Abstract

EU accession countries, including the Republic of Serbia, are under growing pressure to align their plastic waste management systems with EU environmental directives. Despite this, significant challenges remain, including inadequate infrastructure, a limited recycling capacity, and weak enforcement mechanisms. This study employs life cycle assessment (LCA) to evaluate the environmental impacts of polyethylene terephthalate (PET) packaging waste in Serbia, focusing on three end-of-life scenarios (EoL): landfilling, recycling, and incineration. Using GaBi Professional v6.0 software and the ReCiPe 2016 methodology, the results indicate that mismanaged PET waste contributes notably to terrestrial ecotoxicity (3.69 kg 1.4-DB eq.) and human toxicity (non-cancer) (2.36 kg 1.4-DB eq.). In 2023, 14,967.8 tons of PET were collected by authorized operators; however, unreported quantities likely end up in landfills or the natural environment. Beyond the quantified LCA results, this study highlights microplastic pollution as an emerging environmental concern. It advocates for the development of Serbia-specific characterization factors (CFs) for PET microplastics, incorporating localized fate, exposure, and effect data. Tailored CFs would enhance the precision of impact assessments for Serbian terrestrial ecosystems, contributing to more effective, evidence-based environmental policies. These insights are crucial for supporting Serbia’s transition to sustainable waste management and for meeting EU environmental standards.

1. Introduction

Plastic is a synthetic material composed of polymers, which are long, interconnected chains of molecules [1]. Despite its negative aspects, such as low biodegradability and a tendency to absorb harmful toxins, plastic continues to be widely used due to its low production costs and ease of manufacturing, making it a key material in industrial development over recent decades [2]. Global plastic production amounted to 380 million tons in 2022, representing an increase from 353 million tons in 2019, with projections indicating a rise to approximately 590 million tons by 2050 [3]. This continuous rise in plastic production has significantly contributed to the growing levels of plastic pollution in natural environments.

Polyethylene terephthalate is a widely used plastic, commonly employed in the production of water bottles, food packaging, and textiles. Due to its light weight, durability, and versatility, PET has become an essential material in modern society [4]. However, waste generated from PET packaging contributes not only to environmental pollution but also poses significant challenges for waste management and disposal [5]. Given its widespread application—particularly in beverage and food packaging—as well as its significant share in the separately collected plastic waste stream in Serbia, this material was selected as the focus of the research. Its high recyclability potential also makes it especially relevant for assessing different end-of-life management scenarios within the context of circular economy principles.

The scale of the plastic waste problem is both significant and rapidly increasing. If current waste management practices persist, the continued rise in plastic production is projected to result in the accumulation of over 9 billion tons of plastic waste in landfills or the natural environment by mid-century, with some estimates reaching as high as 17 billion tons [6]. Additionally, by 2050, plastics are expected to account for approximately 15% of the annual greenhouse gas emissions allowance compatible with limiting global warming to below 1.5 °C [7]. With the continued increase in plastic production and consumption, it is estimated that 12.0 billion tons of plastic waste will be generated globally by 2050 [8].

Despite the implementation of plastic recycling policies in many countries and regions worldwide—including EU member states—a 2023 report by the United Nations Environment Programme (UNEP) reveals that only 9% of the more than 430 million tons of plastic produced globally each year is recycled [9]. In Europe, less than 30% of total plastic waste is collected for recycling. In recent years, the plastic recycling sector in the EU has faced challenges such as low raw material prices and market uncertainties, while landfilling (31%) and incineration (39%) rates remain relatively high [10]. Although the use of landfills has declined over the past decade, incineration has increased. PET is a fully recyclable plastic that can be reused multiple times; therefore, it should be prioritized for recycling, rather than being disposed of in landfills or released into the environment. Recycling is regarded as the most effective and economically viable method for reducing PET waste [11]. Therefore, while recycling offers clear environmental and economic advantages, achieving higher recycling rates requires addressing these systemic barriers through improved policies, investments in recycling technologies, and increased public awareness. Recognizing these challenges provides a more nuanced understanding of PET waste management and highlights the need for comprehensive strategies that go beyond technical feasibility to practical implementation.

The EU has taken a leading role globally by enforcing strict policies and introducing innovative practices to improve recycling rates and support the circular economy [12]. The EU’s Circular Economy Action Plan (CEAP) focuses on transitioning from traditional waste management to a more sustainable approach. This includes implementing circular economy principles, promoting renewable energy, improving energy efficiency, and reducing reliance on imported resources. Additionally, it aims to foster economic growth and ensure long-term competitiveness within the European economy [13]. The European Strategy for Plastics in a circular economy, adopted in 2018, aims to transform how plastic products are designed, used, produced, and recycled within the EU. The strategy emphasizes that improving the design of plastic products, increasing recycling rates, and producing higher quality recycled materials will help boost the market for recycled plastics. It also supports achieving the UN Sustainable Development Goals, global climate targets, and the EU’s industrial policy objectives [14].

The Republic of Serbia is in the process of accession to the European Union and, as part of this effort, must harmonize its national strategic documents and legislation with EU standards. Serbia has made significant progress in aligning its waste management practices with EU standards. In September 2023, the country adopted key legislative measures, including amendments to the Waste Management Law and new regulations governing the handling of specific waste streams [15]. In 2020, Serbia generated over 356.000 tons of plastic waste within its total municipal waste. However, only a small fraction was properly managed—approximately 13% was recycled, 1% was utilized for energy recovery, and about 1.7% was processed through other recovery methods [16]. In 2023, approximately 44,986.4 tons of PET packaging were introduced to the Serbian market. Of this amount, 14,967.8 tons were officially collected by authorized operators within the national packaging waste management system, reflecting the operational efficiency and scope of formal recovery mechanisms for PET waste in the country [17].

Life cycle assessment is a methodology that is used to evaluate the environmental impacts of products from the production of raw materials to the products’ end of life [18]. The plastic sector was one of the first adopters of LCA [19,20]. This study outlines and compares key technologies for the treatment of PET waste generated in the Republic of Serbia, using Life Cycle Assessment as a decision-support tool. The objective is to identify and promote environmentally and economically viable solutions for managing PET packaging waste.

The analysis focuses on end-of-life treatment options, with the goal of determining best practices that minimize environmental impact and support national waste management targets. Based on LCA findings, this study highlights priority technologies and evaluates their potential for integration into Serbia’s domestic PET waste management system.

2. Challenges in Plastic Waste Management and Environmental Consequences

Plastic waste is accumulating at unprecedented rates, resulting in substantial adverse impacts on environmental systems and human health [21]. A notable example of these impacts is the long-term presence of plastic waste in soil, where it undergoes degradation into microplastics and releases harmful additives such as phthalates [22].

Plastic waste adversely affects ecosystems through multiple pathways. When deposited on land, it contributes to soil pollution, reduces soil fertility, and poses a risk to groundwater quality. In the European Union, approximately 31% of plastic waste is still landfilled, despite efforts to reduce reliance on this disposal method [10]. Microplastics, in particular, disrupt the natural structure of soil by occupying pore spaces between soil particles, thereby reducing porosity and impeding the movement of air and water—both essential for healthy root development and soil microbial activity. Furthermore, larger plastic fragments can form impermeable layers that hinder water infiltration, further degrading soil quality [1].

A significant environmental concern, particularly in maritime countries, is the disposal of plastic waste into marine environments, leading to widespread pollution of seas and oceans. On a global scale, it is estimated that between 5 and 13 million tons of plastic waste, equivalent to approximately 1.5% to 4% of total annual plastic production, are discharged into the world’s oceans each year [10]. Due to limited space and a lack of proper landfill infrastructure, small and underdeveloped countries often resort to incineration or open burning as a means of reducing the mass and volume of plastic waste. However, these practices emit substantial quantities of greenhouse gases (GHGs), carbon oxides (COx), nitrogen oxides (NOx), and various other toxic pollutants into the environment [23].

