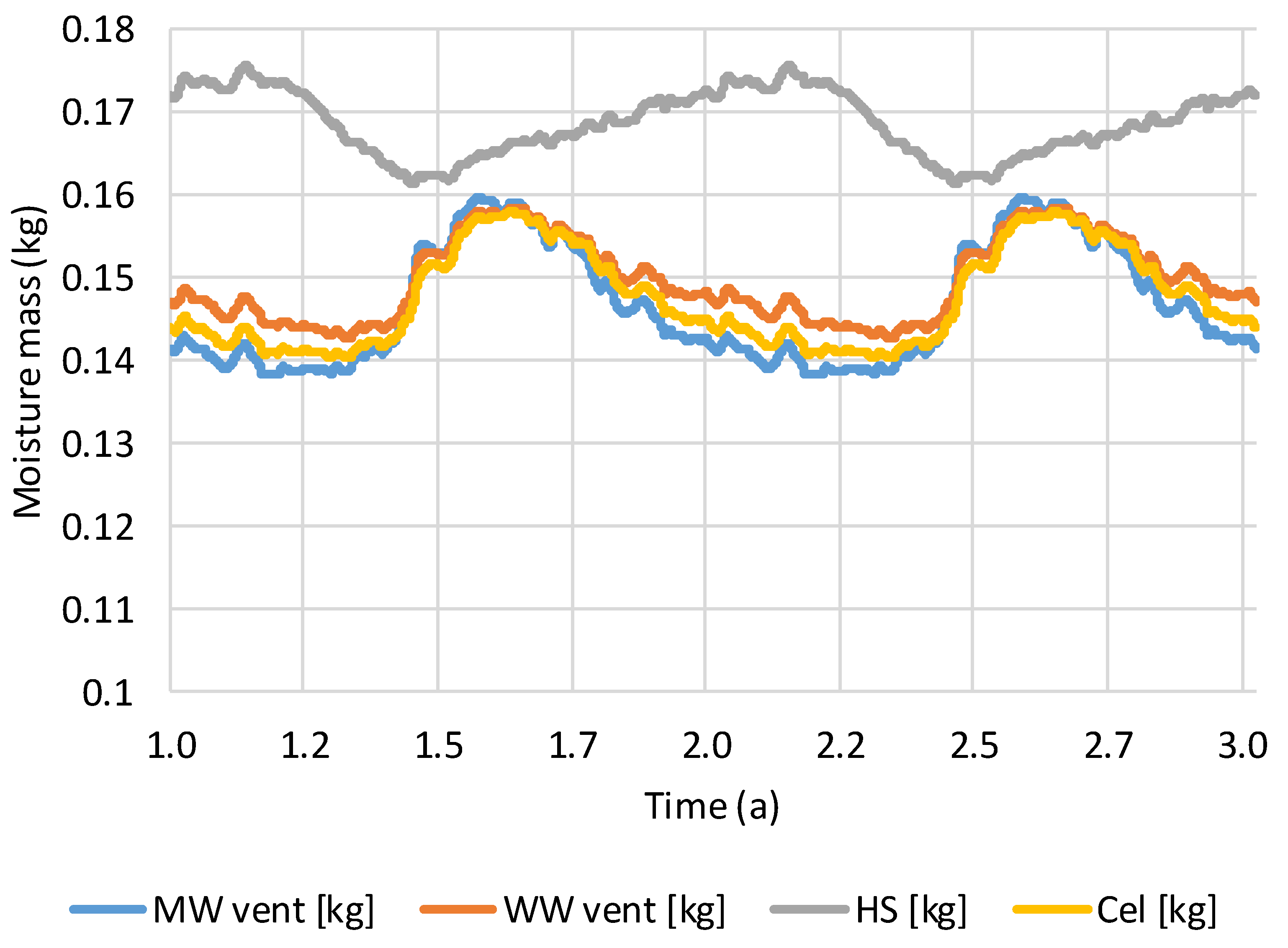

3.4. Accumulation of Moisture in the Interior Plaster

4. Discussion

- HS, as a by-product of the textile industry, has strong potential due to its ability to be safely composted or used as a biological substrate. If no biological degradation is observed, it may also be reused as insulation in a subsequent building. Additionally, it is a material that can be sourced locally.

