Abstract

The mining industry faces increasing pressure to improve efficiency, reduce operational costs, and adapt to modern technological trends. Central to these challenges is digitalization. This paper compares the level of digitalization in the mining industry internationally and in Slovakia, raising the question of the feasibility of implementing digitalization tools in small-scale Slovak mining operations. The presented case study demonstrates the creation of a simulation model and 3D animation for the development of small and medium-sized open pit mines, using Tecnomatix Plant Simulation software version 2302.0004, empirical data collection, and programming with SimTalk 2.0. Internationally, digitalization through modeling and simulation is already at a much higher level, with advanced solutions such as digital twins. In contrast, digitalization in Slovak mining operations is limited to basic simulation approaches, with only a few documented attempts, highlighting substantial opportunities for further development. The simulation model developed in this study enables more efficient planning and management of logistics and transportation processes, with potential benefits for operational improvements, safety, and sustainability. Adopting digitalization, even in small-scale operations, can drive the future development of the Slovak mining industry.

1. Introduction

The primary industry sector faces significant challenges from a logistics perspective, particularly regarding efficiency, costs, and technological trends. These challenges are driving the decline of outdated practices and creating a need for digital transformation, which can enhance operational performance. Inefficiency directly contributes to higher logistics costs, affecting the overall profitability of enterprises [1,2]. Digitalization streamlines business processes, optimizes workflows, reduces operational costs and risks, and improves competitiveness [2,3]. By leveraging advanced data analytics and digital platforms, enterprises can gain insights that improve decision-making and strategic activities within organizations. Furthermore, digitalization is a fundamental pillar supporting innovation and enables enterprises to develop new products and services that meet market demands and, in particular, customer requirements [4,5,6].

Integrating data-based technologies is essential for improving logistics operations; however, many firms lack the managerial strategies needed for effective implementation. The transition to advanced technologies is also associated with rising initial costs. Investment-intensive solutions pose a barrier for many companies. Digitalization is also associated with risks such as job displacement and the ongoing need for technological adaptation. These factors necessitate a balanced approach to digital transformation. Industrial sectors cannot simply adopt new technologies; they must also address the associated socio-economic consequences [1,7].

Modeling, simulation, and various management and monitoring platforms—such as digital twins, real-time analytics, and predictive maintenance tools—are central to the digital transformation of logistics in mining and other industries. These technologies enable the creation of digital representations of physical systems, supporting process optimization, real-time monitoring, and informed decision-making. In Mining 4.0, these technologies provide accurate data on material flows and equipment status, improving planning, inventory management, and risk response. Advanced analytics further help predict failures and minimize downtime. Despite their benefits for operational efficiency and sustainability, challenges like high implementation costs, integration complexity, and the need for skilled personnel continue to limit their full adoption, particularly in dynamic environments [8,9,10,11,12]. It is essential for the mining industry to remain aligned with ongoing trends in digital transformation. This raises the question of the extent to which digital technologies have been implemented in logistics processes within the mining sector, both globally and in Slovakia.

Digitalization in the mining industry is transformative; however, adopting these technologies varies significantly across regions and companies. Numerous factors influence decision-making, including operations’ scale, complexity, and economic conditions. A total of 107 digital technologies have been identified as relevant to the mining sector, with larger operations more likely to implement these technologies than smaller mining enterprises. The complexity and costs associated with digital transformation present considerable challenges. Smaller mining companies may lack the resources necessary to adopt advanced technologies [13,14].

The use of digital twins is expanding internationally in all industry sectors. Digital twins are virtual replicas of physical processes that enable real-time monitoring and predictive maintenance. The implementation of digital twins can optimize resource utilization and reduce environmental impact. These studies provide insight into specific cases of digital twin implementation within the mining industry [15,16,17]. On the other hand, there is no published evidence of implementing the digital twin in the mining sector at the local level in Slovakia.

Digitalization efforts have been documented in the inventorying old mining sites using LiDAR data and the positional accuracy of mining operations [18]. Additionally, 3D modeling and modern technologies have been applied to digitally represent historic mining landscapes in Slovakia [19]. However, these initiatives are not directly related to logistics processes. Logistics has been addressed in a case study of Slovak coal mines, where simulation software was used to propose solutions leading for reducing waste inventory and improved planning within the mining logistics chain [20].

Modeling and simulation are among the key tools of digitalization. The following sample of studies in Table 1 focuses specifically on this tool and its application on an international scale.

Table 1.

Use of simulation in the mining industry on an international scale.

Table 1 presents only a small sample of the available publications on the use of simulation systems in the mining environment. As the purpose of this contribution extends beyond a literature review, additional publications are not included in the table. A common characteristic of the selected publications is the diversity of simulation software and the variety of regions studied. However, most of the research and case studies are relatively dated, with older publication years appearing more frequently as the number of sources increases.

Publications on the use of simulation in the Slovak mining industry are more recent, but their number is significantly lower. A notable commonality among these publications is the authors’ affiliation with the Technical University of Košice. Table 2 summarizes several recent examples from the Slovak mining sector.

Table 2.

Use of simulation in the mining industry at the local Slovak level.

A deeper look at digitalization in the European region highlights ongoing efforts within the mining industry. Historically, the European mining sector has lagged other industrial sectors in adopting modern technologies. However, with strategic support from the European Union and the illuMINEation project, a flexible Internet of Things (IoT) platform tailored to mining needs has been developed. Although Slovakia did not participate in this project, its geographic neighbors Austria and Poland were involved [37]. In the general ranking of business digitalization in Eastern Europe, Slovakia holds the third position. Slovak enterprises achieve above-average results in digitalization, particularly in the implementation of ERP systems and e-invoicing. Further potential lies in the adoption of artificial intelligence (AI) and IoT, which are especially relevant for the mining sector [38]. Ukraine, Slovakia’s eastern neighbor, is not included in the comparison. Surface mines in Ukraine fully leverage digitalization using automated machinery, monitoring systems, autonomous vehicles, IoT, and AI. The main challenges facing the Ukrainian mining sector include the need for employee training, cybersecurity, and addressing environmental and social issues associated with digitalization [39].

Digitalization of the mining industry in Slovakia represents a strategic necessity, even though it faces several barriers such as investment requirements and legislative reforms. While digitalization at the local level in the mining industry demonstrates potential, it continues to lag behind global standards. This lag is primarily due to the peripheral position of the mining sector within national economic policy. Currently, only one institution and a single software solution are engaged in this process, highlighting the significant potential for further development and broader adoption of digitalization. It is also necessary to consider the size, reach, and competitiveness of enterprises within the local mining sector when evaluating digitalization efforts.

This paper compares the level of digitalization in the mining industry internationally and in Slovakia, raising the question of how feasible it is to implement digitalization tools in small-scale Slovak mining operations. The case study, conducted at a Slovak open pit mine, demonstrates the development of a simulation model and 3D animation for mine planning using Tecnomatix Plant Simulation software and programming in SimTalk 2.0. This approach illustrates a form of digitalization that is accessible to even smaller open pit mining operations.

