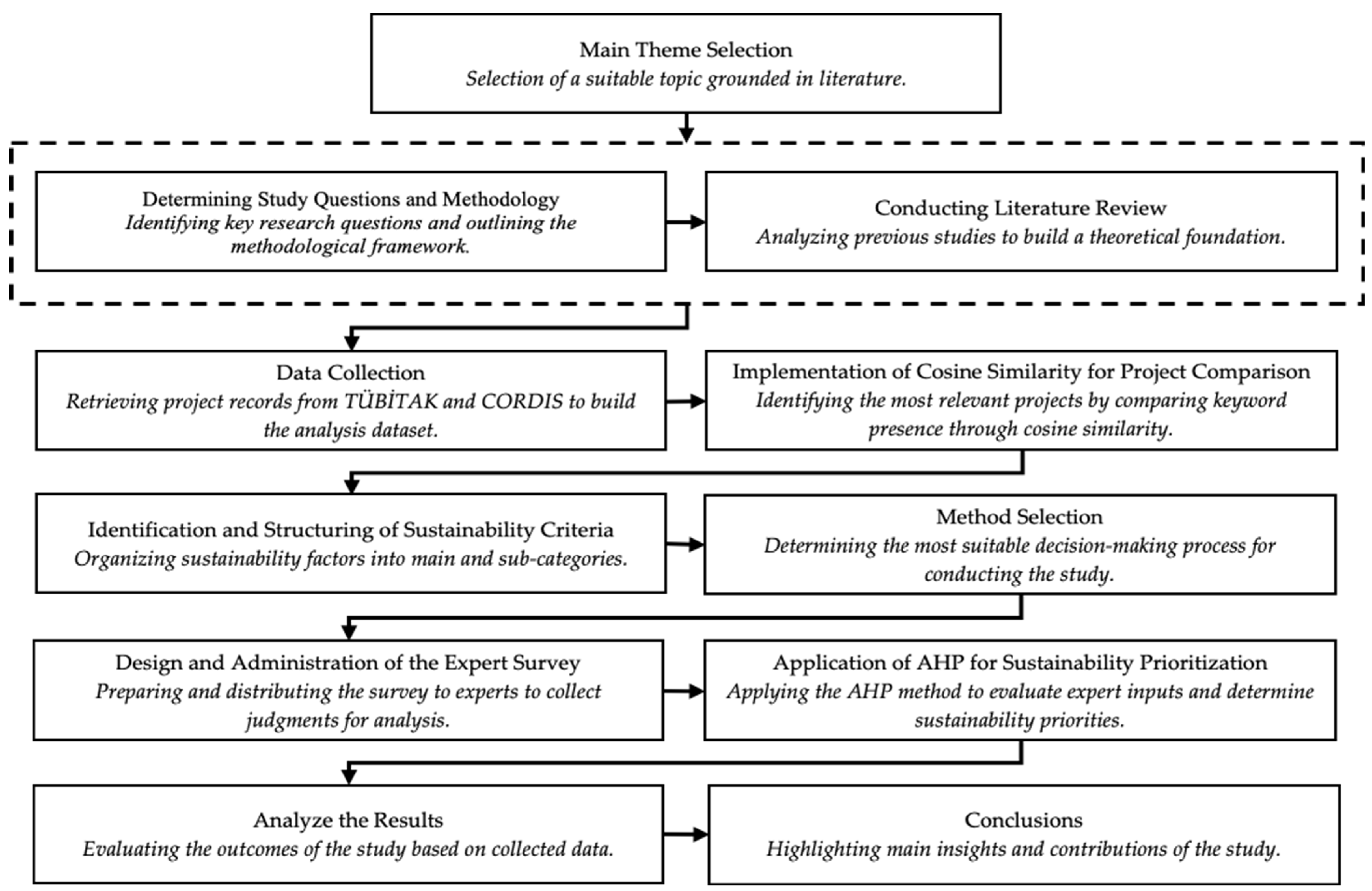

The methodological approach adopted in this research is designed to systematically examine the role of AHP in the development of innovation roadmaps aimed at supporting sustainable innovation [

5]. The research is structured into several distinct phases, beginning with the collection of data and selection of relevant innovation projects. It then proceeds through a series of analytical steps, including the application of cosine similarity algorithms to identify patterns in sustainability alignment [

15] and concludes with the implementation of AHP to prioritize key sustainability criteria. Each phase is carefully structured to ensure methodological rigor by addressing reliability, validity, and replicability. The specific procedures and tools used are detailed in the following sections, beginning with the strategy for data collection and project selection.

2.1. Data Collection and Project Selection

This research is based on the systematic collection and evaluation of data from two major sources: CORDIS and TÜBİTAK. These databases were selected due to their credibility, transparency, and extensive coverage of research and innovation activities. CORDIS, the European Union’s central repository for funded research, includes disciplines such as engineering, energy, and environmental sciences [

11]. It provides structured metadata including project objectives, timelines, funding, and outputs. TÜBİTAK, Türkiye’s leading scientific funding agency, provides a similar project archive with national and regional scope, offering insights into local innovation ecosystems and public Research and Development (R&D) priorities [

12]. Both sources have been widely used in previous studies to analyze research trends, policy outcomes, and the sustainability integration into innovation, making them appropriate for this research’s focus on large-scale innovation strategy analysis.

