1. Introduction

Food waste and loss in the Australian horticulture sector represent significant economic, environmental, and social challenges. In Australia, horticulture, encompassing fruits, vegetables, and ornamental plants, contributes to approximately 33% of the nation’s agricultural food waste, amounting to over 1.3 million tonnes annually [

1]. The high perishability of horticultural products, combined with production inefficiencies, market demands, and consumer expectations, leads to substantial losses at each stage of the supply chain, from initial production to retail [

2]. This waste results in financial losses for growers, distributors, and retailers while imposing broader societal costs, such as resource depletion, greenhouse gas emissions, and strain on food security [

3,

4]. Despite Australia’s commitment to the United Nations Sustainable Development Goal (SDG) target of halving food waste by 2030, achieving this goal in the horticulture sector requires coordinated actions, effective policy, and engagement across the supply chain.

While food waste has received increasing attention in recent years, existing efforts in Australia’s horticulture sector have been primarily ad hoc and lack a comprehensive, sector-specific action plan [

5]. Waste in this sector is often driven by factors such as overproduction, cosmetic standards, and limited options for surplus repurposing, yet these root causes have not been addressed systematically [

6]. Furthermore, current interventions tend to focus on consumer-level waste, with limited emphasis on reducing food loss at earlier stages of the supply chain where substantial waste occurs. Without a targeted approach that reduces food waste in production, distribution, and retail stages, achieving meaningful reductions in horticultural food waste remains unlikely.

Recent literature related to horticulture waste has primarily focused on identifying general causes and volumes of food waste at specific supply chain stages such as consumer-level waste [

7,

8,

9]. However, upstream waste—particularly during production and processing—remains underexplored [

10,

11]. Limited attention has been paid on how policy and industry practices can adapt to address the unique challenges in these upstream stages. While measurement of food waste has gained attention in recent studies [

12,

13,

14], much of this work adopts a reductionist approach, focusing on single points within the supply chain rather than considering systemic interdependencies.

An emerging body of literature emphasizes stakeholder perspectives on waste reduction strategies, particularly regarding factors that influence practical and accepted interventions [

15,

16,

17]. However, stakeholder insights, especially from growers, distributors, and retailers, remain underutilized in existing policy frameworks. This gap limits the development of strategies that account for operational realities and constraints faced by actors across the supply chain. Additionally, few studies have addressed whole-of-chain approaches that integrate business-to-business (B2B) relationships to enhance supply chain coordination [

18,

19,

20].

This study seeks to answer the primary research question: What strategies can systematically reduce food waste across the Australian horticulture supply chain to achieve the national target of halving food waste by 2030? To address this question, the study identifies and analyses waste hotspots, root causes, and evidence-based interventions. Thus, the objective is to develop a comprehensive action plan to reduce food waste in the horticulture sector. Specifically, the study establishes baseline measurements, categorizes actionable strategies into enabling, preventive, and repurposing actions, and fosters stakeholder participation to ensure the plan’s practical relevance and sector-wide adoption.

The remainder of the paper is structured as follows:

Section 2 reviews relevant planning theories for designing methods and processes involved with developing an action plan.

Section 3 details the data collection methods and analytical approach employed in this study.

Section 4 provides an overview of the Australian horticulture sector, including the scale and impact of food waste.

Section 5 presents the key findings, highlighting waste hotspots, root causes, and proposed strategies.

Section 6 outlines the action plan, including priority actions and implementation timelines.

Section 7 discusses barriers to implementation and offers recommendations for future research and practical applications. Finally,

Section 8 concludes the paper.

2. Developing Action Plans

Mainstream planning theories provide essential frameworks for developing structured and evidence-based action plans to tackle complex issues such as food waste in the horticulture sector. Among these, rational planning theory emphasizes systematic, data-driven decision-making. According to de Smit and Rade [

21], rational planning offers a logical, step-by-step approach that is particularly useful for identifying critical issues, such as waste hotspots, and prioritizing interventions. Similarly, van der Werf, et al. [

22] highlights that this theory is well-suited to addressing challenges requiring clear objectives and measurable outcomes, such as reducing food waste.

Collaborative planning theory adds an important dimension to the process by emphasizing stakeholder engagement. Recognized by Turcotte and Pasquero [

23] as a cornerstone of effective planning, this theory posits that co-creating solutions with stakeholders ensures practical, widely accepted interventions. For instance, Krishnan, et al. [

24] advocated participatory approaches for addressing sustainability challenges in multi-actor systems such as horticulture supply chains. By incorporating diverse perspectives, collaborative planning fosters a sense of ownership among stakeholders, which is critical for successful implementation of action plans.

Systems theory complements these approaches by providing a holistic perspective on the interconnected nature of the horticulture supply chain. de Gorter, et al. [

25] underscores the importance of understanding how interventions at one stage, such as production, can have cascading effects on downstream stages like retail. Mansfield and Mendes [

26] similarly note that systems theory helps planners address root causes rather than isolated symptoms, which is essential for long-term sustainability. This theoretical lens aligns with the methodology adopted for this study, which considers the entire supply chain to identify and address systemic inefficiencies.

