The Role of Integrated Information Management Systems in the Relationship Between Product Lifecycle Management and Industry 4.0 Technologies and Market Performance

Abstract

1. Introduction

2. Current Literature on Integrated Information Management Systems, Product Lifecycle Management, Industry 4.0, and Market Performance

3. Hypotheses Development

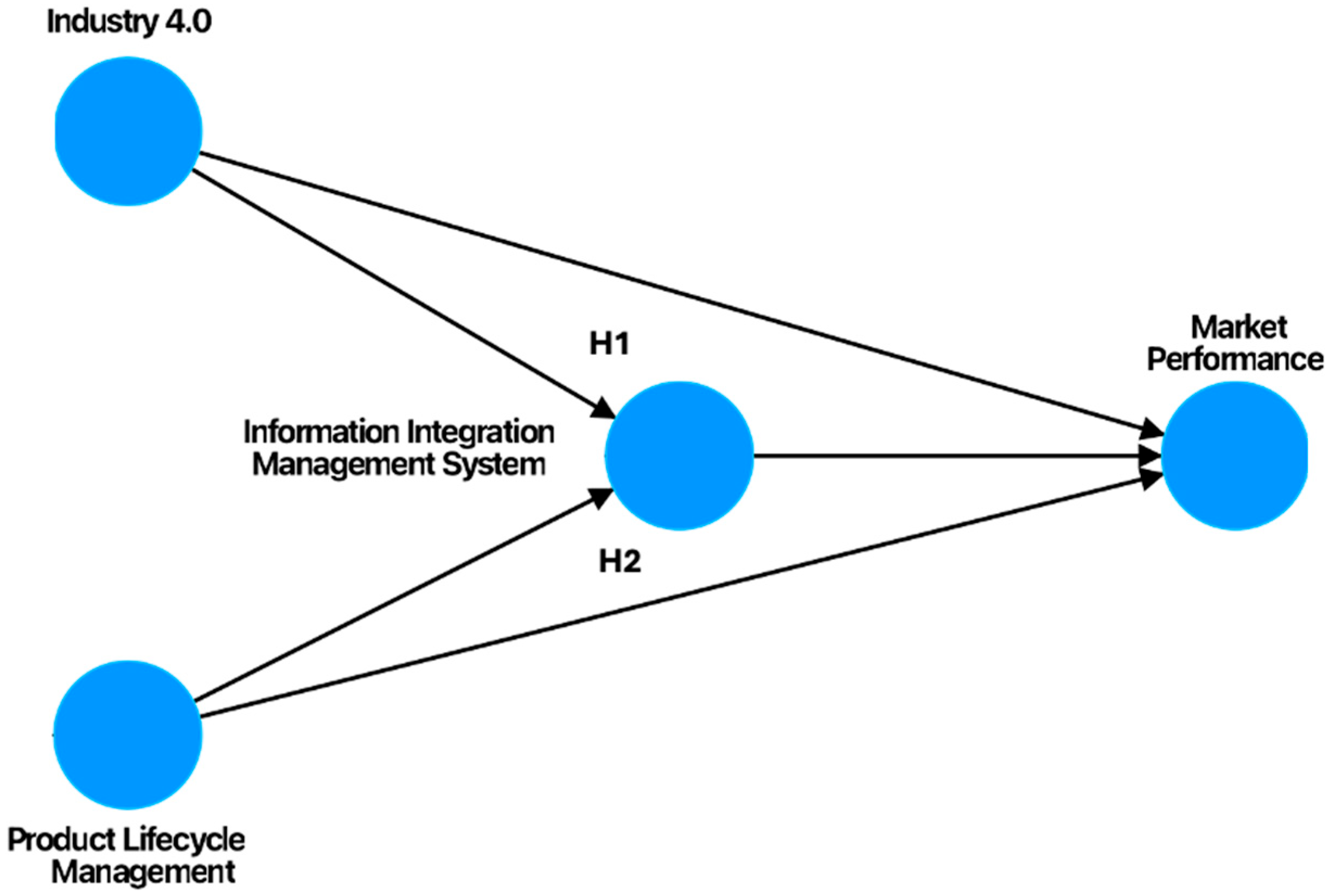

3.1. Industry 4.0, Integrated Information Management Systems, and Market Performance

3.2. Product Lifecycle Management, Integrated Information Management Systems, and Market Performance

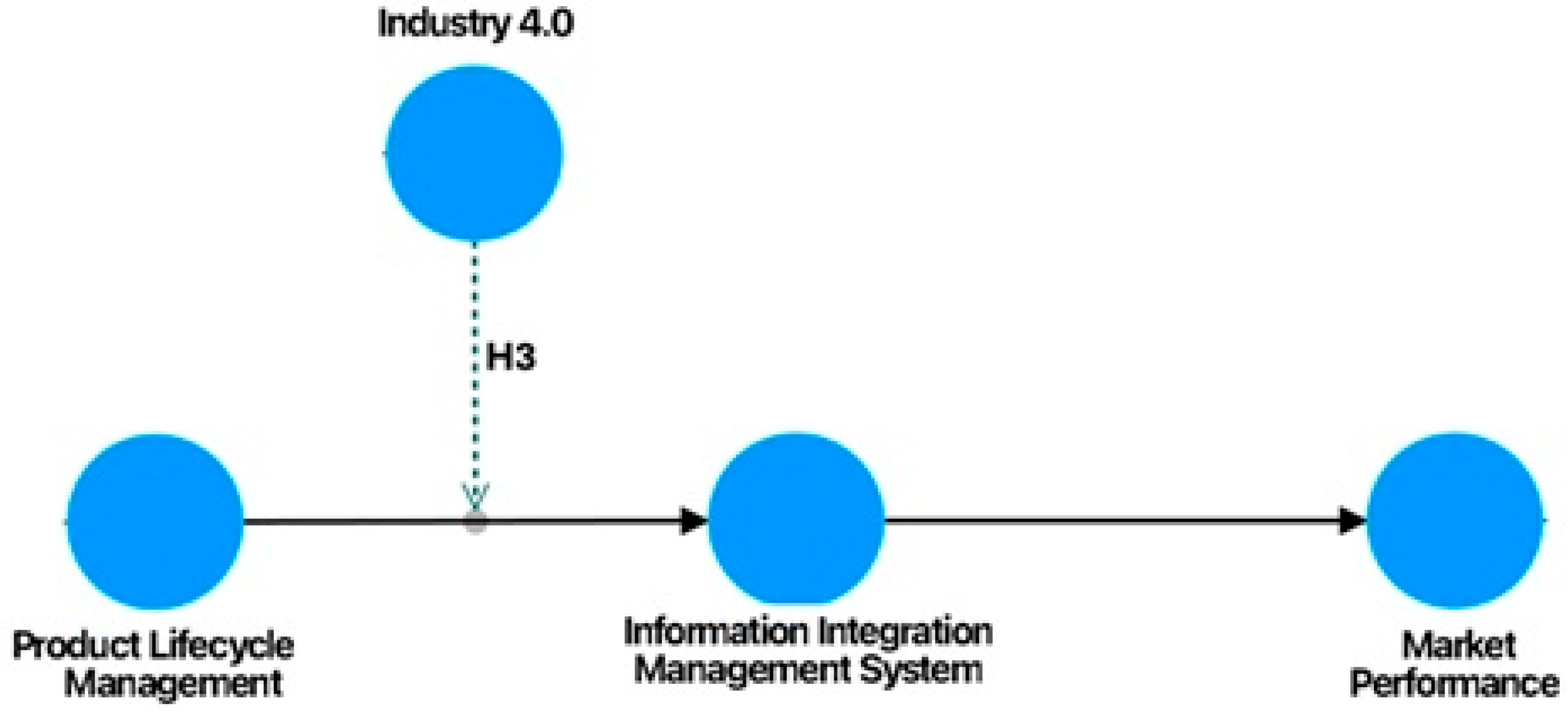

3.3. Mediating or Moderating Effect of I4.0 on the Relation Between PLM and IIMS on MP

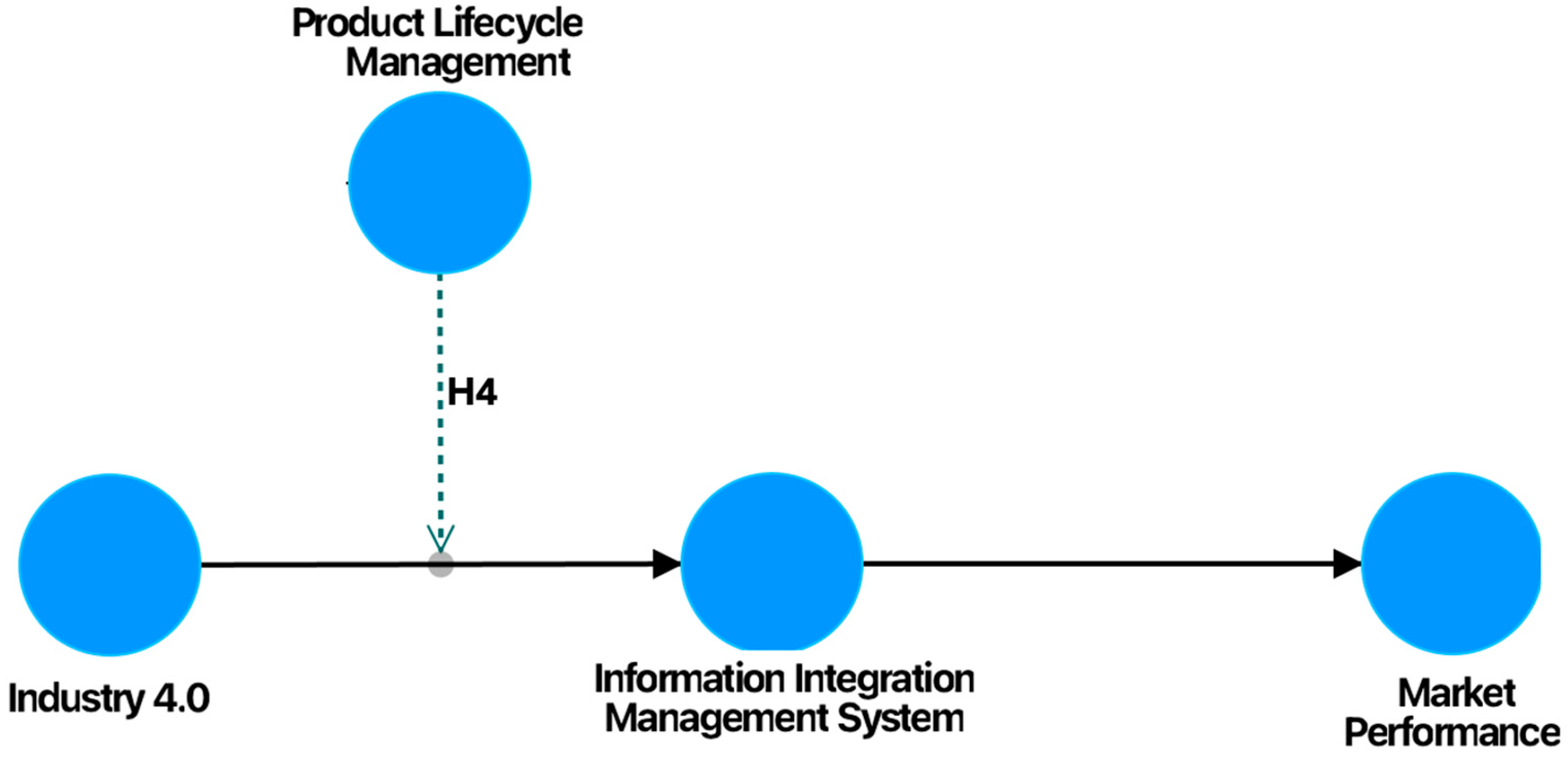

3.4. Mediating or Moderating Effect of PLM on the Relation Between I4.0 and IIMS on MP

4. Research Development

4.1. Sampling

4.2. Survey Instrument

4.3. Exploratory Factorial Analysis

4.4. Confirmatory Factorial Analysis

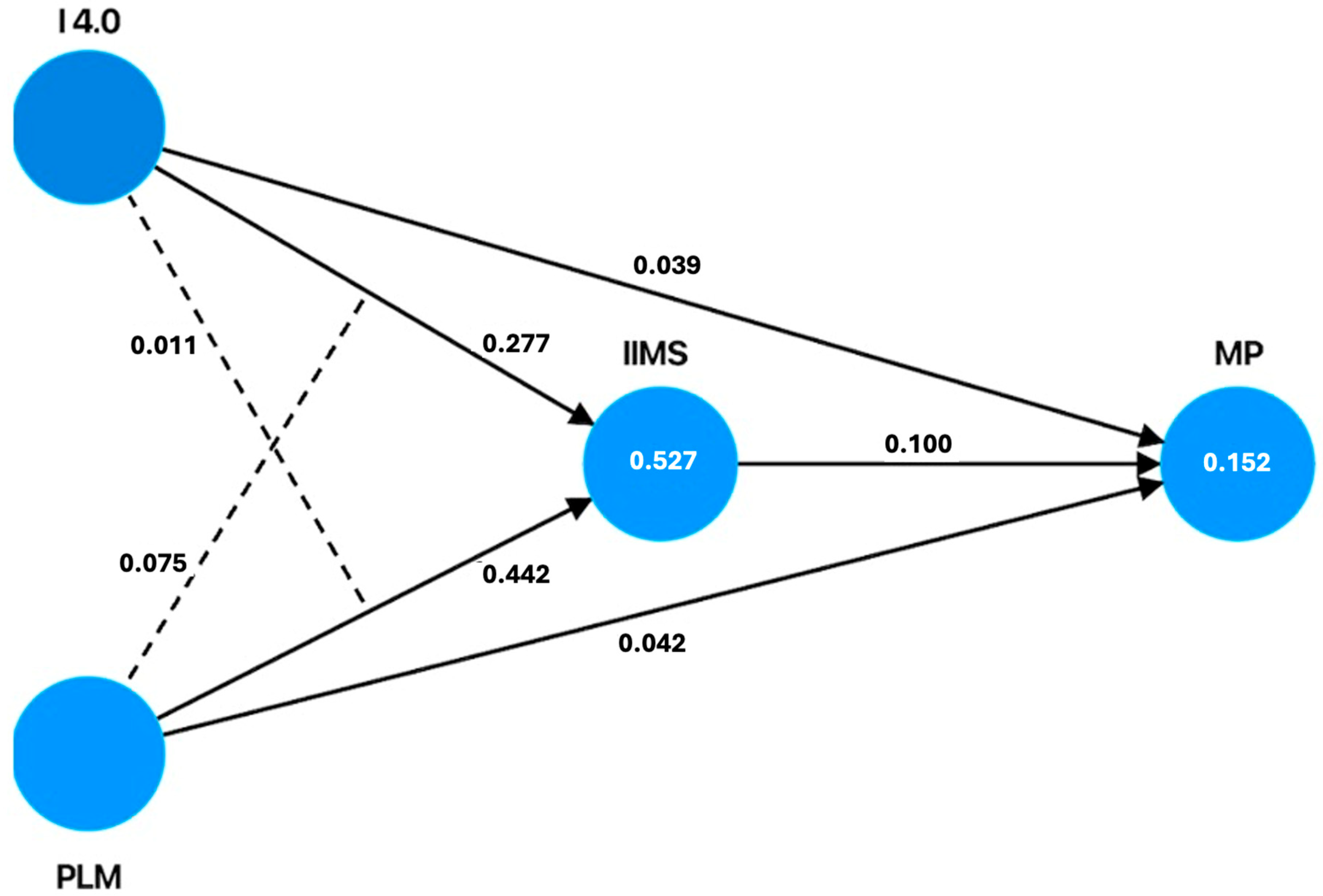

4.5. PLS-SEM Results

5. Hypothesis Outcomes

6. Discussion and Implications

6.1. Practical Implications

- Optimisation of Data and Process Management

- Mediating Impacts and Investment Strategies

- Training and Organisational Culture

- Strategic Planning and Causal Relationships

6.2. Implications for Sustainable Development

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baierle, I.C.; Sellitto, M.A.; Frozza, R.; Schaefer, J.L.; Habekost, A.F. An Artificial Intelligence and Knowledge-Based System to Support the Decision-Making Process in Sales. S. Afr. J. Ind. Eng. 2019, 30, 17–25. [Google Scholar] [CrossRef]

- Storch, L.A.; Nara, E.O.B.; Kipper, L.M. The Use of Process Management Based on a Systemic Approach. Int. J. Product. Perform. Manag. 2013, 62, 758–773. [Google Scholar] [CrossRef]

- Wang, X.; White, L.; Chen, X. Big Data Research for the Knowledge Economy: Past, Present, and Future. Ind. Manag. Amp; Data Syst. 2015, 115, 1566–1576. [Google Scholar] [CrossRef]

- Al Derei, S.K.; Fam, S.F. The Impact of Business Intelligence, Knowledge Sharing and SMEs Innovation on Innovative Work Behavior: A Proposed Framework for SMEs. Qual.-Access Success 2023, 24, 98. [Google Scholar] [CrossRef]

