1. Introduction and Background Literature

The pursuit of sustainable construction and resilient infrastructure has directed the incorporation of new materials and techniques. Resilience provides for long-term durability against many stresses, while sustainability is a mix of recycled and reclaimed materials, lowers the carbon footprint, and extends pavement life [

1]. Conventional asphalt manufacturing depletes natural resources and disrupts ecosystems [

2]. Consequently, the sector has come to adopt non-conventional materials because of resource constraints and growing traffic loads [

3]. Sustainable construction also promotes long-term cost advantages by building climate-resilient roads for the future of sustainability [

4]. Governments are also turning to waste-derived alternatives in road construction for curbing landfill overflows and the optimal use of resources [

5], of which steel slag, waste rubber, RAP, RCA, and construction waste have proven to be effective [

6,

7,

8].

Recycled materials, particularly Recycled Concrete Aggregates (RCAs) and Reclaimed Asphalt Pavement (RAP), have emerged as among the most prominent studies in pavement engineering research [

9,

10]. The construction sector remains one of the leading causes of waste [

11], propelling demand for sustainability strategies that reduce resource dependence, energy consumption, and greenhouse gas emissions [

12]. Construction and Demolition Waste (CDW), driven by rising landfill costs, is an economy-saving practice [

11]. The incorporation of recycled materials in asphalt mixtures enhances structural performance, supports environmental conservation, and mitigates landfill overuse. Although landfilling Recycled Concrete Aggregate (RCA) remains a common practice, it poses serious environmental risks, including leachate generation and groundwater contamination [

13]. Recycling (RCA) not only helps reduce waste disposal volumes and preserve natural limestone resources, but its potential application in asphalt mixtures remains underexplored in current research.

Various studies have investigated the impact of utilizing RCA on pavement performance with different percentages of RCA incorporation. Rizvi et al. (2010) demonstrated optimal performance with 15% RCA, as higher replacement levels compromised both strength and permeability [

14]. Mills-Beale and You (2010) found that although RCA reduced dynamic stiffness, mixtures remained compliant with performance specifications [

15]. Nwakaire et al. (2020) found that a 40% Recycled Concrete Aggregate (RCA) content delivered optimal pavement performance [

16]. Sanchez-Cotte et al. (2020) reported environmental advantages with stable mechanical properties in Hot Mix Asphalt (HMA) [

17]. Al Hassanieh (2014) proposed using 20% RCA for the best stability with increased rut resistance and fatigue cracking at different levels [

6]. Durango et al. (2023) found that RCA replacements of up to 15% provided satisfactory mechanical performance while also offering sustainability benefits [

18].

The application of RCA in asphalt mixtures presents several challenges. Due to its high porosity and water absorption, RCA increases bitumen demand and material costs. Additionally, residual mortar weakens cohesion, particularly under moisture exposure. The low density and strength of RCA further reduce mix stability and water resistance, while its abrasive nature complicates compaction and long-term durability [

19].

On the other hand, reusing RAP in asphalt mixtures provides significant benefits, such as resource conservation, support for circular economy principles, and reduced environmental impacts—including lower leachate and methane emissions [

20]. RAP also improves road durability, decreases dependence on virgin materials, and reduces production costs and energy consumption [

21].

Studies have evaluated RAP’s performance at varying replacement levels. Saha et al. (2017) reported that mixtures containing 20% RAP demonstrated enhanced rutting resistance, whereas 24% RAP mixtures exhibited reduced cracking resistance [

22]. Similarly, Winkle et al. (2016) observed that high-RAP mixes maintained strong performance but became more prone to thermal cracking with prolonged use [

23].

Al-Qadi et al. (2012) investigated high-RAP mixtures with various binders and found that they consistently outperformed conventional mixes especially at 50% RAP content [

24]. However, their study emphasized the need for binder grade adjustments when RAP exceeded 30% to maintain optimal performance [

24].

Colbert and You (2012) demonstrated that fractionated RAP significantly enhanced performance under high-temperature and heavy-load conditions, improving both rutting resistance and resilient modulus [

25]. Meanwhile, Naser et al. (2022) explored combined mixes of RAP and RCA, observing that RAP boosted Marshall stability while RCA primarily affected volumetric properties [

26].

Furthermore, Sapkota et al. tested recycled aggregate contents up to 100%, reporting substantial gains in stiffness, stability, and moisture resistance [

27]. Similarly, Noura et al. (2023) analyzed stiffness and fatigue life in recycled-material mixes, revealing superior properties compared to conventional asphalt [

28]. The work also yielded a highly accurate fatigue prediction model, achieving near-perfect correlation [

28].

Recent research has demonstrated the growing viability of recycled materials in pavement construction. Pradhan et al. (2023) systematically evaluated RAP incorporation rates from 0% to 30%, ultimately recommending 20% RAP as the optimal dosage for achieving balanced strength and durability in bituminous pavements [

29]. These findings are supported by parallel studies from Salehi et al. (2021), Aytekin et al. (2022), and Mariyappan et al. (2023), which collectively highlight the potential of RAP and RCA to substantially reduce construction waste, lower emissions, and minimize reliance on virgin materials [

30,

31,

32,

33,

34]. The mechanical performance of these recycled materials has been rigorously validated with Rout et al. (2023) and Covilla-Varela et al. (2023) confirming RAP’s structural suitability for asphalt mixtures and RCA’s durability in concrete applications [

35,

36]. Notably, research by Behnood (2019) and subsequent researchers has shown that properly rejuvenated RAP mixtures can match or exceed the performance of conventional asphalt [

37,

38,

39]. Similarly, studies by Shaban et al. (2019) and Makul et al. (2021) have demonstrated RCA’s effectiveness in concrete when appropriate processing methods are applied [

40,

41]. Environmental assessments conducted by Yaro et al. (2023) [

33] and Al-Bayati et al. (2018) [

42] further reinforce the sustainability benefits, documenting significant reductions in carbon footprint and landfill dependency [

42,

43,

44,

45]. However, several challenges must be addressed, including material variability due to differing source compositions and processing histories [

46], potential contamination from substances like chlorides or sulfates [

47], and concerns about interfacial bonding between recycled materials and new binders that may affect long-term performance [

47]. These considerations highlight the need for careful quality control and mix design optimization when implementing recycled materials in pavement construction. To mitigate these issues, several approaches have been proposed in the literature and practice: implementing stringent material characterization protocols to manage variability, applying rejuvenators to restore aged binder properties, incorporating anti-stripping agents to enhance moisture resistance, and establishing performance-based limits for recycled content in critical pavement layers. These strategies collectively enable the effective use of RCA and RAP while meeting both sustainability goals and engineering performance requirements in modern pavement design. These strategies help to ensure that the use of RCA and RAP aligns with both sustainability objectives and performance-based design requirements in asphalt pavement engineering.

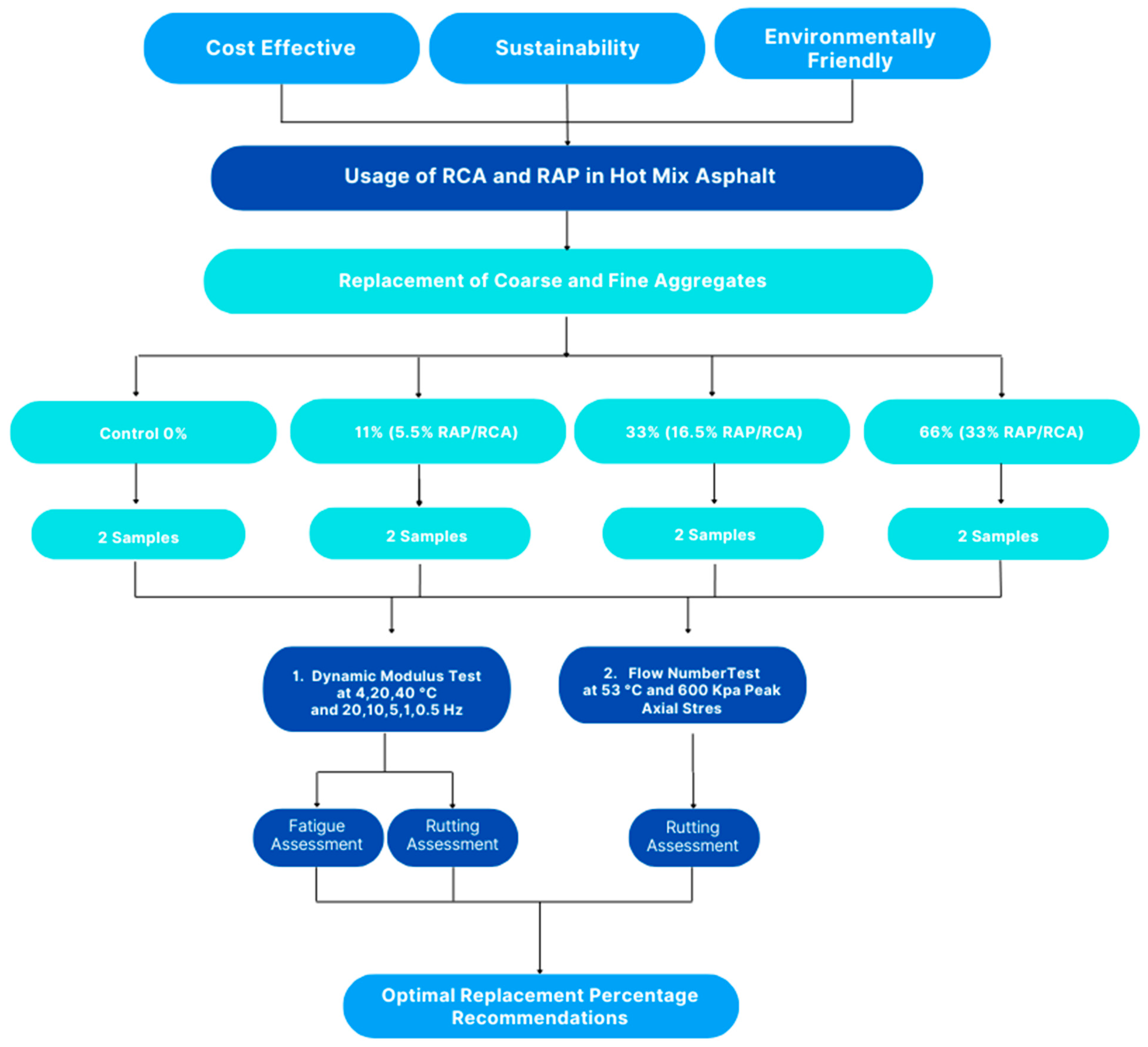

The integration of RAP and RCA presents a promising opportunity to enhance HMA performance while simultaneously reducing both environmental footprint and material costs. Current research, however, has primarily examined these materials in isolation rather than exploring their combined potential. Existing studies have also tended to focus on conventional performance indicators like Marshall stability and moisture resistance, potentially overlooking other critical aspects of pavement performance. This limited scope creates a significant knowledge gap regarding how varying replacement percentages and material combinations affect overall mixture behavior. This research addresses this gap by systematically evaluating integrated RAP–RCA mixtures across multiple performance dimensions. By expanding the assessment beyond traditional metrics, this study provides comprehensive insights that could advance the development of more sustainable and durable road infrastructure solutions.

