Review of Material Passports and Their Application in Industrialised Construction: Enhancing Material Circularity in Construction

Abstract

1. Introduction

2. Issues and Solutions for Material Circularity in Construction

2.1. Need for Material Information and Material Passports

2.2. Need for Industrialised Construction

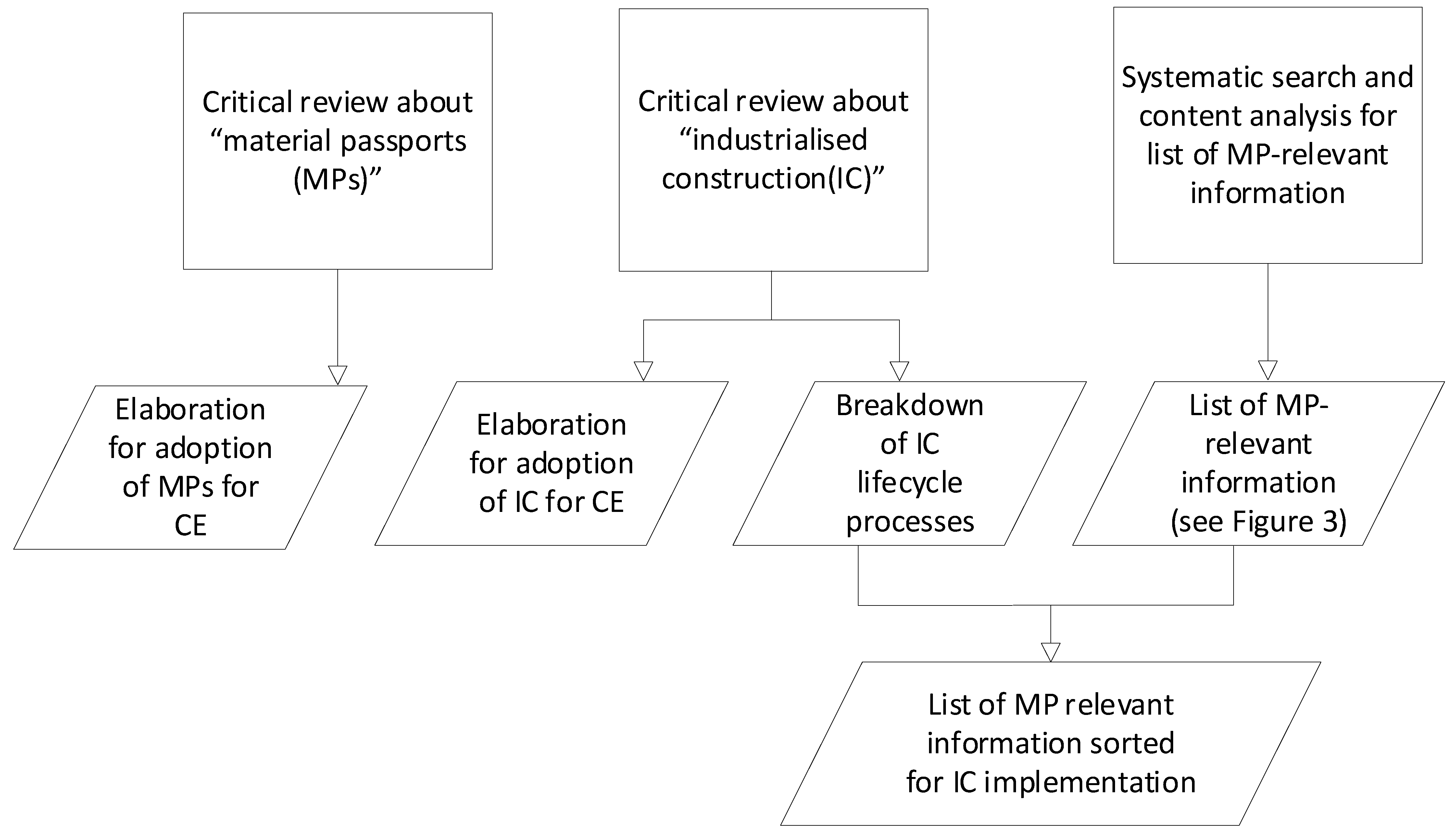

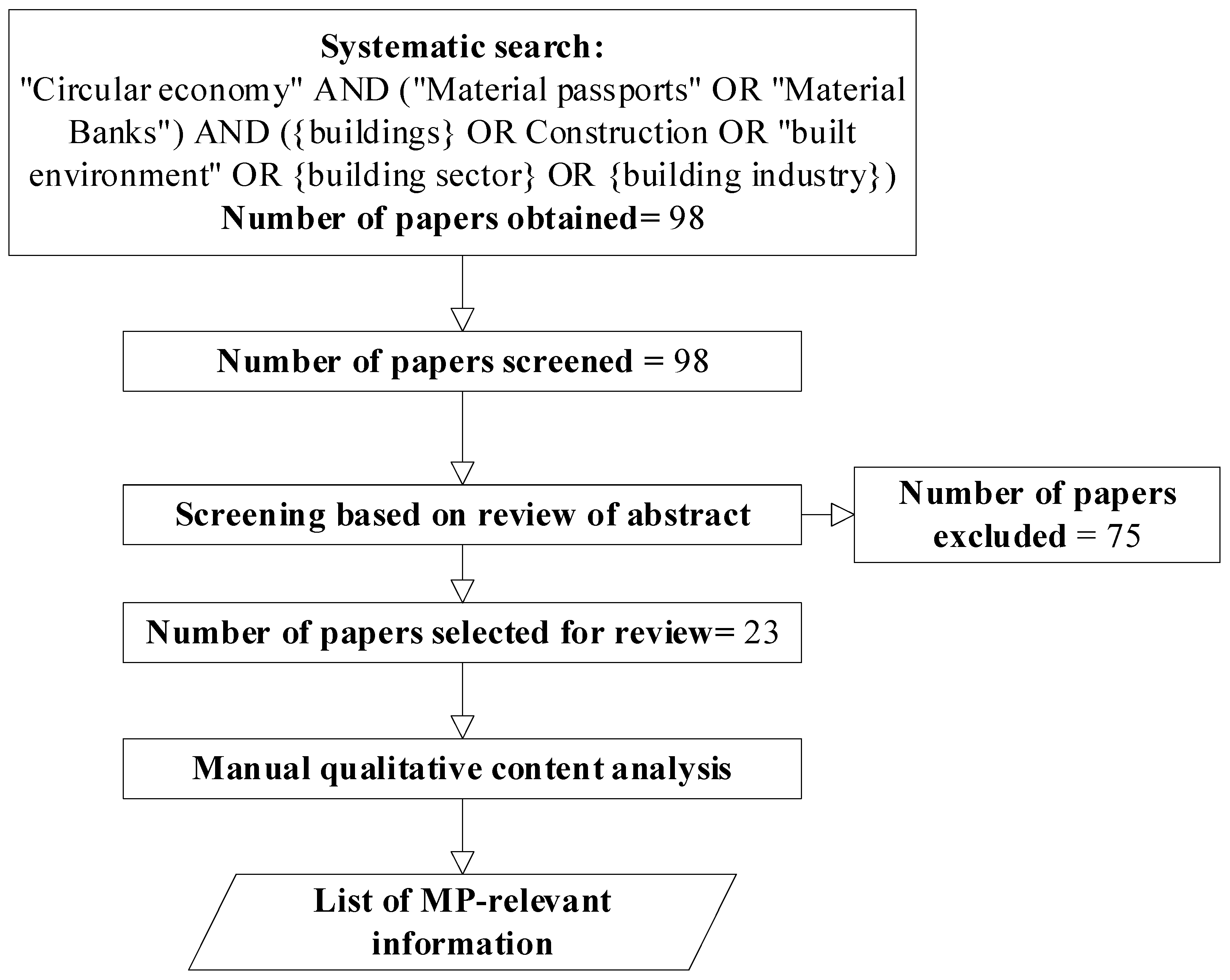

3. Research Method

4. Material Passports for Circular Economy

4.1. Circularity Features of Material Passports

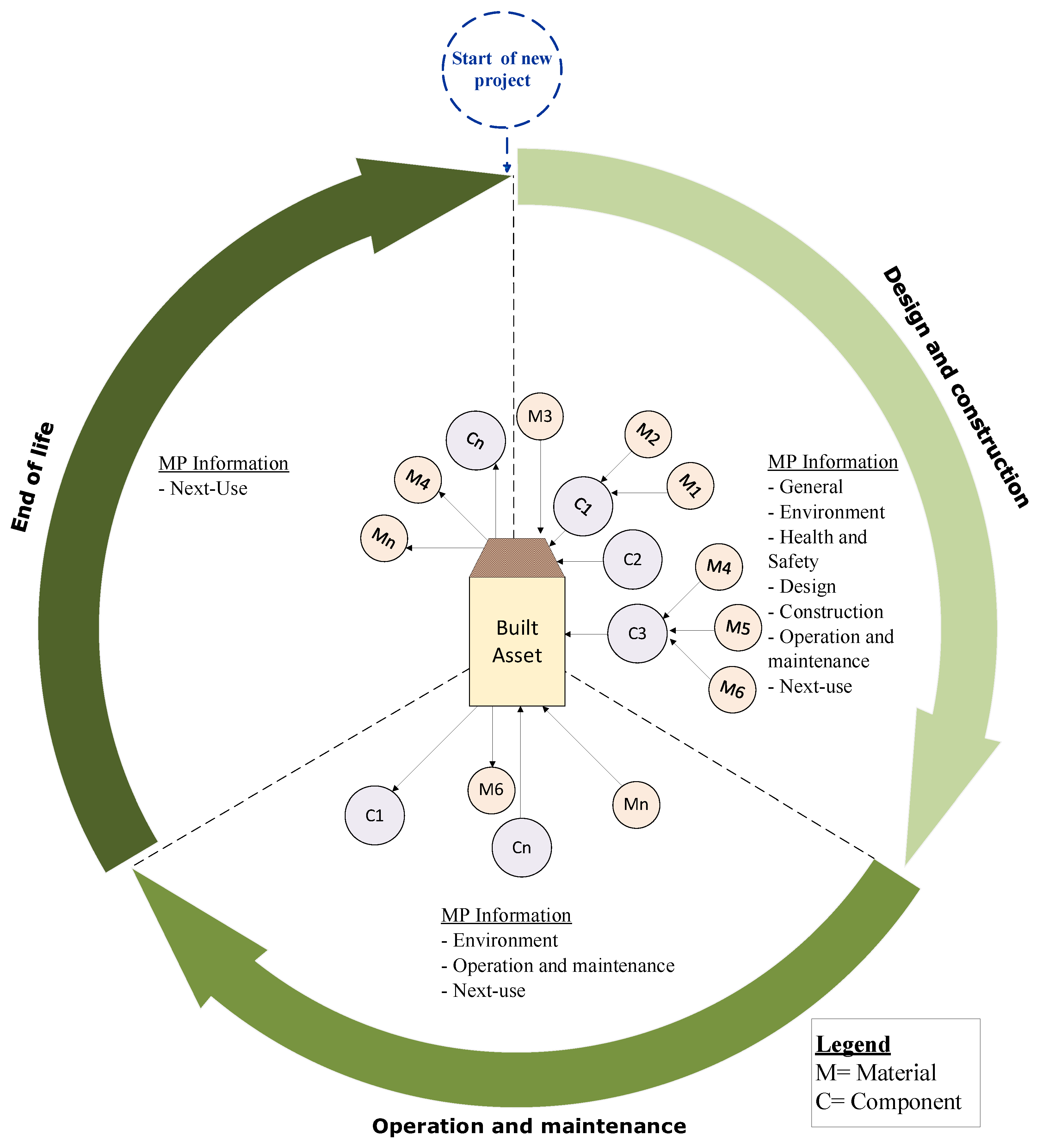

4.2. Material and Information Flows in Built Asset’s Lifecycle

5. Industrialised Construction for Circular Economy

5.1. Circularity Features of Industrialised Construction

5.2. Lifecycle Stages of Industrialised Construction

6. Application of Material Passports in Industrialised Construction

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular economy in the building and construction sector: A scientific evolution analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Soto-Paz, J.; Arroyo, O.; Torres-Guevara, L.E.; Parra-Orobio, B.A.; Casallas-Ojeda, M. The circular economy in the construction and demolition waste management: A comparative analysis in emerging and developed countries. J. Build. Eng. 2023, 78, 107724. [Google Scholar] [CrossRef]

- Global ABC. 2021 Global Status Report for Buidings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; United Nations Environment Programme: Nairobi, Kenya, 2021. [Google Scholar]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- EMF. Towards the Circular Economy—Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2012. [Google Scholar]

- EMF. Towards a Circular Economy: Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- EMF. Circular Economy Introduction—What is Circular Economy. Available online: https://www.ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview (accessed on 25 February 2023).

