Quantifying the Impact of Lean Construction Practices on Sustainability Performance in Chinese EPC Projects: A PLS-SEM Approach

Abstract

1. Introduction

- To categorize lean construction practices in Chinese EPC projects into five groups and examine the extent to which they are adopted by project stakeholders.

- To evaluate the impact of different categories of lean practices on EPC project performance, considering four key performance indicators: efficiency and resource management, quality and safety, stakeholder satisfaction, and organizational and market influence.

- To apply Partial Least Squares Structural Equation Modeling (PLS-SEM) to test the relationship between lean construction practices and EPC project performance.

2. Literature Review

2.1. From Manufacturing to Construction: The Evolution of Lean

2.2. Functional Classification and Research Gaps in Lean Construction for EPC Projects

2.3. Performance Dimensions and the Benefits of Lean Practices in EPC Projects

- Efficiency and Resource Management (ERM) refers to improvements in time, cost, and material usage. Indicators include reduced schedule delays, lower waste rates, and optimized resource allocation [1].

- Quality and Safety (QS) captures outcomes related to product quality and worksite safety. This includes defect reduction, rework minimization, and incident rate improvement [38].

- Organizational and Market Impact (OMI) covers internal outcomes (e.g., process improvement, cross-functional learning, process maturity) and external outcomes (e.g., increased market share, increased project acquisition, enhanced reputation) [56].

- Stakeholder Satisfaction (SS) reflects the perceptions of clients, suppliers, and employees regarding project communication, responsiveness, and collaboration effectiveness [62].

2.4. Research Gap and Study Motivation

3. Materials and Methods

3.1. Research Hypotheses

- H1: Different categories of lean construction practices have a significant impact on the overall performance of EPC projects.

- H2: The influence of lean construction practices varies across different performance indicators in EPC projects.

3.2. Survey Design

- Respondent demographics, including organization type, educational background, work experience.

- The extent of lean construction practice adoption in Chinese EPC projects (20 items).

- Perceived benefits of lean construction, assessing stakeholder views on its impact on project performance (10 items).

