Study on the Seismic Stability of Urban Sewage Treatment and Underground Reservoir of an Abandoned Mine Pumped Storage Power Station

Abstract

1. Introduction

2. Feasibility Study of the Model System

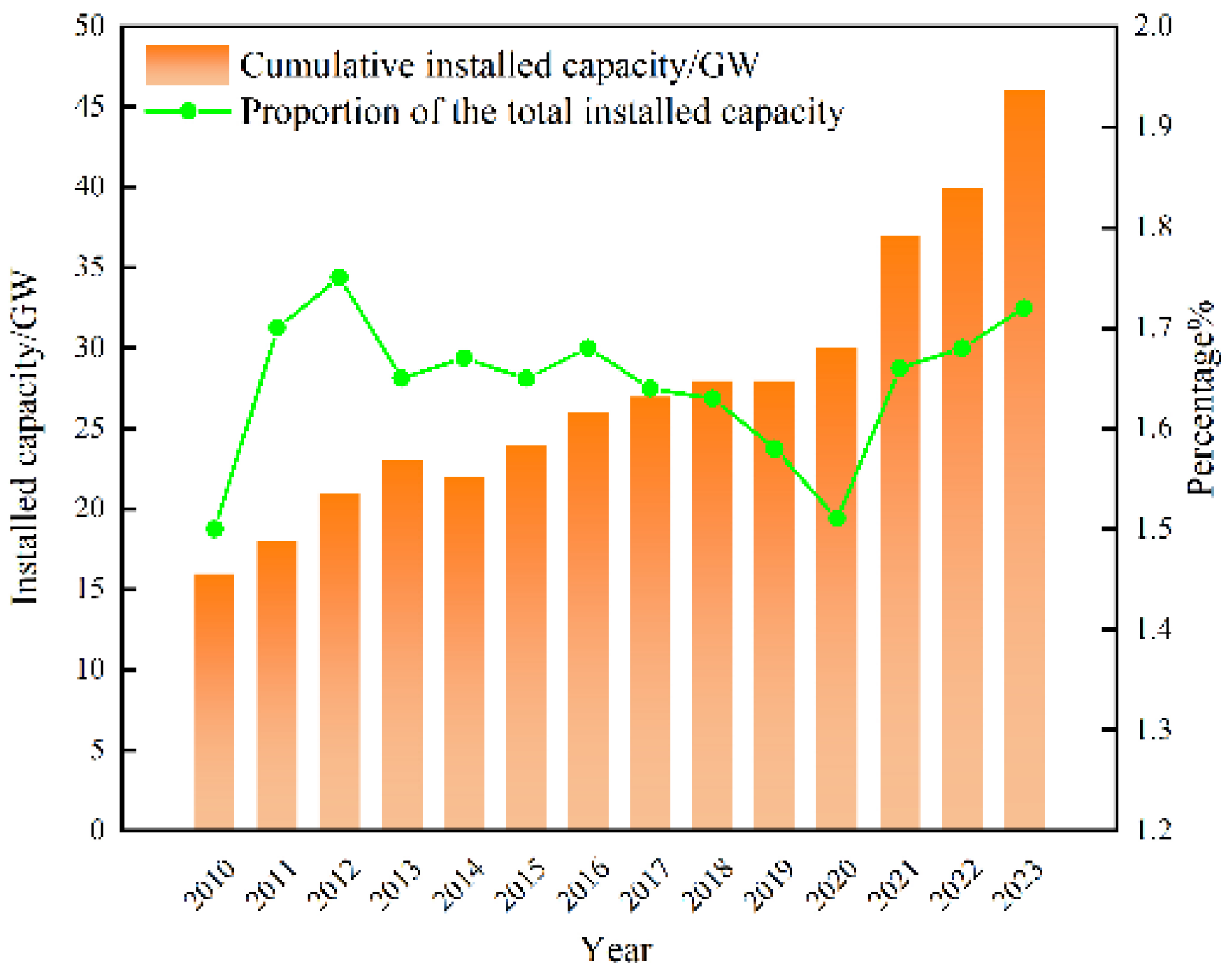

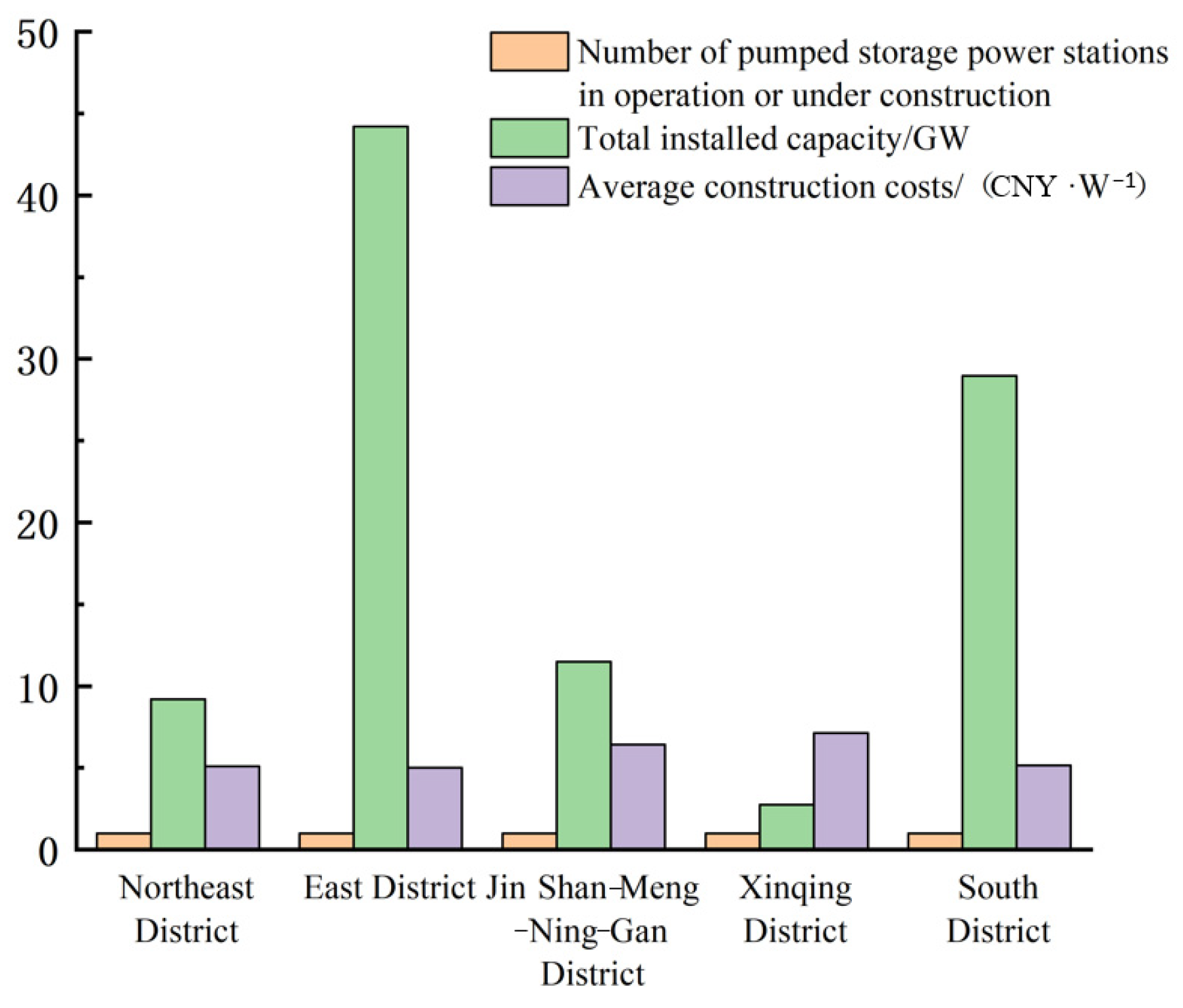

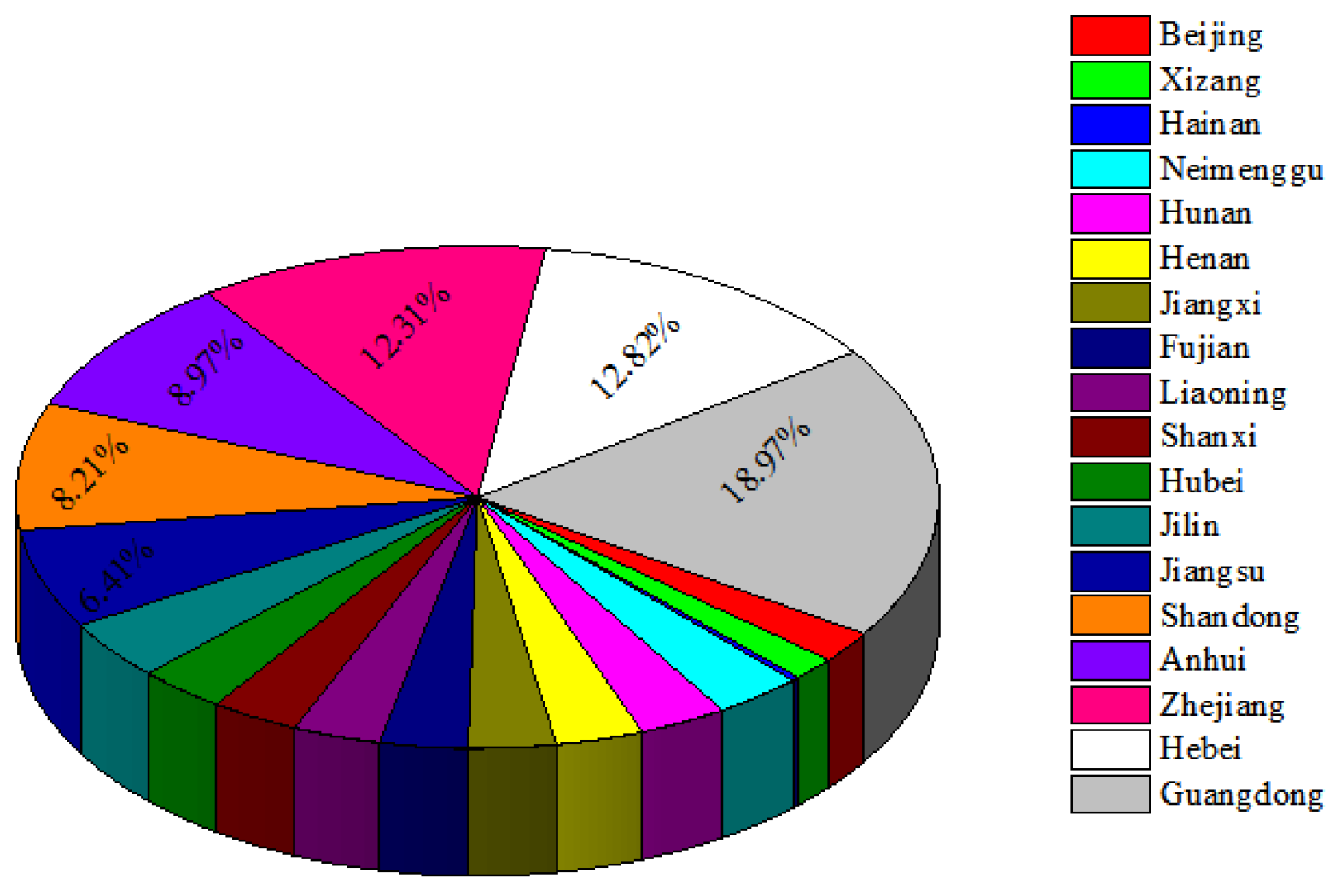

2.1. Research Status of Pumped Storage Power Stations in Abandoned Mines

2.2. Research Status of Multi-Energy Complementary Comprehensive Utilization

2.3. Research Status of Urban Sewage Treatment

3. Model Performance Evaluation

3.1. Power Generation and Storage Assessment

3.2. Assessment of Sewage Treatment Capacity

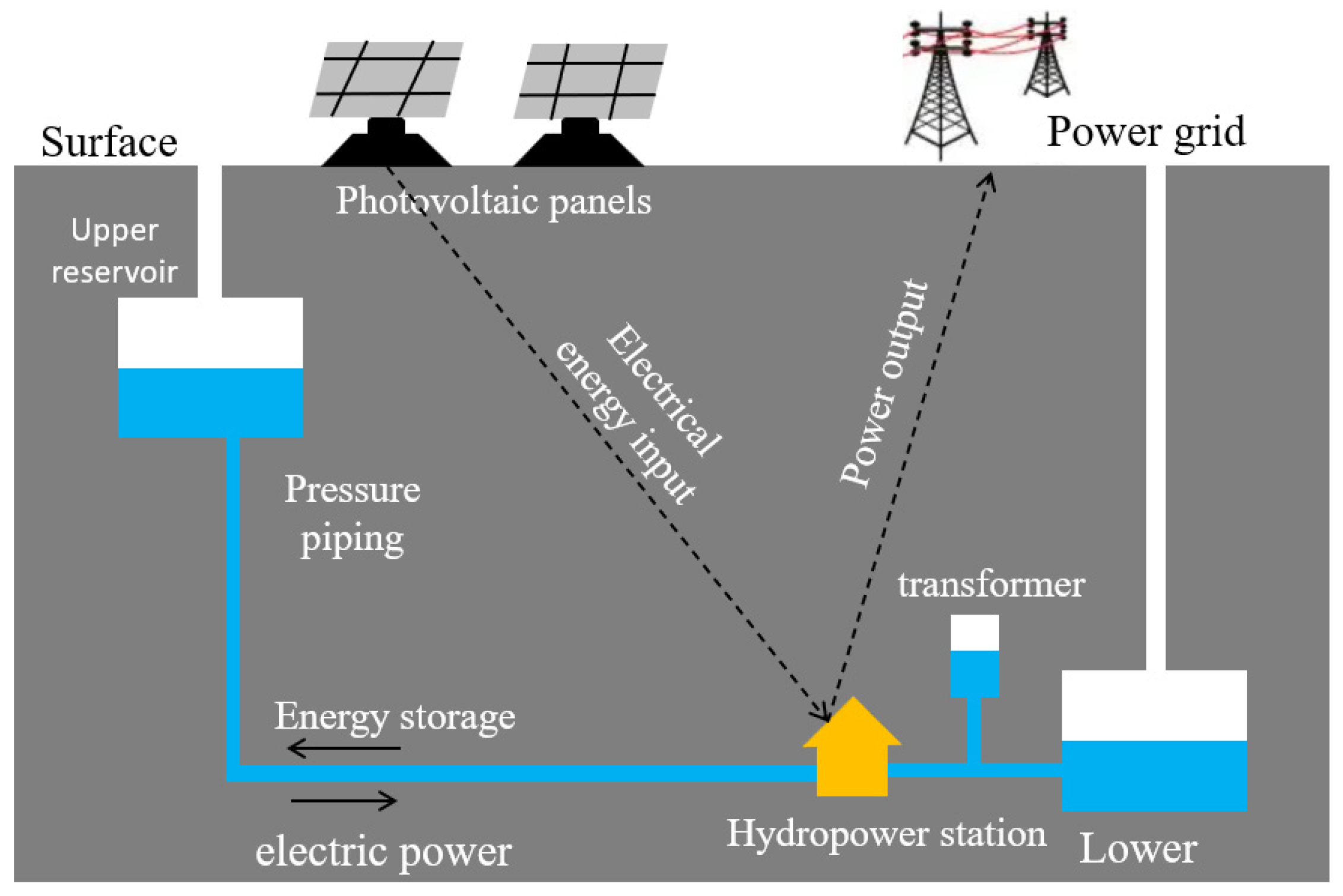

4. Integrated Technology Model of Urban Sewage Treatment by a Multi-Energy Complementary Abandoned Mine Pumped Storage Power Station

4.1. Multi-Energy Complementary Power Generation Mode of Abandoned Mines

4.2. Sewage Treatment Mode of Abandoned Mine Pumped Storage Power Stations

4.3. Integrated Operation Mode of Abandoned Mine Pumped Storage Power Stations

4.4. Analysis of the Comprehensive Utilization Benefits of Abandoned Mine Pumped Storage Power Stations

4.5. Comparison of Investment Cost Between New Pumped Storage Power Stations and Conventional Pumped Storage Power Stations

4.5.1. Cost Source Analysis

4.5.2. Economic Construction Costs

4.5.3. Water Resources Costs

5. Comprehensive Economic Benefits of Multi-Energy Complementary Utilization of Abandoned Mines

5.1. Power Generation Efficiency

- Geographic location and solar irradiance: It is assumed that the PV panels are installed in a representative geographic region with typical solar radiation conditions.

- Efficiency of PV panels: The calculation assumes the use of commercially available monocrystalline silicon PV modules with a conversion efficiency of 18%. This reflects the current mainstream technology in the PV market. Additionally, it is assumed that the panels operate under stable full irradiance conditions without significant efficiency degradation.

- Installation angle and orientation: The panels are assumed to be installed at the optimal tilt angle of 30°, facing the direction of maximum solar exposure. This angle is suitable for most regions and is designed to maximize solar energy capture and improve generation efficiency.

- System losses: A system loss factor of 10% is assumed, accounting for inverter losses, cable losses, and other balance-of-system inefficiencies. Therefore, 10% of the gross generated electricity is deducted to obtain the net usable output.