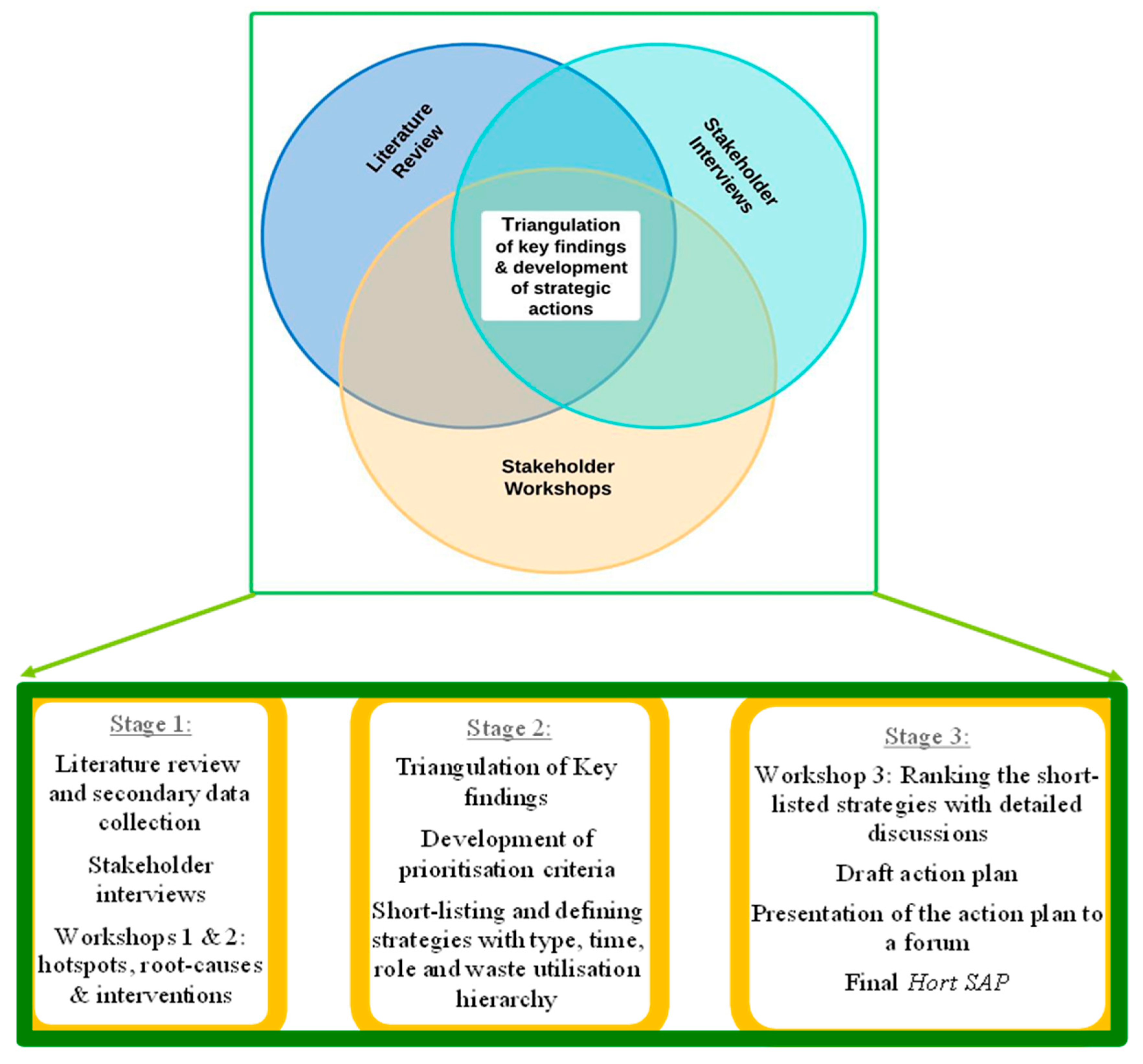

The sector action planning process integrates foundational planning theories (rational, collaborative, and systems theories) through a “review-plan-do” framework and this framework acts as a methodology for the present study. This methodology for addressing food waste has been endorsed by the Australian National Food Waste Strategy Steering Committee. The “review-plan-do” framework ensures systematic data collection, strategy development, and implementation, allowing for continuous refinement based on feedback.

The review phase establishes a strong foundation by collecting data through literature reviews, stakeholder interviews, and workshops to identify waste hotspots and root causes. This evidence-based approach ensures that strategies address the most significant challenges. The plan phase builds on these insights, translating findings into actionable and practical strategies aligned with stakeholder needs. Through consultations with growers, distributors, and retailers, this phase refines solutions while adhering to the food recovery hierarchy, emphasizing prevention, repurposing, and recycling. Finally, the “do phase” implements these strategies across the supply chain, supported by ongoing monitoring and feedback mechanisms. This iterative approach ensures adaptability and continuous improvement, with stakeholders actively shaping adjustments based on real-world outcomes.

A key feature of this methodology is the adoption of a co-designed method, which sets it apart from traditional top-down planning approaches. This participatory model directly involves stakeholders—referred to as the “beneficiaries” of the plan—in every phase of development, ensuring they have a sense of ownership over the plan. Workshops, interviews, and collaborative sessions were designed to include input from growers, processors, retailers, and other supply chain actors, allowing them to identify waste hotspots, propose solutions, and define roles in the implementation process. This approach aligns with the Arnstein [

27] ladder of citizen participation, which emphasizes the importance of shared decision-making for creating relevant and feasible plans. By involving stakeholders at every stage, the study not only addresses their specific needs but also ensures that the strategies are practical and well-supported by those who will implement them. In this way, the methodology integrated the rational, collaborative, and systems-based planning theories, creating a robust action plan for achieving the goal of halving horticultural food waste by 2030.

3. Data and Methods

The study utilized a robust data collection methodology that ensures comprehensive insights into food waste across the horticultural supply chain. Data collection occurred in three distinct stages: literature review and secondary data collection, stakeholder interviews, and workshops. These methods provided a well-rounded understanding of the issue, facilitating the identification of root causes and actionable strategies for reducing food waste.

Figure 1 shows three stages of this methodology and how each stage builds on the previous one to create a practical and adaptable horticulture sector action plan (Hort SAP).

In Stage 1, a detailed literature review and secondary data collection were conducted to establish a baseline understanding of food waste issues in the horticulture sector. A total of 150 relevant academic and industry documents were reviewed. These included journal articles, government reports, technical studies, and policy documents. Databases used for this process included Scopus, Web of Science, Google Scholar, and government portals such as DAFF (Department of Agriculture, Fisheries and Forestry) and FIAL (Food Innovation Australia Limited). The search criteria included a combination of keywords such as “horticulture food waste”, “fruit and vegetable loss”, “food waste Australia”, “food supply chain waste”, and “food recovery strategies”. The review focused on documents published between 2010 and 2024, prioritizing peer-reviewed studies and national reports related to Australian contexts, while also including global best practices for comparison. This systematic review informed the study design, waste hotspot identification, and development of the action plan.

Stakeholder interviews were then carried out with 19 representatives from various sectors, including growers, processors, distributors, and policymakers. The selection of interview participants followed a purposive sampling approach, aiming to include individuals with direct experience and decision-making roles related to food waste management. Participants were identified through existing industry networks, previous project collaborators, and professional referrals. While the number of interviews was limited, efforts were made to ensure diverse geographic and sectoral representation across key horticultural regions in Australia, including Queensland, Victoria, New South Wales, and South Australia. The aim was not to generalize but to collect rich, expert insights that could inform the development of a practical sector-wide action plan. This method aligns with qualitative research practices where in-depth knowledge from a smaller number of informed stakeholders is prioritized over large-scale surveys [

28].