3.3. Data Collection and Sampling

3.4. Data Analysis

3.5. Justification for Using PLS-SEM

4. Result and Discussion

4.1. Respondent Profile

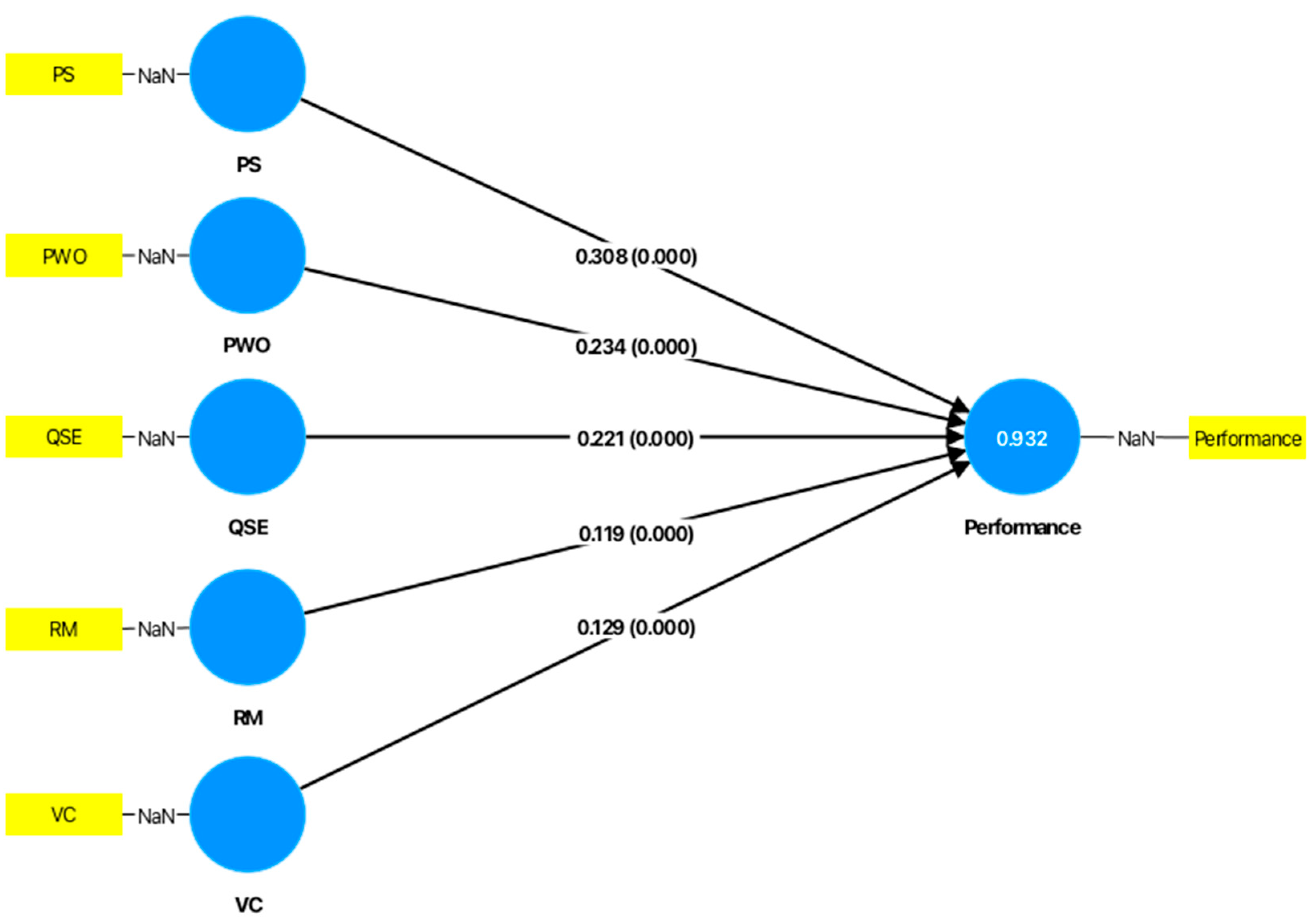

4.2. The Impact of Different Categories of Lean Construction Practices on Overall Performance

4.3. The Impact of Different Categories of Lean Construction Practices on Various Performance Indicators

5. Conclusions

5.1. Key Findings

5.2. Practical Implications

5.3. Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| EPC | Engineering, Procurement, and Construction |

| PLS-SEM | Partial Least Squares Structural Equation Modeling |

| LPS | Last Planner System |

| JIT | Just-in-Time |

| BIM | Building Information Modeling |

| PS | Planning and Scheduling |

| PWO | Process and Workflow Optimization |

| QSE | Quality and Safety Enhancement |

| RM | Resource and Maintenance |

| VC | Visualization and Communication |

| ERM | Efficiency and Resource Management |

| QS | Quality and Safety |

| SS | Stakeholder Satisfaction |

| OMI | Organization and Market Impact |

| TQM | Total Quality Management |

| TVD | Target Value Design |

| ERP | Enterprise Resource Planning |

| TFV | Transformation-Flow-Value |

| PDCA | Plan, Do, Check, Act |

| PCMAT | Plan of Conditions and Work Environment in the Construction Industry |

| TPM | Total Productive Maintenance |

| IMS | Information Management System |

| CAD | Computer-Aided Design |

References

- Ghasemi, M.; Nejad, M.G.; Alsaadi, N.; Abdel-Jaber, M.T.; Ab Yajid, M.S.; Habib, M. Performance measurement and lead-time reduction in EPC project-based organizations: A mathematical modeling approach. Math. Probl. Eng. 2022, 2022, 5767356. [Google Scholar] [CrossRef]

- Chen, L.; Tang, Y. Research on the path of cost control and economic benefit enhancement in construction engineering projects. Appl. Math. Nonlinear Sci. 2024, 9, 1–13. [Google Scholar] [CrossRef]