- El Bazi, N.; Mabrouki, M.; Laayati, O.; Ouhabi, N.; El Hadraoui, H.; Hammouch, F.E.; Chebak, A. Generic Multi-Layered Digital-Twin-Framework-Enabled Asset Lifecycle Management for the Sustainable Mining Industry. Sustainability 2023, 15, 3470. [Google Scholar] [CrossRef]

- Sassanelli, C.; Arriga, T.; Zanin, S.; D’adamo, I.; Terzi, S. Industry 4.0 Driven Result-Oriented PSS: An Assessment in the Energy Management. Int. J. Energy Econ. Policy 2022, 12, 186–203. [Google Scholar] [CrossRef]

- Lenz, J.; MacDonald, E.; Harik, R.; Wuest, T. Optimizing Smart Manufacturing Systems by Extending the Smart Products Paradigm to the Beginning of Life. J. Manuf. Syst. 2020, 57, 274–286. [Google Scholar] [CrossRef]

- Terzi, S.; Bouras, A.; Dutta, D.; Garetti, M.; Kiritsis, D. Product Lifecycle Management—From Its History to Its New Role. Int. J. Prod. Lifecycle Manag. 2010, 4, 360–389. [Google Scholar] [CrossRef]

- Legardeur, J.; Merlo, C.; Fischer, X. An Integrated Information System for Product Design Assistance Based on Artificial Intelligence and Collaborative Tools. Int. J. Prod. Lifecycle Manag. 2006, 1, 211–229. [Google Scholar] [CrossRef]

- Ricardo Serumena, D.; Joko Santoso, A.; Kristyanto, B. SAP ERP Analysis as the Key of the Company’s Procurement Process in the Use of Social Media. Int. J. Sup. Chain. Mgt 2019, 8, 460–467. [Google Scholar]

- AlKheder, S.; AlKandari, Y. Mobile-Based Pavement System Evaluation for Kuwait. Appl. Geomat. 2021, 13, 677–690. [Google Scholar] [CrossRef]

- Harun, S.N.; Hanafiah, M.M.; Aziz, N.I.H.A. An LCA-Based Environmental Performance of Rice Production for Developing a Sustainable Agri-Food System in Malaysia. Env. Manag. 2021, 67, 146–161. [Google Scholar] [CrossRef]

- Kozma, D.; Varga, P.; Larrinaga, F. System of Systems Lifecycle Management—A New Concept Based on Process Engineering Methodologies. Appl. Sci. 2021, 11, 3386. [Google Scholar] [CrossRef]

- Ozturk, G.B. Digital Twin Research in the AECO-FM Industry. J. Build. Eng. 2021, 40, 102730. [Google Scholar] [CrossRef]