The interviews were designed to validate the findings from the literature review and gather industry-specific insights. The distribution of the interview participants was as follows: 6 industry representatives, 3 government, 3 retailers, 2 producers, and 1 each from research, marketing, distribution, processing, and transport sectors. The interviews explored a range of themes: stages of the supply chain where waste occurs, causes of food loss, waste destinations, second-grade produce management, and strategies for waste mitigation. Example questions included the following:

At what stage of the horticulture supply chain does most food waste occur?

What strategies could divert oversupplied products to new markets?

Do cosmetic standards at the retail level contribute to food waste?

What training is required to reduce waste across the supply chain?

Following the interviews, two stakeholder workshops were conducted to gather detailed qualitative data on food waste challenges and possible interventions. The main objective of these workshops was to identify key food waste hotspots across the horticultural supply chain and to uncover the root causes contributing to these waste points. Participants were divided into focus groups based on their roles (e.g., producers, processors, retailers), and each group discussed guided questions prepared by the research team. These questions focused on the types and quantities of waste experienced, the challenges in reducing waste, and the barriers to redistribution or repurposing of surplus produce. Facilitators recorded group discussions using structured templates, and data were later analysed thematically.

Stage 2 involved triangulation of findings from Stage 1 to ensure the robustness and accuracy of the data. This stage also focused on developing prioritization criteria for strategies, allowing for the shortlisting and categorization of interventions based on type, implementation timeframe, and their alignment with the waste utilization hierarchy. Strategies were refined to ensure they addressed the most critical root causes while being practical and feasible for stakeholders.

In Stage 3, a third workshop was held to validate and prioritize strategies developed from earlier stages. The objective of this workshop was to refine and rank the shortlisted strategies using participatory ranking exercises. Each strategy was assessed using pre-agreed criteria, including feasibility, cost, expected impact, and stakeholder readiness. Participants were given a scoring sheet and asked to rate each strategy independently, followed by group discussions to reach consensus. The workshop also served to test the draft version of the Hort SAP before finalization.

All three workshops were conducted over two-hour sessions. These sessions were organised in collaboration with a Project Advisory Group (PAG), which included stakeholders from across the horticulture supply chain. The workshops saw participation from a range of sectors, with 4–5 industry representatives attending each session, along with 1–2 from retail, 2–3 from government, and 1–2 from producers. Researchers, processors, marketers, and distributors were also represented, though numbers varied from 0 to 2 participants per workshop. A range of interactive tools and activities were used to engage participants. These included live polls to assess the level of food waste within their operations and how urgent they considered the issue to be, breakout discussions based on supply chain stages, and anonymous feedback through Mentimeter and Zoom chat. Additionally, participants took part in strategy ranking exercises based on feasibility, impact, and other criteria. Some of the key questions posed during these workshops included the following:

What percentage of food waste occurs at your organisation?

Where are the major hotspots of waste in your supply chain?

What strategies have you implemented to reduce food waste?

Which interventions are ‘quick wins’ vs. long-term solutions?

Findings from the workshops revealed that waste hotspots were most prominent at the production/harvest stage and within retail and distribution centres. The root causes were identified as market oversupply, overproduction, adverse weather, inefficient cold chain logistics, and high consumer expectations. Suggested solutions included improving demand forecasting, adopting new agricultural technologies, developing food rescue programs, enhancing training and education, and investing in infrastructure improvements.

4. Background of the Australian Horticulture Sector

4.1. Overview of the Horticulture Industry

The horticulture industry in Australia includes a wide array of products, ranging from fruits, vegetables, and ornamental plants to specialty items like medicinal and aromatic plants [

29,

30]. This diversity stems from Australia’s varied climate, which supports both tropical and temperate crops, enabling the production of fresh produce year-round. Additionally, Australia’s focus on high-quality produce positions the industry as a critical part of the agricultural sector, providing value both domestically and through exports.

