Abstract

This paper explores the optimal configuration strategies for building-integrated photovoltaic (BIPV) systems in response to the low-carbon transformation needs of semi-outdoor substations, aiming to reconcile the contradiction between photovoltaic (PV) power generation efficiency and indoor environmental control in industrial buildings. Taking a 220 kV semi-outdoor substation of the China Southern Power Grid as a case study, a building energy consumption–PV power generation coupling model was established using EnergyPlus software. The impacts of three PV wall constructions and different building orientations on a transformer room and an air-conditioned living space were analyzed. The results show the EPS-filled PV structure offers superior passive thermal performance and cooling energy savings, making it more suitable for substation applications with high thermal loads. Building orientation plays a decisive role in the net energy performance, with an east–west alignment significantly enhancing the PV module’s output and energy efficiency due to better solar exposure. Based on current component costs, electricity prices, and subsidies, the BIPV system demonstrates a moderate annual return, though the relatively long payback period presents a challenge for widespread adoption. East–west orientations offer better returns due to their higher solar exposure. It is recommended to adopt east–west layouts in EPS-filled PV construction to optimize both energy performance and economic performance, while further shortening the payback period through technical and policy support. This study provides an optimized design path for industrial BIPV module integration and aids power infrastructure’s low-carbon shift.

1. Introduction

According to the 2023 NDC Synthesis Report of the United Nations Framework Convention on Climate Change (UNFCCC) [1], the current decarbonization rate covered by the net-zero emission targets and commitments of countries still falls short of achieving the goals of the Paris Agreement. The International Energy Agency (IEA) reported, in 2023, that buildings’ operations account for 30% of global final energy consumption and 26% of global energy-related emissions [2]. The Global Status Report on Buildings and Construction released by the United Nations Environment Programme (UNEP) showed that the current rate of building retrofit is far below the speed required to reduce carbon emissions by 50% by 2030. The average retrofit rate of the existing building stock is currently around 1% per year, with these retrofits typically achieving less than a 15% reduction in energy intensity. To align with the goals of the Paris Agreement, by 2030, the retrofit rate needs to be increased to between 2.5% and 5%, and building energy consumption needs to be reduced by about 25%, which requires the gradual replacement of fossil fuels and traditional biomass with new energy sources [3]. As one of the industries with the highest global energy consumption and emissions, the construction industry’s transition to low carbon is inevitable in the future. The growing demand for clean energy and the urgency of mitigating climate change have driven the rapid development of photovoltaic (PV) technology as a key renewable energy solution [4]. Solar energy, as an abundant and sustainable resource, plays a crucial role in reducing carbon emissions and enhancing energy security [5]. In recent years, building-integrated photovoltaic (BIPV) structures have attracted much attention for their dual attributes of being both a building material and a power generation facility [6], which can optimize land use and enhance urban energy sustainability [7]. This is a technology that integrates solar photovoltaic power generation modules into buildings [8]; that is, the photovoltaic power generation system is designed, constructed, and installed simultaneously with the building and forms a perfectly integrated solar power generation system within the building. The building itself uses solar energy to produce electricity to meet its own power needs [9]. BIPV technology allows photovoltaic modules to be directly integrated into building structures, such as roofs and walls, effectively utilizing spaces that would otherwise not generate energy [10]. The electricity generated by the BIPV system can be used for self-consumption or fed into the grid for sale, reducing operating costs and bringing economic benefits [11].

However, existing BIPV research has focused more on public or residential buildings, with insufficient attention to the integration potential of industrial building facilities [12]. Take the most common substation as an example. As a hub building in the urban energy network, integrating PV systems into substations can also actively explore the deep integration of photovoltaic power generation and the power grid, promoting the design transformation of power infrastructure [13]. Looking at the building itself, most of them are located in suburban areas away from cities, where solar radiation is not easily blocked, and they have a low window-to-wall ratio and a high proportion of wall area, providing a vast facade area for PV integration, as walls are an underdeveloped carrier. However, the roof area is usually limited and often occupied by ventilation equipment, lightning rods, cable trays, etc. Therefore, when considering PV installation for this type of building, more consideration should be given to attaching the PV module to its facade.

At present, there have been quite a few research results on facade–photovoltaic module integrated structures by predecessors. According to the application of PVs in buildings, different construction methods of PVs combined with the outer envelope structure have been mainly proposed, as well as studies on the passive and active energy-saving effects of PV systems on buildings. ZHANG believes that there are mainly three types of structures for PVs combined with walls. The first is to directly install PV modules on the wall, the second is to form an air cavity between the PV module and the wall, and the third is to use the filling material EPS to seal the air layer between the PV module backplate and the wall [14]. Zhou summarized the research on the heat transfer of building-integrated photovoltaic walls by predecessors and pointed out that the average daily heat gain of photovoltaic walls in summer is 27% lower than that of traditional walls. Further research on the impact of natural ventilation on photovoltaic walls found that ventilation can reduce the exterior wall temperature by 4.5 °C to 7.3 °C, and the heat gain of naturally ventilated photovoltaic walls is reduced by about 25% to 55%, reducing the cooling load by 33% to 50% compared with traditional walls [15]. Peng et al. assessed the annual thermal performance of ventilated photovoltaic walls in Hong Kong and the subsequent reduction in air conditioning energy consumption. The results showed that the wall can reduce indoor heat gain by 51% in summer, reduce heat loss by 32% in winter, and reduce air conditioning system energy consumption by 18.6 kWh per square meter per year [16]. In addition, it has also been proposed that in hot regions, a ventilated cavity should be formed between the photovoltaic module and the wall to reduce heat gain and improve the energy conversion efficiency of the photovoltaic modules [17]. Yang proposed that naturally ventilated photovoltaic walls perform best in reducing solar heat gain and improving power output, effectively reducing heat gain and improving the energy conversion efficiency of photovoltaic modules, while non-ventilated photovoltaic walls perform best in thermal insulation [18]. K. Irshad pointed out that air velocity has a significant impact on the performance of photovoltaic walls with cavity ventilation. Within a certain range, the increase in air velocity can significantly increase the heat transfer coefficient of air, which helps to cool the interior of the building and photovoltaic modules [19]. ElSayed found that the air gap depth has a significant impact on the thermal performance and photovoltaic efficiency of BIPVs. Increasing the air gap depth can reduce heat gain [20]. Su measured the relationship between air flow and cavity depth [21]. It was identified that when photovoltaic modules are integrated with buildings as part of the facade envelope structure, they will affect the building’s energy consumption system from two aspects: the positive benefits of power generation for the energy supply and the passive benefits of protecting the surfaces of the building [22]. First, the most important energy benefit of PV systems is power generation and energy supply. Solar energy is directly converted into electrical energy by photovoltaic panels integrated on the building surface for use by the building itself or for grid connection and sale, which can reduce dependence on external energy, increase energy self-sufficiency, and reduce traditional energy consumption. Second, the application of PV modules to the facade of a building will change the thermal performance of the building envelope, thereby reducing the energy consumption of the air conditioning system, while shading the surface of the building and reducing the total amount of solar radiation projected onto it. The different construction methods also greatly affect their energy saving and power generation efficiency.