The issue of inadequately managed or entirely unmanaged municipal solid waste, particularly plastic waste, is especially pronounced in developing countries, where waste management infrastructure and regulatory frameworks are frequently insufficient [24]. These countries and communities face a range of structural challenges in addressing plastic waste, including limited waste collection systems, inadequate financial and institutional capacity to develop, implement, and enforce effective waste management policies, and persistent systemic poverty that often leads to the acceptance of imported plastic waste from other nations [21].

Landfilling, mechanical recycling, and incineration are conventional methods for managing plastic waste [25]. Contemporary landfill systems incorporate advanced engineering measures, such as impermeable bottom liners, to prevent leachate infiltration and control gas emissions (e.g., methane). Nevertheless, in many regions of the world, particularly in developing countries, landfilling continues to pose serious environmental challenges due to inadequate infrastructure and regulatory oversight [14]. Despite these challenges, landfilling offers several advantages over uncontrolled waste disposal. It is a practical and cost-effective approach that does not require the application of complex technologies. Furthermore, it can serve as a source of energy through the generation of methane during the decomposition of plastic waste, and it emits fewer gases compared to plastic incineration [26]. Nevertheless, landfilling has notable drawbacks, especially when waste is deposited in unsanitary conditions, a common issue in many developing regions. During the landfilling process, gases such as methane (CH4) and carbon dioxide (CO2) are released, both of which are potent greenhouse gases that significantly contribute to global warming and climate change. Landfills also pose safety hazards due to the potential for explosions and fires. Moreover, leachate generated from landfill sites can contaminate groundwater and soil, while persistent unpleasant odors may degrade the quality of life and reduce property values in surrounding areas [27]. Multiple studies have confirmed that landfills represent a potential source of microplastic release, subsequently facilitating their dissemination throughout various environmental systems [14]. Scientific evidence indicates that the degradation of PET in landfills is extremely slow, with only a small fraction, approximately 1% to 5%, of its carbon content breaking down over 150 years. The remainder may persist for millennia, highlighting the inefficiency and environmental unsustainability of landfilling as a long-term disposal method for PET waste [28].

Plastic waste recycling refers to the process of transforming discarded plastic materials into reusable products through a series of mechanical and chemical operations [26]. Mechanical recycling, the predominant method for processing PET waste, encompasses a series of sequential operations, including material collection, classification, size reduction through shredding, decontamination via washing and drying, thermal extrusion into pellets, and further refinement through solid-state polycondensation (SSP) to enhance polymer quality [26]. Despite its widespread use, mechanical recycling faces several limitations, primarily due to polymer degradation that occurs under certain processing conditions. Furthermore, this method is not suitable for heavily contaminated plastic waste and is highly dependent on the effectiveness of sorting operations. As a result of these constraints, only a limited fraction of plastic waste is actually suitable for mechanical recycling [29]. A substantial portion of collected PET bottles is not recycled into new beverage containers, but rather downcycled into lower-quality plastic products with limited or no potential for further recycling [28]. Several scientific studies indicate that plastic recycling facilities may serve as significant point sources of microplastic pollution on a global scale. However, to date, there is no established scientific methodology for quantitatively assessing the generation and environmental release of microplastics during the mechanical recycling of plastic waste at the global level [30].

Incineration is the most extensively studied waste-to-energy (WtE) technology, largely due to its relatively simple and well-established operational procedures [14]. It enables the recovery of energy from waste by converting thermal energy into electrical power, thereby contributing to integrated WtE systems [31]. Various incineration techniques can be distinguished, as this method is applicable to a wide range of waste types beyond just plastics. These include moving grate, fixed grate, rotary kiln, fluidized bed, and specialized incineration methods, such as the burning of combustible materials or thermochemical recycling processes [14]. The negative aspect of plastic waste incineration lies in the release of toxic gases during the combustion process, such as dioxins, furans, and polychlorinated biphenyls (PCBs) [23]. Although incineration is widely regarded as a final solution for plastic waste treatment by converting polymers into carbon dioxide and inert mineral residues, studies have shown that residues such as bottom ash may still contain synthetic fibers. This suggests that microplastics and partially combusted plastic fragments can persist post-incineration, posing a risk of secondary environmental contamination through the improper disposal or reuse of incineration by-products [32].

Overview of Serbia’s Plastic Waste Policies

Serbia aims to develop advanced waste management systems that meet the requirements set by the European Union [33]. According to the latest report on Serbia’s progress in EU integration, the country is largely aligned with EU legislation in the field of waste management. In September 2023, key regulations were adopted, including amendments to the Law on Waste Management and implementing acts for handling specific waste streams [15]. The key strategic document in this area is the Waste Management Program in the Republic of Serbia for the period of 2022–2031, which outlines the strategic objectives for enhancing the national waste management system. It establishes fundamental principles intended to guide all stakeholders in achieving these goals. The program’s implementation is expected not only to mitigate environmental and climate-related impacts but also to create the necessary conditions for integrating waste into the circular economy [34]. The adoption of the Law on Waste Management [35] and the Law on Packaging and Packaging Waste [36] laid the foundation for the establishment and further development of an integrated waste management system in the Republic of Serbia. Additionally, waste management is governed, both directly and indirectly, by a broader set of legal instruments that collectively form the legislative framework for environmental protection and sustainable development in the country.

Currently, there are only 12 sanitary landfills in the Republic of Serbia, which are insufficient to meet the country’s waste disposal needs. As existing landfills reach capacity, some municipalities have started redirecting their municipal waste to neighboring regional landfills. The share of the population covered by organized waste collection is steadily increasing, yet the recycling rate remains low. Limited progress has been made in developing sustainable waste management financing mechanisms and in the application of economic instruments. Some landfills that posed environmental risks have been rehabilitated. However, results in the area of hazardous waste management remain inadequate, and the necessary infrastructure for managing hazardous waste has yet to be established [34]. In the Republic of Serbia, over 120 municipal landfills fail to meet environmental standards and accept organized municipal waste. Additionally, more than 3500 illegal dumpsites exist, beyond the control of municipal utilities, posing significant environmental risks. Approximately 20% of municipal waste is disposed of in these unauthorized sites [17].

According to data from the Serbian Environmental Protection Agency (SEPA) for 2023, eight operators are licensed for packaging waste management. In 2023, the quantity of plastic packaging placed on the market in the Republic of Serbia by legal entities or entrepreneurs who transferred their obligations to licensed operators amounted to 96,483.9 tons. Out of the total quantity of plastic packaging, 44,986.4 tons were composed of PET, while the remaining volume consisted of other plastic polymers. Out of this amount, a total of 14,967.8 tons of PET waste were recovered for reuse [17]. A particular challenge in the Republic of Serbia is the inadequate establishment of a system for the separate collection of households’ packaging waste, resulting in the majority of plastic waste being disposed of as part of mixed municipal waste. This significantly hinders its potential for further utilization and recycling [34]. Additionally, there is currently no dedicated legal or regulatory framework in Serbia that addresses microplastics within waste streams. The absence of specific policies and guidelines for the monitoring, control, and management of microplastics highlights a critical regulatory gap, especially given their increasing presence in the environment and potential risks to human health and ecosystems.