- Anggraini, W.; Harpito; Siska, M.; Novitri, D. Implementation of lean construction to eliminate waste: A case study construction project in Indonesia. J. Tek. Ind. 2022, 23, 1–16. [Google Scholar]

- Hasan, S.; Işık, Z.; Demirdöğen, G. Evaluating the contribution of lean construction to achieving sustainable development goals. Sustainability 2024, 16, 3502. [Google Scholar] [CrossRef]

- Carvajal-Arango, D.; Bahamón-Jaramillo, S.; Aristizábal-Monsalve, P.; Vásquez-Hernández, A.; Botero, L.F.B. Relationships between lean and sustainable construction: Positive impacts of lean practices over sustainability during construction phase. J. Clean. Prod. 2019, 234, 1322–1337. [Google Scholar] [CrossRef]

- Kehinde, T.V.; Fapohunda, C.A. Lean construction practices for sustainable infrastructure: A comparative review between Nigeria and the United States of America. J. Civ. Eng. 2024, 2, 1–10. [Google Scholar]

- Caldera, H.T.S.; Desha, C.; Dawes, L. Exploring the role of lean thinking in sustainable business practice: A systematic literature review. J. Clean. Prod. 2017, 167, 1546–1565. [Google Scholar] [CrossRef]

- Bajjou, M.S.; Chafi, A. Lean construction implementation in the Moroccan construction industry: Awareness, benefits and barriers. J. Eng. Des. Technol. 2018, 16, 533–556. [Google Scholar] [CrossRef]

- Shaqour, E.N. The impact of adopting lean construction in Egypt: Level of knowledge, application, and benefits. Ain Shams Eng. J. 2022, 13, 101551. [Google Scholar] [CrossRef]

- Marhani, M.A.; Jaapar, A.; Bari, N.A.; Shaari, S.M. Reducing over-processing construction waste by using lean construction tools in the Malaysian construction industry. IOP Conf. Ser. Earth Environ. Sci. 2022, 1067, 012048. [Google Scholar] [CrossRef]

- Li, S.; Fang, Y.; Wu, X. A systematic review of lean construction in Mainland China. J. Clean. Prod. 2020, 257, 120581. [Google Scholar] [CrossRef]

- Al Hosani, S. A Framework for the Implementation of Lean Construction Principles in Engineering, Procurement and Construction (EPC) in the Oil and Gas Industry. Ph.D. Thesis, Aberystwyth University, Aberystwyth, UK, 2022. [Google Scholar]

- Su, K.; Huang, S.; Zhang, J. Research on housing project implementation based on lean construction: A case study of the Jiuzhou Garden #58 Project. J. Eng. Manag. 2018, 32, 131–135. [Google Scholar] [CrossRef]

- Fu, F.; Sun, J.; Pasquire, C. Carbon emission assessment for steel structure based on lean construction process. J. Intell. Robot. Syst. 2015, 79, 401–416. [Google Scholar] [CrossRef]

- Chuai, X.; Lu, Q.; Huang, X.; Gao, R.; Zhao, R. China’s construction industry-linked economy-resources-environment flow in international trade. J. Clean. Prod. 2021, 278, 123990. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of China. Several Opinions on Further Promoting the Development of EPC Contracting. 2016. Available online: https://www.gov.cn/gongbao/content/2016/content_5115854.htm (accessed on 4 January 2025).

- General Office of the State Council. Opinions on Promoting the Sustainable and Healthy Development of the Construction Industry. 2017. Available online: https://www.gov.cn/gongbao/content/2017/content_5178192.htm (accessed on 4 January 2025).

- Ministry of Housing and Urban-Rural Development of China. Notice on the Issuance of the Management Measures for the EPC Model of Housing Construction and Municipal Infrastructure Projects. 2019. Available online: https://www.gov.cn/zhengce/zhengceku/2019-12/31/content_5465928.htm (accessed on 4 January 2025).

