Abstract

The development of retail stores is determined by many factors, including the availability of retail space. The construction of a new building requires time, resources, and permits. This article aims to examine the possibilities of implementing small modular retail facilities built on the principles of vending machines, which do not require constant service and social space, by examining important groups of factors: architectural and structural, production, environmental, and costs. A vending machine in modular construction technology provides new opportunities for the development of a retail network in previously inaccessible places. The research presented in this article was conducted based on a literature review and interviews with experts, on the basis of which, using the network thinking methodology, critical factors were isolated and analysed in detail. The research results show the benefits of using modular technology, meeting the assumptions of the circular economy in terms of reducing the carbon footprint and improving the construction stage and investment costs, while taking into account the aesthetics of the surroundings. The results can contribute to the popularisation of the use of modular facilities, which can complement the development of downtown areas, making cities more sustainable.

1. Introduction

Studies conducted in various urban environments indicate that integrated, accessible urban structures and well-planned commercial zones support the development of small-scale retail trade. The division of city space into small plots accessible for small-scale retail trade can increase the resilience of retail trade and contribute to its profitability [1]. Access to shops increases the attractiveness of a given area in terms of the desire to settle. The organisation of local shopping centres and activities that facilitate the location of small shops can be helpful in revitalising areas that are becoming depopulated due to a lack of access to services [2]. Small modular facilities can be used not only as commercial facilities but also to organise co-working or various services, e.g., educational or cultural activities. An example is the Mobile Institute of Culture [3], located in a container, which does not take up much space on a daily basis and can be easily transported to another location. A large number of small facilities increases the diversity of the offer and increases the number of customers. Examples include the well-functioning Boxpark container mall in London, the Downtown Container Park in Las Vegas, or Kontener Art in Poznan. Food fairs are also very popular, such as Smorgasburg in New York or the Food Truck Festival in Melbourne, which shows that access to a diverse range of products attracts more customers. Organising a large shopping area requires ensuring accessibility, i.e., parking spaces and public transport, or proximity to residential estates, especially due to the increasing number of elderly and disabled people. Access to trade and services close to the place of residence eliminates the need to travel to large shopping centres on the outskirts of cities. If there is no large square or empty plot in the dense city centre development, the solution may be to set up individual small modular facilities. Setting up a container may require the consent of local city offices, but these are temporary facilities that are not permanently connected to the ground. Self-service stores technically only need electricity. Setting up this type of facility is much faster than the entire process of designing and building a traditional retail facility.

A new trend is completely self-service stores with an entrance control system that minimises the need for an employee to be present on site, limiting work to replenishing goods and maintaining order. The lack of an employee in the store eliminates the need to provide them with a social room and a toilet, increasing the designated area for goods. This system was implemented in one of the retail chains. In the entrance control system, a payment card is scanned, and then a camera system observes which product was taken off the shelf. After leaving the store, the entire purchase amount is automatically charged to the card. A self-service store is treated as a vending machine. It is a temporary facility and only needs a connection to the power grid. It can be partially powered by its own photovoltaic or wind sources. The advantage of vending machines is that they can be placed in places where it would be very difficult to build a regular store. An example would be a store on a hospital or university campus (Figure 1). The ease of setting up a ready-made container with a specific function allows for the revitalisation of areas that require revitalisation [4] by adding temporarily missing functions in a given area. The store becomes a place of contact only between the customer and the goods, so its design can also be simplified to the necessary minimum.

Figure 1.

External view of vending machine containers (a,b) on the university campus and internal view (c) with cameras recording the selection of goods (photo: author).

Small self-service stores fit the idea of compact stores that are open 24/7, which offer a wide selection of everyday products such as food, drinks, snacks, hygiene products, and many others. Stores are equipped with artificial intelligence and camera systems that automatically track customer traffic and charge for the selected products. In other words, thanks to the latest technologies, they allow customers to enter, take what they need, and leave without having to wait in line or use the cash register [5]. However, small stores offer limited-variety products, tailored to the needs of local customers. The possibility of flexibly adapting the location of the store to demand is often limited by architectural and urban regulations, especially in dense downtown areas. In places where it is not possible to build a new commercial facility, you can consider installing a vending machine, but such a machine has a small capacity and a limited range of products, which causes retail companies to place several machines next to each other, but their appearance does not always match the context, which leads to a deterioration of the aesthetics of the place.

Shopping habits and readiness to use digital tools change with the change of generations. Pandemic isolation has also caused a change in customer attitudes, moving them toward online shopping [6], and time will tell whether this trend will continue [7]. Purchased products are divided into two categories: those for which information can be accessed online and those that require physical examination by potential consumers. Buying food products, especially fresh ones, usually requires a personal visit to the store. In Poland, small grocery stores are often replaced by discount stores, which, in addition to traditional ones, also have a self-service checkout. Many grocery store customers are willing to use self-service checkouts due to convenience and speed of service, but there are also those who are dissatisfied due to technical problems, a lack of assistance, and the impersonal nature of shopping [8]. Making the checkout system easier to use can reduce customer dissatisfaction [5,6]. User proficiency in using modern technology has a positive effect on the perceived ease and usefulness of use [9] and the willingness to use it again. New technologies also offer benefits to store owners, such as RFID (an automatic identification method that can store and retrieve data based on radio frequency). Using artificial intelligence tools to identify products and customer behaviour eliminates the need to manually scan each item [10] and can be linked to online payments. These solutions can reduce labour costs and better target marketing campaigns. The challenge of self-service systems is the high cost of installation and the problem of possible product identification errors. Concerns are also raised by the excessive amount of data collected about the customer, hence the need for appropriate protocols to protect customer data [10]. Self-service machines are often found to be an additional form of 24 h sales, e.g., in Japan or in places with a high tourist density, e.g., in Italy (Figure 2), or we are often dealing with a specific group of customers, e.g., students near a university. The aesthetics of such machines vary, especially when each comes from a different manufacturer. You can buy various products from the machines, including hot meals and even cars. There are examples of car vending machines in China, Singapore, and the United States [11]. It is a tall tower with a lift, as in a vertical garage. Customers can choose a car using an app, test it for a few days, and then decide whether to buy it.

Figure 2.

Self-service machines: (a) in Japan; (b) in Italy (photo: author).

A traditional store is a place where people work. It must meet the requirements for the occupational health and safety of employees, as well as the requirements of architectural and construction regulations. It is necessary to ensure adequate sunlight, thermal insulation, ventilation, and access to a sanitary room, which is why it is necessary to connect to the water supply, sewage, and energy networks. This requires appropriate arrangements and, above all, a permanent connection of the building to the ground, which is related to architectural and urban planning regulations (Polish Construction Law Act) [12]. Regardless of the construction method, buildings must meet the requirements for energy efficiency [13].

2. Study Area

The architecture of container buildings is very diverse: it can either disfigure or enrich the terrain. There are many different ways to connect modules (vertically and horizontally), finishing materials, and shapes, and thanks to this, you can match the size and aesthetics of the building to the surroundings. Currently, ready-made modules can be purchased online directly from Chinese manufacturers, but there are also offers from local manufacturers. On site, only the foundations are necessary, and the required media are available. Construction carried out using the traditional method requires more resources, time, and work than construction in a factory. Container structures are currently also used to create frames for architectural objects due to their durability, low cost, quick construction, and the possibility of various changes in function [14]. The structure consists of four thermally insulated steel panels or a glass facade. Due to dimensional coordination, they can be put together in various combinations, allowing them to meet the needs of different functions [15]. The prefabrication of spatial modules in a finished standard, ready for assembly and use, immediately allows the development of areas in cold regions [16] but also in places where construction work is difficult. It is also a chance for quick adaptation to local needs after disasters [17], e.g., after floods. The disadvantages of container warehouses are a small space, poor thermal insulation, and the associated high costs of heating in winter and cooling in summer.

Harmonising modern buildings in existing urban contexts is often a complex challenge that requires the careful consideration of various factors. Preserving historic character while integrating contemporary design is crucial [18]. The methods of assessing modern buildings in historic areas focus on criteria such as respect for existing structures, reversibility, and responsiveness to local requirements [19]. Visual impact assessments can help determine how new buildings are perceived in historic environments, taking into account factors such as harmony, rhythm, and aesthetic value [20]. Documentation and valuation tools, such as those proposed by INPC and Docomomo, can be adapted to assess modern buildings in a historic context [21]. The successful integration of modern architecture in historical areas can be achieved through principles such as the following [18]:

- preserving the rhythms of the façade;

- repeating dominant elements;

- using background building techniques.

The aesthetic evaluation of architecture involves complex factors, including style, exposure, and historical context. Modern buildings are often perceived as more aesthetically appealing but less organised than older structures [22]. However, harmonising contemporary designs in historical environments remains a challenge. The successful integration of modern housing with historic buildings is possible when taking into account the following [18]:

- shape;

- colour;

- proportions;

- materials.

