1. Introduction

Using wastewater in concrete research has gained importance due to the increasing strain on freshwater resources and the growing demand for sustainable construction methods [

1]. In the construction industry, wastewater presents a significant opportunity for resource conservation despite being primarily perceived as a disposal challenge [

2]. Incorporating treated and untreated wastewater in concrete production helps mitigate environmental concerns related to water scarcity while addressing waste management issues [

3]. Recycling wastewater into concrete improves sustainability by lowering the need for potable water and providing a more affordable option [

4].

The growing worldwide population and swift urbanization have led to an unparalleled demand for construction materials, especially concrete, which depends significantly on water as an essential component. The building industry, producing billions of tons of concrete each year, has become one of the foremost consumers of fresh water. On average, about 150 L of water is used to manufacture one cubic meter of concrete, which can rise to 500 L when considering production and transportation losses [

5]. This significant consumption predominantly worsens the global freshwater crisis, with the construction sector accounting for nearly one trillion cubic meters of water used per year [

6].

Water scarcity is becoming a critical challenge, with projections indicating that by 2025, almost 1.8 billion people will face severe water shortages [

7]. Countries and regions facing significant challenges with fresh water scarcity include Singapore, Japan, Hong Kong, Saudi Arabia, and parts of Pakistan such as Baluchistan and Karachi [

8,

9]. Given the finite nature of potable water resources and their high cost, utilizing alternative water sources (such as seawater and wastewater) in concrete production has gained attention [

10]. This approach offers a dual advantage: conserving fresh water and reducing construction costs by recycling wastewater, which might otherwise pose environmental hazards if discharged untreated [

4].

However, because wastewater has different physicochemical characteristics, using it to make concrete creates complications. The viability of utilizing wastewater for concrete is contingent upon numerous essential factors, including pH, TDS, Electrical Conductivity (EC), organic matter concentration, and ions such as chlorides and sulfates. Maintaining a pH range between 6.0 and 8.5 is essential for achieving optimal concrete performance [

11]. Increased concentrations of TDS and EC can result in salt accumulation, compromising the integrity of concrete structures [

12]. High concentrations of chloride and sulfate ions can accelerate the corrosion of steel reinforcements, which compromises the structural integrity of concrete. Organic matter, if present, can adversely affect the strength and durability of concrete by introducing undesirable chemical reactions during curing [

13]. Highly alkaline wastewater can interfere with the setting process and the long-term performance of concrete structures [

14]. For instance, industrial wastewater often contains hazardous components such as heavy metals and exhibits high alkalinity. Heavy metals and other pollutants in wastewater can weaken the strength and durability of concrete [

15]. These variables underscore the necessity of understanding wastewater composition to assess its appropriateness for concrete manufacturing. The properties of wastewater used in previous studies are listed in

Table 1, and their histograms are presented in

Figure 1.

Most researchers used treated wastewater with nearly identical physicochemical characteristics (see

Figure 1), focusing on concrete’s mechanical and durability properties. Govedarica et al. (2022) explored the innovative use of solidified wastewater treatment sludge as an auxiliary cementitious material in previous concrete pavements to improve the concrete’s mechanical properties [

42]. Almeida and Tonetti (2023) highlighted the advantages of utilizing treated wastewater as a sustainable substitute for potable water in concrete production, demonstrating that this practice conserves freshwater resources while preserving the strength and durability of concrete [

1]. Patel et al. [

43] investigated the use of textile effluent treatment sludge in rubber mold paver blocks, showing that this method enhances the mechanical properties of the blocks [

44]. Although these studies highlight the potential of treated wastewater, they leave unexplored the impact of untreated or partially treated wastewater with diverse compositions on concrete properties. AI and ML offer powerful tools for addressing these gaps [

45].

AI, particularly ML, has become an integral tool in concrete research, offering enhanced predictive capabilities over traditional mechanistic models [

46,

47]. Various ML techniques, including adaptive boosting (AdaBoost), random forest (RF), artificial neural networks (ANNs) [

48], and support vector machines (SVMs), have demonstrated significant proficiency in modeling complex relationships within concrete materials that conventional statistical methods often fail to capture [

49]. In the realm of concrete technology, AI methodologies have been extensively applied to predict and model properties across different stages—fresh [

50], hardening, and hardened states [

51]. For instance, ANNs have been utilized to forecast compressive strength based on input parameters such as water content, cement content, water-to-cement ratio, superplasticizers, and aggregate fractions. Moreover, ML approaches have been employed to detect and diagnose defects in concrete structures. Techniques like convolutional neural networks (CNNs) have been applied to image data for crack detection [

52], enabling early identification of potential issues and facilitating timely maintenance interventions. Additionally, AI has been integrated into the optimization of concrete mix designs [

53]. By analyzing large datasets, AI models can suggest optimal proportions of mix components to achieve desired performance characteristics, thereby reducing the reliance on trial-and-error methods and enhancing efficiency in mix design processes [

54]. These advancements underscore the transformative impact of AI in concrete research, paving the way for more efficient, accurate, and innovative approaches to understanding and improving concrete materials and structures [

54].

Despite the growing body of research on the use of wastewater in concrete production, significant gaps remain unaddressed. Most existing studies have predominantly focused on treated wastewater with relatively uniform physicochemical characteristics, emphasizing its impact on concrete’s mechanical and durability properties as shown in

Figure 1. However, the potential of untreated or partially treated wastewater—which often exhibits diverse chemical compositions due to varying industrial sources—remains largely unexplored. This gap is critical because untreated wastewater can introduce complex variables such as fluctuating pH levels, high concentrations of chlorides, sulfates, heavy metals, and organic matter, all of which can significantly influence concrete performance in unpredictable ways. While traditional experimental methods have provided valuable insights into concrete behavior, they often fall short of capturing the multifaceted interactions between wastewater components and concrete properties. Although AI, particularly in the form of ML techniques, has been successfully applied in concrete research to predict mechanical properties and optimize mix designs, there is a noticeable lack of studies that leverage AI to analyze and predict the specific impacts of untreated wastewater on concrete. Moreover, existing research does not adequately address how advanced predictive models can be used to identify critical wastewater characteristics that affect concrete performance or to develop data-driven strategies for optimizing wastewater use. There is also limited exploration of how AI can guide targeted treatment approaches for wastewater to enhance its suitability for construction applications.

