1. Introduction

In the context of increasing global concerns about climate change, energy efficiency, and environmental degradation, the building sector plays a crucial role in promoting sustainable development [

1]. Buildings account for a substantial share of global energy consumption and greenhouse gas emissions, making it imperative to rethink how construction materials and systems are selected, designed, and evaluated [

2]. The performance of building envelopes, particularly external wall assemblies, is central to achieving the energy and environmental targets set by national and international frameworks. These assemblies influence the thermal behavior, internal comfort, and environmental footprint of buildings throughout their lifecycle [

3].

As policies such as the European Green Deal, the Energy Performance of Buildings Directive (EPBD), and national climate action plans push for a rapid transition towards low-carbon and energy-efficient buildings, professionals in the architecture, engineering, and construction (AEC) sector are increasingly expected to adopt tools and methods that support performance-based and sustainable design [

4]. These policy drivers are not merely recommendations but concrete legislative frameworks that demand innovation in design practices, materials selection, and building performance evaluation [

5]. In this regard, innovative digital technologies offer critical opportunities to improve the way buildings are conceived, modeled, and evaluated [

6].

In recent years, Building Information Modeling (BIM) has emerged as a transformative tool in the AEC industry [

7]. BIM enables the digital representation and management of a building’s physical and functional characteristics throughout its lifecycle [

8]. When combined with parametric design and performance simulation tools, BIM offers opportunities for integrating sustainability assessment into early-stage design decisions [

9]. The capability to model, simulate, and compare multiple design alternatives within a digital environment enhances the accuracy and efficiency of decision-making processes [

10]. This is especially valuable in early design phases, where choices made can affect a building’s long-term energy, environmental, and economic performance.

In parallel, multi-criteria decision-making (MCDM) methods have gained traction for addressing the complexity of evaluating alternative design solutions that involve trade-offs among multiple performance criteria [

11]. Traditional evaluation approaches often fall short in capturing the interdependencies among factors such as cost, energy consumption, material impact, and comfort. MCDM frameworks provide a structured basis for incorporating diverse criteria and stakeholder priorities into a coherent decision-making process [

12]. Among them, the Weighted Sum Model (WSM) is particularly suitable for cases where quantitative comparison of alternatives is desired and where simplicity and transparency are essential.

Despite these technological advancements, there remains a gap in integrated workflows that connect parametric BIM environments with decision support models capable of addressing the multiple dimensions of building envelope performance [

13]. Designers and decision-makers often struggle to balance economic, environmental, and comfort-related considerations within conventional tools or fragmented methodologies [

14]. This fragmentation often leads to inefficient iterations, suboptimal material choices, and limited capacity for design comparison based on objective performance data.

While previous studies, such as Fazeli et al. [

15] and Tan et al. [

16], have demonstrated the potential of BIM–MCDM integrations to support performance-based design, they address isolated criteria—often limited to energy or cost—or rely on external data flows detached from BIM authoring environments. This study advances the state of the art by integrating performance simulation, rule-based compliance (thermal and acoustic), and multi-criteria optimization within a digital workflow built in Revit and Dynamo. Unlike external or post-processing models, this method performs automated parametric adjustment, compliance verification, and weighted performance ranking, enabling real-time optimization aligned with regulatory constraints and sustainability goals during early-stage design.

The object of this research is the multi-layered external wall assembly, which constitutes a fundamental component of the building envelope. The subject of this study concerns the development of a replicable, regulation-aligned, and performance-driven digital workflow for optimizing such assemblies during early design phases, considering thermal, acoustic, economic, and environmental factors simultaneously.

The scientific novelty of this study lies in the integration of regulatory-based parametric modeling, real-time compliance checking, and MCDM within a single BIM environment. Unlike prior research that treats performance simulation and MCDM as post-design analyses or external modules, this study embeds both within the design environment using native Revit–Dynamo scripting. This enables automated generation, verification, and performance ranking of wall configurations based on technical regulations and sustainability metrics. Moreover, the work contributes a validated and generalizable methodology for systematically exploring design alternatives through a structured, transparent, and computationally efficient pipeline, advancing the use of BIM for decision support in sustainable building envelope design.

The proposed methodology is tested through a case study involving twenty-four wall assemblies, each optimized to meet regulatory requirements in terms of thermal transmittance and surface mass. The performance of these assemblies is assessed using the WSM, a widely recognized MCDM technique that enables the ranking of alternatives based on weighted evaluation criteria. The results are discussed to highlight the benefits, trade-offs, and design implications associated with different material combinations. Particular attention is given to the influence of insulation types on the composite performance of the assemblies, including the interaction effects between thermal, acoustic, and environmental behaviors.

By integrating digital tools and decision support frameworks, this research aims to contribute to the development of more informed, transparent, and sustainable design practices. The ultimate goal is to provide architects and engineers with a replicable approach that enhances the quality of design decisions while addressing the pressing challenges of environmental responsibility and occupant comfort in the built environment. Moreover, this study contributes to the broader discourse on how digitalization can support the goals of ecological transition and circular economy within the construction industry.

2. Background

The growing emphasis on sustainable development and the need to reduce the environmental footprint of the construction sector have led to a significant increase in research focusing on high-performance building envelopes [

17,

18]. Among the various components of the building shell, vertical closures—particularly external wall assemblies—play a pivotal role in ensuring thermal efficiency, acoustic insulation, and overall environmental compatibility [

18]. Several studies have explored the thermal performance of different wall configurations, emphasizing the importance of low transmittance values, high thermal inertia, and optimized material layering in minimizing energy demand.

Research by Stazi et al. [

19] and Congedo et al. [

20] has highlighted the role of massive and multi-layered walls in Mediterranean climates, where the mitigation of summer overheating and the optimization of thermal lag are particularly critical. These studies emphasize the importance of passive strategies and thermal inertia in promoting energy savings, especially in regions characterized by intense solar radiation and variable seasonal demands. At the same time, the integration of natural and bio-based materials—such as earth, wood fiber, and cork—has gained traction due to their low embodied energy, renewable origin, and capacity to enhance indoor comfort [

21]. These materials are increasingly featured in environmental product declarations (EPDs) and life cycle assessments (LCAs), which serve as crucial sources of environmental data for comparative analysis [

22]. However, further integration of these materials into mainstream design workflows still faces barriers related to normative standardization, long-term durability validation, and limited market adoption.

Recent studies have strengthened the case for raw earth and bio-based construction systems. Dipasquale et al. [

23] analyzed a tiny house in Chile built with

quincha alivianada, showing that, despite moderate thermal insulation, the wall system offered high thermal inertia and the lowest environmental impacts among five alternatives—thanks to local materials and carbon sequestration. Similarly, Giuffrida et al. [

24] compared eight earth-based walls with equivalent U-values in Southern Italy, identifying those with bio-based insulation (e.g., hemp, cork) as the most environmentally balanced, confirming the viability of raw earth solutions in Mediterranean climates.

The incorporation of acoustic performance into wall design has also garnered increasing interest [

25]. Lee and Aletta [

26] and Jo and Jeon [

27] have shown that acoustic comfort has a substantial impact on occupant well-being and productivity, making it a critical factor in both residential and commercial buildings. Wall systems must therefore be evaluated not only for thermal and environmental behavior, but also for their ability to mitigate airborne sound transmission. This has spurred interest in multi-functional materials and assemblies capable of addressing various performance domains simultaneously. Advanced simulation tools and empirical models—such as those integrated in software like ECHO—now offer increasingly reliable estimations of façade sound insulation, thus supporting the integration of acoustic performance into early design decisions [

28].

In parallel, the widespread adoption of BIM in architectural and engineering practices has enabled more accurate modeling and data management [

29,

30]. BIM’s capacity to represent physical and performance characteristics of building elements in a digital environment has led to its application in sustainability assessment and decision-making processes [

31]. Scholars such as Nizam et al. [

32] and Marrero et al. [

33] have underscored BIM’s potential to support energy modeling, material quantification, and environmental impact estimation when combined with other digital tools. However, despite these advancements, the integration between BIM and performance optimization methods remains a topic of ongoing exploration, particularly with respect to automated compliance verification and scenario-based material analysis [

34]. The lack of standardized data exchange protocols and semantic consistency between BIM models and performance evaluation tools still represents a limitation to full interoperability and methodological robustness [

35].

In recent years, parametric modeling using visual scripting platforms like Dynamo has further enhanced BIM-based workflows, enabling dynamic manipulation of design parameters and automated compliance checking [

36]. Studies by Zhang et al. [

37], Cascone [

38], and Sakiyama et al. [

39] have demonstrated the potential of parametric tools in optimizing building elements based on both geometric and performance-related variables. These tools allow designers to rapidly iterate on alternative configurations and evaluate their implications in terms of thermal behavior, acoustic comfort, and environmental metrics. Such tools contribute to the emergence of performance-driven design processes where simulation and evaluation are embedded in real-time modeling environments. Moreover, parametric approaches facilitate early-stage decision-making by enabling rule-based logic and dynamic relationships among design variables, helping identify configurations that best satisfy user-defined constraints and objectives [

40].

Alongside BIM and parametric modeling, the application of MCDM methods has gained prominence as a means to compare building solutions based on multiple, often conflicting criteria [

41]. MCDM techniques, such as the Analytic Hierarchy Process (AHP), Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS), and Weighted Sum Model (WSM), have been employed in various studies to support the selection of energy systems, construction materials, and retrofit strategies [

42,

43]. According to research by Sharma et al. [

44], Foroozesh et al. [

45], and Konstantinos et al. [

46], these methods are particularly useful when design decisions must consider trade-offs between cost, performance, and sustainability. Despite their strengths, MCDM techniques are still underutilized in early design workflows, often because of the complexity of integrating multiple data sources and the lack of user-friendly interfaces in typical design software environments.