The initial dataset included approximately 500,000 projects obtained from CORDIS and TÜBİTAK, covering sectors such as technology, machine manufacturing, energy, and environmental sciences. To ensure relevance to the research objectives, a structured, multi-phase selection process was implemented. In the first stage, projects were filtered using sector- and theme-specific keywords such as “machinery”, “manufacturing”, “sustainability”, “innovation”, and “sustainable innovation”, selected based on alignment with European Union and TÜBİTAK strategic priorities. In the second stage, cosine similarity was applied to project abstracts using a sustainability-focused term vector. The similarity threshold was defined through expert input and iterative review to ensure thematic consistency while preserving dataset diversity.

This dual-filtering method combined automated text mining with expert validation, improving the selection’s reliability and contextual accuracy. As a result of this process, the dataset was refined to 54,054 projects, representing a diverse cross-section of innovation initiatives embedded with sustainability objectives. These projects were subsequently retained for in-depth analysis in the following phases.

Following the initial filtering process, a final dataset of 54,054 projects were selected for analysis. This sample size balances analytical manageability and statistical representativeness, ensuring a practical yet diverse dataset. The projects were categorized primarily under the machine manufacturing sector, which aligns with the research’s thematic focus. To capture a wide range of innovation approaches, the dataset includes projects from both public and private institutions, thereby reflecting varying organizational priorities, operational contexts, and funding mechanisms [

16]. Project summaries and objectives were also reviewed to validate their relevance, confirming alignment with key sustainability themes such as carbon reduction, renewable energy, social inclusion, and economic resilience. Including projects across sectors and regions enhances the robustness and generalizability of findings, offering a comprehensive view of how sustainability principles are embedded in innovation strategies [

17]. While the framework is methodologically generalizable, its design is shaped by sustainability needs and innovation challenges specific to the machinery manufacturing industry.

The DMs selected for this research were chosen for their active involvement in sustainability-focused innovation and represent a diverse group from academia, industry, and the public sector. Efforts were made to ensure diversity in sector, professional background, and institutional affiliation. Similarly, the project dataset was drawn from two established public sources—CORDIS and TÜBİTAK—and refined using domain-specific keywords and cosine similarity analysis. This dual-filtering method ensured thematic relevance by selecting projects explicitly addressing innovation and sustainability.

However, despite this rigor, the method may exclude relevant initiatives that contribute to sustainability but do not explicitly mention related terms. The dataset reflects publicly available records on CORDIS and TÜBİTAK and may evolve as new projects are added.

2.2. Implementation of Cosine Similarity for Project Comparison

Following the data collection and project selection phases, the next step involved analyzing the text content of selected projects to identify thematic patterns and similarities. For this purpose, the cosine similarity algorithm was used. Commonly applied in NLP and information retrieval, this method quantifies the similarity between two text vectors in high-dimensional space. It calculates the

cosine of the angle between vectors, producing a similarity score from −1 to 1, where 1 indicates complete similarity, 0 represents no correlation, and −1 denotes complete opposition [

18].

Unlike distance-based measures, cosine similarity focuses solely on vector orientation, making it particularly suitable for textual data where document length may vary. This characteristic allows the algorithm to maintain accuracy and interpretability even when analyzing short descriptions or extended abstracts [

19].

The cosine similarity between two vectors,

A and

B, is calculated in Equation (1), as follows:

where

denotes the dot product of vectors and .

and are their respective Euclidean norms (magnitudes).

The dot product is calculated as the sum of the products of corresponding vector components, as follows:

and the magnitudes of each vector are calculated as

In this formulation,

and

represent the

i-th components of the vectors, and

n is the number of dimensions in the vector space, typically corresponding to the number of distinct terms across the document corpus. This vector space model, widely used in text mining and information retrieval, represents documents numerically based on term frequency [

18,

19].

The cosine similarity algorithm was applied to the metadata extracted from the selected projects, including titles, descriptions, and keywords. Each project was represented as a vector in a high-dimensional space, with each dimension corresponding to a unique term or keyword appearing in the corpus. To construct these vectors, the Term Frequency-Inverse Document Frequency (TF-IDF) method was used, which assigns higher weights to terms frequent within a document but rare across the dataset [

20]. This reduces the impact of common words and highlights distinctive terms, improving the semantic precision of similarity calculations [

21].

As a result, the algorithm could more effectively capture the thematic content of each project and quantify their similarity based on shared terminology and conceptual overlap. This vector-based approach enabled the construction of a pairwise similarity matrix, forming the basis for the ranking process in the next step. Cosine similarity scores were calculated for project pairs, forming a square matrix where each element reflected the semantic similarity between two projects. This matrix enabled ranking against a reference set of projects explicitly addressing sustainability-related criteria. Top-ranked projects were selected for further analysis, as they likely contained valuable insights into sustainability-oriented innovation. This ranking process served as a targeted filter to ensure that the subsequent analysis focused on the most contextually relevant project data [

22].

It is important to note that similarity scores were not used to evaluate individual project quality or impact. Instead, they served as thematic indicators to assist filtering. Cosine similarity functioned as a heuristic to detect dominant sustainability patterns across the dataset. While no formal validation metrics (e.g., precision, recall) were applied, the term list for vector modeling was carefully curated based on the literature and policy documents. This is acknowledged as a methodological limitation and discussed further in

Section 2.6.