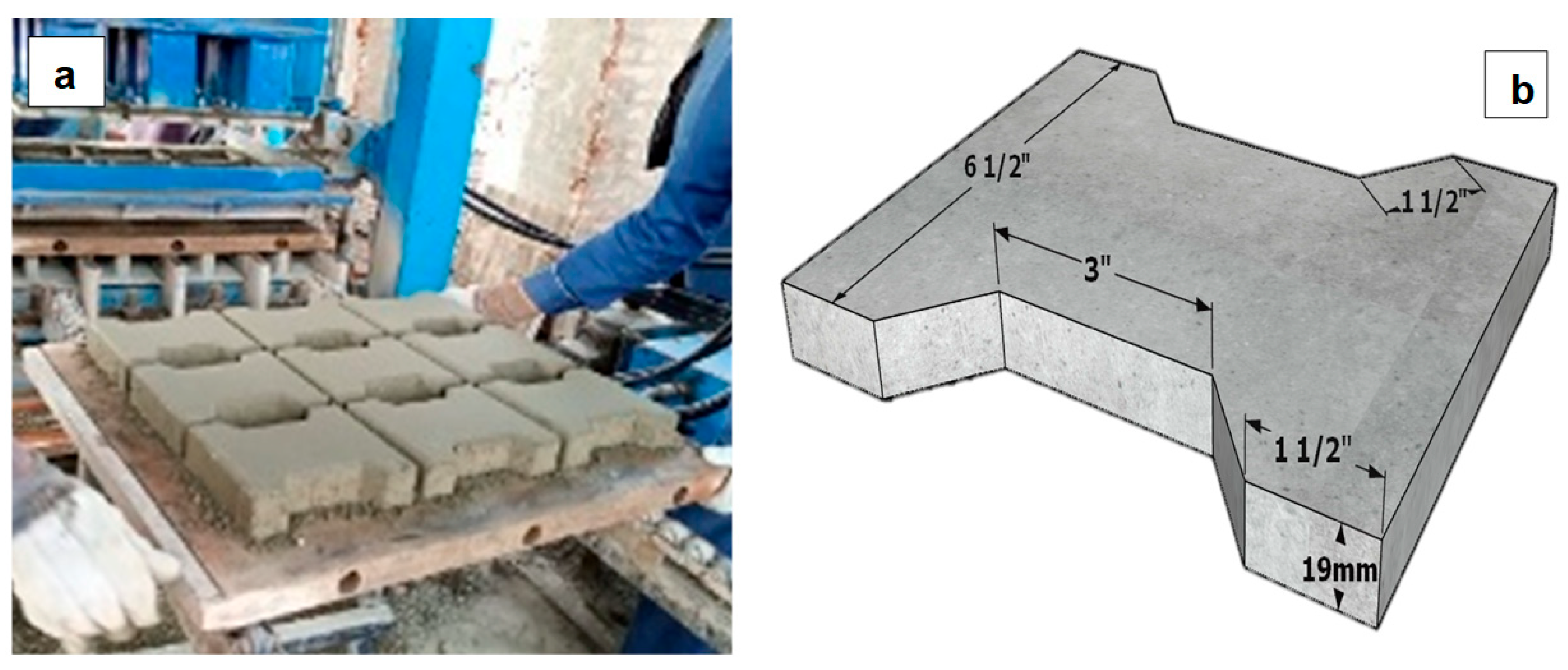

This study bridges experimental investigations with AI-driven modeling to comprehensively assess the feasibility of using untreated wastewater in concrete production. It systematically evaluates key mechanical and durability properties, including compressive strength, water absorption, and UPV, of concrete paver bricks produced with five distinct wastewater sources—sewage, fertilizer industry effluent, sugar industry effluent, textile discharge, and service station wastewater. The experimental data are analyzed using machine learning algorithms to identify critical wastewater characteristics that significantly influence concrete performance. By integrating advanced predictive models, this research not only highlights the most suitable wastewater sources but also quantifies the impact of specific chemical components on concrete behavior. Additionally, it proposes data-driven treatment strategies to optimize wastewater utilization for sustainable and resource-efficient construction practices. By addressing the complex challenges associated with untreated wastewater and leveraging AI for predictive insights, this study fills critical knowledge gaps and offers a strategic framework for harnessing unconventional water resources. The primary research question investigates the feasibility and safety of incorporating untreated or minimally treated wastewater from various industrial sources into concrete paver production. It examines how the physicochemical properties of the wastewater influence critical mechanical properties, including compressive strength, water absorption, ultrasonic pulse velocity (UPV), and dynamic modulus of elasticity (DME). Additionally, it explores the reliability of an XGBoost-based machine learning model in predicting these outcomes to facilitate practical implementation in regions facing water scarcity. Such efforts are pivotal for mitigating fresh water scarcity, minimizing environmental risks, and promoting the long-term sustainability of the construction industry.

4. Results and Discussion

4.1. Experimental Analysis

This section presents the findings of compressive strength, UPV, and water absorption tests on concrete pavers developed from different wastewater origins. These findings underscore the influence of wastewater on strength growth, internal structure, and durability.

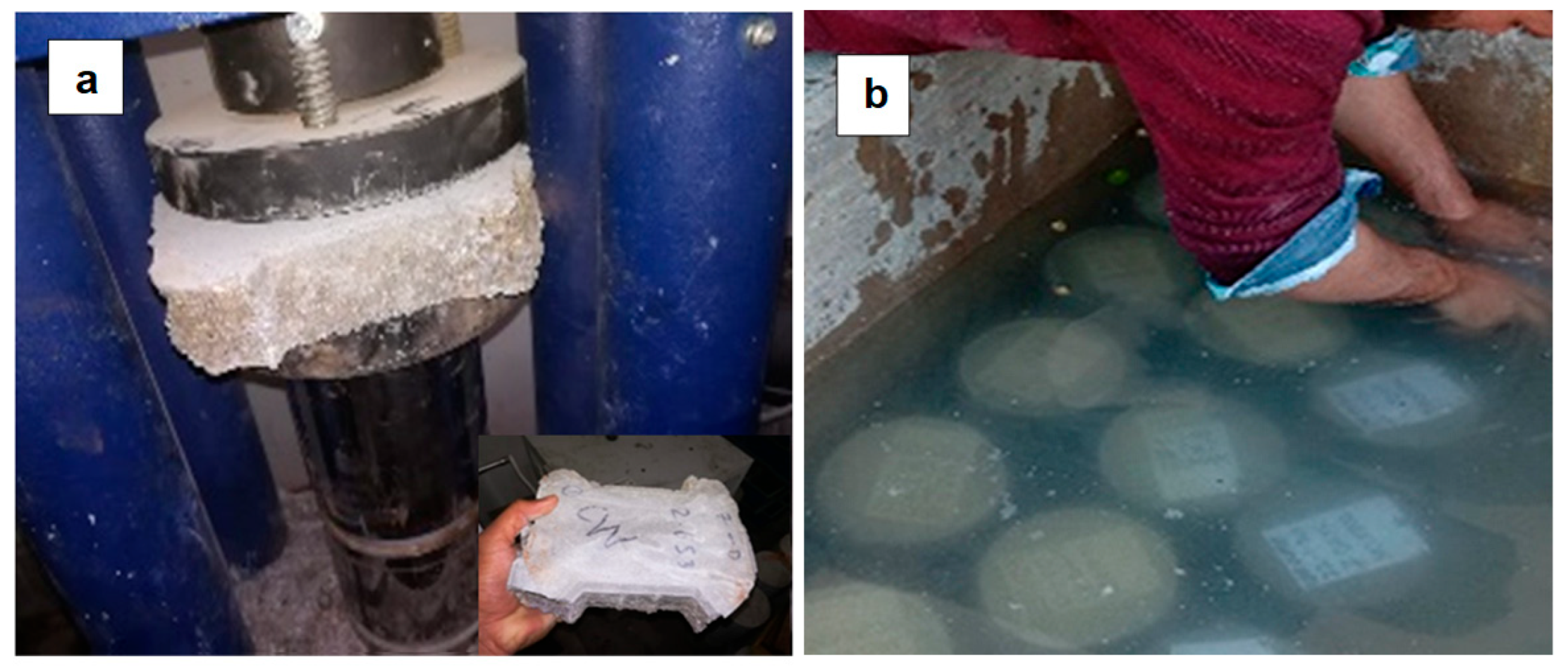

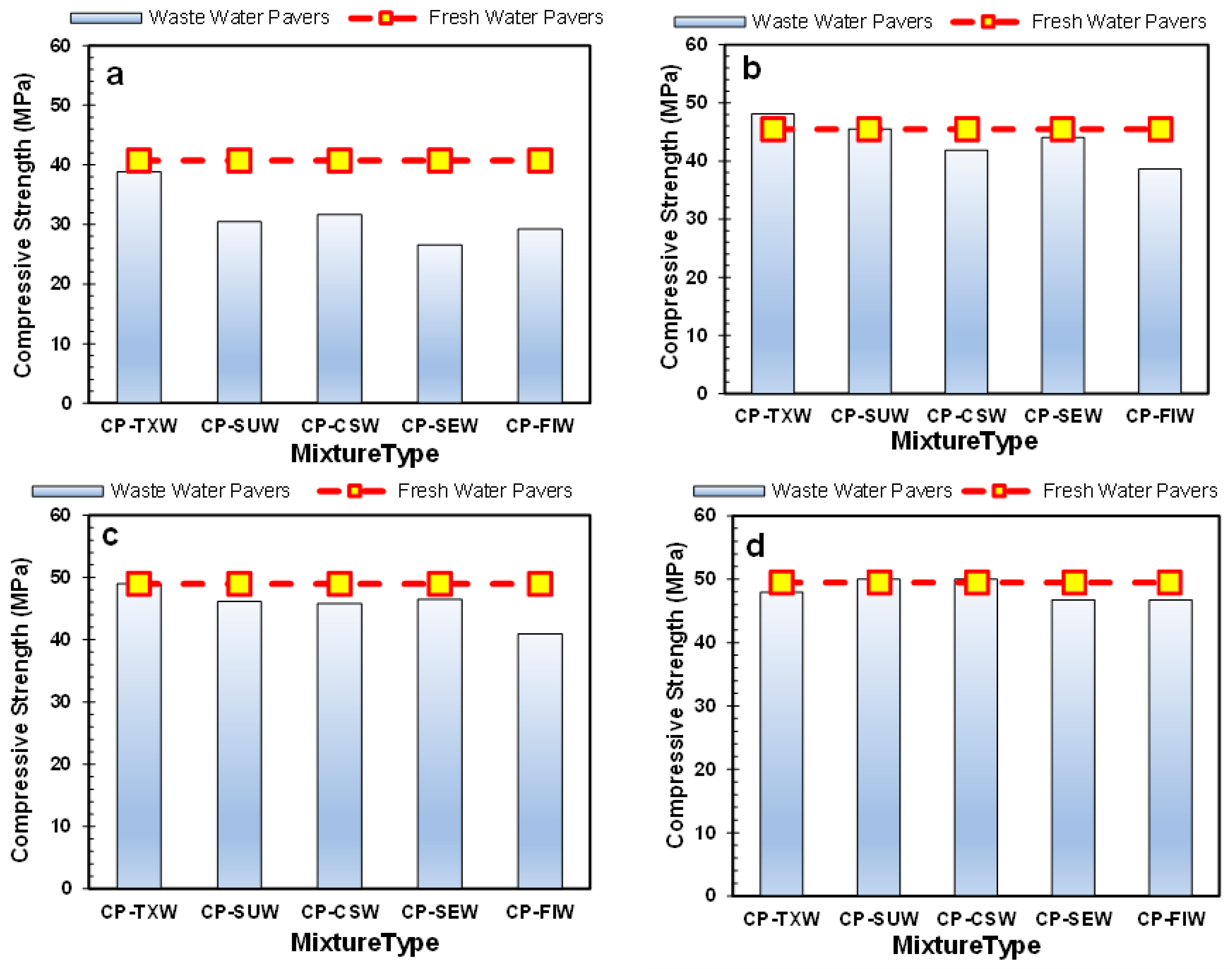

4.1.1. Compressive Strength (CS) Test

Compressive strength performance is one of the primary indicators of concrete quality, especially for concrete pavers used in load-bearing applications. To ensure durability and structural integrity under traffic loads, ASTM C936 states that concrete pavers should have a minimum compressive strength of 55 MPa at 28 days. The compressive strength of concrete pavers made with wastewater and drinking water was evaluated over 7, 14, 21, and 28 days; the results are illustrated in

Figure 8a–d.

