1. Introduction

The global textile industry, a significant part of the manufacturing sector, ranks as the third-largest sector globally, contributing 6.4% of the world’s GDP [

1]. This sector plays a critical role in economic growth and generates numerous employment opportunities. However, the textile industry faces challenges such as increasing consumer demand, expectations for competitive prices and quality, and the necessity to adapt to rapidly changing market trends.

In the Latin American market, Brazil stands out as the fifth-largest textile producer in the world [

2]. However, inefficiencies have been observed in the production and marketing processes in this region. Specifically, macroeconomic issues such as high input costs and insufficient technological infrastructure in countries like Venezuela exacerbate these challenges [

3]. In Peru, the textile industry creates approximately 398,000 direct jobs, but production levels have been declining since 2019. While some improvements have been made, production levels remain well below pre-pandemic levels. Additionally, the annual growth of over 3.4% in low-cost and trend-driven imports from countries like China, Bangladesh, and India presents a strong competitive threat to local producers [

1]. This situation leads to significant challenges for small and micro-sized textile enterprises (MYPEs), which form the backbone of the sector, including higher idle times, increased waste rates, and low production efficiency [

4,

5,

6].

While the impact of lean manufacturing principles on increasing productivity has been proven across various industries, their applicability in Micro and Small-Scale Textile Enterprises (MYPEs) has not been sufficiently researched. Existing studies focus on large-scale enterprises or the individual application of specific lean tools. For example, using the 5S tool has been shown to improve operational efficiency by up to 46.8% [

7,

8]. Similarly, Total Productive Maintenance (TPM) has addressed inefficiencies caused by machine downtime, raising Overall Equipment Efficiency (OEE) to 83.33% and achieving a coverage of 85% in another study [

9,

10]. However, the literature lacks a comprehensive framework that integrates multiple lean tools tailored to the limitations and needs of textile MYPEs. Furthermore, the integration of data-driven approaches with lean manufacturing practices has not been sufficiently developed in this sector.

This study aims to fill these gaps by developing a data-driven lean manufacturing framework specifically for textile MYPEs. The proposed framework seeks to achieve the following objectives by combining lean tools (5S (Sort, Set in Order, Shine, Standardize, Sustain), TPM, and process standardization) with data analytics: identifying and prioritizing inefficiencies in production processes using data-driven approaches, minimizing downtime and reducing waste by optimizing resource usage, and developing a scalable methodology that aligns with the operational realities of textile MYPEs.

The contributions of this study are both theoretical and practical. Theoretically, it deepens the understanding of the application of lean manufacturing principles in resource-constrained environments. Practically, it provides a structured roadmap that enables textile MYPEs to remain competitive in dynamic markets.

This article builds on previous research presented in the paper entitled “

Proposal of Re-Design of Data-base Lean Management—Oriented Business Process in the Textile Industry: Previous Diagnosis”, which explores the causes of low productivity in a textile company and designs a model based on lean tools to optimize production processes [

11]. In that study, the problem identified in the sewing workshop was low productivity. Upon further analysis, the underlying causes of this issue were identified, which included unexpected machine stoppages due to insufficient preventive maintenance and improper maintenance procedures. Another significant cause was the high incidence of rework in the garment production process. This was mainly attributed to a non-standardized production process, where improper sewing and over-sewing techniques led to seams opening during production. Furthermore, deficiencies in the labeling and finishing processes, such as mislabeling sizes, incorrect packaging, or measurements outside the acceptable range, caused garments to be reprocessed, thus consuming additional time and resources while increasing production costs. This article expands and deepens the development of the model, methodologies, and approaches to achieve positive results and benefits with its application.

The paper is structured as follows: The Literature Background section reviews the literature on lean manufacturing tools and their application in the textile industry. The Method section covers the foundations of the proposed model, the model details, and the implementation phases of each tool (5S, TPM-Planned Maintenance, TPM-Education, Training, Standardization). The Results and Discussion section discusses the pilot implementations of the proposed model, validation processes, and the effectiveness of each tool (5S, TPM, Standardization). Finally, the Conclusion section summarizes the findings of the study and provides suggestions for future research. This study presents an innovative and applicable framework that integrates data-driven methodologies with lean manufacturing principles to enhance the productivity of textile MYPEs, addressing gaps in the literature.

2. Literature Background of Lean Management Applications in the Textile Sector

The textile sector is highly competitive, prompting companies to continuously adopt new methodologies to improve their processes. Lean manufacturing has been widely recognized for its ability to enhance productivity and efficiency in various industries, including textiles. Silva et al. (2021) developed the lean manufacturing methodology in their case studies, achieving a 44% increase in productivity through tools such as 5S and Poka Yoke [

4]. As a result of the usage of this method, it gives a 75% reduction in waiting time in the company. Similarly, Ukey et al. (2021) implemented the use of a combination of different lean tools such as 5s, Kaizen, Poke-Yoke, Kanban, and Andon in all departments of the apparel industry in India [

12]. This implementation gives the results of an 8% increase in productivity by reducing the cycle time in the business process, waste in the garment manufacturing, and increasing production quality. Moreover, it gives similar results in another study on the only Poka-Yoke lean method used in Slovakia [

13]. The result of this study shows increasing efficiency, competitiveness, customer satisfaction, and improved employee satisfaction due to the implementation of the Poke-Yoke lean method in the fabric. The collective findings of these three studies suggest that employing a combination of lean tools or the Poka-Yoke lean method to enhance operational efficiency can significantly facilitate systematic organization and error prevention across all departments within the organization.

The literature includes various studies on enhancing productivity and efficiency through Lean Management methods in companies within the textile sector. These studies address different core issues as their primary focus. Ludeña et al. (2022) address the delay time in the security clothing order delivery by the textile company, which causes low productivity for the company [

14]. This study adopts elaborate Lean Manufacturing tools to decrease delivery delay time, so it uses a Value Stream Map (VSM) as a diagnostic tool and a combination of 5s, Single-Minute Exchange of Die (SMED), Poka Yoke, and Kanban as Lean Management methods. Namely, it focuses on business process model re-engineering in this company. Therefore, it finds that delivery time has become better, decreasing by 10%. It also improves the 50.37% production process of the sewing area, too. As a result, the re-engineering of the business process model impacts customer satisfaction for this company, so this study’s findings provide good evidence of the relationship between Lean Management and customer satisfaction. Similarly, Parthasarathi et al. (2021) focus on decreasing the delivery time, so they identified problems using VSM to find squander during assembling and business measurement regarding time losses in business processes [

15]. Thus, the aim of the study is to identify Non-Value Added Activities (NVAs) that cause problems in time efficiency in the workflow and to re-engineer the business process model in order to remove them from the business model. According to the results of this study, the setup time in the company has been reduced by approximately 180 min and the process time by about 98 min, thereby shortening the total production time and increasing efficiency [

15]. This supports the claim that lean manufacturing aims to reduce costs and increase turnover by eliminating non-value-added activities. The findings of this study contribute to the understanding that the implementation of Lean Management tools not only enhances customer satisfaction by improving time efficiency in business processes but also supports companies in achieving their financial goals in terms of revenue and profitability.

Advincula et al. (2022) highlighted the relatively low productivity of SMEs in the textile sector in Latin American countries compared to those in other industries [

16]. In response, they conducted a study aimed at enhancing process standardization to reduce production inefficiencies and improve productivity through the implementation of 5S and Standard Work practices in Peruvian textile Small and Medium-Sized companies (SMEs) [

16]. The proposed model aims to structure existing workflows and design an optimized process, thereby facilitating productivity improvements through the systematic application of lean tools. Similarly, Barrientos-Ramos et al. (2020) conducted a study on improving productivity through the application of Lean management tools in a textile-sector SME in Peru [

17]. The study focuses on the integration of labor, work methods, and production process cycles within manufacturing operations to enhance productivity and minimize waste [

17]. Accordingly, this study demonstrates the implementation of a combination of lean tools through the simulation of three different scenarios. As a result, the case study of a textile SME revealed improvements such as increased sales, a 4% reduction in defective products, and a 2% decrease in machine failures. These outcomes, as highlighted in the conclusion, suggest that the company can sustain growth-oriented operations aligned with continuous improvement strategies, enhance customer satisfaction, and ensure the timely delivery of high-quality products through improved team productivity. Furthermore, this case serves as a valuable example for textile SMEs aiming to align their organizational culture with agile production standards. Therefore, the study draws attention not only to the positive impact of Lean management tools on production efficiency, standardization, and delivery timeliness but also to their contribution to the development of organizational culture. These findings are significant as they demonstrate that the structured application of lean tools not only addresses operational inefficiencies but also contributes to the strategic redesign of workflows, ultimately enabling sustainable productivity gains and supporting long-term organizational competitiveness. According to these studies’ practical results, lean manufacturing philosophy gives a good result in reducing the number of product defects for corporations. So, these studies emphasize cost reduction and waste minimization as critical benefits of lean practices.

