Abstract

Accurate and transparent Life Cycle Assessment (LCA) datasets are essential for reliable sustainability evaluations, particularly in the complex and varied textile industry. Historically, the ecoinvent database has been a foundational source for LCA studies in the textile sector. This paper critically examines the limitations of the ecoinvent v3.7 dataset, which is widely used in academic research, industry tools, and policymaking. While newer versions, such as v3.11, released in 2024, have addressed many issues, including enhanced geographical representation and updated emission profiles for chemicals, this study emphasises the historical implications of earlier data versions. By comparing the cradle-to-gate Global Warming Potential (GWP) of wool and polyester jumpers, this research reveals how aggregated and outdated data underestimated the polyester’s environmental impact while overestimating that of wool. These discrepancies have shaped fibre certification, eco-labelling, and consumer perceptions for years. Understanding the legacy of these datasets is vital for re-evaluating past LCA-based decisions and guiding future assessments toward greater regional relevance and transparency.

1. Introduction

The global textile industry plays a significant role in meeting consumer demand for clothing, home furnishings, and other industrial applications. However, their extensive environmental impact has raised critical sustainability concerns. The Global Warming Potential (GWP) is a critical metric that quantifies the relative contribution of different greenhouse gases (GHGs) to global warming over a specific period, in comparison to carbon dioxide (CO2) [1]. The textile industry is estimated to contribute 8–10% of GHG emissions annually, highlighting a pressing need to address its environmental sustainability challenges [2,3]. These challenges span multiple impact categories, including climate change, water use, and resource depletion [4]. A comprehensive evaluation of such impacts requires robust methodological tools, among which Life Cycle Assessment (LCA) is widely recognised. Within the LCA framework, the accurate characterization of impacts such as GWP is essential for reliable sustainability assessments of textile products [5].

LCA is a scientifically recognised method for quantifying the environmental impact of products and processes, from raw material extraction to products’ end of life. This comprehensive approach identifies environmental hotspots and provides actionable insights into mitigation strategies [4]. LCA has been widely adopted in the textile sector and serves as the foundational methodology for popular assessment tools such as the Higg Material Sustainability Index (MSI) [6,7] and other user-friendly software programmes such as SimaPro, GaBi, and OpenLCA [8]. However, the effectiveness of LCA depends on its reliability and accessibility and the relevance of the underlying datasets.

Polyester is a dominant synthetic textile fibre which has replaced natural fibres globally. In 2022, polyester accounted for a majority (54%) of the global market share, far more than other synthetic fibres (11%), plant-based natural fibres (27%), man-made cellulosic fibres (6.3%), and animal fibres (1.6%) [9]. Polyesters are derived from petroleum-based chemicals, and their production is highly energy-intensive [10]. Additionally, 86% of the global polyester fibre is produced in Asian countries that rely on coal for energy, having a significant environmental footprint [11,12].

Polyesters are also criticised for their role in microplastic pollution, particularly during use and disposal [13,14]. Research has shown that during laundering, 124–308 mg of synthetic microfibers per kilogram of washed fabric is shed, many of which are sufficiently small to bypass wastewater treatment systems and contribute 35% of all microplastic pollution in the marine environment [15]. At the end of life, as polyester decomposes, it releases methane and microplastics in the environment [13], contributing to biodiversity loss, water contamination, and greenhouse gas emissions [16,17]. In addition to microplastic pollution, polyester clothing shows little or no degradation in the marine environment for years or even decades [15].

Contrarily, natural textile material such as wool is fully biodegradable and breaks down naturally, without releasing harmful microfibres in the environment. During laundry, the microfiber shedding from wool knit clothing was found to be 37% less than that from polyester knit clothing [18], and 20% to 23% of wool fibres degrade in seawater in just 90 days [19]. However, despite wool’s superior environmental credentials during use and end of life, its market share remains small, largely because of consumer unawareness of its environmental benefits [20].

Wool often ranks poorly in LCA studies compared to polyester because of the high GWP attributed to methane emissions from sheep, which contributes approximately 75% of the climate impact of wool fibre production [21]. As sheep that grow wool are ruminants, their natural digestion process releases methane, which significantly influences the carbon footprint of wool in standard LCA calculations. Additionally, the environmental impact allocation between wool and meat production plays a crucial role in determining the overall footprint of wool, with different allocation methods leading to variations in the reported impacts [21,22]. These methodological choices often overlook the biodegradability and long-term environmental benefits of wool, affecting its comparative ranking in LCA studies [23].

LCA studies that compared natural materials such as wool and cotton to polyester utilising ecoinvent v2.2 [24] and v3.5 [25] showed polyester to perform better. However, concerns have been raised regarding the accuracy of their conclusions because datasets for polyester production, particularly those for ethylene, a critical raw material derived from crude oil for polyester fibre production, lacked transparency [26]. The ecoinvent dataset for ethylene production, which were widely used in many LCA studies globally before the newer versions 3.10 and v3.11 released in 2024, were based on estimated data from the eco-profiles of the European plastics industry in the 1990s and does not provide details of the upstream processes involved in ethylene production [26,27]. This lack of geographical representation, the outdated nature, and an opaque methodology compromise the reliability of assessments and risks, skewing conclusions in favour of polyester [28,29].

As LCA becomes a foundational tool for evaluating textile sustainability, the reliability of its outcomes depends heavily on the underlying data. The ecoinvent database, one of the most widely used LCI repositories globally, has played a significant role in shaping fibre comparison studies using LCA-based tools such as SimaPro and GaBi. However, the datasets for key materials, such as wool and polyester, have long suffered. A thorough investigation of the datasets can provide critical insights into materials’ environmental impact.

This study examines the environmental impacts of wool and polyester fibre production, with a specific focus on jumpers produced in New Zealand. The study focuses solely on the fibre production phase, omitting the broader life cycle impact of a jumper. The choice of New Zealand as a focal point is significant because it is the third largest producer of wool globally and has unique environmental factors that influence its production [30,31]. However, markets in New Zealand are flooded with clothing made of synthetic materials, such as polyester, acrylic, nylon, and their blends [32]. By analysing 393 g of wool and polyester fibres, the material required for constructing a medium-size women’s jumper, this study offers insights into the sustainability implications of these fibre types within a New Zealand context. While ecoinvent v3.7 was current and accessible at the time of data collection and analysis, we acknowledge that updated versions (v3.10 and v3.11) have since been released [33]. A discussion of these developments is included to ensure transparency and situate the study in its appropriate historical context. By highlighting the past impacts, we aim to contribute to the broader discourse on improving data quality and accountability in textile LCA.

2. Literature Review

Wool is a natural fibre derived from sheep that produce 4 to 5 kg of wool annually. Wool farming includes pasture management, fertiliser use, and supplementary feeding, which may influence its environmental outcome [34,35]. Wool production has been associated with greenhouse gas emissions from sheep’s enteric fermentation and manure [36].