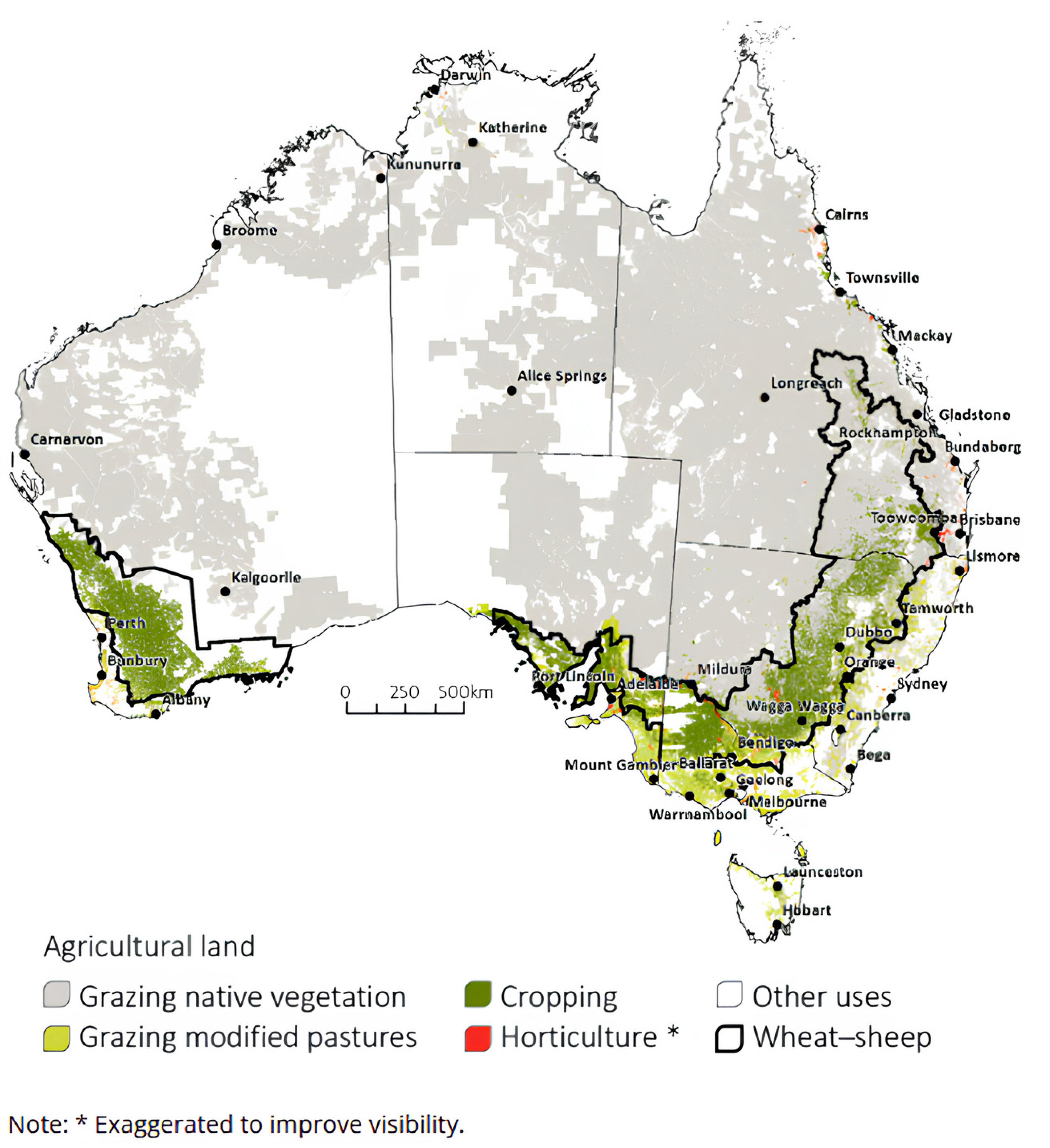

Although horticulture uses a relatively small amount of agricultural land compared to other sectors, its high productivity and profitability make it economically significant [

31].

Figure 2 illustrates the land use distribution for horticulture, which is often concentrated in selective regions particularly suited to profitable production [

32]. These regions are typically those with favourable soil, climate, and access to reliable transport infrastructure, allowing for intensive farming practices. This regional concentration of horticulture may play a vital role in developing targeted food waste reduction strategies, as it enables more focused management of waste hotspots and regional support.

The economic performance of the horticulture sector has also shown resilience, despite recent challenges. During the 2021/22 period, production volume decreased by 1.4% due to issues such as labour shortages, weather extremes, and market fluctuations. However, the sector’s overall value still increased by 4.3%, from AUD 15.2 billion to AUD 15.9 billion, primarily due to rising prices across domestic and international markets [

33]. This increase in value underscores the sector’s potential for growth and profitability, despite operational challenges, and highlights the importance of waste reduction as a means to maximize economic returns on invested resources.

Together, economic significance, geographic concentration, and operational challenges of the horticulture sector reinforce the need for effective, regionally focused waste management strategies. Addressing waste at both local and national levels can help support the sector’s contribution to Australia’s food security, economic stability, and environmental sustainability goals.

4.2. Food Waste in the Horticulture Sector

Food waste is a global issue, affecting economies, the environment, and food security. Globally, an estimated 1.3 billion tonnes of food is wasted annually, resulting in economic losses of approximately USD 940 billion per year [

34,

35]. This issue is particularly relevant in Australia, where food waste costs the national economy about AUD 20 billion annually [

36]. In the horticulture sector, these losses are driven by inefficiencies at various stages of the supply chain, from primary production to retail. Addressing food waste is essential to meeting global sustainability goals, particularly the United Nations Sustainable Development Goal (SDG) 12.3, which aims to halve global food waste per capita by 2030 [

37]. While the UN’s SDGs have raised the profile of food waste reduction, they have been critiqued for lacking clear guidance on implementation [

38].

The environmental impacts of food waste are also severe, as wasted food represents a misuse of essential resources such as water, soil, and energy. Additionally, food waste contributes significantly to greenhouse gas emissions, with 3.3 gigatonnes of CO

2 equivalent released annually, making food waste the third-largest emitter after China and the United States [

39]. These environmental consequences are mirrored in Australia’s horticulture sector, where inefficiencies in production and supply chains exacerbate waste. In the absence of stringent food waste regulations like those in France or Italy [

40], Australia’s approach to food waste relies on voluntary frameworks and strategies.

Globally, horticultural food waste shows wide variation between countries due to differences in production systems, infrastructure, and consumer behaviour. For example, in the United States, fruits and vegetables make up about 39% of total food waste, with significant losses at both farm and consumer levels [

41]. In the European Union, fresh fruit and vegetables account for about 50% of household food waste [

42]. Compared to this, Australia’s horticulture sector generates about 1.3 million tonnes of food waste per year, which is approximately 33% of the country’s total agricultural food waste [

1]. This is broadly similar to other developed countries, although Australia’s large landmass and scattered population create unique challenges in logistics and redistribution.

Recent trends also show that horticulture food waste in Australia has remained high. According to the National Food Waste Baseline Report and subsequent updates by Food Innovation Australia Limited, food waste from primary production in Australia declined slightly between 2016 and 2021. Specifically, waste from primary production dropped by 26%, and manufacturing waste decreased by 17%. However, during the same period, food waste in the retail and hospitality sectors increased significantly. Retail waste rose by 104%, and hospitality waste surged by 275% [

43]. The total horticulture food waste showed little overall improvement, indicating a need for stronger sector-wide actions.

Australia has taken steps to address food waste through initiatives such as the National Food Waste Strategy and the Food Loss + Waste Protocol (FWLP). The FWLP, which has been adopted internationally, provides a standardized methodology for measuring and reporting food waste, focusing on individual supply chain points [

35]. However, this approach has limitations, as it emphasizes quantification without fully addressing systemic interdependencies across the supply chain. For example, Australia’s National Food Waste Baseline reported that 31% of food waste occurs in primary production, 24% in manufacturing, and 34% at the consumer level, with only 3% attributed to retailers [

44]. This reductionist focus on individual sectors often overlooks the systemic pressures, such as retailer-driven standards, that shift waste burdens across the supply chain [

45].

The horticulture industry in Australia, a key contributor to agricultural productivity, epitomizes these challenges. Producing highly perishable goods such as fruits and vegetables, the sector experiences significant waste at both production and distribution stages. These losses are compounded by environmental variability, labour shortages, and stringent cosmetic standards imposed by retailers. Despite these challenges, the industry’s resilience and economic significance highlight its potential to lead national food waste reduction efforts. With coordinated actions and alignment with global frameworks such as the FWLP, Australia’s horticulture sector could play a pivotal role in achieving SDG 12.3 and fostering sustainability across the food supply chain.