At 7 days (

Figure 8a), CP-FRW exhibited the highest compressive strength, followed closely by CP-TXW. CP-TXW consistently demonstrated superior compressive strength compared to the other wastewater types. This performance can be attributed to the presence of organic and inorganic pollutants, reactive dyes, and salts in textile wastewater, which promote early hydration reactions and the formation of secondary calcium silicate hydrate (CSH) gel [

80]. In contrast, CP-SUW, CP-CSW, and CP-FIW recorded comparatively lower compressive strengths, suggesting their suitability for non-structural or delayed-load applications where high early strength is less critical [

81].

At 14 days (

Figure 8b), CP-FRW continued to show the highest compressive strength, while CP-TXW maintained strong performance, confirming its ongoing strength development, with CP-SUW closely following. This strength gain in SUW can be attributed to the fine particles in the sludge, which enhance the water-to-cement interaction and promote consistent hydration over time [

82]. CP-CSW and CP-FIW exhibited modest strength improvements but remained lower than the leading alternatives.

By 21 days, as shown in

Figure 8c, CP-TXW recorded the highest compressive strength, closely followed by CP-FRW. This near-equivalence reinforces CP-TXW’s potential as a reliable substitute for fresh water in concrete production. CP-SUW also achieved comparable strength values, reflecting its competitiveness. Meanwhile, CP-CSW and CP-FIW demonstrated lower strength gains, suggesting limitations in their reactivity or chemical contribution to the hydration process.

At 28 days (

Figure 8d), CP-SUW demonstrated superior compressive strength compared to CP-FRW, underscoring its potential for high-strength concrete applications. This enhancement may be attributed to the acidic nature of sugar mill wastewater, which could accelerate cement hydration and lead to a denser, more refined microstructure [

83]. CP-CSW and CP-TXW also showed impressive strength development, indicating their viability for structural-grade applications [

81]. The consistent progress of CP-TXW throughout the curing periods illustrates its sustainability and potential as a substitute material. Although CP-FIW and CP-SEW exhibited slightly lower compressive strengths, they still met the minimum ASTM requirements for paver applications. These results demonstrate the possibility of specific wastewater sources, especially those from textile and sugar mills, as sustainable alternatives to potable water in the manufacturing of concrete pavers. Their contribution to strength enhancement facilitates overarching objectives for resource-efficient and environmentally sustainable construction methods.

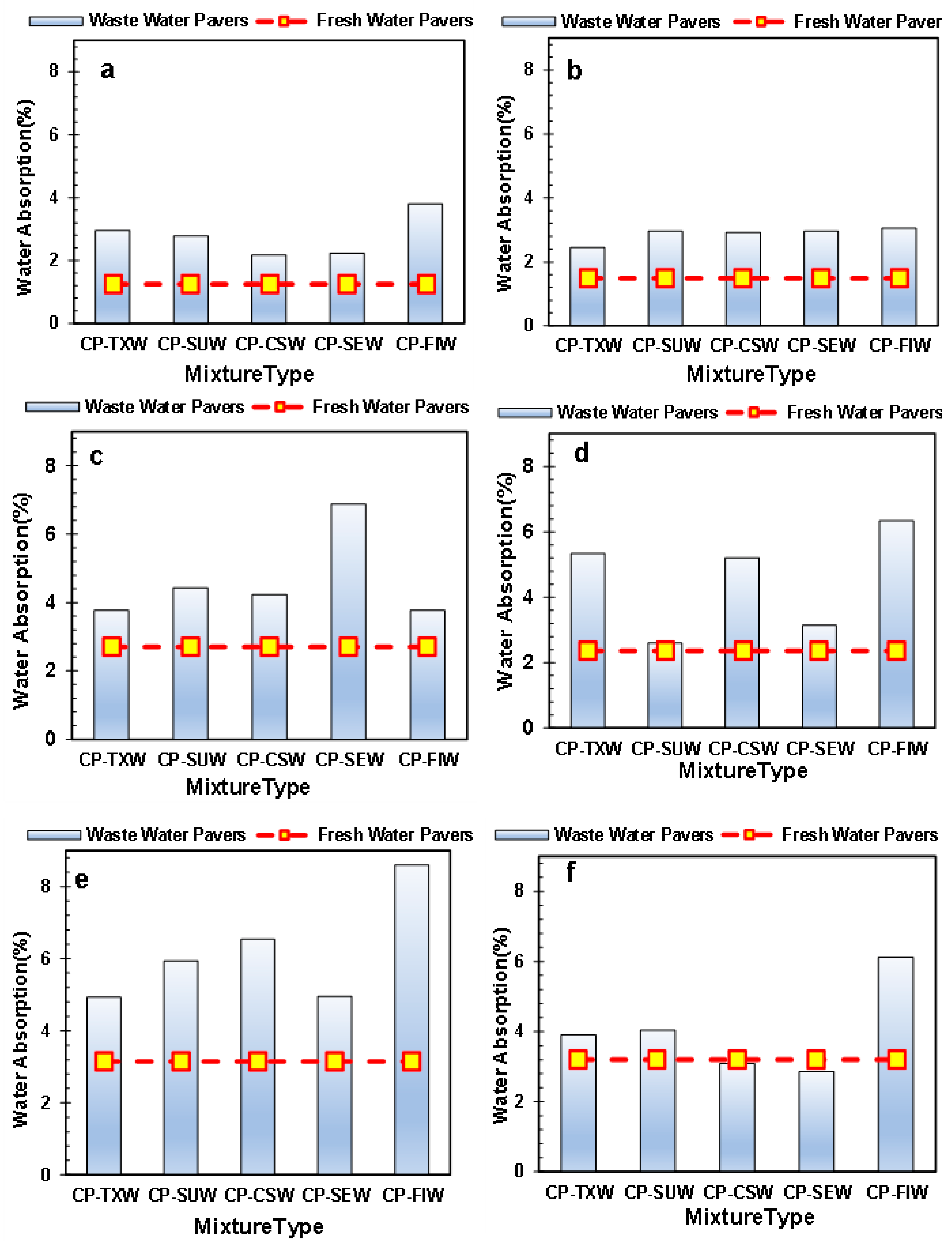

4.1.2. Water Absorption (WA)Test

Water absorption testing is a critical measure of concrete resistance to water infiltration, directly linked to its durability. Lower water absorption indicates better resistance to moisture ingress, which is essential for long-term performance. The results of water absorption tests for all types of concrete pavers are presented in

Figure 9a–f. A mixed trend is observed among wastewater-based concrete pavers, with absorption rates showing variability across different types of wastewaters. Compared to CP-FRW, all wastewater-derived concrete pavers exhibit higher or comparable water absorption at 7, 14, and 21 days.

At 30 min (

Figure 9a), the water absorption properties of wastewater-based concrete pavers exhibited considerable variation. CP-FIW displayed the highest absorption at this early stage, likely attributable to incomplete hydration and increased initial porosity, a typical condition before substantial CSH formation. In contrast, CP-SEW showed low water absorption, indicating early matrix densification potentially facilitated by the calcium and magnesium ions witnessed in sewage effluent, which are recognized for promoting early hydration and reducing permeability [

84].

After one day (

Figure 9b), both CP-TXW and CP-CSW exhibited higher water absorption rates compared to CP-FRW. This behavior can be attributed to the presence of salts, reactive dyes, and organic compounds found in textile and car service wastewater, which contribute to internal moisture retention and slow down pore refinement. In contrast, CP-SEW consistently displayed lower absorption values, underscoring the significance of multivalent cations in facilitating rapid microstructural development and enhancing early-stage durability [

12].

At 7 days (

Figure 9c), a mixed trend in absorption was observed. CP-TXW, CP-CSW, and CP-SUW demonstrated higher or comparable absorption levels to CP-FRW. This phenomenon can be attributed to organic and inorganic matters that hinder hydration and densification. Nevertheless, the early compressive strength of CP-TXW remained high, suggesting that secondary hydration reactions involving reactive dyes and salts may promote the formation of additional CSH gel, effectively countering the increased water absorption [

85].