- Pattanayak, S.K.; Roy, S.; Satpathy, B. Strategic Alliance between Business Processes and Enterprise Resource Planning towards Performances: An Empirical Study. Int. J. Bus. Excell. 2021, 24, 24–52. [Google Scholar] [CrossRef]

- Pexas, G.; Mackenzie, S.G.; Wallace, M.; Kyriazakis, I. Accounting for Spatial Variability in Life Cycle Cost-Effectiveness Assessments of Environmental Impact Abatement Measures. Int. J. Life Cycle Assess. 2021, 26, 1236–1253. [Google Scholar] [CrossRef]

- Romero, N.; Medrano, R.; Garces, K.; Sanchez-Londono, D.; Barbieri, G. XRepo 2.0. Int. J. Progn. Health Manag. 2021, 12, 1412. [Google Scholar] [CrossRef]

- Valsamos, G.; Larcher, M.; Casadei, F. Beirut Explosion 2020: A Case Study for a Large-Scale Urban Blast Simulation. Saf. Sci. 2021, 137, 105190. [Google Scholar] [CrossRef]

- Yang, W.; Lam, P.T.I. An Evaluation of ICT Benefits Enhancing Walkability in a Smart City. Landsc. Urban. Plan. 2021, 215, 104227. [Google Scholar] [CrossRef]

- Saretta, E.; Bonomo, P.; Maeder, W.; Nguyen, V.K.; Frontini, F. Digitalization as a Driver for Supporting PV Deployment and Cost Reduction. EPJ Photovolt. 2022, 13, 1. [Google Scholar] [CrossRef]

- Boldrin, M.T.N.; Formiga, K.T.M.; Pacca, S.A. Environmental Performance of an Integrated Water Supply and Wastewater System through Life Cycle Assessment—A Brazilian Case Study. Sci. Total Environ. 2022, 835, 155213. [Google Scholar] [CrossRef]

- Carlos-Hernández, S.; Díaz-Jiménez, L. Strategy Based on Life Cycle Assessment for Telemetric Monitoring of an Aquaponics System. Ind. Crops Prod. 2022, 185, 115171. [Google Scholar] [CrossRef]

- Czvetkó, T.; Kummer, A.; Ruppert, T.; Abonyi, J. Data-Driven Business Process Management-Based Development of Industry 4.0 Solutions. CIRP J. Manuf. Sci. Technol. 2022, 36, 117–132. [Google Scholar] [CrossRef]

- da Silva Lopes, J.; Kiperstok, A.; de Figueirêdo, M.C.B.; de Almeida Neto, J.A.; Rodrigues, L.B. Assessing the Economic and Environmental Performance of Cleaner Production Practices in Eucalyptus Planted Forests Using Life Cycle Assessment. J. Clean. Prod. 2022, 380, 134757. [Google Scholar] [CrossRef]