WSM, in particular, is frequently favored for its simplicity, transparency, and suitability in contexts where the evaluation criteria are quantifiable and the alternatives are finite [

47]. It allows for the direct aggregation of normalized scores, making it well-aligned with performance-driven design processes that involve comparative analysis of multiple configurations. Despite its simplicity, WSM remains highly adaptable and scalable to various design scenarios, especially when integrated with digital data pipelines. It also lends itself well to educational contexts and collaborative design processes due to its intuitive logic and straightforward implementation [

48].

Despite the wealth of research in these areas, few studies have proposed integrated workflows that combine parametric BIM with automated performance verification and multi-criteria evaluation. Most existing approaches tend to focus on isolated aspects, such as thermal simulation or cost estimation, without a holistic framework capable of handling multiple dimensions simultaneously. This gap justifies the development of methodologies—such as the one proposed in this study—that aim to integrate digital design, performance criteria, and structured decision-making into a coherent and replicable workflow.

3. Materials and Methods

3.1. Workflow Overview

3.1.1. Tools and Digital Environment

This research adopts a structured and integrated workflow that combines parametric design using BIM with MCDM techniques. The primary objective is to evaluate and identify the optimal external wall assembly, or vertical enclosure, that achieves a balance among thermal performance, acoustic insulation, environmental impact, and economic feasibility.

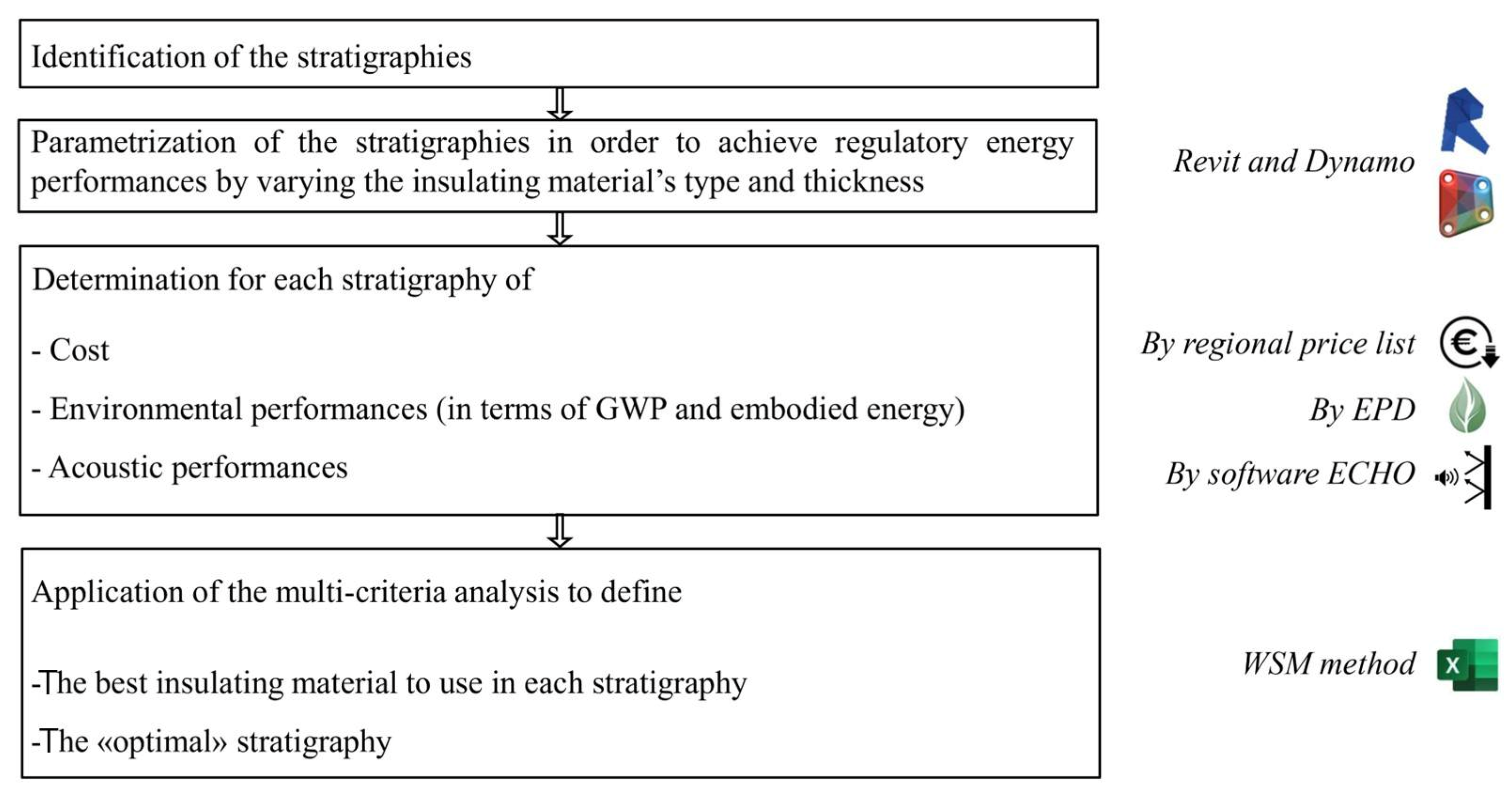

Figure 1 illustrates the structured and iterative digital workflow developed in this study. It integrates BIM in Revit (v2023), parametric scripting in Dynamo (v2.13), and decision-making in Excel (Office 365) through WSM. The diagram highlights key stages, including stratigraphy and insulation material selection, automatic compliance checking for thermal and mass criteria, and multi-criteria performance evaluation.

3.1.2. Parametric Objectives and Logic

To implement this methodology, several digital tools were employed in a complementary fashion. Autodesk Revit served as the main platform for modeling the building envelope, allowing detailed construction of various stratigraphies with precision and consistency. The visual programming environment Dynamo was used in conjunction with Revit to enable parametric control over the design variables, specifically the thickness of the insulation material. Microsoft Excel was used as a tool for data management and computational support in applying the WSM, the selected MCDM method. In addition to these, ECHO software (v8.3) (Blue Bell, PA, USA) was adopted for the estimation of acoustic performance indicators, based on material density and dynamic stiffness.

3.1.3. Implementation Workflow

The workflow begins with the definition of a comprehensive set of wall stratigraphy alternatives, each representing a plausible configuration of layers and construction materials commonly used in sustainable building design. These assemblies are developed within the Revit environment, ensuring geometric accuracy and ease of interoperability with downstream analysis tools. Once modeled, the stratigraphies are linked to a Dynamo script specifically designed to control the variable thickness of the insulation layer, which is treated as a key decision parameter.

This script executes a dynamic adjustment procedure, iterating through varying thickness values until the specific design meets the minimum performance requirements imposed by the applicable regulatory framework. The two primary compliance targets are the thermal transmittance (U-value), which must not exceed the legal threshold of 0.4 W/m2K for buildings in climate zone B, and the surface mass, which must be no less than 230 kg/m2 to ensure appropriate thermal inertia. The automated procedure built into Dynamo reduces the time and effort required for manual testing, while guaranteeing that only technically viable configurations are retained for further analysis.

Thermal performance thresholds were derived from Italian national regulations (D.M. 26/06/2015) [

49], which align with the broader framework defined by the EU Energy Performance of Buildings Directive (EPBD 2018/844) [

50]. Although this study references national limits for thermal transmittance, the methodology can be adapted to alternative benchmarks, including EN ISO 6946 [

51] for U-value calculation, EN 13829 [

52] for airtightness assessment, and ASHRAE 90.1 [

53] for minimum envelope performance in North America. The flexibility of the parametric workflow allows for dynamic substitution of these criteria depending on project location and regulatory context.

The parametric control of insulation thickness was implemented using Dynamo’s visual programming interface, which operates on Revit wall-type families containing modifiable insulation layers. For each of the 24 configurations, the script adjusts the insulation thickness in 1 cm steps, recalculating the wall’s overall thermal transmittance and surface mass after each iteration. If both parameters fall within national regulatory thresholds (U ≤ 0.4 W/m2K and M_s ≥ 230 kg/m2), the configuration is retained; otherwise, the thickness is increased until compliance is achieved. All wall assemblies were modeled using a consistent Revit family template, in which insulation thickness is treated as a parametric instance variable. No custom plug-ins or external tools were required, ensuring the portability and reproducibility of the workflow within standard BIM environments.

Following the compliance verification phase, this study proceeds with the extraction of relevant performance data for each validated wall assembly. This includes the economic cost, calculated using regional price lists; the GWP and embodied energy, both derived from the EPDs of the proposed materials; and the expected acoustic insulation performance, calculated using the ECHO software. All data are structured in a standardized format to enable their seamless integration into the subsequent multi-criteria decision-making process.

The final step in the workflow involves the application of the WSM method in Excel, which first allows for identifying the most suitable insulation material for each type of stratigraphy, and subsequently enables a comparison among the different stratigraphies to determine which one offers the best overall performance. Both analyses are carried out based on the previously defined variables: cost, GWP, embodied energy, and acoustic performance.