By 14 days (

Figure 9d), CP-CSW reached peak absorption, while CP-SUW and CP-FIW began showing a downward trend. This improvement likely results from the delayed pozzolanic activity and ongoing hydration processes enabled by the chemical makeup of the wastewater, particularly nutrients and organic matter that sustain long-term matrix development. CP-SEW continued to show minimal absorption throughout, further supporting its suitability in durability-sensitive applications.

At 21 days (

Figure 9e), the majority of wastewater-based mixtures exhibited additional reductions in water absorption. CP-CSW began to decrease from its peak, whereas CP-SUW continued to improve, indicating prolonged hydration and pore refinement. Although CP-TXW maintained slightly higher absorption values, its compressive strength remained competitive, suggesting that increased moisture retention does not inherently undermine structural integrity when bolstered by ongoing secondary gel formation.

By 28 days (

Figure 9f), all wastewater-derived pavers showed a substantial decrease in absorption rates. Both CP-SUW and CP-FIW attained absorption levels comparable to or lower than those of CP-FRW, highlighting the efficacy of extended hydration and matrix densification over time. This densification is possibly aided by the formation of secondary CSH, a phenomenon supported by previous studies on hydration in chemically enriched environments [

86]. For applications necessitating controlled moisture retention throughout extended curing durations, CP-FIW is a viable solution [

26]. CP-SEW, in contrast, exhibited consistently low absorption rates and sufficient strength, signifying its substantial potential for applications necessitating both durability and strength. In contrast, while CP-TXW and CP-CSW exhibited slightly higher absorption values, they managed to maintain sufficient mechanical performance, rendering them suitable for strength-focused designs with less rigid permeability standards.

These findings collectively indicate that while wastewater may lead to increased porosity and moisture retention of concrete at early ages, the subsequent hydration and densification processes result in acceptable or enhanced water absorption performance by the 28-day mark. This highlights the potential for incorporating treated wastewater into sustainable concrete production without jeopardizing essential durability parameters, as long as the mix design is optimized to address early-age porosity.

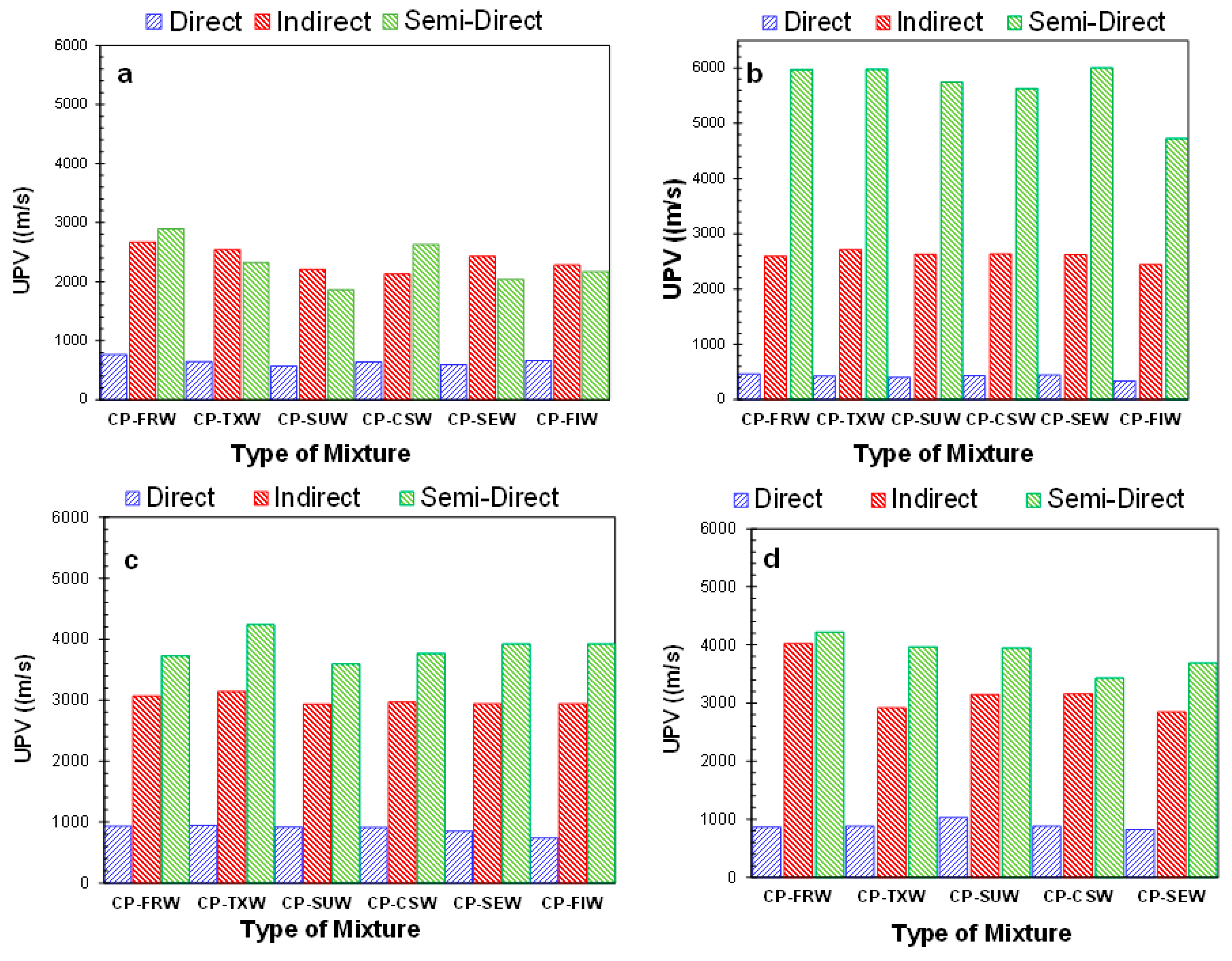

4.1.3. Ultrasonic Pulse Velocity (UPV) Test

The UPV results at 3, 7, 14, and 28 days are presented in

Figure 10a–d. At 3 days (

Figure 10a), CP-FRW demonstrated the highest UPV among all wastewater-based concrete pavers, while CP-TW exhibited comparable values, likely attributable to the beneficial constituents in textile wastewater, including potassium, calcium, and magnesium, which improve the microstructure and hydration [

87]. The fine particulate matter in textile wastewater enhances the density of the matrix by occupying micro voids, leading to elevated UPV values [

80]. In contrast, CP-SSW and CP-SMW demonstrated marginally lower values at this stage, likely due to the presence of organic matter and sugar in SSW and SMW, which may hinder early hydration and compromise the structural integrity of the matrix [

83]. CP-FIW and CP-SWG exhibited the lowest UPV values at this age, correlating with their diminished compressive strength and potentially attributable to their specific chemical compositions.

At 7 days (

Figure 10b), a comparable pattern was noted, with CP-FRW and CP-TW exhibiting the highest UPV values among the samples, suggesting the persistent influence of textile wastewater constituents continued to facilitate microstructural densification. CP-SSW and CP-SMW showed moderate improvements, indicating the progression of hydration and a partial recovery from early-age interference. CP-FIW and CP-SWG again showed the lowest UPV readings, suggesting a slower or less efficient hydration process compared to the other samples.

At 14 days (

Figure 10c), CP-TW nearly equaled CP-FRW in UPV values, indicating ongoing hydration and structural advancement. Both CP-SSW and CP-SMW also exhibited improvement, nearing the UPV levels of CP-FRW and CP-TW. This favorable trend signifies the gradual densification of the matrix due to secondary hydration reactions, particularly in wastewater mixtures. Conversely, CP-FIW and CP-SWG remained comparatively lower, implying that their hydration processes are either slower or less thorough.

At 28 days (

Figure 10d), all wastewater-based concrete pavers demonstrated significant increases in UPV values, with CP-TW achieving the highest UPV among all mixtures, exceeding CP-FRW. This suggests robust microstructural development and pulse velocity response; however, while most wastewater-based mixtures neared CP-FRW levels, CP-FIW and CP-SWG lagged slightly, affirming the impact of chemical composition on long-term hydration and matrix densification.

Figure 10 illustrates the role of the indirect and semi-direct paths in the testing process. These paths, while yielding marginally reduced velocities, provide valuable insights into the surface quality of the concrete pavers due to their heightened sensitivity to surface pores and microcracks. The direct transmission path, on the other hand, consistently yields the highest UPV values as the wave traverses the full thickness, reflecting the bulk density and internal homogeneity of the concrete. This confirms that the testing path influences the measured wave velocity, with the direct path serving as the primary reference for comparing the bulk quality of the concrete pavers.