5. Findings and Analysis

The present study identifies several critical insights into food waste across the horticultural supply chain in Australia. Through a combination of literature review, stakeholder interviews, and workshops, the study pinpoints both of the main hotspots where food waste is most concentrated and underlying root causes contribute to this waste. Each root cause sheds light on specific challenges within the supply chain that, if addressed, could enable significant waste reduction. The following sections provide a summary of these root causes and key statistics, using the data obtained in this study.

5.1. Identification of Food Waste Hotspots

This study identified seven key hotspots in the horticultural supply chain and estimated food waste in Australia, including fruits and vegetables, for 2021 based on the report by FIAL [

43]. The estimation of the food waste calculated by the authors is presented in

Table 1. It is seen from

Table 1 that household is the largest contributor to food waste, responsible for 33.2% (1,271,850 tonnes), primarily due to behavioural factors like over-purchasing and improper storage practices. In contrast, primary production waste, which accounts for 23.7% (908,403 tonnes), is largely driven by systemic challenges such as overproduction and strict cosmetic standards enforced by retailers. The hospitality sector’s contribution of 19.8% (757,992 tonnes) highlights operational inefficiencies, including portion control and the disposal of surplus food. Processing and packaging waste, comprising 10.7% (409,744 tonnes), often arises from stringent quality checks that lead to the rejection of produce. Retail-level waste, at 5.7% (217,433 tonnes), is attributed to practices such as overstocking and cosmetic rejections, while distribution waste, representing 5.4% (208,380 tonnes), stems from inadequate storage and transportation infrastructure. Institutions, including schools and hospitals, contribute the least at 1.5% (57,353 tonnes), primarily due to inefficiencies in meal planning. These findings underscore the need for tailored interventions at each stage, emphasizing prevention at the household level, improved resource management in production, and enhanced logistics in retail and distribution to achieve significant waste reductions.

5.2. Analysis of the Horticultural Food Waste Root Causes

The present study identifies nine root causes of food waste across Australia’s horticulture sector (which are denoted as RC1 to RC9), each contributing to significant losses along different points in the supply chain. These root causes highlight specific challenges that, if addressed, could reduce food waste effectively. These root causes across the stages of production, processing, and retail are discussed below.

RC1-Lack of food waste measurement and monitoring systems: The lack of robust systems to measure and monitor food waste accurately is a significant challenge in Australia’s horticulture sector. Without comprehensive data, stakeholders—growers, distributors, processors, and retailers—struggle to pinpoint where and how much waste occurs, and this can impede the development of targeted strategies for fostering reactive management practices [

2]. The absence of a standardized measurement approach complicates collaboration across the supply chain due to different perceptions of waste volumes and root causes [

46]. While sensor-based blockchain technology shows promise for tracking product freshness and temperature, high costs limit its application for waste measurement [

47]. Developing cost-effective and accessible methods to track and monitor food waste remains an urgent priority [

48].

RC2-Agronomic and environmental factors: Agronomic practices and environmental conditions play a critical role in the quality and yield of horticultural products. Pests, diseases, and adverse weather events such as floods, droughts, heatwaves, or unseasonal frosts can cause significant losses, impacting crop development and reducing fruit yields [

49,

50]. For instance, excessive rainfall may trigger fungal outbreaks, while cold snaps during flowering can limit pollination, leading to out-of-specification produce [

51]. Australia’s climate variability further amplifies these challenges, leaving producers with little control over outcomes [

52]. The perishability of horticultural products adds urgency, as compromised produce deteriorates quickly, exacerbating waste. Resilient waste management strategies that adapt to changing environmental conditions and integrate effective pre- and post-harvest practices are essential to mitigate these risks and maintain product quality.

RC3-Overproduction and demand mismatch: Overproduction is a major contributor to food waste in the horticultural sector, often resulting from uncertainties in market demand, contractual obligations, and efforts to avoid undersupply [

53]. Farmers frequently grow more crops than necessary to account for potential shortfalls or to meet buyer contracts, leading to surplus produce that cannot be sold when demand falls short. This surplus, particularly problematic for perishable crops, is prone to rapid spoilage, further compounding waste. Fluctuations in consumer preferences exacerbate the issue, leaving producers with products that no longer align with market demand [

54]. Addressing this challenge requires improved demand forecasting, flexible supply chain coordination, and enhanced redistribution mechanisms to manage surplus produce effectively and reduce economic losses.

RC4-Workforce shortages and skills gaps: Labour shortages during peak harvest seasons are a significant contributor to food waste in horticulture. High labour costs—accounting for 23–35% of total production expenses—make it difficult for growers to maintain a consistent workforce, especially for smaller producers [

55,

56]. Even when labour is available, many workers lack the necessary training for proper handling, packaging, and transportation, leading to inefficiencies such as delayed harvesting and damaged produce. These issues result in unharvested crops and increased spoilage, exacerbating food loss across the supply chain [

57]. Addressing workforce challenges through targeted recruitment, skill development initiatives, and cost-effective automation solutions is essential to mitigate waste. Effective workforce planning, combined with investment in training and technology, can significantly reduce losses and improve the sustainability of the horticulture sector [

58].

RC5-Strict cosmetic standards: Retailers’ cosmetic standards, which emphasize size, shape, colour, and visual perfection, lead to the rejection of large quantities of edible but imperfect produce [

59]. These standards are largely driven by consumer preferences for aesthetically appealing items, resulting in perfectly edible fruits and vegetables being discarded due to minor imperfections, such as misshapen apples or undersized carrots [

60]. This practice contributes significantly to food waste and imposes financial burdens on growers unable to sell their entire crop. Campaigns promoting the acceptance of “ugly” produce and encouraging retailers to adopt more flexible cosmetic standards can mitigate this issue [

61]. Educating consumers and fostering greater acceptance of visually imperfect produce are essential steps in reducing waste, supporting growers, and enhancing the sustainability of the horticultural supply chain.

RC6-Limited redistribution networks: Redistributing surplus food to charitable organizations is an effective way to reduce waste and support those in need. However, inadequate infrastructure, including insufficient cold storage and limited transport facilities for perishable produce, poses significant challenges [

62]. Food banks and charities often lack the capacity to handle fresh fruits and vegetables, resulting in large quantities of surplus produce being discarded instead of redistributed. Strengthening these networks through investments in logistics, enhanced storage infrastructure, and partnerships with growers and retailers can significantly improve the reach and effectiveness of food recovery programs [

63]. Improved collaboration among stakeholders and targeted investments in cold chain systems can ensure more surplus produce reaches those in need, reducing food waste and enhancing food security.