- Gadekar, R.; Sarkar, B.; Gadekar, A. Key Performance Indicator Based Dynamic Decision-Making Framework for Sustainable Industry 4.0 Implementation Risks Evaluation: Reference to the Indian Manufacturing Industries. Ann. Oper. Res. 2022, 318, 189–249. [Google Scholar] [CrossRef]

- Habib, K.; Saad, M.H.M.; Hussain, A.; Sarker, M.R.; Alaghbari, K.A. An Aggregated Data Integration Approach to the Web and Cloud Platforms through a Modular REST-Based OPC UA Middleware. Sensors 2022, 22, 1952. [Google Scholar] [CrossRef]

- Hamadeh, L.; Al-Habaibeh, A. Towards Reliable Smart Textiles: Investigating Thermal Characterisation of Embedded Electronics in E-Textiles Using Infrared Thermography and Mathematical Modelling. Sens. Actuators A Phys. 2022, 338, 113501. [Google Scholar] [CrossRef]

- Hariyani, D.; Mishra, S.; Sharma, M.K. A Descriptive Statistical Analysis of Barriers to the Adoption of Integrated Sustainable-Green-Lean-Six Sigma-Agile Manufacturing System (ISGLSAMS) in Indian Manufacturing Industries. Benchmarking 2023, 30, 2705–2733. [Google Scholar] [CrossRef]

- Hou, H.; Zhang, Y.; Ma, Z.; Wang, X.; Su, P.; Wang, H.; Liu, Y. Life Cycle Assessment of Tiger Puffer (Takifugu Rubripes) Farming: A Case Study in Dalian, China. Sci. Total Environ. 2022, 823, 153522. [Google Scholar] [CrossRef]

- Knauer, J.; Terhorst, Y.; Philippi, P.; Kallinger, S.; Eiler, S.; Kilian, R.; Waldmann, T.; Moshagen, M.; Bader, M.; Baumeister, H. Effectiveness and Cost-Effectiveness of a Web-Based Routine Assessment with Integrated Recommendations for Action for Depression and Anxiety (RehaCAT+): Protocol for a Cluster Randomised Controlled Trial for Patients with Elevated Depressive Symptoms in Rehabilitation Facilities. BMJ Open 2022, 12, e061259. [Google Scholar] [CrossRef]

- LeBaron, V.; Alam, R.; Bennett, R.; Blackhall, L.; Gordon, K.; Hayes, J.; Homdee, N.; Jones, R.; Lichti, K.; Martinez, Y.; et al. Deploying the Behavioral and Environmental Sensing and Intervention for Cancer Smart Health System to Support Patients and Family Caregivers in Managing Pain: Feasibility and Acceptability Study. JMIR Cancer 2022, 8, e36879. [Google Scholar] [CrossRef]

- Schwarz, C.; Wang, Z. The Role of Digital Twins in Connected and Automated Vehicles. IEEE Intell. Transp. Syst. Mag. 2022, 14, 41–51. [Google Scholar] [CrossRef]

- Staub-French, S.; Pilon, A.; Poirier, E.; Fallahi, A.; Kasbar, M.; Calderon, F.; Teshnizi, Z.; Froese, T. Construction Process Innovation on Brock Commons Tallwood House. Constr. Innov. 2022, 22, 1–22. [Google Scholar] [CrossRef]

- Uwamungu, J.Y.; Kumar, P.; Alkhayyat, A.; Younas, T.; Capangpangan, R.Y.; Alguno, A.C.; Ofori, I. Future of Water/Wastewater Treatment and Management by Industry 4.0 Integrated Nanocomposite Manufacturing. J. Nanomater. 2022, 2022, 5316228. [Google Scholar] [CrossRef]

- Valinejadshoubi, M.; Moselhi, O.; Bagchi, A. Integrating BIM into Sensor-Based Facilities Management Operations. J. Facil. Manag. 2022, 20, 385–400. [Google Scholar] [CrossRef]

- Yang, J.; Son, Y.H.; Lee, D.; Do Noh, S. Digital Twin-Based Integrated Assessment of Flexible and Reconfigurable Automotive Part Production Lines. Machines 2022, 10, 75. [Google Scholar] [CrossRef]

- Annamalah, S.; Paraman, P.; Ahmed, S.; Pertheban, T.R.; Marimuthu, A.; Venkatachalam, K.R.; Ramayah, T. Exploitation, Exploration and Ambidextrous Strategies of SMES in Accelerating Organisational Effectiveness. J. Glob. Oper. Strateg. Sourc. 2023. ahead of print. [Google Scholar] [CrossRef]

- Ardolino, F.; Parrillo, F.; Domenico, C.D.; Costarella, F.; Arena, U. Combined Use of an Information System and LCA Approach to Assess the Performances of a Solid Waste Management System. Appl. Sci. 2023, 13, 707. [Google Scholar] [CrossRef]

- Bathla, G.; Singh, P.; Kumar, S.; Verma, M.; Garg, D.; Kotecha, K. Recop: Fine-Grained Opinions and Sentiments-Based Recommender System for Industry 5.0. Soft Comput. 2023, 27, 4051–4060. [Google Scholar] [CrossRef]

- Bragadin, M.A.; Guardigli, L.; Calistri, M.; Ferrante, A. Demolishing or Renovating? Life Cycle Analysis in the Design Process for Building Renovation: The ProGETonE Case. Sustainability 2023, 15, 8614. [Google Scholar] [CrossRef]

- Chaika, N.K. Aircraft Economics in an Era of Import Substitution. Russ. Eng. Res. 2023, 43, 895–898. [Google Scholar] [CrossRef]

- Dong, L.; Ren, M.; Xiang, Z.; Zheng, P.; Cong, J.; Chen, C.H. A Novel Smart Product-Service System Configuration Method for Mass Personalization Based on Knowledge Graph. J. Clean. Prod. 2023, 382, 135270. [Google Scholar] [CrossRef]

- Haddad, A.N.; Silva, A.B.; Hammad, A.W.A.; Najjar, M.K.; Vazquez, E.G.; Tam, V.W.Y. An Integrated Approach of Building Information Modelling and Life Cycle Assessment (BIM-LCA) for Gas and Solar Water Heating Systems. Int. J. Constr. Manag. 2023, 23, 2452–2468. [Google Scholar] [CrossRef]

- Hajabdollahi Ouderji, Z.; Gupta, R.; Mckeown, A.; Yu, Z.; Smith, C.; Sloan, W.; You, S. Integration of Anaerobic Digestion with Heat Pump: Machine Learning-Based Technical and Environmental Assessment. Bioresour. Technol. 2023, 369, 128485. [Google Scholar] [CrossRef]

- Alvarez, L.; Lastra, M.; Enhancing, J.; Longo, F.; Padovano, A.; Solina, V.; Lago Alvarez, A.; Mohammed, W.M.; Vu, T.; Ahmadi, S.; et al. Enhancing Digital Twins of Semi-Automatic Production Lines by Digitizing Operator Skills. Appl. Sci. 2023, 13, 1637. [Google Scholar] [CrossRef]

- Muhl, M.; Bach, V.; Czapla, J.; Finkbeiner, M. Comparison of Science-Based and Policy-Based Distance-to-Target Weighting in Life Cycle Assessment—Using the Example of Europe. J. Clean. Prod. 2023, 383, 135239. [Google Scholar] [CrossRef]

- Sharma, M.; Joshi, S. Digital Supplier Selection Reinforcing Supply Chain Quality Management Systems to Enhance Firm’s Performance. TQM J. 2023, 35, 102–130. [Google Scholar] [CrossRef]

- Shi, B.; Yin, C.; Léonard, A.; Jiao, J.; Di Maria, A.; Bindelle, J.; Yao, Z. Opportunities for Centralized Regional Mode of Manure and Sewage Management in Pig Farming: The Evidence from Environmental and Economic Performance. Waste Manag. 2023, 170, 240–251. [Google Scholar] [CrossRef]