An essential aspect of enhancing productivity and sustainability in textile companies lies in the ergonomic arrangement of machinery within production facilities. It can be asserted that a human-centered, efficiency-oriented layout is vital for manufacturing plants. This is because ergonomically optimized production lines not only reduce operational errors and time losses but also contribute to increased output. In this context, the study conducted by Kose et al. (2022) provides significant insights [

18]. By implementing the Single-Minute Exchange of Dies (SMED) methodology, the researchers achieved an ergonomic reconfiguration of machinery in a production facility. They subsequently applied the Interval-Valued Pythagorean Fuzzy Analytic Hierarchy Process (IVPF-AHP) in conjunction with the Fuzzy Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) to evaluate the outcomes. Their findings indicate that the proposed model not only validated its effectiveness by reducing machine setup time by 58% but also demonstrated a 19% improvement in ergonomic conditions [

18]. In their 2022 study, Gochel et al. employed the spaghetti diagram within a lean management framework to enhance business processes through ergonomic design in the Hybrid Manufacturing and Machine Building Industry (HMMBI) [

19]. By identifying and addressing bottleneck areas, the study achieved reductions in both operational and waiting times, ultimately leading to an 8.6% improvement in process cycle efficiency. Similarly, Gebeyehu et al. (2022) conducted a study aimed at increasing productivity by redesigning business models through the identification and elimination of non-value-adding activities using a lean management approach [

20]. Utilizing tools such as Value Stream Mapping and the Spaghetti Diagram, the researchers analyzed inefficiencies and losses associated with non-value-adding stages in the workflow. As a result, improvements were realized in production time, process duration, and the waiting and delivery times of raw material, semi-finished, and finished goods. The study reports a 25.59% enhancement in overall process cycle efficiency [

20]. According to these studies’ results, it gives positive impacts on productivity and reduces waste sustainability in companies by using lean management approaches for re-modelling business cycles. In the context of the textile manufacturing sector, several studies have adopted lean management approaches to redesign business models with the aim of enhancing productivity and minimizing waste [

21,

22,

23]. Recent studies in the textile manufacturing sector have increasingly emphasized the role of lean management practices in enhancing operational efficiency and minimizing waste. Alanya et al. (2024) demonstrated the effectiveness of tools such as Value Stream Mapping (VSM), Single-Minute Exchange of Dies (SMED), and work standardization in optimizing the fabric-cutting process, leading to reduced rework and delays, and a notable increase in productivity [

21]. Similarly, Kalwar et al. (2025) highlighted the impact of integrating Overall Equipment Effectiveness (OEE) with Total Productive Maintenance (TPM) and Six Sigma, which significantly improved production efficiency by addressing material and accessory availability issues [

22]. Afum et al. (2024) explored the synergistic application of Lean Practices (LPs) and Quick Response Manufacturing (QRM) in Ghana’s textile industry during the COVID-19 pandemic, revealing that QRM played a mediating role in enhancing both internal process and customer performance [

23]. In the yarn manufacturing context, Narassima et al. (2025) employed a system dynamics approach to implement 5S strategies, resulting in improved throughput and reductions in work-in-progress, processing time, and waste [

24]. Furthermore, Hussain and Figueiredo (2023) utilized VSM to identify non-value-adding activities in the preparatory stage of textile production, achieving improvements in cycle time, lead time, and process visibility [

25]. Collectively, these studies underscore the transformative potential of lean methodologies in reconfiguring business models to drive productivity and sustainability in textile manufacturing.

Recent research has also identified efforts aimed at enhancing sustainability in the textile sector by leveraging data-driven analysis capabilities enabled through digital transformation and Industry 4.0 applications. These studies adopt a lean management framework to improve productivity and mitigate losses, thereby contributing to more sustainable manufacturing practices [

26,

27,

28]. In addition to these contributions, Bhatia and Kumar (2023) conducted an empirical investigation into the critical success factors for Industry 4.0 adoption in Indian manufacturing sectors, including textiles [

26]. Their findings emphasized the importance of organizational support, workforce readiness, technological infrastructure, and data utilization in facilitating successful digital transformation. Complementing this, Ferlito (2024) examined the twin transition—digital and sustainable—of textile firms in Italy’s Prato district, revealing that the integration of Industry 4.0 technologies with lean manufacturing significantly fosters both sustainability and business model innovation [

27]. Furthermore, Azzolini Junior et al. (2025) developed a simulation-based decision-support tool combining Lean practices with optimization algorithms, demonstrating measurable improvements in operational efficiency and throughput in a textile packaging context [

28].

While previous studies have explored the integration of lean practices and Industry 4.0 technologies to improve productivity and sustainability in the textile sector, they have often yielded only incremental gains, particularly in Micro and Small Enterprises (MSEs). For instance, Bhatia and Kumar (2023) [

26] identified key organizational and technological enablers for Industry 4.0 adoption, while Ferlito (2024) [

27] emphasized the synergy between digitalization and sustainability in business model innovation. Azzolini Junior et al. (2025) [

28] further demonstrated the potential of simulation-based tools to support lean implementation. However, the present study offers a distinct contribution by applying a comprehensive methodology that combines 5S, Total Productive Maintenance (TPM), digitization, and advanced data analytics within a Peruvian textile MSE facing a significant productivity gap. Unlike prior research, this study not only addresses productivity challenges through lean and digital tools but also operationalizes data analytics to generate actionable insights for process optimization. This integrated, data-driven approach provides a replicable model for enhancing productivity and economic resilience in small-scale textile enterprises, thereby filling a critical gap in the existing literature.

3. Methodology

The methodology adopted in this case study involves the implementation of core lean manufacturing tools, specifically 5S, Total Productive Maintenance (TPM), and work standardization. In addition, two complementary tools aligned with current technological and sustainability trends—digitization and circular economy principles—are integrated into the framework. Digitization supports enhanced data recording and analysis, while circular economy concepts are embedded through standardization practices aimed at resource efficiency. The proposed model is validated through a pilot study conducted in the apparel division of the company, with the results presented in this paper.

3.1. Innovative Proposal

To address the issue of sewing machine downtime, a model grounded in the core pillars of Total Productive Maintenance (TPM) was implemented, with a particular emphasis on the preventive maintenance pillar. This approach involved assessing the criticality of each machine within the workshop and strategically planning maintenance activities to align with their operational importance. The primary objective was to extend the machines’ service life, enhance their availability, minimize unplanned stoppages, and ensure a more streamlined production process [

29,

30,

31]. Furthermore, the model integrated Industry 4.0 technologies to facilitate collaborative engagement among personnel, encouraging proactive participation in the formulation of maintenance policies. This integration not only strengthened preventive maintenance practices but also contributed to asset longevity and effectively mitigated downtime caused by equipment failures [

29,

30,

31].

In parallel, process standardization models were introduced with the objective of minimizing rework and eliminating waste, thereby elevating operational standards across the organization. Standardization serves as a foundational element for process optimization, aiming to enhance efficiency and, ultimately, improve overall productivity [

