Wood- and Steel-Based Offsite Construction Solutions for Sustainable Building Renovation: Assessing the European and Italian Contexts

Abstract

1. Introduction

2. Materials and Methods

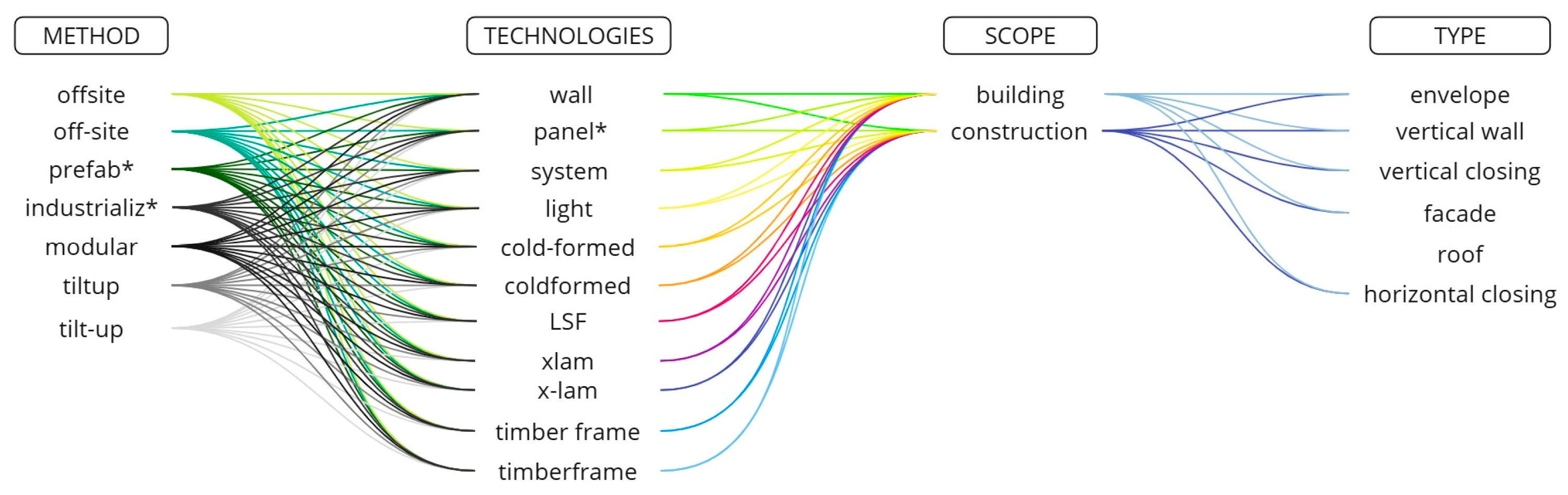

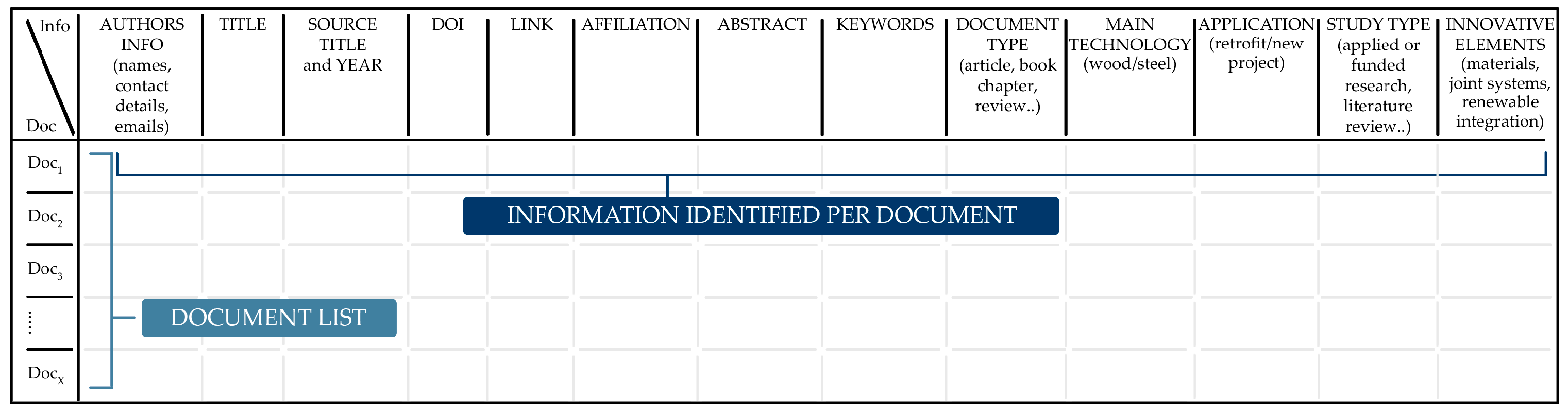

2.1. Literature Review

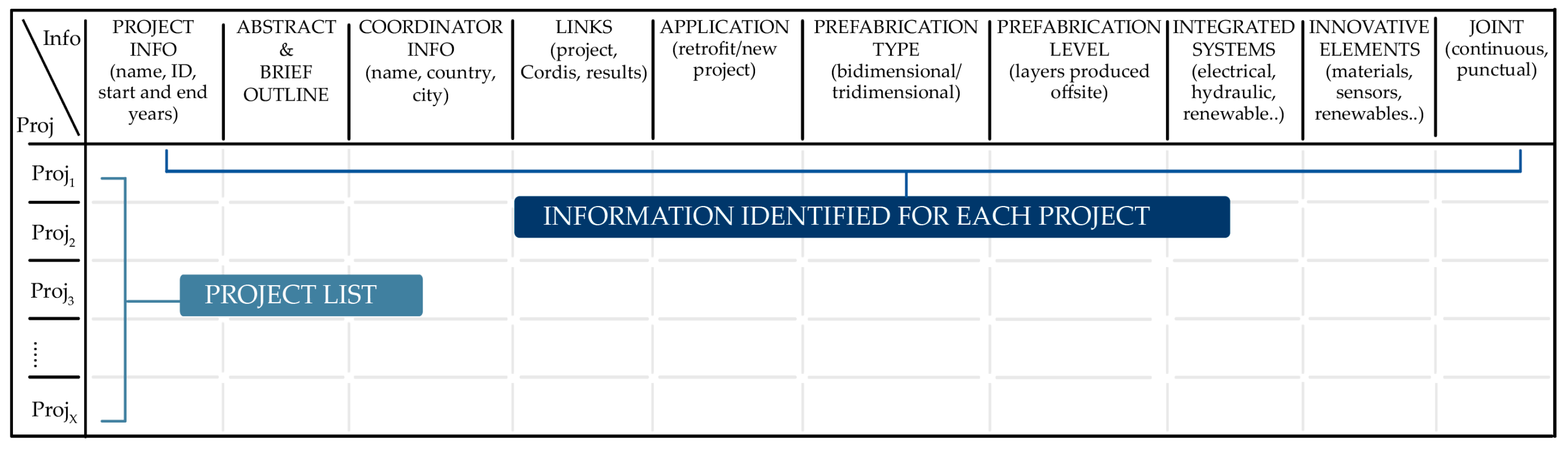

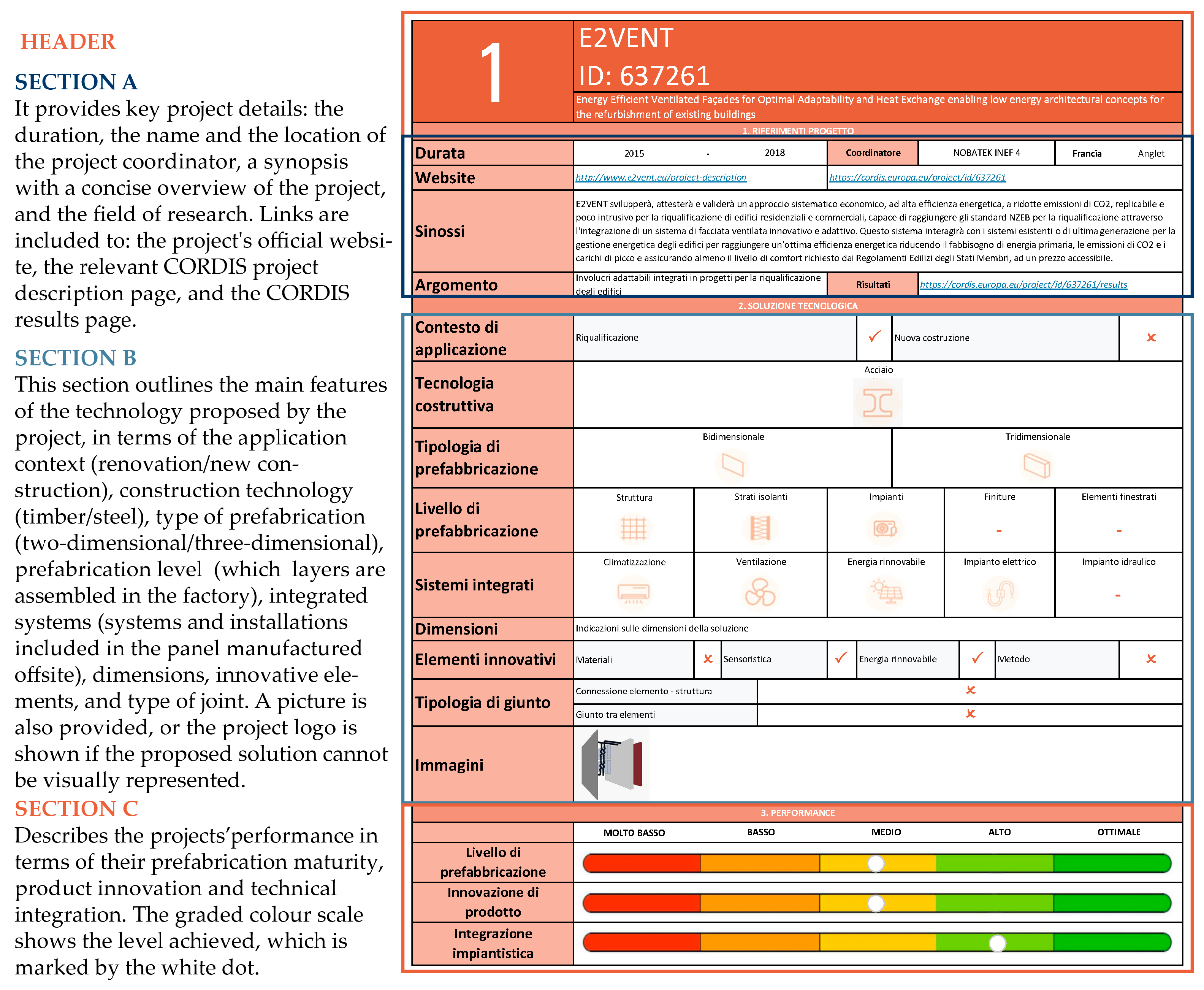

2.2. Funded Research Projects

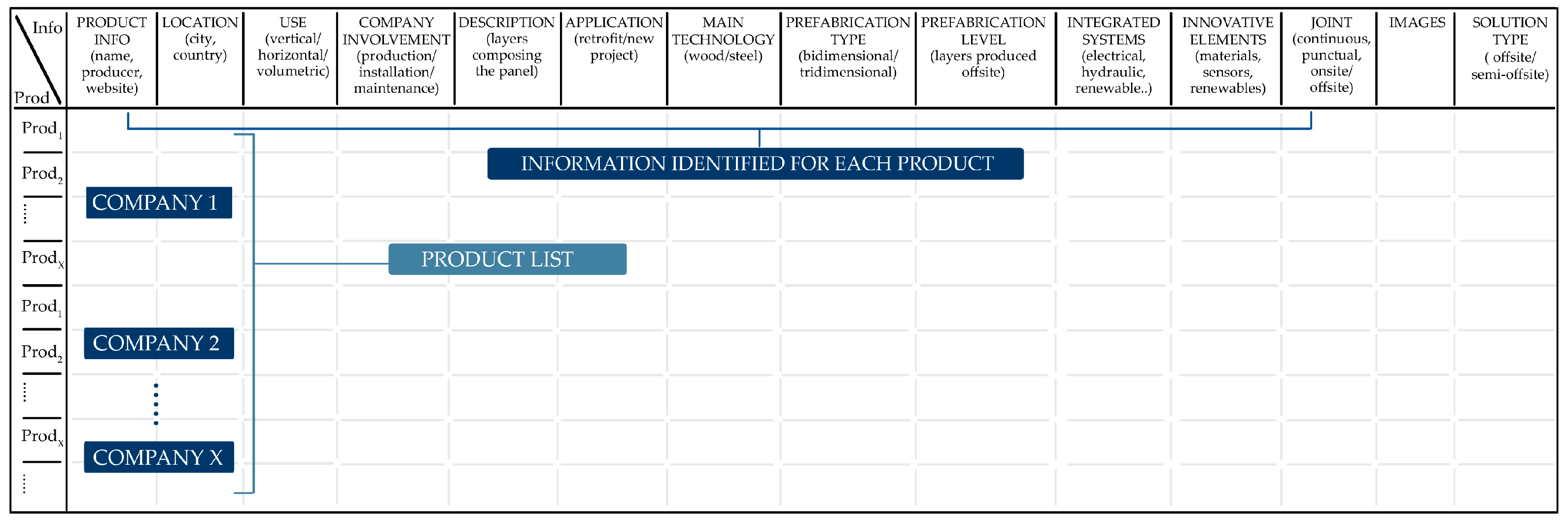

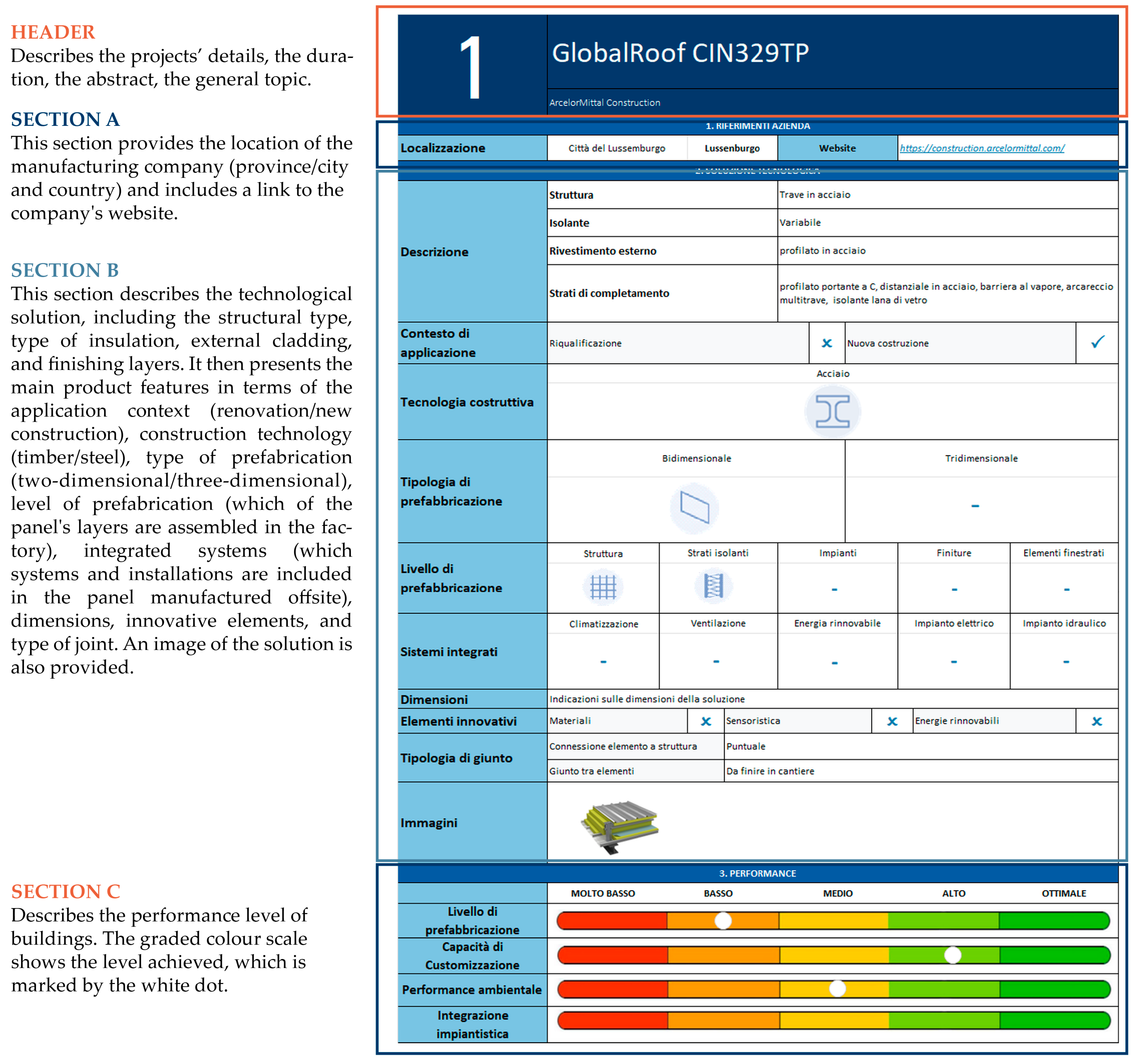

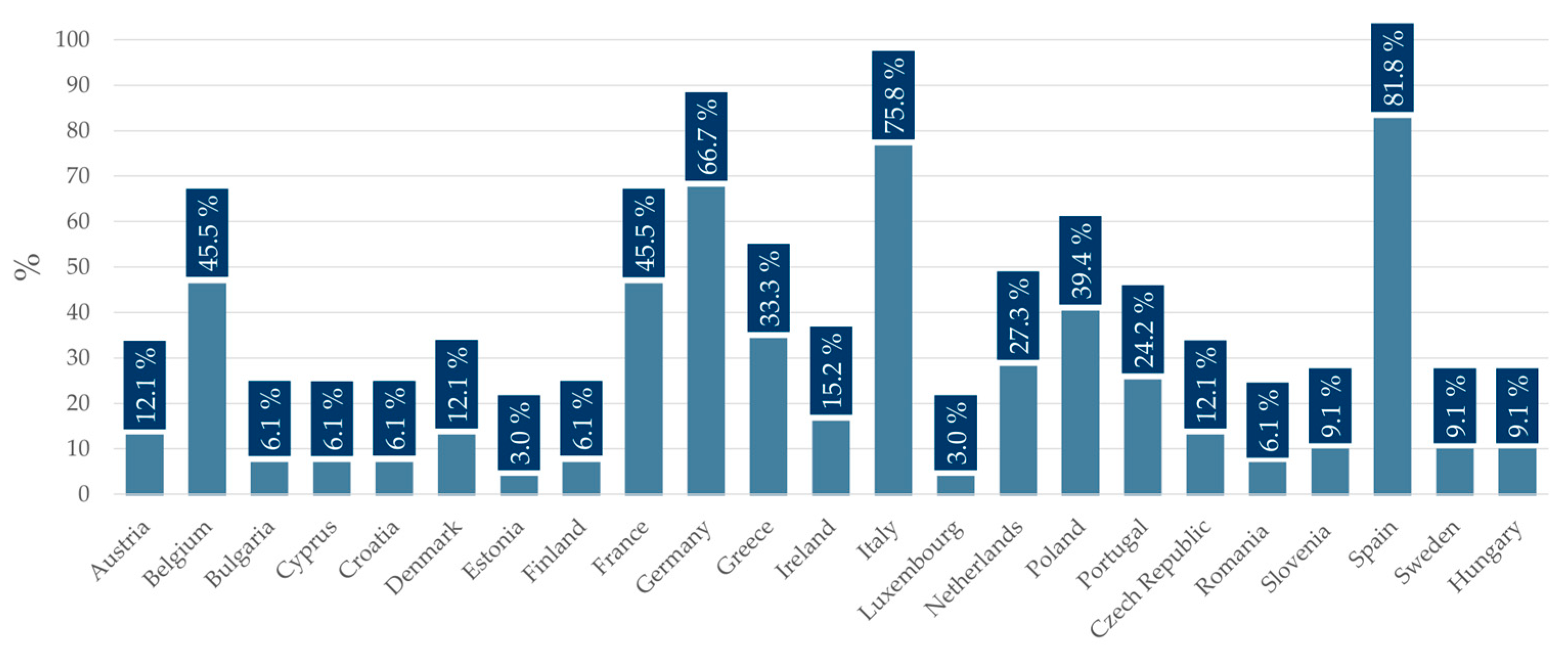

2.3. Market Scanning

3. Results

3.1. Literature Review Results

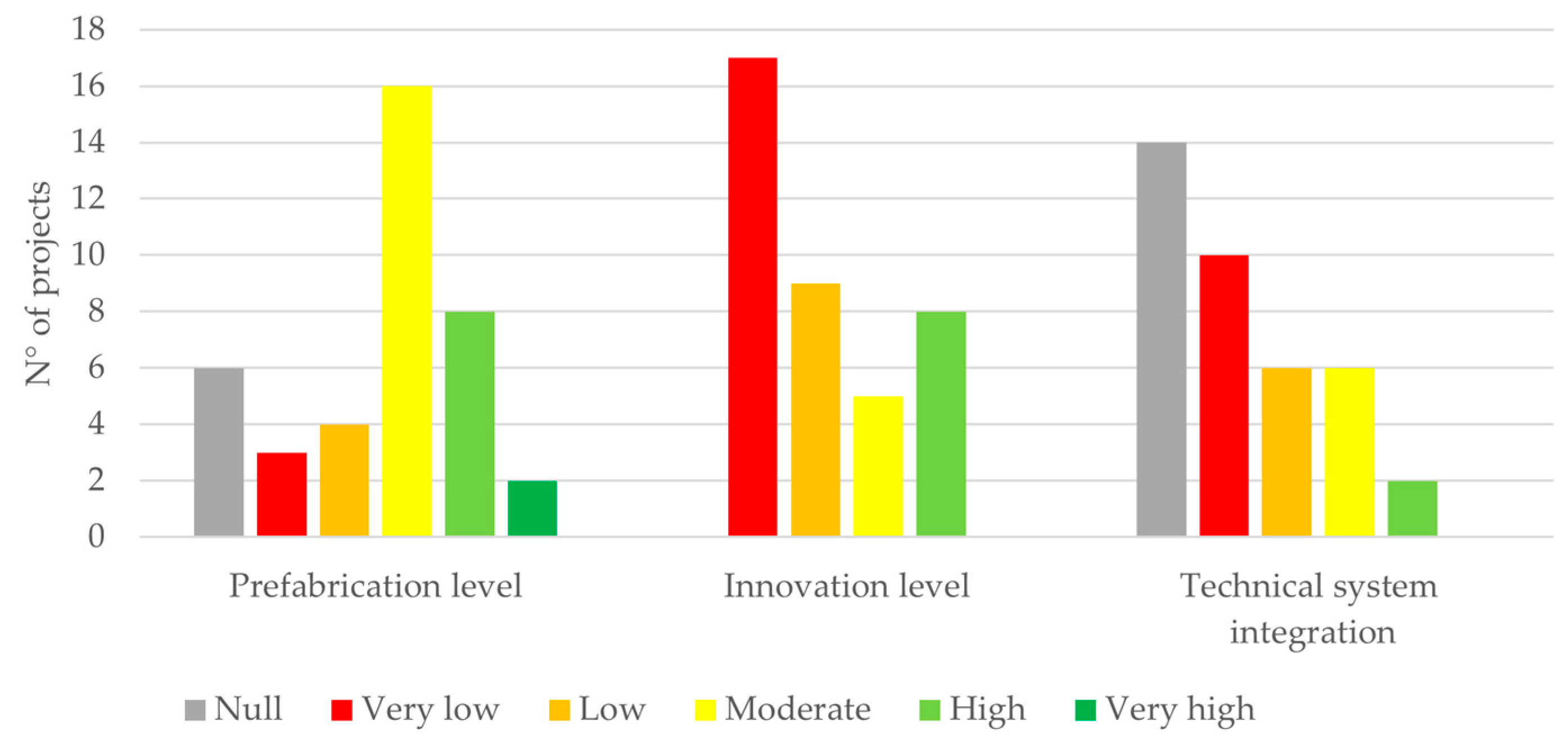

3.2. Funded Research Project Results

3.3. Market Scanning Results

4. Discussion and Conclusions

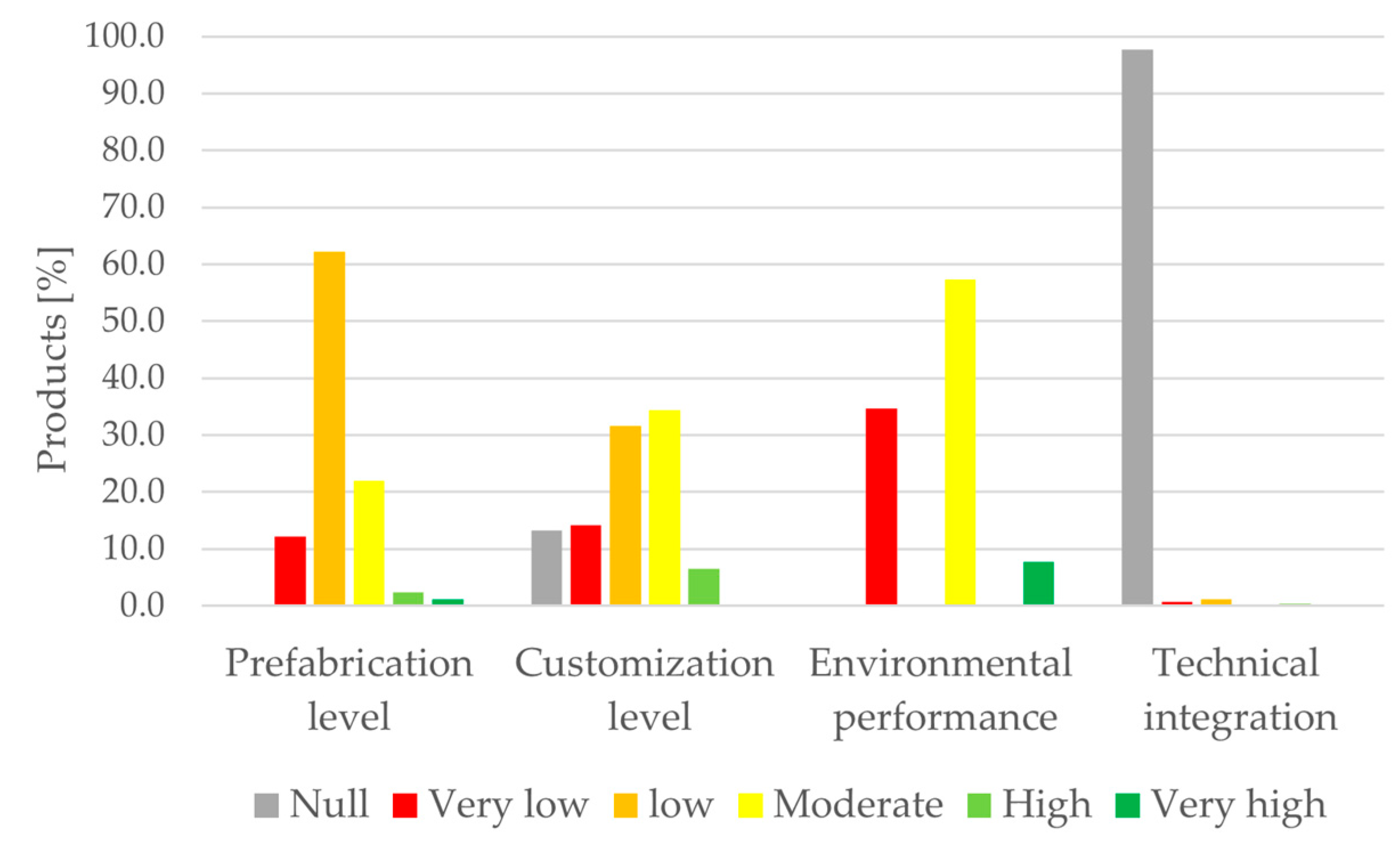

- Limited system integration and industrial scalability. The market remains anchored in low-integration models: of the 541 mapped commercial OSC products, 529 exhibit