However, existing research on building-integrated photovoltaic (BIPV) facades has largely focused on conventional residential and public buildings, with an emphasis on evaluating their energy-saving potential [23], while overlooking the unique operational loads and internal heat sources characteristic of industrial facilities. Taking substations as an example, these buildings typically house a substantial amount of heat-generating equipment, especially transformers, which emit significant heat during operation and require effective ventilation or cooling systems to maintain safe operating temperatures. While the introduction of PV systems may enhance the thermal insulation of building envelopes, it could also hinder heat dissipation, potentially leading to indoor heat accumulation. This, in turn, may impair equipment efficiency, shorten service life, or even increase the risk of safety incidents, ultimately threatening the stability and reliability of the power supply network. Beyond substations, other types of industrial buildings—such as data centers, manufacturing plants, and smelting workshops—often share similar characteristics, including large wall areas, low window-to-wall ratios, and high internal energy demands. Therefore, the BIPV structural designs and energy analysis methods proposed in this study have good generalizability and may be applied to other types of industrial buildings in the future, providing theoretical support and practical reference for cross-sector BIPV technology transfer and system integration [24].

Given the current challenges in integrating BIPV systems into industrial buildings, particularly the difficulty in coordinating photovoltaic construction with environmental control and the uncertainty in post-installation energy performance, we aim to address the following key scientific and practical issues by

- Investigating the comprehensive impact mechanisms of different photovoltaic facade construction layers (such as direct attachment, air cavity, and EPS filling) on building energy consumption and indoor environments and verifying whether these configurations can not only improve building energy performance but also effectively manage the thermal environment of various functional spaces within the substation, thereby ensuring operational safety and comfort.

- Examining the role and constraints of building orientation in optimizing the energy output of BIPV systems, in order to further improve the overall photovoltaic performance.

- Assessing the initial investment, maintenance costs, and economic returns of different structural solutions to determine their feasibility for broader application.

2. Materials and Methods

2.1. Research Object

This paper takes a standard 220 kV semi-outdoor substation of the China Southern Power Grid located in the subtropical region as a case for study. Buildings in this region hold a significant strategic position in the global photovoltaic power generation field [25]. The summer climate is hot, with 30–50% of all their consumed electricity used for cooling and ventilation purposes. Ventilation and air conditioning (HVAC) systems consume a large amount of electricity [26]. Therefore, formulating strategies to reduce energy consumption has become an essential part of the energy-saving and emission-reduction tasks in these countries. Meanwhile, the region also has the most significant solar advantages, with its high solar radiation intensity and sufficient sunshine duration ensuring a competitive overall power generation capacity [27]. As countries in the subtropical region, such as Guangdong Province in China and Singapore, complete their urbanization and industrialization phases, they are increasingly facing the challenges of growing energy demands and land resource shortages [28,29]. This makes the deployment of traditional photovoltaic systems more challenging. Therefore, selecting buildings in this region for research also has far-reaching significance.

In terms of function, the main functional areas of a substation can be divided into two categories based on the user: one is the equipment room, which is specifically for storing substation equipment, and the other is the living room for employees’ long-term use. These two types of rooms have different requirements for environmental control. The living rooms, such as the guard room, water pump room, and fire control room, usually have staff coming and going, so air conditioning needs to be configured to meet the thermal comfort needs of the personnel. The equipment rooms, such as the main transformer room, need ventilation due to the large amount of heat dissipation from the equipment or the need to remove harmful gases, and this usually includes both natural and mechanical ventilation systems. There are also some spaces that have both heat-generating equipment and human activities, so both air conditioning and ventilation environmental control methods are needed. The specific types of spaces are shown in the Table 1.

Table 1.

Functional rooms of substation and their environmental control methods.

The working conditions inside the transformer room are complex. Therefore, when carrying out the photovoltaic integration design, it is necessary to not only consider the power generation of photovoltaics but also fully take into account the changes that the photovoltaic system brings to the original building envelope’s heat transfer and energy structure. This is especially true for the semi-outdoor main transformer room, where ventilation and heat dissipation are crucial for the safe operation of the transformer. Photovoltaic power generation is often accompanied by the heating of the voltaic module’s backplate. Whether the photovoltaic integration design will affect the transformer’s heat dissipation and the temperature control of other equipment rooms is a key issue that this study needs to verify. Therefore, this paper will classify and discuss the impact of façade–photovoltaic module layout configurations on rooms with different working conditions in the substation. The focus of the analysis is the passive influence of photovoltaics on rooms with different working conditions and the changes in power generation performance after integrating the photovoltaic system.

2.2. Research Methods

This paper will utilize the EnergyPlus V23.2.0 software tool for simulating building conditions and calculating energy consumption. This software is capable of comprehensively simulating systems such as lighting, air conditioning, and ventilation within a building, as well as the various physical processes involved. This makes EnergyPlus widely applicable in multiple fields, including the assessment of buildings’ energy-saving performance, design optimization, and energy management, as well as related policy-making [30]. The study will be carried out in three phases:

In the first phase, focusing on the research of facade–photovoltaic system construction, the integration of photovoltaic modules with the facade will be divided into three types: (1) the direct installation of photovoltaic modules in contact with the concrete structure; (2) the formation of an air cavity between the photovoltaic modules and the concrete wall; (3) the use of EPS filling between the photovoltaic modules and the concrete wall. By thoroughly analyzing and comparing the impact of these three types of photovoltaic-module-integrated envelope structures on the indoor thermal performance of the substation, the most suitable construction methods for different room conditions in the substation will be precisely determined.

In the second phase, the research findings from the first phase will be fully utilized to set up the envelope structure, and the influence of orientation on photovoltaic power generation and the overall energy consumption of the substation will be explored. By comparing the overall energy consumption and total energy-saving efficiency of buildings with photovoltaic-module-integrated substations under different orientations, comprehensive and precise guidance will be provided for the facade–BIPV module design of substations, and feasible measures and suggestions will be proposed.

In the third phase, a preliminary cost–benefit analysis is conducted for these types of photovoltaic wall systems to evaluate their economic feasibility. Key factors considered include the procurement and installation costs of PV modules and additional construction layer costs; using the estimated annual electricity output, cost savings and discounted cash flows were calculated to determine the payback period and the net present value (NPV), offering a practical economic reference for BIPV applications.

It should be noted that this study is based on a simulation analysis of a typical 220 kV semi-outdoor substation building under subtropical climate conditions. The climate data, room functions, and equipment load parameters used are highly region-specific. Therefore, these contextual constraints limit the generalizability of the results, meaning that the findings are most applicable to substations with similar climatic conditions, building types, and operational characteristics. Applying these results to substations in other climate zones or with significantly different structural configurations may lead to reduced accuracy and applicability. Nevertheless, the study’s method—classifying indoor environments based on control needs and systematically analyzing PV facade types and building orientation—has strong methodological adaptability. The analytical approach and design logic offer valuable references for promoting the use of BIPV structures in substations of other climates and in broader industrial buildings.

2.3. Parameter Setting

2.3.1. Modeling

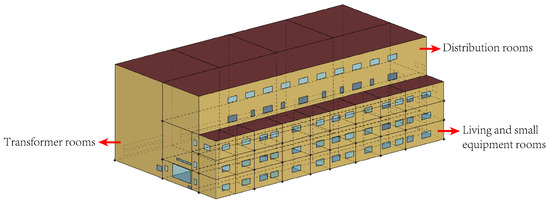

The modeling of the 220 kV substation was carried out based on the OpenStudio 1.7 platform (Figure 1). The substation covers an area of 3561 m2 and houses four transformers. It has three above-ground floors and a partial fourth floor. The main rooms include the transformer rooms, which are located on one side of the long axis, with a total of four rooms. The central part of the building consists of the low-voltage distribution room on the first floor, the 110 kV GIS distribution room on the second floor, and the 220 kV distribution room on the partial fourth floor. On the other side are the living quarters for the transformer room staff and small equipment rooms, such as the capacitor room and reactor room. Each type of room was set as an individual thermal zone in OpenStudio. Based on the actual project configuration, different HVAC parameters, ventilation settings, internal heat gains, and occupant heat disturbances were applied. Detailed settings are shown in Table 2.