3. Literature Review: LCA in Plastic Waste Reduction Strategies

A life cycle assessment is a systematic methodology used to evaluate the environmental impacts of products and processes across their entire life cycle, from raw material extraction through production, use, and final disposal or recovery [18]. Initially, LCA focused on assessing the depletion of material and energy resources [37], but it has since expanded to address a wide array of environmental impact categories, including emissions, toxicity, and resource use [38]. The advancement of extensive databases and sophisticated software tools has enhanced the capacity to analyze and mitigate environmental impacts at different stages of a product’s life cycle [39]. By accounting for emissions and resource consumption throughout the supply chain, LCA offers a comprehensive perspective on the potential environmental burdens associated with products, including plastics [40].

The plastics industry was among the early adopters of LCA to quantify environmental impacts and inform sustainability initiatives [19,20]. Conducting LCAs on plastic products is essential for promoting circular economy strategies that aim to extend product lifespans, reduce resource consumption, and minimize waste generation [41]. Within plastic waste management, LCA studies frequently assess the performance of domestic waste treatment systems over their full life cycles, including detailed evaluations of landfills, incinerators, and integrated energy and cost analyses [42].

A growing concern within plastic waste management is the issue of microplastic pollution. Microplastics originate from a variety of polymers such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and polyethylene terephthalate [20]. Their potential toxicity is linked not only to the original plastic polymer composition but also to their physicochemical properties, which facilitate the transfer of toxic substances into biological organisms [43]. The complexity of microplastic pollution arises from the multitude of primary and secondary sources, complicating efforts to understand their environmental fate and transport [20]. Additionally, the release of toxic monomers, oligomers, and endocrine-disrupting additives introduced during polymer manufacturing raises further health and ecological concerns [44]. Incorporating the manufacturing phase into LCA studies is thus critical for the development of innovative technologies aimed at reducing plastic waste impacts, including strategies for disposal, incineration, and recycling [45].

LCAs of plastics typically consider five key life cycle phases: material extraction (cradle), manufacturing (gate), use (consumer), distribution/transportation, and end-of-life (grave). Studies may analyze the entire value chain or focus on selected segments depending on the research objective [20]. Employing looping methods during production promotes sustainability by maintaining product value and minimizing waste generation [46]. Recent trends in manufacturing include the increased utilization of renewable raw materials and reductions in waste output [47]. While early-stage LCAs may not yield definitive results, they provide valuable insights for comparing scenarios and guiding environmental improvements during planning phases [48].

The International Organization for Standardization (ISO) codifies LCA requirements through standards 14040:2006 [49] and 14044:2006 [50], which remain current following their 2022 review. The LCA process involves four iterative stages: (i) goal and scope definition, (ii) life cycle inventory analysis (LCI), (iii) life cycle impact assessment (LCIA), and (iv) interpretation. The first stage establishes the study’s objectives, system boundaries, and functional unit. The LCI phase involves collecting and verifying data on inputs, outputs, and emissions. The LCIA translates these data into impact metrics such as global warming potential (e.g., kg CO2-equivalents). Finally, the interpretation phase contextualizes findings, discusses uncertainties, and provides recommendations, allowing for model refinement as additional data become available [20,50,51].

LCA has become an indispensable tool for assessing the environmental performance of plastic waste end-of-life options. Numerous studies have demonstrated that incineration can serve as an effective energy recovery method, while reuse and recycling are increasingly recognized for their potential to reduce landfill dependence and lower environmental burdens [42]. Thermochemical post-treatment methods such as gasification, incineration, and pyrolysis generally yield better environmental outcomes than conventional landfilling by mitigating various impacts [51]. Life cycle assessments also indicate that incineration often performs better than landfilling when accounting for credits from avoided electricity generation [52]. Nonetheless, mechanical recycling remains the most sustainable and preferred end-of-life treatment option compared to incineration, offering significant environmental benefits [53].

4. Materials and Methods

4.1. Study Area

This study investigates the environmental impacts of PET packaging waste management in the Republic of Serbia, using data from 2023 reported by the Serbian Environmental Protection Agency (SEPA). In that year, 14,967.8 tons of PET packaging waste were generated, forming the basis for the life cycle assessment conducted in this research. These are official data on the quantities of PET packaging waste collected by authorized operators on the territory of the Republic of Serbia and include mixed (transparent, green, and brown bottles) PET packaging waste. Table 1 presents the total amount collected by packaging waste management system operators in 2023.

Table 1.

Total amount of PET packaging waste collected by packaging waste management system operators [17].

4.2. LCA Modeling Approach

The Life Cycle Assessment was performed using GaBi Professional v6.0 software (Sphera Solutions GmbH, Leinfelden-Echterdingen, Germany) to model and compare three waste management scenarios specific to PET packaging waste in Serbia: landfilling, mechanical recycling, and incineration. The system boundaries were set to include processes from the point at which PET packaging waste enters end-of-life treatment (i.e., post-consumer phase) through to final disposal or material recovery. The functional unit for the analysis is defined as 1 tons of PET packaging waste.

GaBi Professional v6.0 software was selected as the primary tool for conducting the LCA due to its advanced modeling capabilities and alignment with international ISO standards. Renowned for its extensive and high-quality databases (e.g., Ecoinvent, CML2001), GaBi facilitates the accurate representation of complex systems and supports a wide range of impact assessment methodologies, including ReCiPe and TRACI. The platform enables transparent and traceable calculations, features an intuitive user interface, and offers robust functionalities for scenario analysis. Its widespread use across both academic research and industrial applications reinforces its credibility, while its ability to integrate with complementary tools, along with comprehensive documentation and user support, makes it a reliable choice for conducting detailed and scientifically sound LCA studies. The software allowed for high-resolution modeling of material and energy flows, emissions, and environmental impacts (LCIA phase) relevant to the Serbian context.

4.3. Waste Management Scenarios

The three selected treatment scenarios—landfilling, recycling, and incineration—were developed to reflect typical waste handling practices observed in Serbia. While waste generation, collection, and transport stages remain constant across scenarios, the final treatment method varies and serves as the basis for comparative analysis.

Landfilling was modeled as disposal in non-sanitary landfill conditions, which are still common in parts of Serbia.

Mechanical recycling is considered the typical PET bottle recycling process, including sorting, shredding, washing, extrusion, and pelletizing.

Incineration was modeled as waste-to-energy combustion, based on typical European operational parameters.

4.4. Impact Categories and Evaluation

The environmental evaluation focused on selected midpoint impact categories relevant to the study’s objectives and the limitations of Serbia’s current waste infrastructure. The categories analyzed were as follows: climate change, human toxicity, and terrestrial ecotoxicity.

These categories were deliberately prioritized because they are most directly connected to the environmental and health effects of microplastic pollution, an issue intrinsic to PET waste. Microplastics act as carriers of hazardous substances that can enter food webs, thereby influencing both human toxicity and terrestrial ecotoxicity, while climate change reflects the greenhouse gas emissions associated with alternative end-of-life scenarios. Concentrating on these three indicators, rather than including additional metrics such as land use or acidification, enables a focused, policy-relevant evaluation of the environmental performance of competing PET waste management strategies and ensures clarity in the interpretation of results.

4.5. LCA Methodology

Life cycle assessment, as defined by ISO 14040 [49], is a systematic approach to quantify the environmental impacts associated with a product or service throughout its entire life cycle. This study applies the LCA methodology to evaluate the environmental performance of different end-of-life management options for PET packaging waste in the Republic of Serbia.

Following the ISO 14040 framework, the study was conducted in four phases: goal and scope definition, life cycle inventory (LCI) analysis, life cycle impact assessment (LCIA), and interpretation.

4.5.1. Goal and Scope Definition

The primary goal of this study is to quantify and compare the environmental impacts of three PET waste management scenarios—mechanical recycling, landfilling, and incineration—in order to identify the most environmentally sustainable option for Serbia. The system boundary is defined from the point at which PET packaging waste enters end-of-life treatment. The functional unit used for comparison is one metric ton (1 t) of PET packaging waste. The study is based on PET waste data collected from Serbia in 2023.