The application of cosine similarity in this research presented several key advantages. It enabled the efficient processing of large-scale textual datasets, supported reproducible comparisons, and was adaptable to various document formats. These features made it well-suited for analyzing the 54,054 selected projects [

23].

To validate the algorithm results, a manual review of the highest-ranked projects was performed. This ensured their alignment with research objectives and confirmed that similarity scores captured meaningful relationships. Any outliers were flagged for further inspection, enhancing the reliability of the findings.

2.3. Identification and Structuring of Sustainability Criteria

After ranking the projects based on cosine similarity, the next step was to identify and categorize the sustainability criteria most reflected in the selected corpus. These criteria are essential for evaluating innovation projects based on environmental, social, and economic performance, ensuring that project outcomes are aligned with long-term Sustainable Development Goals (SDGs). This classification follows the triple bottom line framework, which emphasizes balance across people, planet, and profit dimensions [

24,

25].

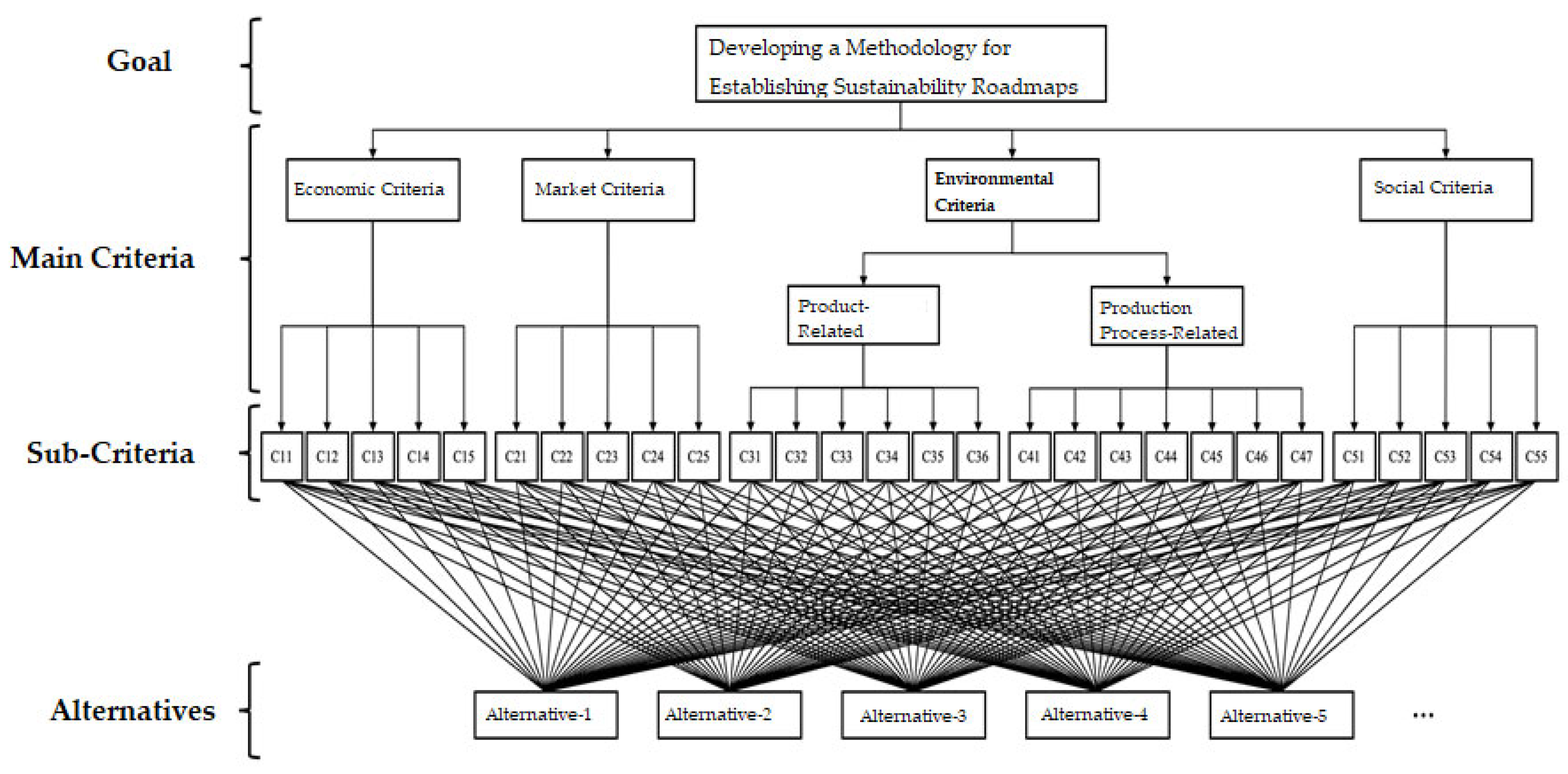

The identified sustainability criteria were grouped into four major dimensions, “Economic”, “Market”, “Environmental”, and “Social”, each with several sub-criteria, forming a multi-level structure. This classification facilitates the precise evaluation of sustainability within innovation projects and supports the prioritization process in later stages using the AHP.

The identification of sustainability criteria initiated a thematic analysis of the selected projects’ textual content, particularly their descriptions and associated metadata. Thematic analysis is a commonly used qualitative method used to identify, analyze, and report patterns—or themes—within text datasets [

26]. This approach is particularly valuable in exploratory research aimed at extracting complex constructs from unstructured data sources, such as sustainability dimensions in innovation [

27].