no integration of technical components, such as HVAC systems or renewable energy solutions. The research projects perform slightly better, with about half showing some level of integration, yet this remains insufficient to demonstrate industrial scalability. The prefabrication levels mirror this divergence: while most market products fall in the low and very low categories, nearly 67% of EU-funded projects display moderate to very high prefabrication, indicating a research focus on more ambitious construction methodologies. However, the absence of effective knowledge transfer mechanisms prevents these research outcomes from entering the commercial pipeline.

- Inadequate applicability of OSC in current renovation practices. This study underscores the limited suitability of the current OSC solutions for energy retrofit applications. A key barrier is the lack of adaptable joint and connection systems that would allow for effective integration with existing buildings. This mapping gap, initially explored in the study but with its investigation abandoned due to a lack of public information, speaks to a broader transparency issue in the sector. Most manufacturers do not disclose technical details essential for assessing the feasibility in renovation, such as the presence of anchoring systems or modular flexibility. This limits the architectural adaptability of OSC in refurbishment, one of the most promising yet underdeveloped markets for OSC.

- Regulatory fragmentation and cultural inertia. The absence of a dedicated legislative framework [49,50], both at the national and EU levels, continues to hinder sectoral growth. Procurement standards remain misaligned with OSC characteristics, and simply adapting traditional construction norms or importing foreign standards (e.g., U.S. codes) is not feasible given Europe’s heterogeneous legislative landscape. Crafting specific legal and