However, recent studies suggest that when properly accounted for, the biogenic carbon flow associated with sheep forage can partially offset GHG emissions from wool’s raw material production stage. Although wool is not directly plant-derived, the forage and crops consumed by sheep absorb atmospheric CO2 through photosynthesis, contributing to the overall carbon balance of wool [37]. Moreover, wool products can extend the carbon sequestration effect over time because of their durability, reusability, and recyclability, which significantly reduces the need for new material inputs [38]. At the end of their life, wool products offer additional environmental advantages: energy recovery from incineration can displace fossil fuel use, and composting, if managed properly, may contribute to soil carbon enrichment, further supporting the role of wool in circular and low-carbon systems [37].

2.1. Available Datasets for Wool Production

Several LCI datasets are available for modelling the environmental impacts of wool production, each differing in scope, geographic specificity, and methodological details. Table 1 presents a comparative overview of the most commonly used LCI datasets in wool LCA studies, including their geographic focus, key attributes, and limitations.

Table 1.

Major LCI databases for wool production.

Among the available LCI datasets, the ecoinvent database is the most widely used and is commonly integrated into LCA software platforms, such as SimaPro and GaBi, providing generalised global data for processes, including greasy wool production [8,39]. Although ecoinvent v3.7 offers global data on wool fibre production, it lacks the regional specificity required to accurately represent key wool-producing systems, particularly in countries such as New Zealand [30]. For example, environmental factors, such as the presence of woody vegetation on New Zealand sheep farms, significantly contribute to on-farm carbon sequestration. When such sequestration is excluded, the cradle-to-farm-gate emissions for New Zealand wool may be overestimated by up to 30% [42].

In contrast, the dataset developed by Wiedemann et al. provides detailed primary, farm-level inventory data for Australian wool systems, incorporating co-product allocation and direct emissions from wool and meat production. However, this dataset is specific to Australian production conditions and is not suitable for use in regions such as New Zealand, where wool systems differ in terms of land use, pasture management, and carbon sequestration dynamics [39,41].

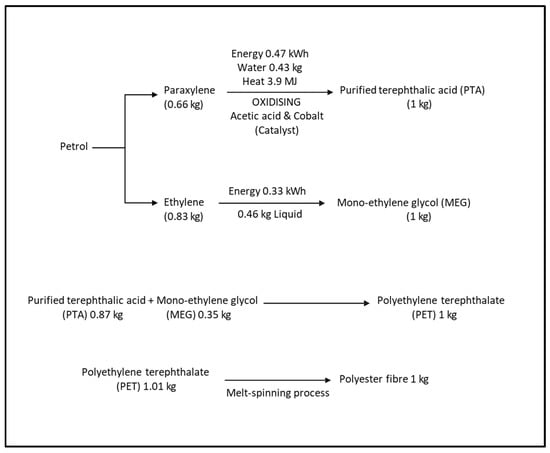

Polyester is primarily made from polyethylene terephthalate (PET). Its production begins with the extraction of crude oil through mining operations and its cracking [43]. Crude oil with a boiling point of 104–157 °C, called naphtha, is broken into smaller reactive molecules of ethylene, propylene, various butylene compounds, and butadiene [26]. Among these, ethylene is the key raw material for PET and, in turn, polyester fibre production. The cracking of naphtha is followed by chemical processes to produce purified terephthalic acid (PTA) and monoethylene glycol (MEG), which are then reacted to form the PET resin. PET resin is then converted into polyester yarns via a melt spinning process [44]. Figure 1 illustrates the transformation of petrochemical feedstocks (ethylene and terephthalic acid) into PET, the precursor to polyester fibre, highlighting the importance of upstream process inclusion in LCA modelling [43,45].

Figure 1.

Polyester fibre production.

The ecoinvent v3.7 database provides a global “rest of world” (RoW) dataset for polyester fibre production. However, recent developments in the ecoinvent dataset v 3.9 and v3.10 have shown that the carbon footprint of PET production has increased (26%) owing to a more comprehensive accounting of methane emissions from other geographical regions such as North America and 44 countries in addition to Europe, which was solely considered in ecoinvent for many years, in versions from v2 to v3.8 [46]. Despite these updates in the dataset, there are issues with its reliability, as it is aggregated and lacks transparency for thorough validation.

2.2. Available Datasets for PET Production

The LCA of PET relies on various datasets that offer complementary insights into its environmental impact. A summary of the major life cycle inventory (LCI) databases used in the production of PET production and of its precursor, ethylene, is presented in Table 2. This table highlights their characteristics and constraints based on their scope, geographic coverage, key attributes, and limitations.

Table 2.

Major LCI databases for PET production.

Among the available datasets for PET production, ecoinvent remains the most widely utilised LCI database, mainly because of its integration into leading LCA software platforms, such as SimaPro and GaBi. These software tools are extensively utilised in sustainability assessment processes within the textile industry [51], and most studies conducted in the fashion sector have employed these platforms in conjunction with the ecoinvent database [52]. The accessibility and standardised methodology of the ecoinvent database make it the preferred choice for researchers conducting comparative impact assessments of textile fibres [8]. Ecoinvent offers broad industrial coverage, including ethylene production; however, it relies on aggregated European data that may underrepresented global production realities and omit process-specific details.

Datasets from Franklin Associates and the NREL provide inventory data specific to the United States and are utilised for region-specific analyses. Meanwhile, the Carbon Minds database stands out for its globally distributed and geographically differentiated LCA data; its limited integration into standard LCA tools reduces its practical adoption.

In the field of textiles, the ecoinvent database has been used to evaluate the environmental profile of different fibre types. Van der Velden et al. conducted a cradle-to-gate analysis to compare polyester, cotton, nylon, acrylic, and elastane. Their study showed polyester having the lowest GWP in the production phase [24]. Similarly, Sandin et al. underscored that wool often scores poorly on GWP but better on biodegradability and ecosystem health, and thus there is a need to include multiple environmental indicators in the LCA of textile fibres [25]. These studies underline the necessity for robust and transparent datasets to avoid skewed conclusions in comparative assessments. The current study leverages the “global” wool production dataset and the “rest of world” polyester dataset from ecoinvent v3.7 to compare the environmental impact of these fibre types.

3. Materials and Methods

Understanding the differences in the environmental impact of wool and polyester jumper production provides critical insights for material selection, sustainable product design, and policy development. This study evaluated the environmental impact of wool and polyester jumper production for 393 g of final product. The wool fibre dataset from the ecoinvent library represents “global” (GLO) production scenarios, whereas the polyester dataset reflects the “rest of world” (RoW) scenario. The analysis focused on the cradle-to-gate impacts of fibre production, emphasising the GWP as the primary impact category. Both datasets were critically assessed for granularity, transparency, temporal relevance, and geographical representation to ensure robustness of the results. Notably, the ecoinvent database is constructed to support various environmental standards, including the ISO 14000 family for Environmental Management, ensuring that the data aligns with internationally recognised methodologies for LCA [53].