RC7-Inadequate technology and infrastructure: Poor access to modern technology and infrastructure, including efficient cooling systems, storage facilities, and transportation, contributes to significant losses of perishable horticultural products [

64]. Many farms, particularly smaller producers in remote regions, lack resources needed for effective handling and preservation of produce. Advanced harvesting equipment and proper cold chain systems are essential to maintain the quality of perishable items, but their unavailability often leads to rapid spoilage, especially for highly perishable fruits and vegetables. Transport logistics further exacerbate the issue, with long travel distances and inadequate refrigeration during transit increasing waste. Remote areas face even greater challenges due to limited access to processing and storage facilities. Investing in technological upgrades and improving infrastructure, particularly in transport and cold chain systems, is vital in reducing waste and preserving the quality of horticultural produce [

65].

RC8-Few value-adding opportunities and limited collaboration: The lack of processing facilities and limited collaboration among stakeholders restrict the potential for value-adding opportunities in the agricultural sector. Transforming surplus or imperfect produce into products like sauces, jams, or dried goods can reduce waste and generate new revenue streams. However, small and medium-sized growers often lack access to necessary equipment or networks for such transformations. This situation is compounded by limited collaboration among farmers, processors, and distributors, further hindering innovation. To overcome these challenges, developing regional value-adding hubs and fostering partnerships can improve the utilization of surplus produce, opening new markets and reducing waste [

66,

67]. Strengthening these connections will create opportunities for growers to access processing facilities and expand their products’ market potential.

RC9-Policy and regulatory challenges: Inconsistent policies and complex regulations across Australia create barriers to reducing food waste. Existing policies often lack sufficient incentives for producers and retailers to minimize waste or repurpose surplus produce. For example, minimal tax relief for food donations and cumbersome regulatory requirements hinder participation in food recovery programs. Additionally, fragmented responsibilities across government levels complicate waste management strategies, preventing cohesive action. Simplifying and harmonizing policies, along with offering incentives for waste reduction and redistribution, could promote sustainable practices throughout the supply chain [

68,

69]. Streamlining regulations and aligning efforts at different levels of government would encourage broader adoption of waste reduction initiatives and enhance the efficiency of food recovery programs.

These root causes of horticultural food waste were reviewed and confirmed during Stakeholder Workshop 2 and through interviews with various stakeholders. Then, the findings from the literature review, interviews, and workshops were carefully cross-checked and triangulated.

6. The Horticulture Sector Action Plan (Hort SAP)

The Hort SAP was developed to address the root causes of food waste, as previously discussed, within Australia’s horticulture industry by implementing targeted strategies across the supply chain to achieve substantial waste reduction. Recognizing the complexity of creating an effective plan for a sector as diverse as horticulture, the action plan was informed by a thorough review of existing research, literature, stakeholder interviews, and insights from Workshops 1, 2, and 3. Instead of attempting to address every issue, the Hort SAP focused on nine key “game-changing” actions that could have the most significant impact on reducing waste.

These nine actions, which are outlined in

Table 2, were categorized into three main strategic approaches: enabling, prevention, and repurposing and redistribution. Each of these strategies was designed to address specific challenges within the sector. The nine actions, including four enabling actions, three prevention actions, and two repurposing/redistributing actions, were tailored to respond to one or more root causes identified. It was also noted that many actions addressed multiple root causes, and several root causes required a combination of actions to be effectively managed. A timeline was also mapped out for each action to ensure efficient implementation and maximum impact across the supply chain.

6.1. Enabling Strategies

Enabling strategies were developed to provide the structural support necessary for food waste reduction in the horticulture industry. These strategies can address gaps in knowledge, collaboration, and resource allocation that hindered previous waste reduction efforts. One essential component is the establishment of a comprehensive food waste measurement and monitoring system. This system will allow stakeholders to track waste volumes accurately, facilitating targeted interventions. The study found that such a system can help build an industry-wide database that will inform data-driven decisions and track progress over time.

Another key enabling strategy is related to policy and regulatory support. Government agencies should be encouraged to simplify and harmonize food waste regulations across different regions to reduce interjurisdictional inconsistencies. Additionally, incentives can be suggested for stakeholders who implement waste reduction practices, such as tax benefits for businesses that donate surplus food. The establishment of a centralized advisory group, with representatives from industry, government, and research institutions, can also be proposed to guide the implementation and coordination of Hort SAP initiatives.

6.2. Prevention Strategies

Prevention strategies in Hort SAP were designed to target waste reduction at the source by minimizing losses during production, processing, and retail stages. These strategies focus on aligning production more closely with market demand and improving practices to reduce surplus and spoilage. One key recommendation is the development of improved demand forecasting tools, which will allow growers to better match production levels with actual consumer demand, thus reducing overproduction and surplus.

Another preventive measure is to introduce more flexible cosmetic standards, allowing produce with minor imperfections to reach consumers. Retailers should be encouraged to adopt “imperfect produce” campaigns, which have been shown to improve acceptance of non-standard fruits and vegetables. Enhanced training programs for workers in handling, harvesting, and storing produce can also be recommended to minimize physical damage and extend shelf life. It is estimated that these prevention strategies can reduce waste by as much as 15–20% if implemented across the sector.

One additional effective prevention approach is the adoption of whole-of-crop purchasing agreements, where retailers and processors commit to buying a wider range of produce from a harvest, including second-grade or cosmetically imperfect items. This practice helps reduce on-farm waste by creating market pathways for products that would otherwise be discarded due to appearance standards. Another important strategy is improved on-farm storage and handling. Supporting growers with better post-harvest practices—such as shading, cooling systems, and timely handling—can minimise spoilage during the critical period between harvest and sale or processing.

In addition, targeted workforce training is essential to reduce handling-related waste. Upskilling workers in harvesting, packing, and storage techniques—tailored to specific commodities and seasonal needs—can significantly reduce physical damage to produce. Better coordination with buyers is another critical strategy. Improving communication between producers and buyers helps align harvest schedules with market demand, reducing the risk of overproduction or rejection due to mistimed deliveries. Lastly, enhancing consumer awareness about food waste and the value of “imperfect” produce plays a vital role in shaping market demand. Educational campaigns and in-store messaging can shift consumer attitudes, increase acceptance of non-standard produce, and reduce waste driven by unrealistic cosmetic expectations. Together, these strategies create a stronger foundation for preventing food waste across the horticulture supply chain and complement the broader aims of the Hort SAP.