4.5.2. Life Cycle Inventory (LCI)

The inventory phase involved collecting data on inputs, outputs, and emissions related to the three waste treatment processes. These data were modeled using GaBi Professional v6.0 LCA software, incorporating unit processes for PET landfilling, recycling, and incineration. Waste generation and treatment data were sourced from the Serbian Environmental Protection Agency (SEPA) and relevant literature to ensure accuracy and representativeness for the Serbian context. Where local data were unavailable, global datasets from GaBi Sphera were used to fill the gaps.

4.5.3. Life Cycle Impact Assessment (LCIA)

Based on previous studies, ReCiPe 2016 has been identified as the most robust and widely accepted life cycle impact assessment (LCIA) method at the midpoint level, making it a suitable choice for assessing environmental impacts in this research. It has been confirmed that ReCiPe 2016, followed by ILCD 2011, CML IA baseline, and IMPACT 2002+, are the most commonly used multi-impact LCIA methods globally [54]. Accordingly, the ReCiPe method integrated within GaBi Professional v6.0 software was employed to evaluate the environmental impacts of PET waste treatment scenarios.

ReCiPe provides comprehensive results through midpoint indicators, such as greenhouse gas emissions, and endpoint indicators covering damage to human health, ecosystems, and resource depletion. This study focused on key impact categories relevant to PET waste management to capture the most critical environmental effects associated with each scenario. The LCA was conducted using GaBi Professional v6.0, utilizing ReCiPe’s capability to measure impacts at both midpoints (individual impact categories). Of the 16 midpoint indicators available, four were selected for detailed evaluation in this study.

4.5.4. Interpretation

The interpretation phase involved comparing the environmental impacts of recycling, landfilling, and incineration of PET waste in Serbia. The results highlight the advantages and disadvantages of each treatment option, with particular attention to impacts related to global warming and ecotoxicity, which are significant due to the predominance of landfill disposal in Serbia. The findings provide evidence-based recommendations to inform the development of more sustainable PET waste management strategies aligned with Serbia’s environmental goals.

5. Results and Discussion

To better understand the environmental impacts of PET waste treatment, selected elementary flows from the life cycle inventory (LCI) are presented in Table 2. These flows reflect direct exchanges with the environment and help explain the underlying mechanisms driving the impact assessment results. Notably, the recycling scenario shows large negative values for resource use and emissions to air and water, indicating avoided environmental impacts due to the substitution of virgin material production. In contrast, landfilling and incineration exhibit consistently positive elementary flows, corresponding to higher resource consumption and pollutant releases.

Table 2.

Selected LCI elementary flows (in kg) for 1 ton of PET waste under different end-of-life scenarios.

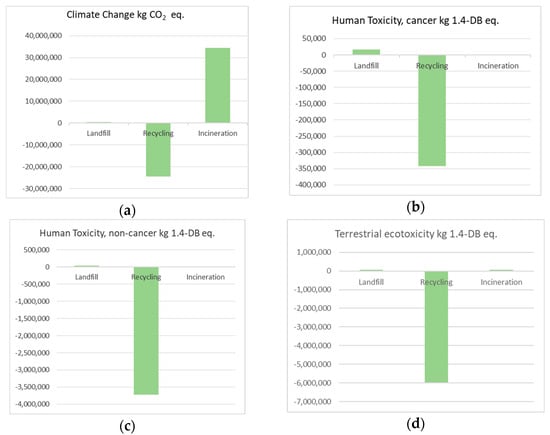

Among the three scenarios, recycling emerges as the most environmentally favorable option across all assessed categories. It is associated with negative values in every impact category, indicating environmental benefits through avoided emissions and resource conservation. Specifically, recycling results in a net reduction of 24.5 million kg CO2 eq., highlighting its substantial mitigation potential for climate change. Likewise, the process contributes to a significant decrease in toxicity indicators, including a reduction of 342,000 kg 1.4-DB eq. in human toxicity and 5.96 million kg 1.4-DB eq. in terrestrial ecotoxicity (Table 3 and Figure 1).

Table 3.

Environmental impacts of end-of-life treatment for 14,967.8 tons of PET packaging, derived using GaBi Professional v6.0 software.

Figure 1.

Environmental midpoint impacts per 14,967.8 ton of PET packaging waste in Serbia: (a) Climate change impact category in kg CO2eq. (b) Human toxicity, cancer impact category in kg 1.4 DBeq. (c) Human toxicity, non-cancer impact category in kg 1.4 DBeq. (d) Terrestrial ecotoxicity impact category in kg 1.4 DBeq.

Given these results, further analysis focuses on comparing landfilling and incineration, which represent less sustainable practices. Landfilling was identified as the least favorable option in two of the four impact categories—human toxicity and terrestrial ecotoxicity—due to high emissions to soil, which lead to long-term environmental degradation. Conversely, incineration had the highest impact on climate change, emitting approximately 34.4 million kg CO2 eq. This outcome underscores the significant air pollution burden associated with the combustion of PET, particularly in terms of carbon dioxide emissions.

To contextualize these findings and ensure comparability with the existing literature, midpoint characterization results were also calculated for the environmental impacts of 1 ton of PET waste in the Republic of Serbia. The most significant contributions were observed in terrestrial ecotoxicity, with emissions of 3.69 kg 1.4-dichlorobenzene equivalents (1.4-DB eq.) resulting from landfill disposal, and in climate change, with 2.29 kg CO2 equivalents emitted due to incineration. These values are consistent with the magnitude and distribution of impacts reported in other studies assessing PET waste treatment, confirming the reliability and relevance of the obtained results [4,5,9,28]. Furthermore, they highlight the distinct environmental profiles of the two EoL scenarios: landfilling has more severe implications for soil ecosystems, while incineration poses a greater threat to atmospheric stability and human health via air emissions. Given these results, further analysis focused on comparing landfilling and incineration, which represent less sustainable practices. Landfilling was identified as the least favorable option in two of the four impact categories—human toxicity and terrestrial ecotoxicity—due to high emissions to soil, which lead to long-term environmental degradation. Conversely, incineration had the highest impact on climate change, emitting approximately 34.4 million kg CO2 eq. This outcome underscores the significant air pollution burden associated with the combustion of PET, particularly in terms of carbon dioxide emissions.

In addition to the modeled impact categories, it is essential to consider the emerging issue of microplastic pollution, which is not yet fully captured in standard life cycle assessment methods. Both landfilling and incineration of plastic waste contribute to the formation and release of microplastics—landfills through physical degradation over time and leaching into soil and water, and incinerators via incomplete combustion or the release of fine particulate residues. These microplastics represent a long-term and poorly understood risk to ecosystems and human health, indicating the need for expanded impact categories and new characterization models within LCA frameworks.

Determining the best EoL treatment option for PET waste requires more complex analyses that include multiple impact categories, normalization, weighting, and sometimes even endpoint modeling. However, even with such detailed analyses, there may not be a universally “best” option, but rather one that is more or less suitable, depending on the priority impact categories or local environmental context.

Therefore, the LCA method should be regarded primarily as a supporting tool for decision-makers, helping to identify environmental hot spots and trade-offs, rather than providing absolute answers. Future enhancements to LCA, particularly the integration of emerging impact pathways such as microplastic pollution, will be crucial to better evaluate the full spectrum of environmental consequences associated with plastic waste management.