4. Results and Discussion

4.1. Volumetric Composition

The optimal asphalt binder content was determined to achieve 4% air voids at the specified number of design gyrations (Ndes). In general, increasing Ndes tends to reduce the asphalt binder content, which may compromise the durability of the mix. Conversely, lowering Ndes usually leads to higher binder content, enhancing the mixture’s durability. In this study, all mixtures were compacted using 75 gyrations, as recommended for mixes intended for low to medium traffic volumes [

85,

86,

87,

88].

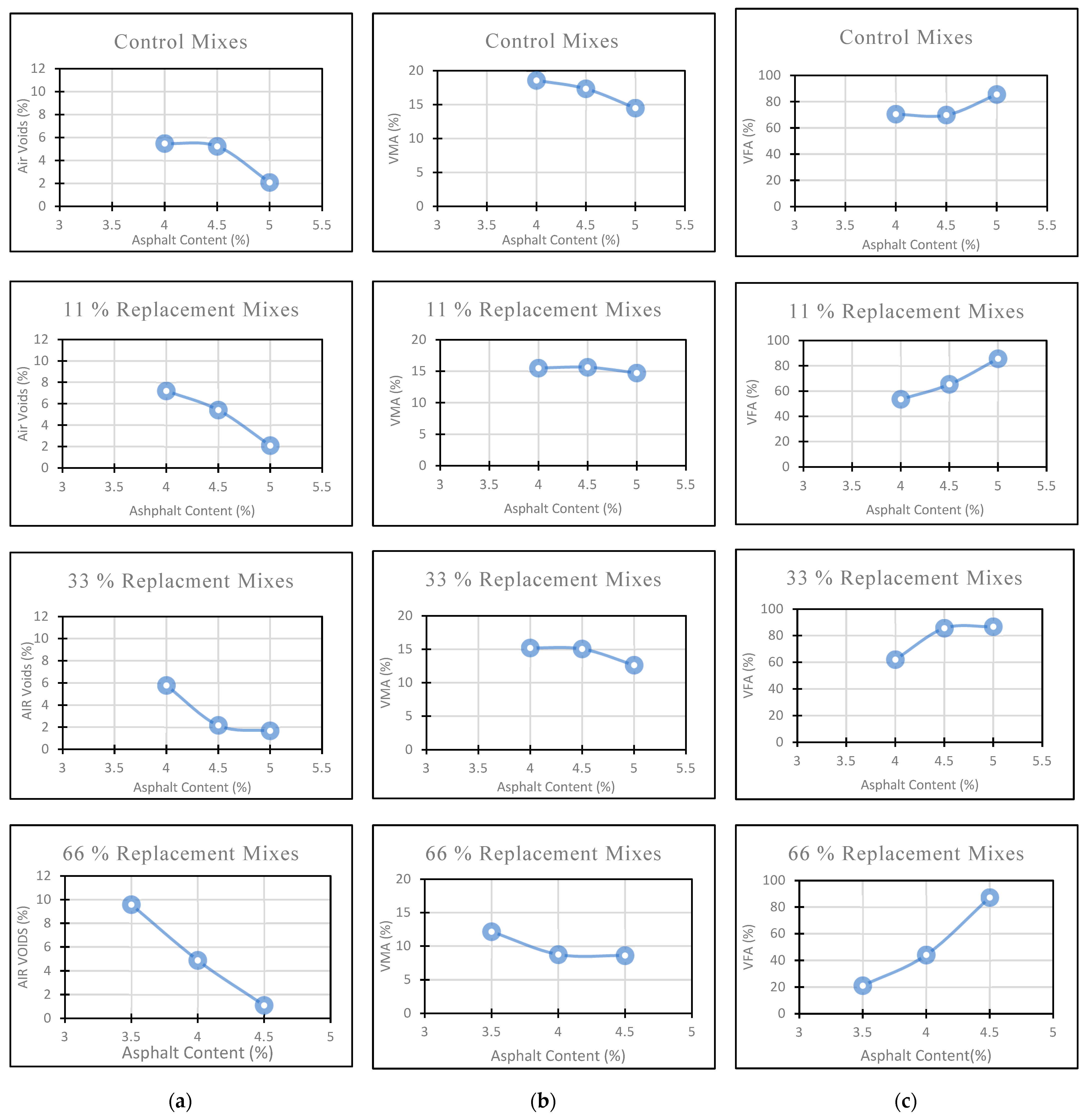

Given that the mixtures incorporate RCA and RAP, which are both recycled materials, they are specifically designed for lower traffic categories. The inclusion of such materials can significantly alter key mixture properties, such as stiffness and viscosity, which in turn affect the mix’s compaction behavior. These changes may reduce the compactive effort required to achieve the target density, potentially requiring fewer gyrations to reach optimal performance levels [

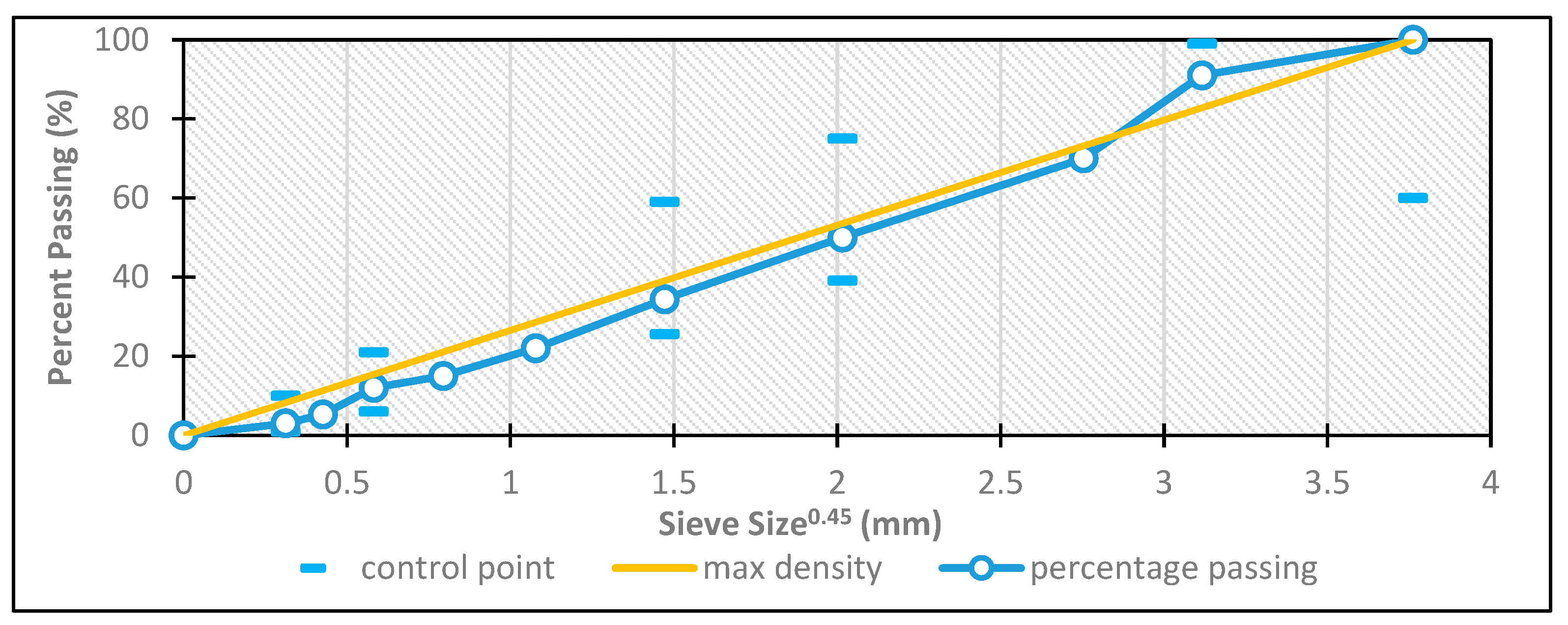

89]. The optimal asphalt binder contents for both the control and modified mixtures along with the volumetric properties of the tested mixtures, which were designed with progressively higher recycled material replacement rates (11%, 33%, and 66%) are summarized in

Table 3. Additionally,

Figure 4 provides a graphical representation showing how asphalt content influences air voids (a), voids in mineral aggregate (VMAs) (b), and voids filled with asphalt (VFAs) (c). The recycled content consisted of equal parts RCA and RAP, each contributing 50% of the total replacement:

The 11% replacement mixture comprised 5.5% RCA and 5.5% RAP.

The 33% replacement mixture included 16.5% RCA and 16.5% RAP.

The 66% replacement mixture contained 33% RCA and 33% RAP.

This systematic increase in recycled content allowed for a comprehensive evaluation of its impact on volumetric properties, as detailed in

Table 3.