In this research, thematic analysis combined manual review and automated text mining techniques. The primary objective was to extract recurring sustainability-oriented themes, including economic viability, market relevance, environmental performance, and social contribution. To ensure rigor and replicability, the analysis followed a structured, five-phase process [

26]:

Initial immersion in project descriptions and metadata to understand the content;

Identification and coding of key sustainability-related terms and expressions such as “cost efficiency,” “market demand,” “carbon footprint,” and “community engagement”;

Organization of the coded items into broader thematic categories aligned with the sustainability criteria framework;

Review and refinement of the thematic groupings to ensure conceptual accuracy and alignment with the research objectives;

Final definition and naming of each theme to establish a coherent analytical structure for subsequent evaluation.

Based on this process, the sustainability criteria were finalized and categorized into four dimensions as outlined below:

Economic Criteria focus on the financial feasibility and economic value of innovation projects. Indicators include cost-effectiveness, Return On Investment (ROI), job creation, and broader contributions to economic development;

Market Criteria address the potential scalability and competitiveness of innovations. Indicators include market demand, customer satisfaction, anticipated market share, and the capacity for expansion;

Environmental Criteria assess the ecological impact, divided into two subcategories:

- -

Product-Related Environmental Criteria: energy efficiency, renewable material usage, recyclability, and reduction in greenhouse gas emissions;

- -

Production Process-Related Environmental Criteria: waste and resource management, energy and water consumption, emission control, and compliance with environmental standards.

Social Criteria consider the societal implications of innovation activities. Indicators include community engagement, equitable labor conditions, gender inclusion, access to education and healthcare, and improvements in overall quality of life.

Together, these criteria constitute a holistic framework for sustainability assessment, aligned with established models of sustainable innovation and the triple bottom line perspective [

25,

28].

To ensure the robustness and global relevance, the criteria were cross-referenced with internationally recognized frameworks, particularly the United Nations Sustainable Development Goals (SDGs) and Global Reporting Initiative (GRI) standards [

14,

29]. This comparison validated the framework’s conceptual soundness and enhanced its applicability across sectors and regions.

The finalized criteria set provides the analytical basis for the next research stages, including the design of the survey instrument and the application of the AHP. By systematically defining, structuring, and validating these criteria, the research ensures methodological rigor and contextual relevance in assessing innovation initiatives. This framework strengthens the research’s capacity to generate actionable insights aligned with the broader objectives of sustainable innovation and strategic decision-making in complex organizational settings.

2.4. Application of the Analytic Hierarchy Process (AHP) for Sustainability Prioritization

At the beginning of the research, several established MCDM methods were reviewed to ensure alignment with the research’s hierarchical structure and objectives. Given the multi-level organization of the sustainability criteria—including main categories and sub-dimensions—AHP was selected as the most suitable method.

Its intuitive structure and clarity made AHP appropriate for a diverse group of DMs with varying levels of expertise. Additionally, AHP facilitates structured reasoning in complex decision environments, integrates both qualitative judgments and quantitative data, and promotes participatory decision-making by incorporating expert and stakeholder input.

Originally developed by Saaty [

6], AHP is a structured MCDM method designed to facilitate complex evaluations involving both qualitative and quantitative inputs. Its hierarchical structure enables DM to decompose a complex problem into a set of interrelated decision elements, including objectives, criteria, sub-criteria, and alternatives [

5,

30]. This structured breakdown allows for systematic comparison and supports transparent and replicable analysis.

AHP is used to determine the relative importance of sustainability criteria identified through thematic analysis. It serves as a bridge between expert judgment and systematic prioritization, allowing the incorporation of stakeholder perspectives into an analytically robust framework [

31,

32]. Using the results of a structured expert survey, AHP derives weightings for both main and sub-criteria, supporting evidence-based decisions in sustainable innovation management.

The AHP implementation process involves the following steps [

5]:

Problem definition and objective determination;

Determination of main and sub-criteria;

Identification of decision alternatives;

Establishing the hierarchical structure;

Constructing pairwise comparison matrices;

Pairwise comparison matrices for main and sub-criteria;

Consistency Ratio (CR) calculation;

Calculation of priority weights;

Determining priorities and calculating alternative scores.

2.4.1. Problem Definition and Objective Determination

The initial phase of AHP involves clearly defining the problem and specifying the objective that the decision-making process seeks to achieve. This step establishes the analytical foundation for evaluating all variables and alternatives under a unified goal. A well-formulated problem statement enhances methodological rigor and improves the reliability of the resulting decisions [

5].

This stage involves identifying root causes, relevant stakeholders, and how the issue affects different domains. If the problem is poorly defined, it can lead to ambiguity in subsequent steps, making it harder to select appropriate criteria or evaluate alternatives, and ultimately weakening the model’s effectiveness.

2.4.2. Determination of Main and Sub-Criteria

Defining evaluation criteria in a structured way is a key step in AHP, as it provides the foundation for valid comparisons and decisions. In this research, the criteria are organized hierarchically into four core dimensions: Economic, Market, Environmental, and Social—a structure derived from the sustainability-focused innovation literature and MCDM frameworks [

28,

33]. To capture both product-level and process-level sustainability aspects, the Environmental criteria are further divided into Product-Related and Production Process-Related categories.