3.2. Performance Criteria and Data Sources

The analysis framework established in this research is grounded on four principal performance criteria, selected for their relevance to both sustainable design practices and the functional requirements of building envelopes. Economic cost is considered to assess the affordability of each wall assembly, with values expressed in cost per square meter. This information is gathered from material price lists and procurement databases, ensuring that the cost estimates reflect market conditions and commonly accepted construction practices.

GWP, measured in kilograms of CO

2 equivalent per square meter, serves as the primary environmental impact indicator. It reflects the contribution of each assembly to climate change based on emissions generated throughout the production phase, including extraction, manufacturing, and transport. These values are derived from EPDs compliant with EN 15804 [

54] standards, focusing particularly on modules A1 to A3, which represent the most significant environmental burden of a product’s life cycle. Qui dobbiamo inventarci qualcosa per spiegare perchè tra i fattori ambientali abbiamo preso in considerazione solo GWP ed embodiede energy.

Embodied energy, expressed in megajoules per square meter, complements GWP by quantifying the total energy consumed during the production phase of each material. The inclusion of embodied energy is crucial for assessing the resource intensity of wall assemblies and gaining a more comprehensive understanding of their overall environmental impact.

Among the various environmental indicators considered within LCA, GWP and embodied energy hold particular relevance. GWP is one of the most widely adopted and internationally recognized indicators, as it directly relates to climate change—one of the most pressing global environmental challenges. Its systemic and global implications also make it especially strategic for decarbonization policies and climate neutrality targets. While embodied energy is not always included among the standard ISO LCA indicators, it is frequently used as an energy-related proxy to evaluate fossil fuel dependency in production processes. Moreover, in many cases—especially in high-performance buildings—the environmental impact of the operational phase is significantly reduced. As a result, impacts associated with the production and construction phases (cradle-to-gate), where GWP and embodied energy are most prominent, become increasingly significant. Other indicators, such as ozone depletion or land use, though valuable, can be more difficult to interpret and apply consistently within early design decision-making frameworks.

In addition to environmental metrics, acoustic insulation performance is incorporated to address both user comfort and regulatory compliance. This is quantified using the standardized D2m,nTw index (in decibels), which measures the façade’s ability to reduce sound transmission under defined conditions. The parameter is estimated through the ECHO software, which calculates performance based on the physical properties of each layer—such as surface mass and dynamic stiffness. The software employs empirical models validated through field and laboratory tests, ensuring reliable approximations of real-world acoustic behavior.

ECHO’s predictive model is based on the procedures defined in the ISO 10140 [

55] standard series for laboratory measurement of sound insulation in building elements. Although direct in situ acoustic measurements were not conducted, the ECHO software employed in this study has been validated in prior research through comparison with empirical data. Its predictive accuracy has been confirmed for multi-layer façade systems using input parameters such as surface mass, material stiffness, and layer sequencing. Nurzyński [

25] and Hu et al. [

28] have demonstrated its reliability for early-stage acoustic estimations, making it a suitable tool for the comparative evaluation adopted here. Nevertheless, future work will focus on benchmarking ECHO’s outputs against in situ or lab-measured acoustic data to further validate the model’s predictive accuracy.

3.3. Parametrization and Compliance Verification

To ensure that all proposed wall assemblies conform to minimum performance standards, a parametrization process was developed using Dynamo, which is embedded within the Revit environment. The primary variables subjected to parametrization are the material composition and thickness of the insulation layer within each stratigraphy. The optimization logic encoded in the Dynamo script incrementally adjusts the thickness of the insulation material for each alternative.

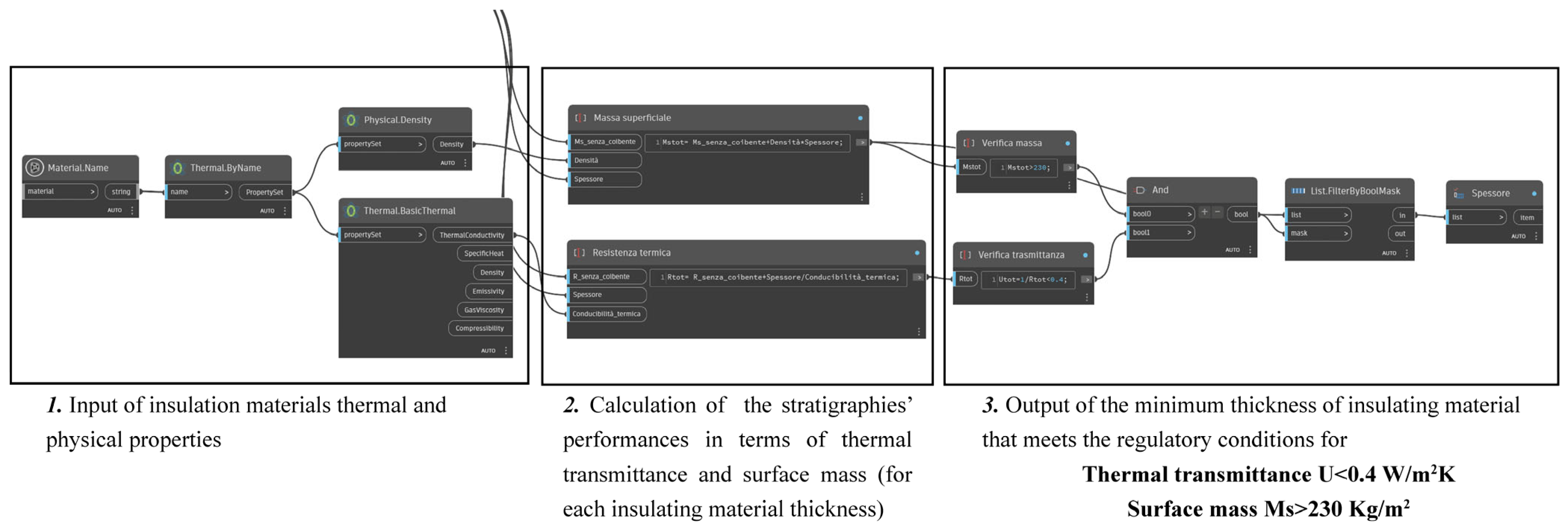

Figure 2 showcases the parametric workflow developed in Dynamo, detailing the automated logic used to adjust insulation thickness in real time. It is divided into three functional blocks: (1) the input of thermal and physical properties of insulation materials, (2) the iterative calculation of thermal transmittance and surface mass for varying thicknesses, and (3) the output of the minimum thickness meeting regulatory thresholds (U ≤ 0.4 W/m

2K and Ms ≥ 230 kg/m

2).

The script not only automates the testing of multiple configurations but also eliminates the need for repetitive manual adjustments, thereby streamlining the design verification phase. This functionality allows designers to explore a wide range of design options with minimal effort, supporting a more comprehensive investigation of material alternatives and construction solutions.