Figure 1.

The substation model, built using OpenStudio.

Table 2.

Table of room thermal zones and parameter settings.

2.3.2. Weather Parameters

The meteorological parameters used in the simulation experiments are sourced from the official website of the China Meteorological Administration (CMA) (http://data.cma.cn), with Guangzhou City (23.12° N, 113.25° E) selected as a typical representative area for the subtropical region. The Typical Meteorological Year (TMY) data includes several parameters that influence the design of BIPV. Key parameters were extracted from the EPW file, as shown in Table 3. In Guangdong, the average hourly global horizontal radiation is 129.75 Wh/m2, peaking at 1252 Wh/m2. Summer temperatures average above 28 °C, with a maximum outdoor dry bulb temperature of 36.6 °C, while winter averages around 14 °C—indicating a typical hot and humid southern climate. High humidity and low wind speeds limit the cooling effect of natural ventilation on PV modules. The prevailing southerly wind supports the analysis of south-facing facade ventilation designs. All the data are sourced directly from official files without manual modification.

Table 3.

Parameters in Guangzhou’s meteorological data file that may affect the simulation.

2.3.3. Indoor Environmental Control Parameters

As can be seen from the description in Section 2.1, there are mainly two working conditions for the indoor environmental control of the substation: one is the transformer room with high-power internal heat sources, where the operating transformers generate a large amount of heat, which needs to be exhausted by thermal pressure ventilation; the other includes the small equipment rooms and living quarters, which have certain heat disturbances inside, need ventilation to remove waste gases, and also need to control the fluctuation of indoor temperature, so both air conditioning and ventilation are needed for environmental control. There is a significant difference between the two working conditions, so they need to be discussed separately.

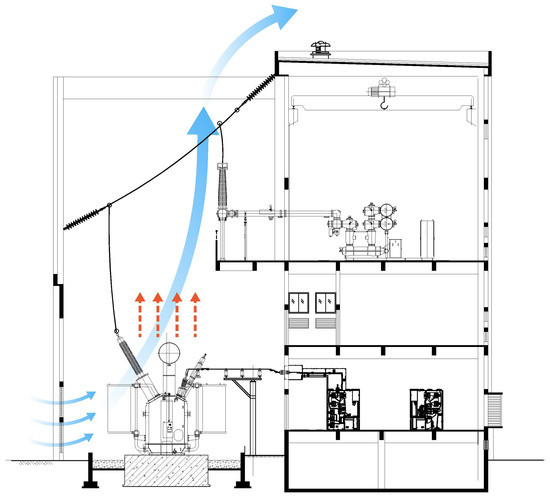

- Working Condition One: Mainly rooms represented by transformers; it is necessary to set the heat dissipation power by the high-power heat sources inside them and the relevant parameters of indoor thermal pressure ventilation. The main transformer room of the semi-outdoor substation adopts a natural air intake mode, introducing fresh air through the louver at the bottom of the main gate. This room does not have a roof and uses the open roof to achieve air exhaustion, thus achieving good ventilation and cooling effects (Figure 2).

Figure 2. Natural ventilation methods of the transformer room. The red arrows indicate transformer heat dissipation, and the blue arrows represent the ventilation paths in the transformer room.

Figure 2. Natural ventilation methods of the transformer room. The red arrows indicate transformer heat dissipation, and the blue arrows represent the ventilation paths in the transformer room.

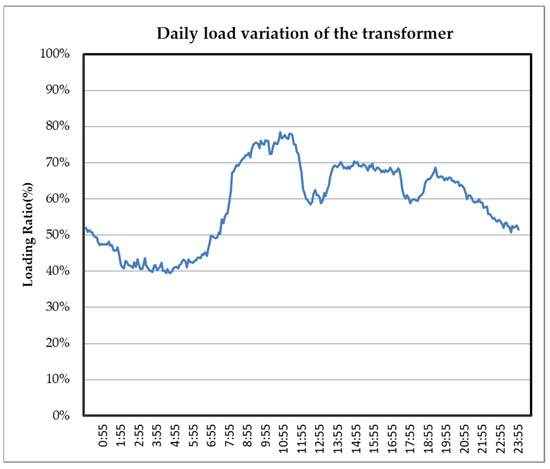

Internal heat source setting: The substation in this investigation has a total of 4 transformers. In engineering, a commonly used method for transformer heat dissipation assumes that the total loss of the transformer equals the heat generated by the equipment. When the transformer is operating normally, the total loss P consists of the no-load loss P0 and the load loss Pf (P = P0 + Pf). The no-load loss P0 is constant, and the load loss Pf is equal to the square of the load ratio multiplied by the load loss Pε at the rated load (Pf = λ2 × Pε) [31]. For the 220 kV main transformer room tested this time, according to the manufacturer’s data, the no-load loss of the transformer is P0 = 95 kW per unit, and the load loss is Pf = 660 kW per unit. In EnergyPlus, no-load and load losses were set as two heat sources. Load variation was applied based on the peak summer day (Figure 3) to achieve more accurate and clear heat dissipation results.

Figure 3.

Daily load variation of the transformer.

Natural ventilation setting: The ventilation design of the semi-outdoor substation mainly relies on the principle of thermal pressure ventilation (Figure 2). When simulating its ventilation effect, the ZoneVentilation:WindandStackOpenArea model of EnergyPlus can be used. By setting the effective opening area of the air inlet, namely the Opening Effectiveness, and the height difference between the air inlet and outlet, the model can more intuitively simulate the ventilation situation. The specific parameters are as follows: the air inlet opening area is 36 m2, the Opening Effectiveness is 0.6, and the height difference is 25 m.

- 2.

- Working Condition Two: Mainly living quarters and other rooms without high-power electrical equipment, including capacitor and reactor rooms, battery rooms, GIS rooms, low-voltage distribution rooms, etc. These rooms need to be equipped with indoor air conditioning and lighting systems. Meanwhile, some rooms also need to be fitted with mechanical ventilation facilities to deal with heat disturbances from personnel and equipment.

Air Conditioning Settings: Most rooms in the substation have clear design requirements for the environmental temperature. For substations in subtropical regions, there is no need to design for winter heating; only summer air conditioning cooling is required. The summer design temperature for capacitor and reactor rooms and GIS rooms should not exceed 40 °C, while that for low-voltage distribution rooms and battery rooms should not exceed 30 °C. For rooms with more frequent human activities, such as relay protection and communication rooms, tool rooms, and document rooms, the summer temperature should be controlled between 26–28 °C. These data provide important references for the HVAC settings in EnergyPlus.

Ventilation Settings: Most rooms in the substation can regulate the environment through natural ventilation. However, some rooms that need to exhaust waste gases in a timely manner have clear mechanical ventilation design requirements. The low-voltage distribution room requires natural air intake and a mechanical exhaust, with an exhaust rate of ≥12 times/h; the relay protection and communication room requires natural air intake and a mechanical exhaust, with an exhaust rate of ≥6 times/h; the GIS room uses mechanical ventilation, and indoor air is not allowed to recirculate, with a normal ventilation rate of no less than 2 times/h. These settings are configured through the ZoneVentilation module in EnergyPlus.