5.2. Effluent Treatment Benefits

5.3. Environmental Benefits

6. Selection and Analysis of Potential Sites of Abandoned Mines

6.1. Application Potential of Abandoned Mines as Urban Sewage Treatment Sites

6.2. Analysis of the Limitation of Abandoned Mines as Urban Sewage Treatment Sites

7. Research on the Seismic Mechanism of Underground Reservoirs in Abandoned Mines

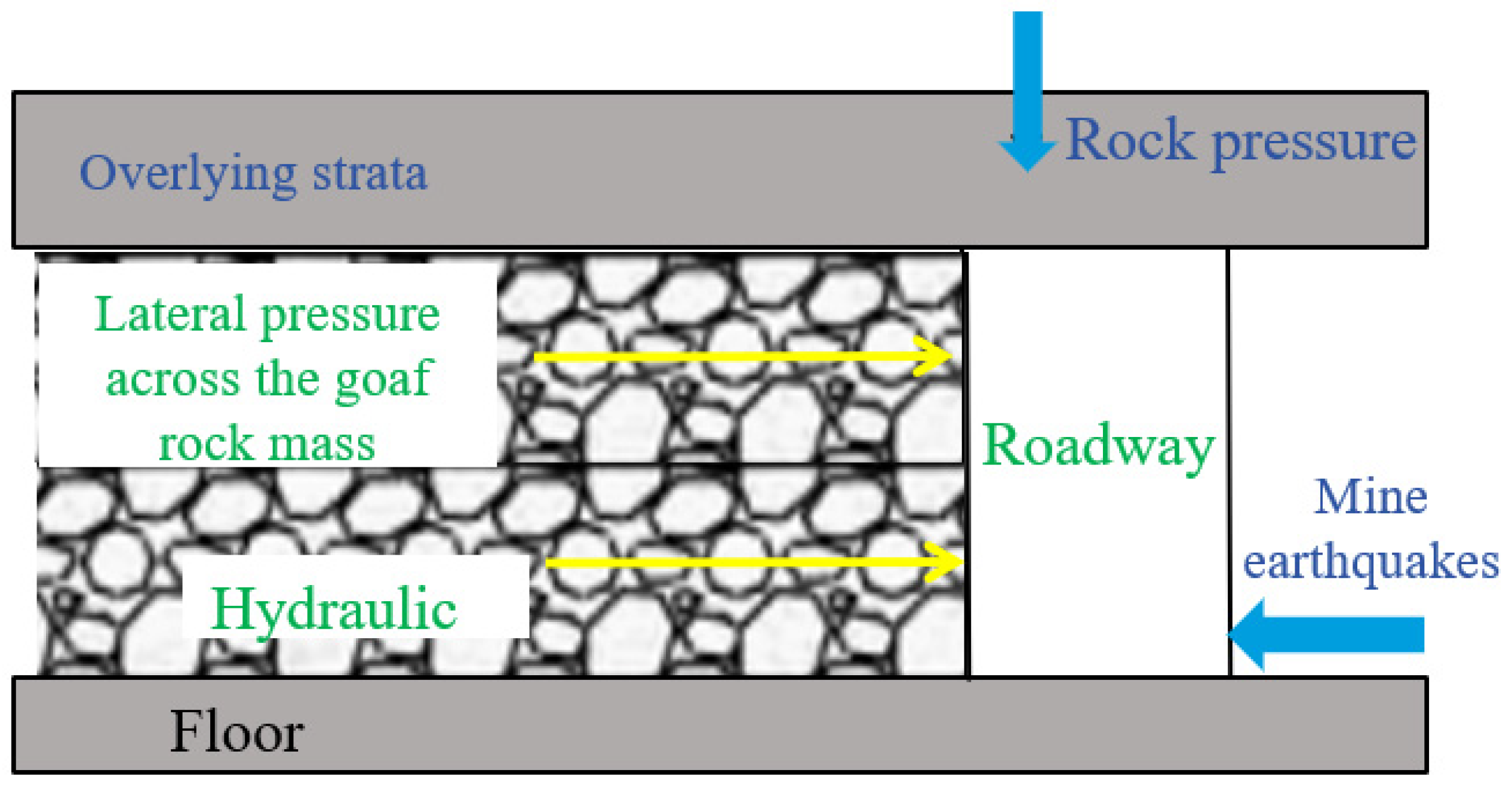

7.1. Influencing Factors of Earthquake-Induced Underground Reservoirs in Abandoned Mines

7.2. Permeation Conditions

7.3. Conditions of Earthquake Occurrence

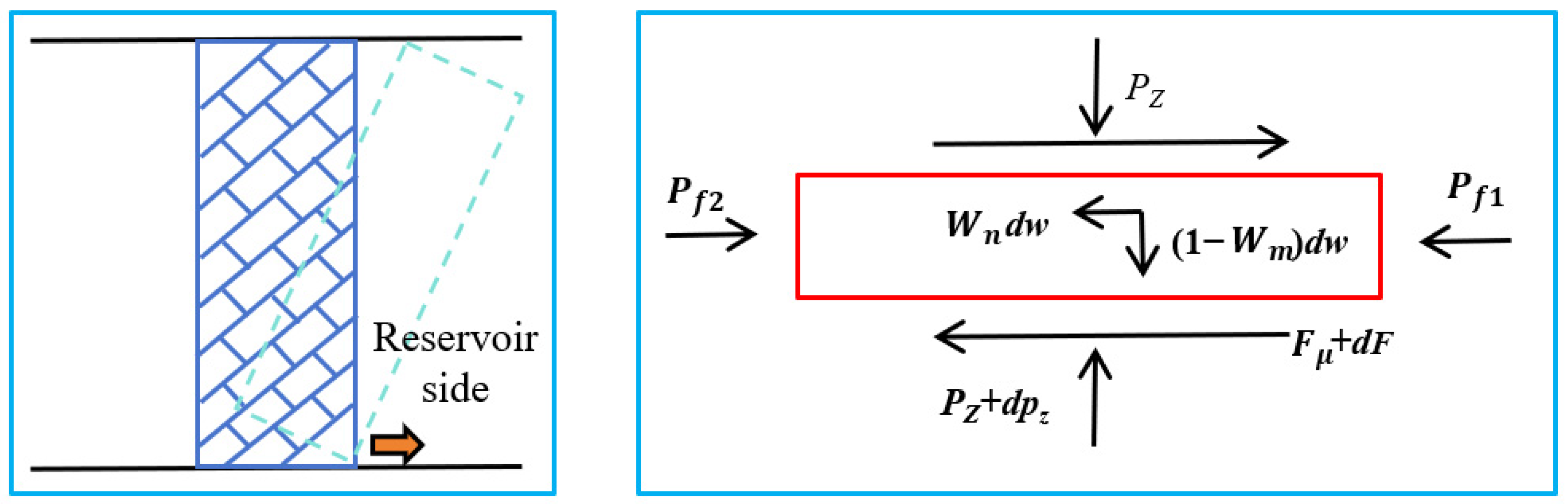

7.4. Analysis of the Seismic Stability of Underground Reservoirs in Abandoned Mines

7.5. Reinforcement Scheme of Underground Reservoirs of Abandoned Mines

- (1)

- When repurposing abandoned mines for hydropower stations, unused roadways must be backfilled to optimize space utilization. Typically, materials such as flocculating agents, plugging agents, clay, stone, cement, and sawdust are used for backfilling. Additionally, plastic concrete may be added to better accommodate rock mass deformation, significantly reducing wall stress and preventing cracking.

- (2)

- To ensure that the strength and permeability of the rock mass beneath the reservoir meet standards, anti-seepage measures are implemented on the mine roadway floor. Primarily, cement grouting is employed for the anti-seepage treatment of the reservoir foundation. In areas where erosion is detected on roadway rock walls or hollowed bottom plates, the affected sections are chiseled until fresh concrete is exposed, after which concrete soil is reapplied to enhance reservoir wall stability.

8. Conclusions

- (1)

- The underground reservoir of a pumped storage power station constitutes a vast system with multiphase and multi-physics coupling, encompassing factors such as the stability of surrounding rock, reservoir capacity, and groundwater dynamics. This study introduces an integrated approach, beginning with the design phase of three types of power stations—pumped storage, wind power, and photovoltaic—to effectively propose a combined technology involving mine sewage treatment plants and pumped storage power generation. This approach simultaneously addresses multiple objectives, including mine water storage, power generation, sewage treatment, and new energy development. The model presents favorable conditions for the establishment and utilization of multi-energy complementary systems, demonstrating feasibility in constructing pumped storage power stations and sewage treatment plants within a multi-energy complementary framework. Such initiatives contribute to subsidence control, ecological balance maintenance in mining areas, and offer far-reaching implications for modern and ecologically sustainable mining, energy efficiency, emission reduction, and green development initiatives.

