Emerging Electron Beam Technology Targeting Hazardous Micropollutants as Quaternary Treatment in Wastewater Treatment Plants

Abstract

1. Introduction

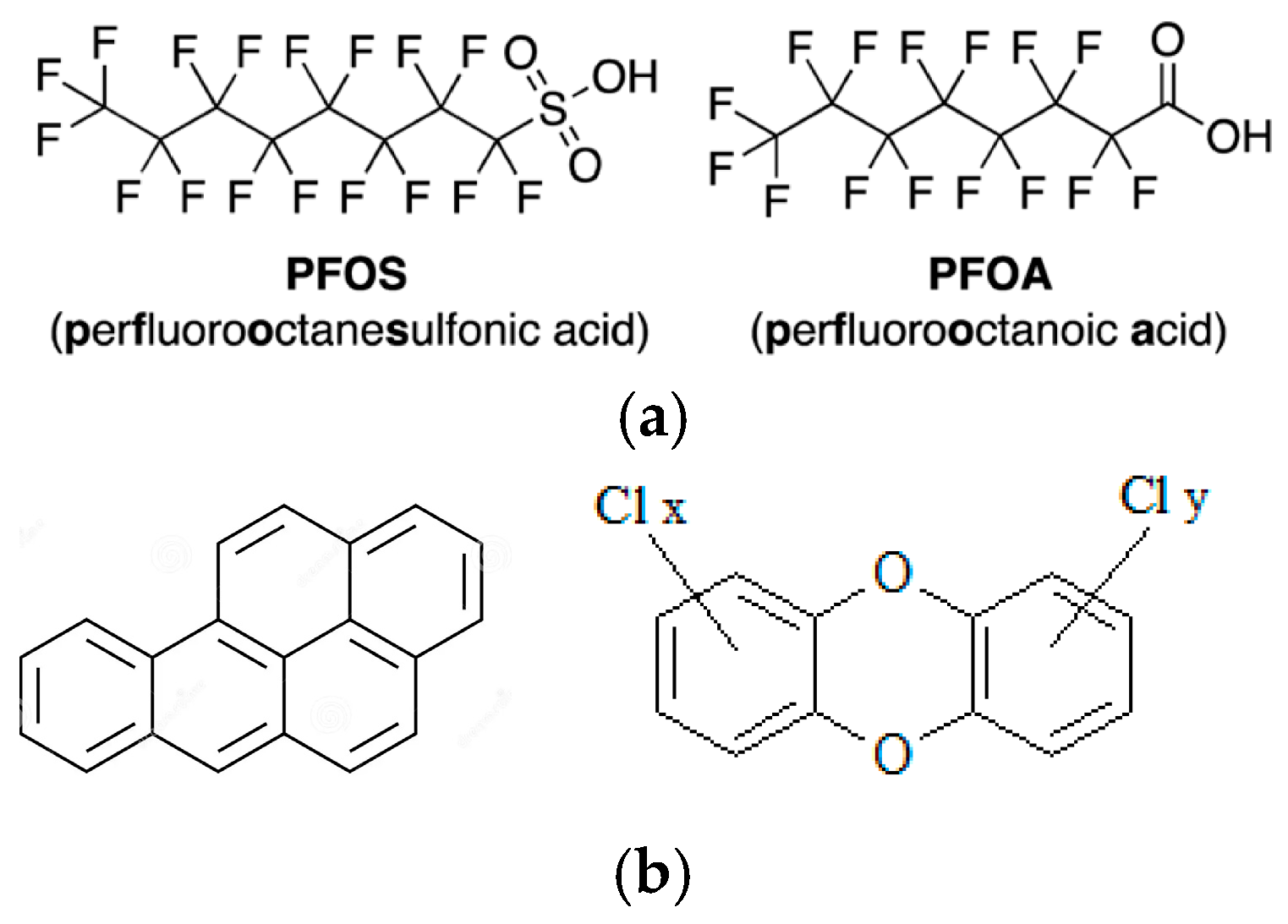

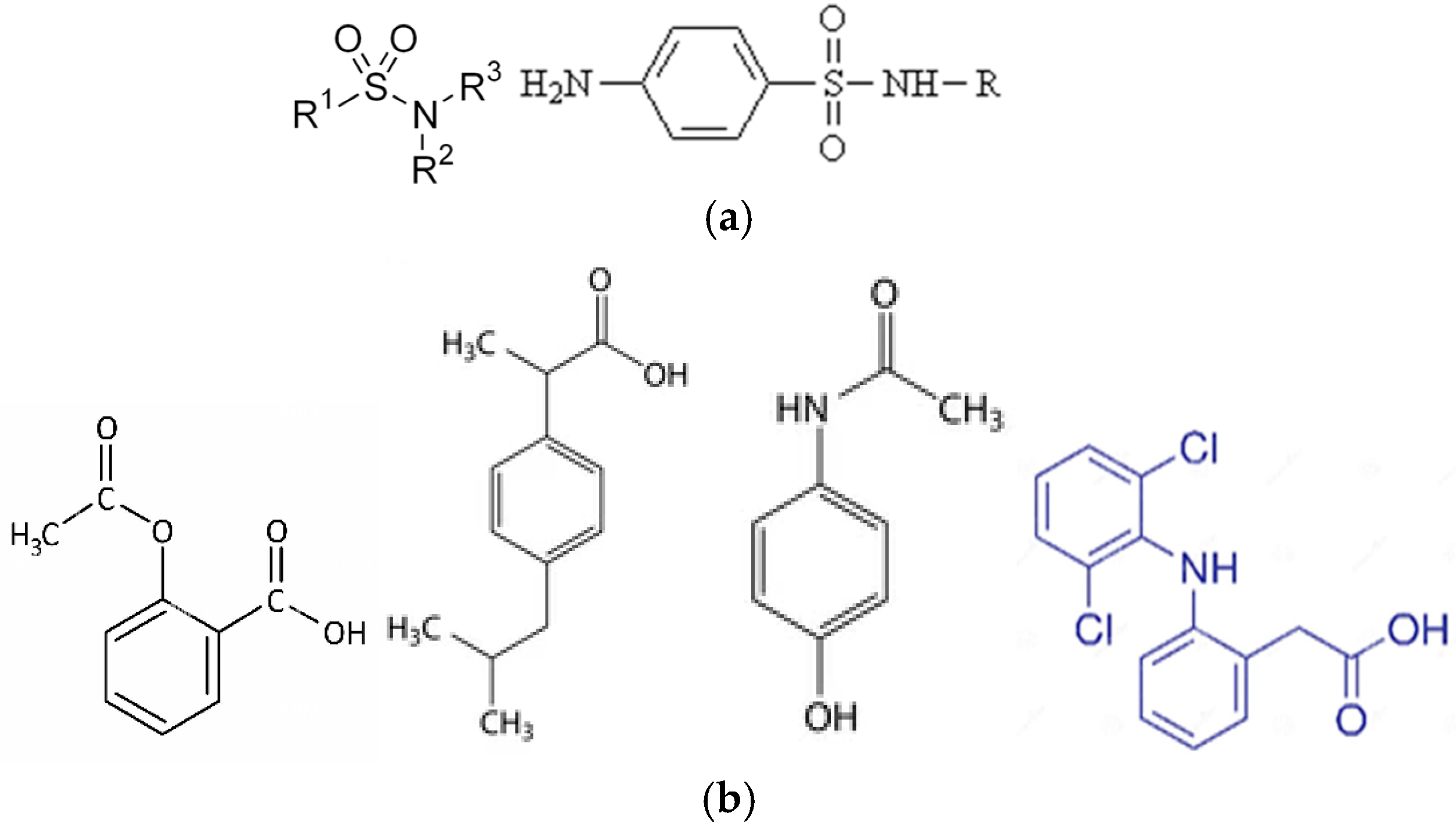

2. Micropollutants

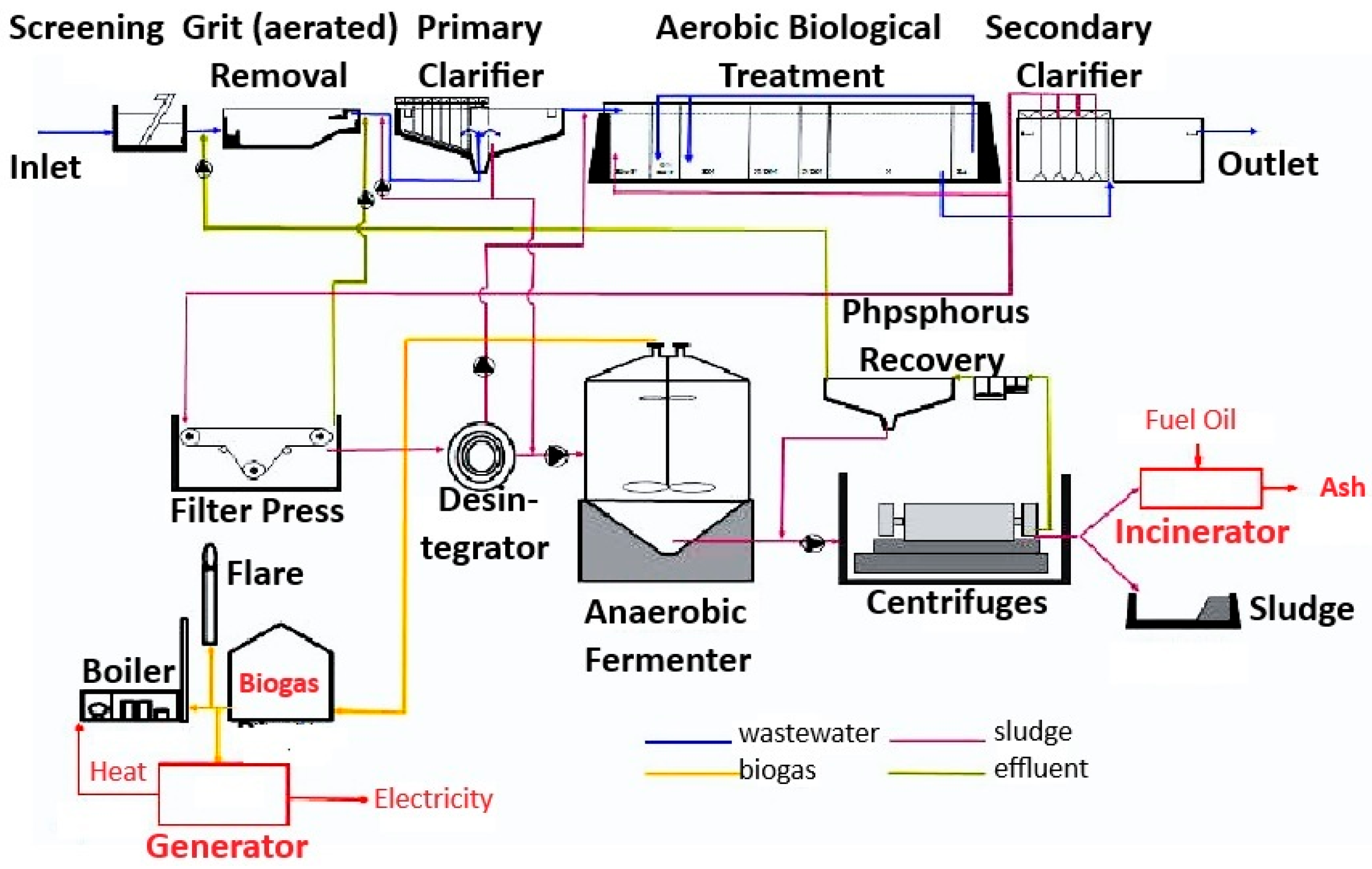

3. The Fate of Micropollutants in Biological WWTPs

4. Micro Pollutant Control Technologies

- (a)

- Stage I: Mechanical pre-treatment;

- (b)

- Stage II: Biological treatment;

- (c)

- Stage III: Chemical treatment or treatment enhancement;

- (d)

- Stage IV: Removal of micropollutants.