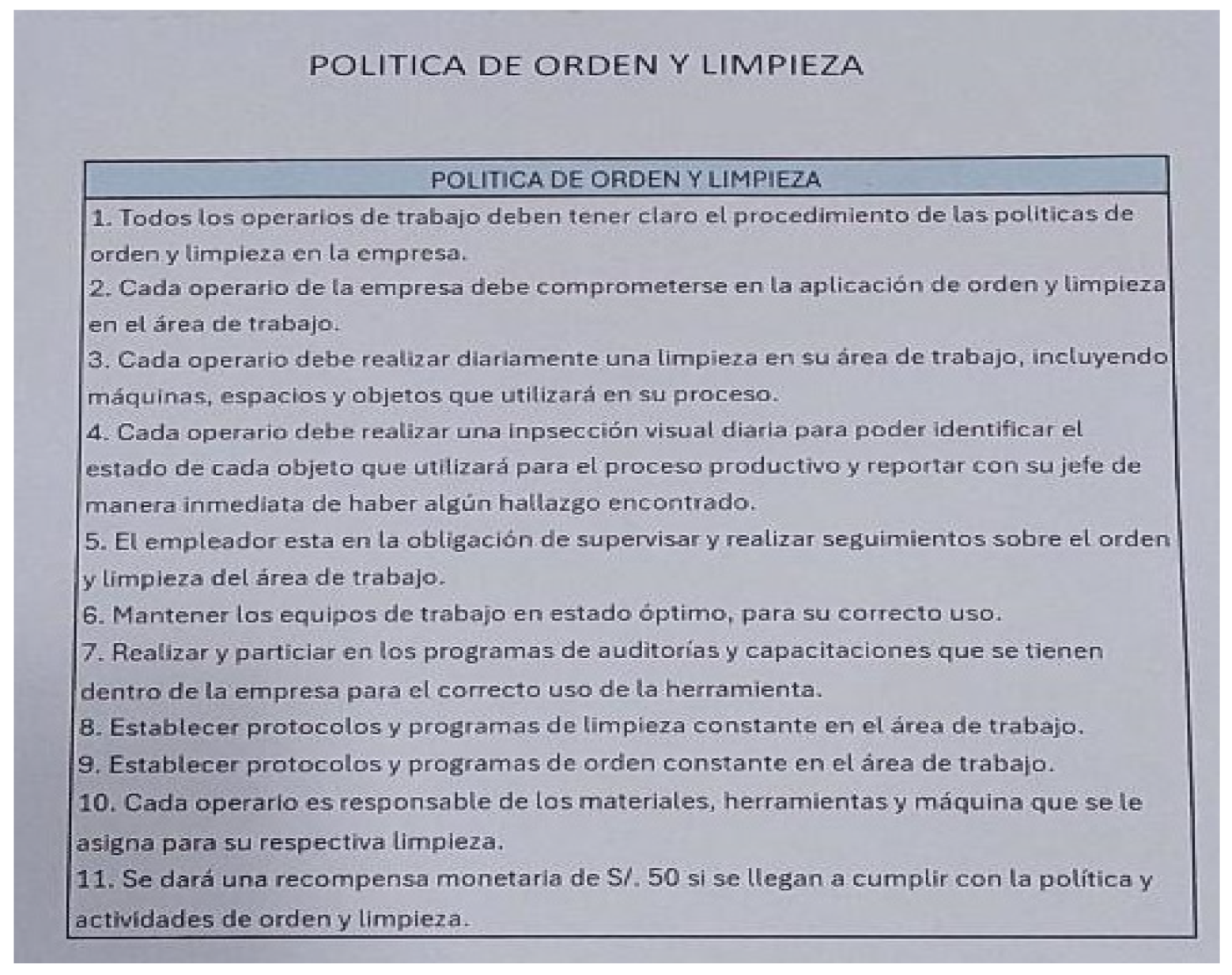

32]. Complementing this, the maintenance of order and cleanliness in the workplace was addressed through the implementation of the 5S methodology. This tool focuses on establishing and institutionalizing standards for workplace organization and hygiene, which are essential for sustaining optimal operational conditions. By reducing unproductive time caused by disorganization, the 5S approach enables workers to perform their tasks more efficiently and consistently, contributing to a more disciplined and productive work environment.

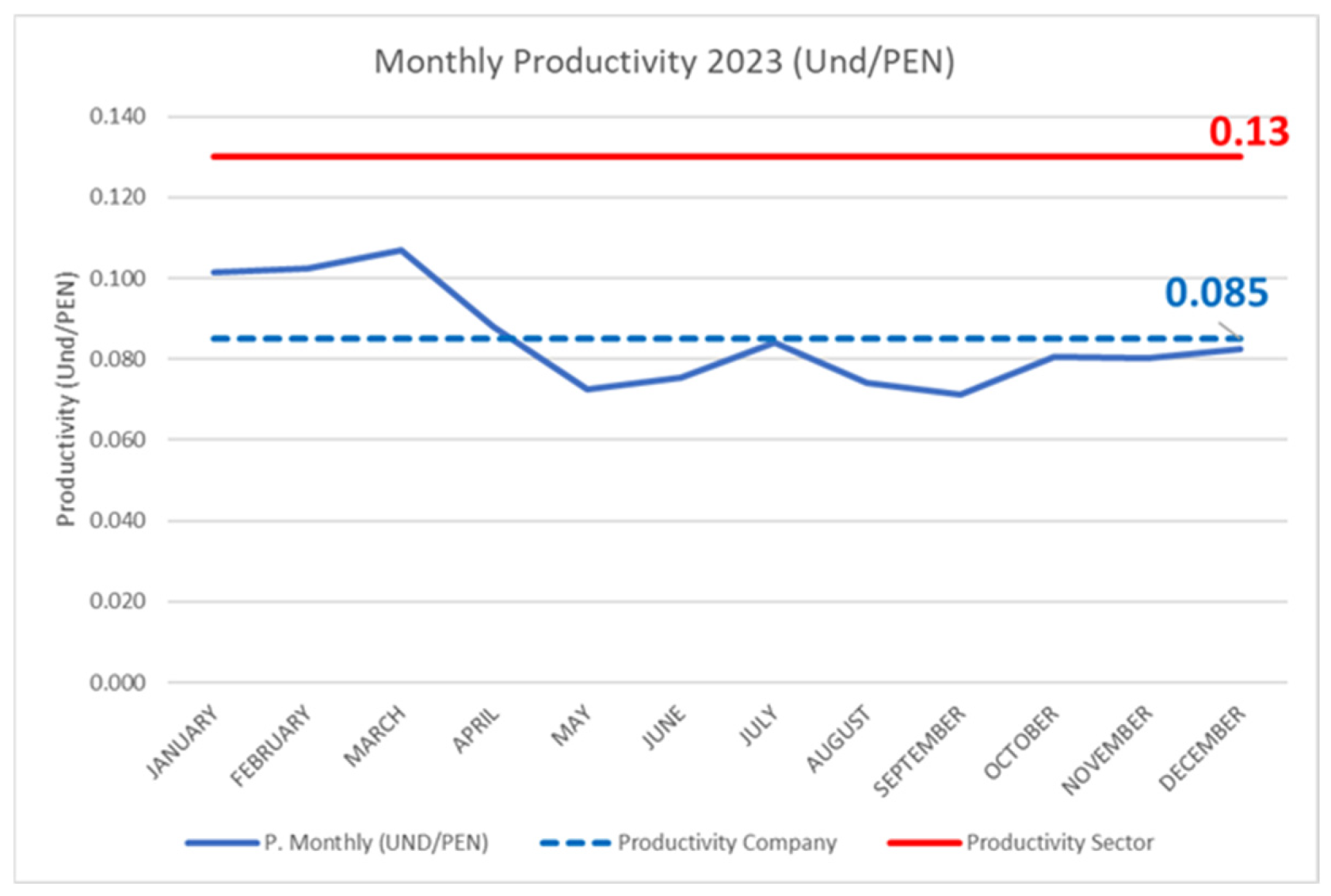

Finally, a significant productivity gap was identified between the sectoral benchmark of 0.13 units per sol [

33] and the company’s recorded productivity rate of 0.085 units per sol in 2023. This discrepancy underscores the urgent need for targeted interventions aimed at optimizing production processes and aligning the company’s performance with industry standards.

Figure 1 illustrates the monthly productivity trend throughout 2023, revealing an average of 0.085 units per sol for the case company, compared to the sectoral benchmark of 0.13 units per sol. This 0.045-unit gap highlights a persistent underperformance and underscores the need for targeted process improvements.

To address this gap, the proposed model draws upon the frameworks of two prior studies that tackled similar productivity challenges using comparable lean tools. The first reference model focuses on optimizing the cutting process in a textile company, aligning closely with the initial context of this research. It systematically defines the required inputs and outputs, establishes key performance indicators, and sets clear productivity objectives. The implementation of this model led to a productivity increase from 26 to 33 units per man-hour, demonstrating its effectiveness in enhancing operational efficiency [

34].

The second model addresses low productivity and yield rates by integrating 5S principles to foster a cleaner, more organized work environment. It targets rework and unproductive downtime through process optimization and emphasizes the active involvement of operators as key agents of change. This participatory approach resulted in a remarkable 79.11% increase in productivity [

35].

Building on these foundations, the proposed model in this study adopts the structural framework and methodological formulation of the aforementioned works, while tailoring the toolset—5S, TPM, digitization, and standardization—to the specific needs of a Peruvian textile MSE. This integrated approach aims to close the productivity gap by enhancing process efficiency, reducing waste, and fostering a culture of continuous improvement.