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.P.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; Planbureau voor de Leefomgeving: Den Haag, The Netherlands, 2017. [Google Scholar]

- Heinrich, M.; Lang, W. Materials Passports—Best Practice—Innovative Solutions for a Transition to a Circular Economy in the Built Environment; Technische Universität München: München, Germany, 2019. [Google Scholar]

- Cai, G.; Waldmann, D. A material and component bank to facilitate material recycling and component reuse for a sustainable construction: Concept and preliminary study. Clean Technol. Environ. Policy 2019, 21, 2015–2032. [Google Scholar] [CrossRef]

- Honic, M.; Kovacic, I.; Rechberger, H. Improving the recycling potential of buildings through Material Passports (MP): An Austrian case study. J. Clean. Prod. 2019, 217, 787–797. [Google Scholar] [CrossRef]

- Munaro, M.R.; Fischer, A.C.; Azevedo, N.C.; Tavares, S.F. Proposal of a building material passport and its application feasibility to the wood frame constructive system in Brazil. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012018. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F.; Bragança, L. Towards circular and more sustainable buildings: A systematic literature review on the circular economy in the built environment. J. Clean. Prod. 2020, 260, 121134. [Google Scholar] [CrossRef]

- Schaubroeck, S.; Dewil, R.; Allacker, K. Circularity and LCA—Material pathways: The cascade potential and cascade database of an in-use building product. IOP Conf. Ser. Earth Environ. Sci. 2022, 1122, 012040. [Google Scholar] [CrossRef]

- Kedir, F.; Hall, D.M.; Brantvall, S.; Lessing, J.; Hollberg, A.; Soman, R.K. Circular information flows in industrialized housing construction: The case of a multi-family housing product platform in Sweden. Constr. Innov. 2023, 24, 1354–1379. [Google Scholar] [CrossRef]

- Honic, M.; Kovacic, I.; Aschenbrenner, P.; Ragossnig, A. Material Passports for the end-of-life stage of buildings: Challenges and potentials. J. Clean. Prod. 2021, 319, 128702. [Google Scholar] [CrossRef]

- Kedir, F.; Hall, D.M. Resource efficiency in industrialized housing construction—A systematic review of current performance and future opportunities. J. Clean. Prod. 2021, 286, 125443. [Google Scholar] [CrossRef]

- Razkenari, M.; Bing, Q.; Fenner, A.; Hakim, H.; Costin, A.; Kibert, C.J. Industrialized Construction: Emerging Methods and Technologies. In Proceedings of the Computing in Civil Engineering 2019: Data, Sensing, and Analytics—Selected Papers from the ASCE International Conference on Computing in Civil Engineering 2019, Atlanta, GA, USA, 17–19 June 2019; pp. 352–359. [Google Scholar]

- Munaro, M.R.; Tavares, S.F. Materials passport’s review: Challenges and opportunities toward a circular economy building sector. Built Environ. Proj. Asset Manag. 2021, 11, 767–782. [Google Scholar] [CrossRef]

- Çetin, S.; Raghu, D.; Honic, M.; Straub, A.; Gruis, V. Data requirements and availabilities for material passports: A digitally enabled framework for improving the circularity of existing buildings. Sustain. Prod. Consum. 2023, 40, 422–437. [Google Scholar] [CrossRef]

- Joensuu, T.; Edelman, H.; Saari, A. Circular economy practices in the built environment. J. Clean. Prod. 2020, 276, 124215. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.D.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Adams, K.T.; Osmani, M.; Thorpe, T.; Thornback, J. Circular economy in construction: Current awareness, challenges and enablers. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2017, 170, 15–24. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to circular construction: An integrated management of construction and demolition waste for resource recovery. J. Clean. Prod. 2020, 244, 118710. [Google Scholar] [CrossRef]

- Mahpour, A. Prioritizing barriers to adopt circular economy in construction and demolition waste management. Resour. Conserv. Recycl. 2018, 134, 216–227. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renew. Sustain. Energy Rev. 2020, 130, 109948. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Luscuere, L.; Mulhall, D. Circularity information management for buildings: The example of materials passports. In Designing for the Circular Economy; Routledge: London, UK, 2018; pp. 369–380. [Google Scholar]

- Lacy, P.A. Waste to Wealth: The Circular Economy Advantage; Palgrave Macmillan: New York, NY, USA, 2015. [Google Scholar]

- Zimmann, R.; O’Brien, H.; Hargrave, J.; Marcus, M. The Circular Economy in the Built Environment; ARUP: London, UK, 2016. [Google Scholar]

- Guerriero, A.; Busio, F.; Saidani, M.; Boje, C.; Mack, N. Combining Building Information Model and Life Cycle Assessment for Defining Circular Economy Strategies. Sustainability 2024, 16, 4561. [Google Scholar] [CrossRef]