2. Materials and Methods

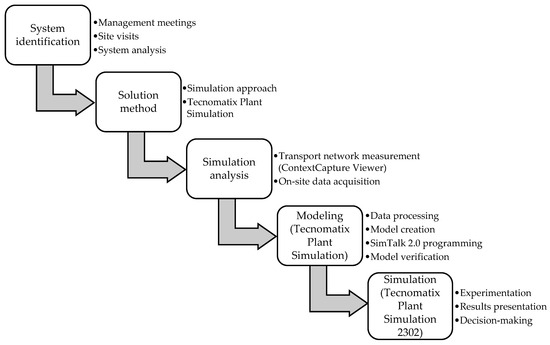

Simulation is a critical tool in the digitalization process, enabling system evaluation and optimization prior to implementation. This approach aids in risk management and enhances both efficiency and decision-making capabilities [40,41]. Figure 1 illustrates the process of digitalizing the mining transport system through modeling and simulation.

Figure 1.

Mining transport system digitalization process.

2.1. Modeling and Simulation Method

Recent advances in computational power, modeling techniques, and software capabilities have enabled more accurate and efficient simulations, fostering innovative solutions to complex transportation challenges. These tools facilitate detailed analysis of transport dynamics, the testing of alternative strategies, and the prediction of outcomes. All these processes are conducted within a virtual environment, which reduces real-world risks and costs [42,43]. Although simulation technologies are well established globally in industries such as automotive manufacturing and supply chain management [44], their application to logistics challenges in the Slovak mining industry remains relatively limited. Nevertheless, interest in digital tools—particularly discrete event simulation—is increasing to enhance efficiency, safety, and strategic planning in mining operations [45].

Simulation offers key advantages for mining logistics, including optimized raw material movement, minimized transport equipment downtime, and reduced energy consumption. As Slovak mining operations face growing pressure to modernize and improve sustainability, digitalization and simulation technologies present a significant opportunity. By modeling various transportation strategies and layout configurations before physical implementation, companies can make informed decisions with lower risk and cost [45].

Modeling and simulation are powerful methods for designing and evaluating complex systems. These tools enable the investigation, understanding, and prediction of complex system behaviors. Modeling abstracts and represents real-world entities, systems, or processes to create simplified reproductions of actual systems. This approach provides a dynamic and interactive means to explore, analyze, and comprehend complex systems or processes [46].

Logistics simulation and modeling are critical tools for optimizing logistics chains and networks, enabling experts to analyze complex systems effectively. The modeling process typically includes developing logistic infrastructures, dynamic process modeling, and probabilistic demand variation analysis, collectively enhancing operational risk evaluation and system dependability [47]. As demonstrated in the AnyLogistix environment, agent-based simulation models allow for the detailed examination of interactions among various supply chain elements, such as production centers and distribution networks [48]. Innovative methods, such as the logistics path network model, facilitate the mapping of logistics paths and equipment and optimize routing and dispatching strategies in complex manufacturing systems [49]. Overall, these methodologies provide essential insights for decision-making in logistics management, ensuring that strategies are tested and refined before implementation [50].

Simulation has become widely used because it eliminates many of the problems and complications associated with experimenting on real objects. The main issues with real-world testing include high costs, time-consuming procedures, potential dangers to people, the environment, or the system itself, and the possibility that the system may not yet exist. Therefore, the primary goal of the simulation is to use a model to accurately replicate a real object or system, analyze it, identify its actual state, errors, and shortcomings, and subsequently address them [51].

Implementing modeling and simulation involves a structured process to ensure the development of credible and effective simulations, encompassing several key steps that are critical for achieving the desired outcomes [52,53,54]:

- Establish Purpose and ScopeDefine the objectives and boundaries of the simulation project to ensure clarity and focus.

- Data Acquisition and AnalysisGather and organize relevant data, including module-specific information, process data, object attributes, and system parameters, to inform model development. It is also important to analyze the behavior of system participants, especially in agent-based modeling.

- Formulation of a Conceptual ModelSelect the appropriate model type, for example, agent-based or discrete event modeling. Create an abstraction that captures the system’s essential features under investigation, facilitating stakeholder discussions. Decompose the model into fundamental elements, and define their interactions, rules, and parameters.

- Model DevelopmentConstruct the simulation model by integrating the acquired data to accurately reflect the conceptual model. The model is implemented in specialized software or programs using programming languages. Set parameters, initialize input data, and define experimental scenarios.

- Verification and ValidationAssess the model’s credibility through rigorous testing to confirm that it accurately represents the real-world system. The model is calibrated based on historical or empirical data so that its output corresponds to real-world observations. Validation is performed by statistically comparing simulation results with real data.

- Experiment Design and ExecutionPlan and run simulations to explore various scenarios, analyzing the outputs for insights. Analyze results statistically, compare them with objectives, and seek optimal solutions.

- Interpretation and Implementation of RecommendationsPresent results, statistics, and proposed measures to stakeholders. Based on the simulation, measures that can be implemented in the actual logistics system are selected.

- Configuration ControlMaintain and manage changes to the model and simulation to ensure consistency and reliability throughout the project.

While a structured approach is essential for success, adapting the process to specific project needs can enhance creativity and innovation in simulation outcomes.

Digitalization at the local level in Slovakia has been implemented in the primary industry sector, particularly in open pit mining. Tecnomatix Plant Simulation 2302 was selected as the simulation tool. Tecnomatix offers a wide range of digital manufacturing solutions that facilitate the digitalization of production processes, transforming concepts and raw materials into finished products. Tecnomatix synchronizes product engineering, manufacturing engineering, production, and service activities to enhance manufacturing efficiency and accelerate innovation.

Digitalization enables faster and more accurate process preparation, while simulation and optimization during the development phase ensure products without costly and time-consuming real-world experiments. The main functions of Tecnomatix include the following [55]:

- Object-oriented modeling with hierarchical structure;

- Open architecture with support for multiple interfaces;

- Library and object management;

- Optimization algorithm functionality;

- Simulation and analysis of energy consumption;

- Automatic result analysis.

2.2. Transport System Inputs

The open pit mine is a significant site supplying essential resources to the region. It specializes in extracting, processing, and distributing raw materials for construction, infrastructure development, and related sectors. This medium-sized open pit mine primarily serves domestic markets, with occasional exports to neighboring countries. Its competitive advantage is its strategic location near major markets and transportation hubs. However, it faces challenges including rising operational costs, environmental regulations, and competition from larger, more technologically advanced open pit mines in Slovakia.

The mine’s operations are divided into two main parts. The first part comprises six extraction benches and a haulage network for heavy-duty trucks, which transport raw material from the benches to the primary crusher. The second part, starting at the primary crusher, includes an automated processing and sorting line, where material is conveyed to final storage locations for products of various fractions and qualities. The second part has been digitized using a modeling and control SCADA system. This article focuses on the digitalization of the first part of the operation through the implementation of a simulation system.

Material transport in the first part of the mine is managed by an external supplier responsible for both the haulage process and the provision of haulage equipment. The mine determines the required number of vehicles for haulage well in advance. The external company supplies the trucks, loaders, drivers, and operators. The external company bills the mine based on hours worked, kilometers driven, and the number of equipment units utilized.