The DME results at 3, 7, 14, and 28 days are illustrated in

Figure 11a–d. At 7 days (

Figure 11a), CP-FRW exhibited the highest DME value among all concrete mixes, with CP-TW closely following due to its advantageous mineral composition and the prompt formation of hydration products that enhance elastic stiffness [

86]. CP-SSW and CP-SMW displayed marginally lower values, likely attributable to sugar and organic interference during the initial hydration phase [

12]. CP-FIW and CP-SWG recorded the lowest DME values, consistent with their diminished UPV and early compressive strength, likely resulting from excessive organic load and delayed C–S–H development [

85].

At 14 days (

Figure 11b), CP-TW demonstrated DME values comparable to those of CP-FRW, suggesting a stable progression of the microstructure. In contrast, CP-SSW and CP-SMW exhibited an upward trend, indicating ongoing hydration of unreacted particles and a reduction in porosity. Meanwhile, CP-FIW and CP-SWG maintained lower DME values, reflecting limited stiffness development at this stage due to incomplete hydration and reduced matrix compactness.

At 21 days (

Figure 11c), DME values for CP-TW closely approached those of CP-FRW, and CP-SSW and CP-SMW showed further improvement. These trends suggest that the delay in hydration initially caused by wastewater constituents may be mitigated over time, allowing the modulus of elasticity to increase steadily [

26]. However, CP-FIW and CP-SWG remained at the lower end, consistent with their limited hydration advancement and nutrient interference in gel formation.

By 28 days (

Figure 11d), most of the wastewater-based concrete pavers showed significant increases in DME values, although they remained slightly lower than those of CP-FRW. CP-TW achieved nearly equivalent DME values, indicating a fully developed microstructure. CP-SSW and CP-SMW demonstrated promising results, confirming their long-term viability. Conversely, while CP-FIW and CP-SWG exhibited some improvement, they still presented relatively lower DME values, suggesting potential limitations in long-term stiffness development associated with their respective wastewater sources [

86]. The DME values are indicative of the UPV measurement path employed, with the direct path DME serving as the primary metric for assessing bulk stiffness in the comparison of concrete quality across the mixes.

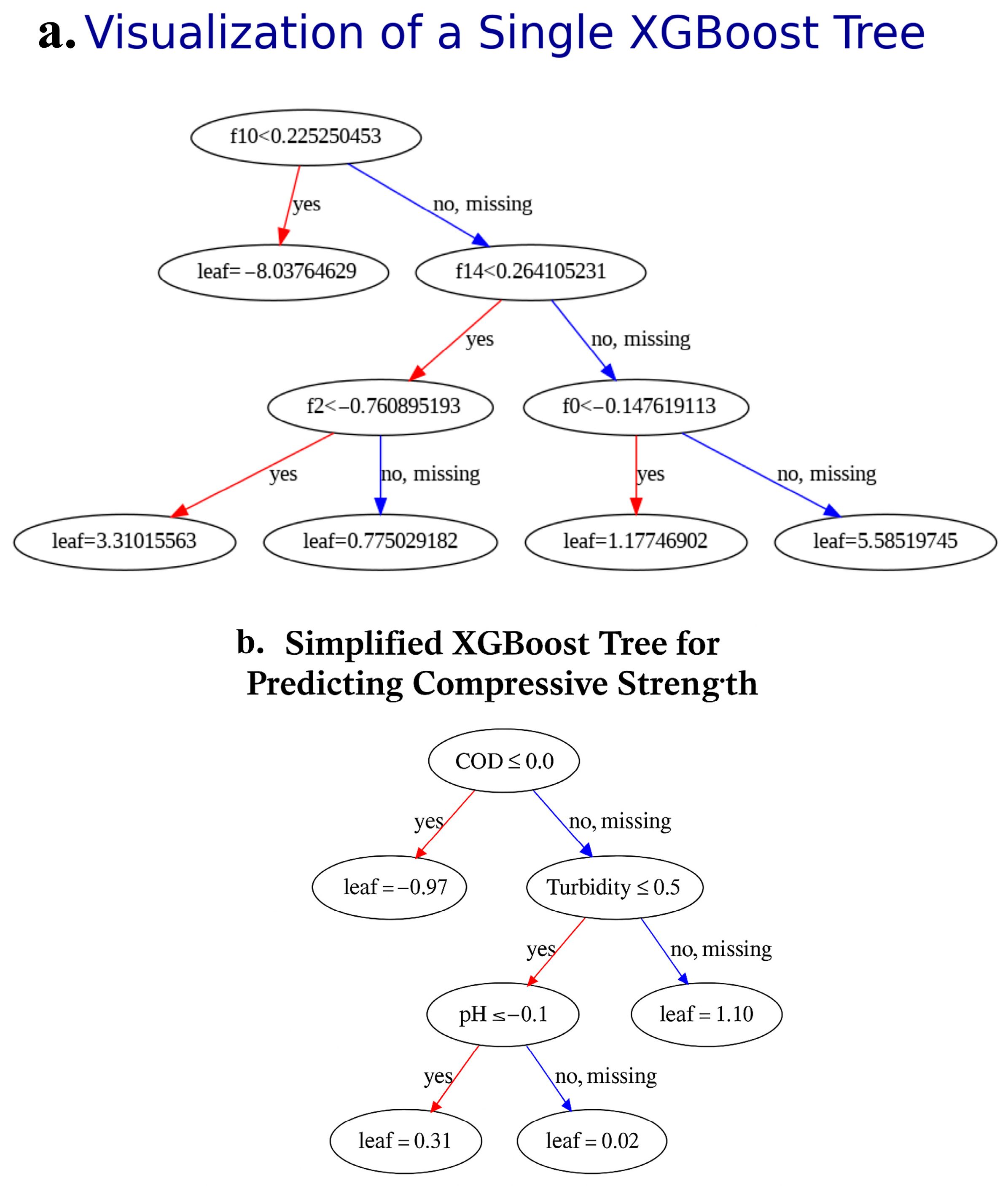

4.2. Machine Learning Model Analysis and Insights

Building upon the experimental performance metrics, this section presents the ML analysis of concrete paver performance, covering model evaluation, feature importance, and composite scoring of wastewater sources. While experimental tests measured CS, WA, UPV, and DME, the ML models provide deeper insights into the influence of individual wastewater properties on these metrics. This integrated approach validates experimental findings and identifies key physicochemical factors critical for optimizing sustainable concrete production.

4.2.1. Model Performance Metrics

The predictive performance of the XGBoost models for various mechanical properties of concrete paver blocks was evaluated using standard metrics (

Table 6): MSE, RMSE, MAE, and R

2. These metrics provide a comprehensive understanding of the model’s ability to replicate observed trends and capture the inherent variability in the data.

For the model’s performance in predicting water absorption (WA) reveals modest accuracy. It achieved an MSE of 7.92, an RMSE of 2.81, and an MAE of 2.04. The R2 value of 0.02 indicates the model struggles to explain the variance in WA, likely due to complex, non-linear interactions between the physicochemical properties of the concrete and the environmental factors influencing water absorption.

In contrast, for compressive strength (CS), the model demonstrated strong predictive capabilities. The MSE was 37.60, with an RMSE of 6.13 MPa and an MAE of 4.94 MPa. Notably, the R2 value of 0.92 indicates that 92% of the variability in CS was captured by the model, reflecting its effectiveness in handling mechanical properties governed by more linear and predictable relationships.

For ultrasonic pulse velocity (UPV) across different configurations—direct, indirect, and semi-direct—the XGBoost models showed exceptional predictive performance. The direct mode achieved an MSE of 41,106.78, an RMSE of 202.75 m/s, and an MAE of 184.72 m/s with an R2 of 0.97, indicating high accuracy. The indirect mode further improved upon this, achieving an MSE of 11,345.74, an RMSE of 106.52 m/s, and an MAE of 66.41 m/s with an outstanding R2 of 0.99, capturing nearly all the variance. While the semi-direct mode exhibited higher errors (MSE of 5,605,807, RMSE of 2367.66 m/s, and MAE of 1223.04 m/s), the R2 remained robust at 0.97, suggesting strong predictive reliability despite the increased variability.

The models also performed commendably in predicting the DME. For the direct mode, the model achieved an MSE of 0.33, an RMSE of 0.57 GPa, and an MAE of 0.36 GPa with an impressive R2 of 0.99. The indirect mode followed closely, with an MSE of 2.32, an RMSE of 1.52 GPa, and an MAE of 1.01 GPa, supported by an R2 of 0.98. However, the semi-direct DME predictions were more variable, as reflected by an MSE of 3355.14, an RMSE of 57.92 GPa, and an MAE of 34.10 GPa. Although the R2 value dropped to 0.80, it still indicates a substantial level of explanatory power, albeit less precise than the direct and indirect modes.

In summary, the performance metrics suggest that XGBoost models excel in predicting mechanical properties with well-defined, linear relationships, such as compressive strength and pulse velocity. The models faced challenges in predicting properties like water absorption and semi-direct DME, where complex, non-linear interactions play a significant role. Nonetheless, the consistently high R2 values across most targets reaffirm the models’ robustness and potential for practical applications, making them valuable tools for predictive modeling in concrete paver block analysis.