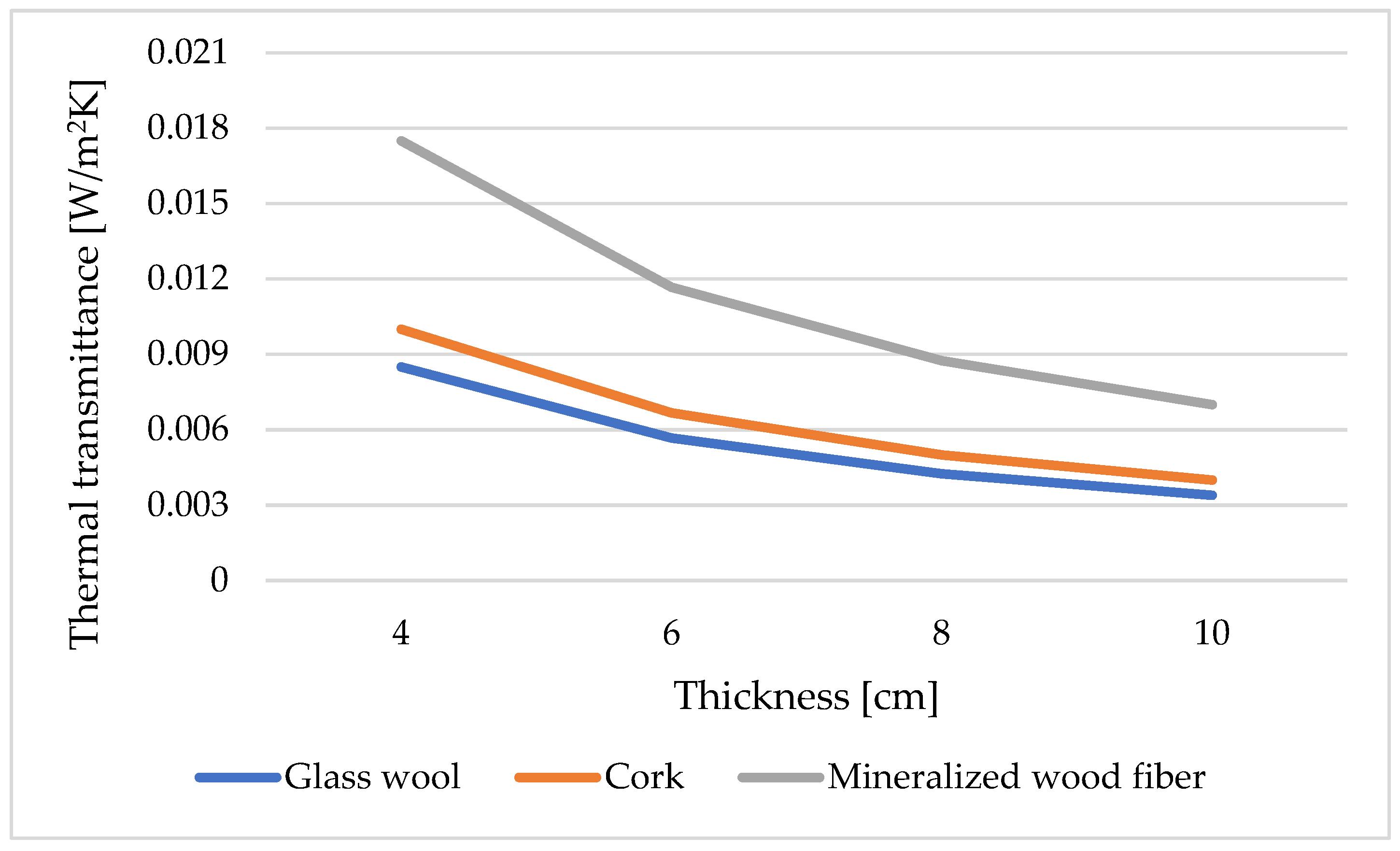

Figure 3 illustrates the inverse relationship between insulation thickness and thermal transmittance for three insulating materials: glass wool, cork, and mineralized wood fiber. As expected, increasing the thickness leads to a reduction in transmittance, with glass wool consistently demonstrating the best thermal performance across all thickness levels. Cork offers slightly higher transmittance values but remains competitive, whereas mineralized wood fiber exhibits the least effective insulation.

Beyond its direct comparative value, this figure also exemplifies how the use of Dynamo allows for the parametric exploration of material behavior by automating the generation of multiple configurations. In this case, the script dynamically adjusts the insulation thickness and calculates the corresponding thermal transmittance values, enabling the identification of optimal configurations that satisfy regulatory constraints.

3.4. Multi-Criteria Decision-Making: WSM Application

To select the optimal insulation material for each type of stratigraphy and the best wall assembly among the validated alternatives, this study employs the WSM, a well-established compensatory method within the domain of MCDM. This technique calculates a composite performance score for each alternative by aggregating its normalized scores across all evaluation criteria, each multiplied by a corresponding weight that reflects its relative importance within the decision-making context.

In this study, the weight assigned to economic cost is set at 0.40, recognizing its central role in determining the financial feasibility of construction choices. Environmental criteria are represented by GWP and embodied energy, which are each assigned a weight of 0.225 to emphasize their collective significance in promoting low-impact design. Finally, acoustic performance is given a weight of 0.15, acknowledging its influence on indoor comfort while accounting for the observation that all analyzed assemblies perform above minimum acoustic thresholds.

Prior to the aggregation process, all raw values are normalized to enable a consistent and comparative evaluation across indicators with different units and scales. Among the environmental indicators typically adopted in LCA, GWP and embodied energy were selected for their particular relevance in the context of early-stage design assessment. GWP is widely recognized and directly linked to climate change, thus representing a strategic reference for decarbonization efforts and climate neutrality policies. Embodied energy is frequently used as an energy-related proxy to assess reliance on fossil fuels in material production processes. This is especially relevant for high-performance buildings, where operational energy impacts are increasingly mitigated, making cradle-to-gate impacts more dominant in the overall environmental profile. Other impact categories—such as ozone depletion or land use—were excluded due to their complexity and lower applicability in comparative, early-phase evaluations.

To normalize the performance data, the Max–Min method is applied. The cost, GWP, and embodied energy are treated as cost-type criteria, where lower values indicate better performance, while acoustic insulation is treated as a benefit-type criterion, where higher values are desirable. This dual classification ensures that both minimization and maximization objectives are coherently captured within the multi-criteria decision-making model. The normalized and weighted scores are then aggregated for each configuration, resulting in a final performance index that supports comparative ranking.

Table 1 outlines the four performance criteria applied in the multi-criteria decision-making process using the WSM. The weights used in the WSM were assigned based on a literature-informed rationale that reflects the most prioritized dimensions in sustainable building design. Greater emphasis was placed on economic cost (weight: 0.40), followed by environmental indicators—GWP and embodied energy—assigned equal weights of 0.225 each and a lower but relevant weight for acoustic insulation (0.15). While no stakeholder consultation or expert elicitation was conducted at this stage, the selected weights are aligned with existing decision support models in similar domains.

Raw performance values were normalized using min-max normalization to transform all criteria to a common 0–1 scale. For a given criterion x, the normalized value x

n was calculated as

where

xmin and

xmax are the minimum and maximum observed values for that criterion across all alternatives. For cost, GWP, and embodied energy (where lower is better), the formula was inverted accordingly.

While this study adopts a predefined set of weights to reflect generalized priorities—such as emphasizing cost feasibility and environmental impact—the WSM structure employed is flexible. The framework allows for the integration of stakeholder-defined preferences, which can be elicited through expert interviews, participatory workshops, or formal techniques such as the AHP. Incorporating context-specific weight sets represents a natural extension of the proposed methodology, especially in design scenarios where performance priorities vary based on client needs, project typologies, or regulatory requirements. Future developments may include the implementation of an interactive, user-friendly tool that enables design professionals to define weights dynamically, supporting more responsive and customized decision-making in practical applications.

4. Case Study

The proposed methodology was applied to a representative case study aimed at testing the effectiveness of the integrated BIM-MCDM approach in evaluating and optimizing different configurations of external wall assemblies. The case study is situated within the context of the Mediterranean climate, specifically corresponding to the climatic characteristics of zone B as defined by Italian legislation. This choice ensures relevance to regions experiencing moderate heating requirements and increasingly critical cooling demands during summer months, thus emphasizing the need for envelopes that perform well in terms of thermal inertia, acoustic comfort, and environmental sustainability.

The reference building model, developed in Autodesk Revit, includes a simplified architectural configuration comprising a series of standardized rooms and surfaces, serving as a neutral base for applying and evaluating alternative wall stratigraphies. The use of a generic building model allowed for controlled comparative analysis, minimizing variability due to geometric complexity or occupancy patterns. The architectural configuration, though schematic, respects standard construction principles and dimensions, thereby maintaining realistic boundary conditions for thermal and acoustic behavior. The use of a simplified building model was a deliberate choice to ensure controlled comparisons between wall assemblies under standardized geometric and boundary conditions. This abstraction enables the isolation of performance differences attributable solely to stratigraphic variations, without interference from spatial or morphological factors. However, the proposed digital workflow—based on BIM in Revit, parametric scripting in Dynamo, and spreadsheet-based multi-criteria analysis—is inherently modular and adaptable. Future applications may test the scalability of this method by applying it to more complex building models, including multi-zone configurations, varying envelope orientations, or articulated volumetric compositions, in order to assess its robustness in more realistic or diverse design contexts.

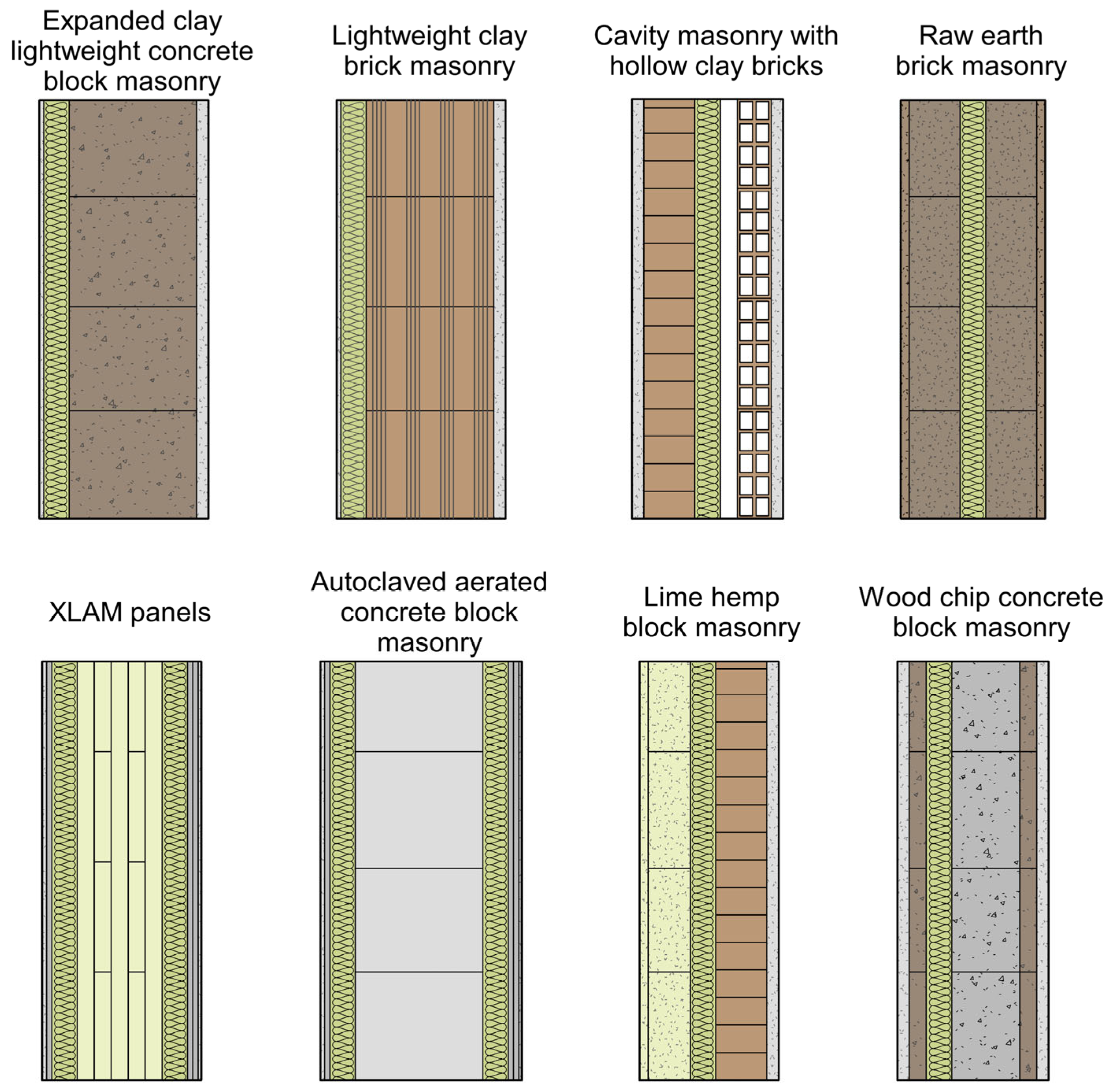

A total of eight base wall configurations were selected for this study, representing a variety of construction approaches, from conventional systems to innovative natural-based solutions. These were categorized into three main groups based on their structural logic and material composition:

Massive systems, such as expanded clay concrete, Poroton blocks, and cement-bonded wood fiber;

Cavity wall systems, including combinations of raw earth, solid bricks, hollow blocks, and lime hemp masonry;

Lightweight single-layer systems, such as cross-laminated timber (CLT) panels and autoclaved aerated concrete (AAC) blocks.

This classification allows for a clearer comparison of performance across construction types and helps highlight the design logic underlying each solution. All stratigraphies were modeled to include a parametric insulation layer, whose thickness is adjusted to comply with regulatory thermal requirements.

Table 2 summarizes the detailed composition and material layering of each base wall assembly used in the optimization process.

Figure 4 visually depicts the eight base wall assemblies modeled in Revit, highlighting the layering and composition of each system. The graphic clarity communicates differences in material arrangement and stratigraphy structure, from traditional masonry and AAC systems to bio-based alternatives like raw earth, lime hemp, and wood chip concrete. The visual coding emphasizes insulation positioning and layer proportions, supporting the understanding of how each wall type accommodates parametric insulation thickness adjustments within a realistic architectural model.

The thermal insulation layer was treated as the primary design variable in the optimization process. For each of the eight base wall stratigraphies, three insulation materials were considered: mineral glass wool, wood fiber, and cork. These materials were selected based on their availability on the market and their distinct physical and environmental characteristics. Glass wool is widely used due to its low cost and good thermal performance.

Wood fiber—particularly at low density—offers favorable environmental credentials, along with hygroscopic and acoustic advantages. Cork is valued for its excellent sound absorption and natural resistance to moisture, although it tends to have a higher embodied energy than low-density wood fiber and lower than high-density alternatives, as noted by Grazieschi et al. [

56], and even higher than mineral wool insulation under certain conditions.

The selection of insulation materials was made to reflect distinct and widely adopted typologies in current practice: a conventional mineral-based insulator (glass wool), a fully bio-based and recyclable natural insulator (expanded cork), and a composite solution (mineralized wood fiber) that integrates both natural and mineral constituents. These materials are among the most used in building applications in Italy and across Europe, and are suitable for a variety of wall stratigraphies.

Their inclusion was also supported by environmental performance studies, such as the critical review by Grazieschi et al. [

56], which highlights distinct levels of embodied energy among insulation materials—glass wool having the lowest, cork moderate, and mineralized wood fiber the highest energy demand. These distinctions are consistent with the EPD data used in the analysis conducted, ensuring that the selected materials provide a gradient of environmental impacts. Thus, the combination of technical relevance, availability, and differentiated environmental profiles makes these three insulators a representative basis for evaluating the adaptability and sensitivity of the proposed optimization workflow.

By combining each of the eight base walls with these three insulation types, a total of twenty-four distinct wall assemblies were generated for evaluation.

Table 3 summarizes the key thermal and environmental properties of the three insulation materials considered in this study.

Glass wool exhibits the lowest thermal conductivity, confirming its high efficiency in limiting heat transfer per unit of thickness. Cork stands out for its negative GWP, reflecting its carbon sequestration capacity during the growth of the raw material, which contributes to its favorable environmental profile.

In contrast, mineralized wood fiber, while providing good acoustic and hygroscopic properties, has the highest embodied energy among the three materials—indicating a greater energy demand in its production process, likely due to more intensive manufacturing and transportation requirements.

It is important to note that the GWP and embodied energy values reported here represent average reference values obtained from EPDs; actual figures may vary depending on the specific product, manufacturing process, and geographic context.

Each wall configuration was subjected to automated optimization through a custom Dynamo script. The script adjusted the thickness of the insulation layer iteratively, seeking the minimum thickness required to satisfy two key performance thresholds: a U-value equal to or lower than 0.4 W/m2K and a surface mass equal to or greater than 230 kg/m2. The optimization process ensured that all selected assemblies were viable from a regulatory standpoint, establishing a common basis for subsequent performance comparison. The iterative adjustment allowed each wall to meet the dual constraint criteria while minimizing the amount of insulation material used, thereby balancing performance with material efficiency.

Upon achieving compliance, each configuration underwent detailed evaluation according to four performance dimensions: economic cost, GWP, embodied energy, and acoustic insulation. Data collection was conducted through a rigorous methodology that combined literature review, EPD databases, technical product documentation, and acoustic simulation using ECHO software. The latter estimated the D2m,nT,w index for each assembly, factoring in density, stiffness, and multi-layer composition effects. All cost data were adjusted to reflect current pricing in the Italian construction sector, ensuring the relevance and realism of the economic evaluation. Environmental parameters were limited to modules A1-A3 of the life cycle to maintain consistency across materials and ensure the comparability of results.

The performance data of all twenty-four alternatives were organized into a tabular format and subjected to the WSM as part of the multi-criteria decision-making process. Each performance criterion was automatically normalized and weighted according to the predefined values, allowing the model to integrate diverse dimensions into a unified score.

The resulting scores were used to generate a ranking of all configurations, revealing the most effective solutions across combined sustainability and comfort metrics. This process enabled a holistic evaluation of each wall assembly’s strengths and weaknesses, highlighting trade-offs and synergies among environmental, economic, and functional parameters.

5. Results

5.1. Performance of Wall Configurations

Table 4 presents the unprocessed data for the 24 wall configurations analyzed, showing a comprehensive comparison across economic, environmental, and acoustic parameters. Notably, bio-based solutions, such as raw earth with cork or hemp fiber, stand out for their low GWP and embodied energy, paired with strong acoustic performance. Conversely, conventional materials like glass wool offer cost efficiency but tend to score lower on environmental metrics. High-performance combinations like CLT with cork or glass wool exhibit excellent acoustic insulation but with higher costs and embodied energy.

At the material level, the acoustic performance of expanded cork can be attributed to its microcellular structure, composed of irregular, closed-cell pores filled with air. This porous morphology, combined with the lightweight and elastic properties of cork, enables effective absorption and dissipation of airborne sound waves across a wide frequency range.

Similarly, the fibrous texture and density of mineralized wood wool panels contribute to their ability to break up sound paths and increase energy dissipation. In contrast, glass wool, although an efficient thermal insulator due to its fine, randomly oriented fibers, may provide slightly lower acoustic performance due to its lower surface mass. These microstructural characteristics directly influence each material’s weighted sound reduction index, as reflected in the simulation results.