3.1. Wool Fibre Production Dataset

The wool production dataset in the ecoinvent v3.7 library provided a comprehensive global inventory of wool and meat production. The dataset includes farm inputs, co-products, and transportation. The dataset in v3.7 is valid for the period from 2011 to 2020 and aggregates information from multiple regions across the globe. Table 3 presents the key parameters associated with the production of 1 kg of wool fibre as documented in the ecoinvent v3.7 database. Table 4 outlines the specific inventory data extracted from ecoinvent and used in this study to model wool fibre production.

Table 3.

Ecoinvent v3.7 inventory for 1 kg of wool production.

Table 4.

Ecoinvent inventory data used for wool fibre production.

3.2. Polyester Fibre Production Dataset

The polyester fibre production dataset in the ecoinvent v3.7 library models a RoW scenario and includes processes such as PET resin production and melt spinning. The dataset represents a cradle-to-gate inventory that captures inputs, such as crude oil extraction, electricity, heat, and water. The dataset assumed a recycling rate of 3.5% for PET granulates during the melt spinning process. Ethylene production, the primary raw material for PET, was included in the dataset, which is based on the European plastics industry eco-profiles. Table 5 provides the input inventory for producing 1 kg of polyester fibre, detailing materials, energy consumption, and process efficiencies as recorded in the ecoinvent v3.7 database. Table 6 outlines the inventory data sources utilised in this study, outlining the key components that underpinned the LCA of polyester fibre production.

Table 5.

Inventory for rest-of-world (RoW) production of 1 kg of polyester fibre in ecoinvent v3.7.

Table 6.

Ecoinvent inventory data used for polyester fibre production.

In this study, the adoption of a cradle-to-grave LCA approach was pivotal in evaluating the GWP associated with the production of wool and polyester fibres used to construct a knitted jumper weighing 393 g. To conduct this assessment, we employed the LCA software SimaPro, which enabled detailed modelling and analysis. The ecoinvent database v3.7 was used as the primary source of LCI data to ensure consistency and reliability of the environmental data inputs. This methodological framework facilitated a robust comparison of the environmental impacts associated with each fibre type across their respective life cycles.

4. Results and Discussion

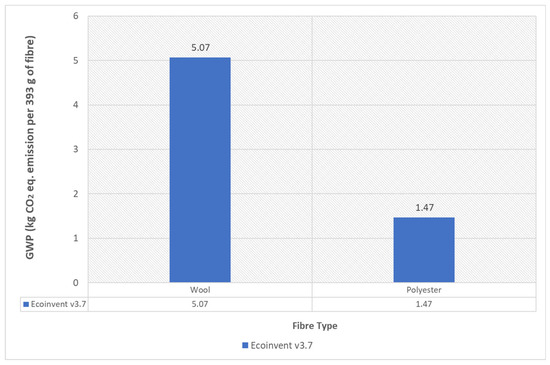

When producing 393 g of a women’s jumper, significant differences were revealed in the GWP of wool and polyester fibre. Wool fibre production resulted in 5.07 kg CO2 eq. emissions, whereas polyester fibre production had a significantly lower impact at 1.47 kg CO2 eq. Although the ecoinvent v3.7 database provides valuable baseline data for comparative studies, limitations for wool and polyester fibre production highlight critical gaps that could influence the outcomes.

The ecoinvent v3.7 dataset for wool does not include country-specific data for major producers such as New Zealand, instead relying on global averages that reflect the production systems in other regions. In this dataset, environmental impacts were allocated between co-products, 0.77 kg of wool and 0.22 kg of meat per functional unit, based on global assumptions [39]. However, in New Zealand, where sheep are raised in dual-purpose systems, the allocation is more accurately represented as 0.31 kg of wool and 0.69 kg of meat [42,54]. This divergence reflects differences in animal productivity and system design. New Zealand farms often produce more meat per animal and less wool per head than fine-wool systems, for example, Australian Merino systems [41]. As noted in the IWTO Guidelines [39], allocation should be based on regionally representative data and reflect the biophysical outputs of a production system. Therefore, applying global default values, such as those in ecoinvent, can misrepresent the relative environmental burdens of wool and meat in New Zealand systems. Moreover, variations in farm inputs, such as fertilisers, feed, pesticides, irrigation, and shearing energy, further reinforce the need for geographically specific data to ensure accurate LCA outcomes for wool production.

To produce polyester, aggregated data for ethylene production from raw material extraction to plant delivery is utilised in the ecoinvent v3.7. This dataset lacks unit process-level transparency, which limits the uncertainty analysis and identification of environmental hotspots in ethylene production [26]. Figure 2 displays the original GWP outcomes from legacy data (ecoinvent v3.7), revealing significant differences between wool and polyester fibre types.

Figure 2.

Difference in GWP for wool and polyester in ecoinvent v3.7.

4.1. Granularity and Transparency in the Datasets

The wool dataset in ecoinvent v3.7 provides detailed inventories of farming inputs at each stage of production, allowing for the identification of specific environmental hotspots, such as GWP contributions from fertiliser use, transportation, and energy use in shearing. In contrast, the dataset for polyester fibre production, particularly for ethylene, is aggregated, making it difficult to trace key inputs, such as energy use in crude oil extraction and chemical consumption in the cracking of naphtha into ethylene. This lack of transparency hinders the identification of high-impact processes and prevents an uncertainty analysis, as the variability in specific emissions remains unquantifiable [26,55]. Table 7 provides a comparative overview of the level of detail and data transparency in the ecoinvent v3.7 inventories for wool and polyester fibre production.

Table 7.

Comparison of data granularity and transparency in ecoinvent v3.7: wool vs. polyester fibre.

Masnadi et al. highlighted significant discrepancies between LCA results obtained using the Oil Production Greenhouse Gas Estimator (OPGEE) and ecoinvent while calculating crude-oil-related emissions in China. The absence of detailed engineering parameters in ecoinvent emerged as a key factor that affects the reliability of emission estimates. Their findings emphasised the need for more engineering-based, bottom-up LCA models to complement process-based databases, such as ecoinvent [56].

Similarly, a forthcoming study by Oberschelp et al. critically examined datasets for chemicals, including ethylene, within the ecoinvent database. The authors contend that reliance on outdated aggregated data from just one source—European plastic industry’s eco-profiles—conceals significant environmental burdens and introduces substantial inaccuracies in LCA outcomes. Their study underscores that the ecoinvent model for ethylene is predicated exclusively on ethylene delivered via pipelines, while the energy-intensive steam cracking process, which is fundamental to ethylene production, is omitted from the accounting of on-site emissions. Furthermore, key processes with a high electricity demand, such as industrial gas liquefaction, were omitted from the dataset, potentially leading to misrepresentation of the actual energy consumption. According to the authors, these methodological limitations contribute to a marked underestimation (up to 44%) of climate change impacts for chemicals, primarily due to unaccounted thermal energy inputs [57]. Given ecoinvent’s widespread application in policymaking, industrial sustainability assessments, and academic research, the study underscores the urgent need to replace generic proxy data with empirically grounded, industry-specific datasets to improve the accuracy and credibility of LCA models.