6.3. Repurposing and Redistribution Strategies

Repurposing and redistribution strategies aim at ensuring surplus produce could be redirected to other uses or to those in need rather than wasted. The Hort SAP recommends expanding partnerships with food banks and other charitable organizations to strengthen the redistribution network, particularly for perishable items like fruits and vegetables. This will involve improving cold storage and transport facilities at redistribution points to handle larger volumes of fresh produce.

Another strategy is to increase the development of value-added products using surplus or imperfect produce. Facilities for processing items into products like sauces, jams, or dried goods can be proposed in major growing regions to reduce transportation costs and create local markets for these items. Collaboration between growers, processors, and distributors can be developed to explore new avenues for repurposing produce, further supporting the reduction of waste within the supply chain.

6.4. Priority Actions and Timeline

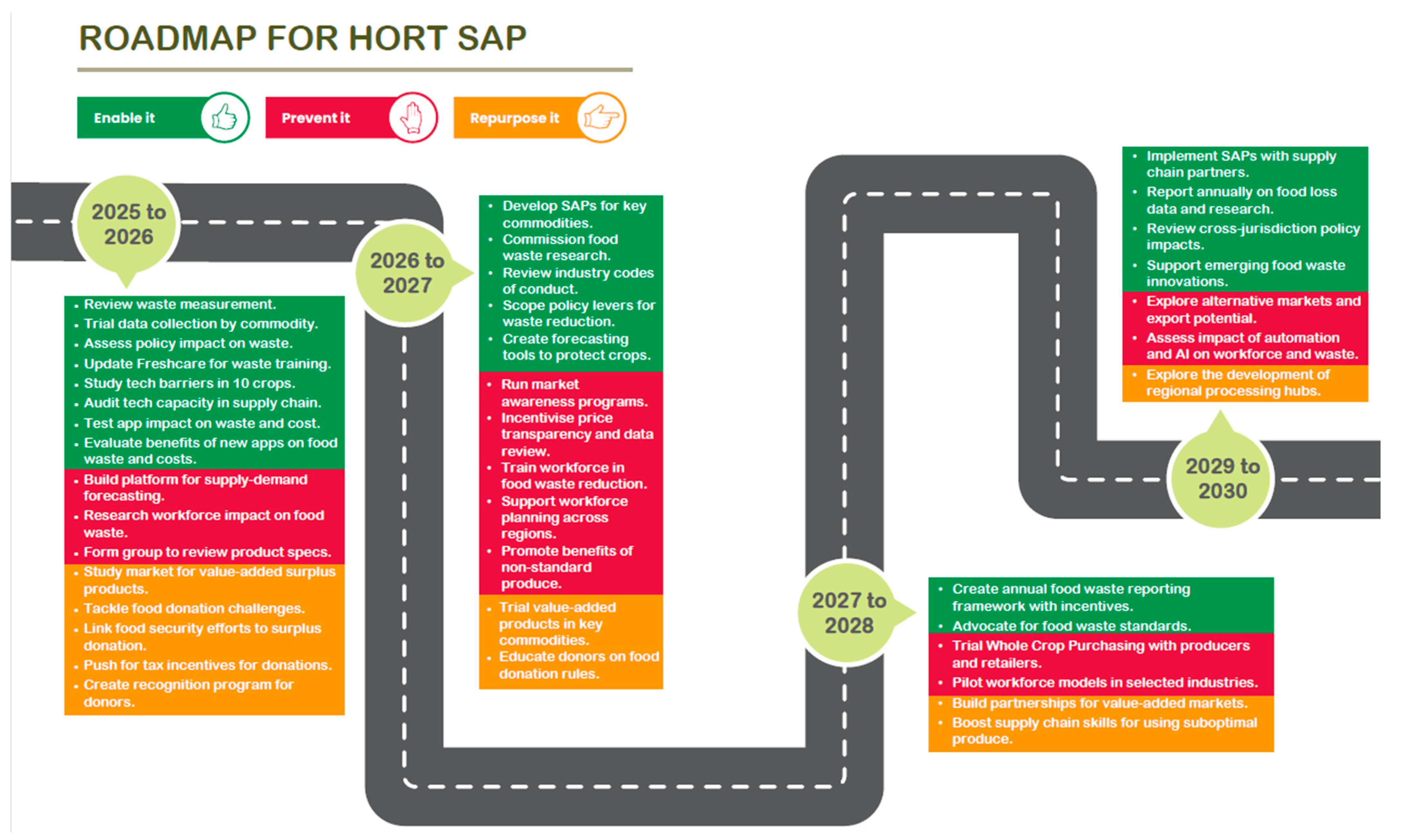

The Hort SAP establishes a roadmap to support the horticulture sector in reducing food waste, with the goal of halving Australia’s horticultural food waste by 2030. This roadmap outlines a phased approach, categorizing priority actions as short-term (0–2 years), medium-term (3–5 years), and long-term (5–10 years) initiatives. Each phase was strategically designed to build on previous progress, gradually establishing sustainable practices across the sector.

Figure 3 provides a visual representation of this roadmap, illustrating the timeline and sub-actions required to meet the 2030 target.

In the short-term (0–2 years), foundational actions should be prioritized to build the capacity for accurate data collection and establish partnerships necessary for effective redistribution. These actions include setting baseline measurements for food waste levels, initiating industry-wide data collection systems, and forming partnerships with organizations in the food rescue and redistribution sectors, such as End Food Waste Australia.

Medium-term actions (3–5 years) emphasize building infrastructure and enhancing operational efficiency. Key actions in this phase include expanding infrastructure for repurposing facilities, implementing advanced demand forecasting tools to reduce overproduction, and aligning cosmetic standards across retailers to minimize rejection of produce based on appearance. These actions are aimed at addressing the root causes of waste and creating consistency in waste reduction practices across the supply chain.

In the long-term (5–10 years), the focus can shift towards embedding waste reduction practices as standard across the horticulture sector, ensuring that initial progress would be sustained. Long-term actions include making food waste monitoring a routine part of horticultural practices and periodically updating regulatory incentives based on industry performance data. Ongoing communication and support from all supply chain organizations, food rescue sectors, not-for-profit organizations, and government tiers were considered essential to meet the 2030 target.