Heat Disturbance Settings: The heat disturbances in these rooms mainly come from human activities and equipment heat generation. Tool rooms, document rooms, and relay protection and communication rooms, which have more frequent personnel movement, are set with a personnel density of 2 to 8 persons in EnergyPlus, according to the substation’s duty situation. In addition, the relay protection and communication rooms also contain a large number of heat-generating equipment cabinets, with the heat disturbance intensity set at 70 W/m2.

Lighting Settings: This part of the heat disturbance is set through the Lights module in EnergyPlus, with the power per unit area set at 4 W/m2 to simulate the energy consumption of the lighting equipment.

2.3.4. Envelope Parameters

To compare the photovoltaic-module-integrated facades suitable for the two working conditions, a computational model for the thermal performance of the building envelope and a thermal balance model for the PV wall were established based on the previously selected typical case. By simulating the performance of ordinary walls and different PV wall constructions, the differences in the thermal insulation effects of the PV walls were compared to determine the optimal wall construction solution.

Typically, building envelopes adopt a uniform multilayer composite system, consisting—from outside to inside—of exterior wall paint, a mortar layer, an EPS insulation layer, and a concrete substrate. The thickness and physical properties of each layer are based on Chinese national standards [32], ensuring that the thermal balance simulations accurately reflect the building’s actual thermal performance and heat transfer characteristics. The integration of PVs with the envelope is implemented in three configurations, PVs + wall; PVs + air gap + wall; and PVs + EPS + wall, with the material parameters listed in Table 4. For the PVs + air gap + wall setup, particular attention should be paid to heat dissipation within the air cavity between the PV panel and the concrete wall. The air gap is set to 100 mm, and heat transfer is modeled using the GapConvectionRadiation model, which accounts for both radiative and convective heat exchange.

Table 4.

Parameters of materials for each layer of the building envelope.

In EnergyPlus, the power generation performance of PV modules can be simulated using three methods: the simple model, the Equivalent One-Diode model, and the Sandia model [33]. The simple model allows users to manually define the conversion efficiency, giving them full control over the PV module’s performance. It does not require electrical or optical parameters; instead, it simulates the PV array based solely on the specified efficiency [34]. Although it is less accurate than other methods, the simple model is commonly used during the early design stage for quick preliminary assessments due to its straightforward setup and rapid computation. In the “PhotovoltaicPerformance: Simple” settings, referring to commonly available photovoltaic module parameters on the market, we set the energy conversion efficiency to 0.18, the power of a single module to 500 W, and the coverage ratio of each surface to 80%.

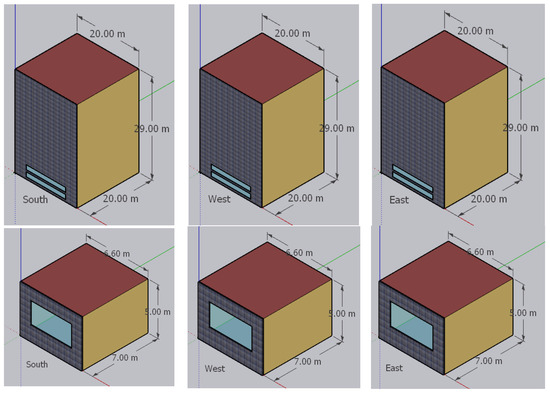

2.4. Numerical Simulation

The simulation study first focuses on different construction layers of PV walls. Initially, for rooms with high-power heat sources inside and using stack ventilation, a transformer room in the model is selected as the test object. Its front side is equipped with a PV-module-integrated wall, while the other three sides are made of ordinary concrete walls. The coldest day in winter and the hottest day in summer each year are chosen as design days. The indoor temperature changes throughout the day when the front side faces east, west, and south, respectively, are detected, serving as the reference basis for the energy-saving effect of the envelope structure under this condition. Secondly, for rooms with personnel movement that require air conditioning for temperature control, a secondary equipment room in the model is selected as the test object. Its front side is equipped with a PV wall, while the other three sides are made of ordinary concrete walls. In summer, with the air conditioning temperature set at 26 °C, the total annual air conditioning energy consumption when the PV panels are laid on the east, west, and south sides, respectively, is detected, serving as the reference basis for the energy-saving effect of the maintenance structure under this condition (Figure 4).

Figure 4.

Photovoltaic panels are laid facing south, west, and east.

Next, analyze the impact of building orientation on the energy-saving performance of substations. By adjusting the building’s long axis to four typical orientations—east, west, south, and north—and installing photovoltaic systems on the three exterior facades excluding the north facade, a coupled model of building energy consumption and PV power generation is established. Based on this, annual dynamic energy consumption simulations and photovoltaic power generation calculations are performed.

The HVAC cooling energy consumption, lighting energy consumption, and ventilation energy consumption of the building are obtained through “Output:Variable”. The sum of these components gives the total building energy consumption Etotal. Meanwhile, the direct current electricity generated by the photovoltaic system Epv is also obtained. In the post-processing stage, the net building energy consumption Enet is calculated as the difference between the total energy consumption and the photovoltaic generation, as shown in Equation (1).

Enet = Etotal − Epv,

In addition, the energy-saving rate is calculated as a reference for evaluating the energy-saving performance of the PV system. This calculation includes two aspects: the passive energy-saving rate ηpassive resulting from the thermal insulation effect of the PV modules, as shown in Equation (2), and the active energy-saving rate ηPVGenerate achieved by replacing conventional electricity with PV generation, as shown in Equation (3). In the equations, EPVfilled represents the building energy consumption under the PV installation scenario with an air gap or EPS-filled insulation layer; EOrdinary represents the baseline energy consumption without PV modules; and EPVGenerate refers to the electricity generated by the photovoltaic system.

ηpassive = (EPVfilled − EOrdinary)/EOrdinary,

ηPVGenerate = EPVGenerate/EOrdinary,

The total energy-saving rate of the substation building η is expressed as the sum of the two components, as shown in Equation (4):

η = ηpassive + ηPVGenerate,

Subsequent evaluations of the PV energy-saving performance will be conducted using both net energy consumption Enet and energy-saving rate η as indicators.

2.5. Economic Analysis Method

This study conducts a preliminary cost–benefit analysis of PV wall structures suitable for installation on the surfaces of substations, based on the life cycle cost (LCC) model of the PV system. The economic evaluation mainly includes the calculation of initial costs and operation costs, PV power generation revenue, and payback period.

The installed capacity of the PV system (P) is the primary factor affecting the initial and operation costs. It can be calculated based on the PV area installed on the building facade (S), and the unit power per area of the PV modules (P1), as shown in Equation (5).

P = P1 × S,

The calculation of the initial cost (Cinitial) and the annual operation and maintenance cost (Cannual) can be derived from the unit installed cost (C1) and the unit operation cost (C2) of distributed PV systems for industrial and commercial use in China. Both C1 and C2 can be obtained from documents published by the China Photovoltaic Industry Association [35]. The calculations are shown in Equations (6) and (7).

Cinitial = P × C1,

Cannual = P × C2,

Based on the simulated annual power generation results (Epv), the annual revenue of the PV system (Rannual) is comprehensively calculated according to the market electricity price (Ce) and the subsidy standards for distributed PV systems set by the Chinese government (Rgov). The revenue includes two parts: electricity cost savings and government subsidies, as shown in Equation (8).