- Wei, Q.; Xiao, Y. A review of research related to risk management of EPC engineering projects and future prospects. Academic J. Bus. Manag. 2023, 5, 25–34. [Google Scholar] [CrossRef]

- Aldhaheri, M.; Bakchan, A.; Sandhu, M.A. A structural equation model for enhancing effectiveness of engineering, procurement and construction (EPC) major projects: End-user’s perspective. Eng. Constr. Archit. Manag. 2018, 25, 1226–1252. [Google Scholar] [CrossRef]

- Xia, M.; Zhao, L.; Zhao, L. A comprehensive risk assessment method for prefabricated buildings using EPC: A case study in China. Sustainability 2022, 14, 1910. [Google Scholar] [CrossRef]

- Tao, Y. Analysis on engineering risk management of international EPC project. BCP Bus. Manag. 2022, 24, 218–225. [Google Scholar] [CrossRef]

- Zhou, Y. Research on the Applicability of Target Value Design Method Based on Lean Thinking in Domestic EPC Projects. Master’s Thesis, Chongqing University, Chongqing, China, 2022. [Google Scholar]

- Gong, P.; Zeng, N.; Ye, K.; König, M. An empirical study on the acceptance of 4D BIM in EPC projects in China. Sustainability 2019, 11, 1316. [Google Scholar] [CrossRef]

- Howell, G.; Ballard, G. Implementing lean construction: Understanding and action. In Proceedings of the 6th Annual Conference of the International Group for Lean Construction, Guarujá, Brazil, 13–15 August 1998. [Google Scholar]

- Koskela, L. An Exploration Towards a Production Theory and Its Application to Construction. Ph.D. Thesis, Aalto University, Espoo, Finland, VTT Technical Research Centre of Finland, Espoo, Finland, 2000. [Google Scholar]

- Habibi Rad, M.; Mojtahedi, M.; Ostwald, M.J.; Wilkinson, S. A conceptual framework for implementing lean construction in infrastructure recovery projects. Buildings 2022, 12, 272. [Google Scholar] [CrossRef]

- Duan, C.; Zhu, X.; Wan, P.; Liu, T.; Zhao, Z. The practice of lean construction with design integration as the core in EPC project. Constr. Mech. 2023, 44, 82–85. [Google Scholar]

- Bamana, F.; Lehoux, N.; Cloutier, C. Simulation of a construction project: Assessing impact of just-in-time and lean principles. J. Constr. Eng. Manag. 2019, 145, 05019005. [Google Scholar] [CrossRef]

- Linde, I.; Philippov, D. Applying lean six sigma in construction: World practice experience. Access J. 2020, 1, 103–111. [Google Scholar] [CrossRef]

- Ashiru, A.R.; Aule, T.T.; Anifowose, K. The use of Total Quality Management (TQM) principles for construction projects in Nigerian tertiary institutions. IOSR J. Mech. Civ. Eng. 2021, 17, 7–12. [Google Scholar]

- Rasanjali, W.A.; Mendis, A.P.K.D.; Perera, B.A.K.S.; Disaratna, V. Implementing enterprise resource planning for lean waste minimization: Challenges and proposed strategies. Smart Sustain. Built Environ. 2024, 13, 330–353. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhang, Z.; Ni, G.; Chen, C.; Wang, W.; Hong, J. Cause analysis of hindering on-site lean construction for prefabricated buildings and corresponding organizational capability evaluation. Adv. Civ. Eng. 2020, 2020, 8876102. [Google Scholar] [CrossRef]

- Anumba, C.J.; Kamara, J.M. Concurrent engineering in construction. In Construction Innovation and Process Improvement; Wiley-Blackwell: Hoboken, NJ, USA, 2012; pp. 277–295. [Google Scholar] [CrossRef]

- Santos, E.; Lima, T.M.; Gaspar, P.D. Optimization of the production management of an upholstery manufacturing process using lean tools: A case study. Appl. Sci. 2023, 13, 9974. [Google Scholar] [CrossRef]