5. Electron Beam (EB) Application as a Quaternary Treatment

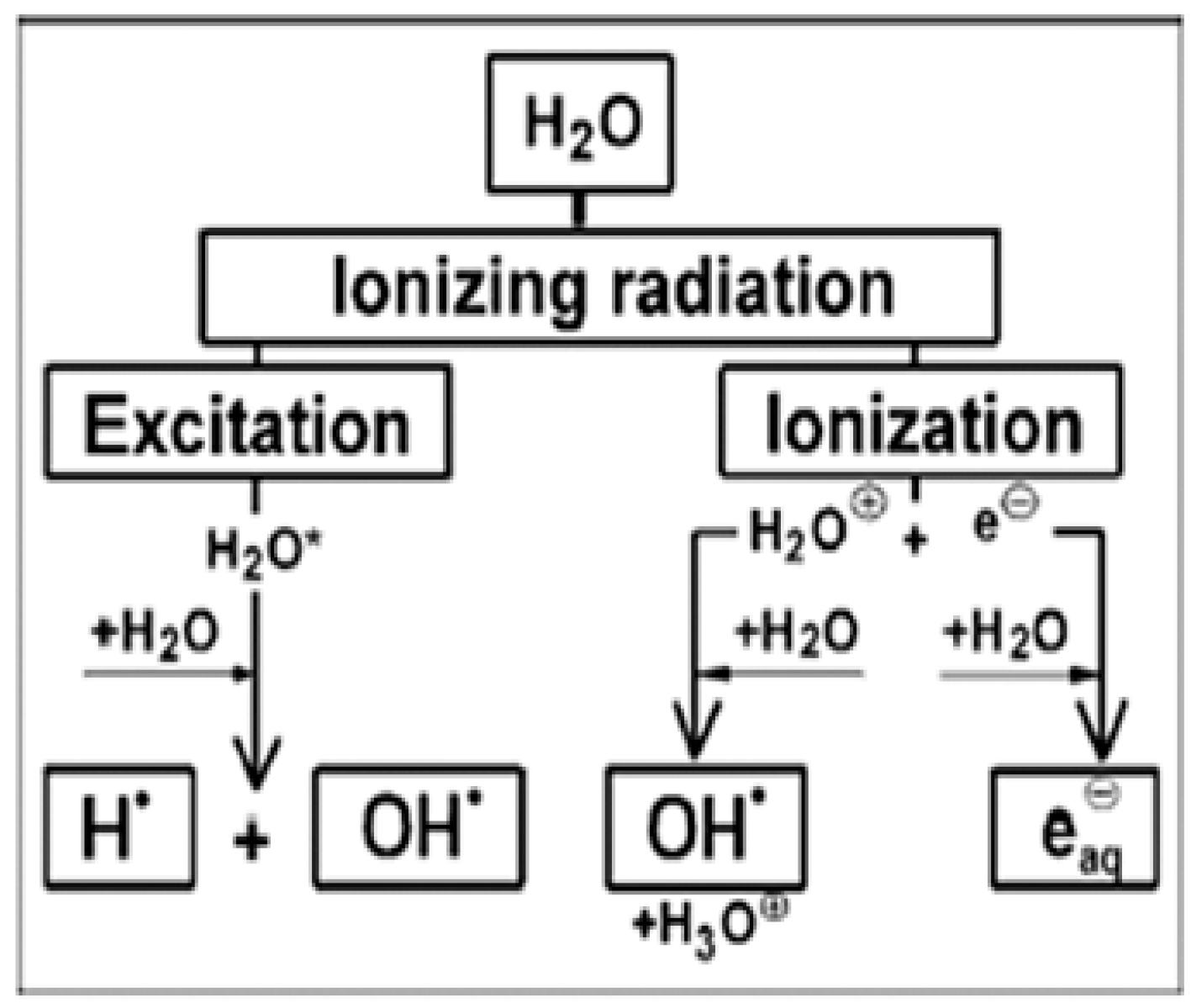

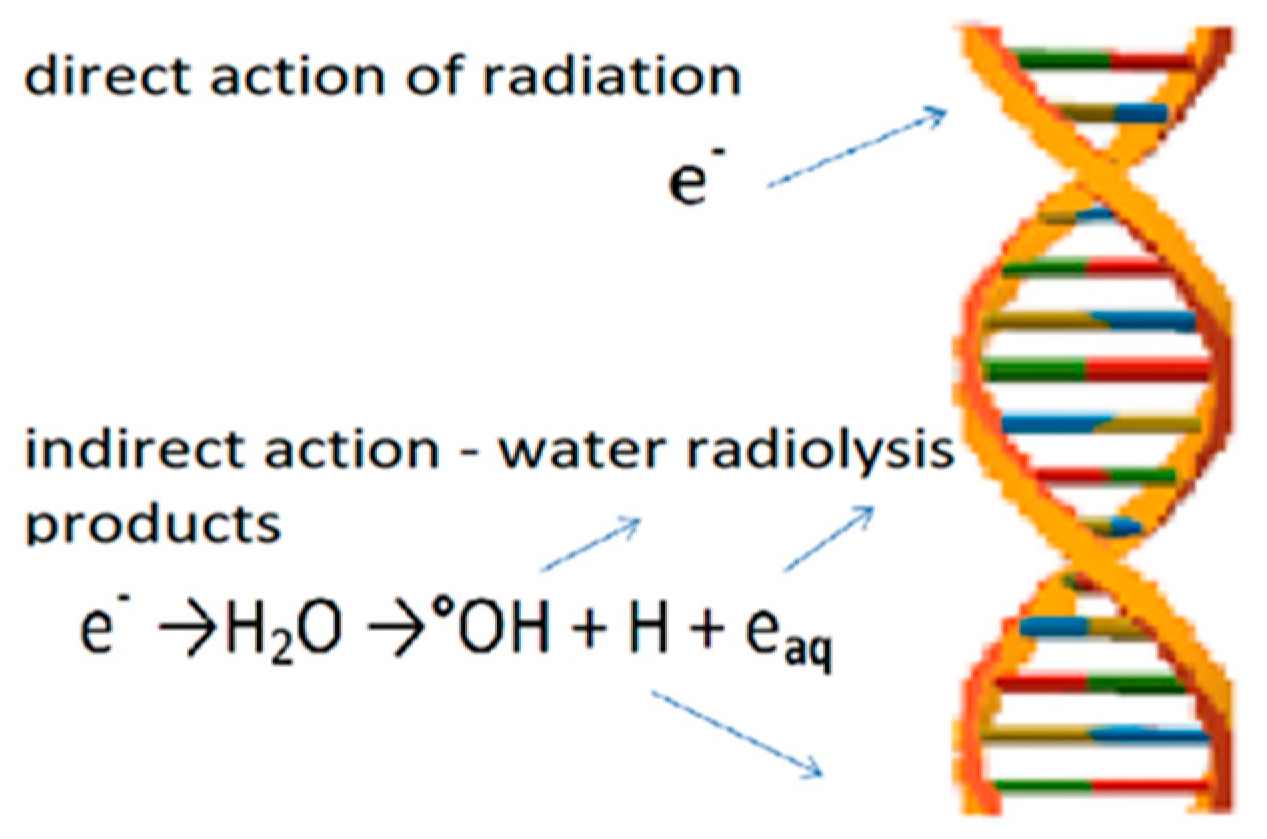

5.1. Main Process Principles

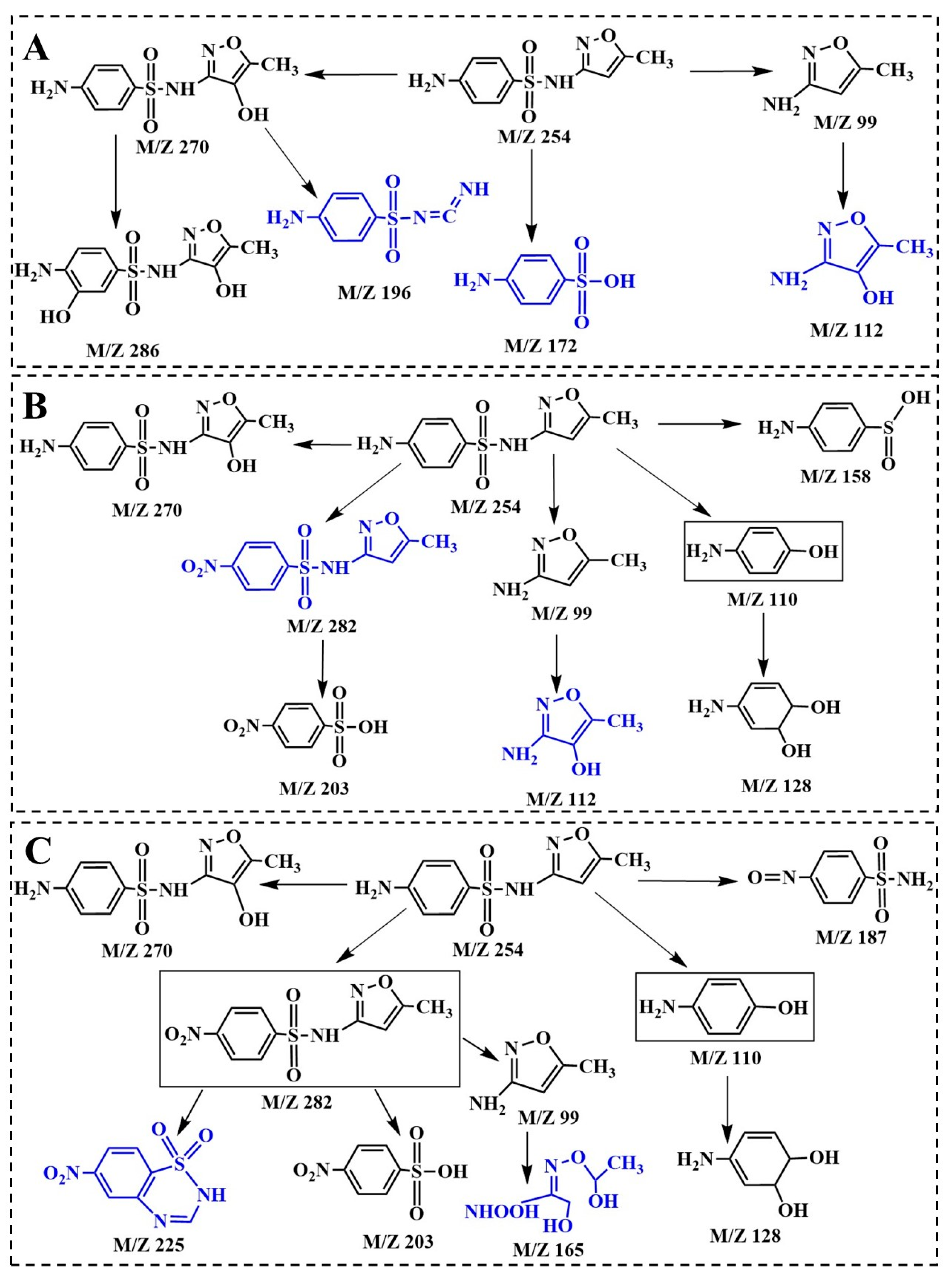

5.2. Destruction of Chemicals by EB

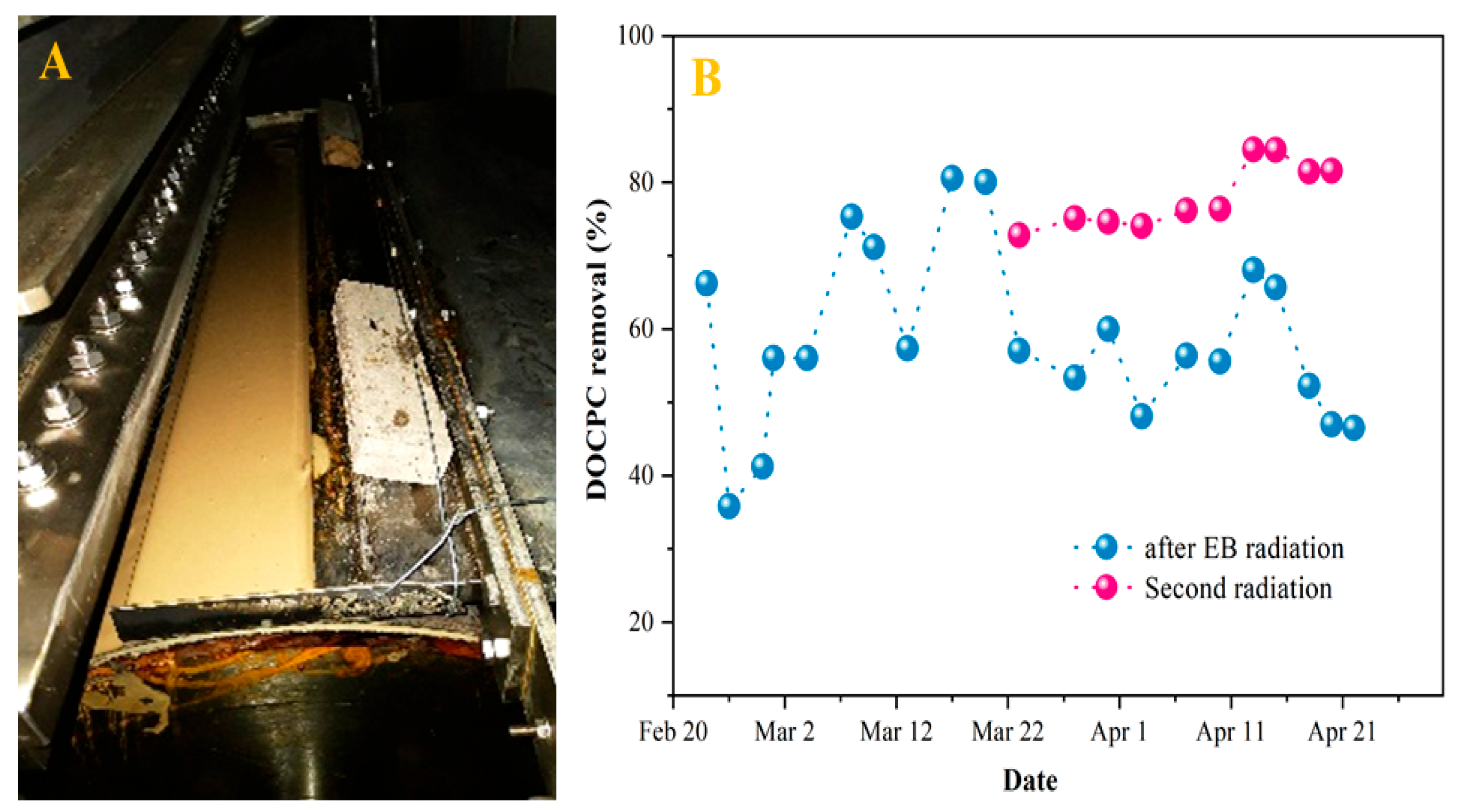

5.3. EB Degradation of Pharmaceuticals in Wastewater

5.4. Microplastic Flocculation and Sedimentation Enhanced by EB

5.5. Destruction of ARGs, ARB, Parasites, Their Ova, and Other Microorganisms in Wastewater and Excess Sludge

6. Technology Targeting Hazardous Micropollutants in WWTPs and Supporting Sustainable Resource Management

- Micropollutant removal (microplastics, organic compounds, and pharmaceuticals);

- Hazardous microbiological contamination control of wastewater and sludge (bacteria, ARB, ARG, parasites, parasite eggs, etc.);

- Enhancement of biogas production;

- Safe organic fertilizer manufacturing;

- The circular economy;

- Energy neutrality.