The aesthetic characteristics of architectural forms are influenced by period preferences and socio-political conditions [23]. When reconstructing historic urban centres, it is crucial to preserve cultural heritage while adapting to modern needs. This requires special knowledge and consideration of the surrounding context, including spatial composition and the built environment [24]. Balance and protection through contemporary design elements are essential for sustainable development and the maintenance of the cultural value of historic buildings.

A unique feature of the container architecture without a human component is the possibility of limiting the form to the technological casing. This gives the possibility of—but does not guarantee—creating a form that blends into the background, limited to a three-dimensional, aesthetically transparent display case, a glass box, or creating an aggressive, characteristic, sculptural form. When introducing a new object into an existing development, it is necessary to consider the preservation of cultural heritage and the integration of new buildings into the historical context [18]. Positive aspects can be obtained by introducing modern architecture in a historical setting. The decision-making process should include the following [25]:

- cooperation between conservators and architects;

- historical assessment to understand what is important in a given place;

- defining measurable assessment criteria;

- formulating flexible guidelines that will allow for a range of acceptable architectural solutions and ensure coherence of the surroundings;

- decision-making by qualified specialists, taking into account the opinions of community stakeholders;

- defining the duration of the operation of the facility.

A good urban solution is succession, that is, continuing what predecessors created in the development of the city, for example, by referring to traditional colours [18]. Stylistic imitation, limiting the number of floors so as not to disturb the silhouette of old buildings, and analysing different viewing directions will allow the addition of a new building while maintaining the historical appearance of the street [26]. However, new development is easily recognisable despite referring to the historical background; it may have a characteristic form, material, colour, and construction, the value of uniqueness, and a positive impact on a given area [19]. The belief that buildings in the old style are more harmonious does not mean that they are perceived as more beautiful or aesthetically rated higher than buildings in the modern style. Buildings in the modern style can be perceived as more attractive in terms of aesthetics than buildings in the older style. The most preferred architecture is one with a moderate level of complexity [27]. Studies on the perception and evaluation of old and modern-style buildings give inconsistent results due to different research methods but also due to individual differences in the compared styles [22] and the feelings of the people surveyed. The successful introduction of a modern building into the context of existing development can be achieved thanks to the following [28]:

- A thorough analysis of the context of the site (geographical location, historical conditions, existing structures, and spatial arrangements) and such selection of the location of the new facility that, while fitting into the surroundings, it becomes a natural element of the landscape.

- Taking into account the height, volume, and proportions of neighbouring buildings and the use of rhythmic elements of the facade, helping to maintain harmony with the existing architecture.

- The selection of the finishing materials, including traditional ones such as bricks, stone, or wood, and high-quality workmanship.

- Consultations with the local community and conservation offices.

- Creating new views, public spaces, and interesting visual combinations in order to create public spaces that are attractive to the local community.

- Maintaining a balance between tradition and modernity (instead of imitating historical styles, using elements that subtly refer to traditional forms and details).

Modular architecture in Poland occurs most often in the form of specially manufactured objects and less often in the form of adapted shipping containers. Modular construction can be used in both temporary and year-round facilities [29]. If they are to be used for a long time, they must be made with special attention to quality. A modular building is built in a factory. The same building materials are used as in traditional construction. Ready-made modules that contain installations, and sometimes equipment elements, are transported to the destination and assembled on prepared foundations. Connections are made on site, and sometimes finishing work and connections to the installations are too [30]. Modules are designed not only for use but also for transport, so after a certain period of use or when needs change, they can be removed, another module can be added, or it can be transported back to the factory and converted into another item. This application is in line with the principles of the circular economy [31,32] and reduces the amount of new materials introduced to the market, thus reducing the carbon footprint of construction. The benefits of manufacturing modules in a factory include savings in materials and transportation costs. The delivery of material to the factory can be organised locally and used to the full capacity of the means of transport. Employees have a favourable working environment regardless of the weather, access to social facilities, working on site, and they do not have to travel long distances for business. Employers can organise the production process in a way that eliminates downtime and runs in parallel. Due to the dry environment on the production floor, the finished product has less moisture and can be put to use faster. The challenge of manufacturing modules in a factory is the need to sometimes apply for a permit to transport oversized loads, which also increases the cost of transportation. There is also a risk of damage to the component during transport and assembly, which causes downtime and the need to return the module to the factory. High precision must be maintained in production and assembly. The use of modular technology can speed up the completion time by 20 to 50% [33]. The greatest time savings occur during the planning and on-site construction phases, as foundation and installation work can be performed at the same time as construction, saving the most time and providing a faster return on investment.

Currently, an important aspect when choosing a construction technology is the impact on the environment. The life cycle analysis of a building is performed on the basis of the EN ISO 14040 and EN ISO 14044 standards [34,35]. In Europe, only a few countries require the calculation of the LCA for the production stage of building materials, i.e., A1-A3. Currently, in Poland, there is no need to calculate the carbon footprint of buildings, which is why the availability of EPD cards for the available building materials in Poland is limited. LCA programmes are based on the amount of materials used in the project. The exact amount of building materials used in the project can be automatically obtained based on a virtual 3D model, which is prepared using BIM (Building Information Modelling) tools. Each element and material has parameters assigned that can be used to perform LCAs, investment cost estimates, or estimate the payback time.

The development of small shops in city centres depends on many factors, and economic, social, legal, and technological factors are distinguished [36,37], with location and accessibility being key. The greater the traffic for pedestrians and the easier access to public transport, the more potential customers. City centres, where spatial accessibility is low but potential market demand is high, are potentially the best place to open one or more new stores [38]. Small stores that actively engage with the local community through events and promotions tend to be developed. The quality of the offer and the building of strong relationships with residents can lead to increased customer loyalty [37,38]. The uniqueness of the offer can also be an opportunity for a small store. Customers are also increasingly paying attention to the availability of ecological products, which improves the reputation of the store [39,40,41]. It is important to adapt the offer to the local type of customer and their financial possibilities. Urban planning policies that include pedestrian-friendly streets and attractive, multifunctional public spaces are in line with current trends in creating sustainable urban spaces. Local pedestrian traffic reduces the use of polluting transport [42,43], but planning should take into account the needs of all residents, providing car parking opportunities, especially for the elderly, those with small children, and those with disabilities.

Traditional retail in the city centre faces clear challenges [44,45,46]. Studies indicate that conventional stores in densely populated urban centres are limited by inflexible, congested layouts and inadequate facilities, such as limited parking and loading areas [43,44]. The development of parcel locker networks in Poland has shown that parcel deliveries by small vans to small machines located close to customers can be effectively implemented even in dense urban centres [47]. Parcel lockers are conveniently located, operate 24/7, and provide the secure storage of parcels, which is why they have dominated the e-commerce delivery system [48]. Small self-service stores operating as 24 h vending machines can provide the products that are purchased most in locations close to customers’ homes, and the range of goods can be customised to local needs.

This article aims to examine the implementation of small modular retail facilities built on the principles of vending machines by examining various groups of factors.

3. Materials and Methods

The search for solutions to reduce resource use should include many aspects that go beyond one field. In the research carried out, the primary objective was to better understand the impact of factors from various fields and to quantitatively calculate an example of a small grocery store to determine how much the impact on the environment can be reduced by changing individual architectural and construction parameters. This article used a triangulation of methods [49]. First, the network thinking methodology was used, which allows one to look at the problem under study from different points of view. The purpose of the investigation was to identify key factors that influence investment in the development of small self-service stores. This article presents the selected elements of the analysis performed according to the network thinking methodology [48,49].

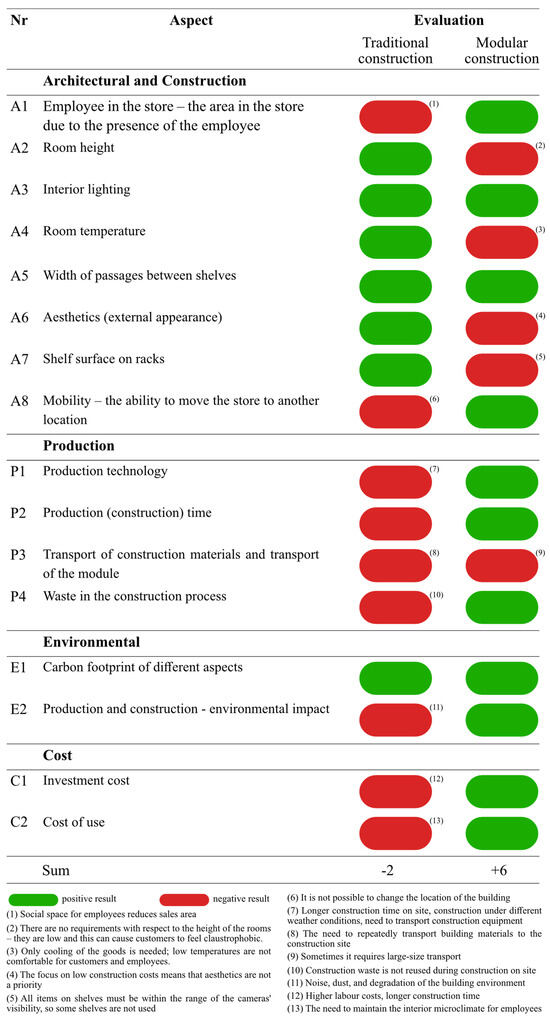

At the beginning of the problem analysis, to analyse the topic in a multifaceted way, the factors were isolated (Figure 3) and grouped into areas:

Figure 3.