technical instruments that recognize OSC’s distinct benefits, including faster delivery, reduced onsite disruption, and enhanced safety, could dispel the prevailing misconceptions and enable broader uptake. In particular, the public sector, despite its strategic importance in leading innovation, remains constrained by traditional procurement and evaluation mechanisms that overlook the time, cost, and safety benefits of offsite systems.

- Lagging environmental assessment and traceability. Environmental performance emerged as one of the weakest areas across both the commercial and research datasets. While the market data shows increasing attention to sustainability claims, the lack of use of robust and standardized environmental metrics, such as life cycle assessments (LCAs), hampers accountability and comparability. This represents a missed opportunity, particularly considering EU decarbonization policies that prioritize circularity and emissions transparency and the explicit GHG reduction underlined in different studies [51].

- Complementary evolution of material supply chains. The trajectories of wood- and steel-based OSC systems appear to be complementary rather than competitive. While wood-based solutions, representing 16% of the mapped products, are technically more advanced, typically using multi-layer panels, steel-based systems are more prevalent but remain largely in use in semi-offsite configurations. Interestingly, nearly 70% of the analyzed research projects focus on steel, indicating a targeted effort to upgrade this material stream. This convergence suggests that cross-material collaboration could yield synergies in terms of technological development, regulatory harmonization, and market expansion. Other synergies may include environmental ones, like the creation of regional shared distribution hubs and the definition of a new EPD category for OSC panels.

