1. Introduction

Hydrogen–oxygen propulsion system has become a core research direction in the field of aerospace propulsion due to its advantages of high specific impulse, clean combustion products, and renewability. Typical liquid hydrogen/liquid oxygen engines, such as Vinci in Europe and LE-5B in Japan, have been successfully applied to the upper stage of launch vehicles [

1]. However, traditional spark ignition faces challenges such as long ignition delay and poor repeatability under pulsed conditions, which limits the rapid response capability of the engine [

2].

Microwave ignition technology has been explored in recent years for improving ignition performance due to its non-contact energy coupling characteristics. Studies have shown that microwave plasma can achieve mixture ignition in the sub-millisecond range and avoid the problem of electrode ablation [

3]. For example, NASA (National Aeronautics and Space Administration) experiments have demonstrated that microwave-assisted ignition can reduce the ignition delay of hydrogen–oxygen mixtures by more than 30% [

4]. However, most of the existing studies focus on steady-state combustion, and there is still a lack of in-depth analysis of the coupling mechanism between microwave ignition and combustion instability under pulsed conditions [

5]. Common plasma discharges include corona discharges [

6], streamer discharges [

7], microwave discharges [

8], and nanosecond pulse repetitive discharges [

9].

In pulse mode, the engine undergoes frequent ignition–shutdown cycles, and the dynamic effects of residual gas and propellant injection significantly affect the combustion stability. Numerical simulations show that the high-temperature residual gas from the previous combustion can change the initial conditions of the secondary ignition [

10], and the phase transition hysteresis caused by supercritical liquid hydrogen injection may trigger combustion oscillations [

11]. Therefore, elucidating the interaction mechanism between microwave ignition and pulsed combustion dynamics is the key to improving engine reliability.

Pertl et al. from West Virginia University elaborated on the design parameters of a Quarter Wave Coaxial Cavity Resonator (QWCCR) igniter and fabricated an efficient igniter. The team conducted ignition tests on a pulsed-burst engine using the improved QWCCR and compared it with a conventional spark plug [

12]. The comparison showed that the QWCCR can enhance the combustion effect of the engine under rarefied combustion conditions, generate plasma that persists for a long time, increase the flame burn rate, and optimize the equivalence ratio. The analysis also indicated that improving the energy delivery system of the QWCCR can alleviate the impedance mismatch problem and further enhance the performance of the igniter.

Zhongli Wang [

13] from the University of Science and Technology of China conducted both experimental and simulation studies on the QWCCR-type microwave discharge igniter. The results show that electron density increases with input power. A low pulse duty cycle favors electron generation, but if the duty cycle is too low, ionizing discharge fails to occur.

Wang Zhi et al. [

14] at Tsinghua University proposed the concept of microwave resonant cavity plasma ignition (MRPI). Based on the microwave resonant cavity theory, a cylindrical fixed-capacity combustion bomb with a diameter of 93 mm and a height of 10 mm was designed to make it satisfy the requirements of microwave resonance, and experimental studies on the ignition performance of the MRPI were carried out within it. It was found that the microwave resonance field can penetrate the mixture to produce a nonequilibrium plasma, and MRPI can realize space ignition by generating a large number of ignition sources compared with the single-point thermally equilibrated plasma produced by conventional spark ignition. The thinning and rich combustion limits of methane–air mixtures can be expanded to equivalence ratios of 0.55 and 3.0, respectively, using MRPI. MRPI combustion is also more stable compared to conventional SI. However, at close stoichiometric ratios, MRPI has a longer ignition delay time compared to SI.

Wang Yaoyao from the University of Science and Technology of China has recently developed two novel types of microwave spark plugs utilizing quarter - wavelength resonators. These are the electrically - coupled and magnetically - coupled spark plugs. The microwave energy in these two types of spark plugs is transferred in the form of an electric field and a magnetic field, respectively [

13]. It was found that the dielectric constant of the resonator and the center conductor size have a large effect on the resonance in the cavity of the electrically coupled spark plug, and the combustion effect is enhanced with the increase in electric field strength. Compared to the magnetically coupled spark plugs, the electrically coupled spark plugs have a better ignition effect, which induces a higher peak pressure, faster flame burning, and fuller combustion under rarefied combustion conditions.

Current microwave ignition technology is immature, and specific designs for hydrogen combustion propulsion are still limited, with no engines based on it having been developed. However, the capacity of this ignition technology is so great that research on it is indispensable. Microwave ignition has been demonstrated as a technologically advanced approach with significant potential in propulsion applications. Extensive research has consistently highlighted its superior performance in enhancing combustion efficiency, minimizing pollutant emissions, and facilitating fuel reforming processes. These distinctive advantages have established microwave-assisted ignition as a focal point in contemporary combustion research within both domestic and international scientific communities.

Benjamin Wolk et al. 2013, USA [

15] investigated the effect of microwave-assisted ignition combustion on the combustion characteristics of methane–air mixtures with different microwave feed moments and feed durations in a 1.45 L constant-capacity combustion chamber. It was found that flame enhancement increased with increasing microwave input time, but flame enhancement gains diminished after the microwave time exceeded 2 ms.

Cheng et al. [

16] used the microwave radiation effect of single-mode resonator to ignite nanocomplexes and investigated the ignition process. It was found that the relationship between microwave ignition delay time and power basically conforms to the negative exponential relationship: the ignition delay time decreases with the increase in power, and the rate of decrease in ignition delay time increases with the increase in power.

Kumari et al. [

17] investigated the effect of microwave radiation control parameters (i.e., pulse width and pulse repetition frequency) on the ignition of n-butane–air mixtures in a constant volume combustion chamber. It was shown that plasma begins to expand when microwave radiation couples with plasma. The expansion of plasma occurs as a result of direct collisions between electrons and molecules through electromagnetic fields and interactions between free electrons.

In 2016 in South Korea, Joonsik Hwang et al. [

18], using a fixed-volume bomb, found that an acetylene–air flame was better enhanced when microwaves were fed before spark plug ignition, and that enhancement was gradually weakened as the moment of microwave feed was delayed.

Zhang et al. investigated the potential application of microwave-assisted spark ignition under exhaust gas recirculation conditions and explored the ignition performance of combustible mixtures under different operating conditions [

19]. The experimental results showed that microwaves significantly increased the propagation velocity of the early fire nucleus, which was attributed to the enhanced chemical reaction and the deformation of the flame due to the collision of high-energy electrons with other particles. Similarly to Wolk’s experimental results, the microwave-induced enhancement effect gradually diminished at high ambient pressure. In addition, Zhang et al. investigated the effect of microwave pulse parameters on the combustion performance of combustible mixtures and found that higher pulse repetition frequency helped enhance the microwave effect, thus improving the energy absorption efficiency of the flame [

20].