The substitution of RCA and RAP in place of conventional limestone aggregates generally met the Superpave VMA design criteria with the exception of the mixture containing 66% replacement. Meeting these volumetric criteria is essential, as they directly influence the durability of asphalt mixtures incorporating recycled materials compared to the control mix. The observed reduction in asphalt binder content across mixtures with RCA and RAP can be attributed to the VMA specification, which defines a minimum binder volume necessary to ensure adequate durability.

Mixtures containing RCA and RAP also demonstrated lower VFA values relative to the control mixture. Although all mixtures satisfied the Superpave minimum VMA requirement, the 66% replacement mix fell below the acceptable threshold. A similar pattern was observed for VFA values, where all mixes remained within the Superpave-specified range, except for the 66% replacement mix, which registered a VFA below the required minimum.

This particular mix, containing the highest proportion of recycled materials, also exhibited the lowest optimum binder content. A clear trend emerged: as the level of RCA and RAP replacement increased, both binder content and VMA/VFA values consistently decreased. Despite failing to meet the VMA and VFA thresholds, the 66% replacement mix was still included in the study for experimental purposes. Specifically, it was subjected to |E*| testing followed by FN evaluation, though it is not considered suitable for practical pavement construction.

4.2. Dynamic Modulus |E*|

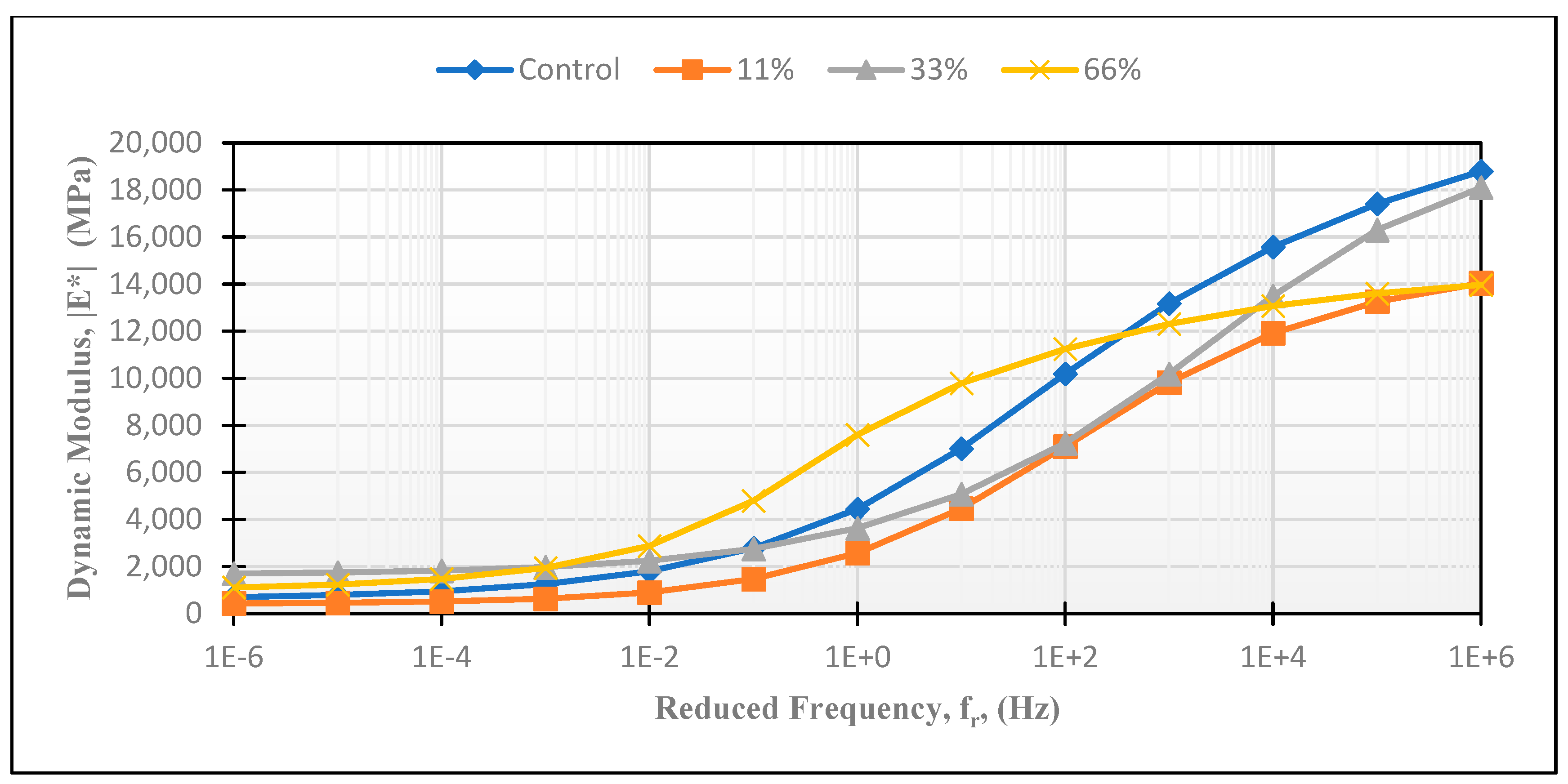

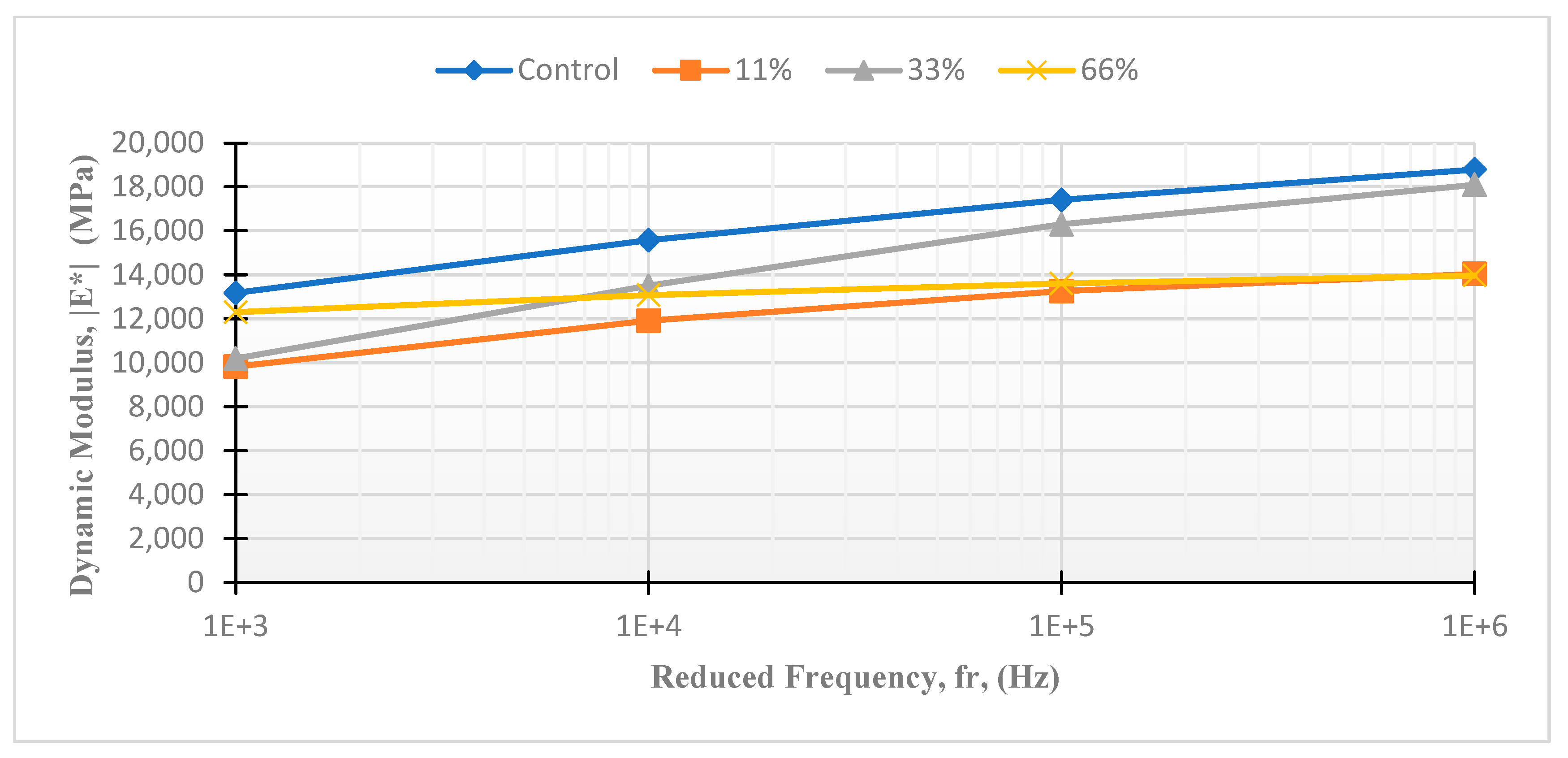

Figure 5 presents a semi-logarithmic plot of the average |E*| master curves for all mixtures containing RCA and RAP. These mixes, incorporating recycled materials, are intended for lower traffic categories compared to the control mixture, which consists entirely of virgin aggregates. For comparison, the master curve of the 0% replacement mix (control) is also included.

