Abstract

While traditional disposal of solid waste from the global wine industry causes significant environmental burden and hazards, a range of value-added by-products can be produced from the grape marc. This review focuses therefore on crucial sustainability-enhancing technologies for pomace dewatering and separation, which constitute a mandatory stage in obtaining storage-stable by-products and final value-added commodities. A number of dryers and separators were considered for pre-treatment of wet grape marc and analysed in terms of their design characteristics, functionality, feasibility, throughput and efficiency. A multi-criteria decision analysis was carried out to compare, rank and select the equipment which is most suitable for the purpose. It was found out that the rotary drum dryer and the drum screen separator with internal blade rotor are the best candidates to fulfil the technology requirements, while the flowsheet that includes an initial separation followed by drying of the resulting fractions is a rather attractive option. Valorising grape waste worldwide contributes substantially to achieving the United Nations Sustainable Development Goals for responsible consumption and production, mitigating climate change, caring for health and well-being, preserving land life and combating hunger.

Keywords:

winemaking; grapes; marc; pomace; waste processing; waste utilisation; waste valorisation; dryers; separators; sustainability 1. Managing Solid Wastes from Winemaking and Alternatives for Their Valorisation in By-Products

The global wine industry is an important agricultural and industrial sector. The world harvest and processing of grapes was approximately 77 million tonnes in 2016 [1]. The solid residue that remains after grapes have been pressed to extract their juice for winemaking is named grape marc, also known as pomace [2]. It is a heterogeneous mixture comprising the skins, seeds, pulp, residual moisture (around 80%), residual sugars (around 1.5%) and organic acids (such as tartaric, acetic and malic acids), and it often includes the stems of the grapes [1,2,3,4]. The marc contains valuable biologically active components such as phenolic compounds, including flavonoids (e.g., anthocyanins), flavanols (catechins, procyanidins), flavonols (quercetin, kaempferol, myricetin and their derivatives), flavones and phenolic acids (such as gallic, caffeic) [5,6]; essential fatty acids, primarily linoleic acid (an omega-6 fatty acid that is up to 60–76% of its total fatty acid content) and alpha-linolenic acid (omega-3) with less than 1% content [7,8,9,10]; tocopherols (vitamin E, up to 700 mg per 1 kg of grape oil) [7]; beta-carotene (provitamin A, up to 13 mg per 1 kg of seed) [11]; and oligosaccharides [9]. The grape marc always represents a significant proportion of the processed grapes, typically between 20 and 25% of the initial weight. It is estimated that up to 14 million tons of solid waste is generated annually by the wine industry worldwide [12].

The traditional disposal of grape marc presents significant environmental burden and hazards, e.g., (i) soil and water contamination through leachates and the release of organic compounds (such as polyphenols and tannins) that have phytotoxic and antimicrobial effects on soil and can inhibit plant growth and disrupt soil ecology [13]; (ii) the release of harmful greenhouse gas emissions due to decomposition under anaerobic conditions [14]; and (iii) economic burdens associated with disposal costs [12,15] and the loss of potential revenue from valuable by-products [1,2].

The management and disposal of winery waste, including grape marc, are increasingly subject to environmental regulations in the European Union [16], the USA [17], Australia [18], New Zealand [19] and the rest of the world. They target the reduction of pollution from winery waste and encourage its utilisation instead of disposal [20].

There exist five general alternatives for valorising grape marc into valuable by-products: (i) agricultural applications; (ii) energy generation; (iii) food industry applications; (iv) cosmetic and pharmaceutical applications; and (v) production of bio-based materials.

The potential for obtaining value-added by-products from grape marc can be ranked in the following three groups:

- (i)

- Low-value by-products having applications in high volumes: soil amendment [21] by composting and vermicomposting [22]; animal feed [9,21]; solid recovered fuel [23,24,25] for direct combustion or pelleting [21,26,27]; biogas (composed mainly of methane) [9,21,22]; hydrochar (a solid fuel material with enhanced energy and carbon content produced by hydrothermal carbonization) [15,28]; lignocellulosic biomass [21]; and a natural dyeing agent for geopolymers [29].

- (ii)

- Medium-value by-products having medium-volume applications: extraction of polyphenols [2,30,31] and antioxidants [2]; dietary fibres [1,9,32]; grape seed oil [2,10,33,34]; tartaric, lactic and citric acids [21] and other organic acids; pectin [32]; functional foods [1,2,5,9]; bioethanol [1,9,21,35,36] and other bio-based chemicals.

- (iii)

- High-value by-products having low-volume applications: cosmetic [9,12,33,37,38] and pharmaceutical [2,9,39] bioactive ingredients; smart food packaging [9] with antioxidant and antimicrobial compounds [40]; production of bio-based and biodegradable polymers, i.e., poly (lactic acid), poly (butylene succinate) and poly (hydroxyalkanoate) [26]; biodegradable polysaccharide pullulan [41]; along with low-alcohol beverages [42].

The duration of the grape processing campaign in wineries is relatively short, ranging from 1 to 3 months. Waste grape marc should be processed quickly to prevent unwanted microbial degradation, release of contaminants and loss of valuable components. On other hand, obtaining value-added by-products requires dry stable marc or its by-products and longer processing time. This determines the bottleneck in the management chain for these solid wastes—the pre-treatment of marc, including rapid dewatering and separation, to obtain by-products that remain microbiologically stable during storage (i.e., with a water activity not exceeding the recommended limits [43]).

The present review focuses therefore on the design and functional characteristics of the equipment for drying and separation of wet grape marc in order to evaluate and compare its feasibility and effectiveness.

2. Flowsheets for Pre-Processing Grape Marc

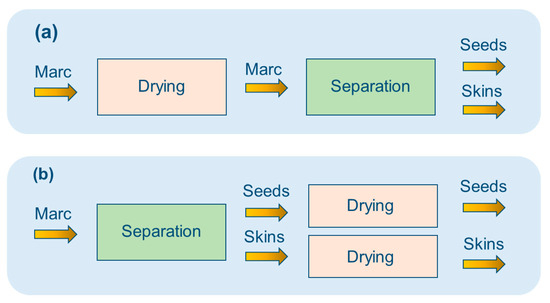

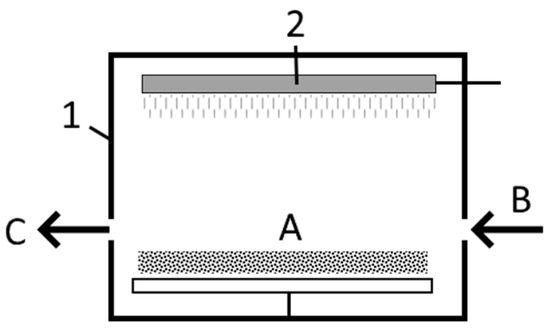

In the processing of wet grape marc from winemaking, two main flowsheets are employed (Figure 1):

Figure 1.

Principal flowsheets for pre-processing grape marc: (a) with preliminary drying, and (b) with initial separation.

- (a)

- preliminary drying of marc and subsequent separation of the dried material into seeds and skins (a more widespread principle, for example [44,45]);

- (b)

- initial separation to the harder, bigger seeds and the softer, finely crushed skins, followed by drying of these two fractions (for instance [46,47]).

The first flowsheet scheme requires an initial application of high-temperature drying, which expends time and energy in the intense winemaking campaign. In the dried marc, seeds and skins stick to each other, and this complicates their separation. In the second scheme, two fractions having a high retention of biologically active components are directly obtained, and these intermediate products can be directly released commercially. These two fractions have a granular structure, and this allows them to be stored for a short intermediate period before their subsequent drying. All this makes the second scheme more attractive for industrial practice.