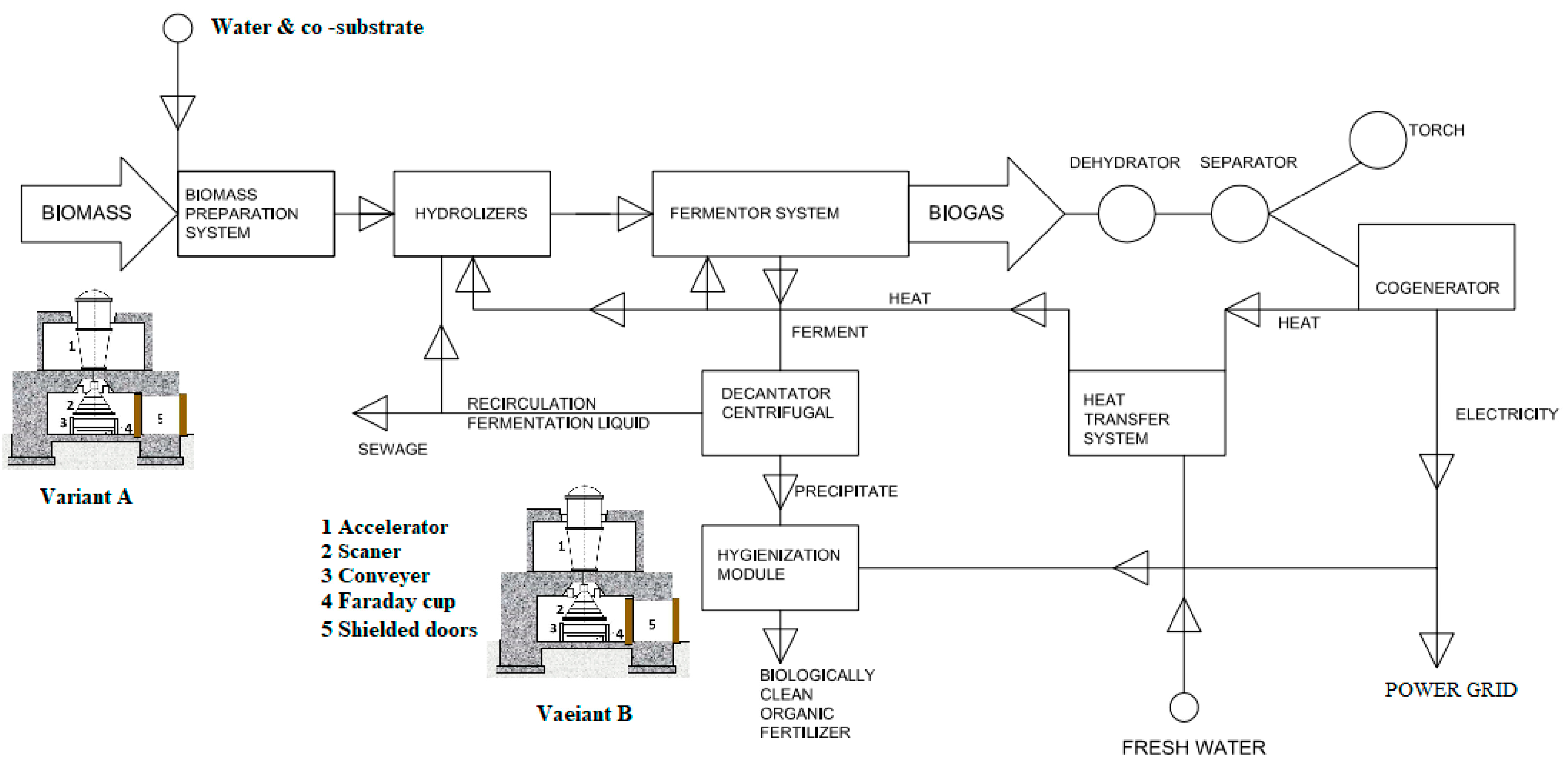

6.1. Disintegration of Excess Sludge to Improve Biogas Production Rate

6.2. Application of EB at WWTPs as Quaternary Treatment

6.3. Electron Accelerators

7. Discussion and Conclusions

- The aforementioned EU Directive introduces in the future the obligation of the industry to remove toxic micropollutants (polluter pays principle) that are released into the environment as a result of the use of their products. This requirement introduces the need to use additional new technologies/devices to meet this condition.

- The wastewater sector should be made energy-neutral and moved towards climate neutrality. This can be achieved by reducing energy consumption, utilizing the extensive areas of some treatment plants for solar or wind energy production, promoting water reuse, and generating biogas from treatment sludge to serve as a substitute for natural gas.

- The introduction of highly efficient wastewater treatment processes has contributed to an increase in the amount of sludge produced. Sewage sludge generation cannot be prevented, and the increase in many countries is estimated at several percent per year. The method of disposal and management of sewage sludge is closely linked to its characteristics. Key factors include the presence of harmful substances or pathogenic organisms, as well as the content of nutrients. These nutrients may be recovered, or the sludge may be converted into fuel or a commercially viable product, such as an organic fertilizer. This is performed to maintain the humus levels in the soil while ensuring chemical and biological purity.

- The technology under development can be used for both the final processing of wastewater treated by biological methods and the initial degradation of non-biodegradable organic pollutants and excess sludge as well. Of course, as with any technology used for pollution control, it is advisable to treat smaller wastewater streams at their sources, such as hospitals, nursing homes, or facilities in the pharmaceutical industry. It meets the main requirements and principles of the EU Directive and can be used as a quaternary treatment of wastewater. Previous studies have shown the possibility of its application to accelerate the sedimentation process of microplastics and destroy various types of chemical and microbiological contaminants, including ARB and ARG parasites and their eggs. In addition, it meets the requirements of the Directive in terms of energy neutrality because it takes into account the efficient production of biogas and the generation of electricity. Concerning the guidelines of the Directive, it enables the production of a safe organic fertilizer that supports the recycling of nutrients, including phosphorus.

- The technology comprising two stages (sludge hygenization and disintegration) advanced to TRL 4. At such a stage, various components were tested in combination, leading to the conclusion that this level has been successfully reached. TRL 5, which builds upon TRL 4, involves validating the technology in a relevant industrial environment. However, a technology at TRL 5 is considered a prototype and requires more extensive testing compared to one at TRL 4. The next phase should be conducted in environments that closely mimic real-world conditions. In our case, this would involve a pilot plant built at a WWTP based on the already developed basic engineering. For the other two segments (a high-activity biogas plant and a wastewater treatment plant in the dye industry and at hospital wastewaters), the development level is at TRL 9. However, R&D on ARBs, ARGs, and selected antibiotics is necessary to advance the technology to the next TRL stage for this specific application. The final objective of the Chinese–Polish research project is the construction of the pilot plant. This plant will be based on previous and ongoing research and aims to integrate the discussed process into the treatment sequence of conventional wastewater treatment plants. The goal is to develop hybrid stages, such as EBs combined with sedimentation, ozone, or sludge disintegration; hydrolysis; and methanogenesis, that function as either the final or internal quaternary treatment stage.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- UN Department of Economic and Social Affairs. Times of Crisis, Times of Change: Science for Accelerating Transformations to Sustainable Development. 2023. Available online: https://sdgs.un.org/gsdr/gsdr2023 (accessed on 31 May 2025).

- Guven, H.; Ersahin, M.E.; Ozgun, H.; Ozturk, I.; Koyuncu, I. Energy and material refineries of future: Wastewater treatment plants. J. Environ. Manag. 2023, 329, 117130. [Google Scholar] [CrossRef]

- Saravanan, A.; Senthil Kumar, P.; Jeevanantham, S.; Karishma, S.; Tajsabreen, B.; Yaashikaa, P.R.; Reshma, B. Effective water/wastewater treatment methodologies for toxic pollutants removal: Processes and applications towards sustainable development. Chemosphere 2021, 280, 130595. [Google Scholar] [CrossRef] [PubMed]

- Zubrowska-Sudol, M.; Bisak, A. Circular Economy Indicators and Measures in the Water and Wastewater Sector—Case Study. In Water in Circular Economy. Advances in Science, Technology & Innovation; Smol, M., Prasad, M.N.V., Stefanakis, A.I., Eds.; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Bajpai, P. Chapter 6—External Treatment Technologies Used for Pulp and Paper Mill Effluents. In Pulp and Paper Industry; Bajpai, P., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 71–92. [Google Scholar] [CrossRef]

- Tran, H.T.; Lesage, G.; Lin, C.; Nguyen, T.B.; Bui, X.-T.; Nguyen, M.K.; Nguyen, D.H.; Hoang, H.G.; Nguyen, D.D. Chapter 3—Activated sludge processes and recent advances. In Current Developments in Biotechnology and Bioengineering; Bui, X.-T., Nguyen, D.D., Nguyen, P.-D., Ngo, H.H., Pandey, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 49–79. [Google Scholar] [CrossRef]

- IAEA. Radiotracer Applications in Wastewater Treatment Plants. Training Course Series No. 49; IAEA: Vienna, Austria, 2022; Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/TCS_49_web.pdf (accessed on 15 May 2025).