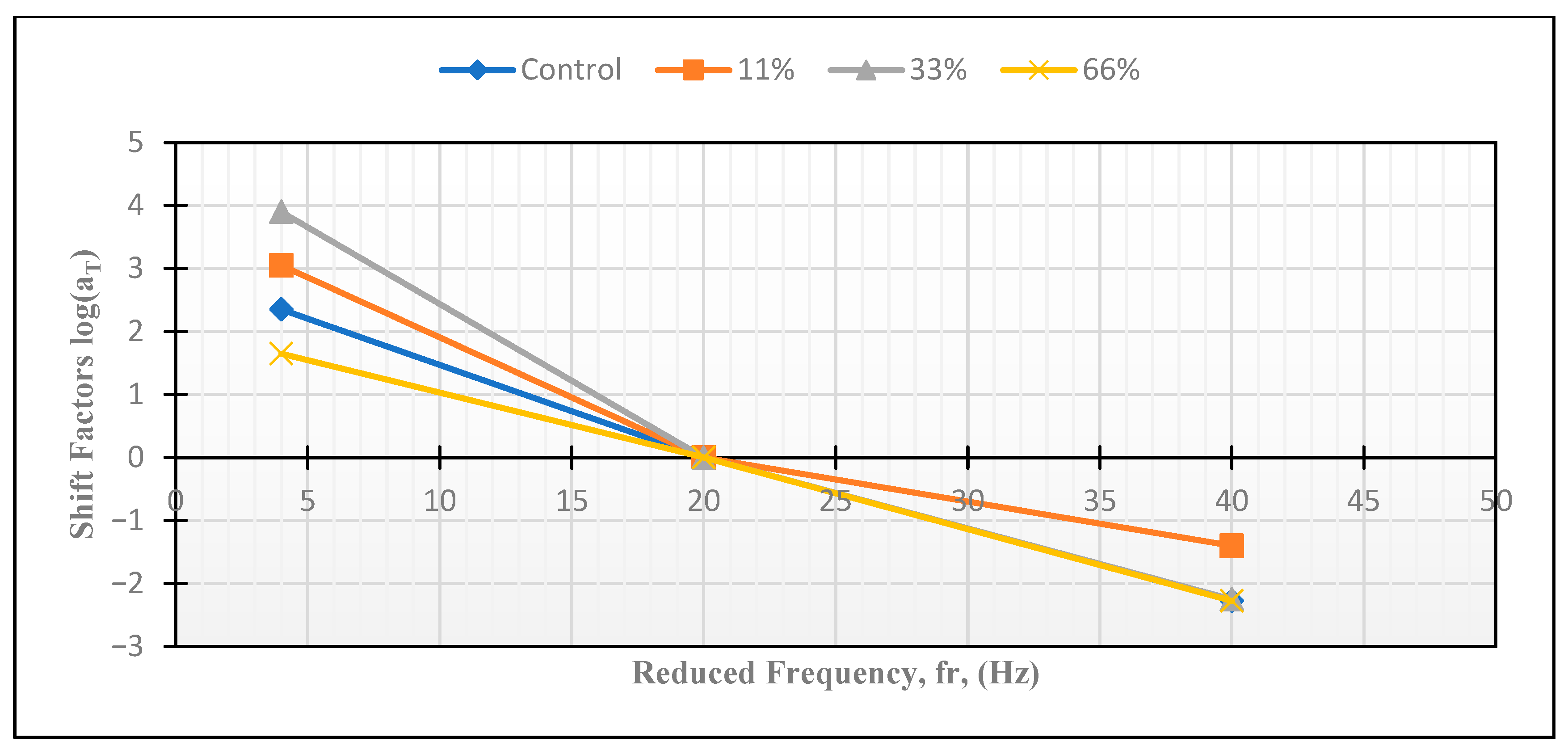

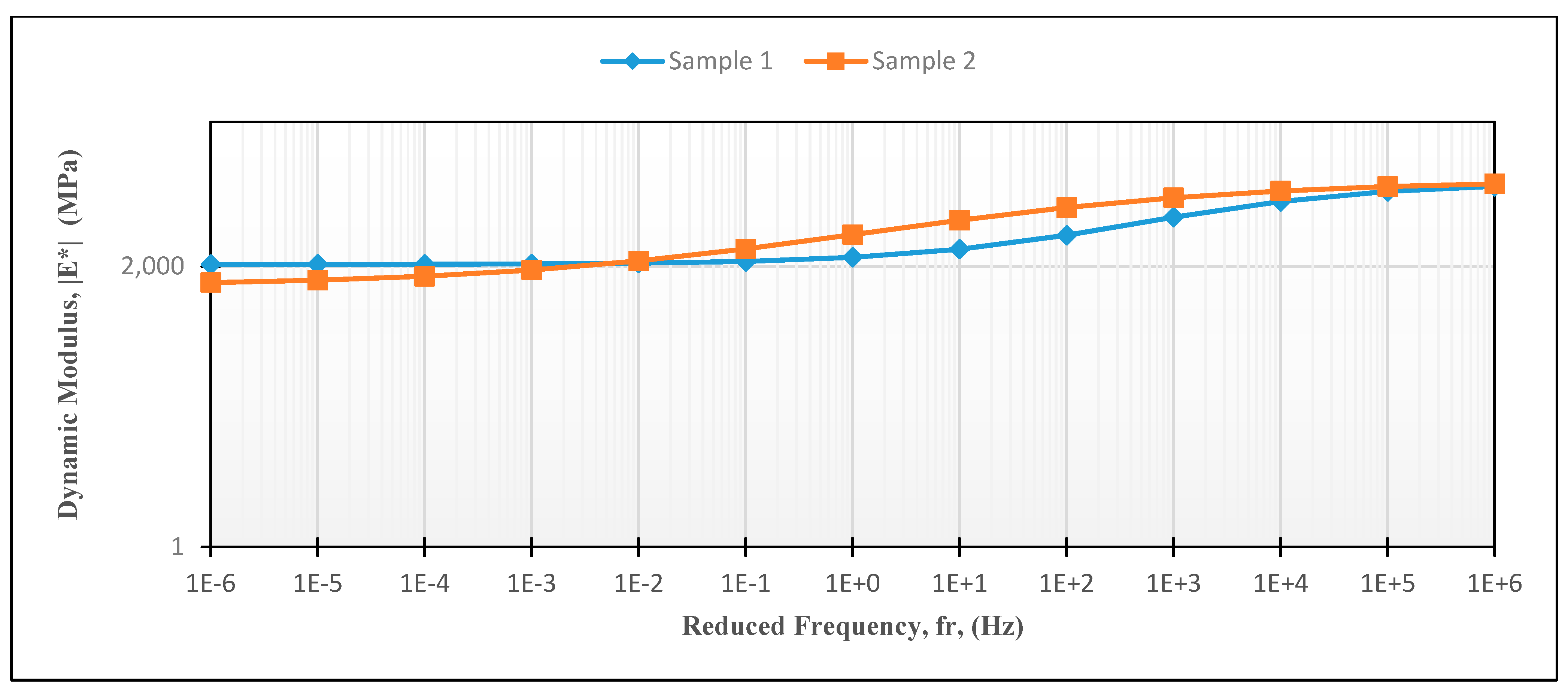

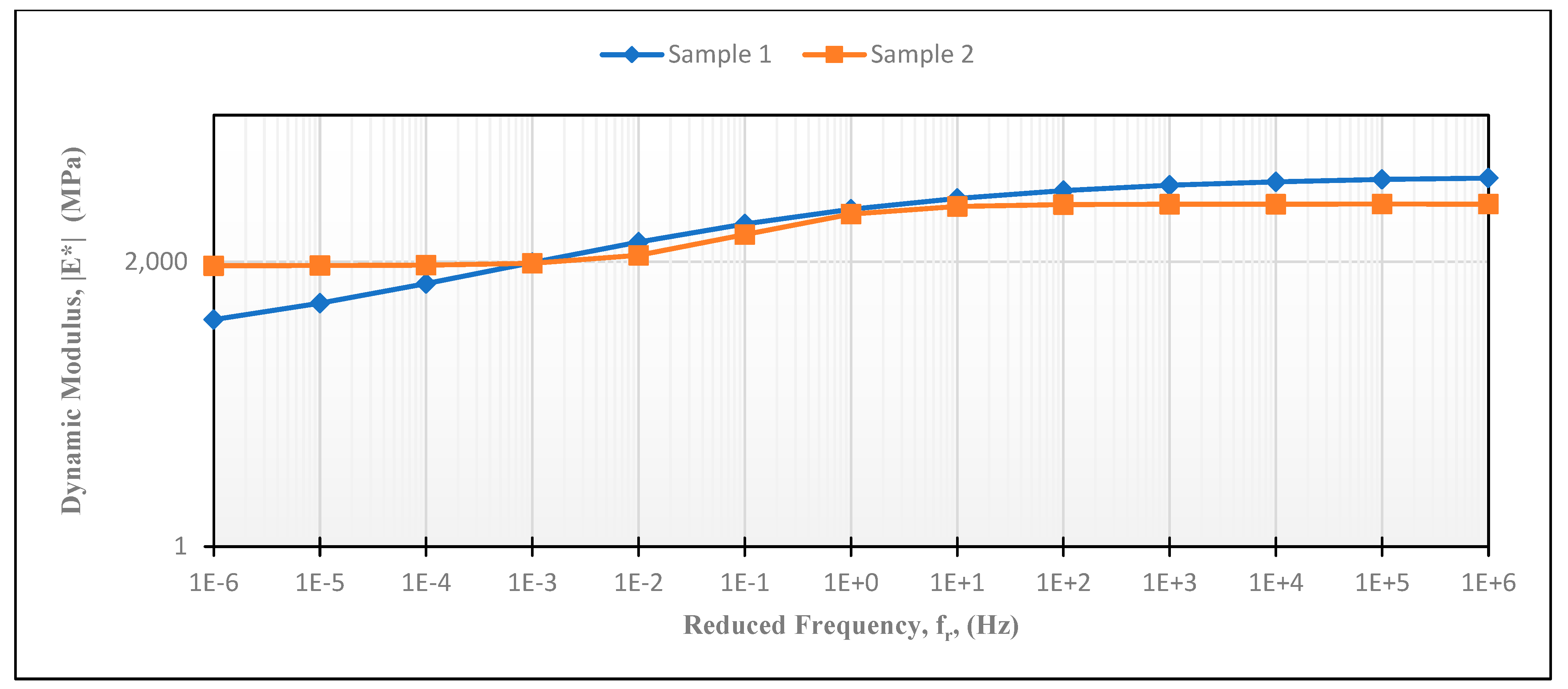

Figure 6 illustrates the corresponding shift factor curves for each mixture, highlighting the time–temperature superposition behavior across varying replacement levels. In addition,