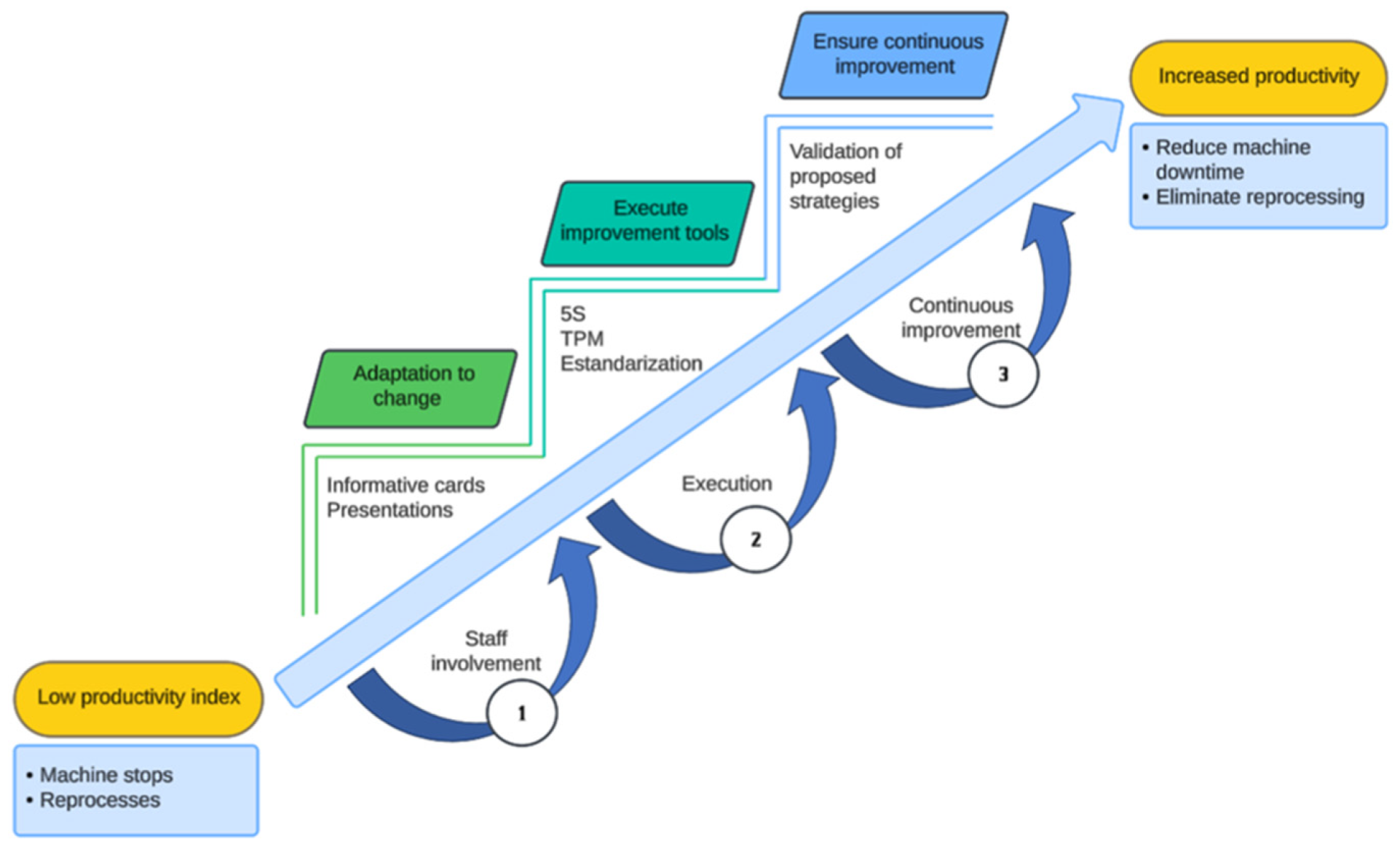

Figure 2 presents the structure of the proposed model, which is organized into three sequential phases: staff involvement (model presentation and awareness), execution (implementation of lean tools), and continuous improvement (validation and strategic refinement). The model also outlines its key inputs and expected outputs, providing a comprehensive framework for application.

Unlike conventional approaches that apply lean tools in isolation, the proposed framework adopts a synergistic and adaptive integration of 5S, Total Productive Maintenance (TPM), and process standardization, tailored specifically to the operational realities of textile microenterprises. These enterprises often face constraints such as limited resources, high variability, and low levels of formalized processes. Within this context, the 5S methodology was not merely used for workplace tidiness but served as a cultural foundation to support the standardization of repetitive tasks. TPM was adapted through simplified visual tools and autonomous maintenance routines co-developed with operators, making it feasible in environments with minimal technical infrastructure.

Standardization, rather than being treated as a static endpoint, was conceptualized as a dynamic mechanism, continuously informed by real-time productivity and failure data to drive sustainable improvements. Moreover, the model integrates digitization and circular economy principles, aiming not only to boost immediate productivity but also to ensure long-term sustainability—both operationally and environmentally—by reducing resource consumption and minimizing waste.

This flexible, data-driven articulation of lean tools enables them to reinforce one another, addressing root causes such as machine downtime and rework through practical, context-sensitive, and scalable solutions. Ultimately, the model’s effectiveness lies not only in the tools themselves but in their ability to evolve within the specific production environment, ensuring a holistic and sustainable transformation.