4.2.2. Feature Importance Across Targets

Building upon the performance metrics, the feature importance analysis provides a deeper understanding of the contributions of individual physicochemical properties to the predictive models.

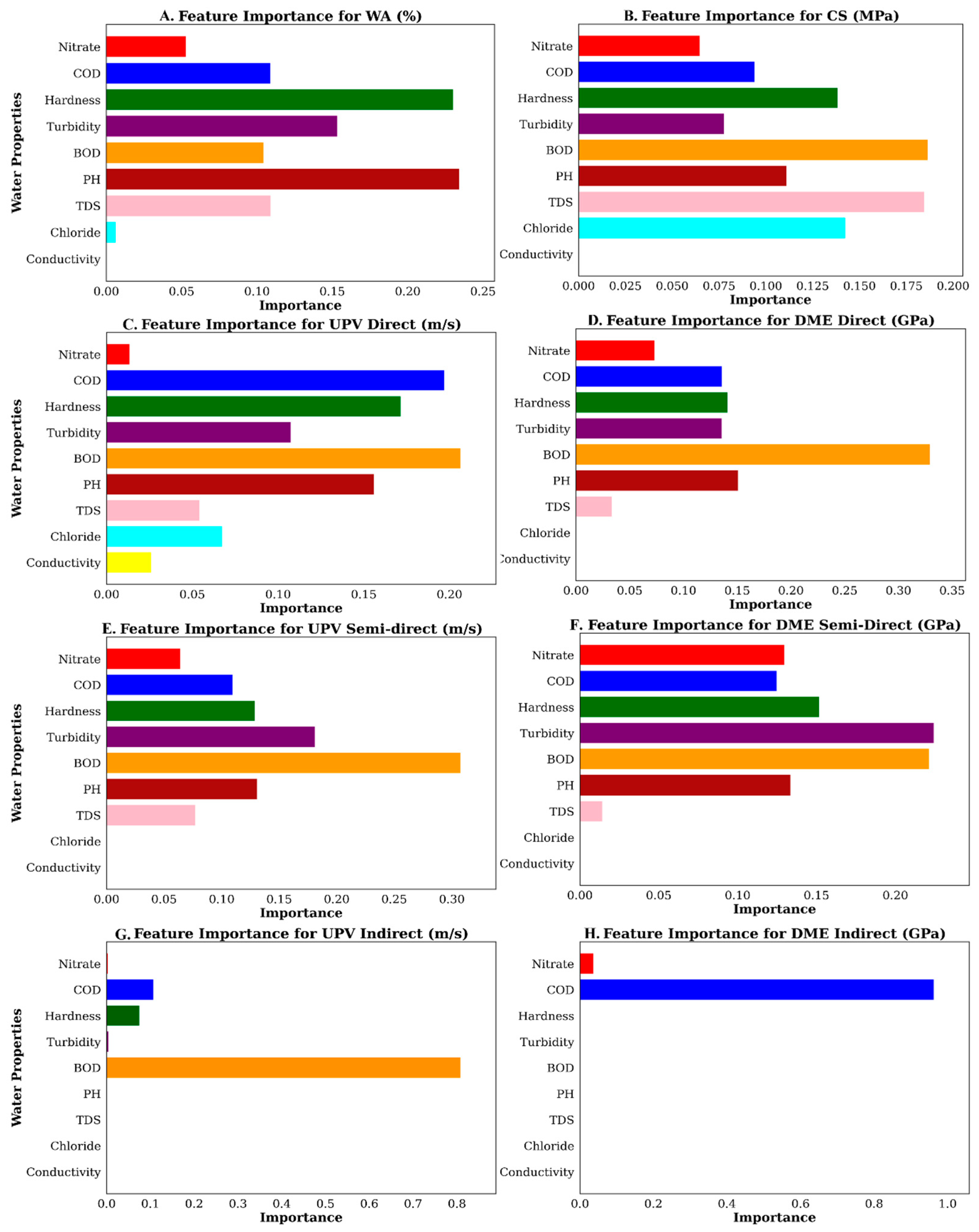

Figure 12 and

Figure 13 collectively illustrate the significance of these features, both at the individual target level and in cumulative terms across all targets.

In

Figure 12A, representing water absorption(WA %), Hardness emerges as the most influential factor, contributing approximately 23.03% to the model’s predictions. This is followed by Turbidity (15.35%) and COD (10.89%), indicating that both mineral content and suspended particles significantly affect the absorption behavior of concrete paver blocks. The relatively high importance of BOD (10.45%) and TDS (13.11%) underscores the role of organic and dissolved content. Nitrate has a lower importance of 5.30%, suggesting a more limited effect in this context.

For compressive strength(CS) in

Figure 12B, BOD (18.65%) and TDS (18.46%) are the most dominant factors, followed closely by chloride (14.24%) and Hardness (13.85%). The significance of pH (11.12%) highlights the role of water alkalinity in cement hydration and strength development. These results collectively suggest that the ionic and organic content of water strongly influence concrete’s mechanical strength.

The ultrasonic pulse velocity (UPV) measurements under different modes highlight varying sensitivities to water properties. In

Figure 12C (UPV Direct), BOD (17.35%) is the most critical contributor, followed by Turbidity (13.82%) and Hardness (11.24%), indicating that both organic content and suspended particles influence wave propagation. In

Figure 12E (UPV Semi-Direct), BOD again dominates (29.37%), alongside Turbidity (16.45%) and Hardness (12.58%). Notably,

Figure 12G (UPV Indirect) reveals an overwhelming influence of BOD (78.21%), far surpassing other features such as COD (4.95%) and Hardness (3.48%). This suggests that organic content significantly alters internal porosity and structural continuity, particularly in indirect UPV assessments.

The dynamic modulus of elasticity (DME) predictions also show mode-dependent feature sensitivities. In

Figure 12D (DME Direct), BOD leads with 33.41% importance, followed by pH (20.14%) and Hardness (13.45%), suggesting that organic matter and alkalinity influence the stiffness and elastic response of the concrete. In

Figure 12F (DME Semi-Direct), while BOD (22.15%) remains dominant, Hardness (15.36%) and pH (13.92%) also contribute substantially, indicating a more balanced dependency across multiple water parameters. In stark contrast,

Figure 12H (DME Indirect) reveals an extreme reliance on COD (98.12%), with negligible contributions from all other features. This points to a highly deterministic and potentially non-linear relationship between COD levels and the material’s dynamic modulus under indirect measurement configurations.

Moving beyond individual targets,

Figure 13A presents the cumulative feature importance across all models. Here, BOD exhibits the highest cumulative importance (≈2.16), followed by COD (1.84) and Hardness (1.04). This highlights the broad relevance of organic and chemical pollutants, as well as mineral content, in shaping various concrete performance metrics. pH (0.91) and Turbidity (0.88) also demonstrate moderate yet consistent contributions, reinforcing their role in influencing hydration reactions and internal structure.

Figure 13B provides a distributional view of feature importance via boxplots. BOD shows the widest range, with a mean importance of 0.27 and values reaching up to 0.81, reflecting its dominant but variable role across targets. COD displays a similar pattern (mean 0.23, max 0.96), especially elevated in DME Indirect. Hardness, while showing lower variability, maintains a consistent influence (mean 0.13), affirming its baseline significance across mechanical and ultrasonic outcomes. Both pH and Turbidity hover around a mean importance of 0.11, indicating moderate but steady impact across prediction tasks.

Overall, BOD consistently ranks among the top predictors, particularly in the UPV and DME models, reinforcing its central role in altering concrete’s internal structure and mechanical response. Hardness and Turbidity are pivotal in WA and UPV analyses, suggesting the importance of physical and mineral composition. COD, despite being less consistent, shows overwhelming dominance in DME Indirect mode, implying potential for model simplification using fewer variables in specific contexts.

In conclusion, this feature importance analysis complements the model performance metrics by elucidating the underlying physicochemical drivers of predictive accuracy. These insights offer valuable guidance for future experimental design, model refinement, and water quality control in concrete applications.

While the XGBoost algorithm itself is well established, the novelty of this research lies in its application context and its integration with experimental validation. To the authors’ knowledge, this is among the first studies to comprehensively model mechanical properties of concrete using untreated industrial wastewater from five distinct sectors—textile, sugar mill, sewage, carwash, and fertilizer—while simultaneously identifying the governing physicochemical parameters for each performance metric [

79]. Through feature importance analysis [

71], the model not only predicts performance but also reveals critical chemical drivers such as BOD, Turbidity, and Hardness. This dual role of forecasting and explanation allows for data-driven selection and ranking of wastewater sources, as demonstrated through the composite scoring system. This approach moves beyond standard regression by combining experimental mechanics, environmental chemistry, and machine learning into a single evaluative framework aimed at guiding practical sustainability decisions in real-world construction contexts.