- Zhong, J.; Su, Z.; She, X. Building construction process optimization based on VSM-GA. J. Civ. Eng. Manag. 2016, 33, 103–109. [Google Scholar] [CrossRef]

- Realyvásquez-Vargas, A.; Arredondo-Soto, K.C.; Carrillo-Gutiérrez, T.; Ravelo, G. Applying the Plan-Do-Check-Act (PDCA) cycle to reduce defects in the manufacturing industry: A case study. Appl. Sci. 2018, 8, 2181. [Google Scholar] [CrossRef]

- Abu Aisheh, Y.I.; Tayeh, B.A.; Alaloul, W.S.; Almalki, A. Health and safety improvement in construction projects: A lean construction approach. Int. J. Occup. Saf. Ergon. 2022, 28, 1981–1993. [Google Scholar] [CrossRef]

- Rodrigues, K.H.C.; de Oliveira, R.P. Programa de Condições e Meio Ambiente de Trabalho na Indústria da Construção (PCMAT). Perquirere 2018, 15, 86–97. [Google Scholar]

- Slavina, T.; Štefanić, N. Facing challenges of implementing total productive management and lean tools in manufacturing enterprises. Systems 2024, 12, 52. [Google Scholar] [CrossRef]

- Mazur, M.; Korenko, M.; Žitňák, M.; Shchur, T.; Kiełbasa, P.; Dostál, P.; Dzhidzhora, O.; Idzikowski, A. Implementation and benefits of the 5S method in improving workplace organization: A case study. Manag. Syst. Prod. Eng. 2024, 32, 498–507. [Google Scholar]

- Sundararajan, S.; Madhavi, T.C. Lean system-based tool for housing projects management in the pandemic period. Buildings 2023, 13, 2507. [Google Scholar] [CrossRef]

- Puspaningtyas, S.D.; Sucipto, S. Integration of Halal Assurance System (HAS) in the Integrated Management System (IMS) to support food industry performance: A review. IOP Conf. Ser. Earth Environ. Sci. 2021, 733, 012045. [Google Scholar] [CrossRef]

- Tzortzopoulos, P.; Kagioglou, M.; Koskela, L. (Eds.) Lean Construction: Core Concepts and New Frontiers; Routledge: New York, NY, USA, 2020. [Google Scholar]

- Shivegowda, M.D.; Boonyasopon, P.; Rangappa, S.M.; Siengchin, S. A review on computer-aided design and manufacturing processes in design and architecture. Arch. Comput. Methods Eng. 2022, 29, 3973–3980. [Google Scholar] [CrossRef]

- Zhijie, Z.; Xiangyang, J.; Yikui, M.; Hanghang, F.; Ran, W. Research on lean construction management mode of EPC project based on BIM. J. Adv. Eng. Technol. 2024, 1, 15–24. [Google Scholar] [CrossRef]

- Aslam, M.; Gao, Z.; Smith, G. Framework for selection of lean construction tools based on lean objectives and functionalities. Int. J. Constr. Manag. 2022, 22, 1559–1570. [Google Scholar] [CrossRef]

- Gómez-Cabrera, A.; Salazar, L.A.; Ponz-Tienda, J.L.; Alarcón, L.F. Lean tools proposal to mitigate delays and cost overruns in construction projects. In Proceedings of the 28th Annual Conference of the International Group for Lean Construction (IGLC28), Berkeley, CA, USA, 6–12 July 2020. [Google Scholar] [CrossRef]

- Ikuma, L.H.; Nahmens, I.; James, J. Use of safety and lean integrated kaizen to improve performance in modular homebuilding. J. Constr. Eng. Manag. 2011, 137, 551–560. [Google Scholar] [CrossRef]

- Moradi, S.; Sormunen, P. Implementing construction lean: A literature study of barriers, enablers, and implications. Buildings 2023, 13, 556. [Google Scholar] [CrossRef]

- Bajjou, M.S.; Chafi, A. Lean construction and simulation for performance improvement: A case study of reinforcement process. Int. J. Prod. Perform. Manag. 2021, 70, 459–487. [Google Scholar] [CrossRef]