4.2. Temporal Relevance

The ethylene dataset for polyester fibre production in ecoinvent has seen minimal updates between 2005 and 2023 (v2 to v3.7), raising concerns regarding its accuracy and relevance to modern LCA studies. This dataset still relies on legacy data from the 1990s, which has not been revised since its inclusion in ecoinvent v2 [26,55]. In the latest ecoinvent v3.9 and v.3.10, the GWP of PET production was updated, including data from other geographical regions. This updated version shows a 26% increase in GWP emissions from PET production [46]. This revision highlights a major concern, as many past studies and policy decisions were based on lower impact values from older ecoinvent versions, potentially influencing sustainability strategies and material choices in a way that underestimates the true environmental footprint of PET and its derivatives such as polyester.

Although the wool dataset in ecoinvent v3.7 has been updated more recently, it still does not fully incorporate regional advancements. Independent studies, such as by Wiedemann et al. for Australia and by AgResearch for New Zealand, highlighting region-specific factors such as carbon sequestration from native vegetation, have still not been made available in the ecoinvent library [54,58]. These limitations underscore the need for more frequent and comprehensive revisions to improve the accuracy of LCA.

4.3. Geographic Representation

The wool dataset in ecoinvent v3.7 represents global production scenarios but lacks regional specificity for key wool-producing nations, such as New Zealand. The International Wool Textile Organisation underscores the necessity for localised LCA data to effectively inform policy and certification processes [58]. Claims have been made that New Zealand’s wool production has a 29% lower GWP than the global average due to factors such as carbon sequestration from indigenous vegetation [54]. Similarly, the polyester dataset in ecoinvent v3.7 exhibits a strong bias toward European production systems, failing to account for major crude oil-producing regions such as North America and Asia, which together contribute approximately 67% of the global plastic production [59]. The recent 26% increase in PET’s GWP (ecoinvent v3.9 and v3.10) was reported while expanding the dataset to include North America and 44 other countries globally [46]. These geographical biases in both the wool and the polyester datasets limit their applicability for region-specific inventory data, particularly for countries such as New Zealand. Similar concerns may exist for other regions. For example, Australian wool production may differ in key respects from the assumptions built into global average datasets, highlighting the need for region-specific modelling [41]. Likewise, polyester production in Asian countries may follow different supply chain pathways, energy mixes, and infrastructure compared to European systems’ production, potentially leading to significant variations in environmental impacts [60]. These considerations reinforce the importance of accounting for regional variability in the LCAs of textiles.

4.4. Circularity Considerations in the LCA of Wool and Polyester

The circular economy concept has become an essential framework for fashion sustainability, promoting material reuse, recyclability, and biodegradability [61]. However, these factors have rarely been integrated into conventional LCAs. The existing ecoinvent dataset fails to account for circularity-related attributes of textile materials [23], further skewing comparative assessments for natural and synthetic textile fibres. Recycled polyesters are presented as a sustainable alternative to natural fibres; however, a small amount of polyester textile is reported to be recycled. In 2019, only 14% of global polyester textile production came from recycled PET, and the majority originated from non-textile sources, such as plastic bottles. The textile-to-textile recycling of polyester remains minimal due to technological barriers, particularly the challenge of decolourising dyed polyester fabrics [62].

Recently, several emerging recycling technologies have attracted significant attention. Innovations such as enzymatic depolymerisation and chemical-to-textile recycling offer more efficient closed-loop processes capable of handling dyed and blended polyester textiles [63]. Additionally, advanced sorting technologies, including hyperspectral near-infrared (NIR) imaging and AI-enabled automated systems, are being developed and scaled to support the separation of textiles [64]. In parallel, the Textile Exchange’s Recycled Polyester Challenge 2025 calls on industry stakeholders to increase the use of textile-to-textile recycled polyester, with a target of at least 45% recycled polyester by 2025 and 90% by 2030 [65].

In contrast, wool is inherently aligned with the principles of a circular economy. It is renewable, biodegradable, and readily recyclable and often does not require complex processing during recycling. Mechanical recycling can transform used wool textiles into new garments or insulation materials. Wool fibres biodegrade harmlessly in soil or marine environments [66]. However, these circularity advantages are not captured in most LCA tools, which typically prioritise emissions during the production phase. This omission results in wool being penalised in environmental assessments, despite its superior circular potential. To enable fairer and more holistic comparisons, LCA frameworks must evolve to incorporate indicators such as biodegradability, reusability, end-of-life outcomes, and regenerative sourcing practices. Without such developments, sustainability metrics may falsely favour material harmful to the environment.

4.5. Case Study: Implications of Flawed LCA Data for Sustainability Assessments in New Zealand

Assessing sustainability in textile production remains a complex challenge, owing to the absence of universally accepted guidelines and consistent data sources. Without standardised criteria, sustainability claims can vary widely, leading to discrepancies in LCA results and their interpretation [67]. This is particularly problematic in New Zealand, where flawed or non-region-specific LCA datasets may inadvertently mislead industry players and policymakers, influencing consumers, labelling, fibre certifications, and sustainability claims.

The Ministry for Primary Industries in New Zealand has previously acknowledged the limitations of applying international LCA data to domestic contexts, particularly in the construction sector, noting that accurate environmental assessments require methodologies tailored to the unique production systems in the country [68]. Similar concerns also apply to the textile industry. As New Zealand moves toward stronger commitments to environmental transparency and carbon labelling, the risk of relying on generic datasets becomes more consequential.

In the assessment of textile fibres, ecoinvent offers a comprehensive starting point; however, its data for polyester fibre production may underestimate impacts by as much as 26–44% owing to the exclusion of key upstream emissions, particularly from the energy-intensive steam cracking of naphtha into ethylene, which is often excluded or oversimplified in aggregated datasets [46,57]. These omissions mask the key sources of GHG emissions and resource use in petrochemical production. Conversely, the impacts of wool production are often overestimated by up to 29%, particularly in pasture-based systems, such as those in New Zealand, where low-input farming is common. However, the datasets tend to reflect more intensive, fertilizer- and energy-dependent systems used globally, leading to inflated impact scores in contexts where such inputs are minimal or absent [54]. This mismatch between dataset assumptions and regional production practices introduces a systematic bias in LCA outcomes, favouring synthetic fibres over natural fibres. Several studies have corroborated these concerns. For instance, Shen et al. and Sandin et al. have noted that LCAs for synthetic fibres often exclude upstream petrochemical processing steps, while Li et al. caution against applying global average data to regionally diverse agricultural systems such as those for wool production [25,37,60].