3. Methods and Equipment for Drying Grape Marc

3.1. Methods for Drying Grape Marc

The following methods, suitable for drying of grape marc and its derivatives, have been outlined [48]:

- 1.

- For grape marc—convective drying with hot air or drying using infrared heating. Drying at temperatures of up to 60 °C allows for the preservation of phenolic components, while drying at 90 °C has also a pasteurising effect, inactivating a considerable proportion of yeasts, moulds and vegetative forms of bacteria [49].

- 2.

- For grape seeds—convective drying with hot air. Higher drying temperatures shorten the drying time but reduce the oxidant stability of the resulting grape seed oil. The recommended temperature of the drying agent is usually in the range of 30 to 60 °C [31,50].

- 3.

- For grape skins—freeze-drying combined with convective drying [45,51].

In freeze-drying the wet material is pre-frozen [52,53,54]. Then, it is heated under vacuum, whereby the water sublimates. For instance, the skins are frozen at −78 °C for 12 h, and sublimation in the next step occurs at a pressure of 2.4 Pa for 24 h [55]. This process, carried out at lower temperatures, enables the antioxidant activity of the phenols, flavonoids and anthocyanins in the product to be largely preserved. However, freeze-drying is an expensive process and therefore it is mostly applied in laboratory practice.

Solar drying is a variety of convective drying. For pre-treatment of wet grape marc and their by-products, solar dryers and open sun drying are also applied [45,48,56,57].

Bio-drying is a relatively new aerobic treatment of biodegradable materials in which the activity of aerobic microorganisms leads to an increase in temperature and resulting evaporation of a part of the water. The processing unit represents a parallelepiped container with a perforated bottom through which atmospheric air is inlet using a fan. After loading the container with wet grape marc, the air supply is started, thereby promoting an increase in microbiological activity and the release of heat and moisture. Italian researchers [23,24] demonstrated the feasibility of using bio-drying for dewatering grape marc and to obtain solid recovered fuel. The latter is stable for storage with minimal risk of microbial self-heating.

3.2. Dryers for Grape Marc

The following exposition addresses convection dryers that are of the greatest interest in an industrial context.

3.2.1. Batch Tray Dryers

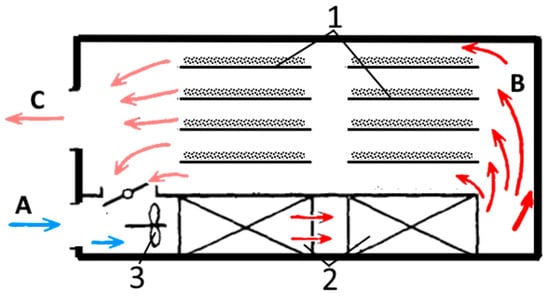

Design [52,54,58]: The dryer is a camera into which trays 1 filled with the wet material are loaded (Figure 2). Atmospheric air A is drawn in by means of a fan 3, heated by means of a calorifier 2, and the hot drying agent B passes over the trays of wet material and absorbs moisture.

Figure 2.

Tray dryer: 1—trays with wet material; 2—calorifier for air heating; 3—fan. Flows: A—fresh air; B—hot air—drying agent; C—exhaust wet air. Adapted from [59].

Action: The dryer has intermittent operation. The wet material is loaded onto the trays 1 and the latter are stacked in the chamber. The fresh atmospheric air A is supplied by a fan 3 and heated by means of the calorifier 2, producing a drying agent—hot air. The latter blows the moist material into the trays, absorbing the moisture from the material. The moisture is released by the exhaust wet air C. The drying process can be controlled by temperature, drying agent speed, drying agent recirculation rate and drying time.

Applicability: This type of dryer is versatile, mass-produced, relatively inexpensive and suitable for processing small volumes of various food products, including grape marc. The typical production capacity of these dryers is 50 to 500 kg of wet material dried per working cycle [60,61]. Convective drying of seeds in a chamber dryer is recommended to be carried out at a temperature of 30–60 °C, a loading rate of 1 kg/m2 and a drying-agent speed of 1 m/s [31]. There are also chamber dryers, in which warm air is heated by the sun. The disadvantages are the high labour costs and low productivity.

3.2.2. Conveyor Dryers

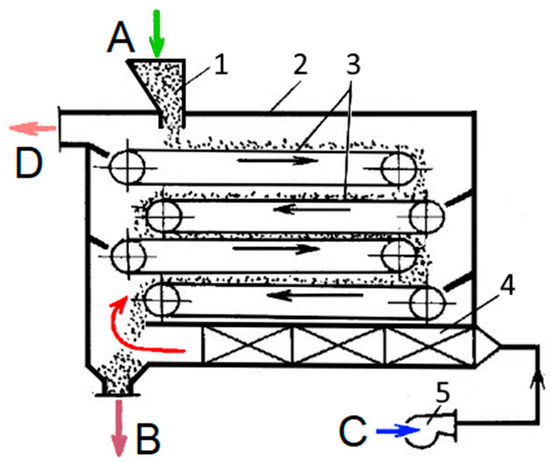

Design [52,53,58]: In the housing 2 of the dryer, several belt conveyors 3, a feeder 1, a calorifier 4 and a fan 5 are mounted (Figure 3).

Figure 3.

Conveyor dryer: 1—feeder; 2—drying chamber housing; 3—belt conveyors; 4—air heating calorifier; 5—fan. Flows: A—wet material; B—dried material; C—fresh air; D—exhaust wet air. Adapted from [62].

The action of the dryer is continuous. By means of the feeder 1, the wet material A is spread on the upper conveyor belt 3. The wet material is further transferred to the lower conveyor belt moving in the opposite direction. Thus, the material is moved downwards, being dried by the drying agent moving upwards. The dried material B is discharged from the lower part of the dryer. The fresh atmospheric air C supplied by the fan 5 is heated by means of the calorifier 4, and the resulting hot drying agent moves upwards in counter-current to the wet material. The moisture absorbed by the spent drying agent is discharged through the upper outlet D.

Applicability: This type of dryer is widely used in practice for processing various agricultural products, but they are generally specialised for a certain type of wet material. The smaller dryers have a capacity of 2 to 12 t/h of wet material, while the larger dryers can operate at capacities of up to 250 t/h. This type of dryer is designed to process bulk fine-grained, powdery materials and those with medium-sized shredded pieces, including grape marc.

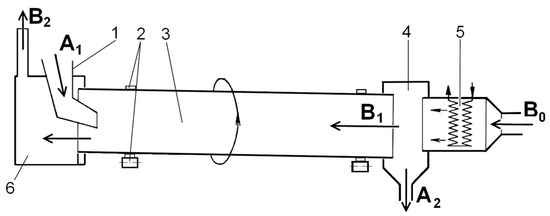

3.2.3. Rotary Drum Dryers

Design [52,53]: The dryer includes a slow-running drum 3 having band wheels 2 for rotation on support rollers (Figure 4). Various guiding internal blades can be mounted in the drum. In its left part, there is a feed chute 1 for the wet material A1 and a chamber 6 for the outlet of the spent drying agent B2. In the right part of the drying chamber, there is a calorifier 5 for heating the drying agent B1 and a chamber 4 for the outlet of the dried material A2.

Figure 4.

Rotary drum dryer: 1—feed chute; 2—band wheel and rollers; 3—drum; 4—chamber for the separation of dried material; 5—calorifier; 6—chamber for separation of entrained material. Flows: A1 and A2—wet and dried material; B0—atmospheric air; B1 and B2—fresh and spent drying agent. Adapted from [63].