- Wu, M.; Sadhukhan, J.; Murphy, R.; Bharadwaj, U.; Cui, X. A Novel Life Cycle Assessment and Life Cycle Costing Framework for Carbon Fibre-Reinforced Composite Materials in the Aviation Industry. Int. J. Life Cycle Assess. 2023, 28, 566–589. [Google Scholar] [CrossRef]

- Ye, Z.; Kapogiannis, G.; Tang, S.; Zhang, Z.; Jimenez-Bescos, C.; Yang, T. Influence of an Integrated Value-Based Asset Condition Assessment in Built Asset Management. Constr. Innov. 2023. ahead of print. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E.; Tatham, R.L. Análise Multivariada de Dados, 6th ed.; Bookman: Porto Alegre, Brazil, 2009; ISBN 0-13-032929-0. [Google Scholar]

- Hayes, A.F. Introduction to Mediation, Moderation, and Conditional Process Analysis: A Regression-Based Approach; The Guilford Press: New York, NY, USA, 2017; Volume 692. [Google Scholar]

- Schaefer, J.L.; Tardio, P.R.; Baierle, I.C.; Nara, E.O.B. GIANN—A Methodology for Optimizing Competitiveness Performance Assessment Models for Small and Medium-Sized Enterprises. Adm. Sci. 2023, 13, 56. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, Z. A New Model to Evaluate the Success of Electronic Customer Relationship Management Systems in Industrial Marketing: The Mediating Role of Customer Feedback Management. Total Qual. Manag. Bus. Excell. 2023, 34, 515–537. [Google Scholar] [CrossRef]

- Lerman, L.V.; Benitez, G.B.; Müller, J.M.; de Sousa, P.R.; Frank, A.G. Smart Green Supply Chain Management: A Configurational Approach to Enhance Green Performance through Digital Transformation. Supply Chain Manag. 2022, 27, 147–176. [Google Scholar] [CrossRef]

- Sen, S.; Yildirim, I. A Tutorial on How to Conduct Meta-Analysis with IBM SPSS Statistics. Psych 2022, 4, 640–667. [Google Scholar] [CrossRef]

- Cheah, J.H.; Magno, F.; Cassia, F. Reviewing the SmartPLS 4 Software: The Latest Features and Enhancements. J. Mark. Anal. 2024, 12, 97–107. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A New Criterion for Assessing Discriminant Validity in Variance-Based Structural Equation Modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef]

- Tatiparti, S.; Mahajan, K.N.; Reddi, S.K.; Aancy, H.M.; Kumar, B. Analyzing the Financial Risk Factors Impacting the Economic Benefits of the Consumer Electronic Goods Manufacturing Industry in India. J. Adv. Manuf. Syst. 2023, 22, 823–847. [Google Scholar] [CrossRef]

- Kaushal, I.; Chakrabarti, A. System Modelling for Collecting Life Cycle Inventory (LCI) Data in MSMEs Using a Conceptual Model for Smart Manufacturing Systems (SMSs). Int. J. Precis. Eng. Manuf.-Green. Technol. 2023, 10, 819–834. [Google Scholar] [CrossRef]

- Skalli, D.; Charkaoui, A.; Cherrafi, A.; Shokri, A.; Garza-Reyes, J.A.; Antony, J. Analysis of Factors Influencing Circular-Lean-Six Sigma 4.0 Implementation Considering Sustainability Implications: An Exploratory Study. Int. J. Prod. Res. 2024, 62, 3890–3917. [Google Scholar] [CrossRef]

- Pilloni, V. How Data Will Transform Industrial Processes: Crowdsensing, Crowdsourcing and Big Data as Pillars of Industry 4.0. Future Internet 2018, 10, 24. [Google Scholar] [CrossRef]

- Feldhusen, J.; Gebhardt, B.; Macke, N.A. A Knowledge-Based Engineering Design Process within Product Lifecycle Management-A Vision. In Proceedings of the TMCE 2004, Lausanne, Switzerland, 12–16 April 2004; Millpress: Bethlehem, PA, USA, 2004. [Google Scholar]

- Enrique, D.V.; Marcon, É.; Charrua-Santos, F.; Frank, A.G. Industry 4.0 Enabling Manufacturing Flexibility: Technology Contributions to Individual Resource and Shop Floor Flexibility. J. Manuf. Technol. Manag. 2022, 33, 853–875. [Google Scholar] [CrossRef]

- Meindl, B.; Ayala, N.F.; Mendonça, J.; Frank, A.G. The Four Smarts of Industry 4.0: Evolution of Ten Years of Research and Future Perspectives. Technol. Forecast. Soc. Change 2021, 168, 120784. [Google Scholar] [CrossRef]

- Schuh, G.; Potente, T.; Wesch-Potente, C.; Weber, A.R.; Prote, J.P. Collaboration Mechanisms to Increase Productivity in the Context of Industrie 4.0. Procedia CIRP 2014, 19, 51–56. [Google Scholar] [CrossRef]

- Sassanelli, C.; Rossi, M.; Terzi, S. Evaluating the Smart Maturity of Manufacturing Companies along the Product Development Process to Set a PLM Project Roadmap. Int. J. Prod. Lifecycle Manag. 2020, 12, 210–225. [Google Scholar] [CrossRef]

- de Carvalho, P.S.; Siluk, J.C.M.; Schaefer, J.L. Mapping of Regulatory Actors and Processes Related to Cloud-Based Energy Management Environments Using the Apriori Algorithm. Sustain. Cities Soc. 2022, 80, 103762. [Google Scholar] [CrossRef]

- Carvalho, P.S.; Siluk, J.C.M.; Schaefer, J.L.; Pinheiro, J.R.; Schneider, P.S. Proposal for a New Layer for Energy Cloud Management: The Regulatory Layer. Int. J. Energy Res. 2021, 45, 9780–9799. [Google Scholar] [CrossRef]

- Schaefer, J.L.; Siluk, J.C.M.; de Carvalho, P.S. Critical Success Factors for the Implementation and Management of Energy Cloud Environments. Int. J. Energy Res. 2022, 46, 13752–13768. [Google Scholar] [CrossRef]

- Mangla, P.; Agarwal, A.; Pandey, P.M. An Investigation of Responsiveness Impact on Productivity Improvement in Indian MSME. Lect. Notes Multidiscip. Ind. Eng. 2020, 101–109. [Google Scholar] [CrossRef]

- Madhusudanan, G.; Padhmanabhaiyappan, S. Multi-Objective Optimization Model for Uncertainty Consideration of RESs & Load Demands with the Optimal Design of Hybrid CCHP by DDAO-RBFNN Strategy. IETE J. Res. 2024, 70, 4287–4304. [Google Scholar] [CrossRef]

- Olıverı, L.M.; Arfò, S.; Matarazzo, A.; D’Urso, D.; Chıacchıo, F. Improving the Composting Process of a Treatment Facility via an Industry 4.0 Monitoring and Control Solution: Performance and Economic Feasibility Assessment. J. Env. Manag. 2023, 345, 118776. [Google Scholar] [CrossRef]