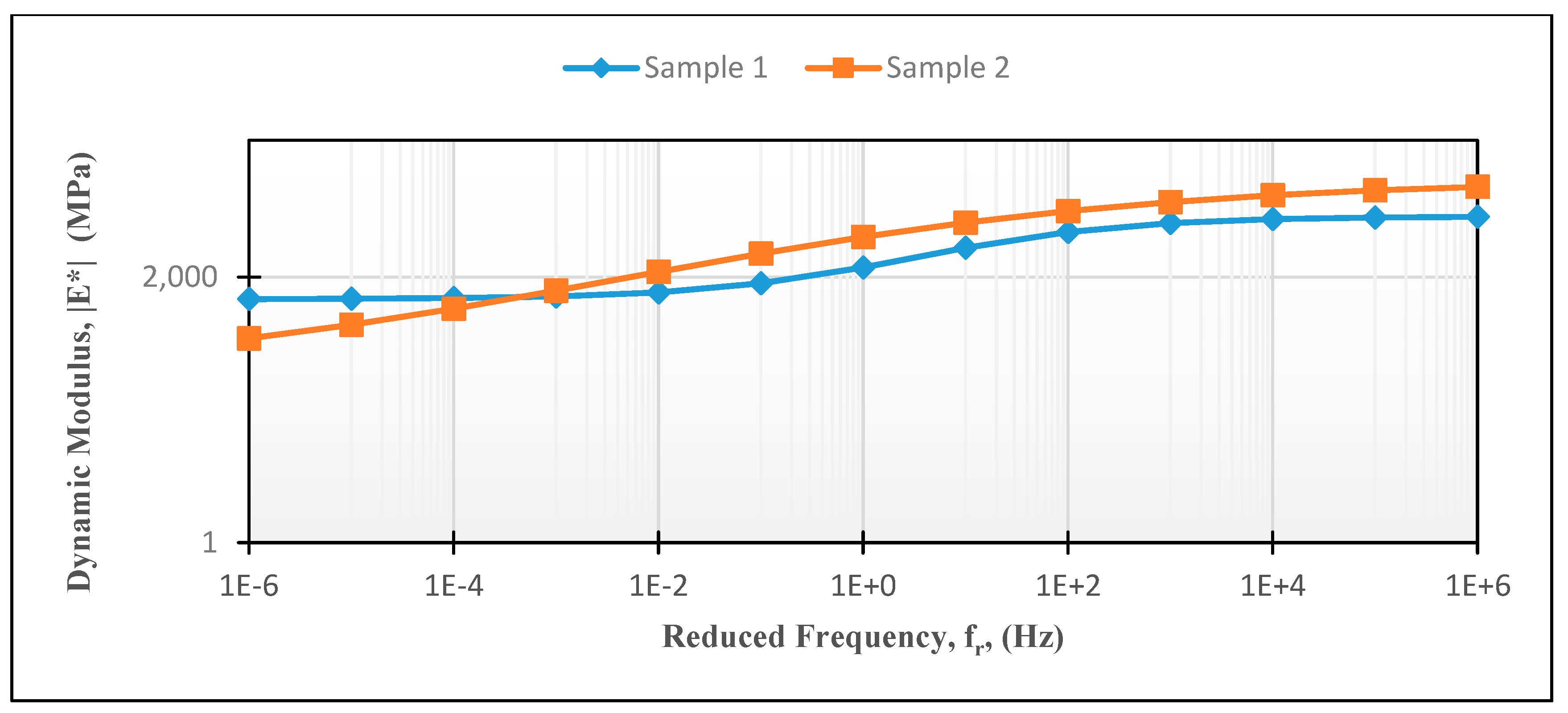

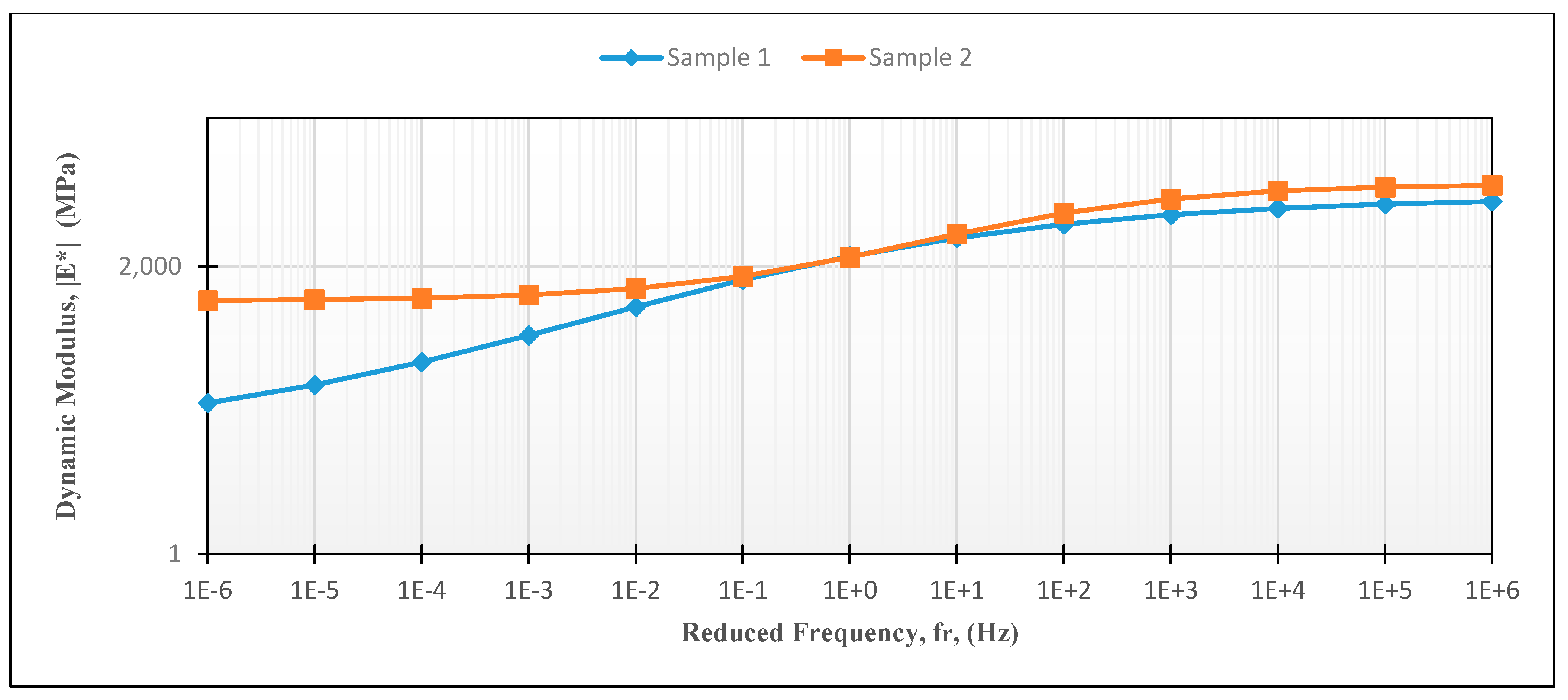

Figure 7,

Figure 8,

Figure 9 and

Figure 10 display the master curves of the two replicates for each replacement percentage, offering insight into the consistency and repeatability of the dynamic modulus results across the different mix designs.

The |E*| value serves as an important indicator of the stiffness of asphalt mixtures under cyclic loading. A higher |E*| value reflects a stiffer material, which generally suggests improved rutting resistance but may also imply a reduction in fatigue performance. As expected, the |E*| value increased with rising loading frequency for all mixtures. This trend is consistent with the physical behavior of asphalt materials, as higher frequencies simulate faster load applications, under which materials tend to exhibit increased stiffness.

Among the tested mixtures, the control mix displayed the highest |E*| values across most frequencies particularly at the upper end of the frequency spectrum. This indicates that the control mix possesses the greatest stiffness overall, likely translating to superior resistance to rutting under repeated heavy loads. However, its relatively high stiffness at low frequencies may also signal greater susceptibility to fatigue cracking, especially under long-duration or slow-moving traffic loads.

In contrast, the 11% replacement mix showed the lowest |E*| values across nearly all frequencies, suggesting that this mixture is the least stiff. Lower stiffness is typically associated with greater flexibility, which can enhance fatigue resistance by allowing the material to absorb stresses more effectively. However, this increased flexibility also results in lower rutting resistance, as evidenced by its modulus values across the frequency spectrum.

The 33% replacement mix demonstrated intermediate stiffness with |E*| values falling between those of the control and 11% mixes. This mixture may offer a balanced performance with sufficient stiffness to resist rutting while remaining flexible enough to mitigate fatigue damage. Such a profile suggests a potential for moderate performance in both rutting and fatigue resistance.

The 66% replacement mix exhibited a more variable behavior. At low frequencies, its |E*| values were similar to the 11% mix, indicating lower stiffness under slow or long-duration loads. However, as the frequency increased, the |E*| values of this mix approached those of the control, reflecting a significant stiffening effect under rapid loading. This behavior implies that the 66% mix may perform well in resisting rutting under high-speed traffic but could be vulnerable to fatigue and thermal cracking under slower or prolonged loads. Combined with previously observed inadequacies in VMA and VFA compliance, this mix may not be suitable for broader application.

To facilitate a more nuanced understanding of each mixture’s behavior, the |E*| master curves can be segmented into three distinct frequency zones, each representing a different pavement loading condition:

Zone 1 (reduced frequencies < 1 Hz): represents soft mix behavior, typically occurring under high temperatures and slow traffic. In this zone, higher |E*| values are desired to reduce the risk of rutting [

90,

91].

Zone 2 (1–10

3 Hz): corresponds to moderate stiffness under average conditions such as moderate temperatures and traffic speeds. This zone is where fatigue cracking is most likely to initiate [

90,

91].

Zone 3 (reduced frequencies > 10

3 Hz): reflects very stiff behavior typically encountered under low temperatures and high traffic speeds, which increases the risk of thermal and fatigue cracking [

90,

91].