Action: This dryer is continuous. The design in Figure 4 has counter-current flow of the wet material and the drying agent. The wet material A1 is fed through the chute 1 and falls into the rotating drum 3, where it is loosened by the rotating guiding internal blades. The dried material A2 is discharged from the bottom of the settling chamber 4. Atmospheric air B0 supplied by a fan (not shown in the figure) is heated in the calorifier 5. The resulting drying agent B1 is fed into the drum 3, moving in counter-current to the wet material. The spent drying agent B2, which has absorbed the moisture, is discharged through chamber 6. At the bottom of the latter, the dust released from the dried material settles. Dryers with a co-current flow of the wet material and the drying agent are also used. The latter are preferred when drying thermolabile materials, as the hot drying agent contacts the wet material, thereby preventing overheating.

Applicability: These dryers are also widely used for drying various small- or medium-grained bulk agro-products including grape marc. The American company FEECO International offers dryers having a capacity of 1 to 200 t/h of dried material as the drum diameter is in the range of 1 to 4.6 m. The Indian company Gem Drytech Systems produces dryers having smaller throughputs of 50 to 1000 kg/h. However, the parameters of each design are developed for a particular type of wet material. An additional advantage is providing a homogeneous product with uniform moisture content throughout its volume. The disadvantages of these dryers are their larger size, because of the low degree (15–20%) to which the drum is filled with the wet product, greater mass of equipment and higher investment costs, as well as noise and dust emissions.

3.2.4. Infrared Dryers

The design [52,53,54,58] includes a drying chamber 1 with infrared emitters 2 (Figure 5). This type of dryer is a convective one assisted by infrared heating. The drying agent B can be heated in an external calorifier and fed in the chamber by a fan.

Figure 5.

Infrared dryer: 1—drying chamber; 2—infrared emitter. Flows: A—moist material; B—hot drying agent; C—exhausted drying agent.

Action: The dryer has an intermittent operation. The wet material A put in the chamber 1 is blown with hot drying agent B and simultaneously heated by infrared emitters 2. There are dryer designs where the wet material is moved by means of a belt conveyor. The latter ensures greater dryer productivity.

Applicability: They are relatively newer dryers. The use of infrared emitters enables rapid heating and the shortening of drying time (up to 48% according to [15]), achieving uniformity and higher quality of the dried material [64]. Studies have been reported on the use of infrared heated drying [65], as well as in combination with convective drying [49], for drying grape marc. In these cases, emitters in the far infrared range (wavelength 30–1000 μm) are used. These infrared rays penetrate almost the entire volume of the wet material.

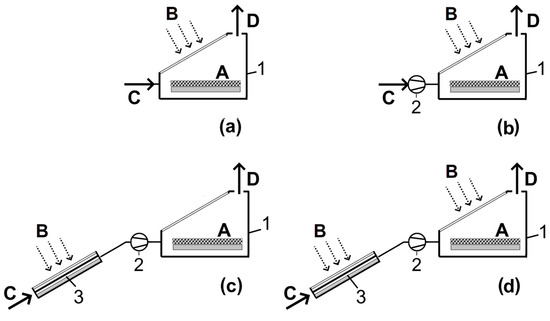

3.2.5. Solar Dryers

The design [52,53] comprises a drying chamber 1, which is usually of the cabinet type (Figure 6). Most often, it is covered with transparent polyethylene film. This drying chamber is convective, where the heated air is used as a drying agent. There are two types of dryers: with natural circulation of the drying agent (Figure 6a) and with forced circulation by means of a fan 2 (Figure 6b–d). According to the heating of the drying agent, the dryers are as follows: (a) with direct heating of the air in the drying chamber 1 (Figure 6a,b); (b) with indirect heating of the drying agent in the air solar collector 3 (Figure 6c); (c) with combined heating by means of the air solar collector 3 and in the chamber 1 (Figure 6d).

Figure 6.

Schematics of solar dryers with (a) direct heating and natural circulation; (b) direct heating and forced circulation; (c) indirect heating and forced circulation; (d) combined heating and forced circulation; 1—drying chamber; 2—fan; 3—air solar collector. Flows: A—wet product; B—solar radiation; C—fresh ambient air; D—exhaust humid air.

Action: The dryer has an intermittent operation. The wet material A is loaded onto trays located in the chamber 1. Atmospheric air C, after heating in an air solar collector 3, flows into the drying chamber 1 and heats the wet product A, and the moisture is removed with the exhaust air D (Figure 6c,d). Atmospheric air C can be heated in the semi-closed chamber 1 itself (Figure 6a,b). In the dryer of Figure 6d, the air is heated both in an air solar collector 3 and in the chamber 1 itself. The forced circulation (Figure 6b–d) created by means of a fan 2 makes it possible to shorten the drying time.

Applicability: This type of convection dryer is also widely used for drying various agricultural products, including wet grape marc, and their derivatives. Their investment and operating costs are the lowest, but the drying time is the longest as compared with other types of convection dryers. Turkish researches [56] found that the duration of drying grape marc to a moisture content of 11% in a solar dryer with forced circulation and combined heating was 78.5 h. The dried product had a water activity of 0.44; the phenolic components were largely preserved, and microbiological contamination was reduced. Solar drying under the open sun took 147.05 h, or 1.9 times longer.

4. Equipment for Grape Marc Separation

4.1. Flat Screen Separators with Horizontal Reciprocate Motion

Such separators are the most widely used for cleaning and calibrating bulk food raw materials and products (most commonly grains). In particular, a review by Romanian researchers presented promising separators of grape seed [66]. The authors point out that screen separators are most commonly used for grape seed separation in practice.

The design [52,67] of these separators comprises one, two or three sieve frames 1, 2, 3 performing low frequency longitudinal reciprocating motion by means of a modified crank mechanism (Figure 7). One, two or three flat inclined sieves are mounted on each of the frames. The sieves have different aperture sizes, with the upper sieves having larger apertures and the lower sieves having smaller apertures. At the inlet of the separator there is a device for dosing the quantity of bulk material fed and distributing it evenly over the width of the sieves. At the inlet and outlet of the air-screen separators two additional air separators 4, 5 are installed. These include a vertical suction channel, a widened settling chamber and a screw transporter (at the bottom) for the removal of trapped light and powdery organic impurities.

Figure 7.

Separator having inclined flat sieves with longitudinal, reciprocating motion and air separators: 1, 2, 3—frames with flat sieves; 4, 5—air separators. Flows: A—incoming mixture; B—coarse impurities; C—coarse fraction; D—fine fraction; E—cleaned product; F—light impurities. Adapted from [68].

Action: The coarse impurities B and coarse fraction C are removed as an oversize fraction in the upper sieve frames and the fine minerals D as an undersized fraction in the lower sieve frame. The cleaned seeds E are separated as oversize fraction from the lowest sieve frame 3. The light impurities F are discharged from the bottom of the settling chambers 4, 5.

Commercial analogues: The productivity of such cleaners reaches up to 100 t/h and of calibrators for the separation into two fractions up to 6 t/h. For instance, Petkus Technologie (Germany) and ELICA PROcessing (Bulgaria) are two producers of this equipment.

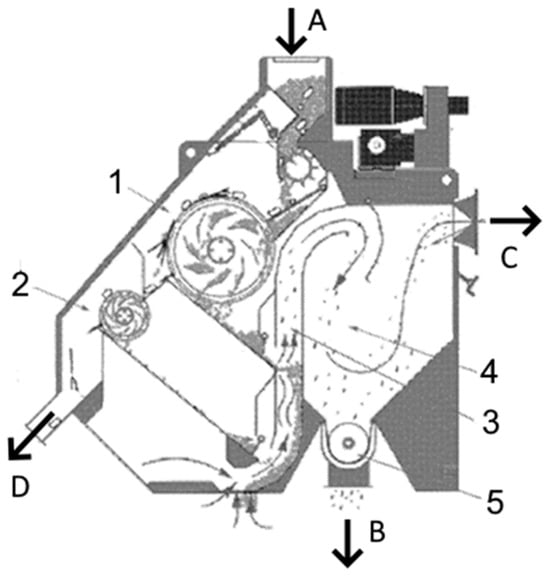

4.2. Drum Screen Separators with Internal Blade Rotor

The design [46,69] consists of a stationary horizontal screen drum 1 with a slight inclination towards the outlet and a rotor 2 with radial blades 3 (Figure 8). The latter are characterized by (a) a slight longitudinal inclination in order to ensure the longitudinal movement of the grape marc being processed and (b) a known transverse inclination making an acute angle to the inner drum surface. In this way, the softer fraction of the skins is blended and its shredded parts pass through the sieve surface.