- Leising, E.; Quist, J.; Bocken, N. Circular Economy in the building sector: Three cases and a collaboration tool. J. Clean. Prod. 2018, 176, 976–989. [Google Scholar] [CrossRef]

- Stephan, A.; Athanassiadis, A. Quantifying and mapping embodied environmental requirements of urban building stocks. Build. Environ. 2017, 114, 187–202. [Google Scholar] [CrossRef]

- Honic, M.; Kovacic, I.; Sibenik, G.; Rechberger, H. Data- and stakeholder management framework for the implementation of BIM-based Material Passports. J. Build. Eng. 2019, 23, 341–350. [Google Scholar] [CrossRef]

- Hart, J.; Adams, K.; Giesekam, J.; Tingley, D.D.; Pomponi, F. Barriers and drivers in a circular economy: The case of the built environment. Procedia CIRP 2019, 80, 619–624. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T. Critical consideration of buildings’ environmental impact assessment towards adoption of circular economy: An analytical review. J. Clean. Prod. 2018, 205, 763–780. [Google Scholar] [CrossRef]

- Berglund-Brown, J.; Kedir, F.; Riabova, A.; Hall, D. Assessing Circular Information Flow in Industrialized Construction: A framework for evaluating data for circular construction. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012005. [Google Scholar] [CrossRef]

- Grant, M.J.; Booth, A. A typology of reviews: An analysis of 14 review types and associated methodologies. Health Inf. Libr. J. 2009, 26, 91–108. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Pranckutė, R. Web of Science (WoS) and Scopus: The Titans of Bibliographic Information in Today’s Academic World. Publications 2021, 9, 12. [Google Scholar] [CrossRef]

- Hoosain, M.S.; Paul, B.S.; Raza, S.M.; Ramakrishna, S. Material Passports and Circular Economy. In An Introduction to Circular Economy; Springer: Singapore, 2020; pp. 131–158. [Google Scholar]

- Hoosain, M.S.; Paul, B.S.; Ramakrishna, S. The impact of 4ir digital technologies and circular thinking on the united nations sustainable development goals. Sustainability 2020, 12, 10143. [Google Scholar] [CrossRef]

- Schaubroeck, S.; Dewil, R.; Allacker, K. Circularity of building stocks: Modelling building joints and their disassembly in a 3D city model. Procedia CIRP 2022, 105, 712–720. [Google Scholar] [CrossRef]

- Çetin, S.; De Wolf, C.; Bocken, N. Circular digital built environment: An emerging framework. Sustainability 2021, 13, 6348. [Google Scholar] [CrossRef]

- Talla, A.; McIlwaine, S. Industry 4.0 and the circular economy: Using design-stage digital technology to reduce construction waste. Smart Sustain. Built Environ. 2022, 13, 179–198. [Google Scholar] [CrossRef]

- Kovacic, I.; Honic, M.; Sreckovic, M. Digital platform for circular economy in aec industry. Eng. Proj. Organ. J. 2020, 9, 16. [Google Scholar] [CrossRef]

- Zhang, N.; Han, Q.; de Vries, B. Building Circularity Assessment in the Architecture, Engineering, and Construction Industry: A New Framework. Sustainability 2021, 13, 12466. [Google Scholar] [CrossRef]

- Çetin, S.; Gruis, V.; Straub, A. Digitalization for a circular economy in the building industry: Multiple-case study of Dutch social housing organizations. Resour., Conserv. Recycl. Adv. 2022, 15, 200110. [Google Scholar] [CrossRef]

- Kovacic, I.; Honic, M. Scanning and data capturing for bim-supported resources assessment: A case study. J. Inf. Technol. Constr. 2021, 26, 624–638. [Google Scholar] [CrossRef]

- Romero Perez de Tudela, A.; Rose, C.M.; Stegemann, J.A. Quantification of material stocks in existing buildings using secondary data—A case study for timber in a London Borough. Resour. Conserv. Recycl. X 2020, 5, 100027. [Google Scholar] [CrossRef]

- KC, A.; Senaratne, S.; Perera, S.; Nanayakkara, S. Review of current digital technologies for material passports to enhance circularity towards net zero. Built Environ. Proj. Asset Manag. 2024; ahead-of-print. [Google Scholar] [CrossRef]

- Bonev, M.; Wörösch, M.; Hvam, L. Utilizing platforms in industrialized construction: A case study of a precast manufacturer. Constr. Innov. 2015, 15, 84–106. [Google Scholar] [CrossRef]