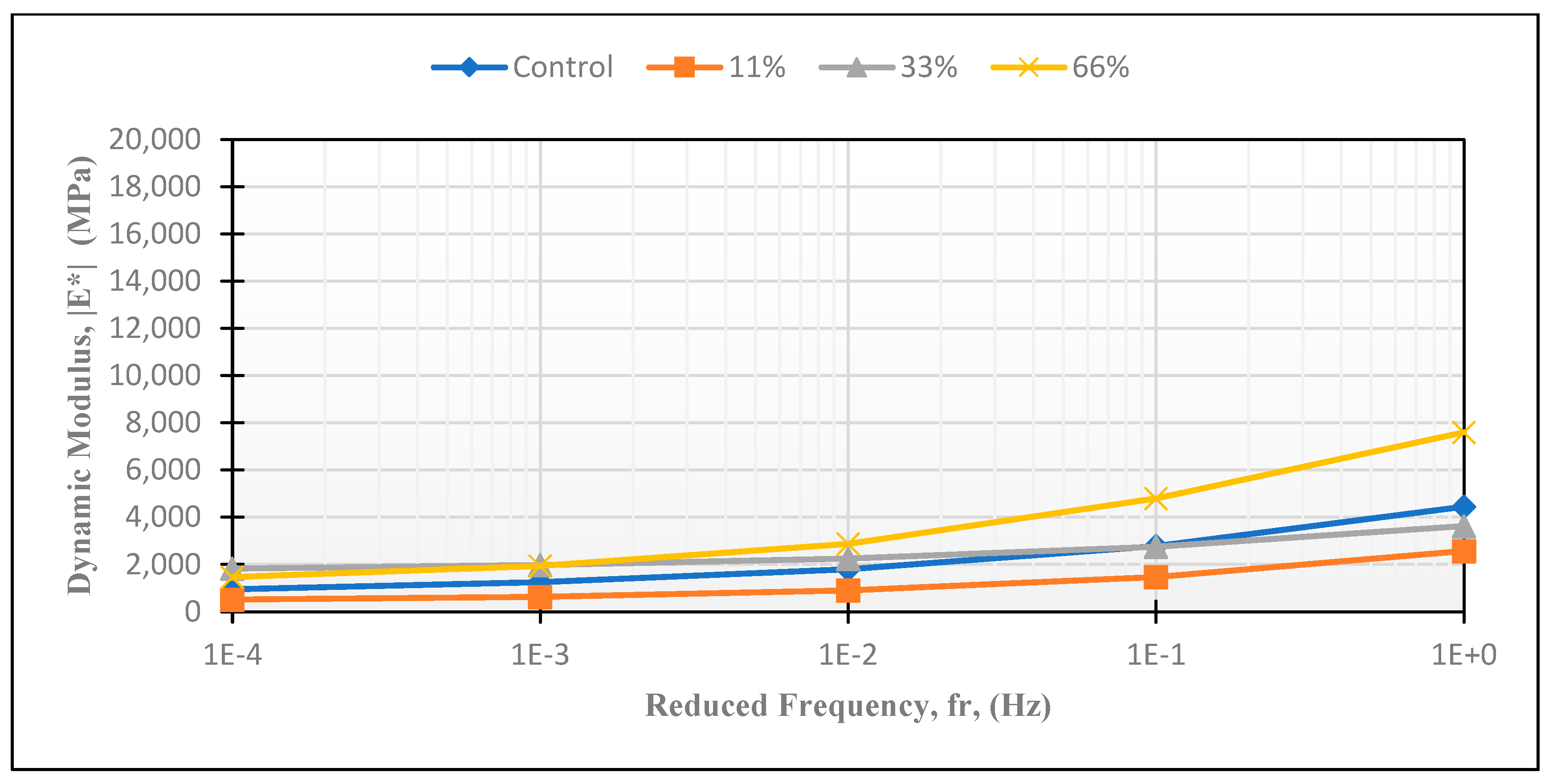

Figure 11,

Figure 12 and

Figure 13 present the segmented |E*| master curves for the fine aggregate replacement mixtures, which were categorized according to these three zones. This breakdown enables a more comprehensive evaluation of each mixture’s expected performance under varying environmental and loading conditions.

In Zone 1, the substitution of natural aggregates with RCA and RAP resulted in |E*| values for the 11% and 33% replacement mixtures relative to the control mixture. In contrast, the 66% replacement mix exhibited a higher |E*| value compared to the control. The reduction in stiffness observed in the 11% replacement mix indicates a greater vulnerability to rutting, as lower stiffness is associated with an increased risk of permanent deformation. This suggests that incorporating RCA and RAP into HMA may lead to reduced resistance to rutting, particularly at lower substitution levels.

As illustrated in

Figure 11, the mixtures with the highest substitution levels demonstrated the least reduction in stiffness across the frequency range in this zone. At the lowest reduced frequency (10

−5 Hz), both the 33% and 66% replacement mixes exhibited higher |E*| values than the control mix. The 66% replacement mix maintained higher stiffness throughout Zone 1 up to the transition frequency of 1 Hz. Meanwhile, the 33% replacement mix began to converge with the control mix around 10⁻

3 Hz, matched it at approximately 10

−4 Hz, and eventually dropped below the control by the end of the zone. The 11% replacement mix consistently demonstrated lower stiffness than the control mix throughout the entire frequency range of Zone 1. These findings suggest that mixtures with higher levels of aggregate replacement (33% and 66%) may offer improved resistance to rutting especially under slow or sustained loading conditions.

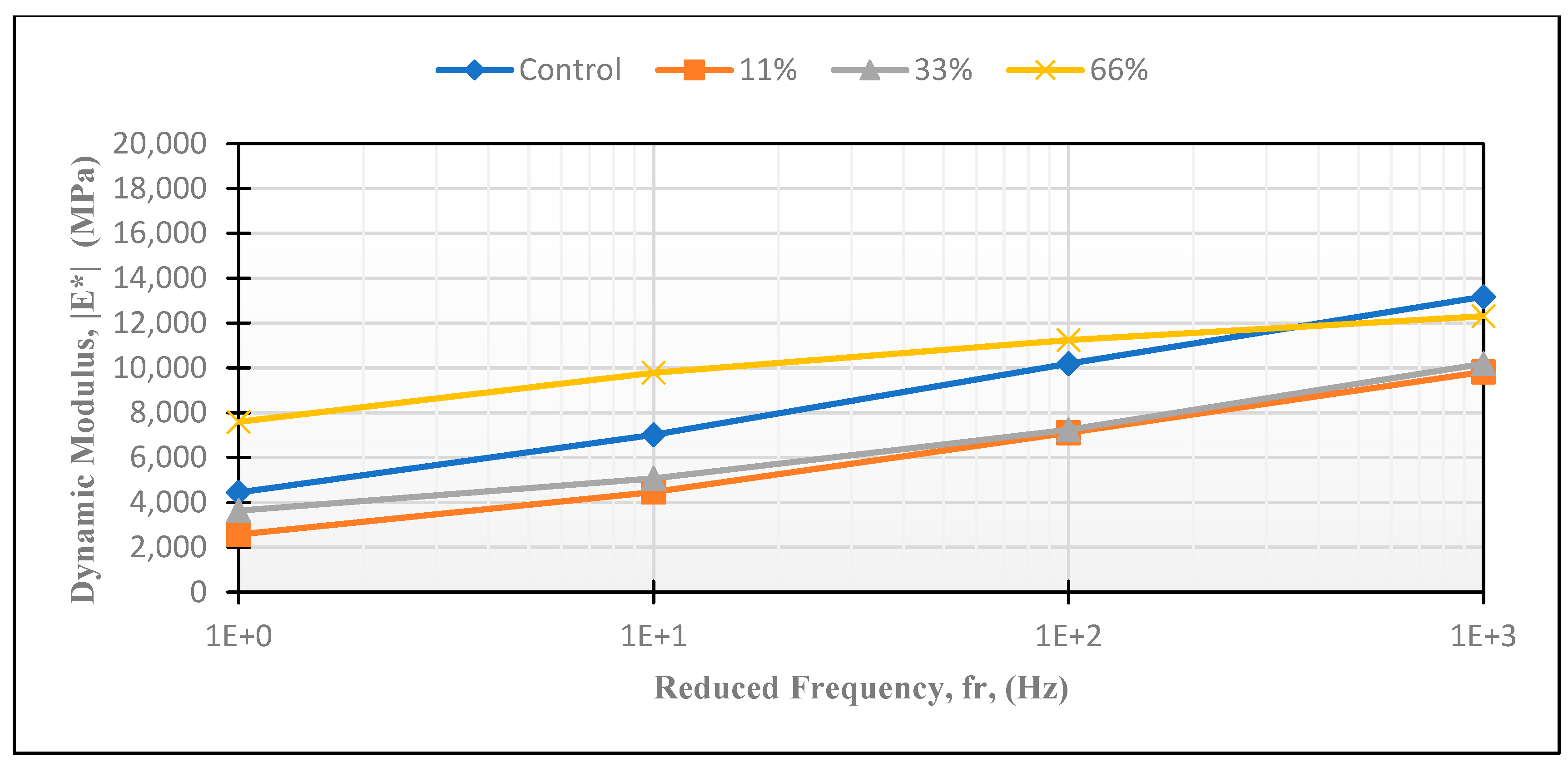

Similarly, in Zone 2, as shown in

Figure 12, the 11% and 33% replacement mixtures continued to exhibit lower stiffness across the entire frequency range when compared to the control. However, the 66% replacement mix showed a different trend: it initially presented higher stiffness than the control mix from 1 Hz to approximately 10

1 Hz. Beyond this point, the stiffness of the 66% mix began to decline, ultimately becoming lower than the control by the end of Zone 2 (around 10

2 Hz). This shift indicates that the advantage in stiffness offered by the 66% mix diminishes under faster loading conditions within this frequency range.