The haulage network roads are moderately maintained, and the rugged terrain of the open pit mine complicates transport. The uneven terrain results in narrow road dimensions, with vehicles able to pass each other only at specific widening points; otherwise, one vehicle must reverse to such a point. Operational transport planning using a simulation model can provide an efficient solution for managing the outsourced haulage process and ensuring the safety and uninterrupted operation of the transport system.

An empirical study was conducted in the open pit mine to identify the complete transport network, its connections, and its elements. Essential input parameters for the model were obtained through observation, measurement, and time snapshots to verify the developed model. An analysis of the mine’s transport regulations—the main document influencing transport processes—was also performed.

The transport network was mapped using drone technology to create a digital map of the mine’s haulage network. Subsequently, the ContextCapture Viewer software Update 17 was used to measure the distances between the transport network elements, as summarized in Table 3. These measurements provide precise spatial data essential for model accuracy and simulation.

Table 3.

Distances of transport network elements.

Model input parameters include technical specifications of the individual vehicles, such as their capacity and speed. For loading and unloading operations, input data also include equipment capacity or processing speed. These data are sourced from the documentation of relevant equipment, vehicles, and transport regulations. In addition to these parameters, time data for individual operations within the transport system must be determined. These data were measured empirically on-site. Table 4 and Table 5 present representative samples of the measured data by vehicle type currently in use.

Table 4.

Higher-capacity vehicle * timetable in seconds.

Table 5.

Lower-capacity vehicle * timetable in seconds.

Based on the collected data and parameters, a transport system model in an open pit mine can be constructed. This model is intended support planning and safety management of the transportation process.

3. Results and Discussion

Developing a simulation model of the transport system in Tecnomatix Plant Simulation 2302 requires the use of the SimTalk 2.0 programming language. The complexity of open pit mine operations—with multiple extraction levels, dynamic truck routing, priority handling at intersections, and conditional logic for loading and unloading—requires the implementation of custom methods that go beyond what the software’s standard objects and blocks offer. Without custom methods defined in SimTalk 2.0, it is not possible to implement the decision-making and process control logic needed to accurately reflect the mine’s transport system behavior.

For example, truck behavior at intersections, conditional path switching based on assigned attributes, and loading sequences can only be implemented via scripted methods. SimTalk 2.0 allows for the definition of flexible and reusable procedures that can be executed at specific points in the simulation. This enables the model to dynamically respond to events, manage complex transport systems, and simulate realistic operational constraints.

3.1. Input Data Preparation

Before developing the model, it is necessary to define the material flow and its unit. Trucks in the model may have varying capacities, while the crusher—the final operation in the processing chain—handle 250 tons of material per hour. The utility capacity of the crusher’s hopper is 40 tons. Therefore, the material flow in the discrete simulation model must be normalized to a unit of 1 ton. As part of this normalization, recalculation of loading and unloading times is required. Based on the average of individual samples measured on-site, it is possible to determine the following:

- Time required to load 1 ton of material into a larger vehicle;

- Time required to load 1 ton of material into a smaller vehicle;

- Average time for loading 1 ton into a different vehicle than those measured;

- Time required to unload 1 ton of material from a larger vehicle;

- Time required to unload 1 ton of material from a smaller vehicle;

- Average time for unloading 1 ton into a different vehicle than those measured;

- Crushing time for 1 ton of material.

The distances between key operations—such as extraction benches, intersections, and the crusher—were measured based on the actual layout of the open pit mine. To ensure the model accurately reflects real-world operations while adhering to the constraints of the simulation environment, the entire system is scaled to a ratio of 1:25. This adjustment is necessary because Tecnomatix Plant Simulation does not support direct paths exceeding 500 m. Many of the actual routes in the mine exceed this distance. Consequently, it is also necessary to adjust vehicle speeds within the model to maintain realistic transport times.

According to the mine’s transport regulations, vehicles may not exceed a speed of 20 km/h. After surveying and digitally mapping the terrain and considering the condition of the open pit mine roads, it is not feasible for vehicles to operate at the maximum permitted speed. Considering all influencing factors and consultations with drivers, the average speed ranges from 9 to 11 km/h. Data from Table 4 and Table 5 are again utilized to determine the average speed of the vehicles. Based on transport time and distance traveled, the average speed of a high-capacity truck is 9.6 km/h, while that of a low-capacity truck is 10.9 km/h. The speed must be recalculated for the simulation model because the distance has been reduced at a scale of 1:25.

The average speed of the larger vehicle is as follows:

The average speed of the smaller vehicle is as follows:

The average speed of other vehicles is as follows:

Before developing the model, it is necessary to specify the final essential input information. Fully loaded trucks cannot safely make the turn from Bench 3 to Intersection 2. As a result, they must proceed to Intersection 3, turn around, and then head to the crusher via Intersection 2. The crusher hopper has a technical capacity of 80 tons, but due to the crushing line’s speed, its operational capacity is set at 40 tons. This limitation ensures the reliable and efficient operation of the primary crusher. During unloading, drivers receive a signal indicating whether the hopper contains enough capacity to accept their load without exceeding the 40-ton operational limit.

3.2. Transport System Simulation Model

The model integrates transport entities representing the currently used trucks, including their respective capacities, speeds, and acceleration profiles. New transport entities with specific technical parameters can be created, supplemented by data from calculations 3, 6, and 10. Loading processes at each level and unloading into the crusher are modeled to replicate real-time operations. The model identifies key performance indicators (KPIs) for efficiency, including transport time and resource utilization.

When creating this model in the Tecnomatix Plant Simulation software 2302, an object-oriented methodology ensures a comprehensive and dynamic model. Each element of the transport system is represented as a separate object. This approach enables modular representation to facilitate management and modification of the simulation as needed. Defining the properties and behaviors of each object enables accurate simulation of the mine’s operations.

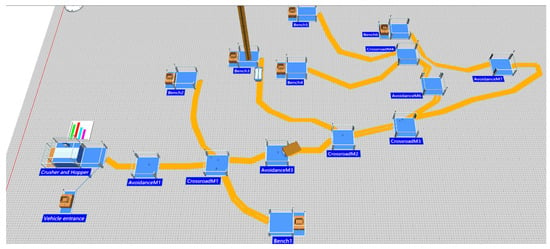

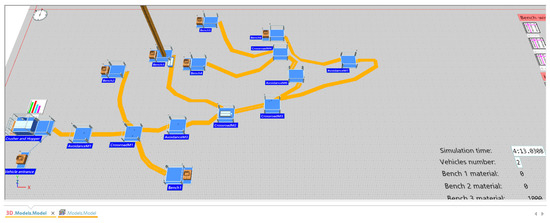

Figure 2 shows a section of the model illustrating the transport network and its elements. Basic blocks such as Buffer, Station, Source, Drain, and Track represent the mine’s benches, intersections, roads, and other equipment. Intersections are modeled using the Buffer block, which stops vehicles and enables decision-making regarding route selection.

Figure 2.

3D visualization of transport network simulation model.