- CF, derived from recycled paper, can be recycled again or, similarly to hemp shives, reused as insulation provided that there is no biological degradation.

- WW, as a finished product, can be reused in prefabrication or subjected to material recirculation.

- MW has the lowest potential in this regard due to the difficulty of material recovery. Moreover, its production process is more energy-intensive compared with the other materials.

5. Conclusions

- The type of insulation used has a significant impact on the hygrothermal behavior of RE walls.

- HS insulation demonstrates a distinct pattern—with peak moisture levels occurring in winter and drying taking place in summer. From a CE perspective, although HS insulation exhibits thermally unfavorable behavior in winter, its strong moisture buffering capacity and natural, biodegradable characteristics suggest high reuse or composting potential. This duality underscores the need to balance performance with end-of-life sustainability.

- The behavior of HS indicates a high potential for moisture regulation in RE walls and clay plasters. HS may be considered a climate-adaptive insulation material, particularly in the context of rising temperatures, due to its excellent performance in reducing overheating.

- Natural origin materials show a better moisture buffering capacity compared with MW. CF and HS have the highest compatibility with CE principles. Their renewable origin, local availability, and ease of reintegration into biological or technical cycles position them as promising candidates for sustainable insulation systems.

- The presence of a ventilated cavity does not significantly affect the temperature distribution across the wall assembly, but it significantly reduces moisture accumulation in the RE and plaster layers—particularly in systems using WW—and may help prevent the biological degradation of HS insulation.

- While MW performs well in stabilizing internal humidity, its low recyclability and high processing energy demand make it less compatible with CE goals. In contrast, CF, HS and WW, though showing higher moisture fluctuations, offer better prospects for reuse and material cycling within a sustainable construction framework.

- To verify the simulation results and better understand material performance over time, it is recommended to construct physical mock-ups of wall sections or demonstration buildings. This would allow for the assessment of insulation impact on structural stability, indoor microclimate, and material recovery potential after disassembly.

- In the context of the CE, HS and CF show the greatest potential. These materials are renewable, biodegradable, and can be reused or reprocessed without a loss of functionality.

- The safety and durability of RE construction largely depend on effective moisture protection. Therefore, the choice of insulation is crucial not only for thermal performance but also for structural integrity.

- In the broader material context, rammed earth (RE) itself presents great potential from a CE perspective: it can often be sourced directly from a construction site, used with minimal processing, and reused as aggregate or infill at the end of its lifecycle. Similarly, clay plasters are not only vapor-permeable and regulate humidity well but can also be reapplied or safely returned to the environment. Lime plasters, while more energy-intensive to produce, offer a carbon capture benefit through carbonation and are recyclable as hydraulic binders. Timber components, if designed for disassembly, can be reused in future constructions—especially when connected using reversible joinery. Together, these elements enhance the regenerative character of the entire wall assembly.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| EU | European Union |

| CE | Circular Economy |

| RE | Rammed Earth |

| HS | Hemp Shives |

| CF | Cellulose Fiber |

| WW | Wood Wool |

| MW | Mineral Wool |

| HF | Heat Flux |

| RH | Relative Humidity |

| CDW | Construction and Demolition Waste |

| GHGs | Green House Gasses |

References

- U.N. Environment Programme. 2022 Global Status Report for Buildings and Construction | UNEP—UN Environment Programme. Available online: https://www.unep.org/resources/publication/2022-global-status-report-buildings-and-construction (accessed on 14 May 2025).

- U.N. Environment Programme. Global Status Report for Buildings and Construction | UNEP—UN Environment Programme. Available online: https://www.unep.org/resources/report/global-status-report-buildings-and-construction (accessed on 16 May 2025).

- US EPA. C-MORE: Construction Material Opportunities to Reduce Emissions. Available online: https://www.epa.gov/greenerproducts/cmore (accessed on 16 May 2025).