- Islam, D.; Mahdi, M.M. Chapter 1—Evaluation of micro-pollutants removal from industrial wastewater using conventional and advanced biological treatment processes. In Biodegradation and Detoxification of Micropollutants in Industrial Wastewater; Haq, I., Kalamdhad, A.S., Shah, M.P., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 1–26. [Google Scholar] [CrossRef]

- Directive—EU—2024/3019—EN—EUR-Lex Directive (EU) 2024/3019 Concerning Urban Wastewater Treatment (Recast). Available online: http://data.europa.eu/eli/dir/2024/3019/2024-12-12 (accessed on 31 May 2025).

- Tomala, L. Science in Poland, 2025, Forever Chemicals, Microplastics, Medicines—Micropollutants Are Growing Problem for Wastewater Treatment Plants. Available online: https://scienceinpoland.pl/en/news/news%2C106264%2Cforever-chemicals-microplastics-medicines-micropollutants-are-growing-problem (accessed on 31 May 2025).

- Thompson, K.A.; Mortazavian, S.; Gonzalez, D.J.; Bott, C.; Hooper, J.; Schaefer, C.E.; Dickenson, E.R.V. Poly- and Perfluoroalkyl Substances in Municipal Wastewater Treatment Plants in the United States: Seasonal Paterns and Meta-Analysis of Long-Term Trends and Average Concentrations. ACS EST Water 2022, 2, 690–700. [Google Scholar] [CrossRef]

- Loganathan, P.; Kandasamy, J.; Ratnaweera, H.; Vigneswaran, S. Treatment Trends and Hybrid Methods for the Removal of Poly- and Perfluoroalkyl Substances from Water—A Review. Appl. Sci. 2024, 14, 2574. [Google Scholar] [CrossRef]

- Gaurav, G.K.; Mehmood, T.; Kumar, M.; Cheng, L.; Sathishkumar, K.; Kumar, A.; Yadav, D. Review on polycyclic aromatic hydrocarbons (PAHs) migration from wastewater. J. Contam. Hydrol. 2021, 236, 103715. [Google Scholar] [CrossRef]

- Wójtowicz, B.; Kordyzon, M.; Bąk-Badowska, J.; Gregorczyk, M.; Gworek, B.; Żeber-Dzikowska, I. Chemicals in wastewater and sewage sludge—An underestimated health and environmental threat. J. Elem. 2022, 27, 847–859. [Google Scholar] [CrossRef]

- Gupta, A.; Kumar, S.; Bajpai, Y.; Chaturvedi, K.; Johri, P.; Tiwari, R.K.; Vivekanand, V.; Trivedi, M. Pharmaceutically active micropollutants: Origin, hazards and removal. Front. Microbiol. 2024, 15, 1339469. [Google Scholar] [CrossRef] [PubMed]

- Magdalou, J.; Fournel-Gigleux, S.; Testa, B.; Ouzzine, M. Biotransformation Reactions. In The Practice of Medicinal Chemistry, 2nd ed.; Wermuth, C.G., Ed.; Academic Press: Cambridge, MA, USA, 2003; pp. 517–543. [Google Scholar] [CrossRef]

- Szymonik, A.; Lach, J. Pharmaceuticals in surface water and drinking water. Environ. Sci. 2013, 7, 735–743. [Google Scholar] [CrossRef]

- Sanusi, I.O.; Olutona, G.O.; Wawata, I.G.; Onohuean, H. Occurrence, environmental impact and fate of pharmaceuticals in groundwater and surface water: A critical review. Environ. Sci. Pollut. Res. 2023, 30, 90595–90614. [Google Scholar] [CrossRef]

- Fernandes, J.P.; Almeida, C.M.R.; Salgado, M.A.; Carvalho, M.F.; Mucha, A.P. Pharmaceutical Compounds in Aquatic Environments—Occurrence, Fate and Bioremediation Prospective. Toxics 2021, 9, 257. [Google Scholar] [CrossRef]

- Zhuang, M.; Achmon, Y.; Cao, Y.; Liang, X.; Chen, L.; Wang, H.; Siame, B.A.; Leung, K.Y. Distribution of antibiotic resistance genes in the environment. Environ. Pollut. 2021, 285, 117402. [Google Scholar] [CrossRef] [PubMed]

- Ondon, B.S.; Li, S.; Zhou, Q.; Li, F. Sources of Antibiotic Resistant Bacteria (ARB) and Antibiotic Resistance Genes (ARGs) in the Soil: A Review of the Spreading Mechanism and Human Health Risks. In Reviews of Environmental Contamination and Toxicology; De Voogt, P., Ed.; Springer: Cham, Switzerland, 2021; p. 256. [Google Scholar] [CrossRef]

- Wang, J.L.; Xu, S.; Zhao, K.; Song, G.; Zhao, S.; Liu, R. Risk control of antibiotics, antibiotic resistance genes (ARGs) and antibiotic resistant bacteria (ARB) during sewage sludge treatment and disposal: A review. Sci. Total Environ. 2023, 877, 162772. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Zhang, Q.; Wang, T.; Xu, N.; Lu, T.; Hong, W.; Penuelas, J.; Gillings, M.; Wang, M.; Gao, W.; et al. Assessment of global health risk of antibiotic resistance genes. Nat. Commun. 2022, 13, 1553. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Kumar, G.; Yang, Y.-H. Understanding microplastic pollution: Tracing the footprints and eco-friendly solutions. Sci. Total Environ. 2024, 914, 169926. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Faith, C.; Matthew, J.; Jun, H.; Thomas, J. A review on the occurrence, distribution, characteristics, and analysis methods of microplastic pollution in ecosystems. In Assessing the Effects of Emerging Plastics on the Environment and Public Health; Joo, S.H., Ed.; IGI Global: Hershey, PA, USA, 2022; pp. 28–48. [Google Scholar] [CrossRef]

- Bień, J.; Nowak, D. Biological Composition of Sewage Sludge in the Aspect of Threats to the Natural Environment. Arch. Environ. Prot. 2014, 40, 79–86. [Google Scholar] [CrossRef][Green Version]

- Obuch-Woszczatyńska, O.; Bylińska, K.; Krzyżowska, M.; Korzekwa, K.; Bąska, P. Parasites in Sewage: Legal Requirements and Diagnostic Tools. Pathogens 2025, 14, 86. [Google Scholar] [CrossRef]

- Zdybel, J.; Cencek, T.; Karamon, J.; Kłapec, T. Effectiveness of selected stages of wastewater treatment in elimination of eggs of intestinal parasites. Bull. Vet. Inst. Pulawy 2015, 59, 51–57. [Google Scholar] [CrossRef]

- Wiśniowska, E.; Moraczewska-Majkut, K.; Nocoń, W. Efficiency of microplastics removal in selected wastewater treatment plants—Preliminary studies. Desalination Water Treat. 2018, 134, 316–323. [Google Scholar] [CrossRef]

- Wiśniowska, E.; Nocoń, W.; Moraczewska-Majkut, K. Microplastics in wastewater and sewage sludge. Gaz Woda I Tech. Sanit. 2018, 7, 114887. [Google Scholar] [CrossRef]

- Miri, S.; Saini, R.; Davoodi, S.M.; Pulicharla, R.; Brar, S.K.; Magdouli, S. Biodegradation of microplastics: Better late than never. Chemosphere 2022, 286 Pt 1, 131670. [Google Scholar] [CrossRef]

- Tavasoli, E.; Luek, J.L.; Malley, J.P.; Mouser, P.J. Distribution and fate of per- and polyfluoroalkyl substances (PFAS) in wastewater treatment facilities. Environ. Sci. Process. Impacts 2021, 23, 903–913. [Google Scholar] [CrossRef] [PubMed]

- Vo, H.N.P.; Ngo, H.H.; Guo, W.; Nguyen, T.M.H.; Li, J.; Liang, H.; Deng, L.; Chen, Z.; Nguyen, T.A.H. Poly-and perfluoroalkyl substances in water and wastewater: A comprehensive review from sources to remediation. J. Water Process Eng. 2020, 36, 101393. [Google Scholar] [CrossRef]

- Belete, B.; Desye, B.; Ambelu, A.; Yenew, C. Micropollutant Removal Efficiency of Advanced Wastewater Treatment Plants: A Systematic Review. Environ. Health Insights 2023, 17, 11786302231195158. [Google Scholar] [CrossRef]

- Shen, C.; He, M.; Zhang, J.; Liu, J.; Wang, Y. Response of soil antibiotic resistance genes and bacterial communities to fresh cattle manure and organic fertilizer application. J. Environ. Manag. 2024, 349, 119453. [Google Scholar] [CrossRef]

- Reynolds, J.I. Gene That Causes Antimicrobial Resistance in Bacteria Discovered in Georgia, CAES Newswire; College of Agricultural & Environmental Sciences: Athens, GA, USA, 2022; Available online: https://newswire.caes.uga.edu/story/8835/antimicrobial-resistance.html (accessed on 5 January 2025).