- Ottinger, E.; Minglani, H.; Gibson, M.; Alexander, A. The four dimensions of industrialised construction. Build. Eng. 2021, 93, 26–29. [Google Scholar]

- Eriksson, P.E.; Olander, S.; Szentes, H.; Widén, K. Managing short-term efficiency and long-term development through industrialized construction. Constr. Manag. Econ. 2014, 32, 97–108. [Google Scholar] [CrossRef]

- Larsson, J.; Eriksson, P.E.; Olofsson, T.; Simonsson, P. Industrialized construction in the Swedish infrastructure sector: Core elements and barriers. Constr. Manag. Econ. 2014, 32, 83–96. [Google Scholar] [CrossRef]

- Jansson, G.; Mukkavaara, J.; Elgh, F.; Lennartsson, M. Breakdown Structure in the Digitalization of Design Work for Industrialized House-Building: A Case Study of Systems Building Using Predefinition Levels of Product Platforms; American Society of Civil Engineers: Reston, VA, USA, 2019; p. 49. [Google Scholar]

- Ekanayake, E.M.A.C.; Shen, G.Q.P.; Kumaraswamy, M.M. Identifying supply chain capabilities of construction firms in industrialized construction. Prod. Plan. Control 2021, 32, 303–321. [Google Scholar] [CrossRef]

- Čuš-Babič, N.; Rebolj, D.; Nekrep-Perc, M.; Podbreznik, P. Supply-chain transparency within industrialized construction projects. Comput. Ind. 2014, 65, 345–353. [Google Scholar] [CrossRef]

- Khoshnava, S.M.; Rostami, R.; Ismail, M.; Lamit, H. Obstacles and drivers in steering IBS towards green and sustainability. Res. J. Appl. Sci. Eng. Technol. 2014, 8, 1639–1647. [Google Scholar] [CrossRef]

- Malmgren, L.; Jensen, P.; Olofsson, T. Product Modeling of Configurable Building Systems a Case Study. J. Inf. Technol. Constr. 2010, 15, 354–368. [Google Scholar]

- Persson, S.; Malmgren, L.; Johnsson, H. Information management in industrial housing design and manufacture. J. Inf. Technol. Constr. 2009, 14, 110–122. [Google Scholar]

- Andersson, N.; Lessing, J. The Interface between Industrialized and Project Based Construction. Procedia Eng. 2017, 196, 220–227. [Google Scholar] [CrossRef]

- RIBA. RIBA Plan of Work 2020 Overview; Royal Institutes of British Architects: London, UK, 2020. [Google Scholar]

- Ribeirinho, M.J.; Mischke, J.; Strube, G.; Sjodin, E.; Blanco, J.L.; Palter, R.; Biorck, J.; Rockhill, D.; Andersson, T. The Next Normal in Construction; Mckinsey & Company: New York, NY, USA, 2020. [Google Scholar]

- Wuni, I.Y.; Shen, G.Q.; Darko, A. Best practices for implementing industrialized construction projects: Lessons from nine case studies. Constr. Innov. 2022, 22, 915–938. [Google Scholar] [CrossRef]

- Aguiar, A.; Vonk, R.; Kamp, F. BIM and Circular Design. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012068. [Google Scholar] [CrossRef]

- Yilmaz, G.; Hutton, C.; Valsaladas, V.; Donovan, C.; Zvirgzda, K.; Charlson, A.; Heaton, R.; Suc, C.; Ahmed-Kristensen, S. Material passport for modular construction. IET Conf. Proc. 2024, 2024, 159–164. [Google Scholar] [CrossRef]

- Heisel, F.; Rau-Oberhuber, S. Calculation and evaluation of circularity indicators for the built environment using the case studies of UMAR and Madaster. J. Clean. Prod. 2020, 243, 118482. [Google Scholar] [CrossRef]

- Gómez-Gil, M.; Askar, R.; Karanafti, A.; Trubina, N.; Blázquez, T.; Güngör, B.; Bragança, L.; Leindecker, G. Unlocking the Potential of Material and Building Passports in the Transition to a Circular Economy in Buildings: A Critical Review. In 4th International Conference “Coordinating Engineering for Sustainability and Resilience” & Midterm Conference of CircularB “Implementation of Circular Economy in the Built Environment”; Springer: Cham, Switzerland, 2024; pp. 404–413. [Google Scholar]