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A New Circular Economy Action Plan for a Cleaner and More Competitive Europe. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:52020DC0098 (accessed on 16 May 2025).

- Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics (accessed on 16 May 2025).

- Directive—2008/98—EN—Waste Framework Directive—EUR-Lex. Available online: https://eur-lex.europa.eu/eli/dir/2008/98/oj/eng (accessed on 17 June 2025).

- Regulation—2020/852—EN—Taxonomy Regulation—EUR-Lex. Available online: https://eur-lex.europa.eu/eli/reg/2020/852/oj/eng (accessed on 17 June 2025).

- Ormondroyd, G.A.; Spear, M.J.; Skinner, C. The Opportunities and Challenges for Re-Use and Recycling of Timber and Wood Products Within the Construction Sector. In Environmental Impacts of Traditional and Innovative Forest-Based Bioproducts; Kutnar, A., Muthu, S.S., Eds.; Springer: Singapore, 2016; pp. 45–103. ISBN 978-981-10-0655-5. [Google Scholar]

- Vargas, M.; Alfaro, M.; Karstegl, N.; Fuertes, G.; Gracia, M.D.; Mar-Ortiz, J.; Sabattin, J.; Duran, C.; Leal, N. Reverse Logistics for Solid Waste from the Construction Industry. Adv. Civ. Eng. 2021, 2021, 6654718. [Google Scholar] [CrossRef]

- Hale, S.E.; Roque, A.J.; Okkenhaug, G.; Sørmo, E.; Lenoir, T.; Carlsson, C.; Kupryianchyk, D.; Flyhammar, P.; Žlender, B. The Reuse of Excavated Soils from Construction and Demolition Projects: Limitations and Possibilities. Sustainability 2021, 13, 6083. [Google Scholar] [CrossRef]

- Mália, M.; de Brito, J.; Pinheiro, M.D.; Bravo, M. Construction and Demolition Waste Indicators. Waste Manag. Res. 2013, 31, 241–255. [Google Scholar] [CrossRef] [PubMed]

- Menegaki, M.; Damigos, D. A Review on Current Situation and Challenges of Construction and Demolition Waste Management. Curr. Opin. Green Sustain. Chem. 2018, 13, 8–15. [Google Scholar] [CrossRef]

- Bansal, A.; Mishra, G.; Bishnoi, S. Recycling and Reuse of Construction and Demolition Waste: Sustainable Approach. In Proceedings of the 7th International Conference on Sustainable Build Environment, Kandy, Sri Lanka, 16–18 December 2016. [Google Scholar]

- Iacovidou, E.; Purnell, P. Mining the Physical Infrastructure: Opportunities, Barriers and Interventions in Promoting Structural Components Reuse. Sci. Total Environ. 2016, 557–558, 791–807. [Google Scholar] [CrossRef]

- Grangeot, M.; Wang, Q.; Beyer, K.; Fivet, C.; Parascho, S. Structural Concrete Rubble Arrangements. In Scalable Disruptors; Eversmann, P., Gengnagel, C., Lienhard, J., Ramsgaard Thomsen, M., Wurm, J., Eds.; Springer Nature Switzerland: Cham, Switzerland, 2024; pp. 15–27. [Google Scholar]

- Kitek Kuzman, M.; Zbašnik-Senegačnik, M.; Kosanović, S.; Miloshevska Janakieska, M.; Novaković, N.; Rajković, I.; Grošelj, P. Architectural Perspectives on Wood Reuse within Circular Construction: A South–Central European Study. Buildings 2024, 14, 560. [Google Scholar] [CrossRef]

- Kanyilmaz, A.; Birhane, M.; Fishwick, R.; del Castillo, C. Reuse of Steel in the Construction Industry: Challenges and Opportunities. Int. J. Steel Struct. 2023, 23, 1399–1416. [Google Scholar] [CrossRef]