- Ongoing transition from semi- to fully offsite production. Several Italian firms currently producing steel solutions semi-offsite are participating in EU-funded projects aimed at achieving higher levels of prefabrication. These cross-sectoral engagements indicate an active willingness within parts of the industry to evolve toward fully offsite manufacturing. This insight highlights an opportunity to address the fragmentation of supply chains, identified by several studies as a major challenge for the sector [52]. However most current fully offsite systems remain focused on 2D rather than volumetric 3D modules, a limitation often linked to transportation and logistical constraints that should be investigated further.

- The enabling role of digital technologies. Digitalization offers transformative potential, particularly in overcoming design and implementation challenges in retrofit applications. Tools such as BIM, parametric design, and digital twin modeling can facilitate adaptive design, streamline project coordination, and enhance modular precision [52,53,54,55]. While their current use is sporadic, these technologies could serve as a bridge between the perceived rigidity and real-world complexity, improving the stakeholder confidence and expanding OSC’s application spectrum.

- Movement toward circularity and sustainability. Wood-based OSC systems, due to their biogenic content, stand to benefit from a stronger alignment with EU climate policies, particularly if coupled with transparent documentation such as EPDs (Environmental Product Declarations). Although OSC’s adoption is still limited, the growing policy emphasis on life cycle emissions and disassembly design could position OSC, especially the wood-based variety, as a preferred option in green public procurement and carbon-neutral development strategies.

- The creation of the OSC solution atlas. One of the most tangible outputs of this study is the development of the OSC solution atlas, a structured mapping tool comprising 541 commercial systems across Europe. By consolidating fragmented data and classifying solutions based on key technical parameters, the atlas serves as a foundational resource for bridging the information gap between researchers, designers, manufacturers, and policymakers. While the tool currently reflects the existing data limitations, it lays the groundwork for future iterations that can progressively enhance the sector’s transparency and comparability, although it will need constant updates to be effective. The final version of the atlas is available on the project website [26].

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EPD | Environmental Product Declaration |

| EPBD | European Performance Building Directive |

| GHGs | Green House Gases |

| HVAC | Heating Ventilation Air Conditioning |

| OFFICIO | Ottimizzazione Filiere oFf-site per la riqualifiCazione dell’ambIente cOstruito |

| OSC | Offsite Construction |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

| KPIs | Key Performance Indicators |

| VIPs | Vacuum-Insulated Panels |

References

- United Nations Environment Programme (UNEP). Building Materials are set to dominate climate change. In Building Materials and the Climate: Constructing a New Future, 1st ed.; Matsny, L., Benzoni, S., Eds.; United Nations Environment Programme: Nairobi, Kenya, 2023; pp. 1–5. [Google Scholar]

- European Commission (Brussels, Belgium). Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions. In The European Green Deal; COM/2019/640 Final; 2019. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:b828d165-1c22-11ea-8c1f-01aa75ed71a1.0002.02/DOC_1&format=PDF (accessed on 17 July 2025).

- European Commission (Brussels, Belgium). Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. In A Renovation Wave for Europe—Greening Our Buildings, Creating Jobs, Improving Lives; COM/2020/662 Final; 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:52020DC0662 (accessed on 17 July 2025).

- Fetting, C. The European Green Deal; ESDN Report; ESDN Office: Vienna, Austria, 2020. [Google Scholar]

- BPIE (Buildings Performance Institute Europe). EU Buildings Climate Tracker: A Call for Faster and Bolder Action. 17 July 2023. Available online: https://www.bpie.eu/publication/eu-buildings-climate-tracker-a-call-for-faster-and-bolder-action/ (accessed on 17 July 2025).

- Sibileau, H.; Broer, R.; Dravecký, L.; Fabbri, M.; Fernández Álvarez, X.; Kockat, J.; Jankovic, I. Deep Renovation: Shifting from Exception to Standard Practice in Eu Policy; Buildings Performance Institute Europe (BPIE): Berlin, Germany, 2021; pp. 8–11. [Google Scholar]

- Filippidou, F.; Navarro, J.; Filippidou, F.; Pablo, J. Achieving the Cost-Effective Energy Transformation of Europe’s Buildings Energy Renovations via Combinations of Insulation and Heating & Cooling Technologies Methods and Data; Publications Office of the European Union: Luxembourg, 2019; pp. 1–10. [Google Scholar]

- European Parliament (Strasbourg, France). The European Parliament and the Council of the European Union Directive (EU) 2024/1275 of the European Parliament and of the Council of 24 April 2024; In Energy Performance of Buildings (Recast); 2024/1275; Official Journal of the European Union. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=OJ:L_202401275&pk_keyword=Energy&pk_content=Directive (accessed on 17 July 2025).

- Maduta, C.; Tsemekidi-Tzeinaraki, S.; Castellazzi, L.; Dagostino, D.; Melica, G.; Paci, D.; Bertoldi, P. Updates on the Energy Performance of Buildings Directive implementation in the EU Member States; Publications Office of the European Union: Luxembourg, 2025. [Google Scholar]

- Mehdipoor, A.; Iordanova, I. Systematic Literature Review on the Combination of Digital Fabrication, BIM and Off-Site Manufacturing in Construction—A Research Road Map. Lect. Notes in Civil Eng. 2023, 247, 283–296. [Google Scholar]

- Bowden, S.; Dorr, A.; Thorpe, T.; Anumba, C. Mobile ICT Support for Construction Process Improvement. Autom. Constr. 2006, 15, 664–676. [Google Scholar] [CrossRef]

- Bergmans, I.J.B.; Bhochhibhoya, S.; Van Oorschot, J.A.W.H. Assessing the Circular Redesign of Prefabricated Building Envelope Elements for Carbon Neutral Renovation. J. Facade Des. Eng. 2023, 11, 169–196. [Google Scholar] [CrossRef]

- Jin Wen Thoy, E.; Go, Y.I. Enhancement and Validation of Building Integrated PV System: 3D Modelling, Techno-Economics and Environmental Assessment. Energy Built Environ. 2022, 3, 444–466. [Google Scholar] [CrossRef]

- Zarghami, E.; Fatourehchi, D. Comparative Analysis of Rating Systems in Developing and Developed Countries: A Systematic Review and a Future Agenda towards a Region-Based Sustainability Assessment. J. Clean Prod. 2020, 254, 120024. [Google Scholar] [CrossRef]