- Li, P.; Froese, T.M.; Cavka, B.T. Life Cycle Assessment of Magnesium Oxide Structural Insulated Panels for a Smart Home in Vancouver. Energy Build. 2018, 175, 78–86. [Google Scholar] [CrossRef]

| Authors | IIMS | PLM | I4.0 | MP | Contribution |

|---|---|---|---|---|---|

| [11] | X | X | X | Provides insights into the use of modern technologies for PLM and IIMS, aligning with the principles of I4.0. | |

| [12] | X | X | X | Compares conventional and organic farming methods, highlighting more sustainable options and their environmental impacts. | |

| [13] | X | X | X | The Systems of Systems Lifecycle Management concept complements the management of complex and interoperable systems, aligning with I4.0 and IoT to promote more efficient and sustainable strategies. | |

| [14] | X | X | X | Addresses the application of the Digital Twin to improve PLM in the AECO-FM sector, reinforcing the importance of an integrated and holistic approach to the management of information and technologies in I4.0. | |

| [15] | X | X | X | Highlights the relevance of integrating business processes with ERP systems, essential for the development of an IIMS framework in I4.0 and shows how technology can improve organisational performance. | |

| [16] | X | X | X | Introduces spatial variability in the assessment of costs and environmental effectiveness, offering insights into how local conditions affect mitigation measures. This aligns with the development of an IIMS framework, providing a valuable perspective to optimise investment decisions and improve the sustainability of production systems. | |

| [17] | X | X | X | Provides a technological solution for PHM education in I4.0, using XRepo 2.0 to process sensor data. Facilitates the development of technical skills and the integration of advanced technologies in information management and educational processes. | |

| [18] | X | X | X | Demonstrates the use of advanced simulations to assess and mitigate the impacts of catastrophic events, providing a useful model for the resilience of systems and structures in I4.0 and IIMS. | |

| [19] | X | X | X | Provides a quantitative approach to assess smart technologies in urban contexts, offering insights into the integration and assessment of emerging technologies in its framework and the economic viability of implementation. | |

| [20] | X | X | X | Highlights how digitalisation and the use of Digital Twin platforms can optimise processes and reduce costs in the photovoltaic sector, illustrating the application of advanced technologies for efficient and sustainable management, aligning with I4.0 trends. | |

| [21] | X | X | X | Explores the application of LCA to assess the sustainability of integrated sanitation systems, providing insights into how improvements can reduce the environmental footprint. Highlights the importance of systematic methodologies and databases for environmental management in infrastructure, complementing the IOPT perspective by demonstrating how LCA can inform decisions about complex systems and sustainable practices. | |

| [22] | X | X | X | Demonstrates the application of Lifecycle Assessment (LCA) to promote sustainability in the management of complex systems, aligning with the objective of integrating I4.0 technologies for efficient and sustainable management of the product lifecycle. | |

| [23] | X | X | X | Illustrates the practical application of I4.0 concepts to improve business processes and highlights data integration and evidence-based decision-making, which are fundamental to IIMS in PLM. | |

| [24] | X | X | X | Highlights how sustainable technologies and practices can improve economic and environmental performance in production systems, aligning with the development of an integrated framework that uses I4.0 to optimise PLM. | |

| [25] | X | X | X | Provides a practical model based on KPIs and a fuzzy approach for risk assessment in the implementation of I4.0 technologies, offering insights into risk management and prioritisation during the transition to I4.0. The analysis of the main risks and decision-making techniques contribute to understanding the challenges in adopting new technologies and practices, helping to develop frameworks for IIMS and system optimisation. | |

| [26] | X | X | X | Presents a solution for interoperability and data integration in IoT systems, using OPC UA and REST-based middleware to promote efficient communication and remote process supervision. | |

| [27] | X | X | X | Provides insights into thermal management in e-textiles, using thermography and mathematical modelling. Essential for optimising the reliability and sustainability of integrated technologies, improving the design and performance of intelligent systems. | |

| [28] | X | X | X | Identifies barriers to the adoption of sustainable and integrated systems, offering insights into challenges and strategies to overcome obstacles in the implementation of sustainable practices, relevant to promoting the adoption of efficient systems in manufacturing. | |

| [29] | X | X | X | Provides a detailed analysis of the environmental impacts of aquaculture, highlighting the importance of environmental assessments and offering practical recommendations to improve sustainable performance, which can contribute to the development of more efficient and sustainable practices in emerging industries. | |

| [30] | X | X | X | Highlights the use of digital technologies in monitoring psychological conditions and their contribution to organisational efficiency and well-being. Relevant for sustainable models when integrating health and performance analysis. | |

| [31] | X | X | X | Shows how technological innovations improve operational efficiency and communication in health, supporting decision-making and information management, aligning with data integration and complexity management in OIPT. | |

| [32] | X | X | X | Highlights the importance of Digital Twins in the automation of connected vehicles, promoting model reuse and data integration. Essential to understand how the evolution of digital models can transform information management, aligning with IIMS and I4.0. | |

| [33] | X | X | X | Offers insights into the integration of innovations in the construction process and how these innovations can be operationalised throughout the project lifecycle, aligning with the development of an IIMS framework in I4.0. | |

| [34] | X | X | X | Explores the application of I4.0 technologies in the manufacturing of nanocomposites for water treatment, offering insights into the integration of emerging technologies for efficiency and sustainability. | |

| [35] | X | X | X | Shows how the integration of BIM with sensor systems improves the management and operational efficiency of facilities. Offers insights into the integration of I4.0 technologies to optimise management throughout PLM, relevant to the IIMS framework and its impact on MP. | |

| [36] | X | X | X | Provides insights into how information models and quantitative assessment can be applied to manage the complexity and flexibility of PLM, informing the development of its integrated framework. | |

| [4] | X | X | X | Proposes a framework for improving innovative behaviour in SMEs through the integration of BI and knowledge sharing. Offers insights to optimise decision-making and organisational performance, essential for IIMS throughout PLM. | |

| [37] | X | X | X | Shows how to integrate strategic flexibility into information management and PLM in contexts of rapid change and uncertainty, relevant to organisational performance and I4.0 technologies. | |

| [38] | X | X | X | Illustrates the integration of information systems with Lifecycle Assessments to optimise performance and sustainability, aligning with the use of advanced technologies and integrated systems in product and information management. | |

| [39] | X | X | X | The integration of detailed feedback and sentiment analysis enhances the personalisation and efficiency of recommender systems, promoting a collaborative and user-centric environment, aligned with the evolution towards Industry 5.0. | |

| [40] | X | X | X | Highlights the application of LCA and information modelling in sustainable building renovation management, aligning with the integration of technologies throughout PLM in I4.0. | |

| [41] | X | X | X | Provides insights into cost management throughout the lifecycle of complex products, such as aircraft, aligning with IIMS and the application of emerging technologies to increase efficiency. | |

| [42] | X | X | X | The knowledge graph-based configuration optimises processes in information management systems and product personalisation, aligning with the integration of I4.0 technologies to improve efficiency and adaptability. | |

| [43] | X | X | X | Shows how the integration of BIM and LCA can optimise the selection of heating systems, improving environmental impact assessment and technical performance, which are essential for sustainable design and reducing the environmental footprint of buildings. | |

| [44] | X | X | X | Provides insights into how the integration of I4.0 technologies can improve environmental and energy efficiency in anaerobic digestion processes, aligning with the development of frameworks for PLM and the holistic approach of OIPT. | |

| [45] | X | X | X | Explores the integration of human capabilities into digital systems, highlighting how the combination of human and technological resources can improve efficiency and operations management. | |

| [46] | X | X | X | Offers a critical view on weighting methods in LCA, enriching the framework with a more comprehensive approach to sustainability and improving environmental assessment in PLM. | |

| [47] | X | X | X | Illustrates how digital supplier selection can optimise supply chain management and business performance, using advanced multi-criteria decision methods, aligning with integration and automation in I4.0. | |

| [48] | X | X | X | Highlights how the centralised mode of bioenergy can improve environmental sustainability and economic viability in waste management in pig farming. Provides valuable insights for optimising sustainable agricultural processes and practices, aligning with the integration of information management and advanced technologies in PLM. | |