In Zone 3, presented in

Figure 13, the replacement of virgin aggregates with RCA and RAP led to a general decrease in stiffness for all modified mixtures in comparison to the control at high reduced frequencies. The 11% replacement mix demonstrated the most significant reduction in stiffness, highlighting its greater flexibility, which is typically favorable for fatigue resistance. These results imply that while the 11% mix may offer less rutting resistance, it could be better suited to resist fatigue cracking, especially in conditions associated with high traffic speeds and low temperatures.

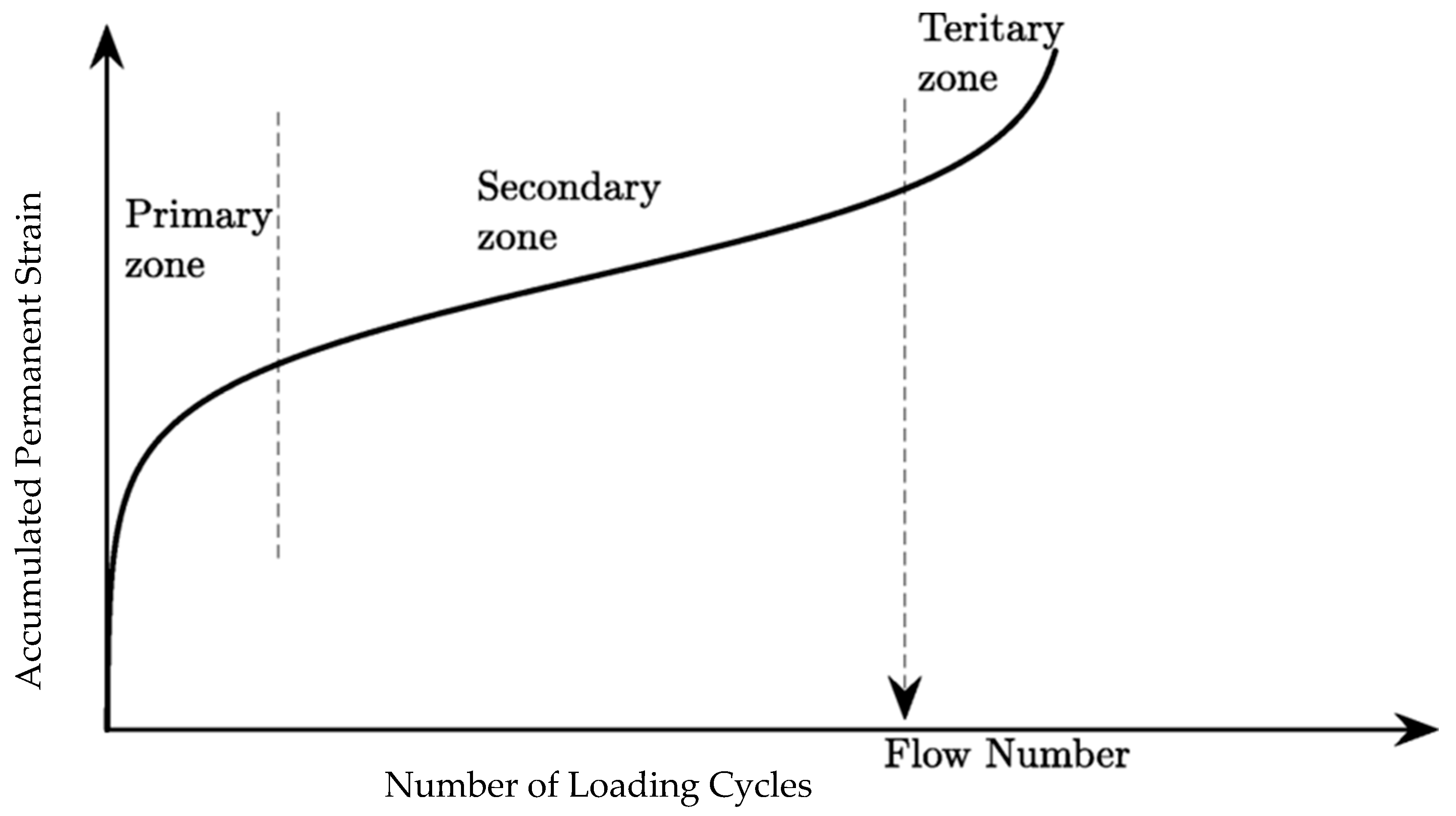

4.3. Flow Number (FN)

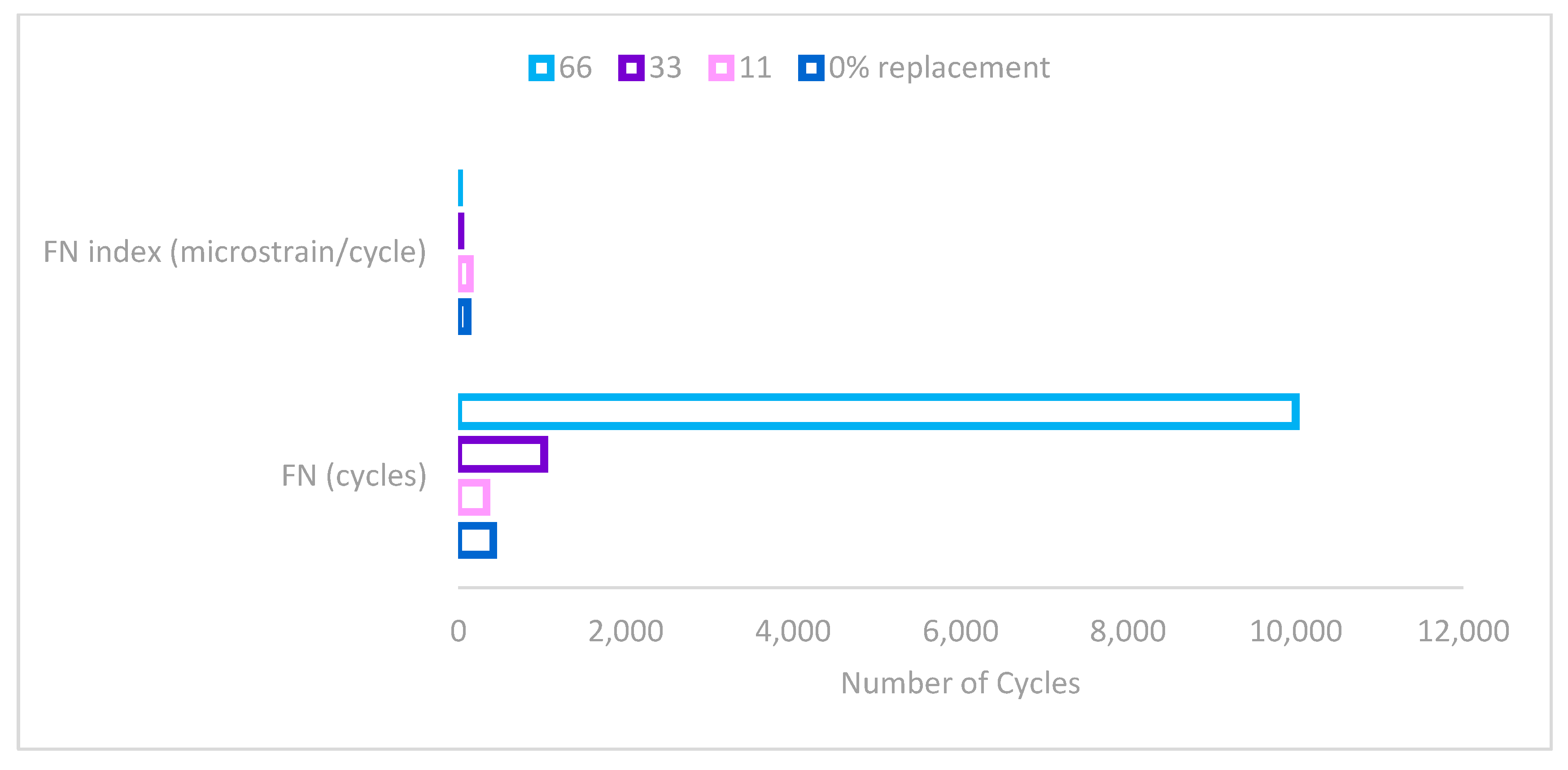

A comparative analysis of the FN test results for the asphalt concrete mixtures is presented in

Table 4. In general, higher FN values are indicative of superior rutting resistance in HMA mixtures, whereas lower values of accumulated permanent strain (εp) and the FN Index also signify improved resistance. It is important to highlight that a strong inverse correlation exists between FN and FN Index values: as FN increases, the FN Index typically decreases and vice versa.

The four fitting coefficients A, B, C, and D were determined using nonlinear regression based on the experimental data from the FN tests. The optimization was performed using a least-squares fitting algorithm, minimizing the error between predicted and observed values of εp. The resulting coefficients are listed below:

A = 6.85 × 109;

B = −2.315;

C = −25,790.44;

D = −0.00315.

To further analyze the behavior of the model, the first and second derivatives of εp with respect to n represented in Equations (4) and (5) were computed:

For mixtures without replacement (0%), the substitution of n = 419 into Equations (3)–(5), along with the corresponding fitting coefficients A, B, C, and D, yielded the following results:

εp (Permanent Axial Strain) = 30,691.20;

(Permanent Axial Strain Rate) =−38.02;

(FN is the cycle where the second derivative changes from negative to positive) = 0.388.

For mixtures containing 11% replacement, the substitution of n = 338 into Equations (3)–(5), along with the corresponding fitting coefficients A, B, C, and D, yielded the following results:

εp (Permanent Axial Strain) = 35,823.66;

(Permanent Axial Strain Rate) = −90.97;

(FN is the cycle where the second derivative changes from negative to positive) = 1.044.

For mixtures incorporating 33% replacement, substituting n = 1027 into Equations (3)–(5), along with the corresponding fitting coefficients A, B, C, and D, resulted in the following outcomes:

εp (Permanent Axial Strain) = 27,028.72;

(Permanent Axial Strain Rate) = −0.390;

(FN is the cycle where the second derivative changes from negative to positive) = 0.000774.