Wu et al.’s team further explored the effects of the microwave pulse waveform and delay time on energy coupling and ignition enhancement. The results showed that higher power and shorter pulse width waveforms were favorable for ignition enhancement and energy coupling, and there was a good correlation between ignition enhancement and coupling energy [

21]. The ignition enhancement was mainly determined by the coupling energy of the electron collision reaction, while the key factor affecting the coupling energy was the shift in the energy coupling mode. Under the conditions of high-pulse power and short delay time, the energy coupling mode changed from non-coupling to saturation coupling.

DeFilippo et al. at the University of California, Berkeley, conducted similar tests on a single-cylinder engine [

22]. Their results indicated that adding microwave energy up to 900 mJ effectively reduces unstable combustion under rarefied conditions. However, beyond 900 mJ, the enhancement effect does not significantly increase. At 1640 mJ, the effect remains similar to that at 900 mJ, suggesting that higher microwave energy does not always yield better results and that an optimal value exists.

In order to have a clearer understanding of the effect of microwaves on flame development, the Wolk et al. team later conducted microwave-assisted ignition tests in a fixed-capacity incendiary bomb [

15]. It was found that the addition of microwaves had an obvious promotion effect on the early stage of flame development, but the effect of microwaves had almost disappeared when the flame developed to the later stage.

In this study, we aim to explore the pulse operating characteristics of a water electrolytic chemical propulsion engine driven by microwave ignition technology. Compared with traditional ignition methods, direct microwave ignition has remarkable advantages. Firstly, it enables local focused heating. Microwave energy can be precisely focused on the local area of the fuel or reactants, directly exciting molecular vibrations and generating heat through friction, which significantly reduces energy dissipation and effectively improves ignition efficiency. Secondly, it has the capability of rapid thermal response. Microwave heating does not require preheating and can reach the ignition temperature within milliseconds, greatly shortening the ignition delay, especially suitable for scenarios that require quick startup. Thirdly, it features excellent parameter adjustability. By adjusting the microwave power, frequency, and irradiation time, the ignition position, temperature, and energy input can be precisely controlled, thus optimizing the combustion process.

To conduct an in-depth study of the technical characteristics, we employed a high-speed camera to capture flame images and utilized a spectrometer and a pressure sensor for precise data quantification. Based on microwave ignition, we will study the transient startup conditions of a hydrogen–oxygen engine, combining flame images, spectral data, and combustion pressure to investigate the response characteristics and ignition mechanisms during the startup process.

2. Experimental Systems and Methods

As illustrated in

Figure 1, the propulsion system employs a microwave-assisted water electrolysis architecture comprising four core modules:

- (1)

Water reservoir;

- (2)

High-efficiency electrolyzer;

- (3)

Segregated gas handling system;

- (4)

Microwave plasma ignition assembly.

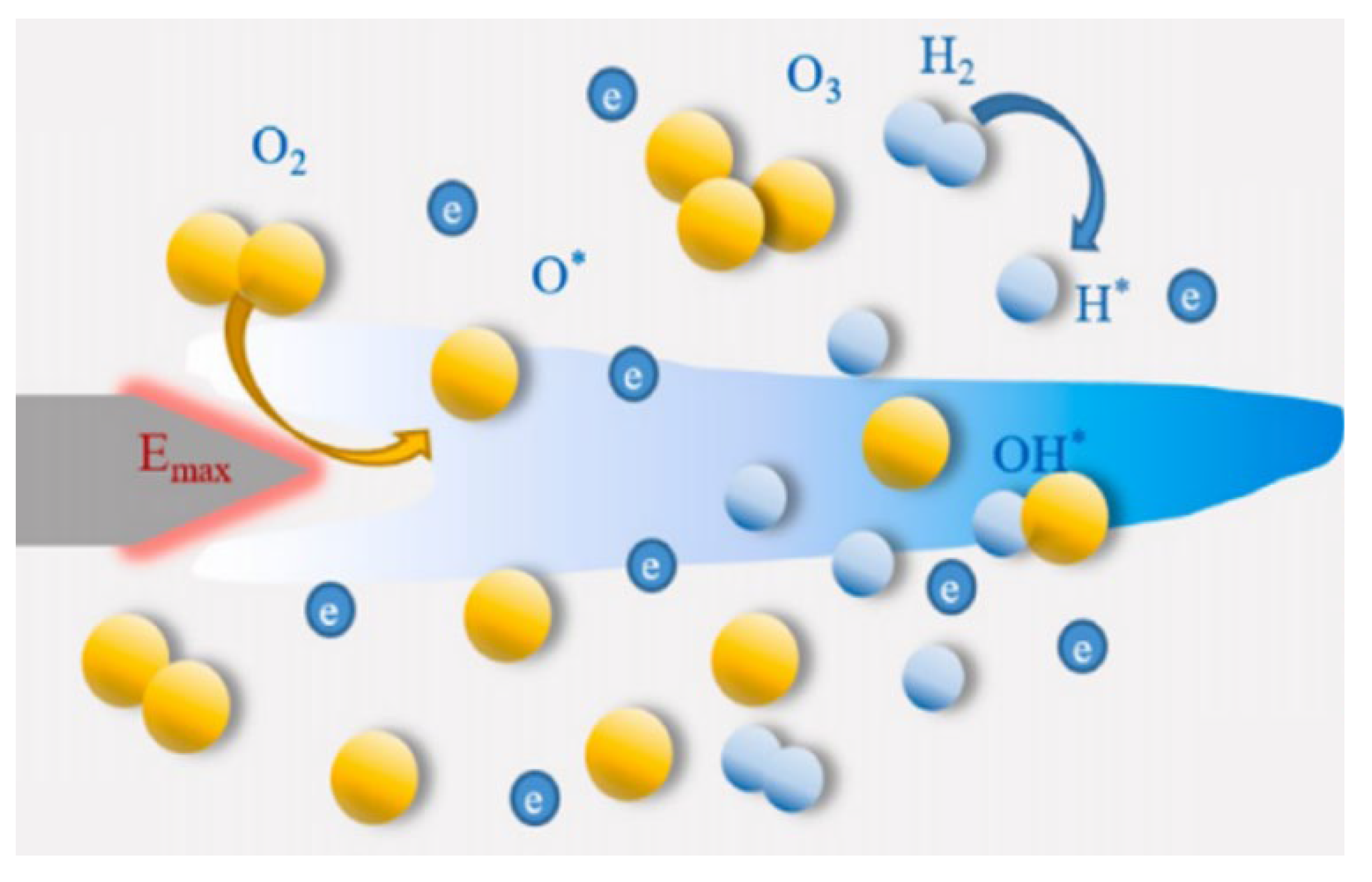

The core workflow operates as follows: Purified water from the storage module undergoes electrolysis, splitting it into hydrogen and oxygen. These gases are then delivered to the combustion chamber through dedicated gas supply lines; hydrogen is directly injected into the combustion chamber, while oxygen is supplied to the microwave ignition module. The module combines a solid-state microwave source with an igniter, using the microwave field to excite oxygen molecules and produce a high-energy plasma torch. This plasma serves as a stable ignition source for hydrogen in the combustion chamber. Upon ignition, the hydrogen–oxygen mixture undergoes vigorous combustion, generating a high-temperature, high-pressure gas. This gas is then accelerated through a converging–diverging nozzle to produce directional thrust.