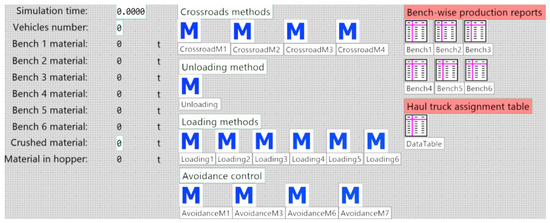

The model interface also requires a second, equally important component to ensure effective control. The control component of the model, as shown in Figure 3, primarily consists of Method blocks programmed in SimTalk 2.0, enabling systematic system management that mirrors real-world operations. DataTable, Display, and Comment blocks are used to provide input data and display key identifiers for both the simulation model and the simulated system.

Figure 3.

The control section of the simulation model.

Bench-wise production reports reflect either the current or planned quantity of raw material at each bench. During the initialization phase, the simulation model loads values from these blocks to configure the loading processes for each bench. This structure ensures the simulation is organized and flexible, allowing independent management and updates of each level’s logic. It also allows the simulation to accurately represent various mining plans, extraction volumes, or operational strategies by adjusting the relevant block values.

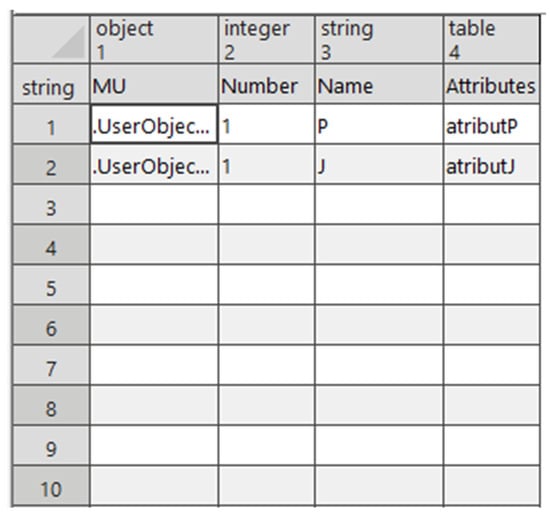

The haul truck assignment table controls and assigns tasks to the designated trucks in the simulation model. Each vehicle is assigned an attribute, numbered from one to six. This value determines each vehicle’s routing at intersections and the target bench for material hauling. Because loading locations typically remain constant during a shift, this method effectively manages multiple vehicles, dynamically directs them, and ensures logical, efficient routing throughout the mine. This approach also allows for easy scalability, as new routes or levels can be added by extending the attribute logic in the haul truck assignment table (Figure 4). A nested table containing the assigned number is included within the attributes, as shown in Figure 4.

Figure 4.

Haul truck assignment table with two trucks.

The decision-making process at intersections is managed using Crossroads methods, which simulate vehicle navigation according to assigned attributes. These methods evaluate each transporter’s assigned attribute at intersections and compare it to predefined routing conditions. Based on this evaluation, the method activates the appropriate path, guiding the transporter through Buffer blocks to the intended destination. This dynamic routing system enables vehicles to autonomously select the correct direction at intersections without manual intervention. These methods are programmed using basic if-else conditions, repeated as necessary to determine the direction from all available options.

Safety and avoidance protocols are essential due to the narrow roads and rugged terrain. The transport network includes seven avoidance spots—areas broad enough for two trucks to pass. Avoidance control methods manage four of these avoidance spots. These methods detect incoming vehicles from both directions and temporarily halt the transporter using a waituntil condition until the path is clear. They also incorporate right-of-way rules as defined by the mine’s layout. The remaining three avoidance spots are managed within Crossroads methods, as they are located at intersections, eliminating the need for separate avoidance logic. In this context, safety protocols are implemented within Method code blocks in the SimTalk 2.0 programming language. This code prevents collisions at avoidance spots and intersections by monitoring route occupancy up to the next available avoidance spot. This approach ensures a 0% rate of collision near-misses in the simulation model. In a real-world system, this can be replicated by directly assigning avoidance spots, which should significantly reduce actual collision near-misses.

A unique routing rule at Avoidance Spot 4, located at the boundary of the third bench and Intersection 2, addresses the challenge of steep terrain. A dedicated method prevents loaded transporters from turning right toward the crusher, rerouting them to the third intersection via the CrossroadM2 method. After passing this point, the CrossroadM3 method checks if the transporter is loaded and, if so, directs it to the crusher. This logic ensures smooth traffic flow; while one vehicle is routed to the third intersection, a second waiting vehicle can enter the third bench from the second intersection, minimizing delays.

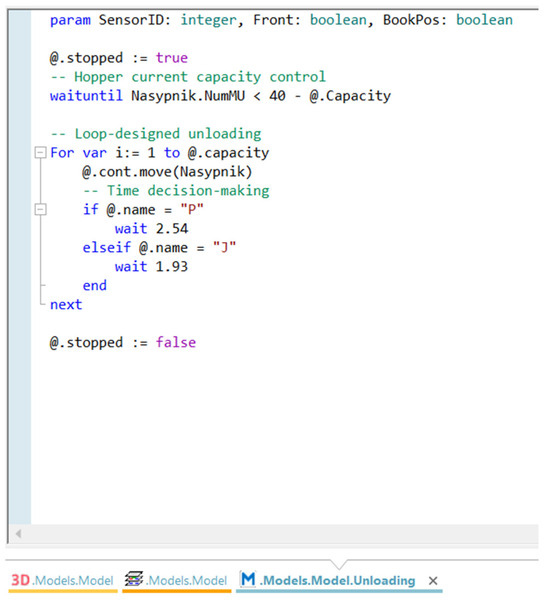

A single unloading method is sufficient for the entire model. The hopper before the primary crusher serves as the final destination for all extracted material. This method is triggered whenever a transporter arrives at the crusher area and manages unloading based on the hopper status and transporter capacity. The method checks if the transporter is loaded and ensures the crusher can receive the material. Given the crusher’s operational capacity of 40 tons, the hopper is filled up to 40 tons minus the loader’s volume to avoid exceeding this limit. The method shown in Figure 5 is easily adaptable, allowing for future enhancements such as alternative unloading rules, capacity checks, or prioritized unloading based on transporter type.

Figure 5.

Unloading method using SimTalk 2.0.

Loading methods operate on the same principle as the unloading method, but with reversed logic: material is transferred from the loading site to the vehicle within a loop. The method verifies the vehicle’s capacity rather than the hopper’s capacity. Each of the six benches in the open pit mine uses a dedicated method, reflecting differences in raw material sources. The methods also verify that sufficient material is available for loading and ensure that no vehicles are loaded simultaneously at the same location, thereby preventing collisions.

3.3. Model Verification and Experimentation

The verification process is an integral part of modeling. To achieve accurate results, it is important to capture the modeled system as faithfully as possible. Several procedures were applied during the verification process. The first method involves observing the animation of the simulation model to detect illogical entity behavior and collisions. Observation confirmed that the model exhibited only logical behavior, with no truck collisions within the transport system.