- Xing, W.; Hao, J.L.; Qian, L.; Tam, V.W.; Sikora, K.S. Implementing lean construction techniques and management methods in Chinese projects: A case study in Suzhou, China. J. Clean. Prod. 2021, 286, 124944. [Google Scholar] [CrossRef]

- Nwaki, W.N.; Eze, C.E. Lean construction as a panacea for poor construction projects performance. ITEGAM-JETIA 2020, 6, 61–72. [Google Scholar] [CrossRef]

- Ghosh, S.; Burghart, J. Lean construction: Experience of US contractors. Int. J. Constr. Educ. Res. 2021, 17, 133–153. [Google Scholar] [CrossRef]

- Demirkesen, S.; Sadikoglu, E.; Jayamanne, E. Assessing psychological safety in lean construction projects in the United States. Constr. Econ. Build. 2021, 21, 159–175. [Google Scholar] [CrossRef]

- Demirkesen, S.; Bayhan, H.G. A lean implementation success model for the construction industry. Eng. Manag. J. 2020, 32, 219–239. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.d.C.D.; Tavares, S.F. Interactions between lean construction principles and circular economy practices for the construction industry. J. Constr. Eng. Manag. 2021, 147, 04021068. [Google Scholar] [CrossRef]

- Awad, T.; Guardiola, J.; Fraíz, D. Sustainable construction: Improving productivity through lean construction. Sustainability 2021, 13, 13877. [Google Scholar] [CrossRef]

- Costa, F.; Denis Granja, A.; Fregola, A.; Picchi, F.; Portioli Staudacher, A. Understanding relative importance of barriers to improving the customer–supplier relationship within construction supply chains using DEMATEL technique. J. Manag. Eng. 2019, 35, 04019002. [Google Scholar] [CrossRef]

- Solaimani, S.; Sedighi, M. Toward a holistic view on lean sustainable construction: A literature review. J. Clean. Prod. 2020, 248, 119213. [Google Scholar] [CrossRef]

- Morshidi, Z.; Othman, M.K.F.; Bohari, A.A.M.; Rais, S.L.A. Awareness and adoption of lean construction tools to enhance safety in construction projects. Int. J. Serv. Manag. Sustain. 2022, 7, 1–20. [Google Scholar] [CrossRef]

- Adhi, A.B.; Muslim, F. Development of stakeholder engagement strategies to improve sustainable construction implementation based on lean construction principles in Indonesia. Sustainability 2023, 15, 6053. [Google Scholar] [CrossRef]

- Koo, M.; Yang, S.-W. Likert-type scale. Encyclopedia 2025, 5, 18. [Google Scholar] [CrossRef]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Romo, R.; Alejo-Reyes, A.; Orozco, F. Statistical analysis of lean construction barriers to optimize its implementation using PLS-SEM and PCA. Buildings 2024, 14, 486. [Google Scholar] [CrossRef]

- Abu, F.; Gholami, H.; Saman, M.Z.M.; Zakuan, N.; Streimikiene, D.; Kyriakopoulos, G.L. An SEM approach for the barrier analysis in lean implementation in manufacturing industries. Sustainability 2021, 13, 1978. [Google Scholar] [CrossRef]

- Sarstedt, M.; Hair, J.F.; Ringle, C.M.; Thiele, K.O.; Gudergan, S.P. Estimation issues with PLS and CBSEM: Where the bias lies. J. Bus. Res. 2016, 69, 3998–4010. [Google Scholar] [CrossRef]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences; Routledge: New York, NY, USA, 2013. [Google Scholar] [CrossRef]

- Dallasega, P.; Rauch, E.; Frosolini, M. A lean approach for real-time planning and monitoring in engineer-to-order construction projects. Buildings 2018, 8, 38. [Google Scholar] [CrossRef]