Results of the multi-aspect assessment of the modular facility in relation to the traditional facility, and justification for awarding a negative assessment are given.

- architectural and construction aspect;

- production aspect;

- environmental aspect;

- cost aspect.

The selection of factors was based on the expert experience resulting from individual interviews conducted with specialists in the field of modular construction. The selection of aspects subjected to the study was deliberate and resulted from individual interviews with specialists (from technical universities and industry practitioners) in both the field of modular construction and small retail stores. Architectural aspects were selected due to their direct impact on the functionality, safety, and aesthetics of the facility. The subject of the analysis is modular facilities; therefore, appropriate structural solutions ensure the durability and stability of the building, while architectural aspects affect the comfort of users and fit the facility into the surroundings. Structural and production aspects in the field of modular facilities are important both in relation to the production process and subsequent transport to the destination and the on-site assembly process. The use of specific technologies and production methods can significantly affect the efficiency of the project implementation. The selection of these aspects justifies the pursuit of optimising the construction process itself but also reducing construction errors and shortening the implementation time. Environmental aspects take into account the impact of the investment on the natural environment, energy consumption, CO2 emissions, and the possibility of using renewable energy sources and ecological materials, which are currently of increasing importance (sustainable development). Cost (economic) aspects are key to any investment. They include an analysis of the profitability, construction, and operating costs of the facility, and long-term benefits resulting from, for example, the use of energy-saving solutions or highly durable materials. Then, the specified factors were analysed from two perspectives: a traditionally and modularly built facility (shop) was compared. In traditional construction, activities are performed successively: from the foundations to the roof, and then installation and finishing work is performed. All building materials are delivered successively to the construction site. Progress in the work is partially dependent on the weather. Modular construction involves carrying out construction work in a hall with the partial use of production automation. The building is constructed in parts (three-dimensional modules), including installations and finishing, and is adapted for transport to the target site on previously prepared foundations. Only connections between modules are made on site.

Figure 3 presents the results of a multi-aspect analysis of these factors, grouped into research areas, which is the result of the interviews mentioned above and the brainstorming session conducted at the end. The traditional variant has an overall negative result, while the balance of the modular variant is positive.

Next, the network thinking methodology was returned. The network thinking methodology has systemic origins and allows for the analysis of the studied phenomena in a holistic way [50,51]. Common mistakes in problem solving are [52] simple cause-and-effect logic and analysing problems in isolation. The network thinking methodology aims to overcome the dynamic complexity of actions and ensure completeness, and thus, the identified actions are combined into a network of dependencies [53]. It is based on the paradigm of a holistic, systemic approach to the problem [54]. Using this methodology requires, above all, using precise and understandable language. It requires a consistency of views—the network of mutual interactions must be thoroughly thought out, and its functioning must be within a specific time frame. Using this methodology allows for the discovery of various limitations and barriers occurring in the decision-making process [55]. The foundations of network thinking, developed in the late 1980s, are based on the concepts and findings of systems theory [55], and its authors are three Swiss scientists: Peter Gomez, Hans Urlich, and Gilbert J. B. Probst [54] provide a broad overview [56] of the problems occurring in the studied area. It is a proposal that allows for a better understanding of the mechanisms occurring in the organisation and an easier solution [57].

The first step is to identify the problem, where the word “problem” is not used in the colloquial sense, which has a negative connotation, but means the difference between the desired and the actual situation. To be sure that all problems are considered, they should be analysed from different points of view [58]. On this basis, a list of key factors defining the problem, the so-called influencing factors, is obtained, which are then combined into a network of relationships. In the second step, after defining the key factors, their mutual relationships must be determined in order to move from a list of independent elements to an integrated whole. First, the relationships between individual factors are established in order to create a so-called networked whole step by step [58]. This process takes place in two stages. First, the relationships are analysed element by element, and these relationships have different properties: they have a direction (one element influences the other, but the reverse may not occur), a degree of impact (it may be a reinforcing, stabilising, or mitigating effect), duration (short, medium or long term), and intensity (low, medium, or strong impact). The relationships are compiled in a so-called influence matrix, which shows all the relationships between all the elements. Then, the intensity of the impact is determined, indicating how strongly all the others influence a given element (passive sum) and how strongly an element influences the others (active sum). Finally, based on the above assessments and using the influence matrix, an intensity map is created with the division of factors into active, passive, critical, and lazy. Using this tool allows you to observe which factors are present in a given situation. If active and critical factors predominate, it means that you can influence the situation through these elements. Conversely, when passive and lazy factors predominate, then the possibilities of interference are much smaller [58].

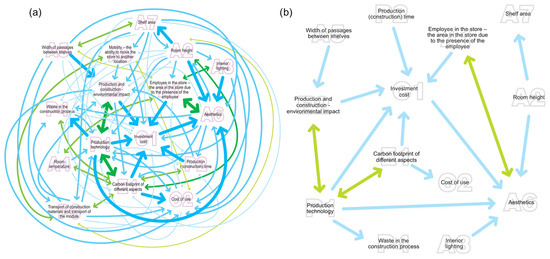

The 16 identified factors were linked to a network of interactions (Figure 4), and the relationships between the individual factors were analysed using three approaches (Appendix A).

Figure 4.

The network of all the dependencies (a) between factors in the network thinking analysis (the thicker line indicates a stronger connection), and the network of dependencies with a very high intensity of impact (b). The green line indicates bilateral interaction, the blue line indicates unilateral interaction.

- Type of impact (IR): bidirectional (B) or unidirectional (U);

- Direction of impact (R): equidirectional (+) or multidirectional (−); each factor was assessed positively (+) or negatively (−) with the aim of reducing material consumption, costs, workload, and environmental impact;

- Intensity of impact (I) on a four-point scale, where 0—no impact, 1—low intensity, 2—high intensity, and 3—very high intensity of impact.

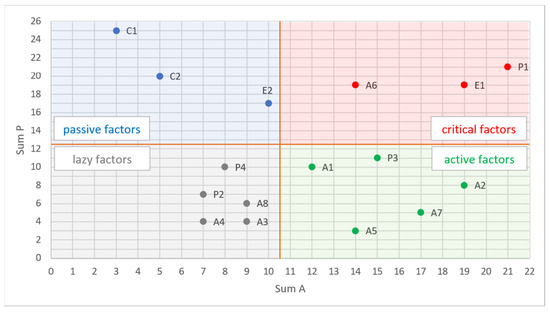

The intensity map (Figure 5) was created as a two-dimensional graph, where the A (activity) values for each factor are placed on the horizontal axis and the P (reactivity) values are placed on the vertical axis. The dots and numbers mark the location of each factor defined in the network of relationships.

Figure 5.

Intensity map and factor classification.

The critical factors (strongly influencing other elements, but at the same time, being strongly influenced themselves) were aesthetics (A6), production technology (P1), and the carbon footprint of different aspects (E1). Active factors (very strongly influencing other elements but not influencing themselves) were employee in the store (A1), room height (A2), width of passages between shelves (A5), shelf surface on racks (A7), and transport of construction materials and transport of the module (P3). The passive factors (they have a small impact on others but are themselves subject to strong influences) turned out to be production and construction—environmental impact (E2), investment cost (C1), and cost of use (C2), while the remaining factors are lazy (they have a weak impact on other elements but are themselves subject to only weak influences). In this article, only critical and passive factors will be analysed, i.e., those that are subject to strong influences (they can be influenced). To perform a multi-aspect analysis of investing in the development of small self-service stores, further consideration was given to the critical factors obtained on the basis of the network thinking methodology in the following order: production technology (P1) in connection with the carbon footprint (E1), and then the aesthetics of the external appearance (A6), and then they were linked to the passive factors: production and construction—environmental impact (E2), investment cost (C1), and cost of use (C2).

A literature review was conducted on the critical factors.

