Recycling of Discarded Mattresses Through Extended Producer Responsibility: Is It More Cost-Effective than Incineration?

Abstract

1. Introduction

1.1. Waste Recycling or Incineration

1.2. Mattress Recycling

1.3. Aims and Structure of This Article

2. Research Context

- Determining the amount of a recycling fee to be added to the mattress price.

- Setting up a collection and recycling infrastructure for municipalities and stores funded by the fee.

- Establishing, and periodically reviewing and revising, performance measures, such as a yearly increase in recycling by 5%, such that a recycling rate of 75% will be reached in 2028.

3. Method

3.1. Mattress Characteristics and Recycling Parameters

3.2. Opportunity Costs

4. Results

4.1. Cost-Effectiveness Analysis

4.2. Sensitivity Analysis

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Scharff, H. Landfill reduction experience in The Netherlands. Waste Manag. 2014, 34, 2218–2224. [Google Scholar] [CrossRef] [PubMed]

- Gradus, R.; Nillesen, P.; Van Koppen, R.; Dijkgraaf, E. A Cost-Effectiveness Analysis for Incineration or Recycling of Dutch Household Plastic waste. Ecol. Econ. 2017, 135, 22–28. [Google Scholar] [CrossRef]

- EUROSTAT 492 kg of Municipal Waste Generated per Person in the EU. 2018. Available online: https://ec.europa.eu/eurostat/web/products-eurostat-news/-/ddn-20200318-1 (accessed on 31 December 2021).

- Kirchherr, J.; D Reike, M. Hekkert. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Dijkgraaf, E.; Gradus, R.H.J.M. An EU recycling target: What does the Dutch evidence tell us? Environ. Resource. Econ. 2017, 68, 501–526. [Google Scholar] [CrossRef]

- Brouwer, M.; Picuno, C.; Thoden van Velzen, E.U.; Kucha, K.; De Meester, S.; Ragaert, K. The impact of collection portfolio expansion on key performance indicators of the Dutch recycling system for Post-Consumer Plastic Packaging Waste, a comparison between 2014 and 2017. Waste Manag. 2019, 100, 112–121. [Google Scholar] [CrossRef] [PubMed]

- Dijkgraaf, E.; Gradus, R.H.J.M. Are Bottle Banks Sufficiently Effective for Increasing Glass Recycling Rates? Sustainability 2021, 13, 9540. [Google Scholar] [CrossRef]

- Dijkgraaf, E.; Gradus, R.H.J.M. Waste Management in the Netherlands. In Handbook on Waste Management; Kinnaman, T., Takeuchi, K., Eds.; Edward Elgar Publishers: Cheltenham, UK, 2014; pp. 287–315. [Google Scholar]

- Ministry of Infrastructure and Water Management. Kennisgeving van het Algemeen Verbindend Verklaren van de Overeenkomst Inzake de Afvalbeheerbijdrage voor Matrassen [Notification of the General Binding Declaration of the Agreement on the Waste Management Contribution for Mattresses]. Staatscourant 17 December 2021, Nr. 49806. Available online: https://mrn.nl/app/uploads/2021/12/AVV-Overeenkomst-Matrassen.pdf (accessed on 8 December 2021). (In Dutch)

- Geyer, R.; Kuczenski, B.; Trujillo, M. Assessing the greenhouse gas savings potential of extended producer responsibility for mattresses and box springs in the United States. J. Ind. Ecol. 2016, 20, 917–928. [Google Scholar] [CrossRef]

- Yamamoto, M.; Kinnaman, T.C. Is incineration repressing recycling? J. Environ. Econ. Manag. 2022, 111, 102593. [Google Scholar] [CrossRef]

- Veses, A.; Sanahuja-Parejo, O.; Martínez, I.; Callén, M.; López, J.M.; García, T.; Murillo, R. A pyrolysis process coupled to a catalytic cracking stage: A potential waste-to-energy solution for mattress foam waste. Waste Manag. 2021, 120, 415–423. [Google Scholar]

- Garrido, M.A.; Font, R.; Conesa, J.A. Pollutant emissions during the pyrolysis and combustion of flexible polyurethane foam. Waste Manag. 2016, 52, 138–146. [Google Scholar] [CrossRef] [PubMed]

- Narinx, M. Op weg naar een Circulaire Matrasketen. Verkenning van de Matrasketen en de Mogelijkheden voor het Sluiten van de Matrasketen in de Regio Utrecht-Amsterdam [Towards a Circular Mattress Chain. Exploration of the Mattress Chain and Possibilities for Closing the Mattress Chain in the Utrecht-Amsterdam Region]; Research Report; Utrecht Sustainability Institute: Utrecht, The Netherlands, 2016. (In Dutch) [Google Scholar]