This trend aligns closely with the observations made in Zone 1 of the |E*| analysis, as shown in

Figure 11. The mixture containing 33% RCA and RAP replacement demonstrated favorable performance, which is characterized by a higher number of load cycles to failure and lower εp and FN Index values compared to the control mixture. These results collectively indicate that the 33% replacement mix exhibits adequate resistance to rutting under repeated loading conditions.

Conversely, the 11% replacement mix was identified as the least resistant to rutting, having registered the lowest FN along with the highest εp and FN Index among all mixtures tested, as depicted in

Figure 14. These findings suggest that the performance of asphalt mixtures in terms of rutting resistance is significantly influenced by the proportion of recycled materials with intermediate replacement levels yielding the most favorable balance of mechanical properties.

During testing of the asphalt concrete specimens containing 66% RCA and RAP replacement, no visible deformation was observed at the completion of 10,000 loading cycles. This outcome suggests that the second derivative of the Francken model remained consistently negative, indicating that the tertiary zone typically characterized by an upward inflection in the permanent strain curve was not reached for this replacement level.

As a result, the FN could not be determined in the conventional manner, since the critical transition into tertiary flow did not occur within the testing window. This phenomenon has been previously discussed in the literature [

84,

92,

93,

94], where it was noted that certain mixtures may fail to exhibit a clear tertiary phase even under extended cyclic loading, thereby challenging the applicability of FN as a sole indicator of rutting behavior in such cases.

In this instance, strain failure was identified independently of the FN values. The accumulated permanent strain curve remained predominantly within the secondary zone, which typically follows the initial rapid strain accumulation of the primary zone and precedes the onset of tertiary flow. Based on these observations, it can be inferred that the 66% replacement mix did not reach tertiary flow within the standard 10,000-cycle limit and that a higher number of cycles would be required to detect the onset of failure.

This behavior is consistent with findings reported in prior studies [

84,

92,

93,

94] and may be attributed to the extremely low VMA and VFA observed in this mix. These factors could potentially delay the development of rutting-related failures but also warrant further investigation to fully understand their influence on the long-term performance of high-replacement asphalt mixtures.

4.4. Statistical Analysis

A statistical analysis was conducted to validate whether the observed differences in the average |E*| curves—corresponding to varying percentages of RCA and RAP replacements—are statistically significant and not merely the result of random variability between sample replicates. This evaluation aimed to determine if there exists a measurable difference between the |E*| values of the control mixture and those of the replacement mixes.

To achieve this, a one-way Analysis of Variance (ANOVA) was performed at three selected reduced frequencies (10⁻

2, 10

2, and 10

4 Hz), which were each representative of a distinct performance zone as described in prior studies [

66]. The hypotheses for this analysis were established as follows:

Hypothesis H0.

(Null Hypothesis) There is no statistically significant difference in the |E*| values across different percentages of RCA and RAP replacement within the same material type.

Hypothesis H1.

(Alternative Hypothesis) Significant differences exist in the |E*| values between different replacement levels within the same material type.

The analysis was carried out at a 5% significance level (α = 0.05). In this context, the p-value indicates the probability of observing the given differences in |E*| values under the assumption that the null hypothesis is true. If the p-value is found to be less than the significance level, the null hypothesis is rejected, suggesting that the observed differences are statistically significant.

The results, summarized in

Table 5, reveal

p-values of 0.015, 0.017, and 0.018 at the reduced frequencies of 10⁻

2, 10

2, and 10

4 Hz, respectively. These values are all below the threshold of 0.05, indicating that RCA and RAP replacements exert a statistically significant influence on the |E*| values at all three frequency zones. Furthermore, the variability between the average |E*| values for the different replacement levels was found to exceed the variability within replicates, reinforcing the conclusion that the material modifications are responsible for the observed trends.

These findings are consistent with the visual differences in stiffness behavior shown in

Figure 12, thereby supporting the assertion that the use of RCA and RAP significantly alters the mechanical response of asphalt mixtures across varying loading conditions.

4.5. Evaluation of Permanent Deformation and Fatigue Cracking Potential

The permanent deformation stiffness factor is determined by calculating the ratio of (|E*|) to the sine value of the phase angle [

95]. Validation of the dynamic modulus test and |E*|/sin(φ) parameter for various frequencies, temperatures, and test conditions was conducted on actual asphalt pavement conditions. Two critical temperatures were selected: 40 °C, which is indicative of rutting resistance, and 20 °C, which is associated with fatigue performance. These tests were conducted under loading frequencies of 0.1 Hz and 10 Hz, respectively. A higher stiffness factor reflects an improved ability to resist permanent deformation, while a lower loss modulus is indicative of enhanced fatigue cracking resistance. The incorporation of these parameters provides a more comprehensive evaluation of the mechanical behavior of each asphalt mixture under realistic traffic and environmental conditions. The corresponding values for each mixture are reported in

Table 6 and

Table 7.

The findings of this study affirm that both the permanent deformation stiffness factor and the |E*| test serve as effective tools for distinguishing between asphalt mixtures of high and low performance [

96,

97,

98]. Furthermore, this stiffness-based parameter has been previously employed by [

99] to assess the permanent deformation susceptibility of asphalt mixtures. A strong correlation was identified between the experimentally derived master curves and the predictive model developed in the study. Two representative temperatures were selected: 20 °C, to evaluate susceptibility to fatigue cracking, and 40 °C, to assess rutting resistance.

To effectively withstand rutting, asphalt mixtures should exhibit elastic behavior characterized by high |E*| values and low phase angles. A frequency of 0.1 Hz was selected for this analysis, as it approximates typical loading scenarios where rutting is most critical. The calculated values of the permanent deformation stiffness factor for each mixture are presented in

Table 7.

According to the results, the inclusion of RCA and RAP in HMA led to an increase in the permanent deformation stiffness factor compared to the control mix. This suggests an enhanced capacity to resist rutting with increased replacement content. While the 11% replacement mix exhibited a reduction in stiffness, a gradual increase was observed at 33%, where the stiffness was nearly double that of the control. Remarkably, the 66% replacement continued this trend, indicating a positive contribution to rutting resistance.

To mitigate fatigue cracking, low |E*| and low phase angle values are desirable at intermediate temperatures. The fatigue cracking stiffness factor, or loss modulus, is calculated as |E*| × sin(φ) and serves as a key metric in evaluating resistance to fatigue [

100]. Lower loss modulus values denote greater fatigue resistance. The values for each mixture, measured at 10 Hz and 20 °C, are summarized in

Table 7.

The results indicate that mixtures incorporating RCA and RAP generally exhibit enhanced resistance to fatigue cracking, especially at 11% replacement, which had the lowest loss modulus among the mixtures. The 33% replacement mix also demonstrated improved fatigue performance, with a reduced loss modulus compared to the control. However, the 66% replacement mixture displayed a higher loss modulus, implying a decline in fatigue cracking resistance relative to the control.

Overall, the results obtained from |E*| testing, FN evaluation, and the analysis of rutting stiffness and loss modulus demonstrate consistent trends. These findings validate the effectiveness of these parameters in assessing the performance characteristics of asphalt mixtures containing varying levels of RCA and RAP.

5. Conclusions and Recommendations

This research explored the potential of integrating Recycled Concrete Aggregate (RCA) and Reclaimed Asphalt Pavement (RAP) as partial replacements for natural aggregates in Hot Mix Asphalt (HMA), aiming to enhance sustainability without compromising performance. The mixtures were tested at replacement levels of 11%, 33%, and 66% and evaluated through volumetric design parameters, dynamic modulus |E*|, and flow number (FN) tests.

In addition to the demonstrated performance benefits, the use of recycled aggregates such as RCA and RAP in optimized asphalt mixtures can yield meaningful reductions in both carbon footprint and material costs. By decreasing the reliance on virgin aggregates and reducing the energy demands associated with material extraction and processing, the adoption of these recycled materials supports more sustainable construction practices. The improved durability and extended service life of the designed mixtures may lead to lower maintenance requirements and life cycle costs, offering long-term economic and environmental advantages for pavement infrastructure systems.

Key insights are summarized as follows:

Increasing RCA and RAP content consistently reduced the optimum asphalt binder content, VMA, and VFA values. While mixes with 11% and 33% replacement satisfied Superpave design requirements, the 66% replacement fell below the VMA and VFA thresholds, making it unsuitable for standard pavement applications despite favorable stiffness.

The 33% replacement mix offered the best overall performance in rutting resistance, as indicated by high FN values and a strong permanent deformation stiffness factor.

The 11% mix showed superior fatigue cracking resistance, correlating with lower stiffness and loss modulus values.

The 66% mix, although mechanically strong in rutting scenarios, is limited by its noncompliance with volumetric standards and should be considered only for experimental or non-structural applications.

One-way ANOVA confirmed significant differences in |E*| across different replacement levels, supporting the impact of RCA and RAP on mixture performance.

A 33% combined replacement is recommended for regions susceptible to both rutting and fatigue.

An 11% replacement is more suitable in areas where fatigue cracking is the primary concern.

The findings from this study offer valuable insights that can inform the refinement of asphalt mixture design guidelines such as Superpave and EN standards. In particular, the observed performance trends at varying RCA and RAP replacement percentages may support the inclusion of recycled materials within certain thresholds without compromising mechanical properties, rutting resistance, or fatigue life. Specifically, the 33% replacement level showed performance characteristics that align with or exceed conventional mixture requirements, suggesting that this level could be a recommended upper limit in specification frameworks. Furthermore, the data may aid in the calibration of performance-based design criteria, particularly in adapting mix design procedures to accommodate recycled content while maintaining constructability and long-term durability.

To build on these findings and address long-term performance, the following directions are recommended:

Future studies should implement viscoelastic continuum damage (VECD) models to better simulate the fatigue behavior of RCA and RAP modified mixtures under repeated loading.

A comprehensive life cycle cost analysis is essential to quantify the economic benefits of using recycled materials over the pavement lifespan.

Long-term field trials across diverse climates and traffic conditions would enhance the reliability of laboratory results and support the development of climate-responsive pavement designs using recycled materials.