- Kasprzyk-Hordern, B.; Dinsdale, R.M.; Guwy, A.J. The removal of pharmaceuticals, personal care products, endocrine disruptors and illicit drugs during wastewater treatment and its impact on the quality of receiving waters. Water Res. 2009, 43, 363–380. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, S.C.; Boxall, A.B. Occurrence and fate of human pharmaceuticals in the environment. Rev. Environ. Contam. Toxicol. 2010, 202, 53–154. [Google Scholar] [CrossRef] [PubMed]

- Mao, D.; Yu, S.; Rysz, M.; Luo, Y.; Yang, F.; Li, F.; Hou, J.; Mu, Q.; Alvarez, P.J.J. Prevalence and proliferation of antibiotic resistance genes in two municipal wastewater treatment plants. Water Res. 2015, 85, 458–466. [Google Scholar] [CrossRef]

- Cui, T.; Zhang, S.; Ye, J.; Gao, L.; Zhan, M.; Yu, R. Distribution, Dissemination and Fate of Antibiotic Resistance Genes During Sewage Sludge Processing—A Review. Water Air Soil Pollut. 2022, 233, 138. [Google Scholar] [CrossRef]

- Zhao, L.; Gao, X.; Liu, X.; Li, H.; Luo, Y.; Qin, S. Reduction of Typical Antibiotic Resistance Genes and Mobile Gene Elements in Sewage Sludge During Sludge Bioleaching with Acidithiobacillus ferrooxidans. Water Air Soil Pollut. 2024, 235, 263. [Google Scholar] [CrossRef]

- Zalewska, M.; Błażejewska, A.; Szadziul, M.; Ciuchciński, K.; Popowska, M. Effect of composting and storage on the microbiome and resistome of cattle manure from a commercial dairy farm in Poland. Environ. Sci. Pollut. Res. 2024, 31, 30819–30835. [Google Scholar] [CrossRef]

- Karwowska, E. Antibiotic Resistance in the Farming Environment. Appl. Sci. 2024, 14, 5776. [Google Scholar] [CrossRef]

- Sun, Z.; Hong, W.; Xue, C.; Dong, N. A comprehensive review of antibiotic resistance gene contamination in agriculture: Challenges and AI-driven solutions. Sci. Total Environ. 2024, 953, 175971. [Google Scholar] [CrossRef] [PubMed]

- Obaideen, K.; Shehata, N.; Sayed, E.T.; Abdelkareem, M.A.; Mahmoud, M.S.; Olabi, A.G. The role of wastewater treatment in achieving sustainable development goals (SDGs) and sustainability guideline. Energy Nexus 2022, 7, 100112. [Google Scholar] [CrossRef]

- Saur, T.; Paillet, F.; Robert, S.; Alibar, J.-C.; Loret, J.-F.; Barillon, B. Fate of Microplastic Pollution Along the Water and Sludge Lines in Municipal Wastewater Treatment Plants. Microplastics 2025, 4, 19. [Google Scholar] [CrossRef]

- Talukdar, A.; Kundu, P.; Bhattacharya, S.; Dutta, N. Microplastic contamination in wastewater: Sources, distribution, detection and remediation through physical and chemical-biological methods. Sci. Total Environ. 2024, 916, 170254. [Google Scholar] [CrossRef]

- Bodzek, M.; Pohl, A.; Rosik-Dulewska, C. Microplastics in Wastewater Treatment Plants: Characteristics, Occurrence and Removal Technologies. Water 2024, 16, 3574. [Google Scholar] [CrossRef]

- Ferrera, I.; Sánchez, O. Insights into microbial diversity in wastewater treatment systems: How far have we come? Biotechnol. Adv. 2016, 34, 790–802. [Google Scholar] [CrossRef]

- EU—Lex. Directive (EU) 2024/3019 of the European Parliament and of the Council of 27 November 2024 Concerning Urban Wastewater Treatment (Recast) (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/eli/dir/2024/3019/oj/eng (accessed on 31 May 2025).

- EU Monitor. Legal Provisions of COM(2022)541—Urban Wastewater Treatment (Recast). Available online: https://www.eumonitor.eu/9353000/1/j4nvhdfcs8bljza_j9vvik7m1c3gyxp/vlxjmg98x5wm (accessed on 15 May 2025).

- Singh, D.; Singh, D.; Mishra, V.; Kushwaha, J.; Sengar, M.; Sinha, S.; Singh, S.; Giri, B.S. Strategies for biological treatment of waste water: A critical review. J. Clean. Prod. 2024, 454, 142266. [Google Scholar] [CrossRef]

- Krzemiński, P.; Popowska, M. Treatment Technologies for Removal of Antibiotics, Antibiotic Resistance Bacteria and Antibiotic-Resistant Genes. In Antibiotics and Antimicrobial Resistance Genes. Emerging Contaminants and Associated Treatment Technologies; Hashmi, M., Ed.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Zheng, J.; Su, C.; Zhou, J.; Xu, L.; Qian, Y.; Chen, H. Effects and mechanisms of ultraviolet, chlorination, and ozone disinfection on antibiotic resistance genes in secondary effluents of municipal wastewater treatment plants. Chem. Eng. J. 2017, 317, 309–316. [Google Scholar] [CrossRef]

- Du, Y.; Lv, X.-T.; Wu, Q.-Y.; Zhang, D.-Y.; Zhou, Y.-T.; Peng, L.; Hu, H.-Y. Formation and control of disinfection byproducts and toxicity during reclaimed water chlorination: A review. J. Environ. Sci. 2017, 58, 51–63. [Google Scholar] [CrossRef]

- Carré, E.; Pérot, J.; Jauzein, V.; Lopez-Ferber, M. Impact of suspended particles on UV disinfection of activated-sludge effluent with the aim of reclamation. J. Water Process Eng. 2018, 22, 87–93. [Google Scholar] [CrossRef]

- Ayilara, M.S.; Olanrewaju, O.S.; Babalola, O.O.; Odeyemi, O. Waste Management through Composting: Challenges and Potentials. Sustainability 2020, 12, 4456. [Google Scholar] [CrossRef]

- Sardar, M.F.; Zhu, C.; Geng, B.; Huang, Y.; Abbasi, B.; Zhang, Z.; Song, T.; Li, H. Enhanced control of sulfonamide resistance genes and host bacteria during thermophilic aerobic composting of cow manure. Environ. Pollut. 2021, 275, 116587. [Google Scholar] [CrossRef]

- Miaśkiewicz, K. Czwarty Stopień Oczyszczania Ścieków Może Wkrótce Stać Się Obowiązkowy. 2024. Available online: https://wilo.com/pl/pl/Narz%C4%99dzia/Cenniki-i-dokumentacja-techniczna/Artyku%C5%82y-techniczne/Czwarty-stopie%C5%84-oczyszczania-%C5%9Bciek%C3%B3w-mo%C5%BCe-wkr%C3%B3tce-sta%C4%87-si%C4%99-obowi%C4%85zkowy!_8320.html (accessed on 31 May 2025).

- Shi, F.; Zhao, H.; Wang, L.; Cui, X.; Guo, W.; Zhang, W.; Song, H.; Li, S. Inactivation mechanisms of electron beam irradiation on Listeria innocua through the integrity of cell membrane, genomic DNA and protein structures. Int. J. Food Sci. Technol. 2019, 54, 1804–1815. [Google Scholar] [CrossRef]

- Sampa, M.H.O.; Takács, E.; Gehringer, P.; Rela, P.R.; Ramirez, T.; Amro, H.; Trojanowicz, M.; Botelho, M.L.; Han, B.; Solpan, D.; et al. Remediation of polluted waters and wastewater by radiation processing. Nukleonika 2007, 52, 137–144. Available online: http://www.nukleonika.pl/www/back/full/vol52_2007/v52n4p137f.pdf (accessed on 15 May 2025).

- Trojanowicz, M.; Bobrowski, K.; Szreder, T.; Bojanowska-Czajka, A. Chapter 9—Gamma-ray, X-ray and Electron Beam Based Processes. In Advanced Oxidation Processes for Waste Water Treatment; Ameta, S.C., Ameta, R., Eds.; Academic Press: Cambridge, MA, USA, 2018; pp. 257–331. [Google Scholar] [CrossRef]

- Trojanowicz, M.; Bojanowska-Czajka, A.; Capodaglio, A.G. Can radiation chemistry supply a highly efficient AO(R)P process for organics removal from drinking and waste water? A review. Environ. Sci. Pollut. Res. 2017, 24, 20187–20208. [Google Scholar] [CrossRef] [PubMed]

- Trojanowicz, M.; Bartosiewicz, I.; Bojanowska-Czajka, A.; Szreder, T.; Bobrowski, K.; Męczyńska-Wielgosz, S.; Nałęcz-Jawecki, G.; Nichipor, H. Application of Ionizing Radiation in Decomposition of Perfluorooctane Sulfonate (PFOS) in aqueous aolutions. Chem. Eng. J. 2019, 379, 122303. [Google Scholar] [CrossRef]

- Londhe, K.; Lee, C.-S.; Zhang, Y.; Grdanovska, S.; Kroc, T.; Cooper, C.A.; Venkatesan, A.K. Energy Evaluation of Electron Beam Treatment of Perfluoroalkyl Substances in Water: A Critical Review. ACS EST Eng. 2021, 1, 827–841. [Google Scholar] [CrossRef]