- Vouri, L.; Ollikainen, M. How to remove microplastics in wastewater? A cost-effectiveness analysis. Ecol. Econ. 2022, 192, 107246. [Google Scholar] [CrossRef]

- Gillingham, K.; Stock, J.H. The Cost of Reducing Greenhouse Gas Emissions. J. Econ. Perspect. 2018, 32, 53–72. [Google Scholar] [CrossRef]

- Nash, J.; Bosso, C. Extended Producer Responsibility in the United States: Full Speed Ahead? J. Ind. Ecol. 2013, 17, 175–185. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission: Ecodesign for Sustainable Products and Energy Labelling Working Plan 2025–2030; COM (2025) 187 Final; European Commission: Brussels, Belgium, 2025. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52025DC0187 (accessed on 3 May 2025).

- Dimitropoulos, A.; Tijm, J.; In’t Veld, D. Extended Producer Responsibility: Design, Functioning and Effects; PBL Netherlands Environmental Assessment Agency/CPB Netherlands Bureau for Economic Policy Analysis: The Hague, The Netherlands, 2021.

- Auping. Circulaire Verdienmodellen [Circular Revenue Models]; Internal Presentation; Koninklijke Auping BV: Deventer, The Netherlands, 2021. (In Dutch) [Google Scholar]

- Garrido, M.A.; Font, R.; Conesa, J.A. Kinetic study and thermal decomposition behaviour of viscoelastic memory foam. Energy Convers. Manag. 2016, 119, 327–337. [Google Scholar] [CrossRef]

- Dijkgraaf, E.; Vollebergh, H.R. Burn or bury? A social cost comparison of final waste disposal methods. Ecol. Econ. 2004, 50, 233–247. [Google Scholar] [CrossRef]

- Morris, J. Recycling versus incineration: An energy conservation analysis. J. Hazard. Mater. 1996, 47, 277–293. [Google Scholar] [CrossRef]

- Matras Recycling Europe. Presentation During Circular Economy Lab, 25 January; Utrecht Sustainability Institute: Utrecht, The Netherlands; Economic Board Utrecht: Utrecht, The Netherlands; Amsterdam Economic Board: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Municipality of Utrecht. ‘Beschrijving Monitoring en Bepaling CO2-Uitstoot Gemeente Utrecht’ [In Dutch]. April. Available online: https://data.utrecht.nl/dataset/co2-uitstoot-gemeente-utrecht (accessed on 8 December 2021).

- IDEMAT Database, 2021. Version 2.4.2. Available online: www.idemat.com (accessed on 8 December 2021).

- Ministry of Economic Affairs and Climate. Regeling Vaststelling Voorschotverlening Duurzame Energieproductie en Klimaattransitie; [Regulation on the Determination of Advance Payments for Sustainable Energy Production and Climate Transition]; Ministry of Economic Affairs and Climate: Den Haag, The Netherlands, 2021. (In Dutch)

- Openbare Vlaamse Afvalstoffenmaatschappij (OVAM). Onderzoek naar het Invoeren van Uitgebreide Producentenverantwoordelijkheid voor Matrassen; Research Report; Openbare Vlaamse Afvalstoffenmaatschappij (OVAM): Mechelen, Belgium, 2013. (In Dutch) [Google Scholar]

- Van Driel, J. De Matrasketen. Cijfers, Drempels en Kansen voor Circulaire Matrassen [The Matras Chain: Figures, Thresholds and Opportunities for Circular Mattresses]; Research Report; Utrecht Sustainability Institute and Alliantie Cirkelregio Utrecht: Utrecht, The Netherlands, 2018; Available online: https://www.cirkelregio-utrecht.nl/kennisartikel/kansen-voor-circulaire-matrassen/ (accessed on 8 December 2021). (In Dutch)

- De Jong, J. (Commercial director AVR, Afvalverwerking Rijnmond). Personal communication, 2021.