5.2. Ranking and Trade-Off Analysis

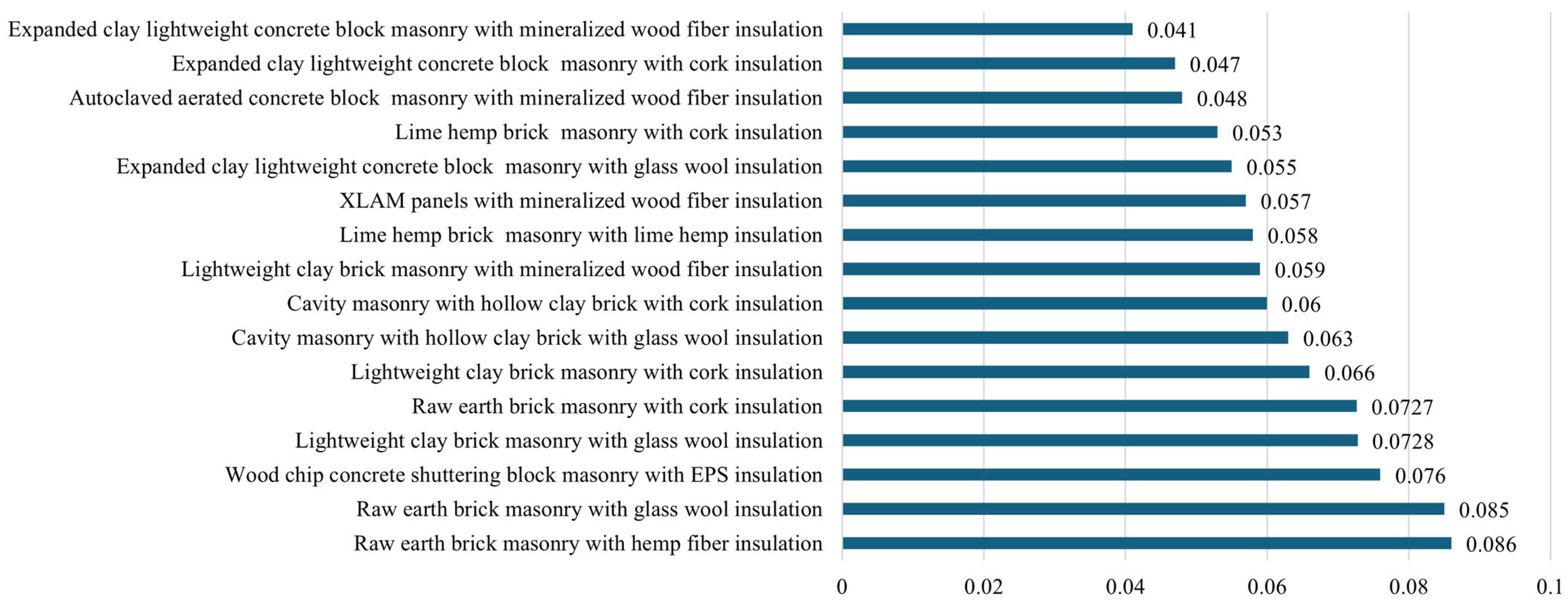

Table 5 presents the normalized and weighted values for each of the four performance criteria, culminating in the final WSM scores used to rank the 24 wall assemblies. This step reveals the holistic performance of each configuration. Bio-based solutions—especially raw earth masonry with hemp fiber or glass wool—achieve the highest scores (0.086 and 0.085), driven by superior acoustic and environmental metrics. In contrast, conventional or industrial solutions often perform well in one area (e.g., cost) but score lower overall due to environmental drawbacks.

The ranking generated by the WSM indicated that the top-performing wall assemblies were those combining natural or low-impact structural materials with insulation layers made from cork or wood fiber.

Figure 5 graphically presents the final WSM scores, ranking all 24 wall configurations based on their integrated performance. It illustrates that wall assemblies combining raw earth masonry with hemp fiber or glass wool insulation achieved the highest scores, reflecting a strong balance across environmental, economic, and acoustic dimensions. Conversely, configurations using conventional materials (e.g., expanded clay blocks with mineralized wood fiber) ranked lower due to poorer environmental or acoustic performance.

In particular, stratigraphies incorporating rammed earth or cross-laminated timber, coupled with cork insulation, achieved high scores across all criteria. These solutions demonstrated particularly low GWP and embodied energy values, while also achieving excellent acoustic insulation due to the inherent density and damping characteristics of the materials.

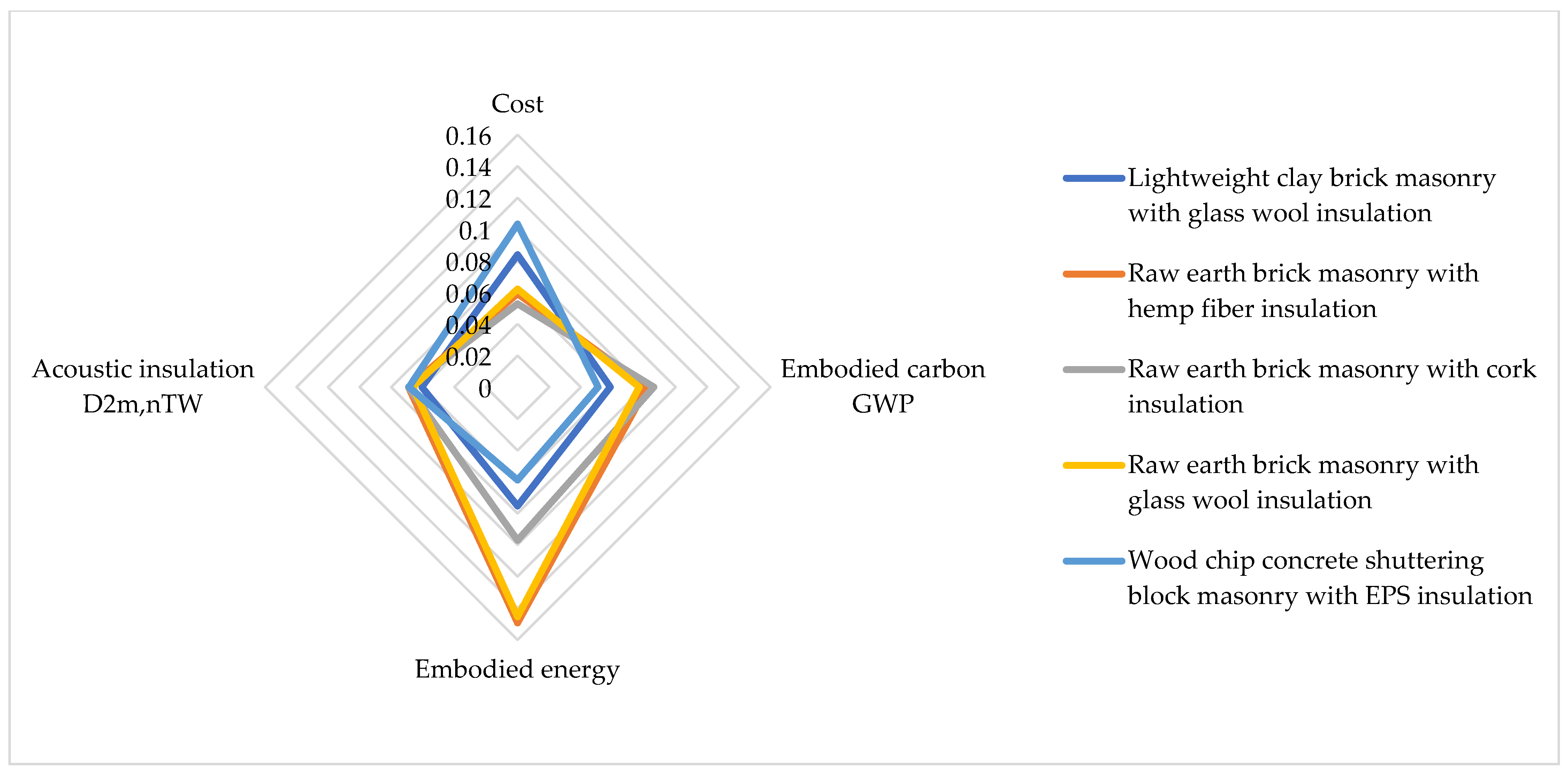

Figure 6 uses a radar chart to visualize the performance profiles of the five highest-ranking wall assemblies across the four evaluation criteria: cost, GWP, embodied energy, and acoustic insulation. The comparison highlights the trade-offs among solutions—particularly how raw earth masonry with hemp fiber excels in acoustic and environmental performance while maintaining moderate cost. In contrast, wood chip concrete with EPS insulation shows economic advantage but weaker environmental metrics.

Despite their higher initial material costs, these assemblies stood out for their ability to fulfill all regulatory requirements while delivering substantial environmental benefits. These findings support the notion that materials with a strong ecological profile and passive performance features can outperform conventional systems when a holistic evaluation approach is applied.

Detailed analysis of the performance indicators revealed how each criterion influenced the overall ranking. For example, assemblies with cork as insulation outperformed others in acoustic performance by an average margin of 3 to 5 decibels, while maintaining competitive values in embodied energy. Conversely, assemblies with glass wool, although cost-effective, typically scored lower in both GWP and acoustic performance. This demonstrates the potential of natural materials to deliver synergistic advantages that contribute to multiple objectives within a sustainability framework.

Furthermore, the stratigraphy based on rammed earth, paired with cork insulation, emerged as one of the most sustainable alternatives overall, achieving the highest performance in environmental metrics. Although the initial costs associated with this solution were slightly above average, its environmental impact was lower, and its acoustic performance was excellent.