6. Environmental Occurrence and Release Pathways of Microplastics from Landfills and Incineration Residues

Landfills represent a significant but often overlooked source of microplastic pollution in terrestrial ecosystems. One of the key pathways for microplastic release into soils is through untreated landfill waste, which undergoes physical and chemical degradation over time. Microplastics have been detected in landfill leachate across several Chinese cities, with concentrations ranging from 0.420 to 24.6 particles per liter. The dominant polymer types identified were polypropylene (PP) and polyethylene (PE), reflecting the widespread use of these plastics in consumer packaging [55].

The challenge is expected to intensify in the coming decades. With the global demand for plastics continuing to rise, it is estimated that approximately 12 billion tons of plastic waste will be generated worldwide by 2050 [8]. When plastic waste is disposed of in landfills, it can persist in the soil environment for extended periods. Through processes such as UV radiation, mechanical abrasion, and chemical weathering, these materials gradually fragment into microplastics, which may also leach toxic additives, including phthalates and other hazardous chemicals [22]. These substances pose potential risks to soil health, groundwater quality, and ultimately, human and ecological health.

Microplastics have been detected in both leachate and solid waste from landfill sites. For example, concentrations in leachate and garbage from a Shanghai landfill reached 8.00 ± 3.00 particles/L and 62.0 ± 23.0 particles/g, respectively [56]. The heterogeneous composition of landfill environments, characterized by high organic matter content, complicates pollutant removal. Conventional pretreatment methods are often insufficient, and extended digestion times or the application of strong acid or alkaline solutions may be required to reduce organic interference. However, subsequent microscopic analysis and classification of microplastics are necessary to improve detection accuracy. Current studies primarily focus on larger microplastics, with limited data available for particles at the micrometer (μm) and nanometer (nm) scales.

Microplastic and heavy metal contamination has also been investigated in fly ash, bottom ash, and surface soil from municipal solid waste incineration (MSWI) facilities. The abundance of microplastics was reported as 23, 171, and 86 particles/kg dry weight in fly ash, bottom ash, and soil samples, respectively. The dominant microplastic type in fly ash was fiber, while fragments were most prevalent in bottom ash (43.0%) and soil (29.3%), followed by films, foams, and fibers in varying proportions. Many particles exhibited physical degradation features such as tearing marks, protrusions, and surface scratches.

Notably, microplastics were found to adsorb heavy metals, including Cr, Cu, Zn, and Pb, indicating a potential vector for pollutant transport. Column leaching experiments demonstrated that both microplastics and heavy metals could be mobilized from bottom ash under simulated precipitation. In particular, acid rain significantly enhanced the leaching of heavy metals into the aqueous phase in the absence of appropriate containment or treatment measures. These findings highlight the potential for combined migration of microplastics and heavy metals from incineration residues and emphasize the need for improved management strategies.

While incineration significantly reduces the volume of municipal solid waste destined for landfilling, it does not eliminate the need for landfill disposal. Incineration produces bottom ash, a residual material that is often returned to the environment. It is generally regarded as an effective method for the destruction of plastic waste, converting polymers primarily into CO2 and inert mineral fractions [8]. However, studies have shown that unburned materials, including synthetic fibers, can persist in bottom ash, suggesting that microplastics (MPs) may survive the combustion process and potentially enter the environment through the reuse or improper disposal of incineration residues [57].

To investigate whether incineration fully eliminates MPs and to quantify their presence in bottom ash, recent research has focused on extracting and characterizing MPs from this waste stream. Findings revealed that bottom ash is a previously overlooked source of microplastics, with reported abundances ranging from 1.9 to 565 particles/kg, corresponding to an estimated 360 to 102,000 microplastic particles per metric ton of incinerated waste. These results highlight the need for further studies on the fate and environmental risks of microplastics in incineration residues.

7. Future Research Directions on PET Microplastic in Serbia

Recent developments in life cycle assessment increasingly address the environmental impacts of microplastics, with a predominant focus on aquatic ecosystems and various polymer types. Notably, several studies have contributed to advancing LCA methodologies by developing characterization factors that quantify the physical and ecotoxicological impacts of microplastic emissions. One such study addresses a critical gap by formulating CFs for microplastics in aquatic environments. Building on the efforts of the MarILCA working group—initiated in 2018 with support from the UN Environment Life Cycle Initiative and the Forum for Sustainability through Life Cycle Innovation (FSLCI)—the study updated exposure and effect factors (EEFs) using recent ecotoxicity data and developed fate factors (FFs) for 11 common polymers, incorporating a range of particle shapes and sizes. The findings emphasize the influence of polymer density and particle size on environmental behavior in aquatic systems. By integrating these parameters, midpoint and endpoint CFs were generated to assess ecosystem damage, with associated uncertainty quantified through Monte Carlo simulations. Case studies involving food packaging illustrated the applicability of these CFs in improving LCA outcomes by accounting for the previously overlooked impacts of microplastics on aquatic biota. Additionally, default CFs based on polymer density classifications (low, medium, and high) and particle morphology (e.g., spheres, fibers, and films) were introduced to support practitioners in scenarios lacking detailed emission data [58].

Complementary research has also focused on biodegradable polymers in marine environments, seeking to fill gaps in accounting for their ecological impacts. Degradation rates for poly (lactic acid), poly (butylene succinate), and poly (ε-caprolactam) were experimentally determined over six months in natural seawater, incorporating variables such as particle size, polymer grade, and temperature. These data informed fate modeling by including key environmental processes such as sedimentation, resuspension, and burial, leading to the development of polymer-specific CFs. When applied to the life cycle of a synthetic sports shirt made from biodegradable fibers, microplastic emissions were found to contribute up to 30% of the total impact on ecosystem quality. This work strengthens the LCA framework by introducing empirically derived CFs that support more informed material selection and environmental assessments [59].

A further advancement involved the development of CFs for aquatic microplastic pollution from polymers such as polypropylene (PP), low-density polyethylene (LDPE), and polyethylene terephthalate. Utilizing the multimedia fate model Simplebox4Plastics, the study modeled environmental fate and assessed ecological effects using species sensitivity distributions. Macroplastic impacts were incorporated using a conversion factor. The resulting CFs were integrated into the ReCiPe2016 life cycle impact assessment (LCIA) method and applied to consumer packaging scenarios. The results revealed a significant contribution of plastic pollution to freshwater and marine ecotoxicity categories, although its effect on endpoint ecosystem quality was comparatively limited. These findings underscore the necessity of integrating plastic-related impacts into mainstream LCIA methods and highlight the need for continued refinement across a broader spectrum of polymer types and fate-effect modeling approaches [60].

With respect to terrestrial ecosystems, CFs have been developed to evaluate the impacts of both fossil- and bio-based plastics, particularly regarding microplastic ingestion and the release of chemical additives. This work assessed polymers such as PP, LDPE, and biopolymers, including polyhydroxyalkanoates (PHA) and PLA. Fate factors were derived from photooxidative degradation data under terrestrial conditions, while effect factors followed USEtox guidelines and incorporated both ecotoxicological and physical impact data. Under the assumption of full bioavailability (exposure factor XF = 1), chemical additives were found to pose substantially higher environmental risks than microplastic ingestion—by up to three to four orders of magnitude—especially in aquatic ecosystems. Importantly, the CFs developed for biopolymers were comparable to those for conventional plastics, indicating that improved waste management strategies are essential for both material types across terrestrial and aquatic environments [61].

Recent research from China highlights the importance of source-specific and transport-sensitive modeling of microplastic emissions. By accounting for particle density, environmental retention, and riverine transport, the study significantly reduced overestimated contributions from sources such as vehicle tires. These findings underscore the need to incorporate local retention rates and fate dynamics into emission modeling. For Serbia, similar modeling approaches should be applied to assess microplastic emissions resulting from different waste management scenarios—such as landfilling, incineration, and recycling of PET waste—by integrating spatial and environmental factors into LCA to improve the accuracy of characterization factors and impact assessments [62].