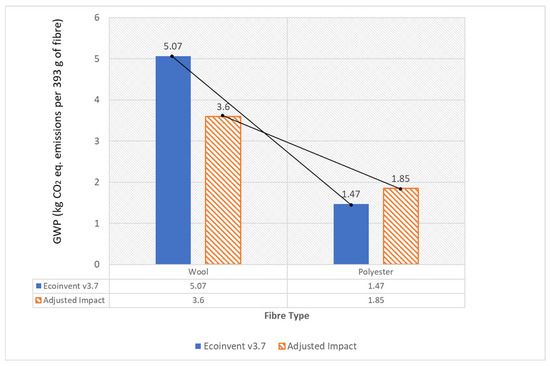

By incorporating updated data from AgResearch and ecoinvent v3.10, the comparative GWP of wool and polyester fibres shifted substantially. The adjusted wool impact was derived from region-specific modelling conducted by AgResearch [54] in parallel to the petrochemical emissions added to ecoinvent v3.10 for polyester fibre [46]. These revisions resulted in a reduction in the wool GWP by approximately 29%, from 5.07 kg CO2 eq. to 3.6 kg CO2 eq., and an increase in the polyester GWP by 26%, from 1.47 kg CO2 eq. to 1.85 kg CO2 eq.

Consequently, the GWP gap between wool and polyester halved, narrowing from 3.60 kg CO2 eq. to 1.75 kg CO2 eq. Figure 3 highlights the narrowing impact gap, illustrating the influence of temporal and regional updates in the LCA datasets. While the revised GWP for wool reflects the benefits of New Zealand’s unique environmental conditions, the updated polyester impact emphasises the significant contribution of major oil production regions across the globe. This reinforces the need to use updated and geographically appropriate datasets when comparing fibre impacts, particularly in policy and certification contexts, where such data directly informs sustainability claims and material rankings.

Figure 3.

Comparison of GWP for wool and polyester in ecoinvent v3.7 vs. adjusted impacts.

This study underscores how the historical dependence on legacy LCA datasets, specifically ecoinvent, has shaped comparative environmental assessments of textile fibres. Although the database is a critical tool for researchers and policymakers, its limitations in granularity, temporal accuracy, and regional specificity may have distorted the sustainability outcomes for key fibres, such as wool and polyester.

The newer releases of the ecoinvent v3.10 and v3.11 in 2024 have addressed many of these shortcomings, such as by incorporating updated supply chain data, regional differentiation, and improved emissions accounting. Ecoinvent v3.11 introduced notable advances in the fuel and petrochemical sectors, including expanded datasets for natural gas liquids, petroleum cracking by-products, and updated chemical inventories for compounds such as ethylene. However, detailed emissions and process-level transparency are still limited, and RoW-based assumptions still underpin several globally traded intermediates, including ethylene, among others [33].

Moreover, these improvements do not retroactively correct the conclusions drawn from earlier versions. Therefore, this study contributes a necessary retrospective lens, emphasising the importance of reviewing and recalibrating historical LCA findings based on newer data. Given the prevalence of tools such as the Higg MSI, which relies on older versions of ecoinvent, this study encourages a re-examination of past textile fibre rankings and sustainability strategies. It also calls for increased scrutiny and version transparency when reporting LCA results, to prevent outdated data from influencing future decisions. Therefore, while v3.11 represents a meaningful step forward, this study provides a necessary retrospective lens, emphasising the importance of reviewing and recalibrating historical LCA findings based on these improvements.

5. Conclusions

This study highlights substantial disparities in the reported environmental impacts of wool and polyester fibre production, which are rooted in the limitations of legacy datasets from the ecoinvent v3.7 library. Although newer versions of the ecoinvent database, most notably, v3.10 and v3.11, have introduced important updates in terms of geographic scope, the findings of this study remain relevant. They serve as retrospective critiques of how outdated aggregated data have historically skewed the LCA results, sustainability labels, and material certifications.

By demonstrating that polyester’s GWP may have been underestimated by up to 44% and that wool’s impact was overstated in a New Zealand context, this study underscores the long-term implications of relying on proxy or European-centred data in global sustainability assessments. These discrepancies have shaped fibre policies and market preferences for over a decade, reinforcing the need for more regionally representative and transparent data in future LCA studies.

As the textile industry and environmental regulators move toward stronger climate accountability, it is essential to use the most updated data and reflect critically on the historical basis of sustainability claims. This study calls for the recalibration of previously established LCA-based benchmarks and encourages greater scrutiny of the application of environmental data to decision-making frameworks in fashion and textiles.

Key Recommendations

- Develop region-specific LCA datasets for wool fibre production in New Zealand

Wool production systems vary across regions. LCA studies should focus on creating region-specific datasets that better reflect local farming practices in the region. New Zealand’s unique production system should be highlighted to ensure that environmental impact assessments are tailored to the local context. To gather relevant data specific to New Zealand, we must collaborate with local industry stakeholders, farmers, and researchers.

- Increase the granularity of the polyester LCA dataset

Polyester production, especially petrochemical-based processes, requires a deeper understanding of upstream processes, such as crude oil extraction and cracking. Currently, LCA studies often overlook these preliminary stages, which impact the accuracy of environmental assessments. There is a need to incorporate more detailed datasets covering the entire lifecycle, from crude oil extraction to polyester fibre production.

- Improve dataset transparency and documentation for ethylene production in ecoinvent

The credibility of LCA findings depends on the transparency of the underlying data sources, methodologies, and assumptions. A clear and documented methodology enables stakeholders to assess the reliability of the data. The ecoinvent dataset for ethylene production is required to establish standardised protocols for documenting the sources, methods, and assumptions used.

- Include additional impact metrics relevant to textile-specific outcomes

Future LCA frameworks should incorporate textile-relevant metrics, such as biodegradation rate, microplastic shedding potential, and end-of-life behaviour. These indicators are essential for capturing long-term environmental consequences, particularly for synthetic fibres such as polyester, and for enabling more accurate fibre comparisons in sustainability assessments.

- Encourage critical engagement with LCA data

Policymakers, brands, and researchers must critically evaluate existing LCA data to avoid misinterpretations that could lead to inaccurate sustainability claims or flawed policies. This is especially true when adapting international datasets to local contexts. Collaboration among LCA experts, industry practitioners, and policymakers is needed to promote a critical review of data sources and contextual relevance in environmental assessments.

- Integrate technological advances into LCA methodologies

LCA methodologies must evolve alongside technological advancements in production systems, such as improvements in fibre processing, recycling techniques, and alternative energy sources. To ensure that datasets reflect the current industry practices, they must be regularly updated to incorporate the latest advancements in fibre production and processing technologies.

- Standardise sustainability metrics for different fibre types

Standardised metrics allow for more meaningful comparisons between natural and synthetic fibres in terms of environmental impact. Ecoinvent should develop and adopt standardised sustainability metrics for all textile fibres, including wool and polyester fibres.