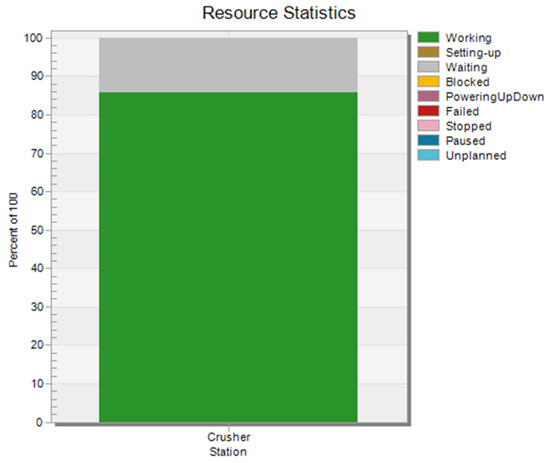

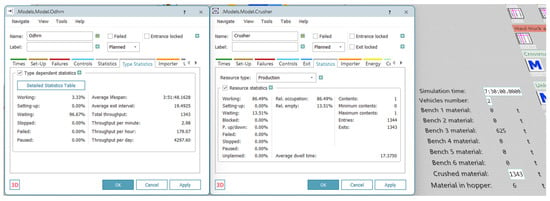

The second verification method involves monitoring the operation of the primary crusher. If the system functions correctly, the primary crusher should operate continuously throughout the simulation period. Figure 6 presents the utilization graph of the primary crusher. Utilization is less than 100% because the current simulation model does not account for the initial raw material in the hopper. As a result, the crusher remains idle until the first truck completes the cycle of loading and unloading at the start of the simulation.

Figure 6.

Crusher utilization during simulation.

Further observations identified a new cause for the decreased utilization of the crusher compared to the real system. At loading sites, operators regularly loaded vehicles with a higher tonnage than specified in the technical documentation. Workers justified this practice by noting that the vehicles could reliably transport more material, a procedure validated by extensive past experience.

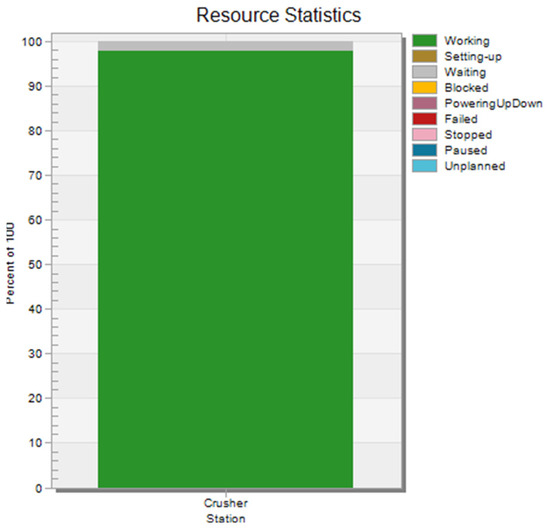

This operational adjustment was incorporated into the model by increasing each vehicle’s loading bay capacity by 5 tons above the original maximum. Subsequent simulations showed crusher utilization at 95%. To achieve peak operational efficiency, the follow-up experiment included 40 tons of material preloaded into the hopper at the start of the simulation, which increased crusher utilization to 97.8%, as shown in Figure 7. Further increasing the maximum vehicle capacity did not affect crusher utilization; it only resulted in a higher amount of material remaining in the hopper at the end of the simulation.

Figure 7.

Crusher utilization after input parameter modification.

The third and most important verification of the simulation model is an experiment based on data from the sixth column of Table 4 and Table 5. The model incorporates a time block that represents system time. During the simulation, it is possible to monitor specific time parameters for particular transport system operations. By setting breakpoints in the code of individual methods, the simulation was paused precisely at the end time of the required operation as specified in the tables, allowing the time to be determined. An example of this process, showing the end of the movement of the larger vehicle to the loading site, is presented in Figure 8.

Figure 8.

Verification experiment simulation.

The simulated vehicle transfer from the crusher to the loading site took 253 s, while verification measurements recorded 219 s, resulting in a deviation of 15.5%. In subsequent operations monitored during the verification experiment, deviations ranged from 13.7% to 18.3%. Such deviations are expected in verification experiments, as models cannot fully capture the highly stochastic influences present in real-world processes. A perfect match between simulation and real-world data would more likely indicate a modeling error than true accuracy. A primary reason for the increased model time deviation is strict adherence to the safety protocol, which increased avoidance delays from 16–17 s to 126–136 s, eliminating collision risk but introducing a trade-off. The verification experiment is considered successful, and the simulation model is suitable for further experimentation. Factors contributing to deviations include weather conditions, roadway physical condition, equipment mechanical state, modeled vehicle speeds (based on averages), and human factors during vehicle operation or other activities.

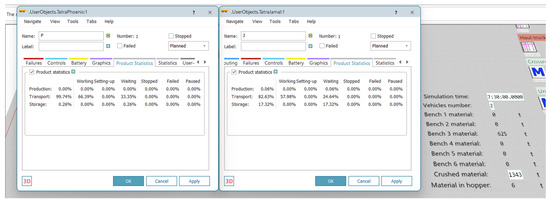

Experimentation with the model can provide essential statistics for decision-making and planning in the open pit mine. As a demonstration, an extraction experiment was conducted at Bench 3, with the simulation lasting 7.5 h to account for a 30 min meal break during an 8 h shift. During the experiment, the model operated with two vehicles, each respecting maximum capacity constraints. Statistics for these vehicles are presented in Figure 9.

Figure 9.

Vehicle statistics after the experiment.

The larger vehicle demonstrates a greater work share compared to the smaller vehicle. The smaller vehicle spent 17% of its time waiting at avoidance spots, while the larger vehicle spent only 0.3%. In terms of transported material, the larger and smaller vehicles moved 750 and 600 tons of raw material, respectively. The complete process can also be monitored statistically. A key performance indicator is system throughput, defined as the amount of material transported from the loading site to the dumping point within a specified period. During the simulated period, the crusher processed a total of 1343 tons of material; additional statistics are presented in Figure 10.

Figure 10.

Main process statistics.

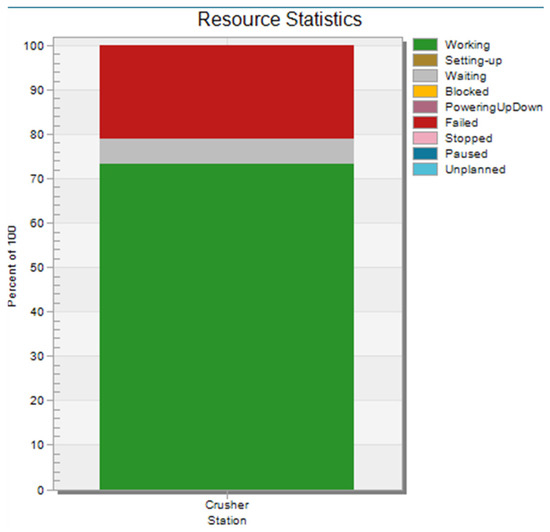

The system throughput per hour is 179 tons of crushed material, with an interval of 19.5 s for the departure of 1 ton from the system. Crusher utilization remains at 86%.