4.2.3. Water Source Composite Score and Ranking

Following the feature importance analysis, the performance of the water sources used in the production of concrete paver blocks is evaluated based on their influence on mechanical properties. The composite scores are calculated by aggregating the contributions of individual performance metrics such as water absorption, compressive strength, pulse velocity, and dynamic modulus.

Table 7 provides the average performance metrics for each water source, while

Figure 14 visually represents their composite rankings.

In

Figure 14, the textile water source demonstrates the highest overall performance with a composite score of 15,169.49. This is primarily attributed to its strong performance in compressive strength (31.31 MPa) and dynamic modulus (direct: 9.39 GPa, indirect: 15.52 GPa, semi-direct: 161.55 GPa), as well as high pulse velocity values across all configurations (direct: 1663.89 m/s, indirect: 2073.75 m/s, semi-direct: 11,218.24 m/s). These metrics indicate that the textile wastewater enhances the mechanical properties of concrete paver blocks significantly.

Sugar wastewater ranks second with a composite score of 14,095.68, closely followed by carwash water at 14,082.83. Sugar water excels in direct pulse velocity (1704.52 m/s) and semi-direct dynamic modulus (149.75 GPa), highlighting its suitability for improving specific mechanical properties. Carwash water, while slightly lower in rank, demonstrates balanced performance across all metrics, achieving notable scores in compressive strength (27.54 MPa) and indirect dynamic modulus (12.05 GPa).

Sewerage wastewater ranks fourth with a composite score of 13,918.35. Despite competitive values for compressive strength (27.31 MPa) and semi-direct pulse velocity (10,316.79 m/s), its overall performance is overshadowed by higher-performing water sources. Fresh water and fertilizer water rank fifth and sixth, with composite scores of 13,849.24 and 12,781.25, respectively. Fertilizer water exhibits lower values across all metrics, particularly in compressive strength (20.64 MPa) and semi-direct dynamic modulus (84.90 GPa), which accounts for its lowest ranking.

Figure 14 reinforces these rankings, visually emphasizing the superiority of textile wastewater in enhancing concrete properties. The bar height for textile water clearly surpasses all other sources, followed by sugar and carwash water. The decline in composite scores from sewerage to fresh and fertilizer water is also evident, reflecting their comparatively lower contributions to concrete performance.

This evaluation highlights the potential of textile wastewater as the most effective alternative for producing high-strength, durable concrete paver blocks, while also demonstrating the practicality of sugar and carwash water in achieving robust performance. Conversely, fertilizer wastewater, with its significantly lower composite score, is less suitable for applications requiring high mechanical performance. These insights serve as a guideline for optimizing the use of alternative water sources in sustainable construction practices.

4.3. Comparative Analysis of Experimental and Machine Learning Results

The comparative analysis between experimental findings and ML predictions demonstrates a strong alignment, particularly for CS, UPV, and DME. The ML models effectively captured the trends observed in the experimental data, accurately predicting the superior performance of concrete pavers made with textile and sugar wastewater. This consistency is further supported by high R2 values (0.92 for CS, 0.97–0.99 for UPV, and 0.98–0.99 for DME), reflecting the models’ robustness in forecasting mechanical properties influenced by the physicochemical characteristics of wastewater.

However, the predictive accuracy for WA was notably lower, with an R2 of 0.02, indicating a weak correlation between the ML predictions and experimental results. This discrepancy can be attributed to the limited dataset and the inherent complexity of water absorption behavior, which is influenced by non-linear interactions between environmental conditions, microstructural variations, and the diverse chemical compositions of wastewater. The relatively small sample size may have constrained the model’s ability to generalize these complex interactions effectively.

Despite this limitation, the overall consistency between the experimental and ML results underscores the reliability of the predictive models in assessing key mechanical properties of wastewater-based concrete. The integration of experimental validation with AI-driven modeling provides a comprehensive framework for optimizing sustainable construction practices, highlighting the feasibility of using wastewater as an alternative resource without compromising structural performance.

5. Analytical Discussion

5.1. Analytical Interpretation of Results

This study integrates experimental findings with ML approaches to establish a comprehensive framework for evaluating the suitability of wastewater in concrete paver block manufacturing. The investigation examines the correlations between key physicochemical characteristics of wastewater—BOD, COD, Turbidity, Hardness, pH, TDS, nitrate, and nitrite—and their influence on vital mechanical properties of concrete, including water absorption, compressive strength, ultrasonic pulse velocity, and dynamic modulus of elasticity. It provides essential recommendations for maximizing the utilization of recycled water with little treatment, thus decreasing dependence on expensive technologies.

The feature importance analysis identifies BOD and COD as the most influential factors affecting all mechanical properties, followed by Hardness and Turbidity, while pH and nitrates exhibit comparatively lower impacts. For water absorption and compressive strength, Hardness shows the highest importance values (0.22–0.25), emphasizing their critical role in concrete’s early-age performance. Experimentally, moderate nitrate levels enhance compressive strength by accelerating hydration and improving early-age strength [

88]. However, excessive nitrate concentrations can cause delayed ettringite formation and reduced long-term durability [

89]. Hardness, COD, and Turbidity are also the principal factors affecting UPV and DME, with feature importance scores ranging from 0.20 to 0.22. Experimentally, wastewater with high COD levels—indicative of substantial organic contamination—hinders hydration processes, increases porosity, and adversely affects strength development. Similarly, high Turbidity compromises a mix of uniformity and workability [

89]. Consequently, wastewater with high Turbidity or COD, such as CSW, FIW, or SUW, is unsuitable for structural applications without appropriate COD and BOD treatment. Nonetheless, such effluent can be efficiently employed for non-structural elements such as masonry blocks and pavers where durability standards are less rigorous. Additionally, chloride content was identified as a key factor influencing UPV, showing a direct correlation in ML analysis. A certain amount of chloride content and Hardness may contribute positively to stiffness and elasticity, making wastewater with these characteristics particularly suitable for precast or rigid concrete elements where rigidity and dimensional stability are critical. However, excessive Hardness can affect workability [

10,

11], and high chloride levels pose a risk of steel reinforcement corrosion [

90], necessitating careful application in unreinforced or non-structural concrete structures. This study focuses on the utilization of untreated wastewater in non-structural concrete components, such as pavers and blocks, which lack steel reinforcement. However, the use of such wastewater in reinforced concrete would result in chloride concentrations surpassing the ASTM threshold, necessitating meticulous treatment and oversight. This is a critical aspect that cannot be overlooked, as it is essential to avert steel corrosion and ensure the structural integrity of the concrete.

Among the various wastewater sources evaluated, textile wastewater appears as a promising prospect for concrete production due to its moderate physicochemical characteristics, with slightly higher Turbidity and TDS, which require minimal treatment. Its widespread availability in industrial regions like Pakistan offers a practical and cost-effective alternative to fresh water, reducing logistical constraints and enhancing sustainability in construction. Enhanced workability and compressive strength development can be achieved with simple treatment methods, such as sand filtration or biological processes, making it suitable for large-scale adoption. However, scalability remains challenging due to transportation, storage, and the need for localized or mobile treatment systems to minimize costs. Regulatory frameworks and standards for wastewater reuse in construction are also required to ensure constant water quality. By addressing these challenges, treated wastewater can be employed more widely in concrete production, opening the door to efficient and ecological building methods.