- (2)

- The reuse of abandoned mine resources serves as the cornerstone for transforming resource-depleted regions. Simultaneously, by repurposing abandoned mines for the construction of pumped storage power stations and utilizing both above- and below-ground reservoirs for urban sewage treatment, this approach breaks through traditional construction modes and land use concepts associated with “abandoned mine construction pumped storage power stations”. This innovative model integrates photovoltaic and wind power stations with pumped storage systems, addressing not only the functional demands of sewage treatment plants but also achieving secondary development goals for abandoned mines. It offers fresh perspectives for establishing environmentally friendly, low-carbon, energy-saving, and sustainable underground sewage treatment plant models in abandoned mine areas.

- (3)

- Underground reservoir-induced earthquakes are contingent upon a specific combination of environmental factors, namely infiltration and seismic conditions. Furthermore, these factors are intricately linked and essential in the seismic induction process. Introducing the concept of the safety factor for coal mine reservoirs, this study theoretically analyzes the seismic safety performance of coal pillar roadways and proposes reinforcement schemes. Additionally, it underscores the need to explore the impact of various seismic wave types on the safety of underground reservoir roadways in coal mines. Moreover, the presence of sewage in the underground reservoir poses a threat to the structural integrity of coal pillar roadways, necessitating a comprehensive safety evaluation of their stability under sewage storage conditions.

- (4)

- Research on utilizing abandoned mines to construct underground reservoirs for pumped storage power stations is in its nascent stages, with a lack of experience in design and construction. Leveraging abandoned mines for this purpose, particularly in treating urban sewage, offers potential benefits for ecological restoration and urban sustainability. However, challenges arise due to the intricate nature of underground spaces and the complexity of urban sewage composition. Notably, hydraulic issues in underground reservoirs are prominent. It is recommended that subsequent research actively address these hydraulic challenges while exploring related fields, thereby offering scientific guidance and ensuring the safe construction of underground reservoirs for pumped storage power stations.