In the open pit mine, two vehicles are used for material transport in the vast majority of cases. However, supplementary experiments were conducted with additional vehicles for raw material transport. The purpose of these experiments is to demonstrate the capability of covering various scenarios in operational planning. The results of these experiments are shown in Table 6.

Table 6.

Supplementary experiments results.

Based on the statistics in Table 6, it is evident that for the current extraction rate in the small open pit mine, transporting material from a single bench to the primary crusher, increasing the number of vehicles is not justified. In this case, the limitation is clearly the crusher’s performance, and the two vehicles currently in use are sufficient to supply it.

Simulation results can be used to develop operational plans for effective management of the transport system. The planning period is flexible, as the simulated time in the model can be adjusted as needed. By appropriately modifying the model’s input data, plans can reflect different options and scenarios. In addition to the number of vehicles, their basic characteristics, and mining plans, the model is also adaptable to changes in other parameters, such as vehicle speeds and operational restrictions on certain roads. For example, due to weather conditions and wet roads, the average speed had to be reduced to 7 km/h, which is defined as 0.078 m/s in the model. The simulation results indicate a throughput of only 143 tons per hour, crusher utilization at 70%, and vehicle waiting times of 0% and 8%, with a total of 1080 tons transported.

The model is capable of simulating special events, maintenance activities, and priority orders in the open pit mine, allowing for dynamic modification of operational plans. For example, if we assume a 10% probability that a piece of material becomes stuck in the crusher, the model can trigger a maintenance mode to remove the obstruction, with the maintenance activity taking 15 min to complete. All relevant parameters must be entered into the Crusher block, specifically in the Failures section. If this failure event occurs, the system’s throughput per hour decreases to 151 tons, and the waiting time for loaded vehicles increases by 10%. Crusher utilization under these conditions is illustrated in Figure 11.

Figure 11.

Crusher utilization with failure.

Furthermore, as both drivers and transport equipment are sourced externally, statistical analyzes and simulation outcomes can serve as reliable resources for vehicle rental decision-making. These tools may also function as supplementary control mechanisms for monitoring the performance of contracted drivers. Involving the external supplier in the simulation process could prove advantageous. Currently, mine management does not archive data related to sustainable transportation. Therefore, data provided by the external supplier and integrated into the model could offer greater specificity regarding environmental sustainability and facilitate the quantification of key metrics such as fuel consumption and CO2 emissions. Safety metrics have already been addressed, with results indicating a reduction in collision rates but an increase in avoidance delays. Beyond operational planning, implementation of the model could enable optimization of environmental indicators, as well as verification of innovations or system expansions.

For such an implementation, the mine would be required to make a moderate initial investment. Effective operation of the simulation tool within the organization necessitates the procurement of a professional license for the SIEMENS Tecnomatix Plant Simulation software 2302, as well as a sufficiently powerful computer capable of supporting the software’s 3D visualization functionalities. Additionally, a dedicated staff member must be assigned to operate the software, generate statistical reports, and potentially participate in planning activities. It is essential that this individual is a trained and proficient user of the simulation tool.

Beyond the context of the studied mine, the developed procedure and model structure can be replicated in other open pit mining operations. While the transport network component is site-specific and cannot be directly transferred to other mines, the control segment of the model is adaptable to varying mining environments. The techniques, programming methodologies, and procedures for constructing the transport network, guiding vehicle movement, managing collision avoidance, and handling loading and unloading operations are fundamental aspects of the simulation software. Therefore, application to other mines requires the provision of relevant input data and the appropriate adaptation and implementation of the described procedures.

4. Conclusions

Digitalization in logistics processes is widespread globally and represents an effective solution for enhancing efficiency and process management within the mining sector. At the international level, digitalization has been utilized for some time, with solutions becoming increasingly sophisticated, modern, and incorporating the latest technologies. However, there are still local contexts where the adoption of digitalization remains limited or lags. In Slovakia, digitalization in the mining industry has been documented in only a few publications, primarily at the level of modeling and simulation. There is no evidence of the implementation of newer, more advanced digitalization approaches. The advancement of digitalization in Slovakia should be more actively promoted, particularly to companies operating in the mining sector. It is essential to communicate the benefits to relevant stakeholders, present successful case studies, and initially focus on investment-friendly solutions that facilitate gradual, small-scale digitalization.

The objective of the case study conducted at a small open pit mine in Slovakia was to develop a simulation model using Tecnomatix Plant Simulation software. Since transportation within the mine is provided by an external supplier, the application of the model can effectively assist in determining the required number of transport vehicles for the company’s operational planning. During the modeling process, programming in SimTalk 2.0 was utilized, which resulted in zero collisions within the model and enabled precise identification of vehicle avoidance locations. However, this increase in safety led to an approximate two-minute increase in vehicle waiting times. The implementation of the developed model into company processes can also offer opportunities for optimization, innovation testing, and change management, owing to the model’s adaptability and modifiability without the need for interventions in the real system.

The main limitations encountered during the development of the model were the limited involvement of the mine management and the absence of cooperation with the external transport supplier. The mine management provided only the information necessary for model creation and verification. The model and its capabilities have already been presented to management; however, a final decision regarding its implementation has not yet been made. On the other hand, collaboration with the supplier of transport vehicles and services would enable further expansion of the model, as new data on transport operations could facilitate the quantification of sustainability indicators such as fuel consumption or carbon footprint measurement.

Further research will be based on the application of the model at multiple levels. The first level involves continuing work at the open pit mine for which the model was developed. The model will need to be supplemented with additional data and will focus on the optimization and quantification of key indicators, with the aim of creating a sustainable and efficient mine operation. Under favorable conditions, this may also lead to a higher degree of digitalization. The second level involves disseminating important findings on digitalization throughout the Slovak mining industry and encouraging companies to adopt modern practices and technologies. Even small-scale digitalization efforts can positively influence their efficiency and competitiveness.

Author Contributions

Each author (M.O., J.S., A.S., L.H. and P.K.) has contributed to this publication. Conceptualization, M.O. and J.S.; methodology, M.O. and P.K.; software, M.O. and P.K.; validation, A.S. and J.S.; formal analysis, M.O. and L.H.; investigation, M.O. and J.S.; resources, M.O. and L.H.; data curation, M.O. and J.S.; writing—original draft preparation, M.O.; writing—review and editing, J.S. and P.K.; visualization, M.O. and A.S.; supervision, A.S.; project administration, A.S. and L.H.; funding acquisition, A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Scientific Grant Agency of the Ministry of Education, Research, Development and Youth of the Slovak Republic and the Slovak Academy of Sciences as part of the research projects VEGA 1/0430/22 “Research, development and concept creation of new solutions based on TestBed in the context of Industry 4.0 to streamline production and logistics for Mining 4.0.” and VEGA 1/0431/25 “Research and development of new methods based on the principles of modelling, logistics and simulation in solving technological and environmental problems with regard to the economic efficiency and safety of raw material extraction”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to thank the anonymous reviewers for their valuable comments, which improved the quality of the manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tran-Dang, H.; Kim, J.-W.; Lee, J.; Kim, D. Shaping the Future of Logistics: Data-Driven Technology Approaches and Strategic Management. IETE Tech. Rev. 2025, 42, 44–79. [Google Scholar] [CrossRef]