Figure 1.

Experimental system diagram of microwave ignition water electrolysis propulsion system.

Figure 1.

Experimental system diagram of microwave ignition water electrolysis propulsion system.

The system operation process is as follows:

- (1)

The electrolyzer is energized and maintained under constant operating conditions until steady-state performance is achieved.

- (2)

The hydrogen supply line isolation valve is actuated to initiate hydrogen injection into both the delivery piping network and combustion chamber.

- (3)

The oxygen manifold control valve is engaged to charge the plasma igniter assembly with high-purity oxygen.

- (4)

A microwave-excited solid-state plasma generator is activated to establish a stable thermal plasma torch within the ignition cavity.

- (5)

Diagnostic instrumentation, including high-speed imaging systems and data acquisition modules, records transient process characteristics and operational parameters throughout the test sequence.

2.1. Homemade Propellers

The thruster’s core component is a quarter-wavelength coaxial resonant cavity (QWCRC). The cavity structure is carefully designed with precise geometrical parameters to support pure transverse electromagnetic (TEM) wave propagation, effectively suppressing higher-order mode interference. Its dimensions are optimized to maximize power handling capacity, approaching the theoretical limit. The resonant cavity incorporates a bottom-mounted compact igniter with a threaded interface, minimizing insertion loss between the microwave pins and the cavity. Surface impedance matching at the contact interface boosts microwave energy transmission efficiency beyond 92%.

The resonant cavity incorporates a multi-stage flow optimization system, featuring a topology-optimized skeletal inlet chamber at its center. A gradually tapered-expanding flow channel configuration reduces and stabilizes the working gas velocity from an initial 25 m/s to 5 ± 0.3 m/s. This configuration yields a laminar flow fraction exceeding 85% throughout the homogeneous flow field within the chamber. The combustion chamber features symmetric Φ2.0 mm air inlets on both sidewalls. Computational fluid dynamics (CFD) simulations demonstrate that this configuration achieves complete turbulent mixing of the C2H4/O2 mixture within 20 ms, with a mixing uniformity index of 0.93, significantly enhancing combustion stability.

COMSOL Multiphysics 3D software is used to analyze the electric field inside the thruster. The version of the software is COMSOL 6.0. The computational domain is maintained at an isothermal condition of 293.15 K under 101.325 kPa.

Simulation results indicate a strong dependence of the near-field electric field distribution on the antenna head geometry. Comparative analysis reveals that a conical tip configuration exhibits superior field-enhancing characteristics due to its high curvature radius at the apex, which induces localized surface charge accumulation. This geometric singularity results in significant enhancement of the electric field intensity at the antenna tip, thereby justifying the selection of a conical profile for optimal field confinement.