- (5)

- After a mine is abandoned, there often remain abundant usable resources, but a lack of awareness regarding reuse persists. Pumped storage power plants have proven to be sustainable, cost-effective energy storage solutions that hold great potential in advancing various renewable energy sources. Relevant departments should establish and improve abandoned mine management organizations and devise reuse plans prior to mine closure. Meanwhile, mining enterprises should effectively leverage technical reserves and strategies to facilitate the reuse and multifunctional utilization of abandoned mines, promoting environmental restoration and economic recovery in mining areas.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Du, K.; Xie, J.; Khandelwal, M.; Zhou, J. Utilization Methods and Practice of Abandoned Mines and Related Rock Mechanics under the Ecological and Double Carbon Strategy in China—A Comprehensive Review. Minerals 2022, 12, 1065. [Google Scholar] [CrossRef]

- Lu, P.; Zhou, L.; Cheng, S.; Zhu, X.; Yuan, T.; Chen, D.; Feng, Q. Main challenges of closed/abandoned coal mine resource utilization in China. Energy Sources Part Recovery Util. Environ. Eff. 2020, 42, 2822–2830. [Google Scholar] [CrossRef]

- Sivakumar, N.; Das, D.; Padhy, N.P.; Senthil Kumar, A.R.; Bisoyi, N. Status of pumped hydro-storage schemes and its future in India. Renew. Sustain. Energy Rev. 2013, 19, 208–213. [Google Scholar] [CrossRef]

- Huang, G.; Rao, X.; Shao, X.; Gu, Q.; Wang, Z.; Li, P.; Huang, J. Distribution of heavy metals influenced by pumped storage hydropower in abandoned mines: Leaching test and modelling simulation. J. Environ. Manag. 2023, 326, 116836. [Google Scholar] [CrossRef]

- Shi, Y.; Liu, X.; Huang, Y.; Zheng, Y.; Wang, Y. Research and Application of Key Technologies for Ultra High Pressure Grouting of Yangjiang Pumped Storage Power Station in Guangdong Province. J. Phys. Conf. Ser. 2024, 2752, 012146. [Google Scholar] [CrossRef]

- Li, S.; Duan, L.; Gao, Q.; Li, M.; Zhang, H.; Jia, Y.; Yang, D.; Ya, T. Wastewater Decarbonization: Neglected Processes outside the Centralized Wastewater Treatment Plant Boundary. Environ. Sci. Technol. Lett. 2024, 11, 1141–1143. [Google Scholar] [CrossRef]

- Xi, F.; Yan, R.; Shi, J.; Zhang, J.; Wang, R. Pumped storage power station using abandoned mine in the Yellow River basin: A feasibility analysis under the perspective of carbon neutrality. Front. Environ. Sci. 2022, 10, 983319. [Google Scholar] [CrossRef]

- Xing, C.; Xiao, J.; Xi, X.; Li, J.; Li, P.; Zhang, S. Two-Layer Optimal Scheduling and Economic Analysis of Composite Energy Storage with Thermal Power Deep Regulation Considering Uncertainty of Source and Load. Energies 2024, 17, 4909. [Google Scholar] [CrossRef]

- Ranieri, E.; D’Onghia, G.; Ranieri, F.; Lopopolo, L.; Gregorio, S.; Ranieri, A.C. Performance of wastewater treatment plants in emission of greenhouse gases. Bioresour. Technol. 2024, 404, 130897. [Google Scholar] [CrossRef]

- Qihu, Q. Present state, problems and development trends of urban underground space in China. Tunn. Undergr. Space Technol. 2016, 55, 280–289. [Google Scholar] [CrossRef]

- Luo, P.; Han, X.; Chen, N. Study on Complexity Planning Model of Pumped Storage in Abandoned Open-Pit Mine: A Case Study of Fushun Open-Pit Mine. Front. Earth Sci. 2022, 10, 808371. [Google Scholar] [CrossRef]

- Wang, M.; Guo, P.; Jin, X.; Dang, G.; Guo, Y.; Li, Y. Evaluation of development potential of pumped hydroelectric storage and geothermal utilization system in abandoned coal mine. J. Cent. South Univ. 2024, 31, 2872–2890. [Google Scholar] [CrossRef]

- Salimi, A.A.; Karimi, A.; Noorizadeh, Y. Simultaneous operation of wind and pumped storage hydropower plants in a linearized security-constrained unit commitment model for high wind energy penetration. J. Energy Storage 2019, 22, 318–330. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, S.; Zhou, B.; Li, G.; Hu, B.; Liu, Y.; Xiao, Z. Multi-time scale trading profit model of pumped storage power plant for electricity market. Front. Energy Res. 2022, 10, 975319. [Google Scholar] [CrossRef]

- Isuru, M.; Hotz, M.; Gooi, H.B.; Utschick, W. Network-constrained thermal unit commitment for hybrid AC/DC transmission grids under wind power uncertainty. Appl. Energy 2020, 258, 114031. [Google Scholar] [CrossRef]

- Khojasteh, M.; Faria, P.; Vale, Z. Scheduling of battery energy storages in the joint energy and reserve markets based on the static frequency of power system. J. Energy Storage 2022, 49, 104115. [Google Scholar] [CrossRef]

- Wang, C.; Ju, P.; Wu, F.; Lei, S.; Hou, Y. Coordinated scheduling of integrated power and gas grids in consideration of gas flow dynamics. Energy 2021, 220, 119760. [Google Scholar] [CrossRef]

- Jia, X.; Yuan, S.; Li, B.; Miu, H.; Yuan, J.; Wang, C.; Zhu, Z.; Zhang, Y. Carbon Nanomaterials: Application and Prospects of Urban and Industrial Wastewater Pollution Treatment Based on Abrasion and Corrosion Resistance. Front. Chem. 2020, 8, 600594. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Q.; Song, Z.; Fang, F. Bottlenecks and Countermeasures of High-Penetration Renewable Energy Development in China. Engineering 2021, 7, 1611–1622. [Google Scholar] [CrossRef]

- Zou, C.; Xiong, B.; Xue, H.; Zheng, D.; Ge, Z.; Wang, Y.; Jiang, L.; Pan, S.; Wu, S. The role of new energy in carbon neutral. Pet. Explor. Dev. 2021, 48, 480–491. [Google Scholar] [CrossRef]

- Hou, Y.; Tai, S.; Li, X.; Zhang, M.; Fu, G.; Zhang, C. Evaluation on key technologies for the construction of low-carbon index of electric power based on “double carbon”. Int. J. Emerg. Electr. Power Syst. 2023, 24, 499–509. [Google Scholar] [CrossRef]

- Liao, M.; Wang, Y. China’s Energy Consumption Rebound Effect Analysis Based on the Perspective of Technological Progress. Sustainability 2019, 11, 1461. [Google Scholar] [CrossRef]

- Zhu, M.; Fang, J.; Ai, X.; Cui, S.; Feng, Y.; Li, P.; Zhang, Y.; Zheng, Y.; Chen, Z.; Wen, J. A comprehensive methodology for optimal planning of remote integrated energy systems. Energy 2023, 285, 129443. [Google Scholar] [CrossRef]

- Castellani, B.; Morini, E.; Nastasi, B.; Nicolini, A.; Rossi, F. Small-Scale Compressed Air Energy Storage Application for Renewable Energy Integration in a Listed Building. Energies 2018, 11, 1921. [Google Scholar] [CrossRef]

- Wan, J.; Sun, Y.; He, Y.; Ji, W.; Li, J.; Jiang, L.; Jurado, M.J. Development and technology status of energy storage in depleted gas reservoirs. Int. J. Coal Sci. Technol. 2024, 11, 29. [Google Scholar] [CrossRef]

- Ji, L.; Dong, J.; Kienberger, T.; Huang, J.; Liu, F.; Wang, L.; Huang, Y.; Gao, H. Quantitative assessment and development utilization modes of space resources in closed and abandoned mines. Energy Sources Part Recovery Util. Environ. Eff. 2023, 45, 10366–10380. [Google Scholar] [CrossRef]

- Colas, E.; Kukla, P.A.; Amann, F.; Back, S. Geological and mining factors influencing further use of abandoned coal mines—A multi-disciplinary workflow towards sustainable underground storage. J. Energy Storage 2025, 108, 115101. [Google Scholar] [CrossRef]