- Ottenhaus, L.-M.; Yan, Z.; Brandner, R.; Leardini, P.; Fink, G.; Jockwer, R. Design for Adaptability, Disassembly and Reuse—A Review of Reversible Timber Connection Systems. Constr. Build. Mater. 2023, 400, 132823. [Google Scholar] [CrossRef]

- Aatheesan, T.; Arulrajah, A.; Bo, M.W.; Wilson, J.L. Beneficial Use of Brick Rubble as Pavement Sub-Base Material. In Advances in Transportation Geotechnics; CRC Press: Boca Raton, FL, USA, 2008; ISBN 978-0-429-20728-0. [Google Scholar]

- Kalinowska-Wichrowska, K.; Pawluczuk, E.; Bołtryk, M. Waste-Free Technology for Recycling Concrete Rubble. Constr. Build. Mater. 2020, 234, 117407. [Google Scholar] [CrossRef]

- Hoffmann, C.; Schubert, S.; Leemann, A.; Motavalli, M. Recycled Concrete and Mixed Rubble as Aggregates: Influence of Variations in Composition on the Concrete Properties and Their Use as Structural Material. Constr. Build. Mater. 2012, 35, 701–709. [Google Scholar] [CrossRef]

- Wyller, M.; Svatoš-Ražnjević, H.; Schad, E.; Menges, A. A Taxonomy of Techniques and Tools for Rubble. In Scalable Disruptors; Eversmann, P., Gengnagel, C., Lienhard, J., Ramsgaard Thomsen, M., Wurm, J., Eds.; Springer Nature Switzerland: Cham, Switzerland, 2024; pp. 3–14. [Google Scholar]

- Grangeot, M.; Bastien-Masse, M.; Fivet, C.; Parascho, S. Large Concrete Rubble as a New Structural Construction Material: Opportunities and Digital Processes for Load-Bearing Walls. Buildings 2025, 15, 1437. [Google Scholar] [CrossRef]

- Giorgi, S.; Lavagna, M.; Campioli, A. Guidelines for Effective and Sustainable Recycling of Construction and Demolition Waste. In Designing Sustainable Technologies, Products and Policies: From Science to Innovation; Benetto, E., Gericke, K., Guiton, M., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 211–221. ISBN 978-3-319-66981-6. [Google Scholar]

- Valenzuela, M.; Ciudad, G.; Cárdenas, J.P.; Medina, C.; Salas, A.; Oñate, A.; Pincheira, G.; Attia, S.; Tuninetti, V. Towards the Development of Performance-Efficient Compressed Earth Blocks from Industrial and Agro-Industrial by-Products. Renew. Sustain. Energy Rev. 2024, 194, 114323. [Google Scholar] [CrossRef]

- Kianfar, E.; Toufigh, V. Reliability Analysis of Rammed Earth Structures. Constr. Build. Mater. 2016, 127, 884–895. [Google Scholar] [CrossRef]

- Ávila, F.; Puertas, E.; Gallego, R. Mechanical Characterization of Lime-Stabilized Rammed Earth: Lime Content and Strength Development. Constr. Build. Mater. 2022, 350, 128871. [Google Scholar] [CrossRef]

- Kang, S.-H.; Kwon, Y.-H.; Moon, J. Quantitative Analysis of CO2 Uptake and Mechanical Properties of Air Lime-Based Materials. Energies 2019, 12, 2903. [Google Scholar] [CrossRef]

- Nouri, H.; Safehian, M.; Hosseini, S.M.M.M. Life Cycle Assessment of Earthen Materials for Low-Cost Housing a Comparison between Rammed Earth and Fired Clay Bricks. Int. J. Build. Pathol. Adapt. 2021, 41, 364–377. [Google Scholar] [CrossRef]

- Hammond, G.P.; Jones, C.I. Embodied Energy and Carbon in Construction Materials. Proc. Inst. Civ. Eng.—Energy 2008, 161, 87–98. [Google Scholar] [CrossRef]

- Arenas, N.F.; Shafique, M. Reducing Embodied Carbon Emissions of Buildings—A Key Consideration to Meet the Net Zero Target. Sustain. Futur. 2024, 7, 100166. [Google Scholar] [CrossRef]