This classification was informed by internationally accepted sustainability standards, including the United Nations SDGs and the GRI Sustainability Reporting Standards, ensuring global relevance and practical applicability [

14,

29].

All sub-criteria and their definitions are presented in Tables (

Table 1,

Table 2,

Table 3,

Table 4,

Table 5 and

Table 6), organized by category and uniquely coded for reference in subsequent AHP analysis. This structure improves transparency, consistency in data collection, and traceability throughout the process.

2.4.3. Identification of Decision Alternatives

In the AHP, the decision-making process is structured into four hierarchical levels: goal, main criteria, sub-criteria, and alternatives. This structure enables DMs to systematically prioritize complex variables and clarify how each component contributes to the final outcome [

5,

31].

At the top is the

goal, which defines the primary objective of the decision process. All criteria and alternatives are evaluated based on how well they support this goal [

5]. Below the goal are the main criteria, representing broad dimensions essential to achieving the objective. These provide a structured basis for assessment [

32]. Each main criterion is further divided into sub-criteria, which offer greater detail and precision in evaluation. This allows DMs to incorporate both expert judgment and quantitative data [

33]. At the lowest level of the hierarchy, the alternatives represent the different options available. These are assessed against all criteria to identify the most suitable solution. The hierarchical structure enhances consistency, transparency, and cognitive alignment in the decision process [

31].

2.4.4. Establishing the Hierarchical Structure

The main and sub-criteria established in this research, along with the hierarchical structure developed for the analysis, are presented in

Figure 2.

2.4.5. Constructing Pairwise Comparison Matrices

In AHP, pairwise comparison matrices are essential for systematically comparing elements such as criteria and alternatives. These matrices allow DMs to evaluate the relative importance of elements by conducting two-by-two comparisons, thus facilitating the quantification of subjective judgments into priority weights [

5].

Each pairwise comparison matrix is square, with the number of rows and columns corresponding to the number of elements being compared. The diagonal entries are always assigned a value of 1, since an element is equally important to itself. If element A is judged to be more important than element B, the corresponding entry in the matrix reflects the relative strength of that preference; the reciprocal of that value is automatically assigned to the inverse comparison (B compared to A). This ensures that the matrix maintains reciprocal consistency.

The judgments are typically expressed using the fundamental scale developed by Saaty [

5], known as the Saaty Scale, which ranges from 1 to 9.

Table 7 summarizes this scale and its qualitative interpretations.

These matrices are constructed separately for both the main criteria and sub-criteria, as well as for the alternatives when needed, depending on the hierarchical structure of the problem. They produce weighted priorities based on the DMs’ evaluations and ensures consistency.

Beyond their intuitive clarity, pairwise comparisons offer mathematical robustness. Combined with consistency checks and eigenvalue calculations, they enhance the transparency and reliability of multi-criteria decisions [

31,

32].

2.4.6. Pairwise Comparison Matrices for Main and Sub-Criteria

The pairwise comparison matrices developed for the main and sub-criteria in this research form the foundation for determining the relative importance of evaluation factors within the AHP framework. These matrices maintain a symmetric structure, where each element reflects the perceived importance of one criterion over another, as assessed by DMs using the Saaty Scale [

5].

As an example, the matrix for the main criteria is shown in

Table 8. Similar matrices were constructed for each sub-criterion group, including economic, market, environmental (product-related and process-related), and social dimensions. To maintain clarity and avoid repetition, the remaining matrices are provided in

Appendix A.

When multiple DMs provide their judgments, it becomes essential to aggregate these evaluations systematically to ensure consistency and reliability. Within the AHP, the geometric mean method is widely accepted as the most appropriate approach for synthesizing individual pairwise comparisons [

5]. This technique enables the combination of individual judgments while minimizing the influence of outliers, thereby offering a more robust and balanced aggregation compared to arithmetic averaging.

The geometric mean for each pairwise comparison is calculated across all DMs according to Equation (2), as follows:

where

represents the final pairwise comparison value;

denotes the pairwise comparison value assigned by the -th DM;

is the total number of DMs.

After deriving the aggregated pairwise comparison matrix, the next essential step is matrix normalization. Normalization ensures that the priority weights extracted from the matrix are both consistent and meaningful by converting the raw scores into a standardized scale. This is achieved by dividing each element of a column by the sum of that column in the aggregated matrix by using Equation (3).

The normalization process is expressed as

where

represents the normalized value in row and column ;

is the original value from the aggregated pairwise comparison matrix;

denotes the sum of all values in column .

This procedure ensures that each column in the normalized matrix sums to one, enabling the direct computation of relative weights.

Normalization also plays a crucial role in minimizing distortions caused by differences in measurement scales. It allows for the comparison of diverse criteria on a common scale, promoting fairness and clarity in the evaluation process.

Once the normalized matrix is obtained, the eigenvector representing the priority weights is computed by averaging the values in each row. This yields the relative importance of each criterion as a proportion of the total, as shown in Equation (4), as follows:

where

denotes the priority weight of criterion ;

represents the normalized value of the , element;

is the total number of criteria.

These priority weights

wi are then assembled into a vector form, known as the eigenvector, as shown in Equation (5)

The eigenvector encapsulates the overall priority distribution among criteria or alternatives, based on the DMs’ input. It transforms qualitative judgments into a quantitative format, enabling a consistent and objective ranking. Also, it serves as the foundation for subsequent steps in the AHP methodology, such as consistency checking and final decision synthesis.