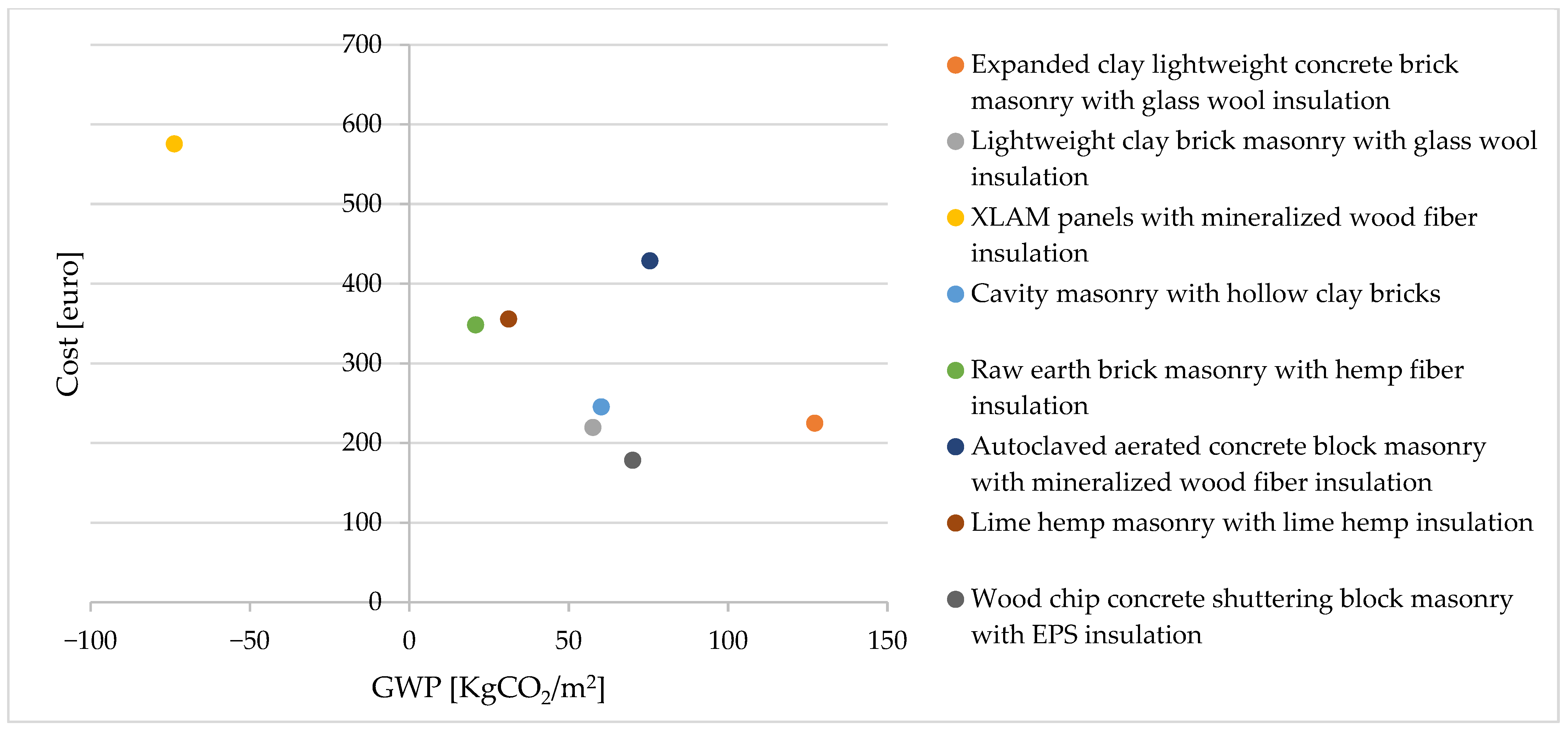

Figure 7 presents a scatter plot comparing the cost and GWP of selected wall configurations, highlighting the trade-offs between economic and environmental performance. Notably, XLAM panels with mineralized wood fiber insulation show the highest cost but a negative GWP, indicating strong environmental benefits at a financial premium. In contrast, expanded clay with glass wool appears as a low-cost, high-GWP option. The positioning of raw earth with hemp fiber in the mid-cost, low-GWP quadrant reinforces its value as a balanced, sustainable solution.

On the other end of the spectrum, wall configurations based on lighter or more industrialized materials, such as AAC, when combined with glass wool insulation, tended to score lower in terms of environmental performance. These solutions were generally more affordable and still compliant with thermal and acoustic regulations, making them viable in contexts where cost constraints are prioritized. However, their higher GWP and embodied energy values resulted in lower overall WSM scores, illustrating the trade-offs that designers must consider when balancing financial and environmental priorities. This contrast underlines the necessity of adopting a multi-criteria decision-making approach, where economic efficiency does not overshadow long-term environmental impact and user comfort.

The results also highlighted the importance of acoustic performance as a differentiating factor. Although all wall assemblies satisfied the minimum surface mass required to provide sufficient sound insulation, those utilizing materials with superior sound-absorbing properties, such as cork and wood fiber, showed higher acoustic indices.

5.3. Acoustic Performance and Robustness of Results

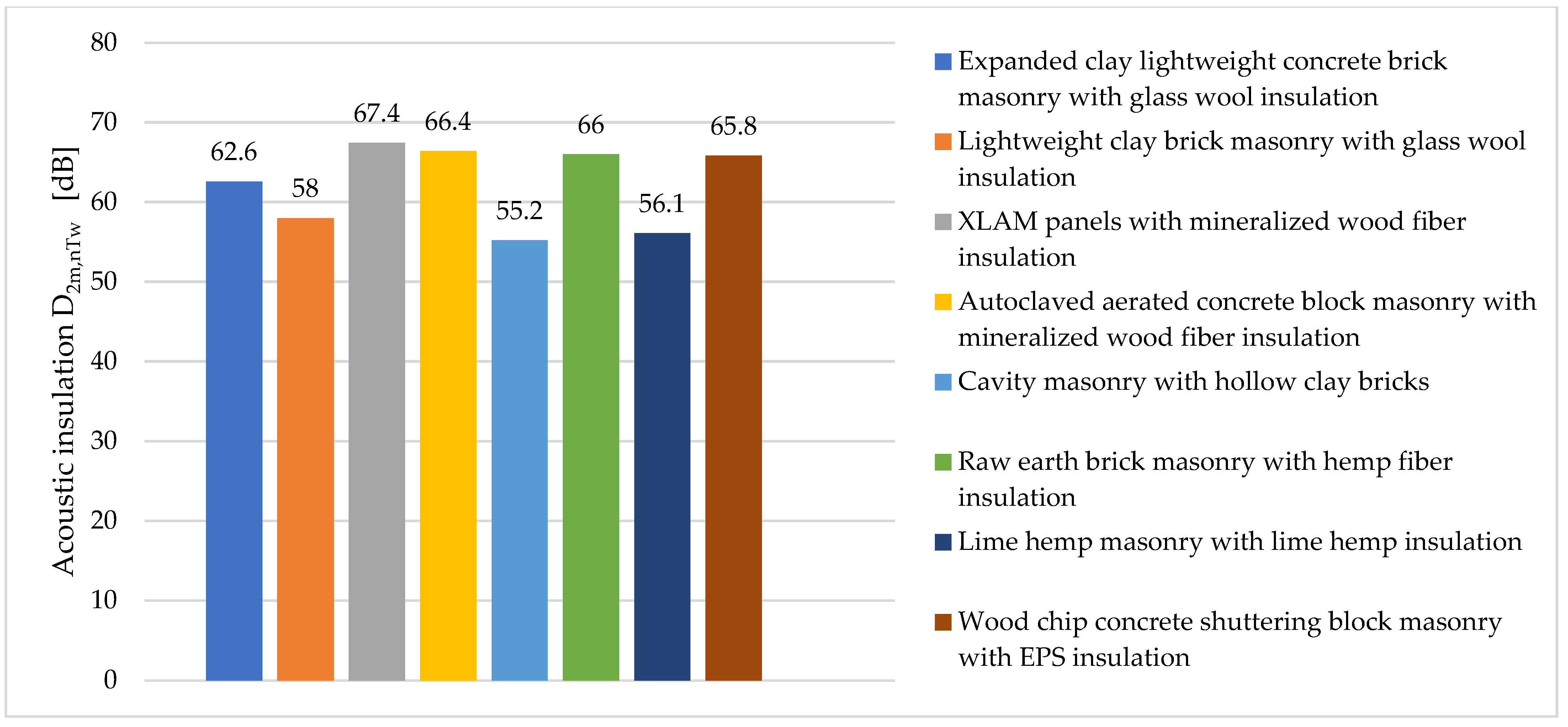

Figure 8 compares the acoustic insulation performance of selected wall configurations, measured in terms of the standardized weighted sound reduction index (D

2m,nT,w). The chart highlights that XLAM panels with mineralized wood fiber, autoclaved aerated concrete with mineralized wood fiber, and raw earth with hemp fiber deliver the highest sound insulation values (above 65 dB), making them particularly suitable for noise-sensitive environments. On the other hand, lightweight clay bricks with glass wool and cavity masonry with clay bricks exhibit lower acoustic performance, falling below 60 dB.

These materials not only contributed to the assemblies’ environmental credentials but also enhanced occupant comfort, which is a key consideration in residential and educational building contexts. The role of acoustic insulation becomes even more pronounced in urban and densely populated areas, where noise mitigation is critical for well-being. In these settings, wall assemblies that achieve superior sound attenuation without compromising environmental performance are particularly valuable.

To assess the robustness of the ranking results, a preliminary sensitivity analysis was conducted by varying the weights assigned to key criteria within a ±10% range. Specifically, the weights for cost, GWP, and acoustic performance were adjusted in separate scenarios while maintaining normalization.

Table 6 reports the WSM scores of the top five wall configurations across these scenarios. The results indicate that the highest-performing assemblies—particularly those combining raw earth masonry with hemp fiber or glass wool insulation—maintain their leading positions consistently, with only marginal fluctuations in score. This suggests a relative stability of the ranking under moderate shifts in design priorities. Nonetheless, the results also reveal that some lower-ranking solutions are more sensitive to weighting changes, especially when score differences are small. These findings confirm the reliability of the proposed method while also highlighting the potential value of a more comprehensive sensitivity analysis in future research, possibly incorporating stochastic methods such as Monte Carlo simulation or expert-based weight variation frameworks.

5.4. Benchmarking with Conventional Solutions

To contextualize the performance of the proposed wall assemblies, benchmarking was conducted using typical conventional wall systems from the literature. For example, common masonry walls with extruded polystyrene (XPS) insulation or aerated concrete with EPS are frequently adopted in Mediterranean climates. Based on data from previous studies, such conventional walls typically present U-values in the range of 0.28–0.40 W/m

2K [

57] and Global Warming Potential (GWP) values around 45–60 kgCO

2eq/m

2 [

58].