- Han, B.; Kim, J.K.; Kim, Y.; Choi, J.S.; Jeong, K.Y. Operation of industrial-scale electron beam wastewater treatment plant. Radiat. Phys. Chem. 2012, 81, 1475–1478. [Google Scholar] [CrossRef]

- Wang, S.; Wang, J.; Chen, C.; He, S.; Hu, J.; Zhang, Y. First full-scale application of electron beam technology for treating dyeing wastewater (30,000 m3/d) in China. Radiat. Phys. Chem. 2022, 196, 110136. [Google Scholar] [CrossRef]

- Rios-Miguel, A.B.; van Bergen, T.J.H.M.; Zillien, C.; Ragas, A.M.J.; van Zelm, R.; Jetten, M.S.M.; Hendriks, A.J.; Welte, C.U. Predicting and improving the microbial removal of organic micropollutants during wastewater treatment: A review. Chemosphere 2023, 333, 138908. [Google Scholar] [CrossRef] [PubMed]

- Zgórska, A.; Grabińska-Sota, E. The toxicity classification of hospital wastewater in relation to the criterion of their harmfulness in reference to water biocenosis. Ecol. Eng. Environ. Technol. 2019, 20, 5–13. [Google Scholar] [CrossRef]

- Boiani, N.F.; Tominaga, F.K.; Borrely, S.I. Toxicity Removal of Pharmaceuticals Mixtures through Electron Beam Irradiation. Braz. J. Radiat. Sci. 2022, 10. [Google Scholar] [CrossRef]

- Huang, X.; Wen, D.; Wang, J. Radiation-induced degradation of sulfonamide and quinolone antibiotics: A brief review. Rad. Phys. Chem. 2024, 215, 111373. [Google Scholar] [CrossRef]

- Wang, S.Z.; Wang, J.L. Radiation-induced degradation of sulfamethoxazole in the presence of various inorganic anions. Chem. Eng. J. 2018, 351, 688–696. [Google Scholar] [CrossRef]

- Liu, N.; Huang, W.-y.; Li, Z.-m.; Shao, H.-y.; Wu, M.-h.; Lei, J.-q.; Tang, L. Radiolytic decomposition of sulfonamide antibiotics: Implications to the kinetics, mechanisms and toxicity. Sep. Purif. Technol. 2018, 202, 259–265. [Google Scholar] [CrossRef]

- Sági, G.; Bezsenyi, A.; Kovács, K.; Klátyik, S.; Darvas, B.; Székács, A.; Mohácsi-Farkas, C.; Takács, E.; Wojnárovits, L. Radiolysis of sulfonamide antibiotics in aqueous solution: Degradation efficiency and assessment of antibacterial activity, toxicity and biodegradability of products. Sci. Total Environ. 2018, 622–623, 1009–1015. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S. Toxicity changes of wastewater during various advanced oxidation processes treatment: An overview. J. Clean. Prod. 2021, 315, 128202. [Google Scholar] [CrossRef]

- Bojanowska-Czajka, A. Decomposition of diclofenac in sewage from municipal wastewater treatment plant using ionizing radiation. Nukleonika 2021, 66, 201–206. [Google Scholar] [CrossRef]

- Sági, G.; Csay, T.; Szabó, L.; Pátzay, G.; Csonka, E.; Takács, E.; Wojnárovits, L. Analytical approaches to the OH radical induced degradation of sulfonamide antibiotics in dilute aqueous solutions. J. Pharm. Biomed. Anal. 2015, 106, 52–60. [Google Scholar] [CrossRef]

- Kim, H.Y.; Kim, T.H.; Cha, S.M.; Yu, S. Degradation of sulfamethoxazole by ionizing radiation: Identification and characterization of radiolytic products. Chem. Eng. J. 2017, 313, 556–566. [Google Scholar] [CrossRef]

- Liu, Y.K.; Wang, J.L. Degradation of sulfamethazine by gamma irradiation in the presence of hydrogen peroxide. J. Hazard. Mater. 2013, 15, 99–105. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.Z.; Wang, J.L. Electron beam technology coupled to Fenton oxidation for advanced treatment of dyeing wastewater: From laboratory to full application. ACS EST Water 2022, 2, 852–862. [Google Scholar] [CrossRef]

- Liu, Y.K.; Hu, J.; Wang, J.L. Fe2+ enhancing sulfamethazine degradation in aqueous solution by gamma irradiation. Rad. Phys. Chem. 2014, 96, 81–87. [Google Scholar] [CrossRef]

- Trojanowicz, M.; Bobrowski, K.; Szostek, B.; Bojanowska-Czajka, A.; Szreder, T.; Bartoszewicz, I.; Kulisa, K. A survey of analytical methods employed for monitoring of Advanced Oxidation/Reduction Processes for decomposition of selected perfluorinated environmental pollutants. Talanta 2018, 177, 122–141. [Google Scholar] [CrossRef]

- Ardestani, S.B.; Akhavan, A.; Kazeminejad, H.; Ahmadi-Roshan, M.; Roozbahani, A. Ionizing radiation effect on the removing of antibiotic pollutants from pharmaceutical wastewater: Identification of radio-degradation products. J. Radioanal. Nucl. Chem. 2024, 333, 4523–4541. [Google Scholar] [CrossRef]

- Trojanowicz, M. Removal of persistent organic pollutants (POPs) from waters and wastewaters by the use of ionizing radiation. Sci. Total Environ. 2020, 718, 134425. [Google Scholar] [CrossRef] [PubMed]

- Demir, I.; Besson, A.; Guiraud, P.; Formosa-Dague, C. Towards a better understanding of microalgae natural flocculation mechanisms to enhance flotation harvesting efficiency. Water Sci. Technol. 2020, 82, 1009–1024. [Google Scholar] [CrossRef]

- Siwek, M.; Edgecock, T.; Chmielewski, A.G.; Rafalski, A.; Walo, M.; Sudlitz, M.; Lin, L.; Sun, Y. The potential of electron beams for the removal of microplastics from wastewater and sewage sludge. Environ. Chall. 2023, 13, 100760. [Google Scholar] [CrossRef]

- Shen, Y.; Zhuan, R.; Chu, L.; Xiang, X.; Sun, H.; Wang, J. Inactivation of antibiotic resistance genes in antibiotic fermentation residues by ionizing radiation: Exploring the development of recycling economy in antibiotic pharmaceutical factory. Waste Manag. 2019, 84, 141–146. [Google Scholar] [CrossRef]

- Chu, L.; Wang, J.; Chen, C.; Shen, Y.; He, S.; Wojnárovits, L.; Takács, E.; Zhang, Y. Abatement of antibiotics and antimicrobial resistance genes from cephalosporin fermentation residues by ionizing radiation: From lab-scale study to full-scale application. J. Clean. Prod. 2021, 325, 129334. [Google Scholar] [CrossRef]

- Sudlitz, M.; Chmielewski, A.G. A Method for WWTP Sludge Valorization through Hygienization by Electron Beam Treatment. Fermentation 2021, 7, 302. [Google Scholar] [CrossRef]

- Kim, J.-K.; Kim, Y.; Han, B.; Yaacob, N.B. Sludge Hygienization Plant with Electron Beam. In Proceedings of the Transactions of the Korean Nuclear Society Spring Meeting, Gyeongju, Republic of Korea, 29–30 May 2008; pp. 633–634. Available online: https://www.kns.org/files/pre_paper/12/353%ED%95%9C%EB%B2%94%EC%88%98.pdf (accessed on 15 May 2025).

- Siwek, M.; Edgecock, T. Application of electron beam water radiolysis for sewage sludge treatment—A review. Environ. Sci. Pollut. Res. 2020, 27, 42424–42448. [Google Scholar] [CrossRef] [PubMed]

- Directive (EU) 2024/3019 of the European Parliament and of the Council of 27 November 2024 Concerning Urban Wastewater Treatment (Recast). Official Journal of the European Union. 2024. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=OJ%3AL_202403019 (accessed on 15 May 2025).

- Ianes, J.; Piraldi, S.; Cantoni, B.; Antonelli, M. Micropollutants removal, residual risk, and costs for quaternary treatments in the framework of the Urban Wastewater Treatment Directive. Water Res. X 2025, 29, 100334. [Google Scholar] [CrossRef]

- Derco, J.; Gulašová, P.; Legan, M.; Zakhar, R.; Žgajnar Gotvajn, A. Sustainability Strategies in Municipal Wastewater Treatment. Sustainability 2024, 16, 9038. [Google Scholar] [CrossRef]

- The United Nations Human Settlements Programme (UN-Habitat) and the World Health Organization (WHO), 2024. Progress on the Proportion of Domestic and Industrial Wastewater Flows Safely Treated—Mid-Term Status of SDG Indicator 6.3.1 and Acceleration Needs, with a Special Focus on Climate Change, Wastewater Reuse and Health. United Nations Human Settlements Programme (UN-Habitat) and World Health Organization (WHO). 2024. Available online: https://www.unwater.org/sites/default/files/2024-08/SDG6_Indicator_Report_631_Progress-on-Wastewater-Treatment_2024_EN_0.pdf (accessed on 15 May 2025).