2.2. Data Collection Device

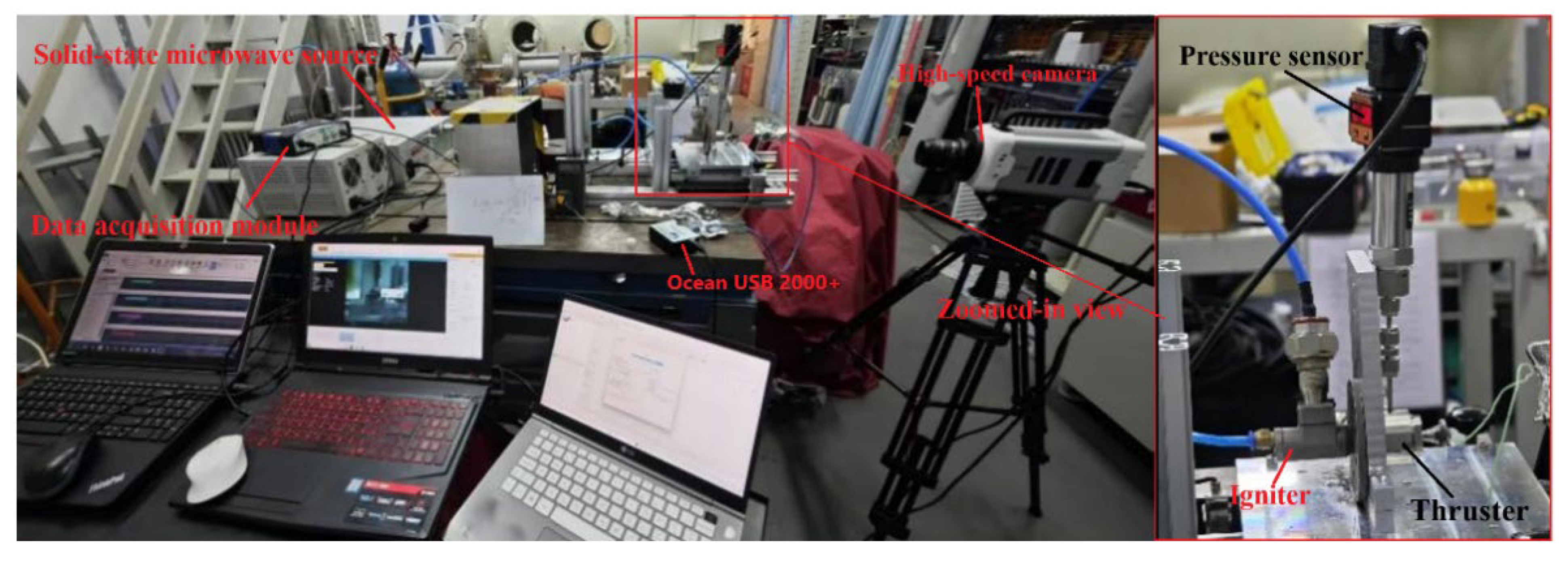

As illustrated in

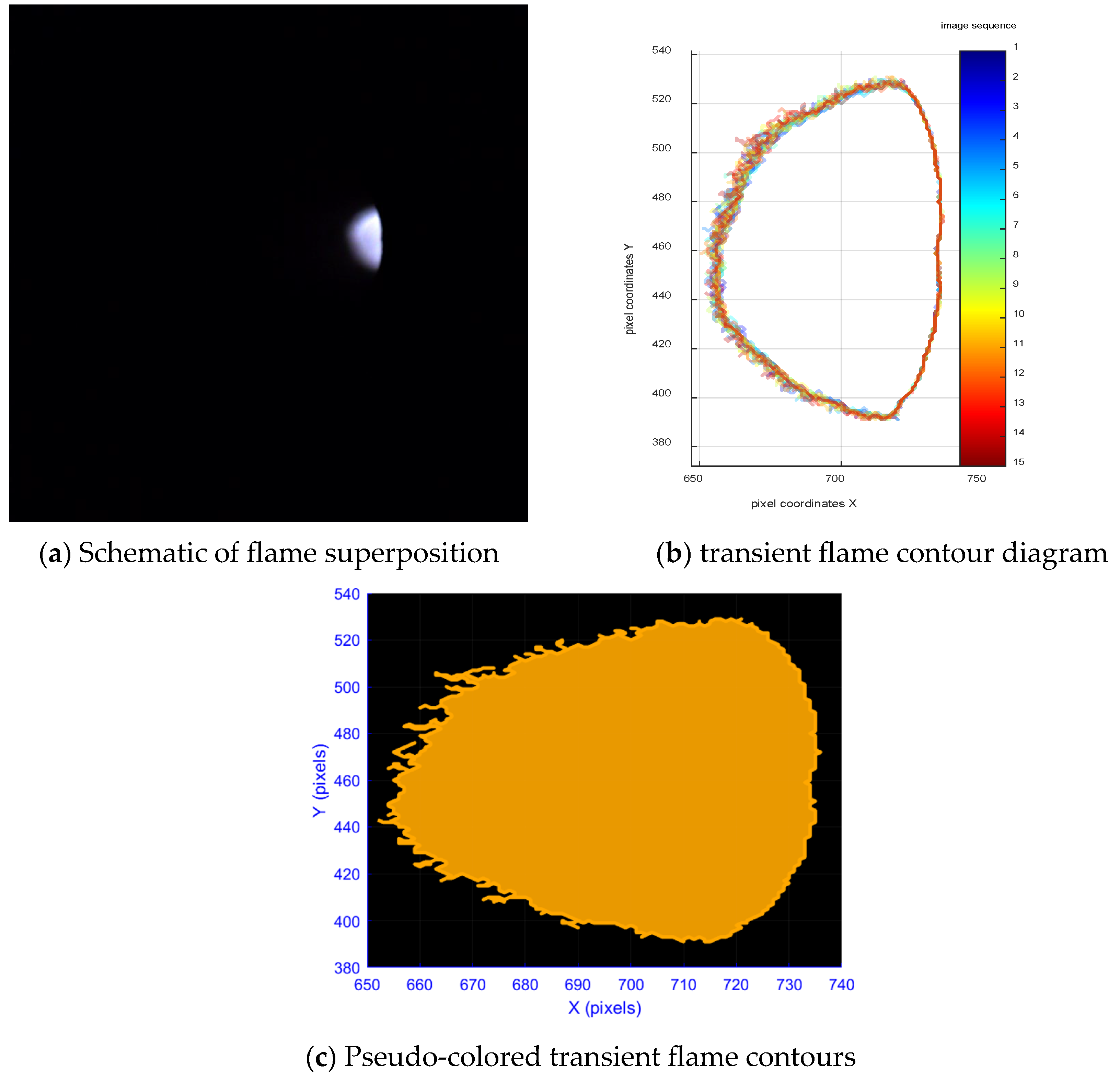

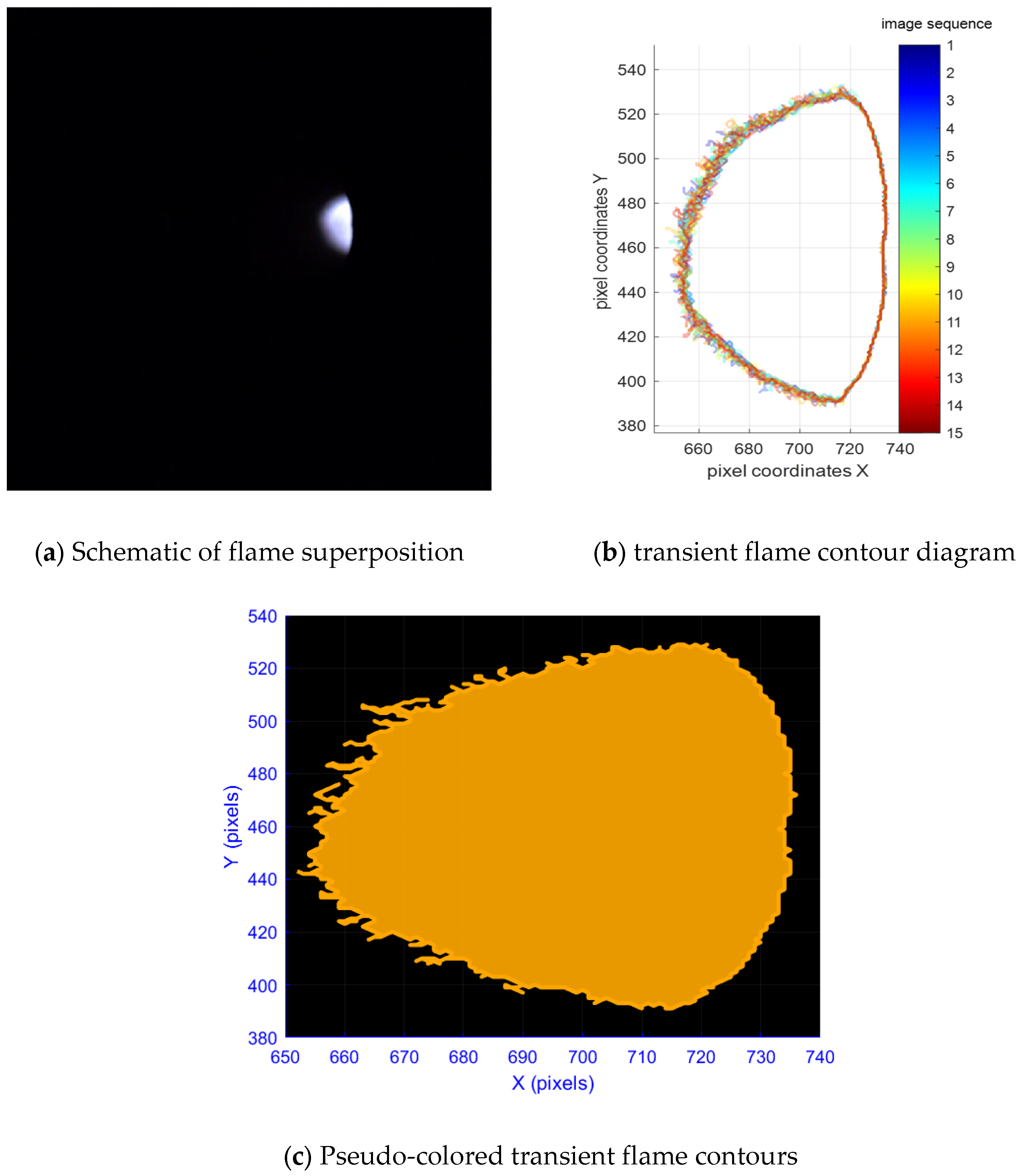

Figure 2, the whole device consists of a high-speed camera, pressure sensor, and a spectrometer. The high-speed camera records at 1000 fps to clearly capture every frame of the flame. It can be seen that the axis of the high-speed camera and the nozzle are not exactly at an angle of 90°, which is measured as θ = 71.5°. The shape of the flame observed in this way is actually a projection of the real flame, and to calculate the quantitative data, it is necessary to divide the calculated data by sin71.5°.