3.2. Validation Process

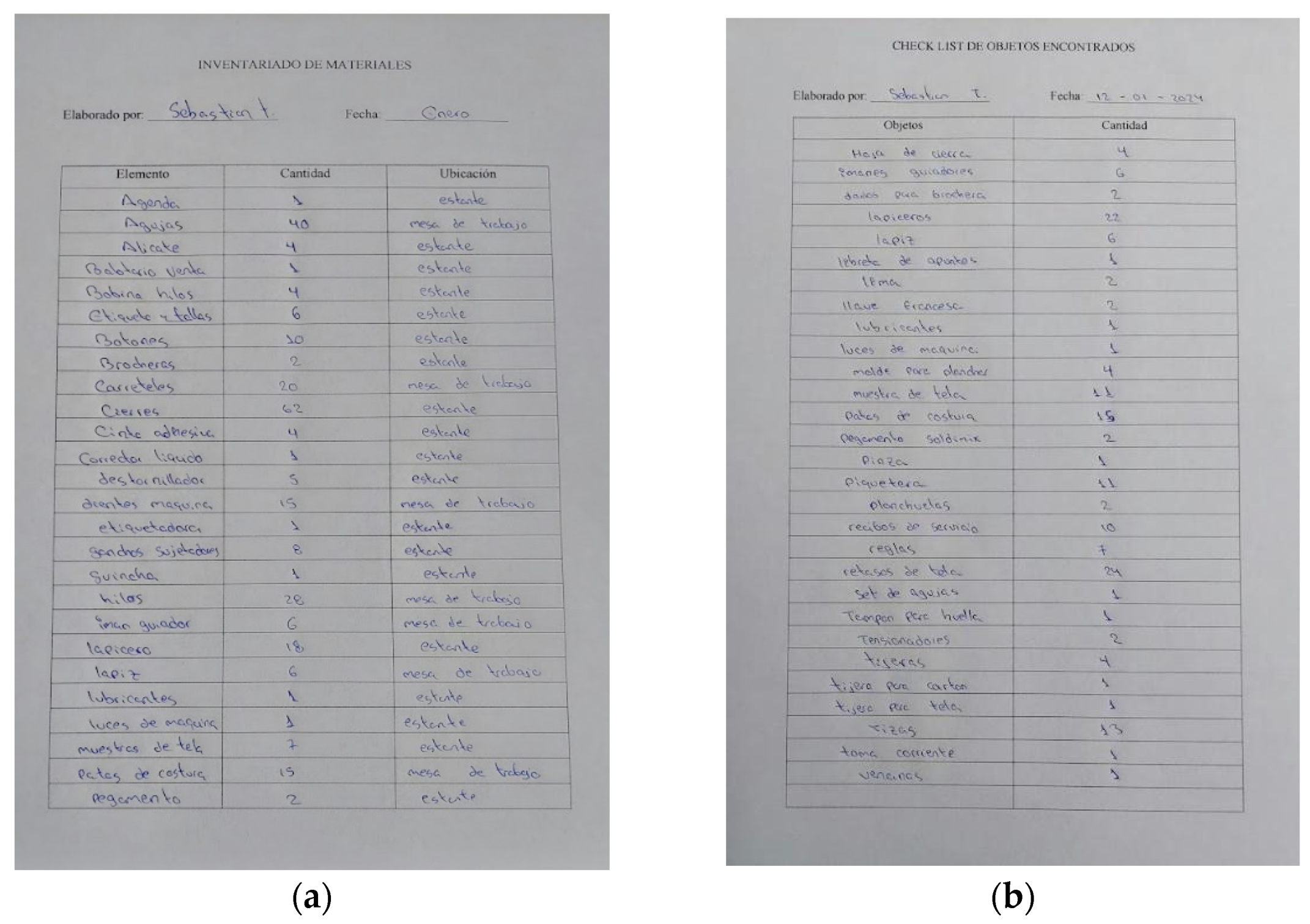

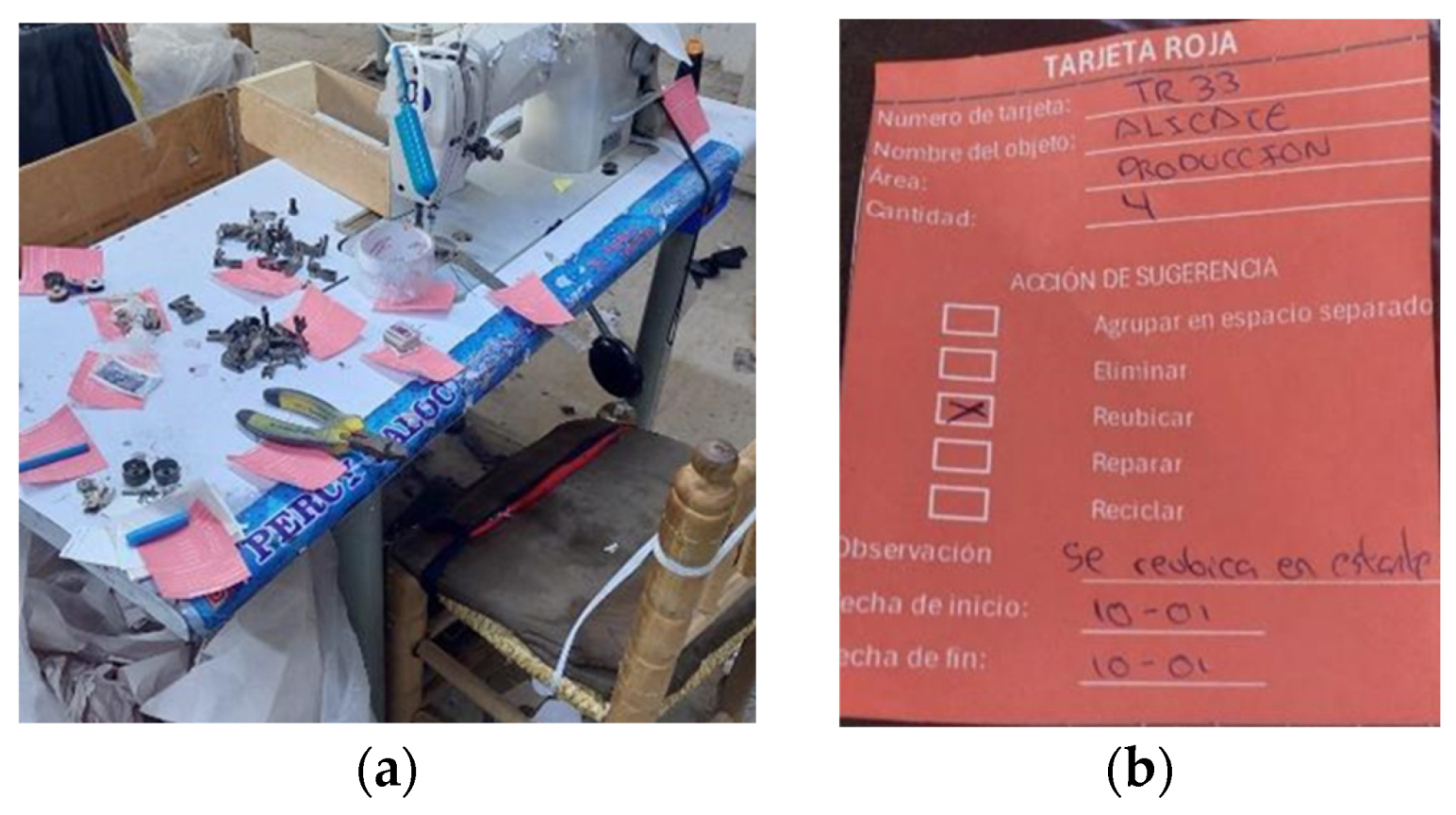

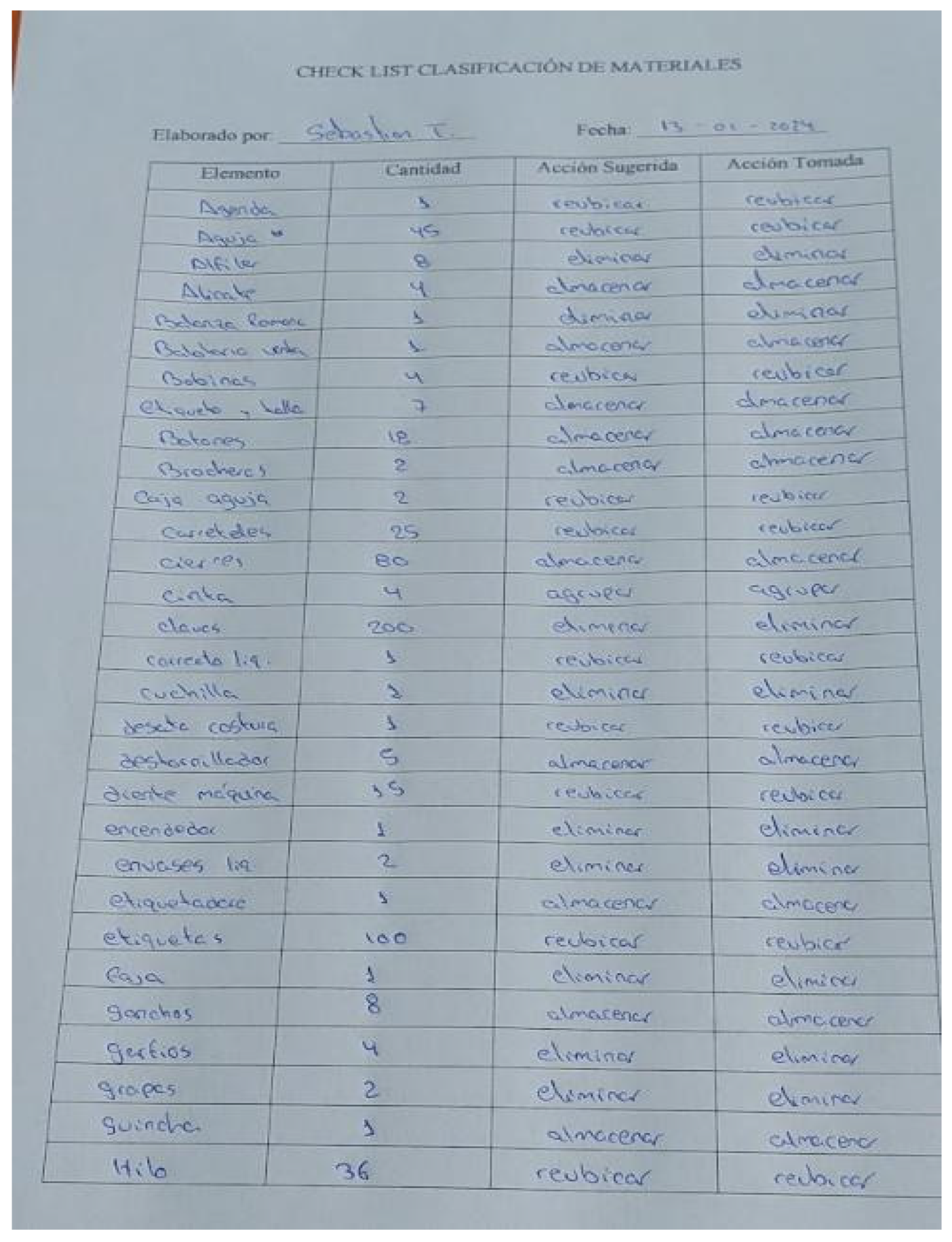

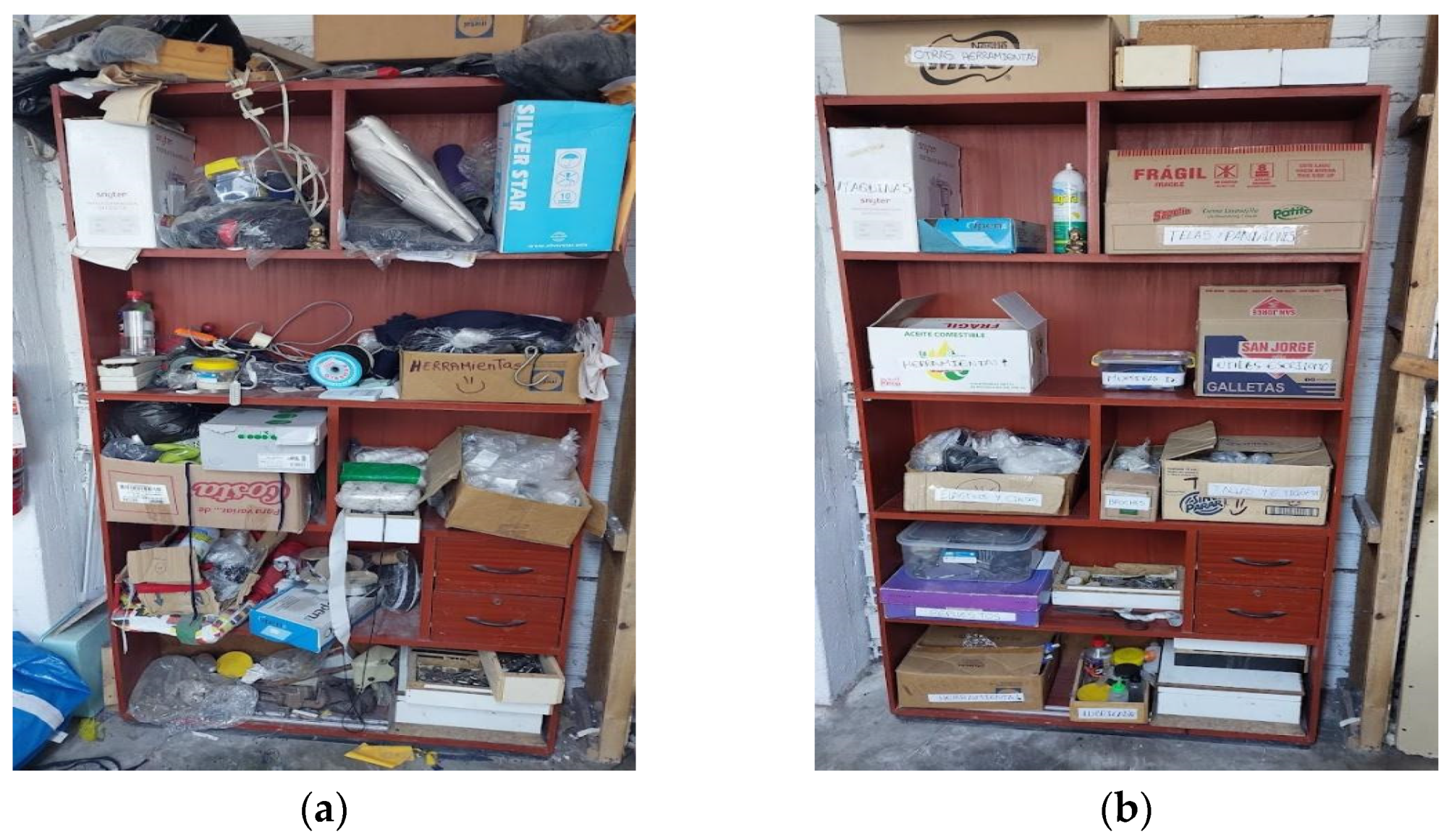

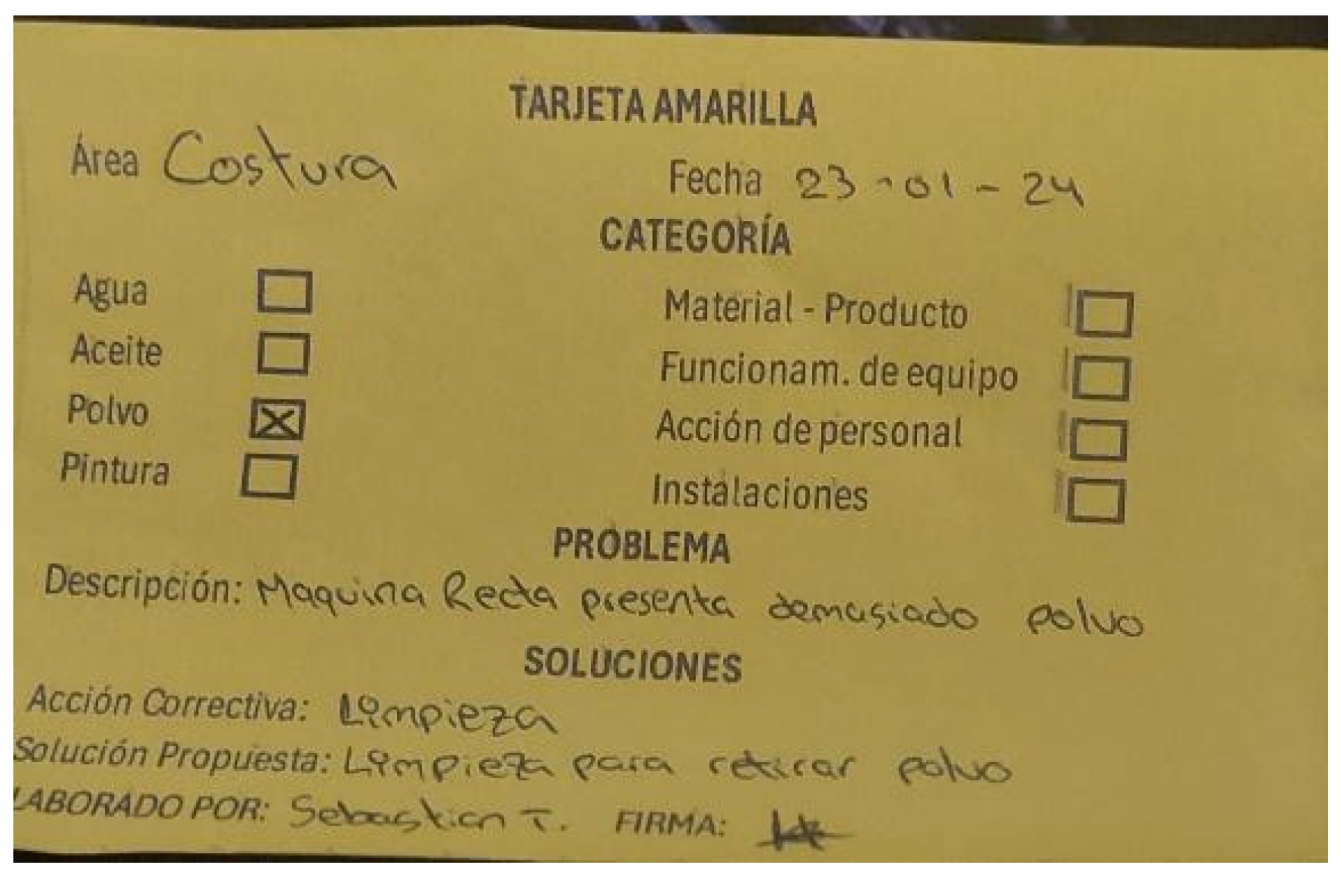

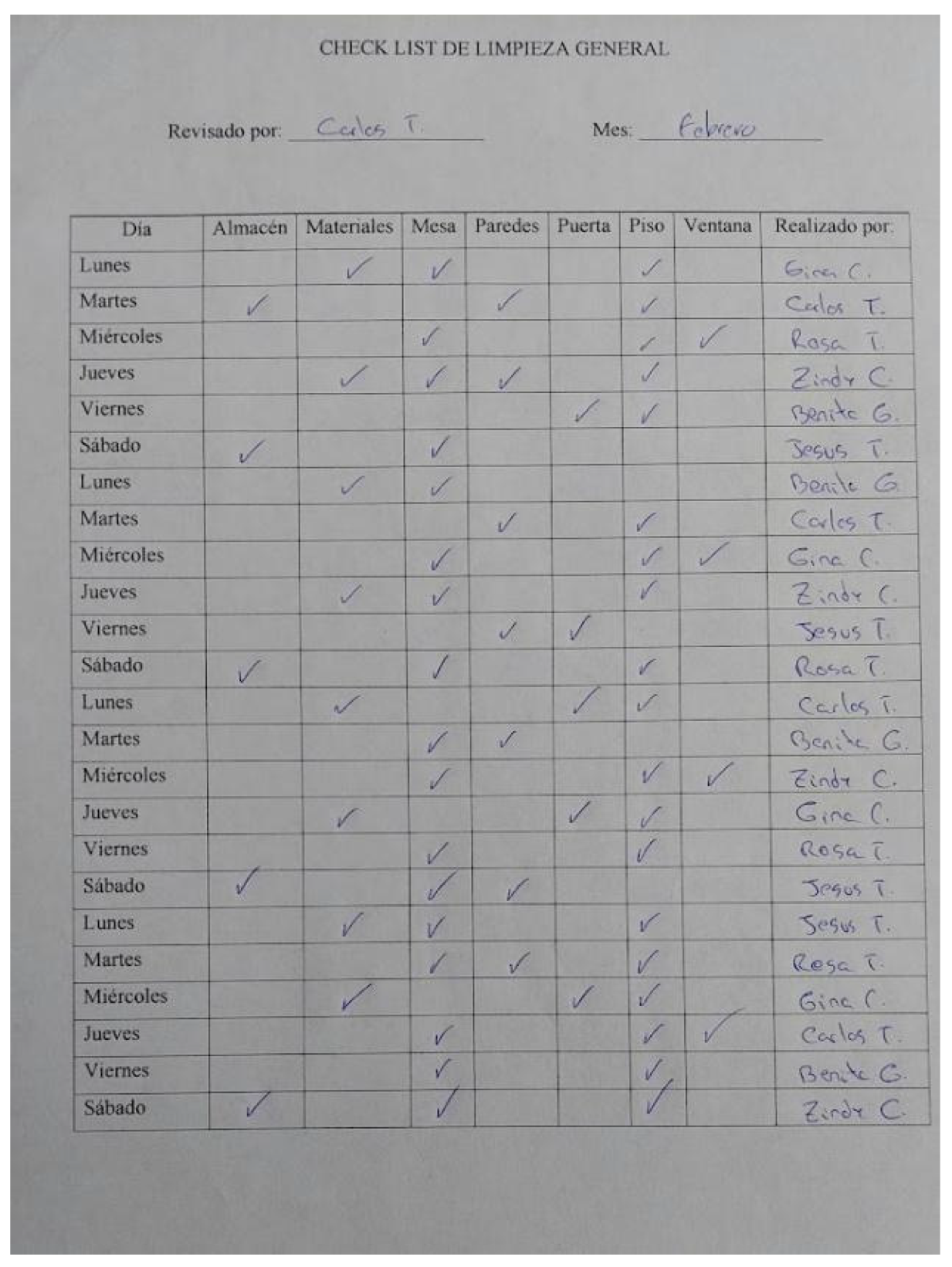

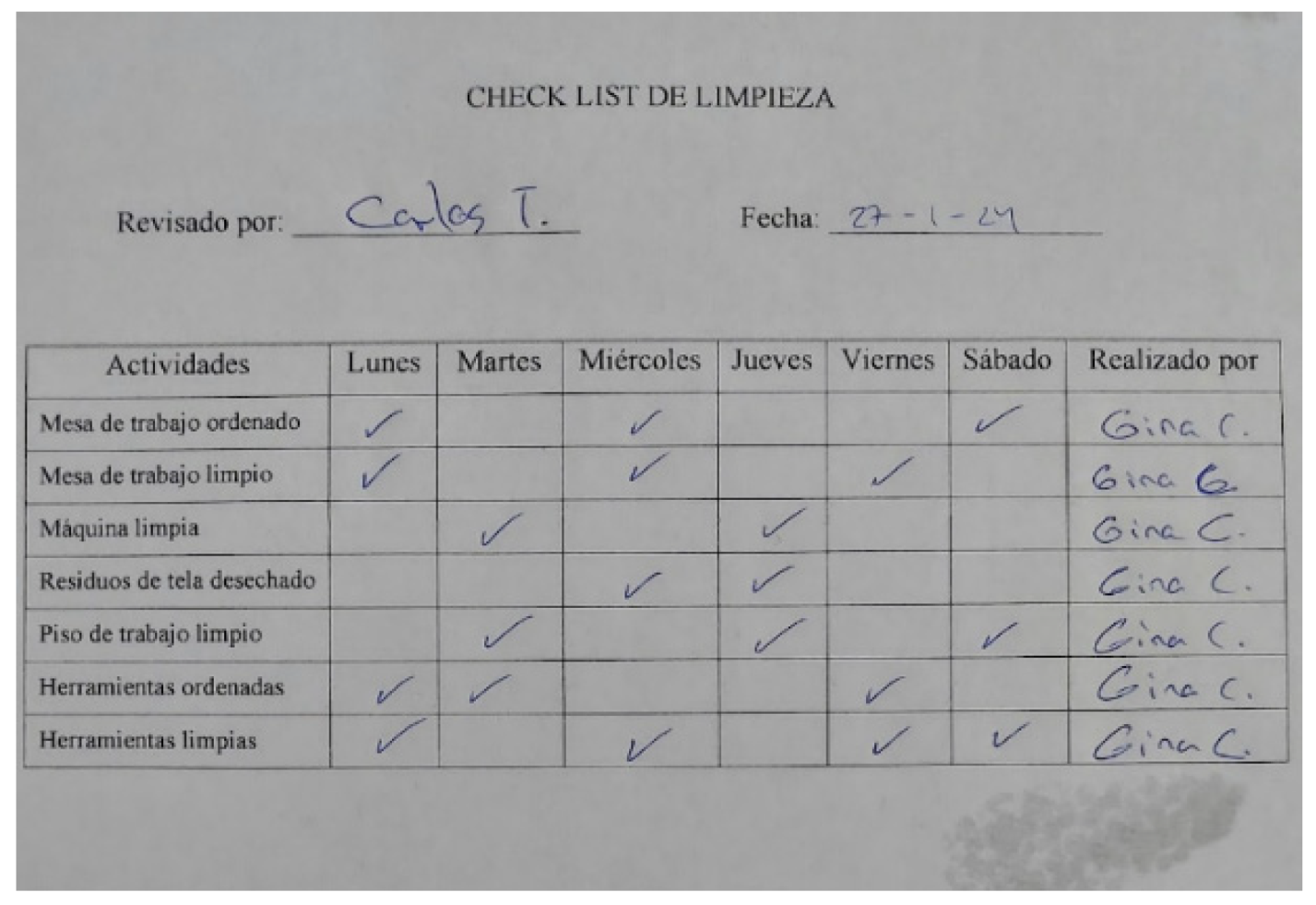