This method not only enhances the transparency of the evaluation process but also ensures that the final decision is well-grounded in a rational, systematic, and mathematically sound framework [

5].

2.4.7. Consistency Ratio (CR) Calculation

To assess whether the assigned importance weights are consistently derived, the CR is calculated [

5]. This process involves computing the Consistency Index (CI) and the Random Index (RI).

The CI is a diagnostic tool for evaluating the degree of consistency within the pairwise comparison matrices. It quantifies how closely the judgments of DMs align with a perfectly consistent matrix. A lower CI indicates greater consistency, whereas a higher CI highlights the need for potential revisions.

The CI is calculated using Equation (6), as follows:

where

is the largest eigenvalue;

is the number of criteria in the comparison matrix.

To calculate the CI, the largest eigenvalue (

) must first be obtained. This involves multiplying the pairwise comparison matrix (A) by the eigenvector (w) derived from the normalized matrix as shown in Equation (7):

where

is the resulting eigenvalue vector;

is the aggregated comparison matrix;

is the priority vector (eigenvector) derived in the previous step.

This operation reflects how well the original matrix corresponds with the calculated priorities, forming the basis for computing .

Next, the largest eigenvalue is calculated as the average ratio of each element in

w′ to the corresponding element in

w, as shown in Equation (8).

where

is the value from the eigenvalue vector;

is the corresponding priority weight;

is the number of criteria.

This step is critical because it reflects the internal coherence of the DMs’ judgments. Once the is known, the CI can be computed using Equation (6).

After determining the CI, the appropriate RI value is selected from “Saaty’s Random Index (RI) Table” (

Table 9), which contains empirically derived average consistency indices for randomly generated matrices of various sizes.

is the size of the matrix;

is the corresponding index.

This value is used in the CR calculation to determine whether the pairwise comparisons exhibit an acceptable level of consistency.

After the CI and RI are calculated, the CR can be determined. The CR is computed as shown in Equation (9).

This ratio indicates whether the level of inconsistency in the pairwise comparisons is acceptable. If CR < 0.10, the level of consistency is considered sufficient. However, if CR ≥ 0.10, it suggests that inconsistencies exist in the judgment data, requiring DMs to revisit and refine their responses.

A consistent matrix confirms that the decision-making process is logical and reliable, strengthening the validity of the results.

2.4.8. Calculation of Priority Weights

In the AHP, the numerical values that reflect the relative importance of criteria or alternatives are referred to as priority weights. These values—also known as eigenvectors—are derived from pairwise comparisons conducted by DMs and form the foundation for subsequent ranking and decision-making processes [

5].

The priority weights constitute a weight vector that quantifies how much influence each criterion or alternative has in relation to the others. This vector ensures that the decision-making process is both systematic and grounded in quantifiable judgments. The accurate computation of these weights is critical to preserving consistency and objectivity across the model.

Once the CR has been verified to fall within an acceptable range (i.e., CR < 0.10), the normalized eigenvector obtained in Equation (4) is interpreted as the set of priority weights. These values are typically expressed as percentages and directly indicate the relative significance of each criterion or the preference level of each alternative within the decision hierarchy.

2.4.9. Determining Priorities and Calculating Alternative Scores

Once the priority weights (eigenvectors) for the criteria have been established, they are ranked from highest to lowest to determine their relative importance [

5]. This ranking facilitates the identification of which criteria hold the greatest weight in the decision-making process.

Following this prioritization, the next step involves calculating the final scores for each decision alternative. This is accomplished by multiplying the priority weight of each criterion by the corresponding performance value of the alternative for that criterion. The resulting weighted scores are then summed to yield an overall score for each alternative.

This method enables a comprehensive and objective evaluation of all alternatives, considering both their individual performances and the relative significance of the criteria. Ultimately, the alternative with the highest aggregated score is considered the most favorable within the context of the established decision framework.

2.5. Design and Administration of the Expert Survey

Following the structured identification and validation of sustainability criteria, the next methodological step involved the development of a tailored expert survey to capture expert evaluations of these criteria. The survey was structured to elicit both qualitative reflections and quantitative assessments, thus enabling a multidimensional understanding rooted in practice and scholarship. Adhering to established survey methodology standards, the design emphasized clarity, logical flow, and respondent accessibility to reduce bias and improve data quality [

34]. This approach ensured that the instrument was both analytically rigorous and user-oriented.

The survey was organized into four main sustainability dimensions: “Economic,” “Market,” “Environmental” (further divided into “product-related” and “production process-related” aspects), and “Social”. In each category, a combination of question types was employed to gather both structured and exploratory responses. Closed-ended items used a nine-point Likert-type scale adapted from Saaty’s fundamental scale to capture participants’ judgments regarding the relative importance of criteria. This scale ranged from 9 (extremely important) to 1/9 (extremely unimportant), enabling precise pairwise comparisons. Open-ended questions were included to elicit qualitative insights, allowing respondents to elaborate on the rationale behind their evaluations and contextual factors influencing their decisions [

35].