- Gomaa, M.; Schade, S.; Bao, D.W.; Xie, Y.M. Automation in Rammed Earth Construction for Industry 4.0: Precedent Work, Current Progress and Future Prospect. J. Clean. Prod. 2023, 398, 136569. [Google Scholar] [CrossRef]

- McGregor, F.; Heath, A.; Maskell, D.; Fabbri, A.; Morel, J.-C. A Review on the Buffering Capacity of Earth Building Materials. Proc. Inst. Civ. Eng.—Constr. Mater. 2016, 169, 241–251. [Google Scholar] [CrossRef]

- Tan, J.; Liang, J.; Wan, L.; Jiang, B. Influence of Non-Constant Hygrothermal Parameters on Heat and Moisture Transfer in Rammed Earth Walls. Buildings 2022, 12, 1077. [Google Scholar] [CrossRef]

- Bui, Q.-B.; Morel, J.-C.; Hans, S.; Walker, P. Effect of Moisture Content on the Mechanical Characteristics of Rammed Earth. Constr. Build. Mater. 2014, 54, 163–169. [Google Scholar] [CrossRef]

- Yu, S.; Hao, S.; Mu, J.; Tian, D.; Zhao, M. Research on Optimization of the Thermal Performance of Composite Rammed Earth Construction. Energies 2022, 15, 1519. [Google Scholar] [CrossRef]

- Dong, X.; Soebarto, V.; Griffith, M. Achieving Thermal Comfort in Naturally Ventilated Rammed Earth Houses. Build. Environ. 2014, 82, 588–598. [Google Scholar] [CrossRef]

- Toufigh, V.; Samadianfard, S. Experimental and Numerical Investigation of Thermal Enhancement Methods on Rammed-Earth Materials. Sol. Energy 2022, 244, 474–483. [Google Scholar] [CrossRef]

- Serrano, S.; de Gracia, A.; Cabeza, L.F. Adaptation of Rammed Earth to Modern Construction Systems: Comparative Study of Thermal Behavior under Summer Conditions. Appl. Energy 2016, 175, 180–188. [Google Scholar] [CrossRef]

- Windstorm, B.; Schmidt, A. A Report of Contemporary Rammed Earth Construction and Research in North America. Sustainability 2013, 5, 400–416. [Google Scholar] [CrossRef]

- Giuffrida, G.; Caponetto, R.; Nocera, F.; Cuomo, M. Prototyping of a Novel Rammed Earth Technology. Sustainability 2021, 13, 11948. [Google Scholar] [CrossRef]

- Giuffrida, G.; Ibos, L.; Boudenne, A.; Allam, H. Exploring the Integration of Bio-Based Thermal Insulations in Compressed Earth Blocks Walls. Constr. Build. Mater. 2024, 418, 135412. [Google Scholar] [CrossRef]

- Schroeder, H. 4—Modern Earth Building Codes, Standards and Normative Development. In Modern Earth Buildings; Hall, M.R., Lindsay, R., Krayenhoff, M., Eds.; Woodhead Publishing Series in Energy; Woodhead Publishing: Cambridge, UK, 2012; pp. 72–109. ISBN 978-0-85709-026-3. [Google Scholar]

- IAL Consultants. The European Market for Thermal Insulation Products; IAL Consultants: London, UK, 2023. [Google Scholar]

- Kosiński, P.; Patyna, K. Practical Use of Materials of Natural Origin as Loose-Fill Insulations in Open-Diffusion Constructions—Observation and Numerical Simulation. Sustainability 2024, 16, 4593. [Google Scholar] [CrossRef]

- Indekeu, M.L.; Janssen, H.; Woloszyn, M. Determination of the Moisture Diffusivity of Rammed Earth from Transient Capillary Absorption Moisture Content Profiles. Constr. Build. Mater. 2022, 318, 125978. [Google Scholar] [CrossRef]

- Dane do obliczeń energetycznych budynków—Ministerstwo Inwestycji i Rozwoju—Portal Gov.pl. Available online: https://www.gov.pl/web/archiwum-inwestycje-rozwoj/dane-do-obliczen-energetycznych-budynkow (accessed on 17 June 2025).