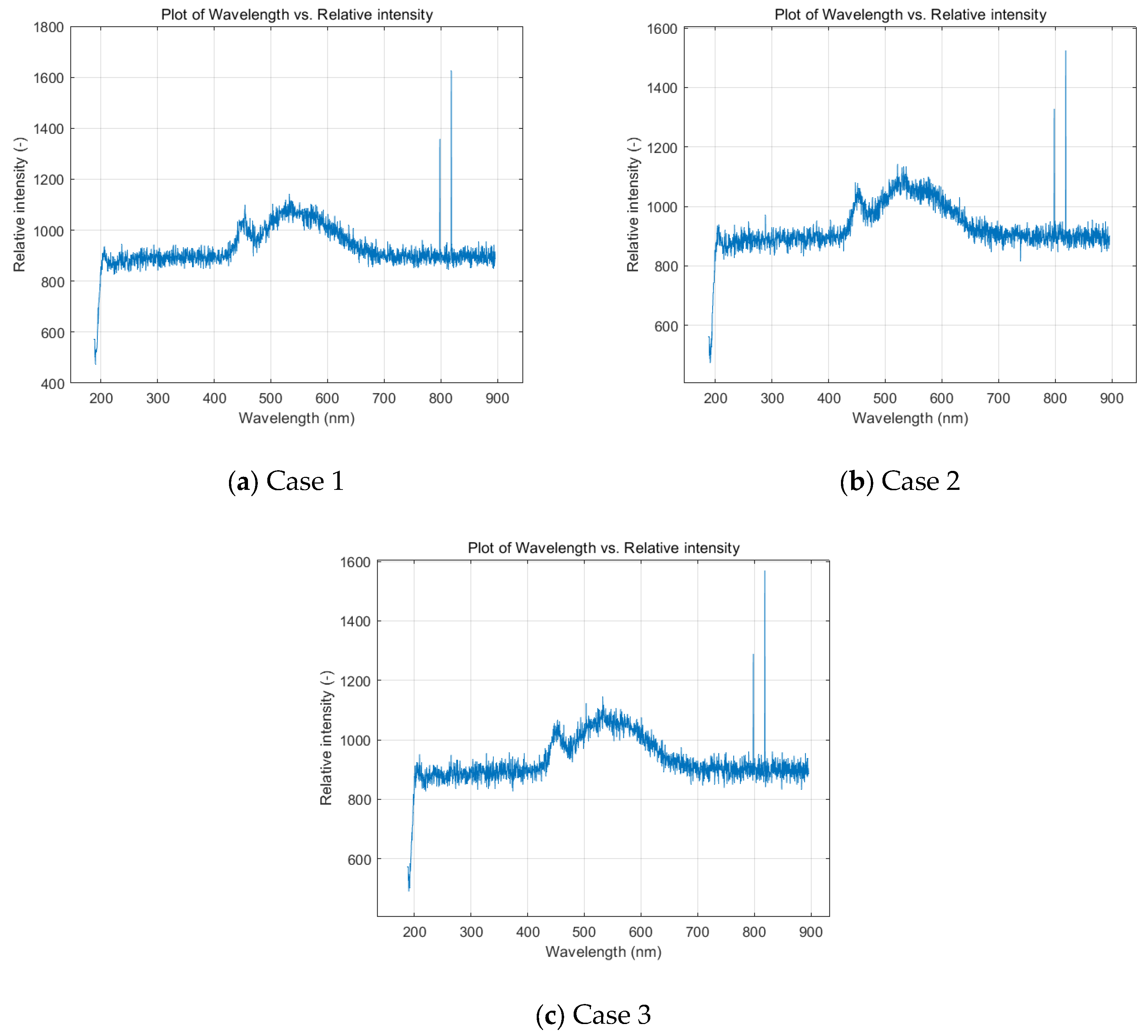

Flame emission spectra were acquired using an Ocean Optics USB2000+ miniature fiber-optic spectrometer, configured with a spectral range of 200–900 nm, an optical resolution of 1.5 nm (FWHM), and an integration time of 1 ms. The spectrometer was coupled to a high-temperature-resistant optical fiber probe positioned at a standoff distance of 10 cm from the ignition point to ensure minimal thermal interference while maintaining sufficient signal intensity.

Spectral data acquisition was performed in real-time using COMSOL Multiphysics 3D software, which facilitated continuous monitoring and recording of radiative emission features across the ultraviolet–visible–near-infrared (UV-Vis-NIR) spectrum. The system was calibrated for wavelength accuracy and relative intensity response prior to experimentation to ensure measurement fidelity.

Figure 2.

Schematic diagram of the image and spectral acquisition system.

Figure 2.

Schematic diagram of the image and spectral acquisition system.