- Fan, J.; Xie, H.; Chen, J.; Jiang, D.; Li, C.; Ngaha Tiedeu, W.; Ambre, J. Preliminary feasibility analysis of a hybrid pumped-hydro energy storage system using abandoned coal mine goafs. Appl. Energy 2020, 258, 114007. [Google Scholar] [CrossRef]

- Jing, Z.; Wang, Y.; Chang, J.; Wang, X.; Guo, A.; Meng, X. Construction of pumped storage power stations among cascade reservoirs to support the high-quality power supply of the hydro-wind-photovoltaic power generation system. Energy Convers. Manag. 2025, 323, 119239. [Google Scholar] [CrossRef]

- Yang, K.; Lyu, X.; Xu, C.; Fang, J.; Duan, M.; Zhang, Z. Research on pumped storage and complementary energy development models for abandoned mines in China. J. Cent. South Univ. 2024, 31, 2860–2871. [Google Scholar] [CrossRef]

- Ren, Y.; Sun, K.; Zhang, K.; Han, Y.; Zhang, H.; Wang, M.; Jing, X.; Mo, J.; Zou, W.; Xing, X. Optimization of the capacity configuration of an abandoned mine pumped storage/wind/photovoltaic integrated system. Appl. Energy 2024, 374, 124089. [Google Scholar] [CrossRef]

- Yang, K.; Fu, Q.; Yuan, L.; Liu, Q.; He, X.; Liu, F. Research on development demand and potential of pumped storage power plants combined with abandoned mines in China. J. Energy Storage 2023, 63, 106977. [Google Scholar] [CrossRef]

- Ashik, F.R.; Mim, S.A.; Neema, M.N. Towards vertical spatial equity of urban facilities: An integration of spatial and aspatial accessibility. J. Urban Manag. 2020, 9, 77–92. [Google Scholar] [CrossRef]

- Yang, T.; Long, R.; Cui, X.; Zhu, D.; Chen, H. Application of the public–private partnership model to urban sewage treatment. J. Clean. Prod. 2017, 142, 1065–1074. [Google Scholar] [CrossRef]

- Yuki, Y.; Takayanagi, E.; Abe, T. Design of Multi-Story Sewage Treatment Facilities. Water Sci. Technol. 1991, 23, 1733–1742. [Google Scholar] [CrossRef]

- Rajpal, A.; Srivastava, G.; Bhatia, A.; Singh, J.; Ukai, Y.; Kazmi, A.A. Optimization to maximize nitrogen removal and microbial diversity in PVA-gel based process for treatment of municipal wastewater. Environ. Technol. Innov. 2021, 21, 101314. [Google Scholar] [CrossRef]

- Al-Hazmi, H.E.; Grubba, D.; Majtacz, J.; Ziembińska-Buczyńska, A.; Zhai, J.; Mąkinia, J. Combined partial denitrification/anammox process for nitrogen removal in wastewater treatment. J. Environ. Chem. Eng. 2023, 11, 108978. [Google Scholar] [CrossRef]

- Kurt, Z.; Özdemir, I.; James R., A. M. Effectiveness of microplastics removal in wastewater treatment plants: A critical analysis of wastewater treatment processes. J. Environ. Chem. Eng. 2022, 10, 107831. [Google Scholar] [CrossRef]

- Yang, G.C.C.; Tang, P.-L. Removal of phthalates and pharmaceuticals from municipal wastewater by graphene adsorption process. Water Sci. Technol. 2016, 73, 2268–2274. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y. Circular economy-driven ammonium recovery from municipal wastewater: State of the art, challenges and solutions forward. Bioresour. Technol. 2021, 334, 125231. [Google Scholar] [CrossRef]

- Huang, C.; Peng, F.; Xiong, L.; Li, H.-L.; Chen, X.-F.; Zhao, C.; Chen, X.-D. Introduction of one efficient industrial system for turpentine processing wastewater reuse and treatment. Sci. Total Environ. 2019, 663, 447–452. [Google Scholar] [CrossRef] [PubMed]

- Al-Hazmi, H.E.; Maktabifard, M.; Grubba, D.; Majtacz, J.; Hassan, G.K.; Lu, X.; Piechota, G.; Mannina, G.; Bott, C.B.; Mąkinia, J. An advanced synergy of partial denitrification-anammox for optimizing nitrogen removal from wastewater: A review. Bioresour. Technol. 2023, 381, 129168. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Naidoo, A.R.; Zhang, X.-F.; Meng, X.-Z. Optimizing sampling strategy for Chinese National Sewage Sludge Survey (CNSSS) based on urban agglomeration, wastewater treatment process, and treatment capacity. Sci. Total Environ. 2019, 696, 133998. [Google Scholar] [CrossRef]

- Jia, J.; Zhang, G.; Zhou, X.; Shi, Z.; Zhu, M.; Lv, X. Research on joint dispatch of wind, solar, hydro, and thermal power based on pumped storage power stations. Front. Energy Res. 2024, 12, 1373588. [Google Scholar] [CrossRef]

- Li, H.; Zheng, H.; Zhou, B.; Li, G.; Yang, B.; Hu, B.; Ma, M. Two-Part Tariff of Pumped Storage Power Plants for Wind Power Accommodation. Sustainability 2022, 14, 5603. [Google Scholar] [CrossRef]

- Kong, Y.; Kong, Z.; Liu, Z.; Wei, C.; Zhang, J.; An, G. Pumped storage power stations in China: The past, the present, and the future. Renew. Sustain. Energy Rev. 2017, 71, 720–731. [Google Scholar] [CrossRef]

- Xiao, B.; Xing, S.; Wang, T.; Yang, Y.; Dong, L.; Yang, H.; Lu, G. Capacity Planning of Pumped Storage Power Station Based on the Life Cycle Cost. Electr. Power Compon. Syst. 2020, 48, 1263–1271. [Google Scholar] [CrossRef]

- Zhang, Z.; Xu, D.; Chan, X.; Xu, G. Research on Power System Day-Ahead Generation Scheduling Method Considering Combined Operation of Wind Power and Pumped Storage Power Station. Sustainability 2023, 15, 6208. [Google Scholar] [CrossRef]

- Shang, D.; Pei, P. Analysis of Influencing Factors of Modification Potential of Abandoned Coal Mine Into Pumped Storage Power Station. J. Energy Resour. Technol. 2021, 143, 112003. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, F.; Bai, Q. Underground space utilization of coalmines in China: A review of underground water reservoir construction. Tunn. Undergr. Space Technol. 2021, 107, 103657. [Google Scholar] [CrossRef]

- Colas, E.; Klopries, E.-M.; Tian, D.; Kroll, M.; Selzner, M.; Bruecker, C.; Khaledi, K.; Kukla, P.; Preuße, A.; Sabarny, C.; et al. Overview of converting abandoned coal mines to underground pumped storage systems: Focus on the underground reservoir. J. Energy Storage 2023, 73, 109153. [Google Scholar] [CrossRef]

- Sun, Z.; Zhao, Y.; Ren, J. Regional development potential of underground pumped storage power station using abandoned coal mines: A case study of the Yellow River Basin, China. J. Energy Storage 2024, 77, 109992. [Google Scholar] [CrossRef]

- Liu, R.; Liu, Z.; Xiong, W.; Zhang, L.; Zhao, C.; Yin, Y. Performance simulation and optimization of building façade photovoltaic systems under different urban building layouts. Energy 2024, 288, 129708. [Google Scholar] [CrossRef]