Among the many factors that influence customer impressions and trust [59], the appearance of the store was important to nearly 30% of the respondents. Visually appealing environments were associated with increased customer engagement [60], characterised by higher satisfaction, loyalty, longer store time, and increased impulse purchases [61]. Studies have shown that improving outdoor branding increases monthly sales by 15% to 19% [62]. Modern looks tend to be well-received by customers and can also fit into existing structures, as exemplified by the Apple Glass Store on 5th Avenue in New York.

The currently promoted reduction in the carbon footprint in various areas of life only partially influences people’s shopping habits. Although millennials value sustainability and the integrated experience of the brand of the customer, these factors are not the main drivers of purchase. Sustainability messages should be authentic but should not be overused in sales [63]. The density of store locations affects emissions during the trip to the store, with fuel savings being a key factor for the customer. Strategies aimed at minimising operating costs from the perspective of the store owner can increase emissions by 67% [64]. In the case of online shopping with home delivery, the carbon footprint increases significantly; it can be reduced by optimising the route and combining several deliveries. The analyses were conducted from the supplier’s perspective [65] but can be compared to deliveries to parcel lockers [48]. Reduced delivery route length is due to the lack of the need to travel to each customer. The delivery of goods to a small self-service store can be optimised and carried out during times of lower traffic in the city, which reduces emissions by shortening the travel time.

Building a small modular store differs from building a traditional brick store in many ways. Modular stores can be built in a few weeks because most of the elements are prefabricated in the factory. The repeatability of the elements facilitates production and streamlines assembly and therefore can reduce construction costs. Construction in a factory is not dependent on weather conditions, allowing production to be carried out throughout the year. The production of modules in controlled factory conditions generates less construction waste. During production, the modules are equipped with joinery, finishing elements, and installations, which means that they can be used immediately after installation, which shortens the payback period. Placing the module on site is quick and does not require lengthy construction work, only a connection to the electricity network. Small commercial modules in the form of vending machines usually do not require foundations, only a hardened area. Depending on the distance from the factory and due to the large size of the modules, the transport costs of the modules can be significant, but they are one-off. Modular structures are easy to adapt and expand. They can be easily moved and reconfigured, making them flexible in terms of adapting to local needs. Despite the repetitive nature of the components, the appearance and function of the modules can be adapted to the specific needs of the user or the requirements of the building’s surroundings. The modules are used for a shorter period than their useful life and usually do not have to be permanently connected to the ground, which means that they are treated as temporary structures, and as a result, the procedure for setting up a store is simpler and shorter. However, in some areas, it may not be possible to erect such a facility because the local spatial development plan may exclude temporary structures.

Traditional construction on site usually means a longer period of time for obtaining permits and the construction process, which can be carried out during the season of higher temperatures because construction work is more dependent on weather conditions. The costs of construction using the traditional method may be lower due to common knowledge of the art of construction and local access to building materials, but construction time increases the costs of labour and equipment rental. Traditional structures may be more durable but also less flexible in the event of the need for adaptation or expansion, especially if they are made of reinforced concrete. Traditional construction generates more construction waste.

Building a modular steel store is faster, more flexible, and can be cheaper than traditional construction. Modular structures are also more environmentally friendly and can be easily adapted to changing needs. In contrast, traditional brick stores offer greater durability and personalization but require more time and resources.

4. Results

4.1. Production Technology (P1)

The first aspect examined is the production technology. The construction of the store was compared in two variants:

- traditional;

- modular.

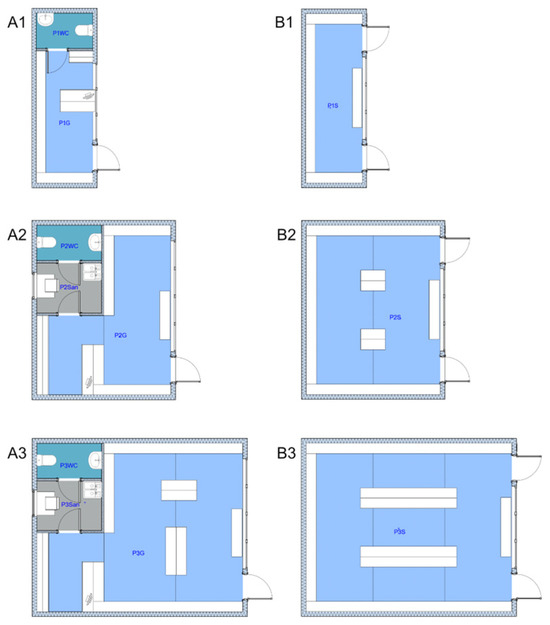

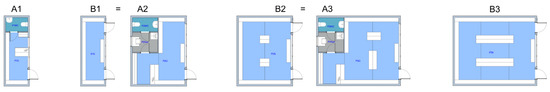

And each variant in three sizes: one, two, and three modules (Figure 6).

Figure 6.

Functional layout of variants: (A1)—one module, with an employee, (A2)—two modules, with an employee, (A3)—three modules with an employee, (B1)—one module, self-service, (B2)—two modules, self-service, (B3)—three modules, self-service.

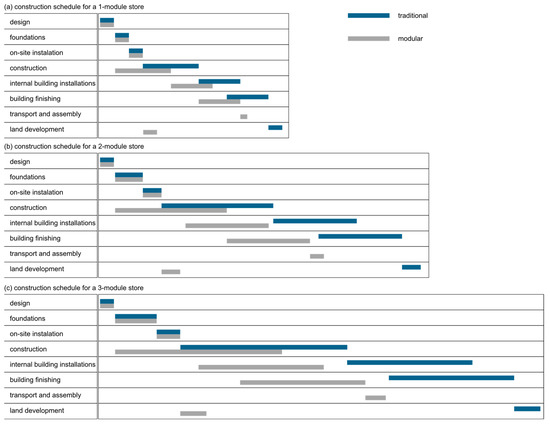

General schedules for the construction of the store were prepared in three sizes corresponding to one, two, and three modules. The analysis assumed the same type of building structure (steel frame with sandwich panel casing), but in the first case, it was constructed in a traditional way, on the construction site, and in the second case, in the factory, in the form of three-dimensional modules. Figure 7 presents a comparison of the construction schedules for both cases. It was assumed that in both technologies, some of the finishing work can be performed simultaneously with the execution of internal installations. In modular technology, after the construction of the first module is completed, the installation work in it begins, and at the same time, the construction of the next module is carried out. The work related to the foundations, installation, and finishing of the building environment can also be carried out simultaneously with the construction of modules in the factory. For modular technology, the time needed for the transport and assembly of modules on site was added.

Figure 7.

Comparison of store construction schedules using traditional and modular technology: (a) 1 module, (b) 2 modules, and (c) 3 modules.

For the analysed variants, the implementation time in the modular technology was shortened compared to the traditional one by the following:

- 81% for the one-module variant;

- 70% for the two-module variant;

- 65% for the three-module variant.

4.2. Carbon Footprint (E1) and Its Impact on the Environment (E2)

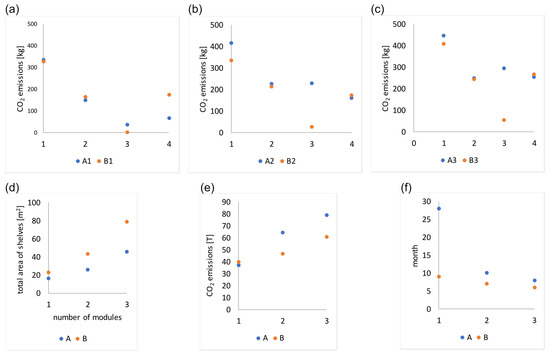

The size of the object (number of modules) affects the surface area of the shelves and the energy needed for heating, cooling, or lighting, which also translates into the carbon footprint of the investment. Virtual models of the modular buildings were made in Archicad 27 (BIM Software) in two variants:

- A shop with an employee;

- A self-service store;

And each variant in three sizes: one to three, two, and three modules. For all cases, the following was calculated:

- Total, usable, and shelf space;

- Consumption of building materials;

- Energy demand for heating, cooling, domestic hot water, and lighting;

- GWP (Global Warming Potential) using materials with a reduced carbon footprint;

- Estimated construction cost in the traditional and prefabricated modular variant;

- Payback time, assuming construction and maintenance costs.

According to labour laws and construction guidelines, a store where an employee works must have sanitary and social rooms that take up space, require additional building materials and connections to the installations, and must be kept at a higher temperature in winter. In a self-service store, these rooms are not needed.

A steel structure module with walls made of sandwich panels with an increased thermal insulation thickness (such as in cold stores) was selected for analysis to achieve greater energy savings for heating and cooling.