- Dereszewska, A.; Cytawa, S. Potential Opportunities for Organic Recycling in a Wastewater Treatment Plant in the Assumptions of Circular Economy. Gaz Woda I Tech. Sanit. 2022, 1, 138805. [Google Scholar] [CrossRef]

- Gupta, A.S.; Khatiwada, D. Investigating the sustainability of biogas recovery systems in wastewater treatment plants—A circular bioeconomy approach. Renew. Sustain. Energy Rev. 2024, 199, 114447. [Google Scholar] [CrossRef]

- Chmielewski, A.G.; Sudlitz, M.; Han, B.; Pillai, S.D. Electron beam technology for biogas and biofertilizer generation at municipal resource recovery facilities. Nukleonika 2021, 66, 213–219. [Google Scholar] [CrossRef]

- United Nations Educational, Scientific and Cultural Organization. The United Nations World Water Development Report. Water for Prosperity and Peace; United Nations Educational, Scientific and Cultural Organization: Paris, France, 2024; Available online: https://www.unwater.org/publications/un-world-water-development-report-2024 (accessed on 15 May 2025).

- Krawczyk, Ł. (Ed.) Kierunki Rozwoju Komunalnych Oczyszczalni Ścieków—Innowacyjne Rozwiązania w Obliczu Gospodarki Cyrkularnej; Instytut Ochrony Środowiska—Państwowy Instytut Badawczy: Wrocław, Poland, 2022; Available online: https://ios.edu.pl/wp-content/uploads/2022/10/Kierunki-rozwoju-komunalnych-oczyszczalni-sciekow.pdf (accessed on 15 May 2025).

- Yoo, K.; Yoo, H.; Lee, J.; Choi, E.J.; Park, J. Exploring the antibiotic resistome in activated sludge and anaerobic digestion sludge in an urban wastewater treatment plant via metagenomic analysis. J. Microbiol. 2020, 58, 123–130. [Google Scholar] [CrossRef]

- Shin, K.S.; Kang, H. Electron beam pretreatment of sewage sludge before anaerobic digestion. Appl. Biochem. Biotechnol. 2003, 109, 227–239. [Google Scholar] [CrossRef]

- Lemée, L.; Collard, M.; Vel Leitner, N.K.; Teychené, B. Changes in Wastewater Sludge Characteristics Submitted to Thermal Drying, E-beam Irradiation or Anaerobic Digestion. Waste Biomass Valorization 2017, 8, 1771–1780. [Google Scholar] [CrossRef]

- Li, X.; Jin, W.; Du, Y.; Tan, Z.; Liu, R.; Xiao, R.; Wang, J.; Wang, J.; Zhou, L. Electron beam irradiation effect on the physicochemical characteristics of municipal excess sludge. Radiat. Phys. Chem. 2021, 180, 109246. [Google Scholar] [CrossRef]

- Stępień, M.; Krawczyk, P.; Wołowicz, M.; Mikołajczak, A. Dezintegracja substratów biologicznych przed procesem fermentacji. Przegląd stosowanych technologii. Rynek Energii 2018, 5. Available online: https://www.rynek-energii.pl/pl/node/3781 (accessed on 22 January 2025).

- Chmielewski, A.G.; Sudlitz, M.; Zubrowska-Sudoł, M. Advanced Technology for Energy, Plant Nutrients and Water Recovery at Wastewater Treatment Plants. Energies 2024, 17, 2749. [Google Scholar] [CrossRef]

- Department of Energy. Technology Readiness Assessment Guide. Chg 1 (Admin Chg). 2015. Available online: https://www.directives.doe.gov/directives-documents/400-series/0413.3-EGuide-04a-admchg1/@@images/file (accessed on 31 May 2025).

- Bruno, I.; Lobo, G.; Covino, B.V.; Donarelli, A.; Marchetti, V.; Panni, A.S.; Molinari, F. Technology readiness revisited: A proposal for extending the scope of impact assessment of European public services. In Proceedings of the ICEGOV’ 20: Proceedings of the 13th International Conference on Theory and Practice of Electronic Governance, Athens, Greece, 23–25 September 2020; pp. 369–380. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S.; Chen, C.; Hu, J.; He, S.; Zhou, Y.; Zhu, H.; Wang, X.; Hu, D.; Lin, J. Treatment of hospital wastewater by electron beam technology: Removal of COD, pathogenic bacteria and viruses. Chemosphere 2022, 308, 136265. [Google Scholar] [CrossRef]

- Gryczka, U.; Zimek, Z.; Walo, M.; Chmielewska-Smietanko, D.; Bułka, S. Advanced Electron Beam (EB) Wastewater Treatment System with Low Background X-ray Intensity Generation. Appl. Sci. 2021, 11, 11194. [Google Scholar] [CrossRef]

- Sun, Y.; Madureira, J.; Justino, G.C.; Cabo Verde, S.; Chmielewska-Śmietanko, D.; Sudlitz, M.; Bulka, S.; Chajduk, E.; Mróz, A.; Wang, S.; et al. Diclofenac Degradation in Aqueous Solution Using Electron Beam Irradiation and Combined with Nanobubbling. Appl. Sci. 2024, 14, 6028. [Google Scholar] [CrossRef]

- Pryzowicz, A.; Pietrzak, K.; Zimek, Z.; Chmielewski, A.G. Biogas Plant. In Preparation of the Design Basis Concerning Application of an Advanced Plant with a Biogas Module and an Advanced Module with an Electron Accelerator for Removing Biological Threats; Biopolinex Sp. z o.o.: Lublin, Poland, 2023; Volume I. [Google Scholar]

- Zimek, Z. Electron accelerator System. In Preparation of the Design Basis Concerning Application of an Advanced Plant with a Biogas Module and an Advanced Module with an Electron Accelerator for Removing Biological Threats; Biopolinex sp. z o.o.: Lublin, Poland, 2023; Volume II. [Google Scholar]

- Rosiński, M. Integrated System of Agricultural Sewage Treatment Plant-Biogas Plant. Master’s Thesis, Warsaw University of Technology, Warszawa, Poland, 2018. Available online: https://ichip.pw.edu.pl/content/download/4243/19327/file/Mateusz%20Rosi%C5%84ski%20Poster.pdf (accessed on 15 May 2025).

- Dhuley, R.C.; Gonin, I.; Zeller, K.; Kostin, R.; Kazakov, S.; Coriton, B.; Khabiboulline, T.; Sukhanov, A.; Yakovlev, V.; Saini, A.; et al. Design of a medium energy, high average power superconducting e-beam accelerator for environmental applications. arXiv 2021. [Google Scholar] [CrossRef]

- Ciovati, G.; Anderson, J.; Coriton, B.; Guo, J.; Hannon, F.; Holland, L.; LeSher, M.; Marhauser, F.; Rathke, J.; Rimmer, R.; et al. Design of a cw, low-energy, high-power superconducting linac for environmental applications. Phys. Rev. Accel. Beams 2018, 21, 091601. [Google Scholar] [CrossRef]

- Ryan, R. Cheaper, Greener Particle Accelerators Will Speed Innovation; Cornell Cronice: Ithaca, NY, USA, 2021; Available online: https://news.cornell.edu/stories/2021/03/cheaper-greener-particle-accelerators-will-speed-innovation (accessed on 15 May 2025).

- The United Nations World Water Development Report 2024: Water for Prosperity and Peace, UNESCO World Water Assessment Programme [605]. ISBN: 978-92-3-100657-9. Available online: https://unesdoc.unesco.org/ark:/48223/pf0000388948 (accessed on 15 May 2025).

| O3 | UV/O3 | EB/O3 |

|---|---|---|

| 3O3 + H2O→2•OH + 4O2 | O3 + H2O + hv → H2O2 + O2 O3 + hv → O2 + O O + H2O → H2O2 H2O2 ↔ HO2− + H+ O3 + HO2−→ •OH + 2O2 H2O2 + hv → 2 •OH | H2O + e− → [2.7] •OH + [2.7] H3O+ + [2.6] e− + [0.7] H2 O2 + [0.6] H + [0.45] H2 O3 + H → •OH + O2 O3 + H2O2 → 2 •OH + O2 e−aq + H3O+ + O3 → H2O + OH + O2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chmielewski, A.G.; Sun, Y.; Wang, J.; Wang, S. Emerging Electron Beam Technology Targeting Hazardous Micropollutants as Quaternary Treatment in Wastewater Treatment Plants. Sustainability 2025, 17, 5963. https://doi.org/10.3390/su17135963

Chmielewski AG, Sun Y, Wang J, Wang S. Emerging Electron Beam Technology Targeting Hazardous Micropollutants as Quaternary Treatment in Wastewater Treatment Plants. Sustainability. 2025; 17(13):5963. https://doi.org/10.3390/su17135963

Chicago/Turabian StyleChmielewski, Andrzej G., Yongxia Sun, Jianlong Wang, and Shizong Wang. 2025. "Emerging Electron Beam Technology Targeting Hazardous Micropollutants as Quaternary Treatment in Wastewater Treatment Plants" Sustainability 17, no. 13: 5963. https://doi.org/10.3390/su17135963

APA StyleChmielewski, A. G., Sun, Y., Wang, J., & Wang, S. (2025). Emerging Electron Beam Technology Targeting Hazardous Micropollutants as Quaternary Treatment in Wastewater Treatment Plants. Sustainability, 17(13), 5963. https://doi.org/10.3390/su17135963