- Li, Q.; Wang, Y.L. Blockchain’s role in supporting circular supply chains in the built environment. In Proceedings of the 2021 IEEE International Conference on Blockchain (Blockchain 2021), Sydney, Australia, 3–6 May 2021; pp. 578–583. [Google Scholar]

- Topraklı, A.Y. Enabling circularity in Turkish construction: A case of BIM-based material management utilizing material passports. Smart Sustain. Built Environ. 2024; ahead-of-print. [Google Scholar] [CrossRef]

| Lifecycle Stages with Distinct Information Flow | Material Information Type Generated and/or Updated | MP-Relevant Information Flow |

|---|---|---|

| Design and construction |

| Material passports added |

| Operation and maintenance |

| Material passports added and dispersed |

| End-of-life |

| Material passports dispersed |

| Group 1: Executive stakeholder—Client | |||

| Lifecycle Stages | Processes | Information | Identifier |

| Planning and Procurement | Scoping of work [66,67] | Building’s name/type/location [21] | G-1 |

| Selection of design or building components [16,66,67] | Drawings, dimensions, and BIM models [21,50,68] | G-2 | |

| Selection of materials/product [16,18,67] | Design with material specifications [16,69] | G-3 | |

| Physical properties (dimensions, weight, density, fire resistance, required storage conditions) [13,16,17,20,21,43,49,50,68,70,71] | G-4 | ||

| Chemical/material composition [13,17,20,21,30,43,71] | G-5 | ||

| Product quantity [21,50,72,73] | G-6 | ||

| Toxicity and hazardous substances [13,20,21,50] | H-1 | ||

| Product function [16,20] | G-7 | ||

| Decision on environmental performance [18] | Environmental performance information (Life Cycle Assessment, Environmental Product Declarations) [12,15,17,48,72] | E-1 | |

| Percentage of renewable materials [16,20,21,49,70,72] | E-2 | ||

| Percentage of recycled/reused materials [16,20,21,49,70,72] | E-3 | ||

| Embodied carbon [16,49,73] | E-4 | ||

| Reuse potential [16,17,20,21,30,49,70,72] | E/N-1 | ||

| Recycle potential [16,17,21,30,43,44,49,70,72] | E/N-2 | ||

| Disassembly potential (properties, actions, environmental and financial impacts of disassembly work) [43,45] | E/N-3 | ||

| Disposal options/decomposability [20,21,49,70] | E-5 | ||

| Cost measurement of environmental impacts [49] | E-6 | ||

| Sustainability certification labels [16,20,69] | E-7 | ||

| Selection of manufacturers and suppliers [66,67] | Components’/products’ commercial name [13,16,20,30,49,70,73] | G-8 | |

| Manufacturer details [16,20,21,30,49,69,72,73] | G-9 | ||

| Manufacturing process and techniques [20,73] | E-8 | ||

| Manufacturing waste [16,17,73] | E-9 | ||

| Product cost [49,50,72] | G-10 | ||

| Safety certifications [20,73] | H-2 | ||

| Product picture [20,21] | G-11 | ||

| Product safety data sheet [13,21,43,44,73] | H-3 | ||

| Security information (warning and recommendation) [20] | G-12 | ||

| Take-back options [16] | N-1 | ||

| Expected lifetime [13,16,20,21,30,49,70] | G-13 | ||

| Warranties [16,20,69] | G-14 | ||

| Material transportation planning [67] | Handling instructions [16,20] | C/O-1 | |

| Group 2: Executive stakeholder—Manufacturing facility | |||

| Lifecycle Stages | Processes | Information | Identifier |

| Manufacturing and production | Manufacturing/ Production [16,66,67] | Manufacturing date [16,20,21] | G-15 |

| Use/handling instructions [13,16,20] | C/H-1 | ||

| Installation and assembly instructions [13,16,20,30] | C-1 | ||

| Product code number (unique product ID) [17,21,45,72,73] | G-16 | ||

| Product Picture [20,21] | G-17 | ||

| Sustainability certification labels [16,20] | E-7 | ||

| Safety certification labels [20] | H-2 | ||

| Ensuring resource efficiency [18] | Manufacturing waste [16,17] | E-9 | |

| Percentage of renewable materials [16,20,21,49,70,72] | E-2 | ||

| Percentage of recycled/reused materials [16,20,21,49,70,72] | E-3 | ||

| Reuse potential [16,17,20,21,73] | E/N-1 | ||

| Recycle potential [16,17,20,21,73] | E/N-2 | ||

| Disassembly potential (properties, actions, environmental and financial impacts of disassembly work) [43,45] | E/N-3 | ||