- Jiang, L.; Chen, M.; Huang, Y.; Peng, J.; Zhao, J.; Chan, F.; Yu, X. Effects of different treatment processes in four municipal wastewater treatment plants on the transport and fate of microplastics. Sci. Total Environ. 2022, 831, 154946. [Google Scholar] [CrossRef]

- Wang, K.; Niu, D.; Yu, M.; Liang, Y.; Yang, X.; Wu, J.; Xu, X. Analysis and Countermeasures of China’s Green Electric Power Development. Sustainability 2021, 13, 708. [Google Scholar] [CrossRef]

- Wu, J.; Tan, Z.; De, G.; Pu, L.; Wang, K.; Tan, Q.; Ju, L. Multiple Scenarios Forecast of Electric Power Substitution Potential in China: From Perspective of Green and Sustainable Development. Processes 2019, 7, 584. [Google Scholar] [CrossRef]

- Qudaih, M.; Engel, B.; Truijen, D.P.K.; De Kooning, J.D.M.; Stockman, K.; Hoffstaedt, J.; Jarquin-Laguna, A.; Ruiz, R.A.; Goseberg, N.; de Vilder, L.; et al. The contribution of low-head pumped hydro storage to grid stability in future power systems. IET Renew. Power Gener. 2023, 17, 3594–3608. [Google Scholar] [CrossRef]

- Chen, X.; Jiang, S.; Chen, Y.; Lei, Y.; Zhang, D.; Zhang, M.; Gou, H.; Shen, B. A 10 MW class data center with ultra-dense high-efficiency energy distribution: Design and economic evaluation of superconducting DC busbar networks. Energy 2022, 250, 123820. [Google Scholar] [CrossRef]

- Xu, T.; Wu, W.; Zheng, W.; Sun, H.; Wang, L. Fully Distributed Quasi-Newton Multi-Area Dynamic Economic Dispatch Method for Active Distribution Networks. IEEE Trans. Power Syst. 2018, 33, 4253–4263. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, B. Study on the hydraulic effect of Tesla valve structure on the end roadway of abandoned coal mine pumped storage. J. Energy Storage 2024, 95, 112586. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, X.; Huang, S.; Xia, Y.; Fan, X.; Mei, S. Evolution of a transmission network with high proportion of renewable energy in the future. Renew. Energy 2017, 102, 372–379. [Google Scholar] [CrossRef]

- Tian, B.; He, Y.; Zhou, J.; Wang, B.; Wang, Y.; Shi, W. Cost-sharing mechanisms for pumped storage plants at different market stages in China. Renew. Energy 2023, 217, 119183. [Google Scholar] [CrossRef]

- Yu, Y.; Zou, Z.; Wang, S. Statistical regression modeling for energy consumption in wastewater treatment. J. Environ. Sci. 2019, 75, 201–208. [Google Scholar] [CrossRef] [PubMed]

- Sharawat, I.; Dahiya, R.; Dahiya, R.P. Analysis of a wastewater treatment plant for energy consumption and greenhouse gas emissions. Int. J. Environ. Sci. Technol. 2021, 18, 871–884. [Google Scholar] [CrossRef]

- Tsalas, N.; Golfinopoulos, S.K.; Samios, S.; Katsouras, G.; Peroulis, K. Optimization of Energy Consumption in a Wastewater Treatment Plant: An Overview. Energies 2024, 17, 2808. [Google Scholar] [CrossRef]

- Pintilie, L.; Torres, C.M.; Teodosiu, C.; Castells, F. Urban wastewater reclamation for industrial reuse: An LCA case study. J. Clean. Prod. 2016, 139, 1–14. [Google Scholar] [CrossRef]

- Han, Z.; Fang, D.; Yang, P.; Lei, L. Cooperative mechanisms for multi-energy complementarity in the electricity spot market. Energy Econ. 2023, 127, 107108. [Google Scholar] [CrossRef]

- Ibáñez-Rioja, A.; Järvinen, L.; Puranen, P.; Kosonen, A.; Ruuskanen, V.; Hynynen, K.; Ahola, J.; Kauranen, P. Off-grid solar PV–wind power–battery–water electrolyzer plant: Simultaneous optimization of component capacities and system control. Appl. Energy 2023, 345, 121277. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, Z.; Liu, Y.; Liang, W.; Li, J.; He, X.; Gao, B. Energy Optimization Model of Multi Energy Interaction in Thermal Power Plants with Wind Power, Photovoltaic, Hydrogen Production and Hydrogen Fuel Cell System. J. Phys. Conf. Ser. 2023, 2474, 012010. [Google Scholar] [CrossRef]

- Chen, J.; He, Y. Excavation and support construction of rock wall crane beam layer in underground powerhouse of a pumped storage power station. J. Phys. Conf. Ser. 2020, 1549, 052019. [Google Scholar] [CrossRef]

- Lyu, X.; Yang, K.; Xu, C.; Fang, J.; Duan, M.; Zhang, Z. Experimental study of mechanical properties of artificial dam for coal mine underground reservoir under cyclic loading and unloading. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 91. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, G.; Zhou, G.; Zhang, Y.; Meng, X.; Zhao, Y.; Chen, M. Stability analysis of artificial dam in coal mine underground water reservoir based on the hydro-mechanical damage model. Geomat. Nat. Hazards Risk 2023, 14, 2190855. [Google Scholar] [CrossRef]

- Liu, F.; Yang, K.; Yang, T.; Gao, Y.; Li, J.; Liu, Q.; Fu, Q. Pumped storage hydropower in an abandoned open-pit coal mine: Slope stability analysis under different water levels. Front. Earth Sci. 2022, 10, 941119. [Google Scholar] [CrossRef]

- Li, Y.; Lei, X.; Wang, N.; Ren, Y.; Xia, X.; Jin, X.; Li, T. Stability analysis of pumped storage hydropower plant in abandoned open-pit mine affected by dynamic surface subsidence of combined mining. Environ. Sci. Pollut. Res. 2024, 31, 19516–19542. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Liu, Q. Failure criterion for soft rocks considering intermediate principal stress. Int. J. Min. Sci. Technol. 2021, 31, 565–575. [Google Scholar] [CrossRef]

- Zhang, C.; Luo, B.; Xu, Z.; Sun, Y.; Feng, L. Research on the Capacity of Underground Reservoirs in Coal Mines to Protect the Groundwater Resources: A Case of Zhangshuanglou Coal Mine in Xuzhou, China. Water 2023, 15, 1468. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, F.; Kou, M.; Li, M. A Review of Stability of Dam Structures in Coal Mine Underground Reservoirs. Water 2024, 16, 1856. [Google Scholar] [CrossRef]

- Chen, Z.; Zhao, X.; Han, Z.; Ji, Y.; Qiao, Z. Reasonable Size Design and Influencing Factors Analysis of the Coal Pillar Dam of an Underground Reservoir in Daliuta Mine. Processes 2023, 11, 2006. [Google Scholar] [CrossRef]

- Mason, D.P.; Fowkes, N.D.; Yemata, R.M.; Onyeagoziri, C.A.; Yilmaz, H. WALL STABILIZATION IN MINES BY SPRAY-ON LINERS. ANZIAM J. 2023, 65, 55–78. [Google Scholar] [CrossRef]