In addition, a recent study from Bangladesh illustrates how microplastic (MP) emissions can be integrated into life cycle assessment. Utilizing SimaPro (v9.5.0.0) and the ReCiPe 2016 methodology, the study compared environmental impacts from healthcare waste management (HCWM) in public and private healthcare facilities, revealing that private facilities contributed more significantly to MP emissions—primarily due to practices such as open burning and uncontrolled dumping. MP emissions were estimated by comparing plastic waste inputs with corresponding emission factors sourced from the literature. Although the absence of a dedicated MP emission database presents a methodological limitation, this study demonstrates a practical approach to incorporating MPs into LCA models. It also underscores the need for improved emission inventories tailored to microplastic release under various waste treatment scenarios. A similar framework could be adapted in Serbia to assess the environmental impacts of PET waste management and to support the development of region-specific characterization factors [63].

Table 4 summarizes key advancements in LCA research related to microplastics, highlighting specific methodological adaptations necessary to incorporate microplastic emissions and impacts. It also outlines the relevance of these adaptations for developing region-specific characterization factors and improving LCA models for PET microplastic pollution in Serbia. This structured approach aims to guide future research by integrating microplastic-specific considerations within established LCA frameworks.

Table 4.

Approach for translating life cycle assessment methodology from conventional plastics to microplastics with focus on PET in Serbia [58,59,60,61,62,63,64,65].

Building on these foundational studies, future research in Serbia should focus on developing region-specific characterization factors for mismanaged PET plastics in the terrestrial environment, taking into account both the physical impacts of microplastic ingestion and the ecotoxicological effects of their additives. This involves tailoring existing LCA methodologies to the unique environmental conditions, soil characteristics, and waste management practices of Serbia.

With inspiration from recent advancements in the LCA modeling of microplastics, it is recommended that PET-based microplastic impacts be assessed by differentiating particles according to their polymer type, shape (fragment, fiber, film), and size. This level of detail enables the more accurate modeling of environmental impacts by capturing how these characteristics influence fate, exposure, and toxicity in soil. Mass estimates for each particle group should be based on geometrically derived volumes and PET density, following established methodological frameworks [64].

A primary objective is to establish the fate factor (FF) for PET plastics in Serbian soils through a combination of laboratory testing and in situ environmental insights. To ensure accurate modeling, the fate assessment should also incorporate local waste management practices, estimated plastic leakage from various sources, the extrinsic and intrinsic properties of plastics, and relevant environmental conditions drawn from national and scientific reports. This integrated approach will support a realistic representation of the dispersion and persistence of PET plastics and their microplastics in terrestrial compartments [58,61,65].

For the exposure factor (XF), initial assumptions may consider full bioavailability (XF = 1), but detailed investigation of soil physicochemical properties such as organic matter content, pH, and moisture will enable refined bioavailability estimates. These data can be sourced from Serbian soil databases and targeted field sampling [61].

The effect factor (EF) should be derived from ecotoxicological data on local terrestrial species, whose sensitivities may differ from those reported in global studies. Chronic toxicity endpoints (e.g., EC10, NOEC, EC50) for soil invertebrates, plants, and microorganisms native to Serbia should be gathered through laboratory assays and literature reviews. Additionally, environmental monitoring data on PET-associated additives in Serbian soils would facilitate assessment of chemical risks [60,61].

By integrating these localized fate, exposure, and effect factors, standardized CFs can be developed to quantify the impacts of PET plastics and microplastics on Serbian terrestrial ecosystems. Such advancements will enhance the precision of LCIA models in Serbia and provide evidence-based support for environmental policymaking and waste management strategies tailored to the country’s specific challenges with plastic pollution [58,59,60,61,62,63,64,65].

8. Conclusions

This study represents the first application of GaBi Professional v6.0 software to assess the environmental impacts of PET waste management in Serbia, an EU accession country. The results demonstrate that recycling is the most environmentally beneficial option, leading to substantial reductions in climate change potential, human toxicity, and terrestrial ecotoxicity. In contrast, landfilling and incineration significantly contribute to environmental degradation, particularly through emissions and the long-term accumulation of pollutants.

Despite data uncertainties and the sensitivity of the results, the findings offer a comprehensive overview of the current baseline scenario for PET waste management in Serbia. They also highlight critical shortcomings in existing waste management practices and identify opportunities to reduce environmental impacts. Furthermore, this research contributes to the growing—yet still limited—collection of LCA studies on plastic waste in regions with similar geographical and socio-economic conditions.

Finally, this paper lays the groundwork for future research in Serbia aimed at developing region-specific characterization factors for microplastics originating from mismanaged PET in terrestrial environments through close collaboration between experimental research and LCA modeling.

Author Contributions

Conceptualization, D.P., J.S. and L.M.; methodology, D.P., J.S. and L.M.; software, D.P., J.S. and L.M.; validation, J.S.; formal analysis, L.M.; investigation, B.P.; data curation, D.P. and J.S.; writing—original draft preparation, D.P.; writing—review and editing, N.S. and M.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Union’s Horizon Europe Project GREENLand—Twinning Microplastic-free Environment under grant agreement number 101079267.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data supporting this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Anuar, S.Z.K.; Nordin, A.H.; Husna, S.M.N.; Yusoff, A.H.; Paiman, S.H.; Md Noor, S.F.; Nordin, M.L.; Ali, S.N.; Ismail, Y.M.N.S. Recent advances in recycling and upcycling of hazardous plastic waste: A review. J. Environ. Manag. 2025, 380, 124867. [Google Scholar] [CrossRef]

- Oyelere, A.; Wu, S. State of the art review on the principles of compatibility and chemical compatibilizers for recycled plastic-modified asphalt binders. J. Clean. Prod. 2025, 492, 144895. [Google Scholar] [CrossRef]

- Poyai, T.; Pongpunpurt, P.; Leknoi, U.; Painmanakul, P.; Chawaloesphonsiya, N. Plastic waste management in urban areas: Key takeaways from the “Send Plastic Home” project in Bangkok, Thailand. Process Saf. Environ. Prot. 2024, 190 Pt A, 1222–1232. [Google Scholar] [CrossRef]

- Joseph, T.M.; Azat, S.; Ahmadi, Z.; Jazani, O.M.; Esmaeili, A.; Kianfar, E.; Haponiuk, J.; Thomas, S. Polyethylene terephthalate (PET) recycling: A review. Case Stud. Chem. Environ. Eng. 2024, 9, 100673. [Google Scholar] [CrossRef]

- Chan, K.; Zinchenko, A. Design and synthesis of functional materials by chemical recycling of waste polyethylene terephthalate (PET) plastic: Opportunities and challenges. J. Clean. Prod. 2023, 433, 139828. [Google Scholar] [CrossRef]

- Saxena, S. Pyrolysis and beyond: Sustainable valorization of plastic waste. Appl. Energy Combust. Sci. 2025, 21, 100311. [Google Scholar] [CrossRef]

- Meys, R.; Kätelhön, A.; Bachmann, M.; Winter, B.; Zibunas, C.; Suh, S.; Bardow, A. Achieving net-zero greenhouse gas emission plastics by a circular carbon economy. Science 2021, 374, 71–76. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Feng, Y.; Lv, S.-W.; Zhang, R.; Ren, X.; Shen, J.; Cong, Y. From waste to wealth: Glycolysis of PET for high-value resource utilization. Waste Manag. 2025, 200, 114768. [Google Scholar] [CrossRef]

- European Commission. A European Strategy for Plastics in a Circular Economy; (COM(2018) 28 final); European Commission: Ispra, Italy, 16 January 2018; Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:2df5d1d2-fac7-11e7-b8f5-01aa75ed71a1.0001.02/DOC_1&format=PDF (accessed on 15 January 2025).