Rannual = Epv × Ce × Rgov,

The payback period of the PV system is determined based on the calculation of costs and revenues. It is important to note that PV systems typically have a relatively long payback period. Therefore, when assessing the return on investment, it is essential to take into account the cumulative discounted cash flow CCF(n) and the net present value (NPV), which together provide a more accurate reflection of the project’s actual return after considering both cost and time factors. The calculations are shown in Equations (9) and (10). The year in which the NPV just falls below zero is considered the payback year.

3. Results and Discussion

3.1. The Passive Energy-Saving Effects of Different Wall Construction Layers

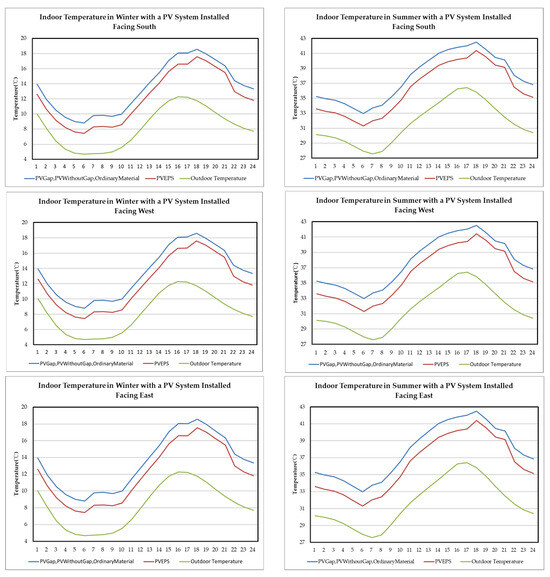

Figure 5 illustrates the changes in the indoor temperature of rooms with similar conditions to transformer rooms when the PV envelope is oriented towards the south, east, and west during the hottest days in summer and the coldest days in winter. Under the climatic conditions of Guangdong, the outdoor dry bulb temperature exhibits a sinusoidal curve characteristic, peaking at noon and reaching the trough from early morning to dawn. The diurnal temperature range is approximately 9 °C in summer and about 7.5 °C in winter. These data are used as the evaluation basis for indoor temperature under different envelope construction layers. By comparing the indoor temperature curves of different envelope materials with the outdoor dry bulb temperature curve, it is found that the indoor temperature of the transformer room is always higher than the outdoor temperature. In both seasons, the daytime peak and night-time trough of the indoor temperature lag behind the outdoor temperature by no more than 1 h. Overall, the hourly indoor temperature change trend remains synchronized with the outdoor air temperature curve. When using ordinary concrete construction, the daytime temperature peak in summer is 6 °C higher than the outdoor temperature, and the night-time temperature is 5–7 °C higher; in winter, the daytime temperature peak is 6 °C higher than the outdoor temperature, and the night-time temperature is 3–6 °C higher. However, when the PV + EPS construction form is adopted, the daytime temperature peak in summer is reduced by 1.5 °C compared to ordinary concrete materials, and the night-time temperature is reduced by about 1.7 °C; in winter, the daytime temperature peak is reduced by 1 °C compared to ordinary concrete materials, and the night-time temperature is reduced by about 3.7 °C. It is worth noting that when PV is in direct contact with the concrete wall or there is an air gap in between, the indoor temperature change curve is highly coincident with the ordinary concrete construction, with a maximum temperature difference of no more than 1 °C. This is because there is a large height difference between the ventilation inlets and outlets of the transformer room, and the efficient stack ventilation makes it difficult for the internal heat to accumulate near the wall. Therefore, the main heat absorbed by the wall still comes from solar radiation. The PV + EPS form can effectively increase the thermal resistance of the wall, providing better insulation to control the rise of the internal temperature. Further analysis of the measured data of different PV facade orientations shows that the daily indoor temperature change curves under the three facade orientations also show basically the same fluctuation characteristics, with peak and trough deviations of less than 1 °C. Therefore, the impact of orientation on indoor thermal environment parameters is relatively small. From the perspective of equipment safety, controlling the rise of the indoor temperature is the key to ensuring the normal operation of equipment in such rooms.

Figure 5.

Indoor temperature in summer and winter with a photovoltaic system installed facing different directions (the temperature differences among PVGap, PVWithoutGap, and OrdinaryMaterials are too small, resulting in overlapping in the figure).

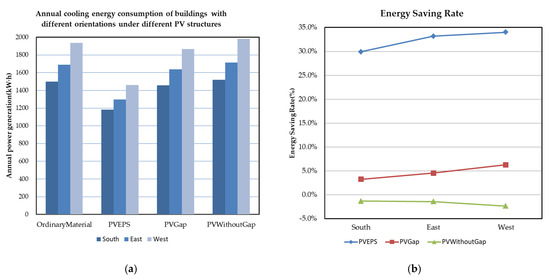

Figure 6 illustrates the annual air-conditioning cooling energy consumption of rooms that rely on air-conditioning for temperature regulation, with the photovoltaic (PV) envelope oriented towards the south, east, and west. Given the climatic conditions of Guangdong Province, all the construction layers show that the cooling energy consumption is highest when oriented towards the west and lowest when oriented towards the south. This indicates that the west facade, due to the angle and duration of sunlight, absorbs more solar radiation heat on the building’s exterior surface, leading to a significant increase in the indoor cooling load. When using ordinary concrete materials, the cooling energy consumption for the south orientation is 1500 kWh, for the east orientation it is 1700 kWh, and for the west orientation it is 1950 kWh. These figures serve as the evaluation basis for indoor temperature under different envelope construction layers. After switching to constructions with air cavities or the PV + EPS construction layers, the energy consumption is reduced. According to Figure 6, the 100 mm thick EPS insulation layer effectively blocks heat transfer within the PV panels, resulting in cooling energy savings of over 30%. The construction with a 100 mm air cavity, which uses air convection for heat dissipation to reduce thermal conduction through the envelope, achieves an energy-saving rate of 3–6%. It is important to note that when PV components are directly attached to the concrete wall, the internal heat generated by photovoltaic power generation is transferred to the interior, which, to some extent, actually increases the indoor cooling energy consumption. The data in Figure 5 further indicates that under this condition, building orientation has a significant impact on the energy consumption regulation of rooms with PV envelopes: the cooling energy consumption of the west-oriented PV system shows the most prominent reduction, with an energy-saving efficiency far exceeding that of the south and east orientations. This phenomenon can be attributed to the strong heat conduction blocking effect of EPS insulation and air cavity insulation on the west facade under the high-radiation environment of Guangdong Province, enabling the west orientation to maximize its thermal insulation efficiency.

Figure 6.

(a) Annual cooling energy consumption of buildings with different orientations under different PV structures. (b) Energy-saving rate of different PV enclosure structures in different orientations.

3.2. The Energy-Saving Effects of Different Building Orientations

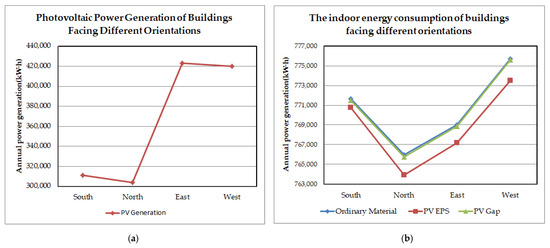

After analyzing the energy-saving effects of the two operating conditions of the substation and the different wall construction layers separately, a comprehensive energy consumption simulation analysis of the entire building under different orientations was further conducted, and a comparative calculation of its annual photovoltaic power generation and building energy consumption was performed. Figure 7 shows the total power generation of the facade photovoltaics when the transformer room’s long axis is oriented towards the south, north, east, and west, with photovoltaics installed on all the facades other than the north facade. When the long axis is oriented towards the south or north, the annual power generation of the building’s facade photovoltaic system is approximately 300,000 to 310,000 kWh; however, when the long axis is oriented towards the east or west, the annual power generation of the building’s facade photovoltaic system increases by about 30% compared to the south or north orientation. This is because the facade where the long axis is located has a larger area available for photovoltaic installation, thereby increasing the total power generation. Although the south orientation has the highest power generation efficiency, this also means that the other side of the long axis will face the north, which has lower power generation efficiency and no photovoltaic installation, thus reducing the total photovoltaic power generation of the building’s facade to some extent. In contrast, when the long axis is oriented towards the east, the favorable solar radiation conditions in the east–west direction lead to an increase in the total power generation.