The calculations were made based on the amount of materials needed, calculated automatically based on a 3D model made in Archicad. The LCA of stage A1–A3 was performed on the OneclickLCA platform based on the EPD cards of building materials (Polish manufacturers, and in the case of unavailability, European manufacturers were selected). Energy consumption calculations for the building use stage (50 years, stage B6-B7 of LCAs) were made in Archicad, which allows the estimation of energy consumption for heating, ventilation, cooling, lighting, and the preparation of hot water. In each variant, the self-service variant has a larger shelf area compared to the service-based store. The largest difference is for the three-module variant (Figure 8d).

Figure 8.

Results of the analysis: annual CO2 emissions in the use phase (a–c), total area of shelves (d), carbon footprint of the 50-year period (e), and the time when the sum of profits exceeds the construction cost (f).

When comparing annual CO2 emissions in the use phase (Figure 8a–c), the largest difference can be seen in the energy required to prepare hot water, which is not needed in self-service stores. Water is only needed for cleaning. Small differences occur in the energy needed for heating, cooling, and lighting. In the case of single-module self-service stores, more energy is needed for lighting because the entire interior is a sales area and must be lit with the same intensity. The analysis does not take into account the possibility of savings by automatically reducing the lighting intensity when there are no customers.

The carbon footprint of the entire 50-year period from the production of building materials, including transport and use, is presented in the graph in Figure 8e. The values are given in thousands of kg of CO2. In the case of a single-module store, the difference is insignificant, but in the case of two- and three-module stores, a significant difference is visible. Self-service stores have more than 20% lower CO2 emissions.

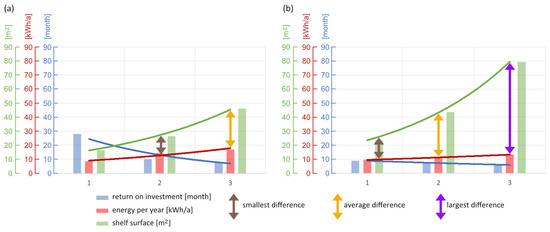

4.3. Influence of Factors on Costs (C1 and C2)

The store’s profit depends on many factors, such as location, assortment, prices, number of customers, etc. The average monthly income of the store (C2) was assumed to estimate the possible return time (C1). It was determined based on the assumption that the store serves about 50–100 customers per day, and the average receipt is PLN 15–30, then the minimum daily income is PLN 750, and the maximum is PLN 3000. Monthly, this is an amount between PLN 22,500 and PLN 90,000, i.e., an average of PLN 56,250. Rounding down to a full amount of PLN 50,000 was assumed. The balance sheet included the cost of labour of two people employed to serve (C2) and the cost of goods at the level of 70% of income (C2). The employee’s gross salary was assumed as follows: PLN 4666, that is, the minimum wage in Poland. Pension contributions (PLN 4666 × 9.76% = PLN 455.62), disability contributions (PLN 4666 × 6.50% = PLN 303.29), accident contributions (PLN 4666 × 1.67% = PLN 77.32), the labour fund (PLN 4666 × 2.45% = PLN 114.32), and the guaranteed employee benefits fund (PLN 4666 × 0.10% = PLN 4.67) were added to this. The total cost for the employer per employee was PLN 5621.22. It was assumed that two employees were employed and that the working time was eight hours in the traditional service-oriented store variant. In the self-service variant, a part of the time and labour costs was assumed: for one-module, 1/16, two-module, 1/8, and three-module, 1/4. The store was assumed to be open for 16 h. In the self-service version, it is assumed that the working time of one person is one eighth; this is the time of replenishing the goods and cleaning. Construction costs (C1) were estimated based on prices applicable in Poland in 2024. The price of the construction depends on the technology and the region of the country. An average of PLN 4000/m2 was assumed, and PLN 70,000 was added for finishing and equipment. The cost of the plot was omitted. A 20% inflation was assumed, and the balance was calculated for the following months. These analyses did not take into account the fact that the self-service store can be used 24 h a day, 7 days a week (profits could be higher). The graph (Figure 8f) shows the month in which the sum of profits exceeded the construction cost. The single-module store with employees has the longest payback time. When comparing two- and three-module stores, self-service stores are more advantageous, but the difference is between 2 and 3 months.

4.4. External Appearance Aesthetics (A6)

To determine the basic criteria for shaping the form of an object depending on the context, we analysed the current trends in shaping small commercial objects and the contemporary directions of integrating modern form in particularly sensitive surroundings, such as areas of historical significance.

The literature analyses emphasise the importance of adapting the building to the existing environment. The simplicity of modular objects allows for a minimalist form that gives a modern and aesthetic appearance. The simplest way to build a wall in a container-type module is glass and a sandwich panel consisting of two layers of profiled sheet metal and thermal insulation between them. From the manufacturers’ offers, you can choose panels of such shapes and colours that will not be associated with a warehouse, a construction-site container, or a transport container but will have an appearance that aligns with the surrounding buildings (Figure 9). Modules can be perceived as less prestigious compared to traditional buildings, but the use of finishing materials with an appearance that refers to nature causes an association with ecology and is received positively. It is currently assumed that contemporary shapes introduced into a historical context should be a sign of their times in an honest and unobtrusive way without using historicalizing stylistics.

Figure 9.

External wall texture: (a) standard in shipping containers, and (b) stylised, referring to the cladding panels (photo: author).

The attractiveness of self-service shops is the architectural synthesis of the idea of trade through direct access to goods for the customer, followed by the simplification of form and function. Therefore, the structure of self-service shops can be as limited as possible, with only the technological casing that enables the arrangement of the interior and ensures safe and convenient access to the goods. This architectural syntheticity can be implemented in the form of a minimalist form of a glazed module with colours limited to shades of grey and black, which harmonise with the simplicity of the form. Such a synthetic creation allows the module to blend neutrally with various surroundings, and the geometric, simple cuboid form is accepted in various contexts of urban space (Figure 10).

Figure 10.

Examples of modern simple rectangular shapes in dark grey (photo: author).

The repetition of modularity and the limitation of distinguishing elements can lead to stylistic impoverishment. In contemporary commercial facilities, the function of identification is often taken over by the logo of the owner of the chain of stores. Carefully designed, sparse lettering, often large-scale, is a noticeable, distinctive element of contemporary urban aesthetics. Moving images are always more noticeable than other visual impressions. This can be compared to the advertisements used at public transport stops, where the posters are often replaced by screens.

5. Discussion

5.1. Production Technology

The comparative analyses of construction schedules have shown the possibility of accelerating the implementation time thanks to the use of modular technology. The more modules, the greater the time gain. The literature also contains information on lower construction costs in the factory, but this parameter depends on the local availability of the manufacturers. A longer transport distance significantly increases its cost. The price of production also depends on the presence of competition.

In modular technology, the elements are designed for transport, so if the needs change, additional modules can be removed, added, or transported for modernisation. This is an important aspect from the point of view of ecology. In traditional construction, the amount of construction waste is greater. Construction also affects the environment in terms of air purity (dust) and acoustics.

The advantages of the prefabricated construction method are that it is manufactured under optimal conditions and many modules can be built at the same time as when the site is prepared for assembly on site. The factory makes better use of the materials, reducing losses and waste. Waste reduction varies greatly, ranging from 10 to 83% [36,57] compared to traditional construction methods. Elements are usually assembled in a dry process, so the structure can be used immediately. The modules are low in height due to wheeled transport, eliminating height work and reducing heavy physical labour. Factory staff are permanent, and workers quickly acquire skills by performing repetitive tasks, which speeds up construction by half [30] and reduces costs [66], as well as improving working conditions. Cost comparisons reveal that modular approaches can reduce construction costs by 20% [67], reduce the price per square metre by approximately 10.6% [38], and reduce waste costs by approximately 48% [68], but another study shows an increase of 8% in costs compared to reinforced concrete structures [69]. Many studies confirm that modular technology allows for shorter construction times [58,60,62]. Modular construction methods can provide many environmental and economic benefits compared to traditional on-site construction [61]. Studies show that modular systems can reduce embodied carbon [69] and reduce material consumption [70].

Modular technology causes certain design restrictions. The size of the modules must be adapted to the dimensions of the road transport gauge and the lifting capacity of the transport equipment. Usually, objects are small. The width and length are less of a problem because the modules can be combined to create one space.

The disadvantage of the prefabricated construction method is the initial high investment cost, which requires the construction of a factory and equipment. The fewer factories there are in a given area, the less competition there is, so the prices of the product are also higher. It is expected that with the widespread use of this production method, the number of factories will increase and competition will force prices down. In addition, the farther the factory is from the construction site, the higher the transport costs of the finished modules. Connecting the modules on site also requires a large number of joints that must be sealed. The repeatability of the dimensions and structural elements is an advantage on the one hand, due to the acceleration of the production process, but it can also be a disadvantage, causing excessive uniformity and instantaneity of the appearance of the buildings.