- Chairat, S.; Gheewala, S.H. Life cycle assessment and circularity of polyethylene terephthalate bottles via closed and open loop recycling. Environ. Res. 2023, 236 Pt 1, 116788. [Google Scholar] [CrossRef]

- Laureti, L.; Costantiello, A.; Anobile, F.; Leogrande, A.; Magazzino, C. Waste management and innovation: Insights from Europe. Recycling 2024, 9, 82. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A New Circular Economy Action Plan—For a Cleaner and More Competitive Europe; (COM(2020) 98 final); European Commission: Ispra, Italy, 11 March 2020; Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:9903b325-6388-11ea-b735-01aa75ed71a1.0017.02/DOC_1&format=PDF (accessed on 20 January 2025).

- Vlasopoulos, A.; Malinauskaite, J.; Żabnieńska-Góra, A.; Jouhara, H. Life cycle assessment of plastic waste and energy recovery. Energy 2023, 277, 127576. [Google Scholar] [CrossRef]

- European Commission. Serbia 2024 Report: Commission Staff Working Document Accompanying the 2024 Communication on EU Enlargement Policy; (SWD(2024) 695 final); European Commission: Ispra, Italy, 30 October 2024; Available online: https://enlargement.ec.europa.eu/document/download/3c8c2d7f-bff7-44eb-b868-414730cc5902_en?filename=Serbia%20Report%202024.pdf (accessed on 20 March 2025).

- Government of the Republic of Serbia. Waste Management Program in the Republic of Serbia for the Period 2022–2031; (Official Gazette of the Republic of Serbia, No. 30/18); Government of the Republic of Serbia: Belgrade, Serbia, 2022. Available online: https://www.ekologija.gov.rs/sites/default/files/2022-02/program_upravljanja_otpadom_u_rs_za_period_2022-2031._god_0_2.pdf (accessed on 5 March 2025).

- Ministry of Environmental Protection, Environmental Protection Agency. Report on Packaging and Packaging Waste Management in the Republic of Serbia; 2023. Available online: https://sepa.gov.rs/wp-content/uploads/2024/10/Ambalaza-2023.pdf (accessed on 3 March 2025).

- Bicalho, T.; Sauer, I.; Rambaud, A.; Altukhova, Y. LCA data quality: A management science perspective. J. Clean. Prod. 2017, 156, 888–898. [Google Scholar] [CrossRef]

- Hunt, R.G.; Franklin, W.E.; Hunt, R.G. LCA—How it came about. Int. J. Life Cycle Assess 1996, 1, 4–7. [Google Scholar] [CrossRef]

- Xayachak, T.; Haque, N.; Lau, D.; Pramanik, B.K. The missing link: A systematic review of microplastics and its neglected role in life-cycle assessment. Sci. Total Environ. 2024, 954, 176513. [Google Scholar] [CrossRef]

- Browning, S.; Beymer-Farris, B.; Seay, J.R. Addressing the challenges associated with plastic waste disposal and management in developing countries. Curr. Opin. Chem. Eng. 2021, 32, 100682. [Google Scholar] [CrossRef]

- Xu, Z.; Xiong, X.; Zhao, Y.; Xiang, W.; Wu, C. Pollutants delivered every day: Phthalates in plastic express packaging bags and their leaching potential. J. Hazard. Mater. 2020, 384, 121282. [Google Scholar] [CrossRef]

- Kibria, M.G.; Masuk, N.I.; Safayet, R.; Nguyen, H.Q.; Mourshed, M. Plastic waste: Challenges and opportunities to mitigate pollution and effective management. Int. J. Environ. Res. 2023, 17, 20. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, Z.; Zhang, J.; Liu, Y.; Chen, L.; Yang, M.; Osman, A.I.; Farghali, M.; Liu, E.; Hassan, D.; et al. Municipal solid waste management challenges in developing regions: A comprehensive review and future perspectives for Asia and Africa. Sci. Total Environ. 2024, 930, 172794. [Google Scholar] [CrossRef]

- Qian, K.; Wang, L.; Teng, J.; Liu, G. Strategies and technologies for sustainable plastic waste treatment and recycling. Environ. Funct. Mater. 2025, advance online publication. [Google Scholar] [CrossRef]

- Salami, L.; Patinvoh, R.J.; Taherzadeh, M.J. Waste plastic char as adsorbent for removal of pollutants from landfill leachates–A critical review. Environ. Adv. 2024, 16, 100522. [Google Scholar] [CrossRef]

- Mor, S.; Ravindra, K. Municipal solid waste landfills in lower- and middle-income countries: Environmental impacts, challenges and sustainable management practices. Process Saf. Environ. Prot. 2023, 174, 510–530. [Google Scholar] [CrossRef]

- Melikoglu, M.; Asci, A. Quantification of Turkey’s wasted, landfilled, recycled and combusted PET. Environ. Dev. 2022, 44, 100773. [Google Scholar] [CrossRef]

- Suzuki, G.; Uchida, N.; Tanaka, K.; Higashi, O.; Takahashi, Y.; Kuramochi, H.; Yamaguchi, N.; Osako, M. Global discharge of microplastics from mechanical recycling of plastic waste. Environ. Pollut. 2024, 348, 123855. [Google Scholar] [CrossRef]

- Nafiu, S.A.; Azeez, M.O.; AlAqad, K.M.; Olarewaju, T.A.; Yerima, E.A.; Tanimu, A. Waste plastic management: Recycling and the environmental health nexus. Clean. Mater. 2025, 15, 100291. [Google Scholar] [CrossRef]

- Bajić, B.Ž.; Dodić, S.N.; Vučurović, D.G.; Dodić, J.M.; Grahovac, J.A. Waste-to-energy status in Serbia. Renew. Sustain. Energy Rev. 2015, 50, 1437–1444. [Google Scholar] [CrossRef]

- Yang, Z.; Lü, F.; Zhang, H.; Wang, W.; Shao, L.; Ye, J.; He, P. Is incineration the terminator of plastics and microplastics? J. Hazard. Mater. 2021, 401, 123429. [Google Scholar] [CrossRef]

- World Bank. Municipal Waste Management in Serbia: Situational Analysisz (May 2023); World Bank: Washington, DC, USA, 2023; Available online: https://thedocs.worldbank.org/en/doc/8c0c355b685476cdcc2154a3ecf42768-0080012024/original/Situational-Analysis-Municipal-Waste-Management-in-Serbia.pdf (accessed on 14 March 2025).

- Republic of Serbia. Waste Management Program of the Republic of Serbia for the Period 2022–2031; [Based on Article 38, Paragraph 1 of the Law on the Planning System of the Republic of Serbia, Official Gazette of the RS, No. 30/18]; Government of the Republic of Serbia: Belgrade, Serbia, 2022. Available online: https://www.ekologija.gov.rs/sites/default/files/2022-03/program_upravljanja_otpadom_eng_-_adopted_version.pdf (accessed on 22 March 2025).

- Law on Waste Management. Official Gazette of the Republic of Serbia; Nos. 36/2009, 88/2010, 14/2016, 95/2018 (Other Law), and 35/2023; Republic of Serbia. 2009. Available online: https://www.paragraf.rs/propisi/zakon_o_upravljanju_otpadom.html (accessed on 25 March 2025).

- Law on Packaging and Packaging Waste (2009/2018). Official Gazette of the Republic of Serbia; Republic of Serbia, Nos. 36/09 and 95/18 (Other Law). Available online: https://www.paragraf.rs/propisi/zakon_o_ambalazi_i_ambalaznom_otpadu.html (accessed on 25 March 2025).