In contrast, the best-performing configurations in this study—such as those combining raw earth with glass wool or cork—achieve U-values around 0.24–0.25 W/m2K and GWP values below 30 kgCO2eq/m2. This demonstrates a 20–35% improvement in thermal performance and a 40–50% reduction in environmental impact, confirming the benefits of biogenic and low-embodied-energy materials in high-performance envelopes.

In summary, the proposed methodology allowed for the generation and ranking of 24 compliant wall assemblies, all meeting the dual regulatory thresholds of U ≤ 0.4 W/m2K and M_s ≥ 230 kg/m2. The top-performing configuration (raw earth with hemp fiber) achieved a WSM score of 0.086, surpassing conventional glass wool solutions by 10–15% in overall performance. Acoustic insulation for this configuration reached 66.1 dB, GWP was as low as 20.8 kgCO2eq/m2, and embodied energy was under 350 MJ/m2. These results demonstrate how natural materials can be optimized not just for environmental impact, but in conjunction with cost and comfort metrics—within a reproducible digital workflow. While the environmental benefits of bio-based materials are qualitatively known, this study provides quantitative evidence of their multi-dimensional performance under parametric and regulatory constraints, highlighting the impact of thickness tuning, material density, and stiffness on final scores. Moreover, the workflow reduces design iteration time by 80–90%, confirming its practical utility and scientific rigor in performance-based design.

6. Discussion

6.1. Methodological Framework and Key Findings

The present study evaluates a limited set of 24 wall assemblies, resulting from the combination of eight stratigraphic layers and three insulation types. This selection was defined to balance representativeness and methodological clarity while ensuring compliance with national regulations for thermal performance. However, the developed workflow—fully embedded in a parametric BIM environment—is scalable to larger design spaces through systematic parametric variation. While a preliminary sensitivity analysis has been conducted to assess the stability of the WSM-based rankings under weight variation, future research will expand the scope of tested configurations and apply statistical validation techniques, such as one-way ANOVA, to test for significant differences across performance indicators. Additionally, uncertainty propagation methods will be adopted to quantify variability in environmental data (e.g., GWP and embodied energy) stemming from dataset selection or material-specific emissions.

From a methodological perspective, the integration of BIM with parametric modeling and MCDM proved highly effective. The automated adjustment of insulation thicknesses using Dynamo streamlined the compliance verification process, reducing design time and minimizing the potential for human error. Furthermore, the structured evaluation enabled by the WSM offered a transparent and repeatable decision-making framework, facilitating informed comparisons between complex and multi-layered solutions. This methodological integration fosters a collaborative and iterative design environment where feedback loops between performance simulation and design adjustments can be rapidly implemented. It also enhances the traceability and reproducibility of the evaluation process, which is essential for institutional validation and knowledge transfer across projects.

While the WSM offers an intuitive and transparent approach for ranking design alternatives based on weighted priorities, it aggregates multiple criteria into a single score, potentially masking trade-offs between conflicting objectives. For example, a configuration with a moderate GWP and low cost might score similarly to one with inverse characteristics. To gain deeper insight into such trade-offs, future work will employ multi-objective optimization tools, such as Pareto front analysis, to visualize and identify non-dominated solutions.

6.2. Practical Implications and Design Priorities

The discussion of the results reveals that the optimal choice of wall assembly depends heavily on the specific goals and constraints of a given project. For projects prioritizing environmental sustainability and acoustic comfort, the use of natural materials such as earth, wood fiber, and cork is recommended, even at the expense of higher material costs. Conversely, for developments operating under tight budgetary constraints, traditional materials combined with mineral insulation may still offer satisfactory performance, especially when environmental criteria are of secondary importance. This adaptability underscores the practical value of the proposed methodology as a tool for design support across diverse project types and priorities. It also demonstrates how strategic material selection can align with broader sustainability targets, such as those promoted by EU Green Deal policies or national energy transition goals.

Ultimately, the findings underscore the value of adopting a multi-criteria perspective in the early stages of design. By leveraging the capabilities of digital tools and structured evaluation methods, architects and engineers can more effectively navigate the complexities of material selection and achieve high-performance, regulation-compliant solutions tailored to the specific demands of each context. The results from this study validate the proposed workflow as a decision support system capable of promoting more sustainable and informed design practices in the construction industry. Moreover, they encourage a broader cultural shift toward integrative and evidence-based decision-making in the architectural and engineering professions. This transformation, supported by digitalization and performance-driven design, can lead to more resilient, efficient, and environmentally responsible buildings in the face of emerging climate and urban challenges.

Beyond performance outcomes, the proposed digital workflow offers advantages in terms of iteration efficiency. The integration of Revit and Dynamo for parametric control allows for automatic compliance checking and stratigraphy reconfiguration, reducing the manual effort required in traditional design workflows.

Compared to commercial solutions such as Tally or OneClick LCA, which offer streamlined environmental analysis but are not fully integrated with parametric geometric control or real-time compliance thresholds [

59], the proposed method emphasizes automation and regulatory alignment during the early design phase. While Tally and OneClick LCA provide material databases and reporting tools, their use still requires manual setup for each configuration and lacks integrated scripting to dynamically adjust wall assemblies [

60].

6.3. Limitations and Future Research

While the proposed methodology demonstrates a replicable, BIM-based framework for the performance optimization of wall assemblies, several limitations suggest avenues for targeted future research.

First, the current implementation focuses on three key performance dimensions—environmental impact (GWP, embodied energy), acoustic insulation, and cost. Future developments should explore multi-physics performance criteria, particularly by integrating hygrothermal simulations to assess moisture accumulation risk, condensation, and long-term durability. This enhancement could be implemented through interoperability between Revit and simulation engines such as WUFI or Delphin, enabling climate-specific material behavior modeling.

Second, while the current study uses a WSM for ranking alternatives, future work will compare this method with Pareto front analysis, TOPSIS, or ELECTRE to identify optimal non-dominated solutions in a multi-objective framework.

Third, the current weighting system is generic and equal-weighted. A valuable development would be the integration of expert-elicited or stakeholder-informed weight sets using the AHP or pairwise comparison methods to improve decision contextualization.

Fourth, a future research hypothesis includes the validation of the simulated acoustic and thermal results through empirical measurements using ISO-compliant laboratory test setups for real wall assemblies constructed from the proposed stratigraphies.

Lastly, the parametric dataset will be expanded to include non-orthogonal wall geometries, curved envelopes, and composite wall assemblies, thus testing the workflow’s adaptability to complex real-world architectural forms.

7. Conclusions

This study developed and validated an integrated, digital methodology for the performance-based optimization of external wall assemblies, addressing the growing demand for sustainable, energy-efficient, and regulation-compliant building design. By coupling BIM with parametric design tools and MCDM techniques, this research introduced a coherent, transparent, and replicable workflow that supports informed material selection and system configuration in the early stages of architectural design.

At the core of the methodology lies a parametric optimization script developed in Dynamo, which automates the adjustment of insulation layer thickness within Autodesk Revit models. This automation ensures that each wall assembly meets stringent performance requirements—specifically, a maximum U-value of 0.4 W/m2K and a minimum surface mass of 230 kg/m2—established for buildings in Italy’s climate zone B. The integration of acoustic simulation using ECHO software further enriched the performance dataset, allowing for comprehensive evaluation across four critical criteria: economic cost, GWP, embodied energy, and sound insulation capacity (D2m,nT,w).

The use of the WSM within a spreadsheet environment enabled a structured comparison of 24 optimized wall configurations derived from eight base stratigraphies combined with three types of insulation materials. This approach not only yielded an objective ranking of alternatives but also facilitated the analysis of trade-offs between different performance dimensions. The results underscore the importance of multi-criteria evaluation frameworks, especially in contexts where performance objectives may be conflicting or subject to project-specific constraints.

Wall assemblies based on natural or bio-based materials, such as rammed earth, CLT, cork, and wood fiber, demonstrated the highest overall scores in terms of sustainability and comfort. These solutions offered substantial reductions in GWP and embodied energy while also achieving superior acoustic performance due to favorable material densities and damping properties. Although their initial construction costs were higher than those of conventional systems, their environmental and functional advantages make them particularly attractive for projects targeting low-carbon design, bioclimatic performance, or green building certification.

On the other hand, more conventional solutions, such as hollow clay blocks paired with mineral wool insulation, were found to be economically advantageous while still meeting the minimum regulatory requirements. These alternatives may be well-suited for developments where budget limitations outweigh sustainability considerations or where regulatory compliance is the principal objective.

This work contributes to the growing body of literature on the digitalization of sustainability in construction, highlighting how parametric BIM workflows can bridge the gap between geometric modeling, material data integration, and performance optimization. It supports the evolution from prescriptive to performance-based design paradigms, in alignment with policy trends like the European Green Deal, the EPBD, and emerging frameworks for life cycle thinking and circular economy in the built environment.

The versatility of the proposed methodology offers numerous opportunities for future research and professional application. Extensions of the framework may include the following:

Additional criteria, such as fire resistance, moisture control, durability, and recyclability;

Adoption of LCC and LCA methods for deeper economic and environmental evaluation;

Integration with optimization algorithms (e.g., genetic algorithms or AI-driven generative design);

Application to other envelope components (e.g., roofs, floors, and façades);

Enhancement of openBIM interoperability via IFC schemas and web-based collaboration platforms.

In conclusion, this research demonstrates that the synergistic use of BIM, parametric scripting, and MCDM can serve as a powerful decision support tool in sustainable design. It empowers stakeholders to navigate the complexities of environmental, regulatory, acoustic, and economic performance in a unified, digital environment.