- Promote collaboration between stakeholders for data collection and sharing

Effective LCA requires collaboration among academia, industry, and policymakers to gather relevant data and ensure transparency. There is a need to establish multi-stakeholder partnerships to create a shared platform for data collection, enabling transparency, accuracy, and the sharing of best practices in LCA studies.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/su17146513/s1, Supplementary Excel File: Supplementary data for wool and polyester fibre production from Ecoinvent v3.7.

Author Contributions

Conceptualization, M.N.; Methodology, M.N.; Validation, D.C.; Formal analysis, M.N. and D.C.; Investigation, M.N.; Writing—original draft, M.N.; Writing—review & editing, D.C., A.H. and A.S.; Visualization, A.H.; Supervision, D.C., A.H. and A.S.; Project administration, M.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Restrictions apply to the availability of these data. Data were obtained from the Ecoinvent library (version 3.7) through the SimaPro software and are provided as a Supplementary Excel File with this manuscript. Access to the Ecoinvent database requires a license from Ecoinvent (https://ecoinvent.org/, accessed on 20 June 2025).

Acknowledgments

The authors would like to express sincere gratitude to Frances Joseph (Professor of Material Futures, Auckland University of Technology) for her valuable guidance in the conceptualisation and methodology of this study. Her thoughtful feedback and continued support throughout the development and review of this paper were instrumental in bringing it to its final stage.

Conflicts of Interest

The authors declare no potential conflicts of interest concerning the research, authorship and/or publication of this article.

References

- IPCC Working Group. The Physical Science Basis. Available online: https://www.researchgate.net/profile/Abha-Chhabra/publication/271702872_Carbon_and_Other_Biogeochemical_Cycles/links/54cf9ce80cf24601c094a45e/Carbon-and-Other-Biogeochemical-Cycles.pdf (accessed on 2 July 2025).

- Dominish, E.; Sharpe, S. Reducing the Footprint?: How to Assess Carbon Emissions in the Garment Sector in Asia. Available online: http://hdl.handle.net/10453/154953 (accessed on 3 April 2025).

- Imran, S.; Mujtaba, M.; Zafar, M.M.; Hussain, A.; Mehmood, A.; Farwa, U.E.; Korakianitis, T.; Kalam, M.; Fayaz, H.; Saleel, C.A. Assessing the potential of GHG emissions for the textile sector: A baseline study. Heliyon 2023, 9, e22404. [Google Scholar] [CrossRef] [PubMed]

- ISO 14040. Environmental Management: Life Cycle Assessment; Principles and Framework. Available online: https://www.iso.org/obp/ui/#iso:std:iso:14040:ed-2:v1:en (accessed on 6 June 2025).

- Peters, G.; Li, M.; Lenzen, M. The need to decelerate fast fashion in a hot climate-A global sustainability perspective on the garment industry. J. Clean. Prod. 2021, 295, 126390. [Google Scholar] [CrossRef]

- Muthu, S.S. Exploring a Framework for Fashion Design for Sustainability. In Handbook of Sustainable Apparel Production; CRC Press: Boca Raton, FL, USA, 2015; pp. 454–467. [Google Scholar]

- Radhakrishnan, S. The sustainable apparel coalition and the higg index. In Roadmap to Sustainable Textiles and Clothing: Regulatory Aspects and Sustainability Standards of Textiles and the Clothing Supply Chain; Muthu, S., Ed.; Springer: Singapore, 2014; pp. 23–57. [Google Scholar]

- Pollini, B.; Lavagna, M.; Rognoli, V. LCA-Based Material Selection in the Early Stages of Design: Environmental Benefits, Tools, Obstacles and Opportunities. Available online: https://re.public.polimi.it/handle/11311/1158028 (accessed on 22 November 2024).

- Textile Exchange. Materials Market Report 2023; Textile Exchange: Lamesa, TX, USA, 2023; Available online: https://textileexchange.org/knowledge-center/documents/materials-market-report-2023/ (accessed on 20 April 2025).

- Radhakrishnan, S.; Vetrivel, P.; Vinodkumar, A.; Palanisamy, H. Recycled polyester—Tool for savings in the use of virgin raw material. In Environmental Footprints of Recycled Polyester; Muthu, S., Ed.; Springer: Singapore, 2020; pp. 49–83. [Google Scholar]

- Cassidy, T.; Goswami, P. Textile and Clothing Design Technology; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Gomes, T.S.; Visconte, L.L.; Pacheco, E.B. Life cycle assessment of polyethylene terephthalate packaging: An overview. J. Polym. Environ. 2019, 27, 533–548. [Google Scholar] [CrossRef]

- DeVoy, J.E.; Congiusta, E.; Lundberg, D.J.; Findeisen, S.; Bhattacharya, S. Post-consumer textile waste and disposal: Differences by socioeconomic, demographic, and retail factors. Waste Manag. 2021, 136, 303–309. [Google Scholar] [CrossRef] [PubMed]

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The environmental price of fast fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar] [CrossRef]

- De Falco, F.; Di Pace, E.; Cocca, M.; Avella, M. The contribution of washing processes of synthetic clothes to microplastic pollution. Sci. Rep. 2019, 9, 6633. [Google Scholar] [CrossRef] [PubMed]

- Aiama, D.; Carbone, G.; Cator, D.; Challender, D. Biodiversity Risks and Opportunities in the Apparel Sector, International Union for Conservation of Nature, Global Business and Biodiversity Programme, Gland, Switzerland. Available online: https://portals.iucn.org/library/efiles/documents/Rep-2016-001.pdf (accessed on 3 March 2025).

- Bick, R.; Halsey, E.; Ekenga, C.C. The global environmental injustice of fast fashion. Environ. Health 2018, 17, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Stanton, T.; Stanes, E.; Gwinnett, C.; Lei, X.; Cauilan-Cureg, M.; Ramos, M.; Sallach, J.B.; Harrison, E.; Osborne, A.; Sanders, C.H. Shedding off-the-grid: The role of garment manufacturing and textile care in global microfibre pollution. J. Clean. Prod. 2023, 428, 139391. [Google Scholar] [CrossRef]

- Collie, S.R.; Ranford, S.; Fowler, I.; Brorens, P. Microfibre Pollution: What’s the Story for Wool? Proceedings of the 19th World Textile Conference-Autex 2019. Available online: https://openjournals.ugent.be/autex/article/id/63730/ (accessed on 16 January 2025).

- Doyle, E.K.; Preston, J.W.; McGregor, B.A.; Hynd, P.I. The science behind the wool industry. The importance and value of wool production from sheep. Anim. Front. 2021, 11, 15–23. [Google Scholar] [CrossRef] [PubMed]

- Sandin, G.; Roos, S.; Johansson, M. Environmental Impact of Textile Fibers, What We Know and What We Don’t Know: Fiber Bible Part 2, Mistra Future Fashion, Sweden. Available online: https://ri.diva-portal.org/smash/get/diva2:1298696/FULLTEXT01.pdf (accessed on 2 March 2023).