Figure 8.

Separator with stationary horizontal screen drum and rotor with blades: 1—screen drum; 2—rotor; 3—radial blades. Flows: A—grape marc; B—seeds; C—soft residues.

Action: The incoming wet grape marc A is fed inside the drum 1. The rotating blades 3 crush the marc and the soft part (mainly crumbled skins) is mashed on the surface of the drum 1, and the soft fraction is discharged through the outer surface of the screen drum. This soft fraction C is collected in a receiver below the separator and discharged by a screw conveyor. The harder and bigger grape seeds are transported longitudinally along the inside of the drum and they are taken out through a chute B.

Commercial analogues: The productivity of this separator is up to 300 kg/h processed grape marc, while its specific energy consumption is 48 kJ/kg [46,69]. The Italian company P.C.M. Srl manufactures similar grape seed separators with a capacity of up to 2000 kg/h marc, a specific energy consumption of about 11 kJ/kg and an operating efficiency of 3–5% residual seeds in the soft residue fraction.

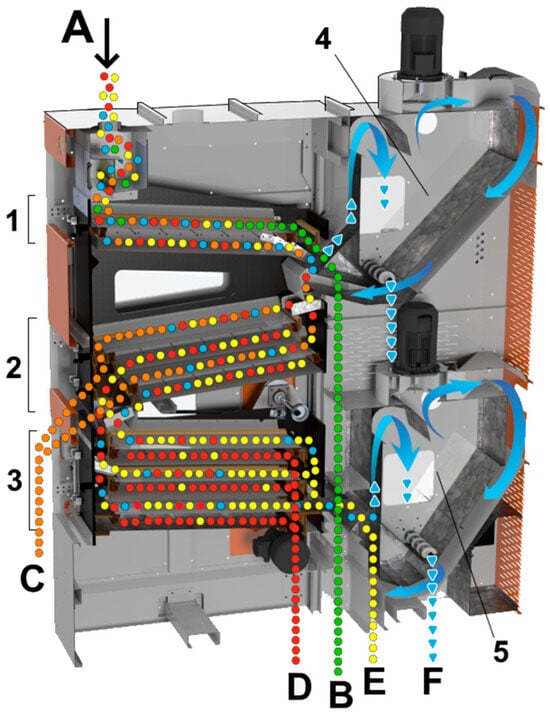

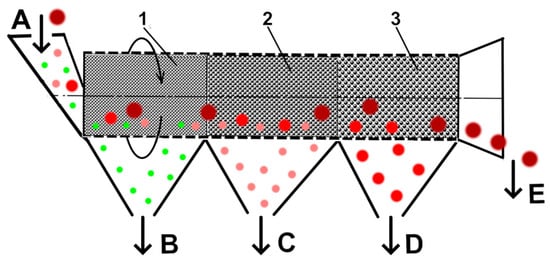

4.3. Air-Screen Separator with Rotary Screen Drums

This separator is part of a patented technology for processing grape pomace waste from fruit juice production [47]. Its purpose is to separate the grape seeds and stems.

The design of this type of separator includes a feeding device with a dosing roller, two horizontal rotating screens 1 and 2, an air separator with a vertical suction channel 3 and a settling chamber 4 (Figure 9).

Figure 9.

Air-screen separator with rotary screen drums: 1, 2—rotating screen drums; 3—vertical suction channel; 4—settling chamber; 5—screw conveyor. Flows: A—grape marc; B—seeds; C—light fraction including parts of skins; D—coarse fraction with grape stems. Adapted from [47].

Action: First, the grape stems are separated from the grape marc A by means of the horizontal rotary screens 1 and 2 as coarse fraction D. The remaining mass is directed into a vertical suction channel 3. The heavier grape seeds B fall to the bottom of a settling chamber 4, from where the seeds are discharged through a screw conveyor 5. The lighter fraction, comprising mainly crumbled skins, is discharged through the opening C. In the patent under consideration [47], an additional air separator is suggested for improving the purification of the grape seed fraction.

Commercial analogues: Some of industrially manufactured separators, recommended in the above-presented patent, are the Vertical Drop Multi-clean Aspirator (VI) MC (USA) and the Cyclo Aspirator (USA). This technical solution aims to process grape marc obtained in the production of grape juice, where the grapes are pressed whole and the stems remain in the residue from the pressing process. In wine production, however, the grape stems are separated first, and then the grape must (wine material) is pressed.

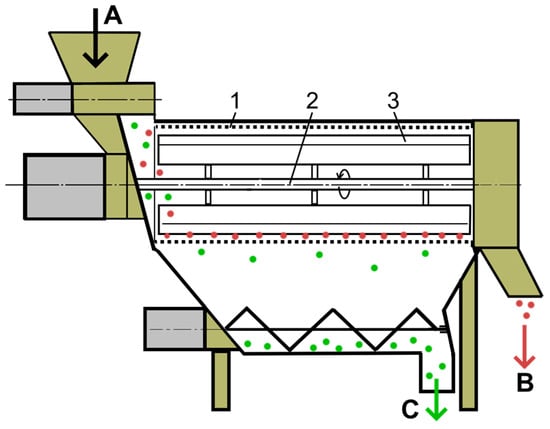

4.4. Rotary Screen Drum Separators

The design [52] includes several coaxial, screen drums 1–3 of the same diameter, with a small 3–5° slope towards the outlet (Figure 10). The drums rotate slowly and together. The inlet (leftmost) drum screen 1 is perforated with the smallest holes and the outlet (rightmost) drum screen 3 has the largest holes. Some constructions are complete with a feeder, a vertical channel for air-separating, and guiding internal blades in drums.

Figure 10.

Separator with rotating screen drums 1–3. Flows: A—inlet mixture; B—fine fraction; C—small fraction; D—medium fraction; E—coarse fraction.

Action: The mixture A for separation is fed into the inside of the inlet (left) drum. As undersized fractions, the finer impurities B are separated from the leftmost drums and the small C and medium D fractions from the next drums. The coarse oversize fraction E is removed at the end of the outgoing drum. This is the grape-seed-enriched fraction. The light organic impurities can be separated by means of an additional air separator.

Commercial analogues: As examples, the separators of the companies Kongskilde (Denmark), Option srl (Italy), CFCAI (France) and Onmak (Turkey) can be pointed out. The capacity of these separators is in the range of 3 to 60 t/h, the drum rotation speed is 5–15 rpm and the drum diameter is 0.6–1.6 m, while the specific energy consumption is about 60 kJ/kg.