- Holmemo, M.D.Q.; Korsen, E.B.H. The growing gap between lean production and digital lean tools. Int. J. Lean Six Sigma 2023, 14, 1188–1206. [Google Scholar] [CrossRef]

- Korsen, E.B.H.; Holmemo, M.D.Q.; Ingvaldsen, J.A. Digital technologies and the balance between control and empowerment in performance management. Meas. Bus. Excell. 2022, 26, 583–596. [Google Scholar] [CrossRef]

- Shehab, L.; Al Hattab, M.; Khalife, S.; El Samad, G.; Abbas, Y.; Hamzeh, F. Last Planner System framework to assess planning reliability in architectural design. Buildings 2023, 13, 2684. [Google Scholar] [CrossRef]

- Wang, S.; Liu, X. Development of EPC model in Chinese public projects: Evolutionary game among stakeholders. J. Asian Archit. Build. Eng. 2022, 21, 2095–2113. [Google Scholar] [CrossRef]

- Sahoo, S. Lean practices and operational performance: The role of organizational culture. Int. J. Qual. Reliab. Manag. 2022, 39, 428–467. [Google Scholar] [CrossRef]

| Categories | Lean Practices |

|---|---|

| 1. Planning and Scheduling (PS) | JIT and LPS [6]; TVD [23]; ERP [32]; |

| Concurrent Engineering [34]. | |

| 2. Process and Workflow Optimization (PWO) | Continuous Improvement Programs [9]; |

| Kanban [35]; VSM [36]; | |

| First Run Studies (Plan, Do, Check, Act—PDCA) [37]. | |

| 3. Quality and Safety Enhancement (QSE) | Six Sigma [30]; TQM [31]; |

| Safety Improvement Program [38]; | |

| Plan of Conditions and Work Environment in the Construction Industry (PCMAT) [39]. | |

| 4. Resource and Maintenance (RM) | Use of Prefabricated Materials [33]; |

| Total Productive Maintenance (TPM) [40]; | |

| 5S Process [41]. | |

| 5. Visualization and Communication (VC) | Increased Visualization [42]; |

| Information Management System (IMS) [43]; | |

| Daily Huddle Meetings [44]; | |

| Computer-Aided Design (CAD) [45]. |

| Author | Reduced Construction Time | Better Inventory Control | Quality Improvement | Customer Satisfaction | Process Improvement | Employee Satisfaction | Increased Market Share | Increased Productivity | Improved Supplier Relationship | Better Health and Safety Record |

|---|---|---|---|---|---|---|---|---|---|---|

| [1] | * | * | * | |||||||

| [8] | * | |||||||||

| [9] | * | * | ||||||||

| [38] | * | |||||||||

| [50] | * | |||||||||

| [51] | * | |||||||||

| [52] | * | * | ||||||||

| [53] | * | |||||||||

| [54] | * | |||||||||

| [55] | * | |||||||||

| [56] | * | * | * | * | ||||||

| [57] | * | |||||||||

| [58] | * | |||||||||

| [59] | * | |||||||||

| [60] | * | |||||||||

| [61] | * |

| Categories | Benefits |

|---|---|

| 1. Efficiency and Resource Management (ERM) | Reduced construction time |

| Better inventory control | |

| Increased productivity | |

| 2. Quality and Safety (QS) | Quality improvement |

| Better health and safety records | |

| 3. Organization and Market Impact (OMI) | Process improvement (internal improvements) |