The spatial configuration of the high-speed imaging system is illustrated in

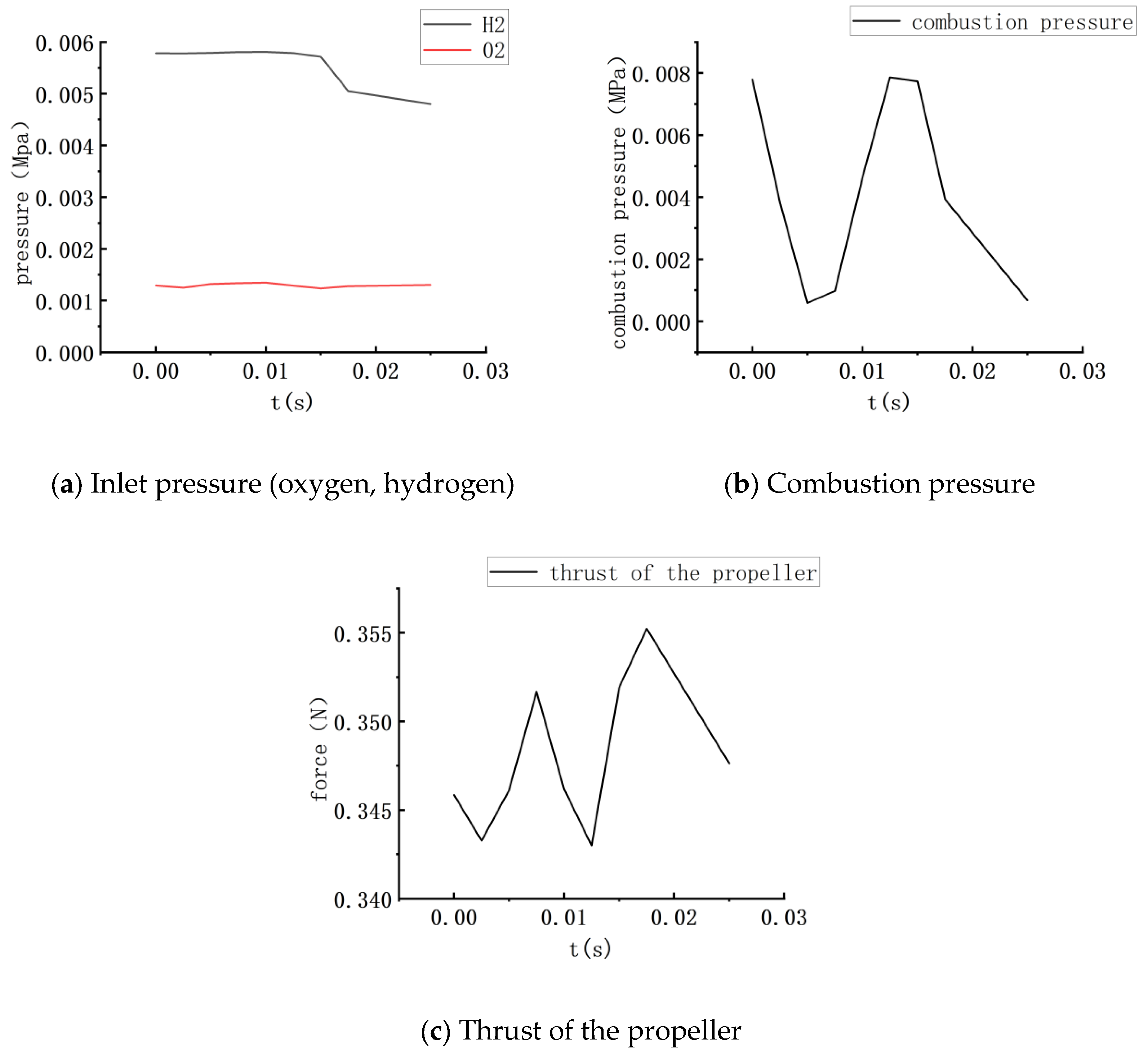

Figure 3. The experimental apparatus was instrumented with three high-precision piezoresistive pressure transducers (accuracy: ±0.5% FS, sampling frequency: 10 Hz, full-scale range: 0–50 SLM, maximum pressure rating: 3 MPa) for simultaneous pressure monitoring of the hydrogen supply manifold, the oxygen delivery line, and the combustion chamber volume.

Through real-time pressure differential measurements across the gas transmission conduits, instantaneous mass flow rates were derived using the isentropic flow equations. The experimental investigations were conducted using a microwave electrothermal propulsion test bench, with the microwave excitation system operating at a constant output power of 300 W (2.45 GHz).

Figure 3.

The actual ignition platform and observation system.

Figure 3.

The actual ignition platform and observation system.

The specific parameters of the experimental apparatus used above are as follows: Ocran USB 2000+ miniature fiber-optic spectrometer for the experiment, fiber-optic probe of about 10 cm from the ignition point, 200–900 nm maximum spectrometer measurement range with a resolution of 1.5 nm, and a 1 ms detection integration interval.

4. Conclusions

Water electrolysis microwave ignition technology provides a disruptive solution for propulsion systems. Compared with the traditional catalytic ignition method, this technology generates plasma jets through direct microwave ionization of mixed gases, which not only eliminates the degradation-prone catalytic bed structure and preheating process, but also significantly improves the ignition reliability and combustion efficiency through highly active particles. Experiments have confirmed that the microwave ionization process can effectively excite hydrogen/oxygen atoms to higher energy states, and this non-equilibrium activation mechanism significantly broadens the flammability limit, while meeting the system’s requirements for lightweight, long-life, and green propulsion.