| Disposal options/decomposability [20,21,49,70] | E-5 | ||

| Real-time tracing of production process and material information [16] | Embodied carbon [16,49,73] | E-4 | |

| Energy consumption [20,21,47,50,73] | E-11 | ||

| Water consumption [20,73] | E-12 | ||

| Environmental performance (impact) information [12,15,17,48,72] | E-1 | ||

| Material specifications [16] | G-3 | ||

| Supply chain and logistics coordination | Transportation and storage of materials [18] | Embodied carbon [16,49] | E-4 |

| Energy consumption [20,21,47,50] | E-11 | ||

| Environmental performance (impact) information [12,15,17,48,72] | E-1 | ||

| Group 3: Executive stakeholder—Contractor | |||

| Lifecycle Stages | Processes | Information | Identifier |

| Assembly | Efficient and safe installation of works [18] | Connection details [13,20,21,30,50,68,71] | C/O-2 |

| Disassembly potential (properties, actions, environmental and financial impacts of disassembly work) [43,45] | E/N-3 | ||

| Disassembly instructions [13,16,20,30,45,71] | O/N-1 | ||

| Maintenance instructions [13,16,21] | O/N-2 | ||

| Safe handling instructions [13,16,20] | C/H-1 | ||

| Works quality assessment [21,71] | C/O-3 | ||

| Installation date in the building [21] | G-18 | ||

| Position and location in the building [13,20,21,30,50,70,72] | G-19 | ||

| Expected lifetime of building [13,16,20,21,30,49,70] | G-20 | ||

| Unique building identifier [16] | G-21 | ||

| As-built drawings and BIM models [21,50,68] | G-22 | ||

| Updating environmental information [18] | Assembly works waste [16,17,71] | E-13 | |

| Embodied carbon [16,49] | E-4 | ||

| Energy consumption [20,21,47,50] | E-11 | ||

| Environmental performance (impact) information [12,15,17,48,72] | E-1 | ||

| Group 4: Executive stakeholder—End user | |||

| Lifecycle Stages | Processes | Information | Identifier |

| Operation and maintenance | Material utility assessment [16,18] | Material integrity condition [21,45,68,71] | O/N-3 |

| Use period [13,20] | O/N-4 | ||

| Latest uses/operations [13,20,30] | O/N-5 | ||

| Updating of information after maintenance (if any needed) [16,18] | Maintenance instructions [13,16,21,71] | O/N-2 | |

| Disassembly instructions [13,16,20,30,45,73] | O/N-1 | ||

| Maintenance/repair log [13,16,20,21,30,68] | O/N-6 | ||

| Updating environmental information [16,18] | Operational carbon [16] | O/E-1 | |

| Energy Consumption [20,21,47,50,71] | O/E-2 | ||

| Water Consumption [20] | O/E-3 | ||

| Operation and maintenance waste [16,17] | O/E-4 | ||

| Renovation details [21,68] | N-2 | ||

| End-of-life | Assessing circularity information [16,18] | Pre-disassembly condition assessment [45] | N-3 |

| Availability time in future for reuse [21,50] | N-4 | ||

| Process data for cascading uses [15,71] | N-5 | ||

| Disassembly potential [43,45] | E/N-3 | ||

| Disposal options/decomposability [20,21,49,70] | E-5 | ||

| Logistics information [16,18] | Disassembled material storage and transportation instruction [13,20,71] | N-6 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

KC, A.; Senaratne, S.; Perera, S.; Nanayakkara, S. Review of Material Passports and Their Application in Industrialised Construction: Enhancing Material Circularity in Construction. Sustainability 2025, 17, 5661. https://doi.org/10.3390/su17125661

KC A, Senaratne S, Perera S, Nanayakkara S. Review of Material Passports and Their Application in Industrialised Construction: Enhancing Material Circularity in Construction. Sustainability. 2025; 17(12):5661. https://doi.org/10.3390/su17125661

Chicago/Turabian StyleKC, Abhishek, Sepani Senaratne, Srinath Perera, and Samudaya Nanayakkara. 2025. "Review of Material Passports and Their Application in Industrialised Construction: Enhancing Material Circularity in Construction" Sustainability 17, no. 12: 5661. https://doi.org/10.3390/su17125661

APA StyleKC, A., Senaratne, S., Perera, S., & Nanayakkara, S. (2025). Review of Material Passports and Their Application in Industrialised Construction: Enhancing Material Circularity in Construction. Sustainability, 17(12), 5661. https://doi.org/10.3390/su17125661