| Increased market share (external market impact) | |

| 4. Stakeholder Satisfaction (SS) | Customer satisfaction |

| Improved supplier relationship | |

| Employee satisfaction |

| Profile | Classification | Frequency | Percentage (%) |

|---|---|---|---|

| Education level | PhD | 35 | 7.68 |

| Master’s | 75 | 16.45 | |

| Bachelor’s | 218 | 47.81 | |

| Diploma and below | 128 | 28.07 | |

| Work experience (Years) | 0–5 | 137 | 30.04 |

| 6–10 | 252 | 55.26 | |

| 11 and above | 67 | 14.69 | |

| Organization Type | Architect | 18 | 3.95 |

| Client | 92 | 20.18 | |

| General contractor | 34 | 7.46 | |

| Subcontractor | 69 | 15.13 | |

| Specialty contractor | 91 | 19.96 | |

| Supplier | 96 | 21.05 | |

| Project management | 12 | 2.63 | |

| Academia | 32 | 7.02 | |

| Government | 12 | 2.63 |

| Performance Indicator | R² Value |

|---|---|

| ERM | 0.847 |

| OMI | 0.786 |

| QS | 0.778 |

| SS | 0.827 |

| Path Coefficient | Sample Mean (M) | Standard Deviation (STDEV) | T Statistics (|O/STDEV|) | p Values | |

|---|---|---|---|---|---|

| PS -> ERM | 0.255 | 0.255 | 0.060 | 4.271 | 0.000 |

| PS -> OMI | 0.276 | 0.278 | 0.068 | 4.065 | 0.000 |

| PS -> QS | 0.184 | 0.184 | 0.063 | 2.904 | 0.004 |

| PS -> SS | 0.400 | 0.401 | 0.064 | 6.270 | 0.000 |

| PWO -> ERM | 0.258 | 0.259 | 0.054 | 4.746 | 0.000 |

| PWO -> OMI | 0.150 | 0.150 | 0.065 | 2.300 | 0.021 |

| PWO -> QS | 0.305 | 0.305 | 0.067 | 4.572 | 0.000 |

| PWO -> SS | 0.167 | 0.166 | 0.061 | 2.727 | 0.006 |

| QSE -> ERM | 0.178 | 0.178 | 0.048 | 3.740 | 0.000 |

| QSE -> OMI | 0.296 | 0.295 | 0.061 | 4.842 | 0.000 |

| QSE -> QS | 0.180 | 0.180 | 0.059 | 3.032 | 0.002 |

| QSE -> SS | 0.191 | 0.191 | 0.058 | 3.295 | 0.001 |

| RM -> ERM | 0.133 | 0.132 | 0.043 | 3.110 | 0.002 |

| RM -> OMI | 0.164 | 0.162 | 0.055 | 2.967 | 0.003 |

| RM -> QS | 0.149 | 0.148 | 0.055 | 2.713 | 0.007 |

| RM -> SS | 0.026 | 0.026 | 0.050 | 0.522 | (0.602) |

| VC -> ERM | 0.141 | 0.141 | 0.057 | 2.480 | 0.013 |

| VC -> OMI | 0.044 | 0.045 | 0.060 | 0.746 | (0.456) |

| VC -> QS | 0.107 | 0.108 | 0.069 | 1.554 | (0.120) |

| VC -> SS | 0.163 | 0.164 | 0.058 | 2.796 | 0.005 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, D.; Ab Rahman, M.N.; Khamis, N.K. Quantifying the Impact of Lean Construction Practices on Sustainability Performance in Chinese EPC Projects: A PLS-SEM Approach. Sustainability 2025, 17, 5665. https://doi.org/10.3390/su17125665

Zhu D, Ab Rahman MN, Khamis NK. Quantifying the Impact of Lean Construction Practices on Sustainability Performance in Chinese EPC Projects: A PLS-SEM Approach. Sustainability. 2025; 17(12):5665. https://doi.org/10.3390/su17125665

Chicago/Turabian StyleZhu, Dewu, Mohd Nizam Ab Rahman, and Nor Kamaliana Khamis. 2025. "Quantifying the Impact of Lean Construction Practices on Sustainability Performance in Chinese EPC Projects: A PLS-SEM Approach" Sustainability 17, no. 12: 5665. https://doi.org/10.3390/su17125665

APA StyleZhu, D., Ab Rahman, M. N., & Khamis, N. K. (2025). Quantifying the Impact of Lean Construction Practices on Sustainability Performance in Chinese EPC Projects: A PLS-SEM Approach. Sustainability, 17(12), 5665. https://doi.org/10.3390/su17125665