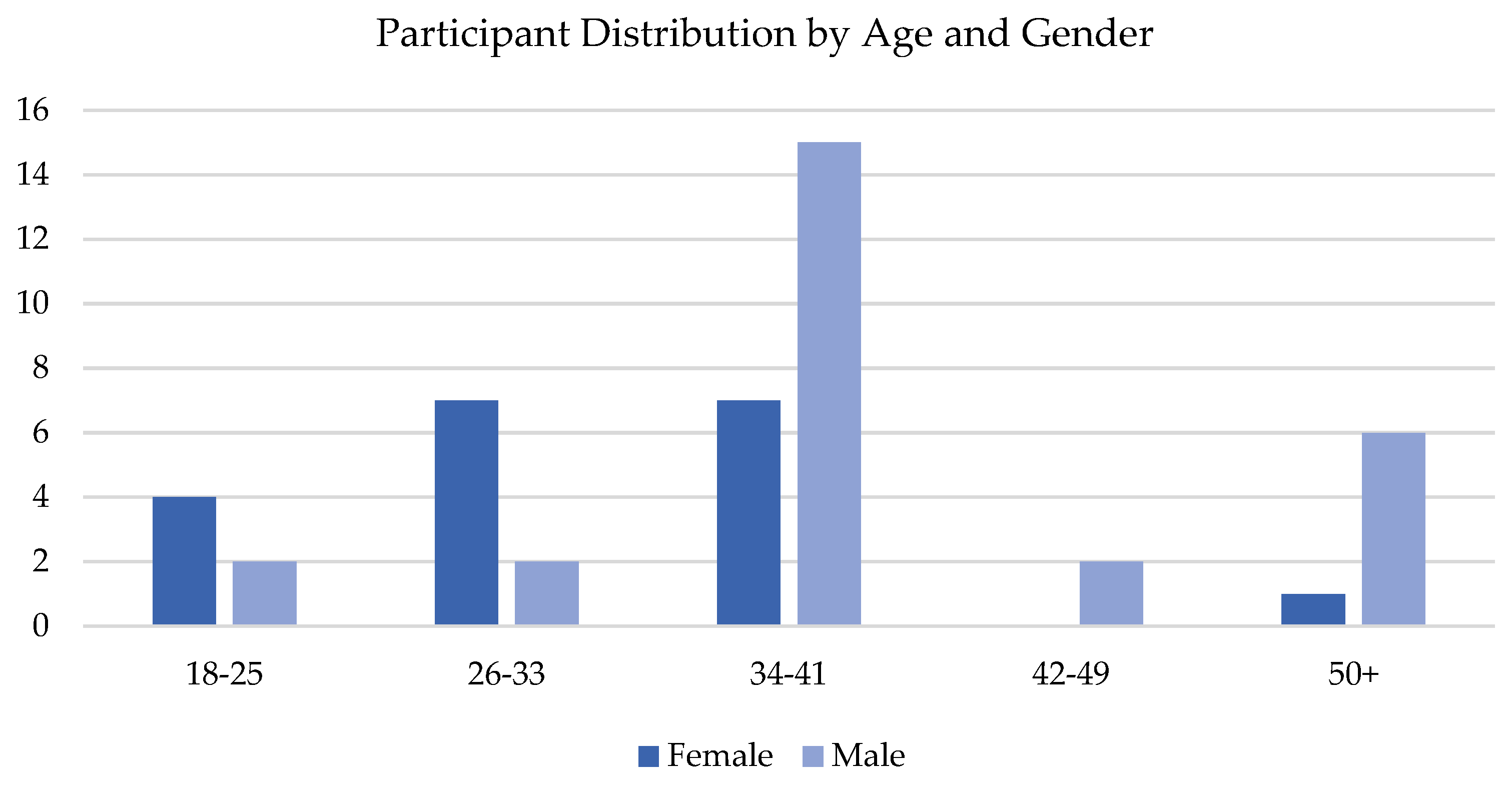

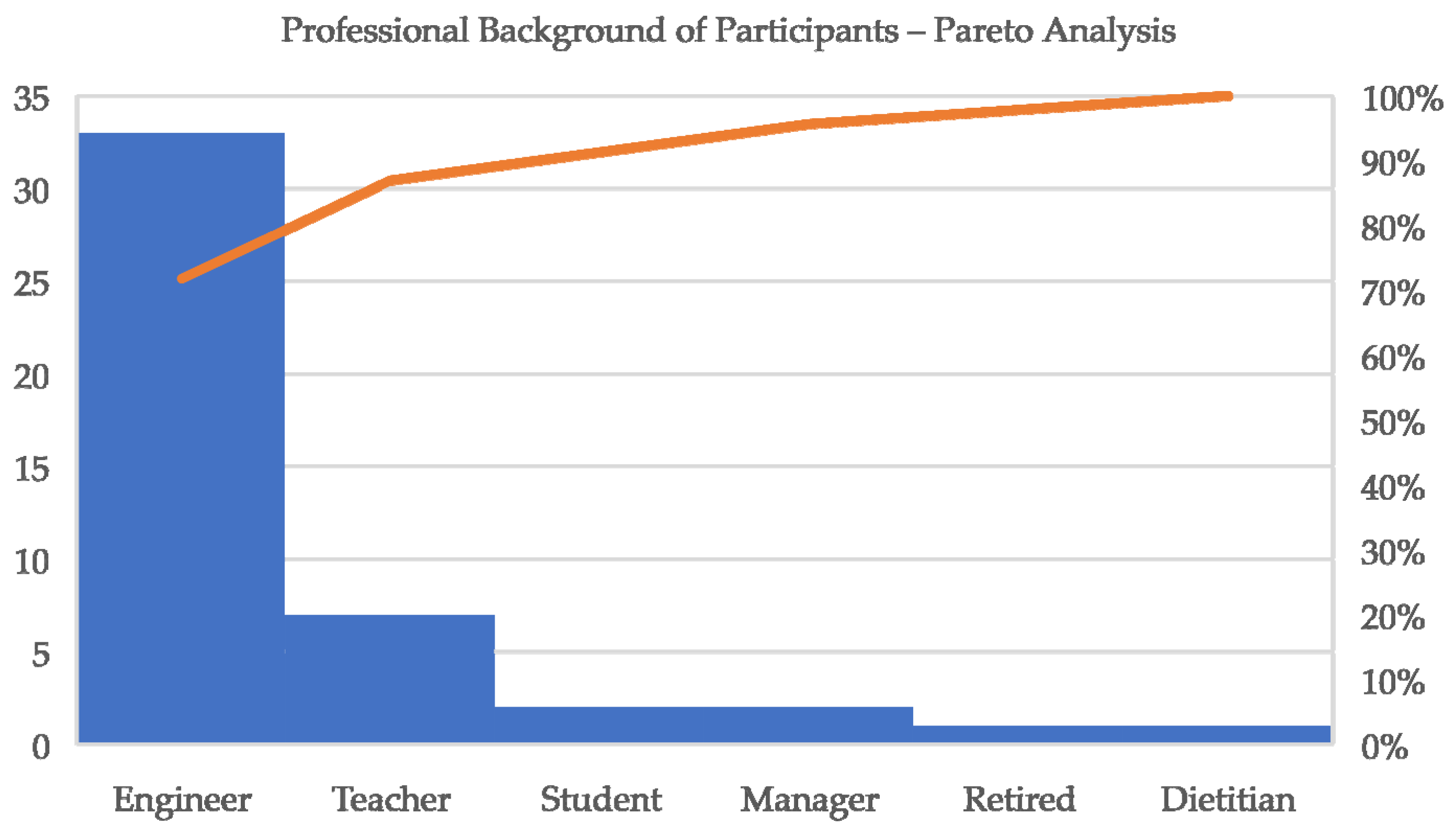

A total of 46 individuals participated in the AHP survey, selected from a national stakeholder database with a focus on demonstrated expertise in sustainability and innovation. Participants were chosen to reflect a diversity of professional backgrounds—including engineers, academics, students, retirees, dietitians, and teachers—with particular emphasis on those engaged in engineering, academic, or administrative roles relevant to the machinery manufacturing context. The selection criteria prioritized individuals with domain-specific knowledge and active involvement in organizational or policy-level sustainability efforts, enhancing both the validity and generalizability of the results [

36]. Prior to the survey, participants received a brief orientation on the AHP methodology, the logic of pairwise comparisons, and the use of the 1–9 rating scale. This training material was also embedded in the online survey form as a downloadable reference to ensure consistency in interpretation. The survey was administered via a secure online platform (Google Forms), allowing for broad geographic access and efficient data collection. Respondents were given two weeks to complete the questionnaire; with reminder emails sent one week after initial distribution to minimize non-response bias [

35]. All responses were anonymized and reported in aggregate to protect privacy.

To interpret the survey data, a dual-method approach was used. Quantitative analysis employed descriptive statistics (means and standard deviations) to rank the sustainability criteria. In parallel, open-ended responses were analyzed using Braun and Clarke’s six-phase thematic analysis framework [

37] This combination revealed both prioritized criteria and the reasoning behind them, enhancing the depth and interpretability of the results [

5].

To reduce the number of comparisons each respondent had to complete, the minimum number of pairwise comparisons was calculated using Equation (10). This ensured that all necessary comparisons were covered without redundancy. By limiting unnecessary repetition, this design reduced cognitive fatigue and improved the accuracy and reliability of responses.