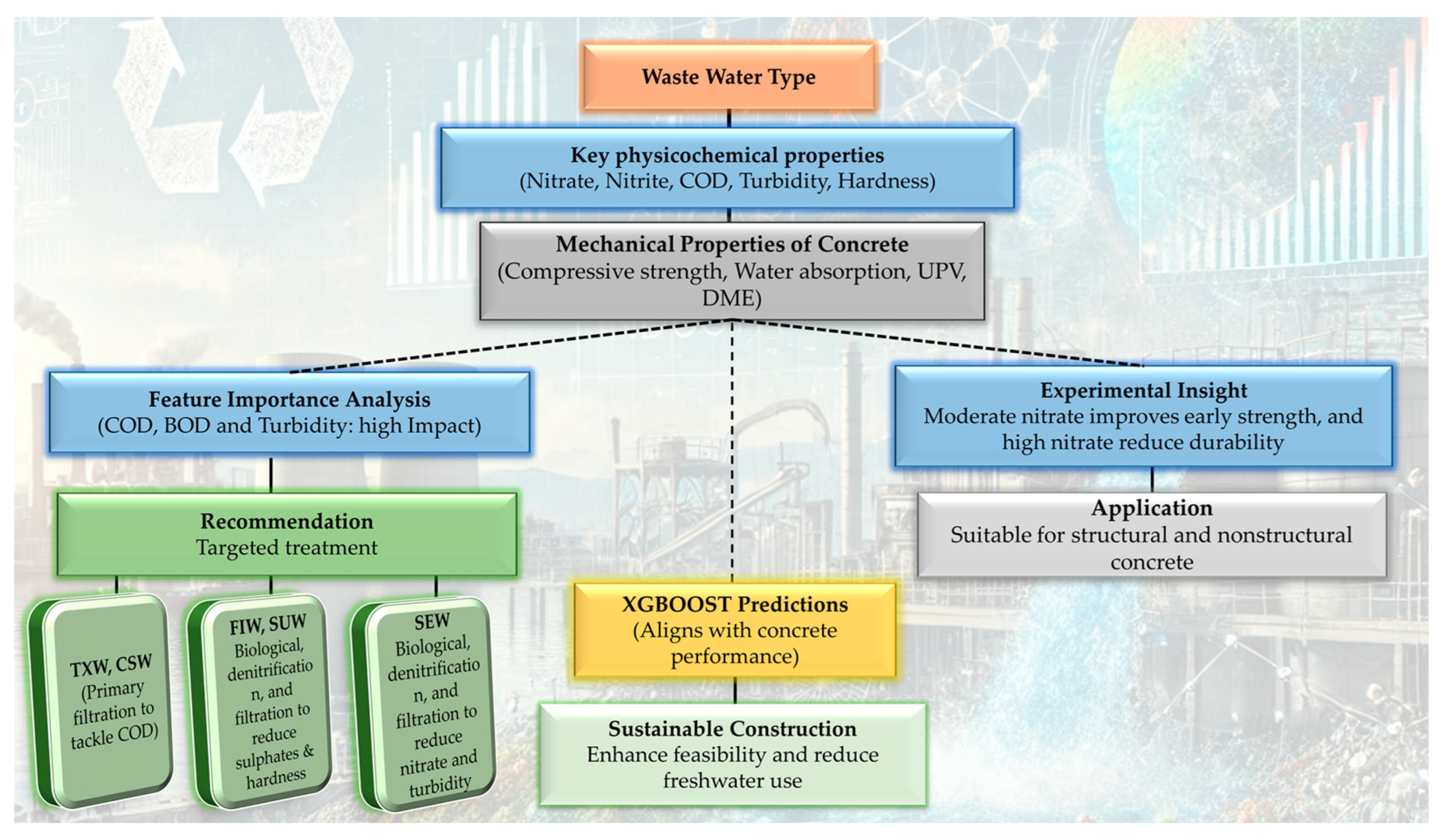

5.2. Practical Application and Objective of Machine Learning

Integrating experimental and ML insights demonstrates the feasibility of using wastewater in concrete production with minimal treatment. Targeted strategies, such as calcium (Ca

2+), magnesium (Mg

2+), and sulfate ion reduction (for fertilizer and sugar mill wastewater) that cause Hardness or nitrate removal (for sewage wastewater), effectively address specific contaminant challenges. Techniques like biological denitrification for the removal of calcium, magnesium nitrate, sulfate, or gypsum precipitation mitigate durability risks without requiring extensive chemical interventions [

91]. On the other hand, wastewater from textiles and service stations, which exhibits moderate Turbidity, and TDS, may only require primary filtration to improve workability [

92], as its COD, BOD, and Hardness levels are within acceptable ranges, making it cost-effective for construction use. Similarly, SUW requires reductions in Turbidity and COD through simple filtration or biological denitrification depending upon the nature of the structural component [

92]. SEW has to reduce Turbidity, BOD, and COD, which can be performed using a sustainable wetland treatment system, where organic pollutants and suspended particles are effectively removed by gravel filtration and plant–root microbial interactions.

This dual experimental–ML approach enables the development of predictive models that align wastewater characteristics with desired concrete properties, facilitating the strategic use of untreated or partially treated wastewater. In addition to supporting sustainable construction practices, this study enhances economic feasibility by addressing critical physicochemical limitations and promoting resource efficiency. The findings underscore the potential of combining experimental methods with advanced computational tools to reduce fresh water reliance and enable the sustainable reuse of wastewater in diverse concrete applications. A representation of the whole process is shown in

Figure 15.

5.3. Long-Term Durability and Environmental Considerations

While the short-term mechanical performance confirms feasibility, long-term durability must also be ensured to prevent deterioration under weathering, sulfate attack, and chloride exposure. Untreated industrial effluent needs to be assessed for long-term environmental safety in addition to physicochemical treatment. Cementitious matrices can immobilize heavy metals and reduce leaching; however, groundwater exposure and weathering may influence their release [

93,

94,

95]. Future research should include standardized leaching tests, durability monitoring, and environmental risk assessments to ensure that wastewater reuse does not negatively impact soil, water, or the lifespan of the concrete.

5.4. Model Generalizability, Dataset Limitation, and Overfitting Considerations

Although the XGBoost model achieved promising predictive performance across various mechanical properties of concrete, it is important to recognize the limitations posed by the dataset used in this study. The data were derived from five distinct industrial wastewater sources, each characterized by specific physicochemical profiles and linked mechanical outcomes. While these sources represent a useful cross-section of common wastewater types, the dataset remains relatively small and may not fully capture the broader variability that could arise from other industrial processes, regional conditions, or seasonal fluctuations.

To address the risk of overfitting and improve generalization, we implemented five-fold cross-validation along with careful hyperparameter tuning, as described in Section Hyperparameter Optimization. These steps helped the model perform consistently within the scope of the available data. However, given the limited number of unique samples and combinations, the model’s ability to generalize to entirely new or highly dissimilar wastewater scenarios may be constrained.

Therefore, the model should be viewed as a practical pre-screening and prioritization tool, not a replacement for established laboratory testing protocols. Its strength lies in helping engineers and practitioners quickly assess which wastewater streams are most likely to yield viable concrete mixes, thereby streamlining early-stage decision-making and reducing redundant testing. To build upon this foundation, future research should aim to expand the dataset by including a wider variety of wastewater types, incorporating long-term sampling to account for temporal variability, and validating the approach across multiple sites or regions. These efforts would enhance the model’s robustness, extend its applicability, and provide stronger support for its integration into sustainable construction practices.

6. Conclusions

This study presents a comprehensive evaluation of the feasibility of utilizing untreated and partially treated wastewater from diverse industrial sources—textile, sugar mill, service station, sewage, and fertilizer industry—for concrete paver block manufacturing. Through a dual experimental–machine learning (ML) approach, key physicochemical characteristics of wastewater and their influence on mechanical properties, including compressive strength, water absorption, ultrasonic pulse velocity (UPV), and dynamic modulus of elasticity (DME), were systematically assessed.

The integration of experimental results with XGBoost-based machine learning models demonstrated strong alignment, particularly in predicting compressive strength (R2 = 0.92) and ultrasonic pulse velocity (UPV) with R2 values of 0.97 (direct) and 0.99 (indirect). The experimental results showed that concrete pavers produced with textile wastewater (CP-TXW) achieved a 28-day compressive strength of 47.95 MPa, closely matching ML-predicted trends. Conversely, water absorption (WA) exhibited limited prediction accuracy (R2 = 0.02), likely due to complex non-linear interactions and limited dataset variability.

Feature importance analysis identified BOD, COD, and Hardness as critical determinants of mechanical performance. BOD exhibited the highest cumulative feature importance (~33.4% for direct DME and ~29.4% for semi-direct UPV), directly correlating with experimental findings where wastewater with moderate BOD levels, such as CP-SEW, maintained superior compressive strength (46.73 MPa) and low water absorption (2.80%). COD, influential in both ML models and experimental durability outcomes, negatively impacted hydration in high concentrations (e.g., CP-FIW with COD > 1000 mg/L showed a reduced strength of 20.64 MPa).

The finding demonstrates the viability of using untreated wastewater, particularly from textile and sugar industries, in concrete production with minimal treatment requirements. Concrete pavers made from CP-TXW and CP-SUW exhibited compressive strengths exceeding 48 MPa and UPV values surpassing 1700 m/s after 28 days, in line with ASTM C936 standards. This strength is suitable for non-structural or light-duty paving applications, such as footpaths and pedestrian walkways, where the typical compressive strength requirements range between 40 and 50 MPa. Specific treatments, including primary filtration for high-COD wastewater (e.g., CSW) and biological denitrification for SEW, improve performance while reducing resource consumption, thereby promoting sustainable construction practices and decreasing reliance on fresh water.

This study underscores the viability of wastewater reuse in concrete production, particularly for non-structural applications, with minimal treatment interventions. The strategic utilization of wastewater not only reduces fresh water dependency but also promotes sustainable construction practices by addressing environmental and economic challenges associated with industrial effluents. The integration of ML in material performance prediction further enhances decision-making for sustainable construction, paving the way for broader adoption of unconventional water resources in the construction industry. However, this study indicates promising short-term results; it is crucial to verify the long-term durability of the concrete against weathering, sulfate, and chloride effects to ensure its service life under practical conditions. Future efforts will focus on extensive long-term durability testing, standardized leaching assessments, and cost–benefit analyses to guarantee environmental safety, material longevity, and economic viability in sustainable construction practices.