Figure 7.

(a) Photovoltaic power generation of buildings facing different orientations. (b) The indoor energy consumption of buildings facing different orientations.

This figure reveals the correlation between the substation orientation and the building’s annual energy consumption. The study shows that when the building’s long axis is oriented towards the west, the energy consumption reaches its peak. For a building using ordinary concrete materials, the energy consumption is 775,500 kWh, while the energy consumption is the lowest when the long axis is oriented towards the north, with the same material, the energy consumption drops to 766,000 kWh. This phenomenon is due to the fact that the long axis facade of the transformer room has a higher window-to-wall ratio compared to other facades. When oriented towards the west, the large transparent surface area leads to a significant increase in solar radiation heat gain. Conversely, the north orientation effectively reduces the cooling demand by minimizing direct solar radiation. It is worth noting that although the north orientation is beneficial for energy saving, its photovoltaic system has a lower power generation efficiency and generally does not have photovoltaic installations. Therefore, a photovoltaic power generation—building energy consumption coupling model should be established to reflect the synergistic relationship between the comprehensive optimization of building orientation and photovoltaic energy systems through the net building energy consumption. This figure quantitatively analyzes the impact mechanism of building orientation and photovoltaic-integrated facade construction on energy consumption performance. The data shows that both the photovoltaic construction with an air cavity and the photovoltaic construction with EPS can improve the thermal insulation performance of the envelope structure. The energy-saving rate of PVs + gap relying on thermal insulation is between 0.02% and 0.03%, with differences of less than 0.01% for different orientations. The thermal insulation effect of PVs + EPS is more significant, with an energy-saving rate of about 0.12% to 0.28% relying on thermal insulation (differences of less than 0.14% for different orientations) (Table 5). However, it is important to note that relying solely on thermal insulation measures has a limited impact on the overall energy consumption. The core regulatory element of net building energy consumption is still the efficiency of photovoltaic power generation. Specifically, when the building’s long axis is oriented towards the north–south direction, the photovoltaic system can contribute an energy-saving rate of around 40%, with a corresponding net energy consumption of about 460,000 kWh. In contrast, due to the increased solar radiation intensity, the photovoltaic power generation energy-saving rate for east–west orientations reaches around 55%, with the net energy consumption significantly reduced to around 350,000 kWh. This confirms the decisive impact of photovoltaic power generation on the net building energy consumption. When the building’s long axis is aligned with the high irradiation direction (east–west direction), photovoltaic power generation can offset more than half of the building’s energy consumption. In design, it is essential to coordinate building orientation with photovoltaic system spatial layout, achieving energy-saving goals through the regulation of radiation gain and facade construction layers.

Table 5.

Comparison of energy-saving performance of building photovoltaic systems under different orientations and materials.

3.3. Sensitivity Analysis and Uncertainty Evaluation

To test the sensitivity of the results to key parameters and verify the robustness of the proposed PV configuration and building orientation strategies, this study applies the One-at-a-Time (OAT) method. Based on the EnergyPlus simulation model, key variables affecting power generation and thermal performance were selected for analysis, as listed in Table 6.

Table 6.

Key parameters for power generation and thermal performance in sensitivity analysis.

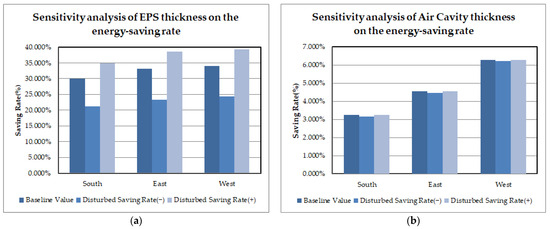

Figure 8 compares how changes in EPS thickness and air cavity thickness affect the system’s energy-saving rate. The results show that EPS thickness has a strong impact: increasing it can boost the energy-saving rate by up to 5%, while decreasing it can reduce the rate by up to 9%. This highlights the high sensitivity of PV-module-integrated systems to the thermal resistance of the building envelope, with EPS thickness being a key factor. In contrast, air cavity thickness has minimal influence, with changes in the energy-saving rate staying within ±1%, indicating good system stability. Therefore, in design optimization, priority should be given to the accurate selection and construction of highly sensitive parameters like EPS thickness to improve system performance and reliability.

Figure 8.

(a) Sensitivity analysis of the effect of EPS thickness on the energy-saving rate; (b) Sensitivity analysis of the effect of air cavity thickness on the energy-saving rate.

In simple PV system models, power generation is theoretically proportional to PV coverage and conversion efficiency. Therefore, changes in these parameters lead to proportional fluctuations in the output. As Table 7 shows, a ±5% change in the original 18% efficiency results in about a ±27.8% variation in annual power generation. When the long side of the transformer room faces south or north, the fluctuation in power generation is around ±40,000 kWh. When the long side faces east or west, due to better solar exposure, the power generation is up to ±50,000 kWh. The corresponding variation in the energy-saving rate ranges from approximately 5% to 6%. Similarly, A ±10% change in the original 80% coverage ratio leads to about a ±12.5% change in power generation. For a north–south orientation, the power generation may vary by ±90,000 kWh, with the energy-saving rate fluctuating around 10%. For an east–west orientation, the variation in power generation can reach ±120,000 kWh, with the energy-saving rate increasing up to approximately 15%. In summary, the PV system’s energy savings are highly sensitive to conversion efficiency and coverage ratio changes, especially in east–west layouts. Since PVs + gap and PVs + EPS mainly affect insulation, which contributes little to total energy savings, the construction type has a limited impact on energy-saving under power generation disturbances. In design, priority should be on maintaining the PV module’s efficiency and coverage stability to ensure the overall system performance and reliability.

Table 7.

Sensitivity analysis of coverage ratio and conversion efficiency thickness on the energy-saving rate.

3.4. Economic Analysis of Different Installation Methods

Common PV panels on the market are rated at 500 W. When the substation transformer room’s long side faces different orientations, the installable PV area and capacity for each side are shown in Table 8. The initial investment for commercial and industrial distributed PV systems in China mainly includes the costs for panels, inverters, mounts, cables, construction, grid connection, primary equipment, and secondary equipment. In 2024, the initial cost is about 2.70 CNY/W with an operation cost of 0.046 CNY/(W·year). If EPS material is used, an additional 20 CNY/m2 is added. Based on installation method and capacity, the corresponding costs are shown in Table 8.

Table 8.

Installed PV module’s capacity and costs.