- Faber, M.; Heens, F.; Spanbroek, N.; Lijzen, J.P.A.; van Drongelen, A.W. Recycling van Matrassen: Analyse van Risico’s van Verwerking en Nieuwe Toepassingen [Mattress Recycling: Analysis of Risks of Processing and New Applications]. RIVM-briefrapport 2021-0131; Rijksinstituut voor Volksgezondheid en Milieu (RIVM): Bilthoven, The Netherlands, 2021. Available online: https://www.rivm.nl/bibliotheek/rapporten/2021-0131.pdf (accessed on 8 December 2021). (In Dutch)

- Mulder, A. Matrasrecycling. Een Kans om Niet te Laten Liggen [Mattress Recycling. An Opportunity Not to Be Missed]; Research Report; ABN AMRO: Amsterdam, The Netherlands, 2018. (In Dutch) [Google Scholar]

- Van Zoelen, B. Fabrikanten gaan betalen voor oude matrassen—Maar niet die vieze natte uit Amsterdam. [Manufacturers will pay for old mattresses—But not the dirty wet ones from Amsterdam]. Het Parool, 23 August 2021. (In Dutch) [Google Scholar]

- Liberati, G.; Biagi, F.; Nanni, A.; Parisi, M.F.; Barbaresi, L.; Querci, L.; Ceccarelli, S.; Regazzi, M.; Bonoli, A.; Colonna, M. Mechanical recycling of foam from end-of-life mattresses by AIR-LAY process for the production of new mattresses with a fully circular approach. Clean. Mater. 2024, 12, 100249. [Google Scholar] [CrossRef]

- Serrano, D.; Horvat, A.; Mata, R.M.; Costa, P.; Paraleda, F. Pressurized pyrolysis of mattress residue: An alternative to landfill management. Waste Manag. 2024, 181, 11–19. [Google Scholar] [CrossRef] [PubMed]

- Bel, G.; Sebő, M. Watch your neighbour: Strategic competition in waste collection and service quality. Waste Manag. 2021, 127, 63–72. [Google Scholar] [CrossRef] [PubMed]