Research shows that prefabricated construction can contribute to sustainable construction [71] in densely populated urban areas, owing to several aspects:

- reduction in construction waste;

- shortening the construction time;

- reducing noise during construction in the built-up area;

- using the space between buildings that will not be able to be built with traditional buildings;

- flexible adaptation to current needs of residents thanks to the temporary nature of modular buildings;

- reducing the distance of the pedestrian route from commercial facilities and small services, which is particularly important for the elderly, people with small children, and people with disabilities.

Modular construction is becoming increasingly popular and may be the future of the global construction industry [72].

5.2. Carbon Footprint

Modular technology is designed with transport in mind, so after a period of use, objects can be transported to a factory to be rebuilt into another object. Elements that have worn out can be dismantled and recycled.

Using ecological materials for construction, including recycled materials, makes it possible to reduce the impact on the environment. Once built, materials do not generate CO2 later, and their reuse or recycling after the removal of the object can be included in the balance sheet as a negative value.

When a store is compared to traditional service with a vending machine, a reduction in the energy demand for the period of use is observed. Assuming that the energy comes from power plants, mainly coal-fired in Poland, this is an important aspect.

5.3. Aesthetics

Using a self-service store results in the highest efficiency of space utilisation. In the variants analysed, it was assumed that the width of the passages between the shelves allows two people to pass each other and a person moving in a wheelchair to change direction. A certain difficulty is the structure of the building connected to the floor and the thickness of the floor resulting from the requirements of the regulations on the thermal protection of buildings, which causes a relatively high threshold at the entrance. For the elderly and people moving in wheelchairs, comfortable steps and/or a ramp should be added, or the module should be placed in a lowered area. The mobility of the module allows for a change of location in a situation where the investment will not bring the expected profits in a given place. Similarly, modular solutions allow for the addition of additional objects that expand the offer when there is a greater demand in a given location. The simplicity of modular objects allows for an economical, minimalist form, which gives a modern and aesthetic appearance.

6. Conclusions

After collecting the results of all the analyses on three parameters: payback time, energy needed to use the building, and shelf area related to the parameters, it can be concluded that a single-module store with an employee is the least profitable (Figure 11). A two-module store with an employee is comparable to a single-module self-service store, and similarly, a three-module store with an employee is comparable to a two-module self-service store (Figure 12). The best investment among those analysed may be a three-module self-service store.

Figure 11.

Comparative analysis of three parameters: payback time, energy required to use the building, and shelf space related to the size of the profit for 1-, 2-, and 3-module variants; (a) shop with employees, (b) self-service shop.

Figure 12.

Conclusion of the comparison of the rentability of variants ((A1)—one module, with an employee, (A2)—two modules, with an employee, (A3)—three modules with an employee, (B1)—one module, self-service, (B2)—two modules, self-service, (B3)—three modules, self-service).

The multi-aspect assessment showed the advantage of a self-service store (modular vending machine) over a service store building because it has a higher percentage of the area dedicated to the presentation of goods. The construction time on site is limited to placing the machine on the prepared site and connecting the utilities, and the construction of the factory structure is more friendly to both employees and the environment. The aesthetics of the external appearance of the module should be adapted to the place of installation. The minimalist style of modern forms, a limited number of elements, and subdued colours can help to match the module to any background of the existing environment, which will result in greater acceptance by local users and respect for the context.

Studies show that the short distance from the store and the trust of the customers are the basis of the sustainable competitive advantage of small stores, especially in urban areas. The price, assortment, and possibilities of implementing loyalty programmes are identified as the main strategic competitive advantages of large-format stores [73]. Small modular stores, also in the form of vending machines, fit into the concept of human-centred design (HCD) in the context of sustainable urban planning, combining the principles of human-centred design with the goals of sustainable urban development.

The concept of transit-orientated development (TOD) is popular in urban planning, which assumes the densification of urban areas around transport hubs. Due to this, residents have easy access to public transport, reducing the intensity of car traffic. In areas of dense pedestrian traffic, it is necessary to locate various types of commercial offers and services. In dense downtown development, often of a historical nature, it is not always possible to rebuild or expand in order to locate new facilities, but there is usually room to add mobile modules. From the point of view of customers who rush to the metro, a large number of small sales points is better than one large store, where the bottleneck is the cash register. Small self-service stores reduce shopping time to a minimum.

Small self-service stores use a mix of design principles that promote both urban sustainability and economic viability in medium-density residential areas. Integrating digital tools—such as smartphone payments and computerised inventory management—can help increase operational agility. The use of intelligent technology can be used to optimise the energy consumption of vending machines. Due to the lack of employees in a self-service store, there is no need to maintain a higher temperature in winter; a lower temperature is even more beneficial due to the cooling of food products; in summer, however, energy is needed to cool the interior and it is worth considering the use of photovoltaic panels on the roof of the module to use renewable energy and reduce the demand for electricity from the network. The efficiency of this system depends on the location in terms of latitude but also on shading by the surrounding buildings and trees. Sales data provide information about the needs of residents and should be used to tailor the offer to their needs, both in terms of planning access to services in a given area and optimising the commercial offer in small self-service stores.

Designing the module architecture should include open layouts that improve product visibility and consider targeted shelf relocations to promote healthier choices. Given the high fragmentation of modular retail facilities, an emphasis should be placed on agile supply chains to reduce last-mile delivery costs. Retail offerings can be complemented with other services based on local needs to enhance community integration. Public space management should be focused on creating high-quality public spaces that are accessible, safe, and attractive to residents by offering various services and responding to the needs of different groups of residents. Good public space management should support social integration and improve quality of life. Inclusive design takes into account the needs of all residents, including the elderly, people with disabilities, and other marginalised groups. The goal is to create urban spaces that are accessible and friendly to everyone. Small mobile modules can be used to organise not only stores but also other functions or periodically organised events. Sustainable urban planning integrates the principles of ecology, economy, and community. Designed urban spaces should be functional for people and respect the environment. It is beneficial to include the space needed for greenery, which improves air quality, helps lower the temperature on hot days [74,75], and creates a space where people like to spend time. Due to dense development, various possibilities for greening the space should be sought [76]. In small areas, these can be vertical gardens on walls and green roofs [63,69]. Small gardens also help to retain water on a small scale. The use of modular buildings is in line with the assumptions of the circular economy because after the period of use of the facility, they can be transported back to the factory and dismantled, and the materials can be used to build other facilities or recycled. This technology reduces waste and increases circularity.

Due to many socio-environmental benefits, it is beneficial to use modular facilities with different functions in cities. It is worth adapting local regulations on permits for the construction of such facilities in urban spaces to facilitate the procedure. Support for companies that produce modular facilities will also be beneficial. The more factories there are, the lower the construction cost should be.

Research suggests that carefully balancing digital innovation, adaptive physical layouts, and community-oriented service models can support sustainable urban development, provided that economic challenges are managed effectively.

This article contributes to a better understanding of the factors that influence investment efficiency in a small store and can be helpful in choosing the production technology and the way the store operates. The results of the analyses showed significant differences between a traditional and modular store, in favour of the second solution.

When you look at the labour market and the rising costs of business, but also at the development of technology in trade and the changing consumer, it can be said that the concept of small self-service stores is a starting point for creating solutions that will take retail trade to the next stage of development.

Plans for further research:

The results of the presented research can be used as a reference point that will inspire future analyses on the potential use of modular facilities in urban spaces in different parts of the world, customer opinions on the use of self-service stores (without checkouts), and forecasts regarding the development of modular construction. Additionally, the aesthetic aspect of modular stores can be assessed to distinguish the forms, colours, and materials that are commonly accepted.

Author Contributions

Conceptualization, M.S. and B.S.; methodology, M.S. and A.G.; software, M.S.; validation, M.S., B.S., A.G., A.S.-G. and B.K.; formal analysis, M.S., B.S. and A.G.; investigation, M.S., B.S., A.G., A.S.-G. and B.K.; resources, M.S., B.S., A.G., A.S.-G. and B.K.; data curation, M.S., B.S., A.G., A.S.-G. and B.K.; writing—original draft preparation, M.S.; writing—review and editing, M.S., B.S., A.G., A.S.-G. and B.K.; visualisation, M.S. and B.S.; supervision, M.S., B.S., A.G., A.S.-G. and B.K.; project administration, M.S., B.S., A.G., A.S.-G. and B.K.; funding acquisition, A.S.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

The procedure for isolating factors based on the network thinking methodology.