- Huang, J.; Lu, H.; Du, M. Can digital economy narrow the regional economic gap? Evidence from China. J. Asian Econ. 2025, 98, 101929. [Google Scholar] [CrossRef]

- Lu, X.; Taghipour, A.A. Review of Supply Chain Digitalization and Emerging Research Paradigms. Logistics 2025, 9, 47. [Google Scholar] [CrossRef]

- Kızıldağ, D.; Uğurlu, Ö.Y. Digitalization and Business. In Digital Transformation and Innovation; Routledge: Abingdon, UK, 2023; pp. 69–85. [Google Scholar]

- Mottaeva, A.; Khussainova, Z.; Gordeyeva, Y. Impact of the Digital Economy on the Development of Economic Systems. E3S Web Conf. 2023, 381, 02011. [Google Scholar] [CrossRef]

- Gradillas, M.; Thomas, L.D.W. Distinguishing Digitization and Digitalization: A Systematic Review and Conceptual Framework. J. Prod. Innov. Manag. 2025, 42, 112–143. [Google Scholar] [CrossRef]

- Anaba, D.C.; Kess-Momoh, A.J.; Ayodeji, S.A. Optimizing Supply Chain and Logistics Management: A Review of Modern Practices. Open Access Res. J. Sci. Technol. 2024, 11, 020–028. [Google Scholar] [CrossRef]

- Okorie, O.; Charnley, F.; Salonitis, K. A Framework to Support a Simulation-Based Understanding of Digitalisation in Remanufacturing Operations. In Proceedings of the International Conference on Remanufacturing, Amsterdam, The Netherlands, 23–25 June 2019. [Google Scholar]

- Nezzi, C.; De Marchi, M.; Vidoni, R.; Rauch, E. Modeling and Simulation of Mechatronics Equipment for a Digital Twin-Enabled Demonstrator. In Proceedings of the 2024 10th International Conference on Control, Decision and Information Technologies (CoDIT), Valletta, Malta, 1–4 July 2024; pp. 2526–2529. [Google Scholar] [CrossRef]

- Lazarenko, Y.; Garafonova, O.; Marhasova, V.; Tkalenko, N. Digital Transformation in the Mining Sector: Exploring Global Technology Trends and Managerial Issues. E3S Web Conf. 2021, 315, 04006. [Google Scholar] [CrossRef]

- Sri Chandrahas, N.; Surendra Babu, A.; Malleshwara Rao, T.; Hareesh Babu, S.; Singh, K. Role of Digital Transformation in Mining Industry: Enhancing Efficiency, Safety and Sustainability. Min. Revue 2025, 31, 1–11. [Google Scholar] [CrossRef]

- Torres, L.C.C. Case Study: Simulation and Artificial Intelligence Application for the Optimization of the Hauling and Loading Process in an Open-Pit Mining System. Adv. Control Optim. Dyn. Syst. 2022, 55, 265–269. [Google Scholar] [CrossRef]

- Barnewold, L.; Lottermoser, B.G. Identification of Digital Technologies and Digitalisation Trends in the Mining Industry. Int. J. Min. Sci. Technol. 2020, 30, 747–757. [Google Scholar] [CrossRef]

- Chatterjee, C.; Sindhwani, R.; Mangla, S.K.; Hasteer, N. Digitization of the Mining Industry: Pathways to Sustainability Through Enabling Technologies. Resources Policy 2025, 100, 105450. [Google Scholar] [CrossRef]

- Ghahramanieisalou, M.; Sattarvand, J. Digital Twins and the Mining Industry. In Technologies in Mining; Intechopen: London, UK, 2024. [Google Scholar] [CrossRef]

- Cranford, R. Conceptual Application of Digital Twins to Meet ESG Targets in the Mining Industry. Front. Ind. Eng. 2023, 1, 1223989. [Google Scholar] [CrossRef]

- Bertoni, A.; Machchhar, R.J.; Larsson, T.; Frank, B. Digital Twins of Operational Scenarios in Mining for Design of Customized Product-Service Systems Solutions. Procedia CIRP 2022, 109, 532–537. [Google Scholar] [CrossRef]

- Gergelová, M.; Labant, S.; Mizák, J.; Šustek, P.; Leicher, L. Inventory of Locations of Old Mining Works Using LiDAR Data: A Case Study in Slovakia. Sustainability 2021, 13, 6981. [Google Scholar] [CrossRef]

- Hronček, P.; Gregorová, B.; Tometzová, D.; Molokáč, M.; Hvizdák, L. Modeling of Vanished Historic Mining Landscape Features as a Part of Digital Cultural Heritage and Possibilities of Its Use in Mining Tourism (Case Study: Gelnica Town, Slovakia). Resources 2020, 9, 43. [Google Scholar] [CrossRef]

- Lehaney, B.; Malindzák, D.; Khan, Z. Simulation Modelling for Problem Understanding: A Case Study in the East Slovakia Coal Industry. J. Oper. Res. Soc. 2008, 59, 1332–1339. [Google Scholar] [CrossRef]

- Saadatmand Hashemi, A.; Sattarvand, J. Application of ARENA Simulation Software for Evaluation of Open Pit Mining Transportation Systems—A Case Study. In Advances in Sustainable Mining; Springer: Cham, Switzerland, 2015; pp. 213–224. [Google Scholar]

- Huayanca, D.; Bujaico, G.; Delgado, A. Application of Discrete-Event Simulation for Truck Fleet Estimation at an Open-Pit Copper Mine in Peru. Appl. Sci. 2023, 13, 4093. [Google Scholar] [CrossRef]

- Fioroni, M.M.; dos Santos, L.C.A.; Franzese, L.A.G. Logistic Evaluation of an Underground Mine Using Simulation. Mineração 2014, 67, 447–454. [Google Scholar]

- Quelopana, A.; Órdenes, J.; Wilson, R.; Navarra, A. Technology Upgrade Assessment for Open-Pit Mines through Mine Plan Optimization and Discrete Event Simulation. Minerals 2023, 13, 642. [Google Scholar] [CrossRef]

- Baek, J.; Choi, Y. Simulation of Truck Haulage Operations in an Underground Mine Using Big Data from an ICT-Based Mine Safety Management System. Appl. Sci. 2019, 9, 2639. [Google Scholar] [CrossRef]

- Bodon, P.; Fricke, C.; Sandeman, T.; Stanford, C. Modeling the Mining Supply Chain from Mine to Port: A Combined Optimization and Simulation Approach. J. Min. Sci. 2011, 47, 202–211. [Google Scholar] [CrossRef]

- Krysa, Z.; Bodziony, P.; Patyk, M. Discrete Simulations in Analyzing the Effectiveness of Raw Materials Transportation During Extraction of Low-Quality Deposits. Energies 2021, 14, 5884. [Google Scholar] [CrossRef]