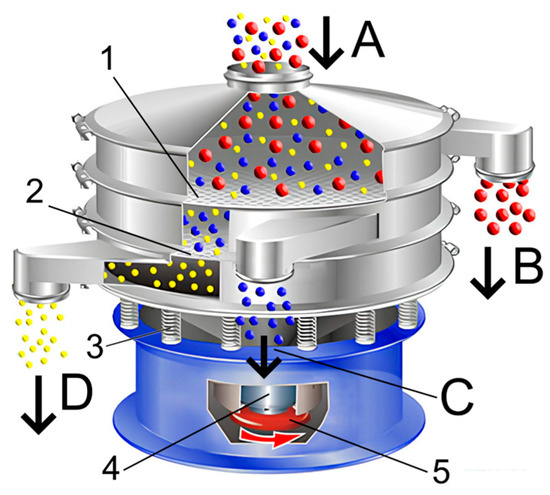

4.5. Separators with Vibrating Round Sieves

The design [52] comprises three trays placed one above the other. Round sieves 1,2 with large and small apertures are fitted under the upper and middle trays (Figure 11). The latter are closed but easily disassembling. There are designs that include more trays to separate the mixture into more fractions. The package of trays is mounted to the machine body by spiral damping springs 3. The package of trays is driven in vibratory motion by means of an electric motor 4 and counterweights 5 mounted to the motor shaft. This mechanism generates a circular rotational oscillation in the horizontal plane.

Figure 11.

Separator with vibrating circular sieves: 1, 2—circular sieves with large and small holes; 3—spiral damping springs; 4—electric motor; 5—counterweights. Flows: A—input mixture; B, C and D—coarse, medium and fine fractions. Adapted from [66].

Action: The mixture to separate is fed through the upper inlet A and falls into the upper tray. Under the action of vibration, the material is spread over the sieve 1, moving in a spiral. The fine fraction passes through the openings of the sieve and the coarse fraction is discharged through chute B. The movement of the bulk material in the other trays is similar, as the medium fraction is discharged through chute C and the fine fraction through chute D.

Commercial analogues: The companies Vibrowest S.r.l. (Italy) and Rotajet system (UK) manufacture equipment for separating up to five fractions, as the diameter of sieves is in the range of 400 to 2200 mm.

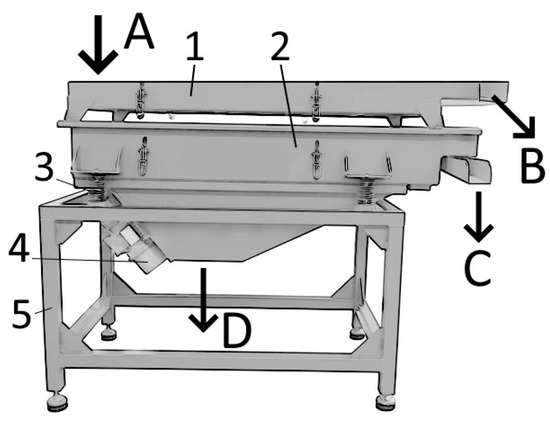

4.6. Flat Screen Separators with Vibration Motion

The design [52] comprises one or two frames 1, 2 with inclined sieves mounted on a machine body 5 by means of spiral damping springs 3, and one or two motor vibrators 4 (Figure 12). The electric motor of the latter runs two unbalancing masses rotating on a common shaft. These vibrogenerators impart a medium-frequency oscillation to the sieves as the direction of these oscillations is at an angle of about 15° to the horizon.

Figure 12.

Separator with vibrating flat screens: 1, 2—frames with flat sieves; 3—spiral damping spring; 4—motor vibrator; 5—machine body. Flows: A—inlet mixture; B, C and D—coarse, medium and fine fractions. Adapted from [70].

Action: The mixture A is fed into the left edge of the upper sieve 1. The particles of this mixture (located on the vibrating sieve 1) are moved in small bounces over the sieve, with the finer fraction passing down through the sieve holes to the lower frame 2. The oversize fraction from sieve 1 is discharged through chute B as a coarse fraction. The undersized fraction is discharged from the frame 2 through the lower chute D as the fine fraction, and the oversize fraction is discharged through the chute C for the medium fraction.

Commercial analogues: The capacity of these separators is in the range of 2 to 120 t/h. Buhler (Switzerland), Kaifeng Hyde Machinery (China) and Onmak (Turkey) are some of the producers of such equipment.

5. Multi-Criteria Equipment Selection

For comparing and assessing the feasibility and efficacy of the considered dryers and separators, a simple multi-criteria decision analysis [71,72,73] was carried out.

The dryers considered in Section 3 were scored and ranked by means of the following criteria/indicators:

- Drying duration.

- Quality of dried product and retention of valuable biological-active components.

- Uniformity in moisture content and size of dried product.

- Investment and operating costs.

The indicators 1 and 4 can be assessed quantitatively, the indicators 2 and 3 qualitatively. They were evaluated by the expert panel of authors, based on the information collected in this survey and their practical experience. Higher effectiveness of the equipment is associated with shorter process duration (indicator 1), higher retention of components (indicator 2), higher moisture uniformity (indicator 3) and lower cost (indicator 4). The indicators were evaluated by normalised score (NS), varying from 0 to 1 (between minimum and maximum effectiveness, respectively). The generalised score (GS) for each equipment type was determined as the sum of its normalised scores, so that the maximum value of GS can reach 4.

For indicator 1, the average drying duration of grape marc, as per the present review, is E1 = 4 h in a tray dryer, E2 = 12 h in a conveyor dryer, E3 = 1.2 h in a rotary drum dryer, E4 = 0.6 h in an infrared dryer, E5 = 80 h in a solar dryer, and E6 = 36 h in a freeze-dryer. From the data for Ei (i = 1 to 6), the normalised score NS1 was calculated as follows:

where Emax and Emin are the maximum and minimum values among Ei (i = 1 to 6).

NS1 = (Emax − Ei)/(Emax − Emin)

The normalised scores for each indicator NSj (j = 1 to 4), along with the generalised score GS for each dryer type, are shown in Table 1.

Table 1.

Comparing the considered dryers.

For indicator 4, the relative investment and operating costs for each type of drying equipment were evaluated, and NS4 was then calculated analogously to Equation (1). For indicators 2 and 3, the effectiveness level was assessed qualitatively by the expert panel and normalised scores were assigned by using the guidance in Table 2.

Table 2.

Guidance for assigning normalised scores depending on the effectiveness or functional ability of equipment.

The equipment compared in Table 1 includes dryers presented in Section 3.2 and freeze-dryers (which are mainly of interest to laboratory investigations).

The rotary drum dryer has the highest generalised score GS of 3.19. Thus, it may be assumed to be the most convenient industrial dryer for grape marc. Simultaneously, the solar dryer appears to be the most resource-saving and environmentally friendly solution for pre-treatment of grape marc and its by-products.

The following criteria/indicators were chosen for comparing the separators presented in Section 4:

- Ability for direct processing of wet grape marc and expeditious derivation of valuable by-products.

- Efficiency of separation and obtaining by-products with higher purity.

- Ability to perform several operations.

- Reduced organic dust release during processing.

Indicator 2, for effectiveness, and indicators 1, 3 and 4, for functionality, were also evaluated by using the guidance from Table 2. The normalised scores for each of the four indicators NSj (j = 1 to 4) and the generalised score GS for each separator type are presented in Table 3.

Table 3.

Comparing the considered separators.

As regards criterion 1, only the separators of types 2 and 3 are designed for processing wet grape marc. Concerning criterion 2, the separator of type 2 ensures an accurate separation of the seeds from the skins by puréeing the soft matter of the marc. As for criterion 3, only the separator of type 2 provides an opportunity to combine crushing the grape marc, puréeing the soft skins through the drum screen and separating the grape seeds. The separator of type 3 can segregate three fractions of stems, seeds and skins. For criterion 4, the separators of types 2 and 3 can process wet marc, so that the dust emission is eliminated in practice. In the separator of type 2 with suction channels and settling chambers, the dust emission is minimised.

As shown in Table 3, the drum screen separator with internal blade rotor (type 2) deserved the highest GS of 4, so that this separator turned out to perform best when processing grape marc.