where

represents the total number of criteria included in the evaluation.

2.6. Limitations, Generalizability, and Future Research

This research proposes a structured, data-driven framework for prioritizing sustainability criteria using AHP and cosine similarity analysis. Despite its methodological strengths, several limitations must be acknowledged.

First, AHP depends on subjective expert input. The prioritizations may reflect individual perceptions, biases, or institutional roles. Although efforts were made to diversify the panel of 46 decision-makers from academia, industry, and public sectors, the sample was still centered on the machinery manufacturing context in Türkiye and Europe. This may limit the generalizability of the results to other sectors or regions.

Second, the project dataset was filtered using domain-specific keywords and cosine similarity. While effective in ensuring thematic relevance, this method may have excluded projects that support sustainability but lack explicit terminology. Moreover, the filtering process was not formally validated using standard metrics such as precision or recall, introducing uncertainty about completeness.

Third, the research lacks qualitative depth. While the AHP and text-based methods provided quantitative structure, the absence of expert interviews or case-based inquiry limits understanding of contextual motivations behind criteria rankings.

To overcome these limitations, future research should consider the following:

Using longitudinal methods to track how sustainability priorities evolve in response to policy, technology, and social change;

Expanding the geographic and industrial diversity of expert participants to improve generalizability;

Incorporating qualitative methods—such as semi-structured interviews, focus groups, and case studies—to enrich interpretation and support triangulation.

Combining these approaches would strengthen both the theoretical grounding and practical relevance of future decision-support models. Ultimately, this can help create more adaptive and inclusive frameworks for sustainability-focused innovation.