- Jensen, A.A.; Hoffman, L.; Møller, B.T.; Schmidt, A. Life Cycle Assessment—A Guide to Approaches, Experiences and Information Sources; European Environment Agency: Copenhagen, Denmark, 1997; Available online: https://www.eea.europa.eu/publications/GH-07-97-595-EN-C (accessed on 20 February 2025).

- Colangelo, F.; Forcina, A.; Farina, I.; Petrillo, A. Life Cycle Assessment (LCA) of different kinds of concrete containing waste for sustainable construction. Buildings 2018, 8, 70. [Google Scholar] [CrossRef]

- Bach, R.; Mohtashami, N.; Hildebrand, L. Comparative overview on LCA software programs for application in the façade design process. J. Facade Des. Eng. 2019, 7, 13–25. [Google Scholar]

- Nessi, S.; Sinkko, T.; Bulgheroni, C.; Garcia-Gutierrez, P.; Giuntoli, J.; Konti, A.; Sanye-Mengual, E.; Tonini, D.; Pant, R.; Marelli, L. Comparative Life Cycle Assessment (LCA) of Alternative Feedstock for Plastics Production—Part 1; Joint Research Centre—European Commission: Luxembourg, 2020. [Google Scholar]

- European Environment Agency. Circular Economy in Europe—Developing the Knowledge Base; (EEA Report No. 2/2016); EEA: Copenhagen, Denmark, 2016. [Google Scholar]

- Xu, T.; Yang, J.; Shao, Z.; Shen, C.; Yao, F.; Zheng, J.; Wu, Y.; Kan, S. Life cycle assessment of plastic waste in Suzhou, China: Management strategies toward sustainable express delivery. J. Environ. Manag. 2024, 360, 121201. [Google Scholar] [CrossRef]

- Rahman, A.; Sarkar, A.; Yadav, O.P.; Achari, G.; Slobodnik, J. Potential human health risks due to environmental exposure to nano and microplastics and knowledge gaps: A scoping review. Sci. Total Environ. 2021, 757, 143872. [Google Scholar] [CrossRef]

- Shi, C.; Wang, M.; Wang, Z.; Qu, G.; Jiang, W.; Pan, X.; Fang, M. Oligomers from the synthetic polymers: Another potential iceberg of new pollutants. Environ. Health 2023, 1, 228–235. [Google Scholar]

- Mannheim, V. Life cycle assessment model of plastic products: Comparing environmental impacts for different scenarios in the production stage. Polymers 2021, 13, 777. [Google Scholar] [CrossRef]

- Geueke, B.; Groh, K.; Muncke, J. Food packaging in the circular economy: Overview of chemical safety aspects for commonly used materials. J. Clean. Prod. 2018, 193, 491–505. [Google Scholar]

- European Bioplastics, Bioplastics—Facts and Figures; European Bioplastics: Berlin, Germany, 2017.

- Villares, M.; Isildar, A.; van der Giesen, C.; Guinée, J. Does ex ante application enhance the usefulness of LCA? A case study on an emerging technology for metal recovery from e-waste. Int. J. Life Cycle Assess 2017, 22, 1618–1633. [Google Scholar]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Antelava, A.; Damilos, S.; Hafeez, S.; Manos, G.; Al-Salem, S.M.; Sharman, B.K.; Kohli, K.; Constantinou, A. Plastic Solid Waste (PSW) in the Context of Life Cycle Assessment (LCA) and Sustainable Management. Environ. Manag. 2019, 64, 230–244. [Google Scholar] [CrossRef]

- Bjorklund, A.; Finnveden, G. Recycling revisited—Life cycle comparisons of global warming impact and total energy use of waste management strategies. Resour. Conserv. Recycl. 2005, 44, 309–317. [Google Scholar] [CrossRef]

- Jiao, H.; Ali, S.S.; Alsharbaty, M.H.M.; Elsamahy, T.; Abdelkarim, E.; Schagerl, M.; Al-Tohamy, R.; Sun, J. A critical review on plastic waste life cycle assessment and management: Challenges, research gaps, and future perspectives. Ecotoxicol. Environ. Saf. 2004, 271, 115942. [Google Scholar] [CrossRef]

- Rybaczewska-Błażejowska, M.; Jezierski, D. Comparison of ReCiPe 2016, ILCD 2011, CML-IA Baseline and IMPACT 2002+ LCIA methods: A case study based on the electricity consumption mix in Europe. Int. J. Life Cycle Assess. 2024, 29, 1799–1817. [Google Scholar] [CrossRef]

- He, P.; Chen, L.; Shao, L.; Zhang, H.; Lu, F. Municipal solid waste (MSW) landfill: A source of microplastics? Evidence of microplastics in landfill leachate. Water Res. 2019, 159, 38–45. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, Z.; Wu, D.; Zhan, L.; Shi, H.; Xie, B. Occurrence of microplastics in landfill systems and their fate with landfill age. Water Res. 2019, 164, 114968. [Google Scholar] [CrossRef]

- Chimenos, J.M.; Segarra, M.; Fernández, M.A.; Espiell, F. Characterization of the bottom ash in municipal solid waste incinerator. J. Hazard. Mater. 1999, 64, 211–222. [Google Scholar] [CrossRef]

- Corella-Puertas, E.; Hajjar, C.; Lavoie, J.; Boulay, A.-M. MarILCA characterization factors for microplastic impacts in life cycle assessment: Physical effects on biota from emissions to aquatic environments. J. Clean. Prod. 2013, 418, 138197. [Google Scholar] [CrossRef]

- Pellengahr, F.; Corella-Puertas, E.; Mattelin, V.; Saadi, N.; Bertella, F.; Boulay, A.-M.; van der Meer, Y. Modeling marine microplastic emissions in life cycle assessment: Characterization factors for biodegradable polymers and their application in a textile case study. Front. Toxicol. 2025, 7, 1494220. [Google Scholar] [CrossRef]

- Schwarz, A.E.; Herlaar, S.; Cohen, Q.M.; Quik, J.T.K.; Golkaram, M.; Urbanus, J.H.; van Emmerik, T.H.M.; Huijbregts, M.A.J. Microplastic aquatic impacts included in life cycle assessment. Resour. Conserv. Recycl. 2024, 209, 107787. [Google Scholar] [CrossRef]

- Vázquez-Vázquez, B.; Lazzari, M.; Hospido, A. Terrestrial characterization factors for bio- and fossil-based plastics: Microplastics ingestion and additives release. Waste Manag. 2025, 196, 106–114. [Google Scholar] [CrossRef]

- Xiao, S.; Liang, Y.; Zhu, X.; Kyes, S.; Cai, X. Are Vehicle Tires Major Contributors to Microplastic Emissions into the China Seas? A Simple Model Perspective. Sci. Total Environ. 2024, 920, 171003. [Google Scholar] [CrossRef]

- Zheng, X.; Zhong, S.; Alam, O.; Hossen, S.J.; Du, D. Microplastics and Heavy Metals Emissions from Healthcare Waste Management: A Comparative Life Cycle Assessment. Waste Manag. 2025, 204, 114932. [Google Scholar] [CrossRef]

- Alibekov, A.; Meirambayeva, M.; Yengsebek, S.; Aldyngurova, F.; Lee, W. Environmental Impact of Microplastic Emissions from Wastewater Treatment Plant through Life Cycle Assessment. Sci. Total Environ. 2025, 962, 178378. [Google Scholar] [CrossRef]

- Chamas, A.; Moon, H.; Zheng, J.; Qiu, Y.; Tabassum, T.; Jang, J.H.; Abu-Omar, M.; Scott, S.L.; Suh, S. Degradation rates of plastics in the environment. ACS Sustain. Chem. Eng. 2020, 8, 3494–3511. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).