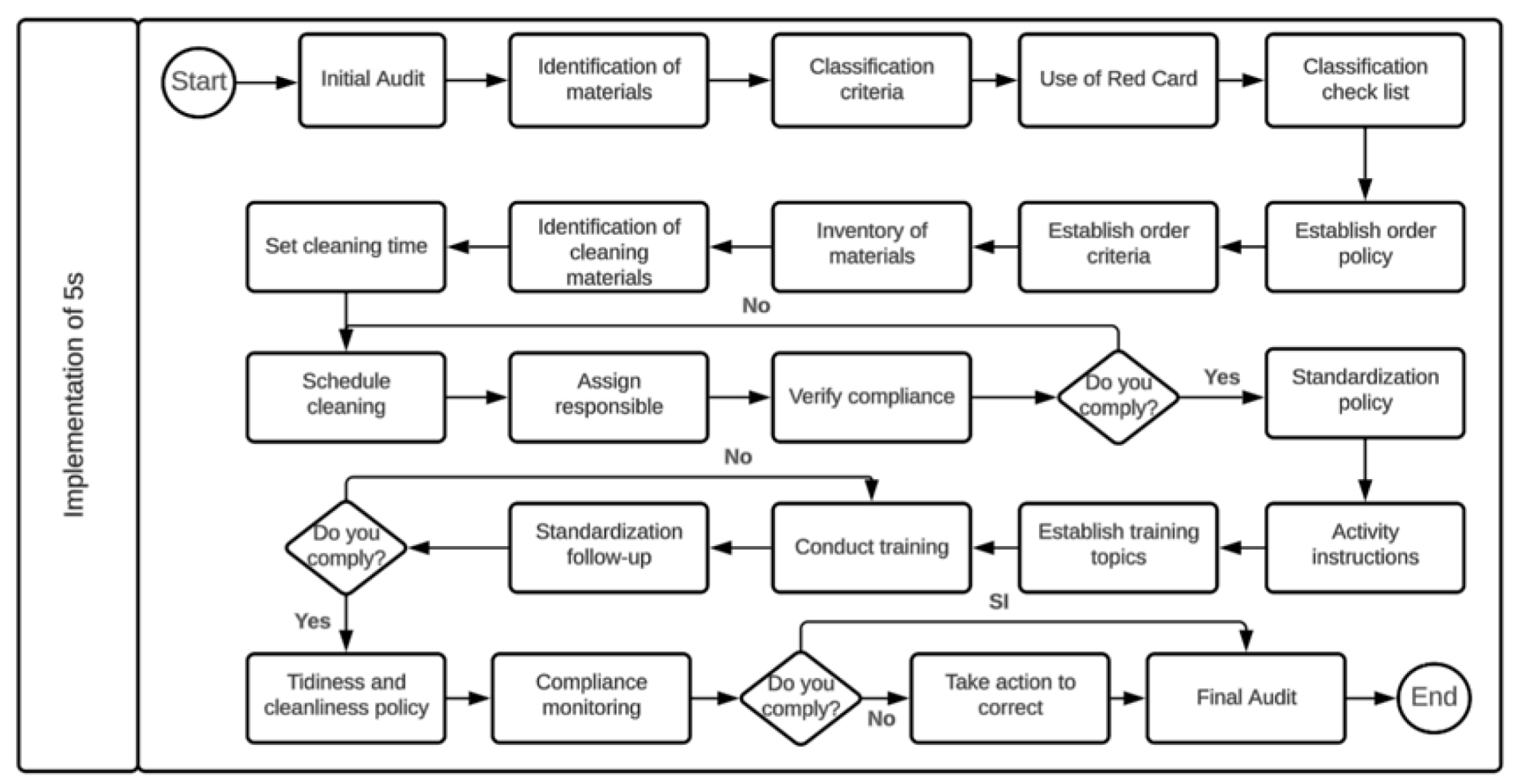

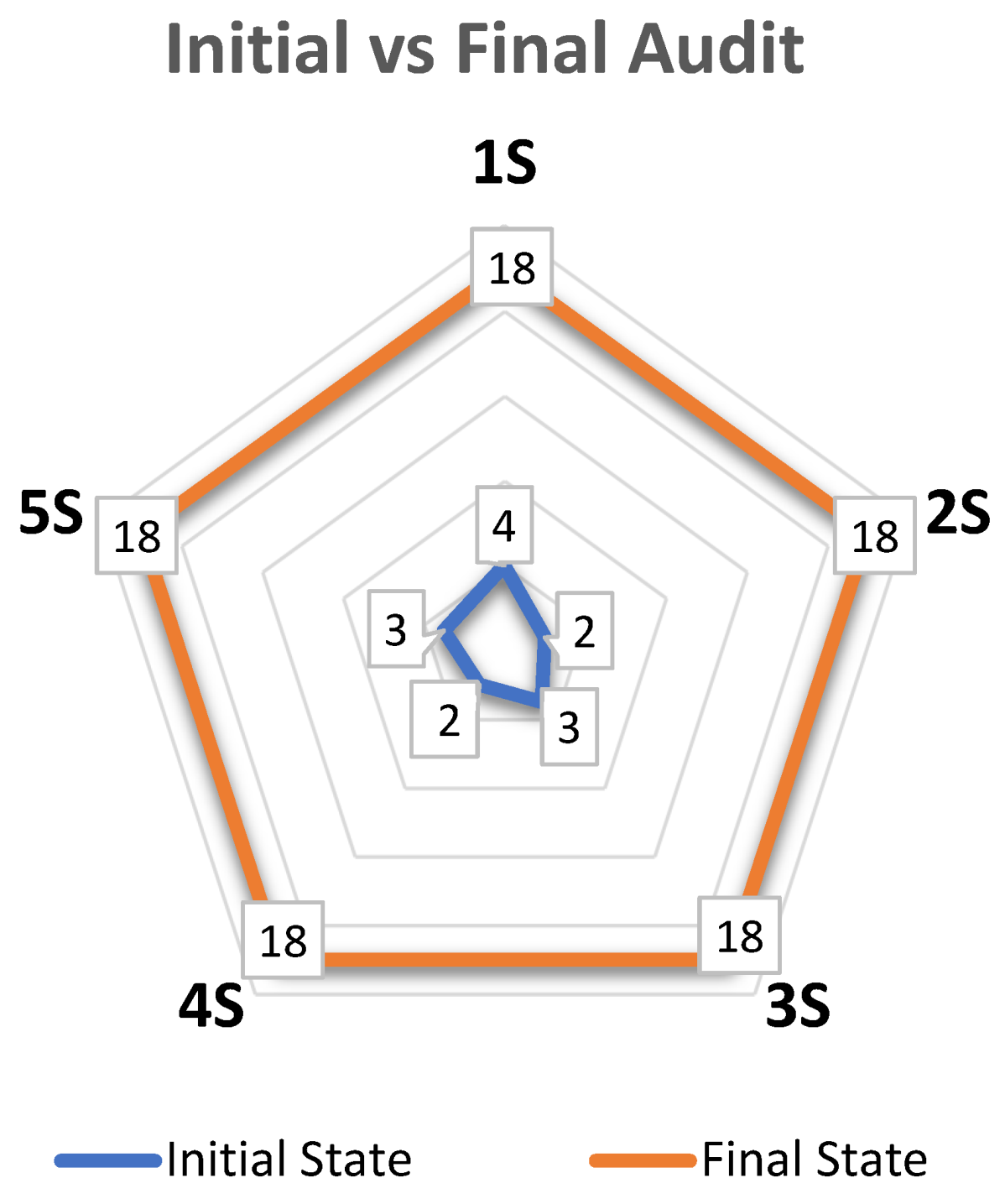

The proposed model integrates a set of interrelated methodologies designed to enhance productivity and operational efficiency within the textile sector. The implementation process begins with the application