7. Discussion and Future Research Directions

The findings of this study highlight significant opportunities and challenges in addressing food waste within Australia’s horticulture sector. The development of the Hort SAP provides a comprehensive framework for systematically reducing food waste through targeted, evidence-based strategies. However, the study also underscores the complexity of achieving these goals, given the interplay of economic, environmental, and social factors.

The identification of key waste hotspots—primary production, processing, and retail—illustrates the disproportionate concentration of food waste at specific points in the supply chain. Primary production is one of the highest producers of waste, driven by factors such as overproduction, agronomic variability, and strict cosmetic standards. These findings align with global literature emphasizing the critical role of upstream interventions in achieving meaningful reductions in food waste [

70,

71]. Addressing these hotspots requires a multi-faceted approach that combines prevention, repurposing, and enabling strategies, as outlined in the Hort SAP.

Stakeholder participation emerges as a vital component of the Hort SAP’s development. The co-design process ensures that strategies are tailored to the operational realities of growers, distributors, and retailers, enhancing their practical applicability. This participatory approach is consistent with collaborative planning theory, which posits that shared ownership and engagement are critical to the success of complex initiatives [

24]. By involving stakeholders in every phase of the process, the Hort SAP fosters a sense of accountability and commitment, which is essential for long-term sustainability.

The adoption of a systematic “review-plan-do” framework demonstrates the importance of evidence-based planning in tackling food waste. The initial review phase provides a robust understanding of waste hotspots and root causes, while the subsequent phases translate these insights into actionable and adaptive strategies. This iterative approach, supported by continuous monitoring and feedback, ensures that interventions remain responsive to emerging challenges and opportunities.

Despite these strengths, the study identifies several barriers to the effective implementation of the Hort SAP. Financial constraints, particularly for small- and medium-scale growers, limit the ability to invest in advanced technologies and infrastructure. Behavioural resistance among stakeholders, coupled with entrenched consumer preferences for aesthetically perfect produce, further complicates efforts to adopt more flexible practices. Technological limitations, including inadequate cooling and storage solutions in remote areas, exacerbate spoilage rates and hinder supply chain efficiency.

Policy and regulatory inconsistencies also present significant challenges. The lack of cohesive national standards for food waste reduction, coupled with fragmented responsibilities across jurisdictions, creates obstacles to coordinated action. Additionally, while frameworks such as the Food Loss and Waste Protocol (FWLP) provide valuable metrics for quantifying waste, they fall short in addressing the systemic interdependencies that drive waste across the supply chain [

35].

Even with reduced horticultural food waste, the remaining waste still has environmental impacts that must be addressed. One key strategy is sustainable treatment and reuse of unavoidable waste. For example, organic waste from fruits and vegetables can be converted into compost, which helps improve soil health and reduces the need for chemical fertilizers [

72]. Anaerobic digestion is another promising option, where food waste is processed to produce biogas and nutrient-rich digestate, which can be used as renewable energy and organic fertilizer, respectively [

73]. These circular approaches help close the loop and lower greenhouse gas emissions from waste disposal. In addition, improving cold chain efficiency and using renewable energy in storage and transport can further reduce the environmental footprint of handling horticultural products. Future research should focus on expanding the use of such technologies and practices to ensure environmental sustainability even when food waste cannot be fully avoided.

Future research should prioritize the development of innovative solutions to address barriers and enhance the effectiveness of food waste reduction strategies. A critical area for investigation involves exploring financial mechanisms such as subsidies, tax incentives, and grants to alleviate the economic burden on small-scale producers and encourage investment in sustainable practices. Comparative studies of successful models from other countries, such as France’s legislative framework for food waste reduction, could provide valuable insights [

40]. Understanding consumer attitudes toward “imperfect” produce is also crucial for designing effective educational campaigns. Future studies should evaluate the impact of social media, retailer-led initiatives, and public awareness programs on reducing cosmetic waste while exploring how industry stakeholders can be incentivized to adopt flexible standards and collaborative practices.

Technological innovations present another vital research avenue. Low-cost, portable solutions for cooling, storage, and transportation could significantly reduce spoilage rates in remote areas. Mobile processing units that convert surplus produce into value-added products, such as sauces or dried goods, are particularly promising. Additionally, research into digital tools for real-time waste monitoring and demand forecasting could further enhance supply chain efficiency [

74]. On the policy front, studies should focus on harmonizing regulations across regions and creating clear frameworks that encourage participation in food redistribution and recycling initiatives. The development of scalable models for public-private partnerships could further support the expansion of redistribution networks for surplus food.

Another important area for future research is the estimation of the carbon footprint associated with horticultural food waste. Calculating the environmental impact of wasted produce, along with potential emission reductions from implementing countermeasures, would provide a clearer picture of the sustainability benefits of food waste reduction. Such analysis could enhance the evidence base for policy and industry decisions and align with the broader climate action goals under SDG 13.

Research into successful models of food recovery and redistribution, both domestically and internationally, could inform the design of more effective networks in Australia. Collaborative approaches involving growers, food banks, and logistics providers should address gaps in cold storage and transportation infrastructure [

75]. Finally, standardized methodologies for tracking food waste across supply chains are essential for measuring progress and identifying areas for improvement. Future studies should refine metrics that capture systemic dynamics, moving beyond the reductionist focus of current frameworks like the FWLP [

45].

8. Conclusions

This study developed the Horticulture Sector Action Plan (Hort SAP) to address food waste challenges within Australia’s horticultural supply chain. Findings revealed that overproduction, strict cosmetic standards, limited redistribution infrastructure, and inadequate technology are key drivers of approximately 1.1 million tonnes of annual waste, particularly in fruits and vegetables. The study identified nine root causes of waste across the supply chain, with primary production accounting for the largest share. By addressing these issues, the Hort SAP aims to achieve a 50% reduction in horticultural food waste by 2030, aligning with Australia’s sustainability targets under SDG 12.3.

The Hort SAP provides a structured roadmap with nine prioritized actions categorized into enabling, preventive, and repurposing strategies. These include standardized waste tracking, enhanced redistribution networks, and regional processing facilities for value-added products. The plan’s short-term goal of a 20% reduction in food waste within five years lays the foundation for long-term improvements, supported by a co-design process that ensures stakeholder engagement and practical relevance. In a nutshell, the Hort SAP represents a replicable model for advancing sustainability in horticulture and beyond by addressing the root causes of waste and leveraging systemic solutions.