- Peri, P.L.; Rosas, Y.M.; Ladd, B.; Díaz-Delgado, R.; Martinez Pastur, G. Carbon footprint of lamb and wool production at farm gate and the regional scale in Southern Patagonia. Sustainability 2020, 12, 3077. [Google Scholar] [CrossRef]

- Wiedemann, S.G.; Nguyen, Q.V.; Clarke, S.J. Using LCA and Circularity Indicators to Measure the Sustainability of Textiles—Examples of Renewable and Non-Renewable Fibres. Sustainability 2022, 14, 16683. [Google Scholar] [CrossRef]

- Van der Velden, N.M.; Patel, M.K.; Vogtländer, J.G. LCA benchmarking study on textiles made of cotton, polyester, nylon, acryl, or elastane. Int. J. Life Cycle Assess. 2014, 19, 331–356. [Google Scholar] [CrossRef]

- Sandin, G.; Roos, S.; Spak, B.; Zamani, B.; Peters, G. Environmental Assessment of Swedish Clothing Consumption—Six Garments, Sustainable Futures; Mistra Future Fashion: Stockholm, Sweden, 2019; 169p. [Google Scholar] [CrossRef]

- Hischier, R.; Hellweg, S.; Capello, C.; Primas, A. Establishing life cycle inventories of chemicals based on differing data availability. Int. J. Life Cycle Assess. 2005, 10, 59–67. [Google Scholar] [CrossRef]

- Gervet, B. The Use of Crude Oil in Plastic Making Contributes to Global Warming; Department of Civil and Environmental Engineering: Luleå, Sweden, 2007. [Google Scholar]

- Kassatly, V.B.; Baumann-Pauly, D. The Great Green Washing Machine Part 2: The Use and Misuse of Sustainability Metrics in Fashion; Eco Age: London, UK, 2022; 64p. [Google Scholar]

- Klepp, I.G.; Laitala, K.; Haugrønning, V.; Sigaard, A.S.; Tobiasson, T.S. The Fate of Natural Fibres in Environmental Evaluations: A Question of Volume; Palgrave Macmillan: Cham, Switzerland, 2022; pp. 35–59. [Google Scholar]

- Barber, A.; Pellow, G. LCA: New Zealand Merino Wool Total Energy Use, 5th Australian Life Cycle Assessment Society (ALCAS) Conference, Melbourne, Australia; Agribusiness Group. Available online: https://proyectaryproducir.com.ar/public_html/Seminarios_Posgrado/Material_de_referencia/Lana%20-%20LCA%20in%20NZ%20Barber%20Pellow.pdf (accessed on 2 July 2025).

- Jackson, A. Baa, Baa, Black Sheep Have You Any Wool? Developing the RBV Through a Study of the New Zealand Merino Clothing Industry. Master’s Thesis, School of Management, Victoria University of Wellington, Wellington, New Zealand, 2023. Available online: http://researcharchive.vuw.ac.nz/handle/10063/1931 (accessed on 11 January 2023).

- Nautiyal, M. Unpublished report on women’s knitwear clothing in New Zealand. 2020. [Google Scholar]

- FitzGerald, D.; Bourgault, G.; Vadenbo, C.; Sonderegger, T.; Symeonidis, A.; Fazio, S.; Valente, A.; Müller, J.; Dellenbach, D.; Stoikou, N.; et al. Documentation of Changes Implemented in the Ecoinvent Database v3.11(2024.11.19); Ecoinvent Association: Zürich, Switzerland, 2024. [Google Scholar] [CrossRef]

- Biswas, W.K.; Graham, J.; Kelly, K.; John, M.B. Global warming contributions from wheat, sheep meat and wool production in Victoria, Australia–a life cycle assessment. J. Clean. Prod. 2010, 18, 1386–1392. [Google Scholar] [CrossRef]

- Eady, S.; Carre, A.; Grant, T. Life cycle assessment modelling of complex agricultural systems with multiple food and fibre co-products. J. Clean. Prod. 2012, 28, 143–149. [Google Scholar] [CrossRef]

- Gavrilova, O.; Leip, A.; Dong, H.; MacDonald, J.D.; Bravo, C.A.G.; Amon, B.; Rosales, R.B.; del Prado, A.; de Lima, M.A.; Oyhantcabal, W.; et al. Emissions from Livestock and Manure Management; IPCC: Geneva, Switzerland, 2019; Volume 4. [Google Scholar]

- Li, X.; Li, X.; Sun, L.; Zhang, Y.; Li, Q.; Zhu, L.; Wang, L. Discussion on key issues of carbon footprint accounting for wool products. J. Clean. Prod. 2024, 445, 141336. [Google Scholar] [CrossRef]

- Klepp, I.G.; Laitala, K.; Wiedemann, S. Clothing lifespans: What should be measured and how. Sustainability 2020, 12, 6219. [Google Scholar] [CrossRef]

- Henry, B.; Ledgard, S.; Nebel, B.; Wiedemann, T. Guidelines for Conducting a Life Cycle Assessment of the Environmental Performance of Wool Textiles; International Wool Textile Organisation (IWTO)-Wool LCA Technical Advisory Group: Brussels, Australia, 2016; Available online: https://iwto.org/wp-content/uploads/2020/04/IWTO-Guidelines-for-Wool-LCA.pdf (accessed on 3 May 2025).

- Durlinger, B.; Tyszler, M.; Scholten, J.; Broekema, R.; Blonk, H. Agri-footprint; A life cycle inventory database covering food and feed production and processing. In Proceedings of the 9th International Conference on Life Cycle Assessment in the Agri-Food Sector, San Francisco, CA, USA, 8–10 October 2014; pp. 310–317. [Google Scholar]

- Wiedemann, S.G.; Ledgard, S.F.; Henry, B.K.; Yan, M.-J.; Mao, N.; Russell, S.J. Application of life cycle assessment to sheep production systems: Investigating co-production of wool and meat using case studies from major global producers. Int. J. Life Cycle Assess. 2015, 20, 463–476. [Google Scholar] [CrossRef]

- Ledgard, S.; Falconer, S.; Mazzetto, A. Carbon Footprint of New Zealand Beef and Sheep Exported to Different Markets, Report for the Meat Industry Association and Beef+ Lamb New Zealand, New Zealand. Available online: https://beeflambnz.com/sites/default/files/levies/files/BLNZ_review_report.pdf (accessed on 6 May 2025).