6. Concluding Remarks

Solid waste from the global wine industry, primarily grape marc, poses a significant environmental hazard due to traditional disposal methods, along with the challenge of its valorisation into a range of value-added by-products. Pre-treatment of grape marc, including rapid dewatering and separation, is a crucial stage for obtaining storage-stable transitional by-products and for further production of final value-added commodities. The present article reviewed critically the potential equipment for drying and separation of wet grape marc. A multi-criteria analysis of this equipment revealed that the rotary drum dryer and the drum screen separator with internal blade rotor turned out to be the most convenient equipment for pre-treatment of grape marc. On the other hand, the solar dryer appears to be the most resource-saving and environmentally friendly solution. The flowsheet that involves an initial separation followed by drying of the two fractions obtained is rather attractive for industrial practice. Based on the above findings, an improved separator was patented [74].

Valorised by-products from grape marc significantly contribute to global sustainability and to adequately meeting several of the Sustainable Development Goals (SDGs) of the United Nations [75]. For instance, SDG 12 ‘Responsible Consumption and Production’ is directly supported by utilising a significant waste stream of grape marc for a range of value-added by-products [76]. The production of biofuels (as bioethanol, biogas, solid recovered fuels) from grape marc contributes to SDG 13 ‘Climate Action’ by reducing dependence on fossil fuels and lowering greenhouse gas emissions [27]. A promising path for carbon sequestration is the transformation of grape marc into biochar by pyrolysis [76] and hydrochar by hydrothermal carbonisation [15,28]. Soil amendment employing grape marc for composting and vermicomposting [21,22,76] contributes to SDG 15 ‘Life on Land’ by improving soil health and reducing the need for synthetic fertilizers. SDG 3 ‘Good Health and Well-being’ is supported by providing a range of biologically active components and ingredients derived from grape marc (such as polyphenols, antioxidants, dietary fibres, grape seed oil, organic acids, pectin, etc.) to be included in diverse functional foods [1,2,5,9], alongside nutraceuticals, cosmetics [9,12,33,37,38] and pharmaceuticals [2,9,39] having various health benefits [76]. Last but not least, SDG 2 ‘Zero Hunger’ is supported by including grape marc and its by-products as sustainable and cost-effective sources for animal feed [9,21,77] and as a fertilizer for improving crop yields [76].

Although challenges such as the variable composition and high moisture content of grape waste persist, ongoing research and technological advancements are yielding increasingly efficient methods of utilising this resource. Supportive policies and growing consumer demand for sustainable products are paving the way for wider adoption of grape marc valorisation. This establishes grape marc as a vital component of a sustainable future for the wine industry, as well as a valuable contributor to broader global sustainability efforts.

Author Contributions

Conceptualisation, S.A. and K.F.; methodology, S.A.; formal analysis, S.A.; investigation, S.A. and K.F.; resources, G.G. and A.T.; data curation, S.A., K.F. and G.G.; writing—original draft preparation, S.A.; writing—review and editing, S.A. and K.F.; visualisation, S.A.; supervision, K.F. and A.T.; project administration, G.G. and A.T.; funding acquisition, G.G. and A.T. All authors have read and agreed to the published version of the manuscript.

Funding

The co-authors S. Akterian and G. Georgiev are funded by the Project № BG16RFPR001-1.001-0064 “Developing waste-free technologies and equipment, implemented as a mechatronic unit to improve environmental friendliness, efficiency and the assortment of production” under Priority Axis 1 “Strengthening the economic and social impact of research and innovation” in the framework of the Bulgarian Operational Programme “Innovation and Competitiveness” 2021–2027. The participation of the co-authors K. Fikiin and A. Terziev in this study is financed by the European Union—NextGenerationEU—through the National Recovery and Resilience Plan of the Republic of Bulgaria, Project No. BG-RRP-2.004-0005.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

This study presents and analyses the existing state of the art in the field, so that no additional data is available from the authors.

Acknowledgments

While the authors occasionally used Google Gemini AI to find sources of information, they are entirely responsible for the content of this publication.

Conflicts of Interest

The co-author Georgi Georgiev is employed by the company Ecobiotechproduct, which holds a patent in the concerned field. The remaining co-authors declare that the present survey was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Frîncu, M.; Teodorescu, R.I.; Bărbulescu DITudor, V.; Dumitrache, C.; Hîrjoabă, L.N.; Matei, F. The grape marc as potential source of biologically active compounds. Sci. Pap. Ser. B Hortic. 2019, 2, 103–107. [Google Scholar]

- Lourenço, S.; Alves, A.; Mateus, N.; de Freitas, V.; Bronze, M.R. Valorization of wine industry by-products: Characterization of phenolic profile and investigation of potential healthy properties. BIO Web Conf. 2023, 74, 04016. [Google Scholar] [CrossRef]

- INRAE; CIRAD; AFZ. Grape Pomace, Dried. Tables of Composition and Nutritional Values of Feed Materials. Available online: https://www.feedtables.com/content/grape-pomace-dried/ (accessed on 12 May 2025).

- Australian Wine Research Institute (AWRI). Technical Review Issue 213: Winery Wastewater Management. Available online: https://www.awri.com.au/files/attachment/technical_review_issue_213_hixson/ (accessed on 12 May 2025).

- Liu, Z.; de Souza, T.S.P.; Wu, H.; Holland, B.; Dunshea, F.R.; Barrow, C.J.; Suleria, H.A.R. Development of phenolic-rich functional foods by lactic fermentation of grape marc: A review. Food Rev. Int. 2024, 40, 1756–1775. [Google Scholar] [CrossRef]

- Negro, C.; Tommasi, L.; Miceli, A. Phenolic compounds and antioxidant activity from red grape marc extract. Bioresour. Technol. 2003, 87, 41–44. [Google Scholar] [CrossRef]

- Carmona-Jiménez, Y.; Igartuburu, J.M.; Guillén-Sánchez, D.A.; García-Moreno, M.V. Fatty acid and tocopherol composition of pomace and seed oil from five grape varieties southern Spain. Molecules 2022, 27, 6980. [Google Scholar] [CrossRef]

- Garavaglia, J.; Markoski, M.M.; Oliveira, A.; Marcadenti, A. Grape seed oil compounds: Biological and chemical actions for health. Nutr. Metab. Insights 2016, 9, 59–64. [Google Scholar] [CrossRef]

- Bordiga, M.; Travaglia, F.; Locatelli, M. Valorisation of grape pomace: An approach that is increasingly reaching its maturity—A review. Int. J. Food Sci. Technol. 2019, 54, 933–942. [Google Scholar] [CrossRef]

- MasterClass. What Are the Benefits of Cooking with Grapeseed Oil? Available online: https://www.masterclass.com/articles/what-is-grapeseed-oil-learn-how-to-cook-with-oil-made-from-grape-seeds (accessed on 12 May 2025).

- Hegedüs, I.; Andreidesz, K.; Szentpéteri, J.L.; Kaleta, Z.; Szabó, L.; Szigeti, K.; Gulyás, B.; Padmanabhan, P.; Budan, F.; Máthé, D. The utilization of physiologically active molecular components of grape seeds and grape marc. Int. J. Mol. Sci. 2022, 23, 11165. [Google Scholar] [CrossRef]

- BTL Liners. How Winemaking Affects the Environment. Available online: https://www.btlliners.com/how-winemaking-affects-the-environment (accessed on 12 May 2025).

- Gabur, G.D.; Teodosiu, C.; Fighir, D.; Cotea, V.V.; Gabur, I. From waste to value in circular economy: Valorizing grape pomace waste through vermicomposting. Agriculture 2024, 14, 1529. [Google Scholar] [CrossRef]

- Olson, L. Winemakers Are Reimagining Grape Waste as a Resource|SevenFifty Daily. Available online: https://daily.sevenfifty.com/winemakers-are-reimagining-grape-waste-as-a-resource/ (accessed on 12 May 2025).