- Masoud, S.S.; Parviz, M.; Ebrahim, Y. Optimizing and slope determination of final wall for Maiduk Mine with consideration of destabilizer factors. Int. J. Min. Sci. Technol. 2016, 26, 501–509. [Google Scholar] [CrossRef]

- Wang, X.; Cheng, H.; Wu, T.; Yao, Z.; Huang, X. Numerical Analysis of a Novel Shaft Lining Structure in Coal Mines Consisting of Hybrid-Fiber-Reinforced Concrete. Crystals 2020, 10, 928. [Google Scholar] [CrossRef]

- Guo, J.; Yang, W.; Zhao, Y.; Zhang, W. Stability Analysis of a Mine Wall Based on Different Roof-Contact Filling Rates. Minerals 2024, 14, 673. [Google Scholar] [CrossRef]

- Shi, J.; Ma, T.; Gao, L. Analysis of seismic performance of gravity dam based on ultra-high performance concrete reinforcement. IOP Conf. Ser. Earth Environ. Sci. 2020, 560, 012067. [Google Scholar] [CrossRef]

- Xu, Q.; Zhang, T.; Chen, J.; Li, J.; Li, C. The influence of reinforcement strengthening on seismic response and index correlation for high arch dams by endurance time analysis method. Structures 2021, 32, 355–379. [Google Scholar] [CrossRef]

| Performance Index | Traditional Surface Sewage Treatment Plant | Underground Treatment System Based on Abandoned Mines | Comparative Result |

|---|---|---|---|

| Occupied area | High (about 5−10 m2/person) | Very low (basically no new surface area) | The reuse of underground space and the release of surface space are especially suitable for the areas with limited land resources around the city. |

| Construction cost | Medium to high (1.5–3 million CNY/10,000 m3/d) | Medium (depending on the needs of mine transformation) | The mine infrastructure can be reused, and the cost of civil engineering can be reduced, but the cost of transformation depends on the mine conditions. |

| Operation energy consumption | High (0.3–0.6 kWh/m3) | Medium (rely on gravity flow to reduce energy consumption) | The energy consumption of drainage can be reduced by using the vertical water level difference of the mine. |

| Temperature fluctuation | Obviously (5–35 °C, need additional adjustment) | Stable (underground temperature 12–18 °C) | The underground constant temperature is conducive to the stability of the flora and reduces the energy consumption of temperature control. |

| Flocculant dosage | Conventional (15–25 mg/L) | Decrease (10–15 mg/L) | Reduce the use of chemical agents with the help of a slow settling environment and stable reaction conditions |

| Hydraulic retention time | Short (6–12 h) | Prolonged (12–48 h) | The large volume of mine space is conducive to the realization of longer biochemical reaction time. |

| Treatment of water quality stability | Affected by temperature and water fluctuation | High (constant temperature, small hydraulic disturbance) | The large volume of mine space is conducive to achieving longer biochemical reaction time. |

| Urban sewage response capacity (sudden increase flow) | Medium (expansion or diversion required) | High (can be used as a temporary reservoir) | The mine has strong water storage capacity and certain buffering and storage functions. |

| Environmental impact | Need to manage noise, odor, landscape, etc. | Small underground closed operation) | The underground system basically does not affect the surface environment, and the environmentally sensitive areas have more advantages. |

| Parameter Type Check | Parameter Name | Design Value | Analysis of Influencing Factors |

|---|---|---|---|

| Water parameters | Effective head | 100–600 m | Depending on the height difference between the upper and lower libraries |

| Flow rate | 10–100 m3/s | Depending on the energy storage capacity and the number of units to determine | |

| Pipe parameters | Inlet/Outlet pipe diameter | 1.5–5 m | Matched with the design meteor and flow velocity |

| limit of velocity | 2.5–5 m/s | Ensure economic flow rate and reduce head loss | |

| Reservoir parameter | Upper/Lower reservoir capacity | 104–10° m3 | Meet the peaking/frequency modulation operation requirements |

| Anti-seepage performance of reservoir | K < 1 × 10−7 cm/s | Ensure closure and avoid water leakage | |

| Pump/Power Generation Equipment Parameters | Pump turbine efficiency | 85–93% | According to the model and operating conditions |

| Adjustable running time | 4–8 h | Depending on the power grid regulation demand and water storage capacity setting | |

| Other environmental requirements | Minimum depth of waste mine | ≥100 m | Ensure effective bit difference and capacity safety |

| Stability of rock mass | RMR ≥ 60 (moderate to good) | Ensure the safety and reliability of the reformed roadway structure |

| Cost Items | Traditional Pumped Storage System | Pumping Sauce Energy System of Abandoned Mine | Analysis of Cost Advantages |

|---|---|---|---|

| Underground space development and excavation | High: necessary to build new upper and lower reservoirs and diversion tunnels, and the amount of excavation is large. | Low: direct use of existing mine roadways and goafs. | Save 50–70% civil engineering cost. |

| Foundation and slope treatment Slope and foundation treatment | High: large-scale stable edges are required. | Low: the original roadway has a certain bearing capacity of rock mass. | The engineering quantity of slope and foundation treatment is greatly reduced. |

| Upper reservoir construction | High: site selection, land acquisition and new construction of large-scale storage reservoir. | Optional: can be combined with the existing mining subsidence area or transformation of small reservoirs. | Save part or all of the civil construction investment of the upper reservoir. |

| Installation of piping system and pumping equipment | Medium: standard installation cost. | Medium: similar to the traditional system. | The cost of major equipment is similar. |

| Land requisition and environmental restoration | High: wide range of land acquisition, strict environmental approval. | Low: abandoned mine stock resources, land use pressure is small. | Avoid land acquisition and additional ecological compensation. |

| Sewage pretreatment and transportation system construction | Not involved or high (if new dedicated sewage system is required). | Medium: need to transform access to municipal sewage or industrial wastewater system. | The initial investment is controllable, which is conducive to the recycling of water resources. |

| Operation, maintenance, and safety management | Medium: routine inspection and equipment management. | Medium to high: it is necessary to strengthen underground stability monitoring and gas/settlement control. | The initial safety investment is slightly higher, but the long-term stability is controllable. |

| Estimate total cost (relative) | 100% (baseline). | About 60–70% (relative to the traditional system). | expected to save 30–40% of the initial construction cost. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, B.; Gao, L.; Zhao, H. Study on the Seismic Stability of Urban Sewage Treatment and Underground Reservoir of an Abandoned Mine Pumped Storage Power Station. Sustainability 2025, 17, 5620. https://doi.org/10.3390/su17125620

Wei B, Gao L, Zhao H. Study on the Seismic Stability of Urban Sewage Treatment and Underground Reservoir of an Abandoned Mine Pumped Storage Power Station. Sustainability. 2025; 17(12):5620. https://doi.org/10.3390/su17125620

Chicago/Turabian StyleWei, Baoyu, Lu Gao, and Hongbao Zhao. 2025. "Study on the Seismic Stability of Urban Sewage Treatment and Underground Reservoir of an Abandoned Mine Pumped Storage Power Station" Sustainability 17, no. 12: 5620. https://doi.org/10.3390/su17125620

APA StyleWei, B., Gao, L., & Zhao, H. (2025). Study on the Seismic Stability of Urban Sewage Treatment and Underground Reservoir of an Abandoned Mine Pumped Storage Power Station. Sustainability, 17(12), 5620. https://doi.org/10.3390/su17125620