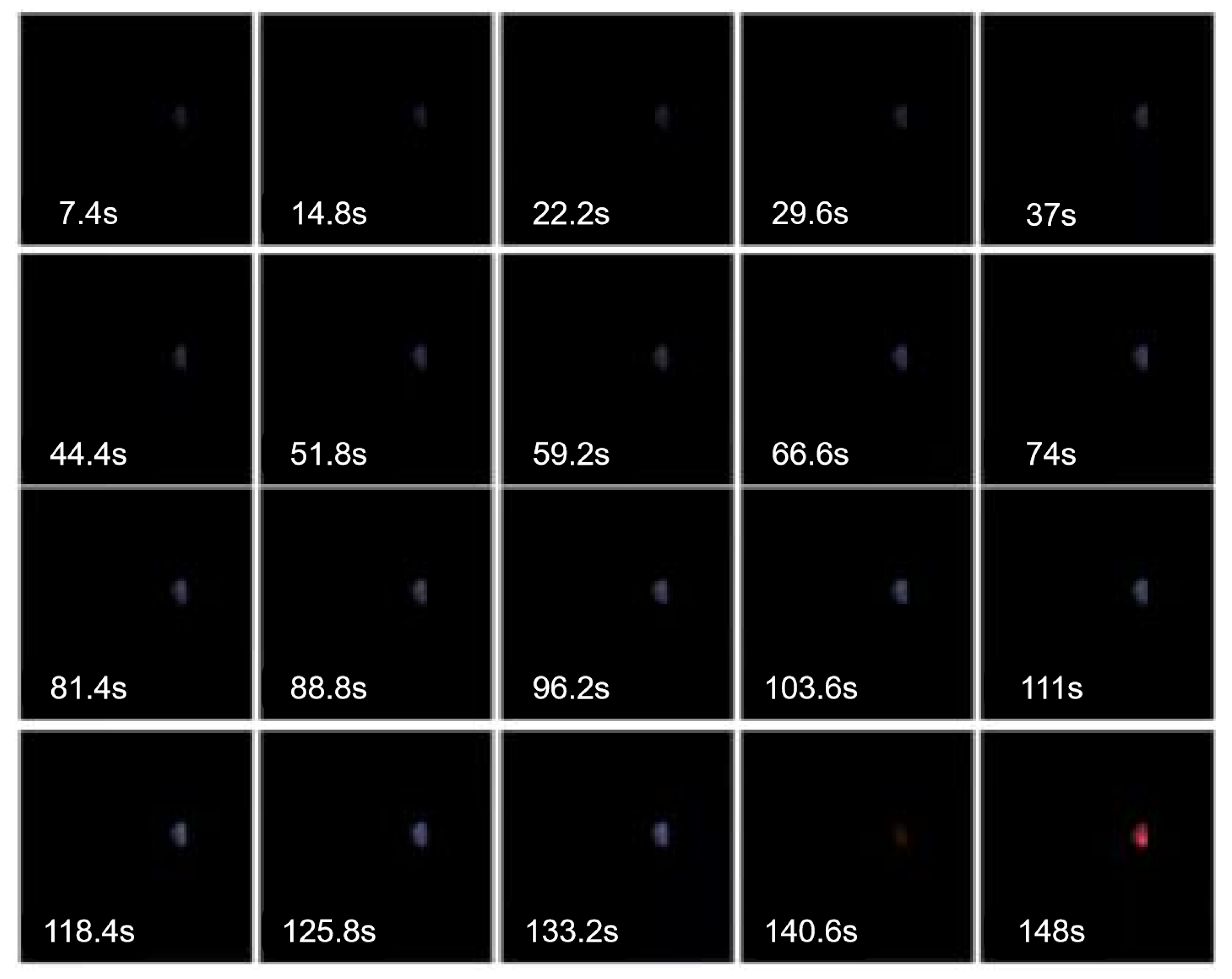

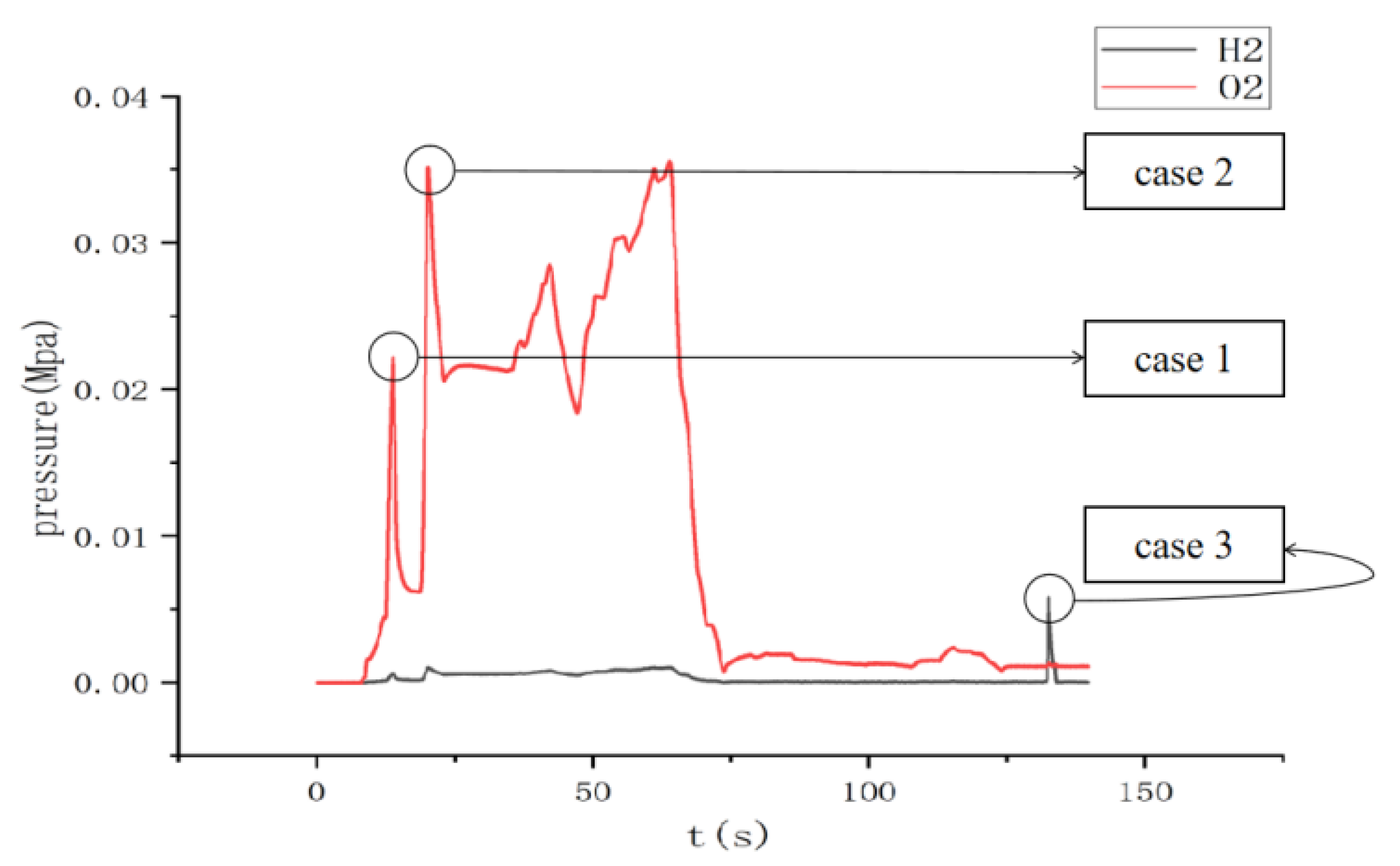

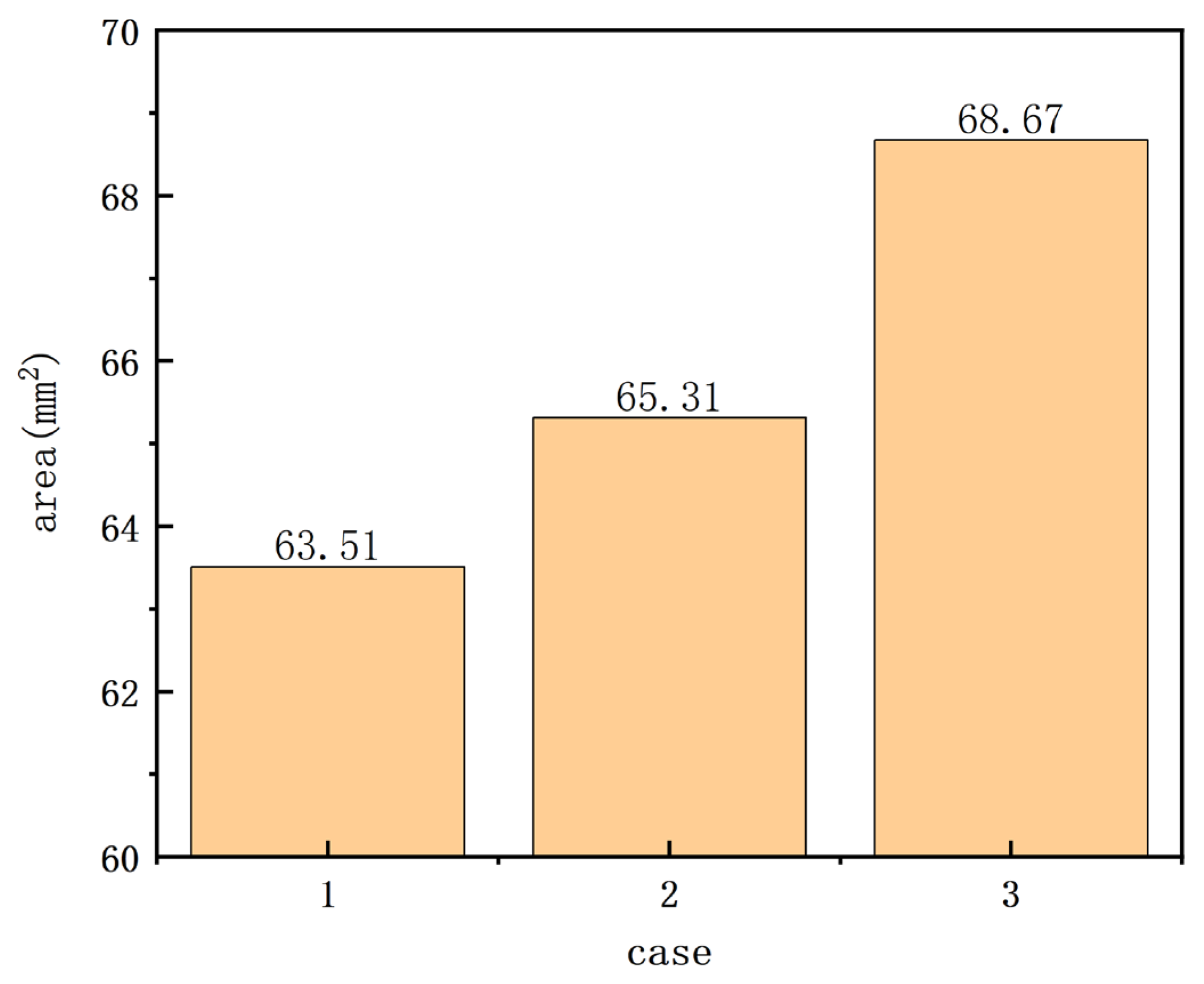

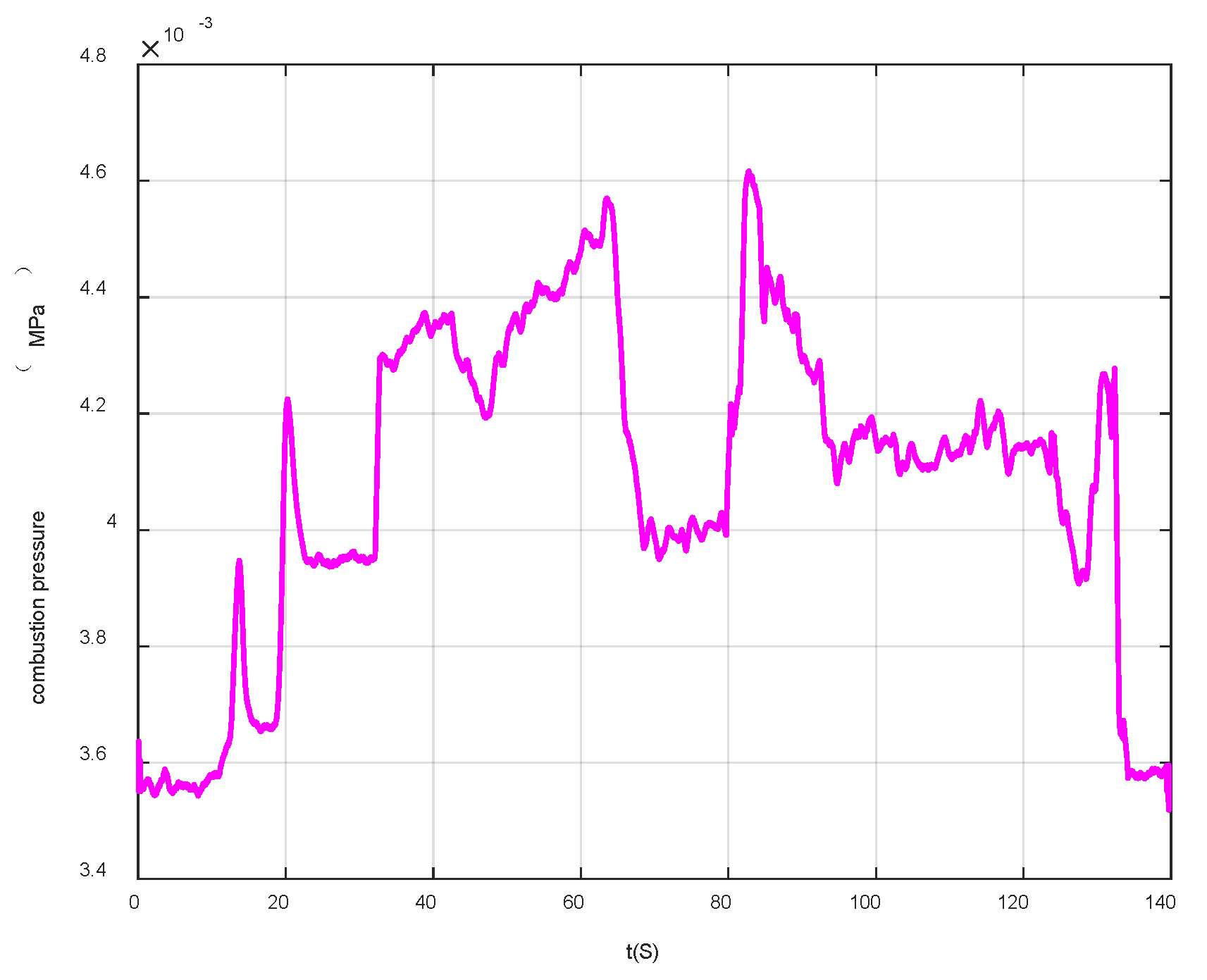

As time progresses, the brightness of both the internal and external regions of the flame increases, with the internal region of the flame showing a bright white color and the external region of the flame having traces of blue color. The combustion pressure was enhanced by 25% from Case 2 to Case 3, and the maximum thrust produced was increased by 508% compared to Case 2. Although the spectral intensity of the three conditions changed, the change rule of spectral intensity with wavelength was consistent.

In this study, we experimentally investigated the pulse operating characteristics of the water electrolysis chemical propulsion engine based on microwave ignition technology and verified the technological advantages of this propulsion system in terms of fast response, controlled combustion, and clean products. From the perspective of sustainability, water electrolysis propulsion technology takes water as the reaction medium, and its combustion products are only hydrogen, oxygen atoms, and trace nitrogen components, which completely avoids the emission of carbon-containing pollutants or greenhouse gases from traditional chemical propellants and is in line with the development trend of aerospace greening. The efficient energy utilization of microwave ignition technology further reduces the energy consumption of the system, and the renewable characteristics of water resources make this technology have the potential of closed-loop application. In the future, the combination of renewable power systems and material cycle design could build a whole-life low-carbon chain from energy input to propellant preparation, providing a power solution for small spacecraft that meets sustainable development goals. Subsequent research should focus on optimizing the system’s energy efficiency ratio and resource utilization in order to enhance its environmentally friendly characteristics in space missions.