- Tsapekos, P.; Koufos, K.; Gentili, F.; Katsoulas, N.; Bartocci, P.; Fava, G.; Malamis, S.; Vecchiocattivi, L.; Moneti, F.; Nikolau, G.; et al. An Overview on management and valorisation of winery wastes. Sustainability 2023, 13, 5063. [Google Scholar] [CrossRef]

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste (OJ L 312, 22.11.2008, pp. 3–30). Available online: https://eur-lex.europa.eu/eli/dir/2008/98/2018-07-05 (accessed on 29 May 2025).

- Seaside Sustainability. Wineries: Improving Sustainability Through Legislation. Available online: https://www.seasidesustainability.org/post/wineries-improving-sustainability-through-legislation (accessed on 12 May 2025).

- Environment Protection Authority South Australia (EPA). A Guide to Pollution Control for Wineries. Available online: https://www.epa.sa.gov.au/files/4771373_guide_wineries.pdf (accessed on 12 May 2025).

- Envirolink. Review of Guidelines for the Management of Winery Wastewater and Grape Marc. Available online: https://envirolink.govt.nz/assets/Envirolink/Reports/1042-MLDC68.pdf (accessed on 3 May 2025).

- CORDIS. Reducing Winery Pollution|SUSTAVINO Project|Results in Brief|FP7|CORDIS|European Commission. Available online: https://cordis.europa.eu/article/id/92397-reducing-winery-pollution (accessed on 12 May 2025).

- International Organisation of Vine and Wine. Managing by-Products of Vitivinicultural Origin. Available online: https://www.oiv.int/public/medias/6267/managing-viticulture-by-products-web.pdf (accessed on 15 May 2025).

- Gómez-Brandón, M.; Lores, M.; Insam, H.; Domínguez, J. Strategies for recycling and valorization of grape marc. Crit. Rev. Biotechnol. 2019, 39, 437–450. [Google Scholar] [CrossRef] [PubMed]

- Rada, E.C.; Ragazzi, M.; Fiori, L.; Antolini, D. Bio-drying of Grape marc and other biomass: A comparison. Water Sci. Technol. 2009, 60, 1065–1070. [Google Scholar] [CrossRef] [PubMed]

- Rada, E.C.; Ragazzi, M. Potential of bio-drying applied to exhausted grape marc. Wine Stud. 2022, 1, 3–6. [Google Scholar] [CrossRef]

- Mäkelä, M.; Kwong, C.W.; Broström, M.; Yoshikawa, K. Hydrothermal treatment of grape marc for solid fuel applications. Energy Convers. Manag. 2017, 145, 371–377. [Google Scholar] [CrossRef]

- Nanni, A.; Parisi, M.; Colonna, M. Wine by-products as raw materials for the production of biopolymers and of natural reinforcing fillers: A critical review. Polymers 2021, 13, 381. [Google Scholar] [CrossRef]

- Oliveira, M.; Teixeira, B.M.M.; Toste, R.; Borges, A.D.S. Transforming wine by-products into energy: Evaluating grape pomace and distillation stillage for biomass pellet production. Appl. Sci. 2024, 14, 7313. [Google Scholar] [CrossRef]

- Basso, D.; Patuzzi, F.; Baratieri, M.; Fiori, L. In deep analysis on the behavior of grape marc constituents during hydrothermal carbonization. Energies 2018, 11, 1379. [Google Scholar] [CrossRef]

- Casazza, A.A.; Aliakbarian, B.; Lagazzo, A.; Garbarino, G.; Carnasciali, M.M.; Perego, P.; Busca, G. Pyrolysis of grape marc before and after the recovery of polyphenol fraction. Fuel Process. Technol. 2016, 153, 121–128. [Google Scholar] [CrossRef]

- Karastergiou, A.; Gancel, L.; Jourdes, M.; Teissedre, L. Valorization of grape pomace: A review of phenolic composition, bioactivity, and therapeutic potential. Antioxidants 2024, 13, 1131. [Google Scholar] [CrossRef]

- Sridhar, K.; Charles, A.L. Mathematical modeling and effect of drying temperature on physicochemical properties of new commercial grape “Kyoho” seeds. J. Food Process Eng. 2020, 43, e13203. [Google Scholar] [CrossRef]

- Wang, C.; You, Y.; Huang, W.; Zhan, J. The high-value and sustainable utilization of grape pomace: A review. Food Chem. X 2024, 24, 101845. [Google Scholar] [CrossRef] [PubMed]

- Tourangelle, L. Grapeseed Oil: Uses and Health Benefits. Available online: https://latourangelle.com/blogs/general/grapeseed-oil-uses-and-health-benefits (accessed on 12 May 2025).

- Gunnars, K. Grapeseed Oil—Is It a Healthy Cooking Oil? Available online: https://www.healthline.com/nutrition/grape-seed-oil (accessed on 12 May 2025).

- CABI Digital Library. Grape Marc as a Source of Carbohydrates for Bioethanol: Chemical Composition, Pre-Treatment and Saccharification. Available online: https://www.cabidigitallibrary.org/doi/full/10.5555/20153301593#core-collateral-purchase-access (accessed on 12 May 2025).

- Sciencedaily. Grape Waste Could Make Competitive Biofuel. Available online: https://www.adelaide.edu.au/news/news80162.html (accessed on 15 May 2025).

- Tsiapali, O.I.; Ayfantopoulou, E.; Tzourouni, A.; Ofrydopoulou, A.; Letsiou, S.; Tsoupras, A. Unveiling the utilization of grape and winery by-products in cosmetics with health promoting properties. Appl. Sci. 2025, 15, 1007. [Google Scholar] [CrossRef]

- BTLLiners. Beneficial Uses of Winery Waste. Available online: https://www.btlliners.com/beneficial-uses-of-winery-waste (accessed on 12 May 2025).

- Ferrer-Gallego, R.; Silva, P. The Wine industry by-products: Applications for food industry and health benefits. Antioxidants 2022, 11, 2025. [Google Scholar] [CrossRef] [PubMed]

- Piryaei, M.; Azimi, S. Preparation and evaluation of smart food packaging films with anthocyanin Sardasht black grape based on Astragalus gummifer and chitosan nanoparticles. Int. J. Biol. Macromol. 2024, 254, 27974. [Google Scholar] [CrossRef]

- Mahato, R.P.; Kumar, S. A review of pullulan nanopolymer derived from agro-food waste and its applications. Iran. Polym. J. 2024, 33, 1493–1526. [Google Scholar] [CrossRef]

- Telini, B.d.P.; Villa, L.C.; Vainstein, M.H.; Lopes, F.C. From vineyard to brewery: A review of grape pomace characterization and its potential use to produce low-alcohol beverages. Fermentation 2025, 11, 57. [Google Scholar] [CrossRef]

- Sant’Anna, V.; Englert, A.H.; Corrêa, A.P.F.; Brandelli, A.; Ferreira Marczak, L.D.; Tessaro, I.C. Grape Marc Powder: Physicochemical and Microbiological Stability During Storage and Moisture Sorption Isotherm. Food Bioprocess Technol. 2014, 7, 2500–2506. [Google Scholar] [CrossRef]

- Jones, J.; McLaren, S.; Chen, Q.; Seraj, M. Repurposing Grape Marc; Research Report to Marlborough District Council: Blenheim, New Zealand, 2020; Available online: https://mro.massey.ac.nz/items/ebd9cb3f-f6a7-4f0b-a721-878f36fd1746 (accessed on 12 May 2025).