- Luna, A.; Gonzalez-Trevizo, M.E.; Bojorquez, G.; Romero Moreno, R.A.; Martínez-Torres, K.E. Structural Insulation Panel System (SIP) as an Alternative for Cooling Energy Saving, Decarbonization, and Energy Cost Reduction in Hot and Dry Climates. A Simulation-Based Approach. Energy Sources Part A Recovery Util. Environ. Eff. 2024, 46, 17267–17292. [Google Scholar]

- D’Oca, S.; Ferrante, A.; Ferrer, C.; Pernetti, R.; Gralka, A.; Sebastian, R.; Veld, P. op t. Technical, Financial, and Social Barriers and Challenges in Deep Building Renovation: Integration of Lessons Learned from the H2020 Cluster Projects. Buildings 2018, 8, 174. [Google Scholar] [CrossRef]

- Gibb, A.G.F. Standardization and Pre-Assembly- Distinguishing Myth from Reality Using Case Study Research. Constr. Manag. Econ. 2001, 19, 307–315. [Google Scholar] [CrossRef]

- EDERA. Materiali. Industrialized Deep Renovation Outlook. Available online: https://edera.city/materiali/ (accessed on 17 July 2025).

- BUILD UP. The European Portal for Energy Efficiency and Renewable Energy in Buildings. Market Potential of Offsite Construction for Housing Supply. Report. Available online: https://build-up.ec.europa.eu/en/resources-and-tools/publications/offsite-construction-key-more-affordable-housing-report (accessed on 17 July 2025).

- Han, Y.; Wang, L. Identifying Barriers to Off-Site Construction Using Grey DEMATEL Approach: Case of China. J. Civ. Eng. Manag. 2018, 24, 364–377. [Google Scholar] [CrossRef]

- Alvarez-Alava, I.; Elguezabal, P.; Jorge, N.; Armijos-Moya, T.; Konstantinou, T. Definition and Design of a Prefabricated and Modular Façade System to Incorporate Solar Harvesting Technologies. J. Facade Des. Eng. 2023, 11, 1–28. [Google Scholar] [CrossRef]

- Masip, D.; Marrone, G.; Rafols Ribas, I. Implementation of a Multifunctional Plug-and-Play Façade Using a Set-Based Design Approach. J. Facade Des. Eng. 2023, 11, 71–96. [Google Scholar] [CrossRef]

- Diallo, T.M.O.; Zhao, X.; Dugue, A.; Bonnamy, P.; Javier Miguel, F.; Martinez, A.; Theodosiou, T.; Liu, J.S.; Brown, N. Numerical Investigation of the Energy Performance of an Opaque Ventilated Façade System Employing a Smart Modular Heat Recovery Unit and a Latent Heat Thermal Energy System. Appl Energy 2017, 205, 130–152. [Google Scholar] [CrossRef]

- Energiesprong Global Alliance. Available online: https://energiesprong.org/ (accessed on 10 June 2024).

- Energiesprong IT Edera. Available online: https://www.energiesprong.it/il-processo/edera/ (accessed on 17 July 2024).

- OFFICIO. Costruire il Future—Off-Site e Riqualificazione Edilizia in Italia. Available online: https://progetto-officio.it/ (accessed on 17 July 2025).

- Page, M.; McKenzie, J.; Bossuyt, P.; Boutron, I.; Hoffmann, T.; Mulrow, C.; Shamseer, L.; Tetzlaff, J.; Akl, E.; Brennan, S.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Iturralde, K.; Mediavila, A.; Elguezabal, P. Automation Process in Data Collection for Representing Façades in Building Models as Part of the Renovation Process. J. Facade Des. Eng. 2023, 11, 123–144. [Google Scholar] [CrossRef]

- European Commission CORDIS—EU Research Results. Available online: https://cordis.europa.eu/ (accessed on 6 February 2025).

- Li, Y.; Chen, L. Investigation of European Modular Façade System Utilizing Renewable Energy. Int. J. Low-Carbon Technol. 2022, 17, 279–299. [Google Scholar] [CrossRef]

- Favoino, F.; Perino, M.; Serra, V. Advanced Integrated Facades: Concept Evolution and New Challenges. In Proceedings of the Thermal Performance of the Exterior Envelopes of Whole Buildings, American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), Clearwater Beach, FL, USA, 9–12 December 2019. [Google Scholar]

- Atsonios, I.; Katsigiannis, E.; Koklas, A.; Kolaitis, D.; Founti, M.; Mouzakis, C.; Tsoutis, C.; Adamovský, D.; Colom, J.; Philippen, D.; et al. Off-Site Prefabricated Hybrid Façade Systems a Holistic Assessment. J. Facade Des. Eng. 2023, 11, 97–122. [Google Scholar] [CrossRef]

- Du, H.; Huang, P.; Jones, P. Modular Facade Retrofit with Renewable Energy Technologies: The Definition and Current Status in Europe. Energy Build. 2019, 205, 109543. [Google Scholar] [CrossRef]

- Bock, M. A Building Integrated Solar Thermal Collector with Active Steel Skins. Energy Build. 2019, 201, 134–147. [Google Scholar] [CrossRef]

- Chen, T.; Tai, K.F.; Raharjo, G.P.; Heng, C.K.; Leow, S.W. A Novel Design Approach to Prefabricated BIPV Walls for Multi-Storey Buildings. J. Build. Eng. 2023, 63, 105469. [Google Scholar] [CrossRef]

- Favoino, F.; Goia, F.; Perino, M.; Serra, V. Experimental Analysis of the Energy Performance of an ACTive, RESponsive and Solar (ACTRESS) Façade Module. Sol. Energy 2016, 133, 226–248. [Google Scholar] [CrossRef]

- Van Roosmalen, M.; Herrmann, A.; Kumar, A. A Review of Prefabricated Self-Sufficient Facades with Integrated Decentralised HVAC and Renewable Energy Generation and Storage. Energy Build. 2021, 248, 111107. [Google Scholar] [CrossRef]

- Goldstein, D.J. Façade-Integrated Mechanical Systems (FIMS): A New Approach for Non-Invasive Deep Energy Retrofits. In Proceedings of the Fifth International Conference on Efficient Building Design: Material and HVAC Equipment Technologies; ASHRAE, Beirut, Lebanon, 20–21 October 2022. [Google Scholar]

- Katsigiannis, E.; Gerogiannis, P.; Atsonios, I.; Manolitsis, A.; Founti, M. SmartWall Towards Residential NZEB with Off-Site Prefabricated Hybrid Façade Systems Using a Variety of Materials. J. Facade Des. Eng. 2023, 11, 29–50. [Google Scholar] [CrossRef]

- Zabala Innovation-Dissemination and Communication Actions REZBUILD. Integration of New Technologies for the Retrofitting of Near Zero-Energy Buildings. Available online: https://www.zabala.eu/projects/rezbuild/ (accessed on 29 May 2025).