The central (middle) column contains 16 factors, network elements. The left part of the table contains the factors that affect the analysed factor (influencing factors—From), while the right part contains those that are affected by the given factor (factors subject to influence—To). The analysis of the connections between individual factors was carried out using three approaches:

- Type of impact (IR): bidirectional (B) or unidirectional (U);

- Direction of impact (R): equidirectional (+) or multidirectional (−); each factor was assessed positively (+) or negatively (−), with the aim of reducing the consumption of materials, costs, workload, and environmental impact;

- Intensity of impact (I) on a four-point scale, where 0—no impact, 1—low intensity, 2—high intensity, and 3—very high intensity of impact.

Based on the summary table of network factors (Table A1), an influence matrix (Table A2) was developed, to which the impact intensity values (value I from Table A1) were transferred. The values obtained show the activity (Sum A) and reactivity (Sum P). Based on the influence matrix, an intensity map was prepared, where the position of a factor in the selected category results from the value of parameters A (activity) and P (reactivity) on the intensity map, and based on it, factors are classified as active, passive, critical, or lazy.

Table A1.

Network factors and their mutual impact: positive (+), negative (−).

Table A1.

Network factors and their mutual impact: positive (+), negative (−).

| From | IR | R | I | Factors | To | R | I |

|---|---|---|---|---|---|---|---|

| A3 | B | + | 2 | A1. Employee in the store—the area in the store due to the presence of the employee | A3 | + | 2 |

| A4 | B | + | 2 | A4 | + | 2 | |

| A5 | B | + | 1 | A5 | + | 1 | |

| A6 | B | + | 3 | A6 | + | 3 | |

| A2 | U | + | 2 | C1 | + | 3 | |

| C2 | + | 1 | |||||

| A6 | B | + | 2 | A2. Room height | A6 | + | 3 |

| A7 | B | + | 2 | A7 | + | 3 | |

| P1 | B | + | 1 | P1 | + | 2 | |

| P3 | B | − | 1 | P3 | + | 1 | |

| E1 | B | + | 2 | E1 | + | 2 | |

| A1 | + | 2 | |||||

| A3 | − | 2 | |||||

| A4 | − | 1 | |||||

| A8 | − | 1 | |||||

| C1 | + | 1 | |||||

| C2 | + | 2 | |||||

| A1 | B | + | 2 | A3. Interior lighting | A1 | + | 2 |

| A2 | U | − | 2 | A6 | + | 3 | |

| P1 | + | 2 | |||||

| C2 | + | 2 | |||||

| A1 | B | + | 2 | A4. Room temperature | A1 | + | 2 |

| E1 | B | + | 2 | E1 | + | 2 | |

| A2 | U | − | 1 | P1 | + | 2 | |

| C2 | + | 1 | |||||

| A1 | B | + | 1 | A5. Width of passages between shelves | A1 | + | 1 |

| A7 | B | − | 2 | A7 | − | 2 | |

| A6 | + | 2 | |||||

| P1 | + | 1 | |||||

| P3 | − | 2 | |||||

| E2 | + | 3 | |||||

| C1 | + | 1 | |||||

| C2 | + | 2 | |||||

| A1 | B | + | 3 | A6. Aesthetics (external appearance) | A1 | + | 3 |

| A2 | B | + | 3 | A2 | + | 2 | |

| P1 | B | + | 3 | P1 | + | 2 | |

| C1 | B | + | 3 | C1 | + | 2 | |

| A3 | U | + | 3 | P2 | + | 2 | |

| A5 | U | + | 2 | P4 | + | 2 | |

| C2 | U | + | 2 | E2 | + | 1 | |

| A2 | B | + | 3 | A7. Shelf surface on racks | A2 | + | 2 |

| A5 | B | − | 2 | A5 | − | 2 | |

| A8 | + | 2 | |||||

| P1 | + | 1 | |||||

| P2 | + | 1 | |||||

| P3 | − | 2 | |||||

| E1 | + | 1 | |||||

| E2 | + | 2 | |||||

| C1 | + | 1 | |||||

| C2 | + | 2 | |||||

| P3 | B | + | 2 | A8. Mobility—the ability to move the store to another location | P3 | + | 2 |

| C2 | B | + | 1 | C2 | + | 1 | |

| A2 | U | − | 1 | P4 | + | 1 | |

| A7 | U | + | 2 | E1 | + | 1 | |

| E2 | + | 2 | |||||

| C1 | + | 2 | |||||

| A2 | B | + | 2 | P1. Production technology | A2 | + | 1 |

| A6 | B | + | 2 | A6 | + | 3 | |

| P3 | B | + | 2 | P3 | + | 2 | |

| P4 | B | + | 2 | P4 | + | 3 | |

| E1 | B | + | 3 | E1 | + | 3 | |

| E2 | B | + | 3 | E2 | + | 3 | |

| A3 | U | + | 2 | P2 | + | 1 | |

| A4 | U | + | 2 | C1 | + | 3 | |

| A5 | U | + | 1 | C2 | + | 2 | |

| A7 | U | + | 2 | ||||

| E1 | B | + | 2 | P2. Production (construction) time | E1 | + | 2 |

| A6 | U | + | 2 | E2 | + | 2 | |

| A7 | U | + | 1 | C1 | + | 3 | |

| P1 | U | + | 1 | ||||

| P3 | U | + | 1 | ||||

| A2 | B | + | 1 | P3. Transport of construction materials and transport of the module | A2 | − | 1 |

| A8 | B | + | 2 | A8 | + | 2 | |

| P1 | B | + | 2 | P1 | + | 2 | |

| E1 | B | + | 2 | E1 | + | 2 | |

| A5 | U | − | 2 | P2 | + | 1 | |

| A7 | U | − | 2 | P4 | + | 2 | |

| E2 | + | 2 | |||||

| C1 | + | 1 | |||||

| C2 | + | 2 | |||||

| P1 | B | + | 3 | P4. Waste in the construction process | P1 | + | 2 |

| E1 | B | + | 2 | E1 | + | 2 | |

| A6 | U | + | 2 | E2 | + | 2 | |

| A8 | U | + | 2 | C1 | + | 2 | |

| P3 | U | + | 2 | ||||

| A2 | B | + | 2 | E1. Carbon footprint of different aspects | A2 | + | 2 |

| A4 | B | + | 2 | A4 | + | 2 | |

| P1 | B | + | 3 | P1 | + | 3 | |

| P2 | B | + | 2 | P2 | + | 2 | |

| P3 | B | + | 2 | P3 | + | 2 | |

| P4 | B | + | 2 | P4 | + | 2 | |

| C2 | B | + | 2 | C2 | + | 3 | |

| A7 | U | + | 1 | C1 | + | 3 | |

| A8 | U | + | 1 | ||||

| E2 | U | + | 2 | ||||

| P1 | B | + | 3 | E2. Production and construction—environmental impact | P1 | + | 3 |

| A5 | U | + | 3 | E1 | + | 2 | |

| A6 | U | + | 1 | C1 | + | 3 | |

| A7 | U | + | 2 | C2 | + | 2 | |

| A8 | U | + | 2 | ||||

| P2 | U | + | 2 | ||||

| P3 | U | + | 2 | ||||

| P4 | U | + | 2 | ||||

| A6 | B | + | 2 | C1. Investment cost | A6 | + | 3 |

| A1 | U | + | 3 | ||||

| A2 | U | + | 1 | ||||

| A5 | U | + | 1 | ||||

| A7 | U | + | 1 | ||||

| A8 | U | + | 2 | ||||

| P1 | U | + | 3 | ||||

| P2 | U | + | 3 | ||||

| P3 | U | + | 1 | ||||

| P4 | U | + | 2 | ||||

| E1 | U | + | 3 | ||||

| E2 | U | + | 3 | ||||

| A8 | U | + | 1 | C2. Cost of use | A8 | + | 1 |

| P1 | B | + | 2 | P1 | + | 1 | |

| E1 | B | + | 3 | E1 | + | 2 | |

| A1 | U | + | 1 | A6 | + | 2 | |

| A2 | U | + | 2 | ||||

| A3 | U | + | 2 | ||||

| A4 | U | + | 1 | ||||

| A5 | U | + | 2 | ||||

| A7 | U | + | 2 | ||||

| P3 | U | + | 2 | ||||

| E2 | U | + | 2 |

Table A2.

Influence matrix (X—no influence).

Table A2.