- Kosiński, P.; Brzyski, P.; Tunkiewicz, M.; Nagy, B.; Gotkowska-Płachta, A. Moisture Properties, Microstructural and Microbiological Characteristics of Flax and Hemp Shives Used in Construction Industry. J. Nat. Fibers 2024, 21, 2356695. [Google Scholar] [CrossRef]

| Properties | Lime Plaster | RE | Light Clay Plaster | MW | CF | HS | WW |

|---|---|---|---|---|---|---|---|

| Thickness (m) | 0.010 | 0.300 | 0.020 | 0.150 | 0.180 | 0.188 | 0.150 |

| Density (kg/m3) | 1498.4 | 2240.0 | 900.0 | 100.0 | 60.0 | 115.0 | 50.0 |

| Porosity (m3/m3) | 0.43 | 0.33 | 0.47 | 0.92 | 0.78 | 0.79 | 0.82 |

| Specific heat (J/(kg⋅K)) | 802.4 | 837 | 1000.0 | 840.0 | 2500 | 1600.0 | 1660 |

| Thermal conductivity (W/(m⋅K)) | 0.41 | 0.551 | 0.23 | 0.040 | 0.0495 | 0.051 | 0.039 |

| Diffusion resistance (-) | 9.3 | 4.5 | 30.0 | 1.00 | 3.5 | 3.5 | 1.2 |

| Temperature (°C) | CF | HS | WW Vent | MW Vent | WW Plast | MW Plast |

|---|---|---|---|---|---|---|

| Winter | ||||||

| Internal surface | 19.41 | 19.12 | 19.35 | 19.41 | 19.31 | 19.40 |

| RE/insulation joint | 16.16 | 14.49 | 15.77 | 16.18 | 16.36 | 16.03 |

| Summer | ||||||

| Internal surface | 20.00 | 19.94 | 19.98 | 20.02 | 19.99 | 20.01 |

| RE/insulation joint | 20.14 | 19.86 | 20.03 | 20.25 | 20.01 | 20.26 |

| Relative Humidity (%) | CF | HS | WW Vent | MW Vent | WW Plast | MW Plast |

|---|---|---|---|---|---|---|

| Winter | ||||||

| Min | 31.0 | 58.0 | 38.0 | 25.0 | 39.0 | 25.0 |

| Max | 46.0 | 80.0 | 47.0 | 45.0 | 47.0 | 45.0 |

| Summer | ||||||

| Min | 51.0 | 56.0 | 52.0 | 52.0 | 52.0 | 52.0 |

| Max | 64.0 | 74.0 | 66.0 | 72.0 | 65.0 | 72.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kosiński, P.; Jabłoński, W.; Patyna, K. Parametric Analysis of Rammed Earth Walls in the Context of the Thermal Protection of Environmentally Friendly Buildings. Sustainability 2025, 17, 6886. https://doi.org/10.3390/su17156886

Kosiński P, Jabłoński W, Patyna K. Parametric Analysis of Rammed Earth Walls in the Context of the Thermal Protection of Environmentally Friendly Buildings. Sustainability. 2025; 17(15):6886. https://doi.org/10.3390/su17156886

Chicago/Turabian StyleKosiński, Piotr, Wojciech Jabłoński, and Krystian Patyna. 2025. "Parametric Analysis of Rammed Earth Walls in the Context of the Thermal Protection of Environmentally Friendly Buildings" Sustainability 17, no. 15: 6886. https://doi.org/10.3390/su17156886

APA StyleKosiński, P., Jabłoński, W., & Patyna, K. (2025). Parametric Analysis of Rammed Earth Walls in the Context of the Thermal Protection of Environmentally Friendly Buildings. Sustainability, 17(15), 6886. https://doi.org/10.3390/su17156886