| [49] | X | X | X | Provides a robust framework for evaluating advanced materials, combining environmental and economic analysis. The methodology is useful for assessing the impact of emerging technologies and new materials on PLM, essential for the development of an IIMS framework. The use of graphical tools for integrated comparisons can also improve data visualisation and communication in I4.0. | |

| [50] | X | X | X | Offers a practical approach to integrating advanced digital technologies into asset management, providing insights into optimisation, collaboration, and cost and risk reduction. |

| Construct Element | Variable | Variable | EFA—Factor Loadings | CFA—Factor Loadings | CFA—Error Variance | CFA Measures |

|---|---|---|---|---|---|---|

| IIMS—Integrity | VAR01 | Verifying the identity of the user or system attempting to access a resource | 0.699 | 0.7869645 | 0.3806868 | RMSEA—0.089 CFI—0.987 TLI—0.979 AVE—0.750 Alpha—0.9468 CR—0.9473 |

| VAR02 | Validating and protecting the identity of users in information systems | 0.619 | Removed | Removed | ||

| VAR21 | Implementation of mechanisms to guarantee the information non-repudiation and the traceability of the actions | 0.777 | 0.8750153 | 0.2343483 | ||

| VAR22 | Maintenance of a system of registration or log of all activities performed | 0.805 | 0.8920751 | 0.204202 | ||

| VAR23 | Policies or procedures to preserve digital evidence in the event of legal disputes | 0.726 | 0.9125343 | 0.1672811 | ||

| VAR24 | Treatment of records and digital signatures | 0.654 | 0.8361371 | 0.3008748 | ||

| VAR25 | Adoption of controls and protocols to prevent the unauthorised manipulation or deletion of records or logs | 0.678 | 0.8890158 | 0.2096509 | ||

| IIMS—Provenance | VAR03 | Adopting robust authentication methods, such as two-factor authentication | 0.501 | 0.7488319 | 0.4392508 | RMSEA—0.095 CFI—0.986 TLI—0.977 AVE—0.908 Alpha—0.948 CR—0.9555 |

| VAR16 | Permission to verify where data and resources originated | 0.720 | 0.8509173 | 0.2759397 | ||

| VAR17 | Permission to track how data and resources have been modified or processed over time | 0.848 | 0.8991795 | 0.1914763 | ||

| VAR18 | Current ownership of data and resources | 0.833 | 0.9122964 | 0.1677153 | ||

| VAR19 | Ensuring verification of who has had access to data and resources | 0.752 | 0.9021847 | 0.1860627 | ||

| VAR20 | Permission to track how data and resources have been used in different parts of the network | 0.771 | 0.8941641 | 0.2004706 | ||

| IIMS—Authentication | VAR04 | Granting appropriate permissions for users to access a specific resource | 0.594 | Removed | Removed | RMSEA—0.075 CFI—0.993 TLI—0.986 AVE—0.733 Alpha—0.9317 CR—0.93206 |

| VAR05 | Establishing authorisations and access restrictions | 0.615 | Removed | Removed | ||

| VAR06 | Classification of confidential information or data | 0.584 | 0.8152095 | 0.3354335 | ||

| VAR07 | Permission to access confidential information | 0.612 | Removed | Removed | ||

| VAR08 | Establishment of protocols that prevent confidential information from being manipulated or intercepted by third parties | 0.638 | 0.878864 | 0.2275981 | ||

| VAR09 | Secure disposal of confidential information | 0.645 | Removed | Removed | ||

| VAR10 | Control and monitoring of information over time | 0.605 | 0.8744643 | 0.2353122 | ||

| VAR11 | Informing the user which personal data is being collected and stored | 0.749 | 0.8322043 | 0.3074359 | ||

| VAR12 | Allowing the user to know who has access to the information collected | 0.739 | Removed | Removed | ||

| VAR13 | Guaranteeing transparency to the user regarding the purposes for which the information collected is used | 0.784 | Removed | Removed | ||

| VAR14 | Allowing the user to control the sharing of their information | 0.712 | Removed | Removed | ||

| VAR15 | Informing the user of the policies and regulations on how their rights are protected | 0.802 | 0.8781872 | 0.2287872 | ||

| IIMS interference on PLM Introduction | VAR26 | Sharing relevant information and data when introducing the product | 0.748 | 0.8830942 | 0.2201446 | RMSEA—0.075 CFI—0.993 TLI—0.988 AVE—0.771 Alpha—0.9317 CR—0.9525 |

| VAR27 | Conducting market studies before producing your products | 0.812 | 0.9261034 | 0.1423325 | ||

| VAR28 | Conducting preliminary research on the products you want to manufacture | 0.842 | 0.9317065 | 0.131923 | ||

| VAR29 | Developing product and process diversification projects | 0.819 | 0.9201888 | 0.1532525 | ||

| VAR30 | Conducting environmental impact studies related to your production | 0.741 | 0.8464296 | 0.283557 | ||

| VAR31 | Development of growth studies for your products during the manufacturing process | 0.727 | Removed | Removed | ||

| VAR32 | Implementation of monitoring plans integrated with the SGII | 0.635 | Removed | Removed | ||

| VAR33 | Investment in technology aligned with the SGII to improve the growth of your products | 0.814 | Removed | Removed | ||

| VAR35 | Development of practices to improve and accept your products in the market during growth | 0.718 | 0.7452543 | 0.4445961 | ||

| IIMS interference on PLM Maturity | VAR34 | Implementation of material reuse projects during the growth phase | 0.644 | 0.8036853 | 0.3540899 | RMSEA—0.084 CFI—0.988 TLI—0.982 AVE—0.789 Alpha—0.9621 CR—0.96306 |

| VAR36 | Search for partnerships in the market to keep your products in the maturity phase | 0.736 | 0.9139678 | 0.1646629 | ||

| VAR37 | Development of innovation practices seeking to guarantee the maturity of your product in the market | 0.712 | Removed | Removed | ||

| VAR38 | Conducting productivity studies of your products in the maturity phase | 0.779 | 0.9509515 | 0.0956912 | ||

| VAR39 | Conducting studies to improve products and processes during the maturity phase | 0.748 | 0.937634 | 0.1208425 | ||

| VAR40 | Establishing partnerships that aim to guarantee the availability of qualified labour during the maturity phase | 0.808 | 0.925719 | 0.1430443 | ||

| VAR41 | Implementation of practices for withdrawing products from the market | 0.804 | 0.8073125 | 0.3482465 | ||

| VAR42 | Analysis of the lifecycle of your products after the end of their cycle | 0.853 | Removed | Removed | ||

| VAR43 | Development of techniques to prepare for the next generation of products when there is low demand in the market | 0.803 | Removed | Removed | ||

| VAR44 | Preparation of the production environment for the launch of new products | 0.784 | 0.8659285 | 0.2501678 | ||

| VAR45 | Adoption of different production techniques during the decline phase of your products | 0.790 | Removed | Removed | ||

| IIMS interference on I4.0—IoT | VAR46 | Application of sensors and connected devices to collect real-time data on the production line | 0.841 | 0.9682911 | 0.0624123 | RMSEA—0.086 CFI—0.996 TLI—0.989 AVE—0.823 Alpha—0.9482 CR—0.9489 |

| VAR47 | Use of the Internet of Things to remotely monitor and control industrial equipment and processes | 0.769 | 0.8669021 | 0.2484807 | ||

| VAR48 | Use of RFID (Radio Frequency Identification) technology to track and manage assets in the production chain | 0.801 | 0.9020688 | 0.1862719 | ||

| VAR49 | Integration of inventory and production control systems with IoT sensors to optimise resource management | 0.761 | Removed | Removed | ||