Influence matrix (X—no influence).

| Factors | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | P1 | P2 | P3 | P4 | E1 | E2 | C1 | C2 | ƩA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | X | 2 | 2 | 1 | 3 | 3 | 1 | 12 | |||||||||

| A2 | 2 | X | 2 | 3 | 3 | 1 | 2 | 1 | 2 | 1 | 2 | 19 | |||||

| A3 | 2 | X | 3 | 2 | 2 | 9 | |||||||||||

| A4 | 2 | X | 2 | 2 | 1 | 7 | |||||||||||

| A5 | 1 | X | 2 | 2 | 1 | 2 | 3 | 1 | 2 | 14 | |||||||

| A6 | 3 | 2 | X | 2 | 2 | 2 | 1 | 2 | 14 | ||||||||

| A7 | 2 | 2 | X | 2 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 17 | |||||

| A8 | X | 2 | 1 | 1 | 2 | 2 | 1 | 9 | |||||||||

| P1 | 1 | 3 | X | 1 | 2 | 3 | 3 | 3 | 3 | 2 | 21 | ||||||

| P2 | X | 2 | 2 | 3 | 7 | ||||||||||||

| P3 | 1 | 2 | 2 | 1 | X | 2 | 2 | 2 | 1 | 2 | 15 | ||||||

| P4 | 2 | X | 2 | 2 | 2 | 8 | |||||||||||

| E1 | 2 | 2 | 3 | 2 | 2 | 2 | X | 3 | 3 | 19 | |||||||

| E2 | 3 | 2 | X | 3 | 2 | 10 | |||||||||||

| C1 | 3 | X | 3 | ||||||||||||||

| C2 | 2 | 1 | 2 | X | 5 | ||||||||||||

| ƩP | 10 | 8 | 4 | 4 | 3 | 19 | 5 | 6 | 21 | 7 | 11 | 10 | 19 | 17 | 25 | 20 | 189 |

References

- Efeoglu, H.E.; Joutsiniemi, A.; Mozuriunaite, S. Exploring the Plot Patterns of the Retail Landscape: The Case of the Helsinki Metropolitan Area. Environ. Plan. B Urban Anal. City Sci. 2024, 51, 1210–1226. [Google Scholar] [CrossRef]

- Manika, S. Transforming Vacant Commercial Spaces: From Localized Hotspots of Urban Shrinkage to “Smart” Co-Working Places. JSS 2020, 08, 86–97. [Google Scholar] [CrossRef]

- Mobile Institute of Culture (In Polish: Mobilny Instytut Kultury). Available online: https://mobilnyinstytutkultury.pl/mobilny-instytut-kultury-na-poznanskim-strzeszynie/ (accessed on 20 June 2025).

- Ginelli, E.; Pozzi, G.; Lazzati, G.; Pirillo, D.; Vignati, G. Regenerative Urban Space: A Box for Public Space Use. In Regeneration of the Built Environment from a Circular Economy Perspective; Della Torre, S., Cattaneo, S., Lenzi, C., Zanelli, A., Eds.; Research for Development; Springer International Publishing: Cham, Switzerland, 2020; pp. 137–147. ISBN 978-3-030-33255-6. [Google Scholar]

- Kucharska, B. Unmanned store as an innovative retail format a post-pandemic perspective (In Polish: Sklep bezobsługowy jako innowacyjny format handlu detalicznego–perspektywa postpandemiczna). SiP 2023, 188, 25–42. [Google Scholar] [CrossRef]

- Hashem, T.N. Examining the Influence of COVID 19 Pandemic in Changing Customers Orientation towards E-Shopping. MAS 2020, 14, 59. [Google Scholar] [CrossRef]

- Duarte, P.; Silva, S.C.; Linardi, M.A.; Novais, B. Understanding the Implementation of Retail Self-Service Check-out Technologies Using Necessary Condition Analysis. IJRDM 2022, 50, 140–163. [Google Scholar] [CrossRef]

- Turner, J.J.; Szymkowiak, A. An Analysis into Early Customer Experiences of Self-Service Checkouts: Lessons for Improved Usability. Eng. Manag. Prod. Serv. 2019, 11, 36–50. [Google Scholar] [CrossRef]

- Gümüş, C.; Findikli, S.; Saygin, E.P. Behavioral Intentions of Customers Under the Technology Acceptance Model (TAM): Example of Migros Jet Kasa. İnsan Toplum Bilim. Araştırmaları Derg. 2023, 12, 1874–1903. [Google Scholar] [CrossRef]

- Computer Vision and AI Self-Checkout Solutions. Available online: https://www.dogtownmedia.com/computer-vision-and-ai-powered-self-checkout-solutions/ (accessed on 20 June 2025).

- Car Vending Machine Market Size. Available online: https://www.adroitmarketresearch.com/industry-reports/car-vending-machine-market (accessed on 20 June 2025).

- Polish Construction law (In Polish: Obwieszczenie Marszałka Sejmu Rzeczypospolitej Polskiej z Dnia 10 Marca 2023 r. w Sprawie Ogłoszenia Jednolitego Tekstu Ustawy-Prawo Budowlane). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20230000682 (accessed on 20 June 2025).

- Regulation on Technical Requirements for Buildings and Their Location (In Polish: Obwieszczenie Ministra Rozwoju i Technologii z Dnia 15 Kwietnia 2022 r. w Sprawie Ogłoszenia Jednolitego Tekstu Rozporządzenia Ministra Infrastruktury w Sprawie Warunków Technicznych, Jakim Powinny Odpowiadać Budynki i Ich Usytuowanie). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20220001225 (accessed on 20 June 2025).

- Al-Khatib, K.; Makkawi, J.; Kobeissi, A. Potentials Of Containers In Creating Modular Architectural Spaces. APJ 2021, 27, 3. [Google Scholar] [CrossRef]

- Pereira-de-Oliveira, L.A.; Bernardo, L.F.A. Architectural Building Design with Refurbished Shipping Containers: A Typological and Modular Approach. JER 2022, 10, 1A. [Google Scholar] [CrossRef]

- Sun, Z.; Mei, H.; Ni, R. Overview of Modular Design Strategy of the Shipping Container Architecture in Cold Regions. IOP Conf. Ser. Earth Environ. Sci. 2017, 63, 012035. [Google Scholar] [CrossRef]

- El Messeidy, R. Adapting Shipping Containers as Temporary Shelters in Terms of Recycling, Sustainability and Green Architecture. Reuse as Accommodation in Egypt. Eng. Res. J. 2018, 160, 173–191. [Google Scholar] [CrossRef]

- Popovych, D. Comparison of the Features of the Harmonization of Volume and Spatial Architecture of Modern Public and Residential Buildings in the Historical Building of Cities. Curr. Probl. Arch. Urban Plan. 2023, 66, 214–226. [Google Scholar]

- Gençer, F. Assessment Method of Modern Buildings Constructed in a Historical Area; as a Case Study İMÇ Blocks. Iconarp Int. J. Arch. Plan. 2023, 2, 807–837. [Google Scholar]

- Kizilkan, G.; Yeşildal, Ö. Tarihi Dokuda Çağdaş Kültür Yapısının Görsel Etki Değerlendirmesi: Odunpazarı Modern Müze Örneklem Alanı. İdealkent 2021, 12, 471–491. [Google Scholar] [CrossRef]

- Auquilla-Pulla, M.P.; Sinchi-Toral, I.P. Herramientas de Valoración y Documentación de la Arquitectura Moderna en Relación al Contexto Construido. Daya 2020, 18, 197–220. [Google Scholar] [CrossRef]

- Ng, C.F. Perception and Evaluation of Buildings: The Effects of Style and Frequency of Exposure. Collabra Psychol. 2020, 6, 44. [Google Scholar] [CrossRef]

- Güney Yüksel, F.C.; Rezafar, A. Aesthetic Evaluation of a Modern Period Architecture: The Case of Çınar Hotel. Modul. J. 2023, 6, 18–33. [Google Scholar] [CrossRef]

- Goussous, J.; Hmood, K.F. Reconstruction of the Urban Historical Centre: Contemporary Problems, Difficulties, and Perspectives. Probl. Ekorozw. 2023, 18, 263–267. [Google Scholar] [CrossRef]

- Lardinois, S. Contemporary Architecture in the Historic Environment: Recent International Perspectives. Change Over Time 2017, 7, 252–271. [Google Scholar] [CrossRef]

- Хараборська, Ю.О.; Сушко, С.П. Some features of the construction of new facilities in a historic environment (In Ukrainian: Деякі особливості будівництва нових обє’ктів в історичному середовищі (на прикладі м. Київ). Kyiv Natl. Univ. Archiv. 2016, 42, 126–136. [Google Scholar]

- Akalin, A.; Yildirim, K.; Wilson, C.; Kilicoglu, O. Architecture and Engineering Students’ Evaluations of House Façades: Preference, Complexity and Impressiveness. J. Environ. Psychol. 2009, 29, 124–132. [Google Scholar] [CrossRef]

- Golding, F. Building in context. In New Development in Historic Areas; English Heritage CABE: London, UK, 2021. [Google Scholar]

- Chen, C. Advantages and Barriers of Modular Construction Method in Constructing Buildings. Proc. Inst. Civ. Eng.-Smart Infrastruct. Constr. 2023, 176, 75–84. [Google Scholar] [CrossRef]