- Tamoor, M.; Samak, N.A.; Yang, M.; Xing, J. The cradle-to-cradle life cycle assessment of polyethylene terephthalate: Environmental perspective. Molecules 2022, 27, 1599. [Google Scholar] [CrossRef] [PubMed]

- Periyasamy, A.P.; Militky, J. LCA (life cycle assessment) on recycled polyester. In Environmental Footprints of Recycled Polyester; Muthu, S., Ed.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 1–30. [Google Scholar]

- Singh, A.; Rorrer, N.A.; Nicholson, S.R.; Erickson, E.; DesVeaux, J.S.; Avelino, A.F.; Lamers, P.; Bhatt, A.; Zhang, Y.; Avery, G. Techno-economic, life-cycle, and socioeconomic impact analysis of enzymatic recycling of poly (ethylene terephthalate). Joule 2021, 5, 2479–2503. [Google Scholar] [CrossRef]

- Renewable Carbon News. Products Made from Crude Oil Have a Significantly Higher CO2 Footprint Than Previously Assumed, Renewable Carbon Initiative. Available online: https://renewable-carbon.eu/news/products-made-from-crude-oil-have-a-significantly-higher-co2-footprint-than-previously-assumed/ (accessed on 3 May 2024).

- Muñoz, I.; Weidema, B.P. Ethylene and propylene production from steam cracking in Europe: A consequential perspective. Int. J. Life Cycle Assess. 2024, 29, 745–758. [Google Scholar] [CrossRef]

- Yao, Y.; Graziano, D.J.; Riddle, M.; Cresko, J.; Masanet, E. Understanding variability to reduce the energy and GHG footprints of US ethylene production. Environ. Sci. Technol. 2015, 49, 14704–14716. [Google Scholar] [CrossRef] [PubMed]

- NREL. U.S. Life Cycle Inventory Database. Available online: https://www.lcacommons.gov/nrel/search (accessed on 15 June 2025).

- Stellner, L.; Kalousdian, A.; Goßen, J.; Ossolińska, A.; Kätelhön, A.; Vögler, O.; Hermanns, R.; Suh, S.; Bardow, A.; Meys, R. Methodology cm.chemicals Version 2.01, Carbon Minds GmbH, Cologne. Available online: https://www.carbon-minds.com/wp-content/uploads/2024/11/cm_chemicals_methodology_V2.01_2024.pdf (accessed on 14 May 2025).

- Herrmann, I.T.; Moltesen, A. Does it matter which life cycle assessment (LCA) tool you choose? A comparative assessment of SimaPro and GaBi. J. Clean. Prod. 2015, 86, 163–169. [Google Scholar] [CrossRef]

- Speck, R.; Selke, S.; Auras, R.; Fitzsimmons, J. Life cycle assessment software: Selection can impact results. J. Ind. Ecol. 2016, 20, 18–28. [Google Scholar] [CrossRef]

- Ecoinvent Website. Data with Purpose. Available online: https://ecoinvent.org/ (accessed on 3 September 2024).

- Foster, G. Wool’s Impact: Carbon Footprint, New Zealand. Available online: https://woolimpact.com/wp-content/uploads/2024/04/Wools-Impact-Carbon-footprint-2023.pdf (accessed on 23 May 2024).

- Frischknecht, R.; Jungbluth, N.; Althaus, H.-J.; Doka, G.; Dones, R.; Heck, T.; Hellweg, S.; Hischier, R.; Nemecek, T.; Rebitzer, G. The Ecoinvent database: Overview and methodological framework. Int. J. Life Cycle Assess. 2005, 10, 3–9. [Google Scholar] [CrossRef]

- Masnadi, M.S.; El-Houjeiri, H.M.; Schunack, D.; Li, Y.; Englander, J.G.; Badahdah, A.; Monfort, J.C.; Anderson, J.E.; Wallington, T.J.; Bergerson, J.A.; et al. Global carbon intensity of crude oil production. Science 2018, 361, 851–853. [Google Scholar] [CrossRef] [PubMed]

- Oberschelp, C.; Hellweg, S.; Bradford, E.; Pfister, S.; Huo, J.; Wang, Z. Poor data and outdated methods sabotage the decarbonization efforts of the chemical industry. ChemRxiv 2023. [Google Scholar] [CrossRef]

- Wiedemann, S.; Biggs, L.; Nebel, B.; Bauch, K.; Laitala, K.; Klepp, I.; Swan, P.; Watson, K. Environmental impacts associated with the production, use, and end-of-life of a woollen garment. Int. J. Life Cycle Assess. 2020, 25, 1486–1499. [Google Scholar] [CrossRef]

- Plastics Europe and EPRO. Plastics—The Facts 2022. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2022/ (accessed on 18 March 2025).

- Shen, L.; Worrell, E.; Patel, M.K. Open-loop recycling: A LCA case study of PET bottle-to-fibre recycling. Resour. Conserv. Recycl. 2010, 55, 34–52. [Google Scholar] [CrossRef]

- Smith, T.; Ehrnström-Fuentes, M.; Hagolani-Albov, S.E.; Klepp, I.G.; Tobiasson, T.S. Rethinking the (Wool) Economy; Springer: Berlin/Heidelberg, Germany, 2022; pp. 133–170. [Google Scholar]

- Roungpaisan, N.; Srisawat, N.; Rungruangkitkrai, N.; Chartvivatpornchai, N.; Boonyarit, J.; Kittikorn, T.; Chollakup, R. Melt Spinning Process Optimization of Polyethylene Terephthalate Fiber Structure and Properties from Tetron Cotton Knitted Fabric. Polymers 2023, 15, 4364. [Google Scholar] [CrossRef] [PubMed]

- Payne, J.; Jones, M.D. The chemical recycling of polyesters for a circular plastics economy: Challenges and emerging opportunities. ChemSusChem 2021, 14, 4041–4070. [Google Scholar] [CrossRef] [PubMed]

- Kainz, M.; Krondorfer, J.K.; Jaschik, M.; Jernej, M.; Ganster, H. Supervised and unsupervised textile classification via near-infrared hyperspectral imaging and deep learning. In Proceedings of the OCM 2025-7th International Conference on Optical Characterization of Materials, Karlsruhe, Germany, 26–27 March 2025; Conference Proceedings. KIT Scientific Publishing: Karlsruhe, Germany, 2025. Available online: https://arxiv.org/pdf/2505.03575 (accessed on 3 June 2025).

- Textile Exchange. 2025 Recycled Polyester Challenge, First Annual Report. Available online: https://textileexchange.org/app/uploads/2022/07/2025-Recycled-Polyester-Challenge_2022.pdf (accessed on 6 June 2025).

- Sun, Y.; Li, B.; Zhang, Y.; Dou, H.; Fan, W.; Wang, S. The progress and prospect for sustainable development of waste wool resources. Text. Res. J. 2023, 93, 468–485. [Google Scholar] [CrossRef]

- Tharian, B. A new philosophy for sustainable consumerism. Manag. Sustain. Dev. 2023, 15, 10–17. [Google Scholar] [CrossRef]

- Nebel, B.; Alcorn, A.; Wittstock, B.; SCION. Life Cycle Assessment: Adopting and Adapting Overseas LCA Data and Methodologies for Building Materials in New Zealand. Available online: https://www.mpi.govt.nz/dmsdocument/6280-life-cycle-assessment-adopting-and-adapting-overseas-lca-data-and-methodologies-for-building-materials-in-new-zealand?utm_source=chatgpt.com (accessed on 22 February 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).