- Sokač, T.; Gunjević, V.; Pušek, A.; Tušek, A.J.; Dujmić, F.; Brnčić, M.; Ganić, K.K.; Jakovljević, T.; Uher, D.; Mitrić, G.; et al. Comparison of drying methods and their effect on the stability of Graševina grape pomace biologically active compounds. Foods 2022, 11, 112. [Google Scholar] [CrossRef]

- Romaniello, R.; Tamborrino, A.; Leone, A. Development of a centrifugal separator for grape marc: Effect of the blade position and rotor speed on grape seed separation performance. Heliyon 2019, 5, e01314. [Google Scholar] [CrossRef]

- May, G.; Greenberg, S. Processing Pomace from Grape Crush to Harvest Grape Seeds. U.S. Patent US20230025086A1, 26 January 2023. [Google Scholar]

- Wang, J.; Mujumdar, A.S.; Mu, W.; Feng, J.; Zhang, X.; Zhang, Q.; Fang, X.-M.; Gao, Z.-J.; Xiao, H.-W. Grape drying: Current status and future trends. In Grape and Wine Biotechnology; InTechOpen: London, UK, 2016. [Google Scholar]

- Sui, Y.; Yang, J.; Ye, Q.; Li, H.; Wang, H. Infrared, convective, and sequential infrared and convective drying of wine grape pomace. Dry. Technol. 2014, 32, 686–694. [Google Scholar] [CrossRef]

- Ergović-Ravančić, M.; Obradović, V.; Mesić, J.; Svitlica, B.; Marčetić, H.; Prtenjačak; Škrabal, S. The influence of grape seed drying temperature on the quality of grape seed oil. J. Process. Energy Agric. 2020, 24, 22–25. [Google Scholar] [CrossRef]

- Suescun–Ospina, S.T.; Ávila–Stagno, J.; Vera-Aguilera, N.; Astudillo-Neira, R.; Trujillo-Mayol, I.; Alarcón-Enos, J. Effects of drying method on bioactive compounds contents, rumen fermentation parameters and in vitro methane output of waste dried país grape (Vitis vinifera L.) marc. Food Biosci. 2023, 51, 102154. [Google Scholar] [CrossRef]

- Saravacos, G.D.; Kostaropoulos, A.E. Handbook of Food Processing Equipment; Springer Science+Business Media: New York, NY, USA, 2002. [Google Scholar]

- Mujumdar, A.S. Handbook of Industrial Drying, 4th ed.; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Heldman, D.R.; Lund, D.B.; Sabliov, S.M. Handbook of Food Engineering, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- De Torres, C.; Schumacher, R.; Alañón, M.E.; Pérez-Coello, M.S.; Díaz-Maroto, M.C. Freeze-dried grape skins by-products to enhance the quality of white wines from neutral grape varieties. Food Res. Int. 2015, 69, 97–105. [Google Scholar] [CrossRef]

- Taşeri, L.; Gülcü, M.; Aktaş, T. Comparison of grape pomace drying using a solar dryer and under open sun conditions. Vitic. Stud. 2023, 3, 31–40. [Google Scholar] [CrossRef]

- Srinivasan, G.; Rabha, D.K.; Muthukumar, P. A Review on solar dryers integrated with thermal energy storage units for drying agricultural and food products. Sol. Energy 2021, 229, 22–38. [Google Scholar] [CrossRef]

- Zhang, M.; Bhandari, B.; Fang, Z. Handbook of Drying of Vegetables and Vegetable Products; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- cf.ppt-online.org. Tray Dryer. Available online: https://cf.ppt-online.org/files/slide/s/sWQv31Y9JINFBw4GzUOEPZSb26KjmecACduLDo/slide-88.jpg (accessed on 12 May 2025).

- Larrauri, J.A.; Rupérez, P.; Saura-Calixto, F. Effect of drying temperature on the stability of polyphenols and antioxidant activity of red grape pomace peels. J. Agric. Food Chem. 1997, 45, 1390–1393. [Google Scholar] [CrossRef]

- Goula, A.; Thymiatis, K.; Kaderides, K. Valorization of grape pomace: Drying behavior and ultrasound extraction of phenolics. Food Bioprod. Process. 2016, 100, 132–144. [Google Scholar] [CrossRef]

- cf.ppt-online.org. Belt Dryer. Available online: https://cf.ppt-online.org/files/slide/s/sWQv31Y9JINFBw4GzUOEPZSb26KjmecACduLDo/slide-92.jpg (accessed on 12 May 2025).

- Akterian, S. Technological Equipment for the Production of Vegetable Oils; Academic Publishing of UHT: Plovdiv, Bulgaria, 2017. (In Bulgarian) [Google Scholar]

- Sabbaghi, H.; Nguyen, P.N. Infrared Drying in Food Technology: Principles and Practical Insights. In Drying Technologies in Food Science; IntechOpen: London, UK, 2025. [Google Scholar] [CrossRef]

- Celma, A.R.; López-Rodríguez, F.; Blázquez, F.C. Experimental modelling of infrared drying of industrial grape by-products. Food Bioprod. Process. 2009, 87, 247–253. [Google Scholar] [CrossRef]

- Milea, D.; Vişan, A.; Păun, A.; Bogdanof, C.; Stroescu, G. Performant equipment designed for grape marc seeds separation and calibration for superior capitalization in food and phytopharmaceutical industry. Ann. Fac. Eng. Hunedoara Int. J. Eng. 2019, 17, 185–192. [Google Scholar]

- Akterian, S. Machines for Mechanical and Hydraulic Processing; Academic Publishing of UHT: Plovdiv, Bulgaria, 2010. (In Bulgarian) [Google Scholar]

- ELICA PROcessing Co. Cleaners. Available online: https://elica-pro.com/wp-content/uploads/2021/08/ENG_WEB_10_23_CLEANERS.pdf (accessed on 12 May 2025).

- Tamborrinoa, A.; Romaniellob, P.; Leone, A. Use of a centrifugal separator to separate grape seeds from marc: Mechanical settings and thermographic evaluations. Chem. Eng. Trans. 2019, 75, 19–24. [Google Scholar] [CrossRef]

- Onmak Co. Vibrating Sieve Separator. Available online: www.onmak.com.tr (accessed on 12 May 2023).

- Ishizaka, A.; Nemery, P. Multi-Criteria Decision Analysis: Methods and Software; John Wiley & Sons: West Sussex, UK, 2013. [Google Scholar]

- Triantaphyllou, E. Multi-Criteria Decision Making Methods: A Comparative Study; Springer Science+Business Media: Dordrecht, The Netherlands, 2000. [Google Scholar]

- Kulkarni, A.J. Multiple Criteria Decision Making. Techniques, Analysis and Applications; Springer Nature: Singapore, 2022. [Google Scholar]

- Georgiev, G. Separator for Fruit and Vegetable Seeds and Method for Separating Fruit and Vegetable Seeds in a Separator. BG/P/2023/113709/31.05.2023. 2024. Available online: https://portal.bpo.bg/bpo-registers/patents/view/BG_P_2023_113709 (accessed on 29 June 2025). (In Bulgarian).

- United Nations. Sustainable Development Goals. Available online: https://www.un.org/sustainabledevelopment/ (accessed on 12 May 2025).

- Caponio, G.R.; Minervini, F.; Tamma, G.; Gambacorta, G.; De Angelis, M. Promising Application of Grape Pomace and Its Agri-Food Valorization: Source of Bioactive Molecules with Beneficial Effects. Sustainability 2023, 15, 9075. [Google Scholar] [CrossRef]

- Tian, X.; Li, D.; Zhao, X.; Xiao, Z.; Sun, J.; Yuan, T.; Wang, Y.; Zuo, X.; Yang, G.; Yu, T. Dietary grape pomace extract supplementation improved meat quality, antioxidant capacity, and immune performance in finishing pigs. Front. Microbiol. 2023, 14, 1116022. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).