- Rina S.p.a. RINNO. Potenziare l’efficienza Energetica Delle Abitazioni Europee. Available online: https://www.rina.org/it/media/CaseStudies/RINNO (accessed on 13 May 2025).

- LEITAT Technological Center HOUSEFUL. Innovative Circular Solutions and Services for the Housing Sector. Available online: https://leitat.org/es/blog/houseful/ (accessed on 22 May 2025).

- Circuit Consortium CIRCUIT. Circuit Construction in Regenerative Cities. Available online: https://report.circuit-project.eu/ (accessed on 22 May 2025).

- Università di Bologna. Dipartimento di Architettura—DA ABRACADABRA. Assistant Buildings’ Addition to Retrofit, Adopt, Cure and Develop the Actual Buildings up to ZeRo Energy. Available online: https://da.unibo.it/en/research/research-projects/project-archive/abracadabra (accessed on 19 May 2025).

- Iceberg Circular Economy of Building Materials. Available online: https://iceberg-project.eu (accessed on 13 May 2025).

- National Technical University of Athens PLURAL. Plug-and-Use Renovation with Adaptable Lightweight Systems. Available online: https://www.plural-renovation.eu/ (accessed on 19 May 2025).

- European Commission SMAS. Sustainable Modular Architectural System. Available online: https://cordis.europa.eu/project/id/718020/reporting (accessed on 12 May 2025).

- Eco-Sandwich Project Partners ECO-SANDWICH®—Energy Efficient, Recycled Concrete Sandwich Facade Panel. Available online: https://www.eco-sandwich.hr/ (accessed on 12 May 2025).

- Mao, C.; Shen, Q.; Pan, W.; Ye, K. Major Barriers to Off-Site Construction: The Developer’s Perspective in China. J. Manag. Eng. 2015, 31, 04014043. [Google Scholar] [CrossRef]

- Gan, X.; Chang, R.; Zuo, J.; Wen, T.; Zillante, G. Barriers to the transition towards off-site construction in China: An Interpretivestructural modeling approach. J. Clean. Prod. 2018, 197, 8–18. [Google Scholar] [CrossRef]

- Pervez, H.; Ali, Y.; Petrillo, A. A quantitative assessment of greenhouse gas (GHG) emissions from conventional and modular construction: A case of developing country. J. Clean. Prod. 2021, 294, 126210. [Google Scholar] [CrossRef]

- Opabola, E.A.; Galasso, C. A probabilistic framework for post-disaster recovery modeling of buildings and electric power networks in developing countries. Reliab. Eng. Syst. Saf. 2024, 242, 109679. [Google Scholar] [CrossRef]

- Zohourian, M.; Pamidimukkala, A.; Kermanshachi, S.; Almaskati, D. Modular Construction: A Comprehensive Review. Buildings 2025, 15, 2020. [Google Scholar] [CrossRef]

- Wang, Y.; Bian, S.; Dong, L.; Li, H. Multiresolution Modeling of a Modular Building Design Process Based on Design Structure Matrix. Buildings 2023, 13, 2330. [Google Scholar] [CrossRef]

- Regona, M.; Yigitcanlar, T.; Xia, B.; Li, R.Y.M. Opportunities and adoption challenges of AI in the construction industry: A PRISMA review. J. Open Innov. Technol. Mark. Complex. 2022, 8, 45. [Google Scholar] [CrossRef]

| KPIs | Calculation Method |

|---|---|

| Prefabrication level | It accounts for the functional layers in the commercialized solution, with 1 point assigned for each of the following components included in the panel: insulation, load-bearing structures, technical systems (e.g., electrical systems), external cladding or coatings, and windows or doors. |

| Innovation level | Up to 3 points may be awarded if the project focuses on the following innovation areas: 1 point each for the use of innovative materials, renewable energy, and new research methodologies. An additional 2 points are awarded if the project integrates sensors within the panel. |

| Technical integration | It verifies the inclusion of specific systems within the solution. Up to 5 points may be awarded, with 1 point assigned for each of the following integrated components: an electrical system, plumbing, climatization, ventilation, and renewable energy technologies. |

| KPIs | Calculation Method |

|---|---|

| Prefabrication level | The same as for the funded projects; see Table. |

| Customization level | The evaluation depends on the maturity of the solution (offsite: 1 point; semi-offsite: 0 points), the type of application (renovation or new construction: 1 point if both applications are feasible; 0 points if only one is applicable), the possibility to customize the insulation layer (1 point if customization is possible; 0 points if not), and the number of solutions offered (0 points when less than 15 products are available, 2 points if more products are provided). |

| Environmental performance | Points are given based on the biogenicity of the insulation layer, with a default score of 3 points if it is variable. Synthetic materials (e.g., PIR): 1 point; composite materials (e.g., phenolic foam panels): 2 points; mineral-based materials (e.g., rock wool): 3 points; vegetal materials (e.g., wood fiber): 5 points. |

| Technical integration | The same as for the funded projects; for reference see Table. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salvalai, G.; Gadusso, F.; Benedetti, M. Wood- and Steel-Based Offsite Construction Solutions for Sustainable Building Renovation: Assessing the European and Italian Contexts. Sustainability 2025, 17, 6799. https://doi.org/10.3390/su17156799

Salvalai G, Gadusso F, Benedetti M. Wood- and Steel-Based Offsite Construction Solutions for Sustainable Building Renovation: Assessing the European and Italian Contexts. Sustainability. 2025; 17(15):6799. https://doi.org/10.3390/su17156799

Chicago/Turabian StyleSalvalai, Graziano, Francesca Gadusso, and Miriam Benedetti. 2025. "Wood- and Steel-Based Offsite Construction Solutions for Sustainable Building Renovation: Assessing the European and Italian Contexts" Sustainability 17, no. 15: 6799. https://doi.org/10.3390/su17156799

APA StyleSalvalai, G., Gadusso, F., & Benedetti, M. (2025). Wood- and Steel-Based Offsite Construction Solutions for Sustainable Building Renovation: Assessing the European and Italian Contexts. Sustainability, 17(15), 6799. https://doi.org/10.3390/su17156799