| VAR50 | Applying efforts to explore IoT application opportunities to improve efficiency and safety in operations | 0.746 | 0.8886428 | 0.210314 | ||

| IIMS interference on I4.0—Automation | VAR51 | Use of automation systems to control and optimise production processes | 0.665 | 0.8848284 | 0.2170786 | RMSEA—0.094 CFI—0.985 TLI—0.975 AVE—0.731 Alpha—0.9413 CR—0.9420 |

| VAR52 | Use of robots and automated machines to perform repetitive and low-value-added tasks | 0.751 | 0.872101 | 0.2394398 | ||

| VAR53 | Adoption of automated control and monitoring systems to ensure product quality | 0.712 | 0.9212256 | 0.1513434 | ||

| VAR54 | Application of automation in your logistics and storage processes | 0.605 | 0.8952624 | 0.1985052 | ||

| VAR55 | Search for automation opportunities in new areas of your business | 0.632 | Removed | Removed | ||

| VAR56 | Using machine learning algorithms for demand analysis and forecasting | 0.777 | 0.7585294 | 0.4246332 | ||

| VAR57 | Implementing chatbots or virtual assistants to interact with customers | 0.716 | Removed | Removed | ||

| VAR58 | Applying AI to optimise scheduling and resource allocation in your production | 0.823 | Removed | Removed | ||

| VAR59 | Using computer vision systems for automated inspection and quality control | 0.762 | 0.787117 | 0.3804469 | ||

| VAR60 | Using AI in advanced data analysis to identify insights and opportunities for improvement | 0.818 | Removed | Removed | ||

| IIMS interference on I4.0—Cloud | VAR61 | Using cloud storage services to securely share data | 0.886 | 0.8932597 | 0.2020871 | RMSEA—0.235 CFI—0.978 TLI—0.935 AVE—0.865 Alpha—0.9614 CR—0.96237 |

| VAR62 | Hosting applications and systems in the cloud to ensure availability and scalability | 0.881 | 0.9804021 | 0.0388117 | ||

| VAR63 | Using Cloud Computing services for high-performance data processing | 0.832 | 0.9470244 | 0.1031448 | ||

| VAR64 | Adopting cloud-based data backup and recovery solutions | 0.886 | Removed | Removed | ||

| VAR65 | Using cloud-based collaboration platforms to improve internal communication and collaboration | 0.847 | 0.8965861 | 0.1961333 | ||

| IIMS interference on MP—Productivity | VAR66 | Effect on company productivity | 0.812 | 0.8543626 | 0.2700646 | RMSEA—0.086 CFI—0.986 TLI—0.972 AVE—0.615 Alpha—0.9413 CR—0.88798 |

| VAR67 | Significant contribution to production efficiency | 0.630 | Removed | Removed | ||

| VAR68 | Change in the productivity of its processes | 0.741 | 0.7950155 | 0.3679503 | ||

| VAR69 | Direct impact on the optimisation of the company’s production resources | 0.754 | 0.6888882 | 0.5254331 | ||

| VAR70 | Avoids failures or errors in the production system | 0.667 | 0.7392386 | 0.4535263 | ||

| VAR71 | Existence of a correlation between the adoption of SGII and the change in productivity | 0.712 | 0.8307619 | 0.3098347 | ||

| IIMS interference on MP—Responsiveness | VAR72 | Contribution to agility and responsiveness to market demands | 0.757 | 0.849474 | 0.2783939 | RMSEA—0.076 CFI—0.987 TLI—0.974 AVE—0.731 Alpha—0.8466 CR—0.9420 |

| VAR73 | Allows the company to be responsive to market changes | 0.759 | Removed | Removed | ||

| VAR74 | Demonstration of the ability to adapt and respond to customer needs | 0.711 | 0.8924634 | 0.2035091 | ||

| VAR75 | Provides an efficient flow of information | 0.600 | 0.7012303 | 0.5082761 | ||

| VAR80 | Contributes to the control and development of human resources | 0.545 | 0.5108994 | 0.7389818 | ||

| VAR82 | Allows the identification of market opportunities and the development of competitive and effective strategies | 0.737 | 0.6664024 | 0.5559079 | ||

| VAR83 | Plays a fundamental role in improving the company’s competitive position | 0.793 | Removed | Removed | ||

| IIMS interference on MP—Competitiveness | VAR76 | Allows for agile and accurate decision-making | 0.558 | 0.7142274 | 0.4898792 | RMSEA—0 CFI—1.0 TLI—1.019 AVE—0.535 Alpha—0.9614 CR—0.85045 |

| VAR77 | Changes competitive responsiveness | 0.601 | 0.7441114 | 0.4462982 | ||

| VAR78 | Has an impact on the company’s productive competitiveness | 0.641 | 0.8538926 | 0.2708674 | ||

| VAR79 | Results in financial advantage | 0.689 | 0.5941861 | 0.6469428 | ||

| VAR81 | Has an impact on environmental controls | 0.777 | 0.7284681 | 0.4693342 |

| Cronbach Alpha | Composite Reliability (rho_a) | Composite Reliability (rho_c) | Average Variance Extracted (AVE) | |

|---|---|---|---|---|

| MP | 0.932 | 0.944 | 0.940 | 0.500 |

| I4.0 | 0.961 | 0.963 | 0.965 | 0.666 |

| PLM | 0.977 | 0.978 | 0.979 | 0.746 |

| IIMS | 0.971 | 0.972 | 0.974 | 0.685 |

| MP | I4.0 | PLM | |

|---|---|---|---|

| I4.0 | 0338 | - | - |

| PLM | 0.353 | 0.885 | - |

| IIMS | 0.371 | 0.695 | 0.718 |

| MP | IIMS | |

|---|---|---|

| I4.0 | 0.066 | 0.277 |

| PLM | 0.087 | 0.442 |

| IIMS | 0.100 | - |

| I4.0 > PLM-IIMS | 0.008 | 0.011 |

| PLM > I4.0-IIMS | 0.044 | 0.075 |

| MP | IIMS | |

|---|---|---|

| I4.0 | 0.002 | 0.042 |

| PLM | 0.003 | 0.101 |

| IIMS | 0.031 | - |

| I4.0 > PLM | - | 0.011 |

| PLM > I4.0 | - | 0.011 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, C.E.M.; Correia Filho, P.T.d.J.; Canciglieri Junior, O.; Schaefer, J.L. The Role of Integrated Information Management Systems in the Relationship Between Product Lifecycle Management and Industry 4.0 Technologies and Market Performance. Sustainability 2025, 17, 5260. https://doi.org/10.3390/su17125260

Santos CEM, Correia Filho PTdJ, Canciglieri Junior O, Schaefer JL. The Role of Integrated Information Management Systems in the Relationship Between Product Lifecycle Management and Industry 4.0 Technologies and Market Performance. Sustainability. 2025; 17(12):5260. https://doi.org/10.3390/su17125260

Chicago/Turabian StyleSantos, Carlos Eduardo Maran, Pedro Tondela de Jesus Correia Filho, Osiris Canciglieri Junior, and Jones Luís Schaefer. 2025. "The Role of Integrated Information Management Systems in the Relationship Between Product Lifecycle Management and Industry 4.0 Technologies and Market Performance" Sustainability 17, no. 12: 5260. https://doi.org/10.3390/su17125260

APA StyleSantos, C. E. M., Correia Filho, P. T. d. J., Canciglieri Junior, O., & Schaefer, J. L. (2025). The Role of Integrated Information Management Systems in the Relationship Between Product Lifecycle Management and Industry 4.0 Technologies and Market Performance. Sustainability, 17(12), 5260. https://doi.org/10.3390/su17125260