According to energy simulations, all PV electricity is for substation self-use. For simplicity, the electricity price is set at 0.75 CNY/kWh and the subsidy at 0.3 CNY/kWh. The annual revenue and payback periods (PBPs) are calculated according to Table 9. This study uses an annual discount rate of 3% to evaluate the payback periods of different building orientations and BIPV-module integration methods, considering both the initial investment and operation and maintenance costs of various PV construction types. The results show that with a 25-year system lifespan, the PBPs generally range from 20 to 25 years, which is close to the lower limit of the system’s life. Due to the annual performance degradation of PV modules, overall returns are relatively slow. Although the PVs + EPS structure adds some initial cost, its payback period is less than one year longer than that of the PVs + gap structure, indicating minimal economic impacts from EPS in this case. In contrast, building orientation significantly affects annual power generation and payback time. When the substation’s long axis faces east–west, solar efficiency improves, shortening the payback period by about 4–5 years compared to a north–south orientation. The results show that under the current subsidy or incentive conditions, the substation’s BIPV system has the potential for cost recovery, but the PBP is long and its economic attractiveness is limited. To improve its feasibility for engineering applications, further efforts should focus on structural optimization, system efficiency enhancement, and the introduction of external incentive mechanisms.

Table 9.

Annual revenue and payback periods.

4. Conclusions

This study focuses on the low-carbon transformation needs of semi-outdoor substations under subtropical climatic conditions and systematically explores the optimal configuration of building-integrated photovoltaic (BIPV) systems to balance the synergy between photovoltaic power generation efficiency and the regulation of the indoor environment of industrial buildings. By comparing three types of photovoltaic envelope construction forms—direct installation, the formation of a ventilated cavity, and filling with EPS material—and combining them with different orientations of the building’s long axis (east, south, west, north), the energy-saving potential of two core functional areas, namely the high-heat-load transformer room and the living quarters requiring air-conditioning temperature control, is quantitatively assessed. The core research conclusions are as follows:

4.1. Differential Impact of BIPV Wall Construction on Passive Energy Saving

The comparison of various BIPV wall configurations indicated that the PVs + EPS composite structure demonstrated relatively better energy-saving potential under typical substation conditions. In high thermal load environments, such as transformer rooms, it helps reduce the indoor temperature rise by enhancing the thermal resistance of the building envelope. In air-conditioned living spaces, it also contributes to a noticeable reduction in the cooling energy demand. In contrast, the PVs + air cavity structure relies on convective heat dissipation and shows limited thermal regulation in naturally ventilated spaces, though it can still provide some cooling energy savings in conditioned environments. Notably, the sensitivity analysis showed that the thickness of the filler material in BIPV wall structures affects the building energy use by altering the thermal performance of the envelope. EPS thickness has a more efficient impact on energy savings compared to air cavities. Therefore, the energy-saving performance can be influenced by adjusting its thickness. However, its application should still be evaluated based on actual operating conditions.

4.2. Determinative Role of Building Orientation on PV Power Generation and Net Energy Consumption

Research indicated that the PV system output is the dominant factor influencing a building’s net energy consumption, with a greater impact than the passive thermal performance of the envelope. The simulation results suggested that orienting the transformer room along the east–west axis can notably increase annual PV generation compared to a north–south layout, thereby improving the energy saving rate. This advantage is primarily attributed to higher average annual solar radiation on east and west facades. The sensitivity analysis further showed that even with moderate variations in parameters such as the system efficiency or the coverage ratio, the east–west orientation maintains a relatively strong energy-saving performance, demonstrating a degree of robustness. Under favorable lighting conditions, it is recommended to prioritize an east–west longitudinal layout, combined with an optimized facade–PV module coverage design, to enhance the total energy output efficiency of the system.

4.3. Prospects for Economic Viability

The BIPV system in this study showed some cost recovery potential under current electricity prices and cost levels, but the long payback period limits its economic attractiveness. In the future, improvements in PV systems’ efficiency, better system integration, and lower installation costs are expected to reduce the unit investment costs and enhance the economic performance. Furthermore, where architectural conditions permit, additional photovoltaic systems can be installed in areas with better solar exposure and higher generation efficiency, such as rooftops or ground-level spaces, to enhance the power output and shorten the payback period. Additionally, government subsidies or other incentives could further improve the project’s return on investment, thereby increasing the feasibility of BIPV systems in the industrial building sector.

The photovoltaic structural optimization method and the building energy consumption simulation framework proposed for the 220 kV semi-outdoor substation in this study are also applicable to other types of industrial buildings with high thermal loads and complex environmental control requirements, such as data centers, industrial plants, and smelting workshops. Future research can further extend the model’s applicability by incorporating the operating conditions of different industrial scenarios and deepening the investigation of cross-disciplinary integration strategies for BIPV systems. This will promote the expansion of BIPV technology from power infrastructure to a broader range of industrial building types.

Author Contributions

Conceptualization, X.W.; Methodology, X.W. and Y.W.; Software, Y.W. and Y.T.; Validation, X.W., Y.W. and Y.T.; Formal analysis, X.W. and Y.W.; Investigation, Y.T.; Resources, X.W. and P.S.; Data curation, Y.W.; Writing—original draft, X.W., Y.W. and Y.T.; Writing—review & editing, P.S.; Visualization, Y.T.; Supervision, P.S.; Project administration, P.S.; Funding acquisition, P.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Science and Technology Project of China Southern Power Grid Co., Ltd. (GDKJXM20230406).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Xiaohui Wu and Yanfeng Wang were employed by the company Power Grid Planning Research Center of Guangdong Power Grid Co., Ltd.; the remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The authors declare that this study received funding from Southern Power Grid Co., Ltd. The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article or the decision to submit it for publication.

References

- UNFCCC. Nationally Determined Contributions Under the Paris Agreement. In Proceedings of the Conference of the Parties Serving as the Meeting of the Parties to the Paris Agreement (CMA), CMA 5, Dubai, United Arab Emirates, 30 November–12 December 2023; p. 45. [Google Scholar]

- International Energy Agency. Tracking Clean Energy Progress: Buildings. Available online: https://www.iea.org/reports/tracking-clean-energy-progress-2023 (accessed on 14 October 2024).

- United Nations Environment Programme. 2023 Global Status Report for Buildings and Construction: Beyond Foundations—Mainstreaming Sustainable Solutions to Cut Emissions from the Buildings Sector; United Nations Environment Programme: Nairobi, Kenya, 2024; ISBN 978-92-807-4131-5. [Google Scholar]

- Li, G.; Zhao, X.; Ji, J. Conceptual Development of a Novel Photovoltaic-Thermoelectric System and Preliminary Economic Analysis. Energy Conv. Manag. 2016, 126, 935–943. [Google Scholar] [CrossRef]

- Mutule, A.; Borscevskis, O.; Astapov, V.; Antoskova, I.; Carroll, P.; Kairisa, E. PV Energy Communities in Residential Apartments: Technical Capacities and Economic Viability. Sustainability 2025, 17, 2901. [Google Scholar] [CrossRef]

- Yang, R.J.; Imalka, S.T.; Wijeratne, W.M.P.; Amarasinghe, G.; Weerasinghe, N.; Jayakumari, S.D.S.; Zhao, H.; Wang, Z.; Gunarathna, C.; Perrie, J.; et al. Digitalizing Building Integrated Photovoltaic (BIPV) Conceptual Design: A Framework and an Example Platform. Build. Environ. 2023, 243, 110675. [Google Scholar] [CrossRef]

- Chen, L.; Baghoolizadeh, M.; Basem, A.; Ali, S.H.; Ruhani, B.; Sultan, A.J.; Salahshour, S.; Alizadeh, A. A Comprehensive Review of a Building-Integrated Photovoltaic System (BIPV). Int. Commun. Heat Mass Transf. 2024, 159, 108056. [Google Scholar] [CrossRef]