| Input | Figure | Source |

|---|---|---|

| Mattress characteristics | ||

| Energy content mattress | 30.0 MJ/kg | [23] |

| Waste incineration parameters | ||

| Collection costs mixed waste | EUR 70/t | [2] |

| Incineration costs mixed waste | EUR 125/t | [2] |

| Recycling parameters | ||

| Mattress recovery percentage | 90% | [9] |

| Recycling fee municipalities | EUR 375/t | [20] |

| Post-collection | EUR 250/t | [20] |

| Market costs recycling PU foam | EUR −34/t | [20] |

| Market costs bonded PU foam | EUR 50/t | [20] |

| Market costs spring steel | EUR 1100/t | LME: average price 2020 |

| Composition of average mattress | ||

| PU Foam | 40% | [24] |

| Ticking | 25% | [24] |

| Spring steel | 20% | [24] |

| Latex | 10% | [24] |

| Residual materials (e.g., plastics) | 5% | [24] |

| New product | 1040 kg CO2/t | [25] |

| Production PE for new mattress | −1200 kg CO2/t | [25] |

| CO2 emissions incineration | −2666 kg CO2/t | [25] |

| Electricity yield plant | 1085 kg CO2/t | [25] |

| Heat output plant | 170 kg CO2/t | [25] |

| Transport parameters | ||

| Distance to incinerator/sorting | 100 km | Assumption: 50 km twice |

| CO2 road transportation | 0.073 kg/km t | [26] |

| Road transport costs | EUR 0.043/km t | [26] |

| Price parameters | ||

| Electricity price | EUR 98.67/MWh | Based on average cal. 2021 APX prices |

| Heat and steam price | EUR 14.8/MWh | [27] |

| Recycling | Incineration | |

|---|---|---|

| Remuneration costs | 375 | 74 |

| Processing | 250 | 125 |

| Revenues | −203 | −124 |

| Subtotal | 422 | 75 |

| Opportunity costs of energy | 112 | |

| Opportunity costs of secondary material | 234 | |

| Total | 533 | 309 |

| Recycling | Incineration | |

| Energy recovery | 0.27 | 2.67 |

| Recycling | 0.16 | |

| Transport | 0.02 | 0.01 |

| Subtotal | 0.45 | 2.67 |

| Opportunity emissions of energy | 0.76 | |

| Opportunity emissions of mattress waste | 0.16 | |

| Total | 1.21 | 2.83 |

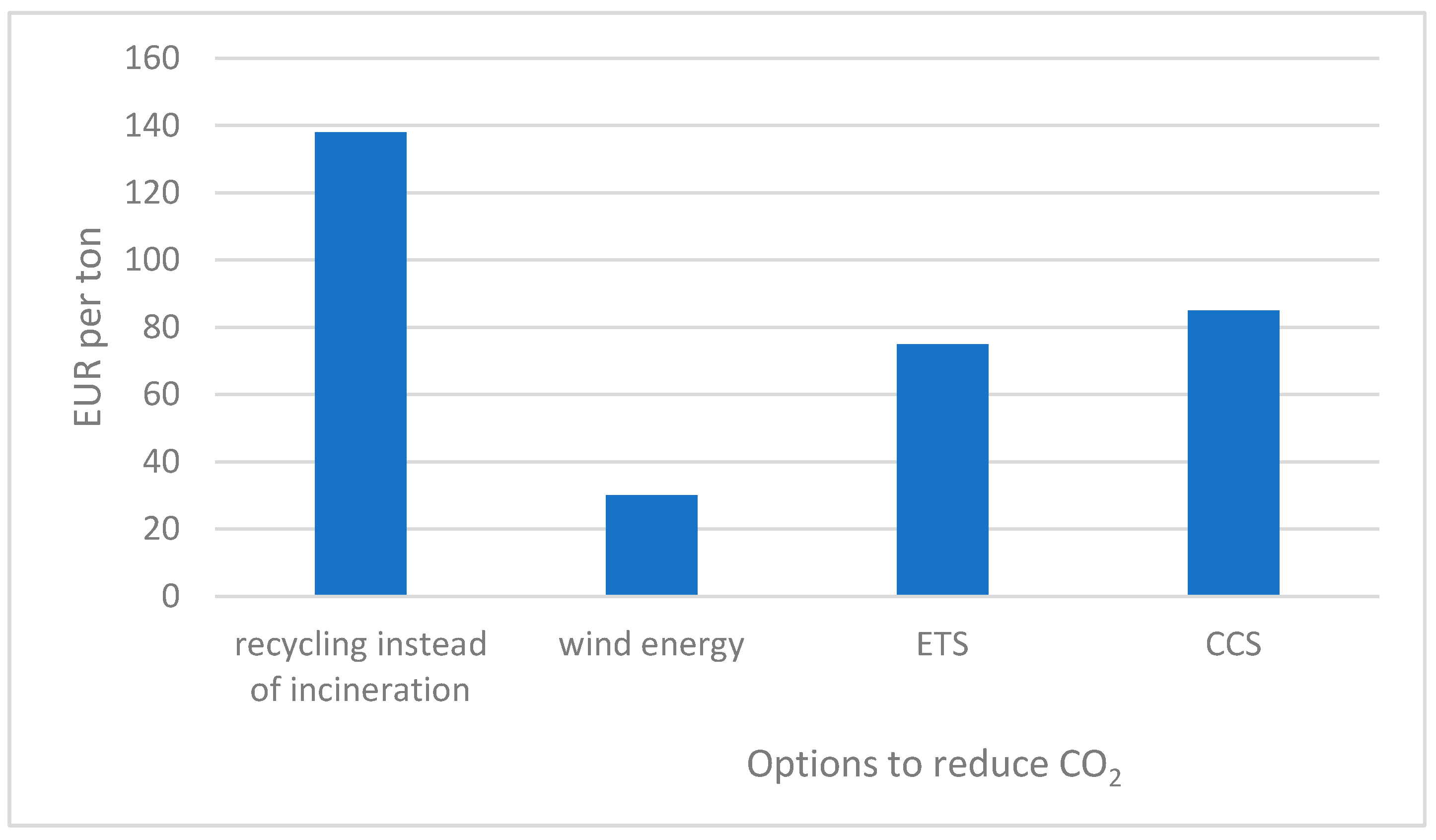

| Cost Gap (EUR) | CO2 Emission Gap (t) | Cost of CO2 Reduction (EUR/t) | |

|---|---|---|---|

| Base Scenario | 224 | 1.62 | 138 |

| Scenario 1: CO2-neutral replacement energy | 224 | 2.39 | 94 |

| Scenario 2: Treatment costs of incineration double | 99 | 1.62 | 61 |

| Scenario 3: EPR of EUR 10.47 | 123 | 1.62 | 76 |

| Scenario 4: Proportion of 25% mattresses incinerated | 245 | 1.35 | 181 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faber, B.; Gradus, R. Recycling of Discarded Mattresses Through Extended Producer Responsibility: Is It More Cost-Effective than Incineration? Sustainability 2025, 17, 5542. https://doi.org/10.3390/su17125542

Faber B, Gradus R. Recycling of Discarded Mattresses Through Extended Producer Responsibility: Is It More Cost-Effective than Incineration? Sustainability. 2025; 17(12):5542. https://doi.org/10.3390/su17125542

Chicago/Turabian StyleFaber, Bram, and Raymond Gradus. 2025. "Recycling of Discarded Mattresses Through Extended Producer Responsibility: Is It More Cost-Effective than Incineration?" Sustainability 17, no. 12: 5542. https://doi.org/10.3390/su17125542

APA StyleFaber, B., & Gradus, R. (2025). Recycling of Discarded Mattresses Through Extended Producer Responsibility: Is It More Cost-Effective than Incineration? Sustainability, 17(12), 5542. https://doi.org/10.3390/su17125542