- Greberg, J.; Salama, A.; Gustafson, A.; Skawina, B. Alternative Process Flow for Underground Mining Operations: Analysis of Conceptual Transport Methods Using Discrete Event Simulation. Minerals 2016, 6, 65. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Z.; Bi, L.; Wang, L.; Gu, Q. Determination of Truck–Shovel Configuration of Open-Pit Mine: A Simulation-Method Based on Mathematical Model. Sustainability 2022, 14, 12338. [Google Scholar] [CrossRef]

- Pop-Andonov, G.; Mirakovski, D.; Despodov, Z. Simulation Modeling and Analysing in Underground Haulage Systems with Arena Simulation Software. Int. J. Sci. 2012, 5, 48–50. [Google Scholar]

- Janic, P.; Jadlovská, S.; Zapach, J.; Koška, Ľ. Modeling of Underground Mining Processes in the Environment of MATLAB/Simulink. Acta Montan. Slovaca 2019, 24, 44–52. [Google Scholar]

- Saderová, J.; Rosová, A.; Kačmáry, P.; Šofranko, M.; Bindzár, P.; Małkus, T. Modelling as a Tool for the Planning of the Transport System Performance in the Conditions of a Raw Material Mining. Sustainability 2020, 12, 8051. [Google Scholar] [CrossRef]

- Straka, M.; Saderová, J.; Bindzár, P. Simulation and Modelling of Transport Processes for the Needs of Mineral Resources Delivery Support. In Smart and Efficient Decision-Making Systems; Springer: Cham, Switzerland, 2020; pp. 93–101. [Google Scholar]

- Šaderová, J.; Rosová, A.; Muchová, P.; Ondov, M. Transport Capacity of Mining Hoisting Equipment—Calculation Based on Simulation. Int. Multidiscip. Sci. GeoConf. SGEM 2024, 24, 399–406. [Google Scholar] [CrossRef]

- Šaderová, J.; Ambriško, Ľ.; Marasová, D.; Muchová, P. Proposal of a Transport Planning Model for the Removal of Quarry Stone Using a Simulation. Appl. Sci. 2024, 14, 5130. [Google Scholar] [CrossRef]

- Ondov, M.; Špirková, S.; Ďuriška, M.; Kleinová, L. Modular Elements of Mining Transport Systems in a Simulation Program. Acta Logist. Moravica 2023, 13, 41–49. Available online: https://vslg.cz/wp-content/uploads/2023/10/ALM.2023.1.pdf (accessed on 20 May 2025).

- CORDIS. Accelerating the Digitalisation and Automation of Europe’s Mining Sector. Available online: https://cordis.europa.eu/article/id/454758-accelerating-the-digitalisation-and-automation-of-europe-s-mining-sector (accessed on 18 June 2025).

- Tutak, M.; Brodny, J. Technological progress in central and eastern Europe: Digitalization and business innovation leaders and outsiders. J. Open Innov. Technol. Mark. Complex. 2024, 10, 100404. [Google Scholar] [CrossRef]

- Kunytska, M.; Piskun, I.; Kotenko, V.; Kryvoruchko, A. Digital modelling technologies in the mining industry: Effectiveness and prospects of digitalisation of open-pit mining enterprises. Bull. Cherkasy State Technol. Univ. 2024, 29, 52–61. [Google Scholar] [CrossRef]

- Ruane, P.; Walsh, P.; Cosgrove, J.W. Validation of a Digital Simulation Model for Maintenance in a High-Volume Automated Manufacturing Facility. Adv. Control Optim. Dyn. Syst. 2022, 55, 127–132. [Google Scholar] [CrossRef]

- Gunal, M.M.; Karatas, M. Industry 4.0, Digitisation in Manufacturing, and Simulation: A Review of the Literature. In Industry 4.0 and Simulation; Springer: Cham, Switzerland, 2019; pp. 19–37. [Google Scholar]

- Šofranko, M.; Wittenberger, G.; Škvareková, E. Optimisation of technological transport in quarries using application software. Int. J. Min. Miner. Eng. 2015, 6, 1–13. [Google Scholar] [CrossRef]

- Kasher, J.-D.; Sardarabady, N.J.; Durst, S. Towards a Taxonomy of Digitalization Technologies in Road Freight Transportation Logistics Business Processes. In Proceedings of the 58th Hawaii International Conference on System Sciences, Big Island, HI, USA, 7–10 January 2025; HICSS: Big Island, HI, USA, 2025; pp. 1463–1472. Available online: https://hdl.handle.net/10125/109016 (accessed on 17 June 2025).

- Winkelhake, U. Technologies for Digitalization Solutions. In The Digital Transformation of the Automotive Industry; Springer: Berlin/Heidelberg, Germany, 2025; pp. 49–92. [Google Scholar] [CrossRef]

- Kováčová, M.; Novak, A.; Machova, V.; Carey, B. 3D Virtual Simulation Technology, Digital Twin Modeling, and Geospatial Data Mining in Smart Sustainable City Governance and Management. Geopolitics Hist. Int. Relat. 2022, 14, 9–25. [Google Scholar]

- Meyers, R.A. Encyclopedia of Physical Science and Technology, 3rd ed.; Academic Press: Cambridge, MA, USA, 2001; p. 15453. ISBN 9780122274107. [Google Scholar]

- Bukowski, L. Modelling and Simulation of Logistic Networks. In Modelling and Simulation for Logistics; Springer: Cham, Switzerland, 2019; pp. 151–213. [Google Scholar]

- Dimitrov, R. Simulation Modelling of Multi-Agent Logistics Model in AnyLogistix Environment. Southeast Eur. Eng. J. 2024, 9, 75–82. [Google Scholar] [CrossRef]

- Ding, G.; Jiang, H.; Fu, J.; Zou, Y.; Zhang, J.; Ding, G. Logistics Modeling and Simulation Method of Complex Discrete Manufacturing System Based on Logistics Path Network. CN201811187173.3, 1 March 2019. [Google Scholar]

- Rosca, E.; Rusca, A.; Popa, M.; Rusca, F.; Olteanu, S. Modelling and Simulation for Intermodal Transportation in Logistics Chains. In Modern Trends and Research in Intermodal Transportation; Springer: Cham, Switzerland, 2022; pp. 1–49. [Google Scholar]

- Turčok, L. Simulácia Podnikových Procesov v Manažmente, 1st ed.; Vysokoškolský Podnik Liberec, spol. s.r.o.: Liberec, Czech Republic, 2015; 90p, ISBN 978-80-7494-186-3. [Google Scholar]

- Higashida, A.; Kodama, S.; Fujita, M. Simulation Method and Simulation System. Patent 17/258663, 2 September 2021. [Google Scholar]

- Birta, L.G.; Arbez, G. Modelling and Simulation Fundamentals. In Modelling and Simulation Fundamentals; Springer: Cham, Switzerland, 2019; pp. 19–53. [Google Scholar]

- Labelle, A.; Frayret, J.-M. Word-of-mouth in agent-based simulation model of reverse logistics. Front. Sustain. 2024, 5, 1264461. [Google Scholar] [CrossRef]

- Siemens. Tecnomatix Digital Manufacturing Software. Available online: https://plm.sw.siemens.com/en-US/tecnomatix/ (accessed on 20 May 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).