- Wijeratne, W.M.P.U.; Samarasinghalage, T.I.; Yang, R.J.; Wakefield, R. Multi-Objective Optimisation for Building Integrated Photovoltaics (BIPV) Roof Projects in Early Design Phase. Appl. Energy 2022, 309, 118476. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P.; Mamat, R. Solar PV and BIPV System: Barrier, Challenges and Policy Recommendation in India. Renew. Sust. Energ. Rev. 2018, 82, 3314–3322. [Google Scholar] [CrossRef]

- Martin-Chivelet, N.; Kapsis, K.; Wilson, H.R.; Delisle, V.; Yang, R.; Olivieri, L.; Polo, J.; Eisenlohr, J.; Roy, B.; Maturi, L.; et al. Building-Integrated Photovoltaic (BIPV) Products and Systems: A Review of Energy-Related Behavior. Energy Build. 2022, 262, 111998. [Google Scholar] [CrossRef]

- Jhumka, H.; Yang, S.; Gorse, C.; Wilkinson, S.; Yang, R.; He, B.-J.; Prasad, D.; Fiorito, F. Assessing Heat Transfer Characteristics of Building Envelope Deployed BIPV and Resultant Building Energy Consumption in a Tropical Climate. Energy Build. 2023, 298, 113540. [Google Scholar] [CrossRef]

- U.S. Department of Energy (DOE). Summary of the Challenges and Opportunities for Building-Integrated Photovoltaics (BIPV) RFI. Available online: https://www.energy.gov/eere/solar/summary-challenges-and-opportunities-building-integrated-photovoltaics-rfi (accessed on 7 April 2025).

- Joshi, S.; Sharma, V.K.; Deegwal, J.K. Renewable Energy Integration in Conventional Grid: Potential, Challenges, and Aspects. ECS Trans. 2022, 107, 3255–3266. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, Y.; Liu, W.; Gong, T.; Liu, K. Heat Transfer Model Founded and Regional Suitability Analysis of Photovoltaic Walls with Different Structures. J. Therm. Sci. 2022, 31, 1970–1989. [Google Scholar] [CrossRef]

- Zhou, L.; Qi, F.; Yan, X. A Review of Research on the Passive Effect of Building Photovoltaic Systems and Analysis of Influencing Factors. Sol. Energy 2024, 278, 112766. [Google Scholar] [CrossRef]

- Peng, J.; Curcija, D.C.; Lu, L.; Selkowitz, S.E.; Yang, H.; Mitchell, R. Developing a Method and Simulation Model for Evaluating the Overall Energy Performance of a Ventilated Semi-Transparent Photovoltaic Double-Skin Facade. Prog. Photovolt. 2016, 24, 781–799. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H.; Ma, T. Comparative Study of the Thermal and Power Performances of a Semi-Transparent Photovoltaic Facade under Different Ventilation Modes. Appl. Energy 2015, 138, 572–583. [Google Scholar] [CrossRef]

- Yang, S.; Cannavale, A.; Prasad, D.; Sproul, A.; Fiorito, F. Numerical Simulation Study of BIPV/T Double-Skin Facade for Various Climate Zones in Australia: Effects on Indoor Thermal Comfort. Build. Simul. 2019, 12, 51–67. [Google Scholar] [CrossRef]

- Irshad, K.; Habib, K.; Thirumalaiswamy, N. Performance Evaluation of PV-Trombe Wall for Sustainable Building Development. In Proceedings of the 12th Global Conference on Sustainable Manufacturing—Emerging Potentials, Johor Bahru, Malaysia, 22–24 September 2014; Selige, G., Yusof, N.M., Eds.; Elsevier Science Bv: Amsterdam, The Netherlands, 2015; Volume 26, pp. 624–629. [Google Scholar]

- ElSayed, M.S. Optimizing Thermal Performance of Building-Integrated Photovoltaics for Upgrading Informal Urbanization. Energy Build. 2016, 116, 232–248. [Google Scholar] [CrossRef]

- Su, Y.; Zhao, B.; Lei, F.; Deng, W. Numerical Modelling of Effect of Channel Width on Heat Transfer and Ventilation in a Built-in PV-Trombe Wall. J. Phys. Conf. Ser. 2016, 745, 032069. [Google Scholar] [CrossRef]

- Taser, A.; Koyunbaba, B.K.; Kazanasmaz, T. Thermal, Daylight, and Energy Potential of Building-Integrated Photovoltaic (BIPV) Systems: A Comprehensive Review of Effects and Developments. Sol. Energy 2023, 251, 171–196. [Google Scholar] [CrossRef]

- Albinius, N.; Rau, B.; Riedel, M.; Ulbrich, C. A Comprehensive Case Study of a Full-Size BIPV Facade. Energies 2025, 18, 1293. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, D.; Li, J.; Zhang, L.; Shen, T.; Yin, Y. A Study on the Exploration of the Development Process of Regenerative Applications of Energy Technologies in Industrial Warehouse Buildings: Bibliometric Research from 2004 to 2024. Buildings 2024, 14, 4019. [Google Scholar] [CrossRef]

- Audebert, P.; Milne, E.; Schiettecatte, L.-S.; Dionisio, D.; Sinitambirivoutin, M.; Pais, C.; Proenca, C.; Bernoux, M. Ecological Zoning for Climate Policy and Global Change Studies. Nat. Sustain. 2024, 7, 1294–1303. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, S.; Lin, H.; Liu, S.; Xiao, Y. Ventilation and Thermal Comfort Performances of Combined Climate-Buffer-Zone Systems in Subtropical Area. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 042029. [Google Scholar] [CrossRef]

- Tripathi, A.K.; Aruna, M.; Sharma, S.; Kumar, C.; Didwania, M. Performance Assessment of Solar PV Panels under Varying Environmental Conditions: A Laboratory and Field-Based Approach for Sustainable Energy in Mining Operations. In Environmental Science and Pollution Research; Springer: Berlin/Heidelberg, Germany, 2025. [Google Scholar] [CrossRef]

- Khoong, W.K.; Bellam, S. Evaluating the Growth of Singapore’s Solar Electricity Capacity towards Green Plan 2030 Targets and beyond Using System Dynamics Modelling Approach. Appl. Energy 2024, 376, 124091. [Google Scholar] [CrossRef]

- Yao, H.; Zang, C. The Spatiotemporal Characteristics of Electrical Energy Supply-Demand and the Green Economy Outlook of Guangdong Province, China. Energy 2021, 214, 118891. [Google Scholar] [CrossRef]

- Queiroz, N.; Westphal, F.S.; Ruttkay Pereira, F.O. A Performance-Based Design Validation Study on EnergyPlus for Daylighting Analysis. Build. Environ. 2020, 183, 107088. [Google Scholar] [CrossRef]

- Yin, K. Principles of Transformer Design; China Electric Power Press: Beijing, China, 2010. [Google Scholar]

- GB 50176-2016; Thermal Design Code for Civil Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2016.

- Kratochvil, J.; Boyson, W.; King, D. Photovoltaic Array Performance Model; SAND2004–3535; U.S. Department of Energy: Oak Ridge, TN, USA, 2004.

- EnergyPlus. Engineering Reference: EnergyPlus 8.0 Documentation. Available online: https://bigladdersoftware.com/epx/docs/8-0/engineering-reference/page-111.html (accessed on 14 October 2024).

- China Photovoltaic Industry Association. China PV Industry Development Roadmap; China Photovoltaic Industry Association: Beijing, China, 2025; pp. 53–56. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).