of the 5S methodology. An initial audit is conducted to assess the current state of the workplace. Subsequently, the elements within the work area are identified and categorized, materials are systematically arranged, and thorough cleaning is performed. These activities are then standardized to ensure consistency, followed by the promotion of a workplace culture centered on order and cleanliness. The cycle concludes with a final audit to evaluate improvements and ensure adherence to the established standards.

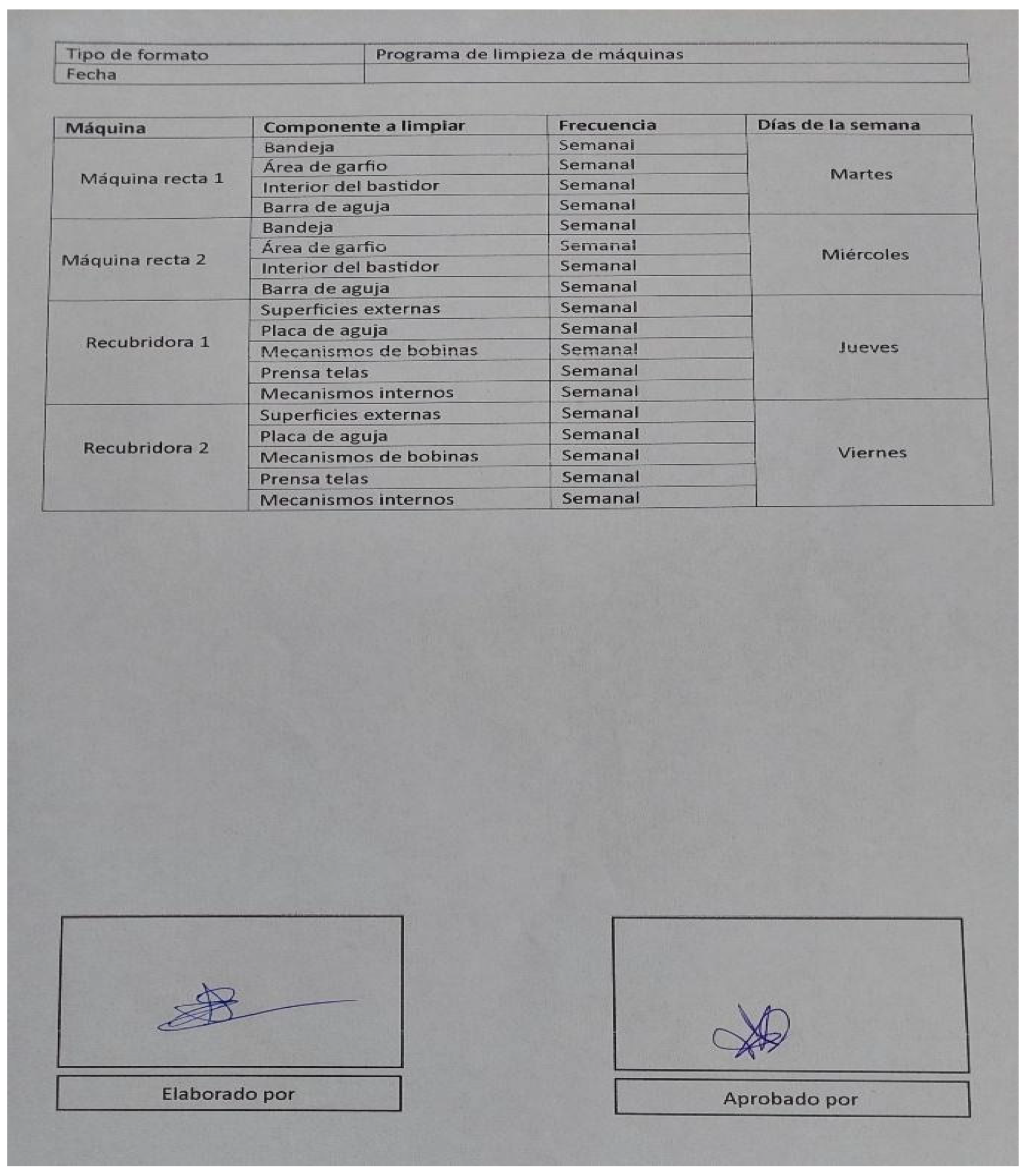

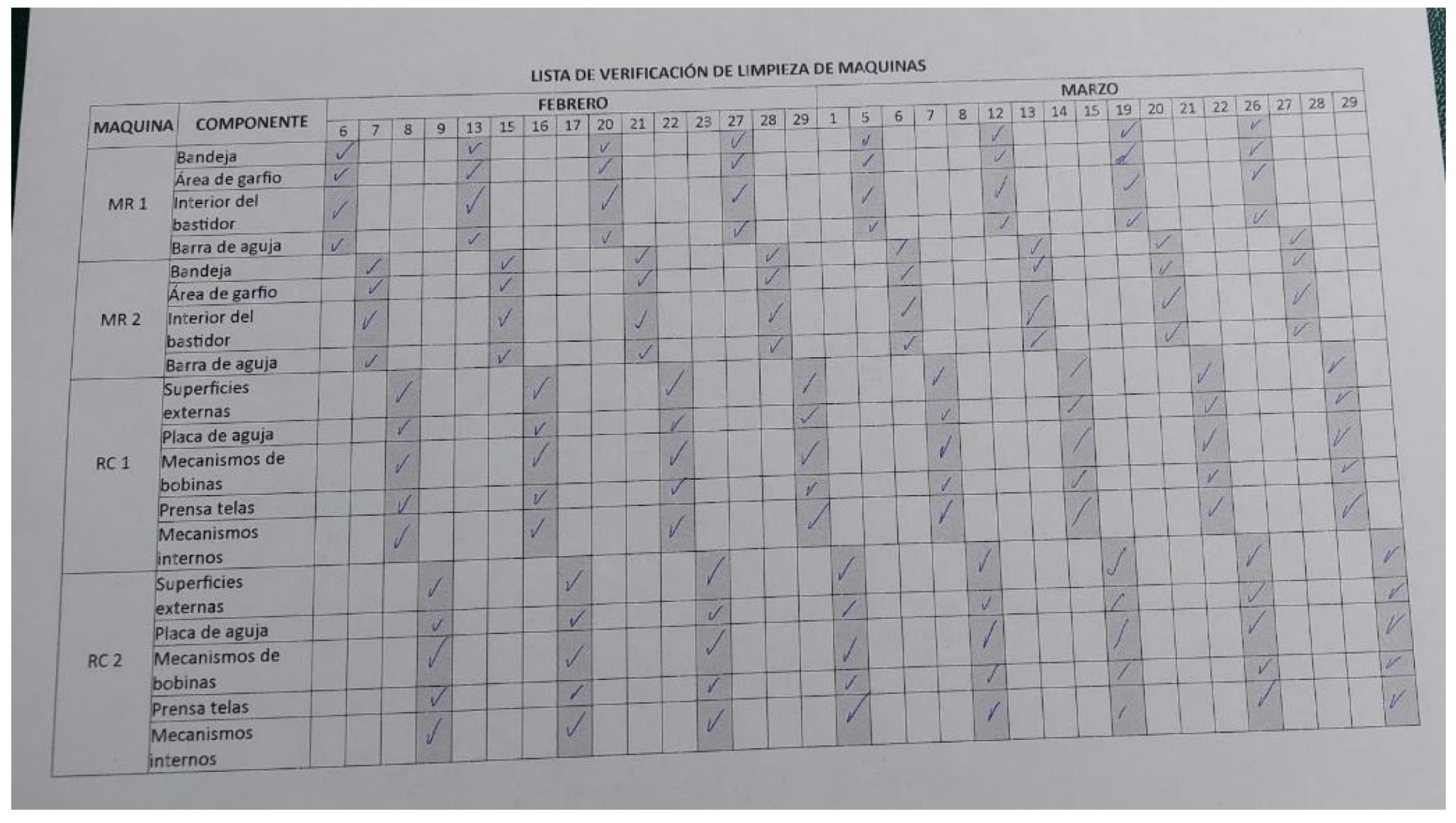

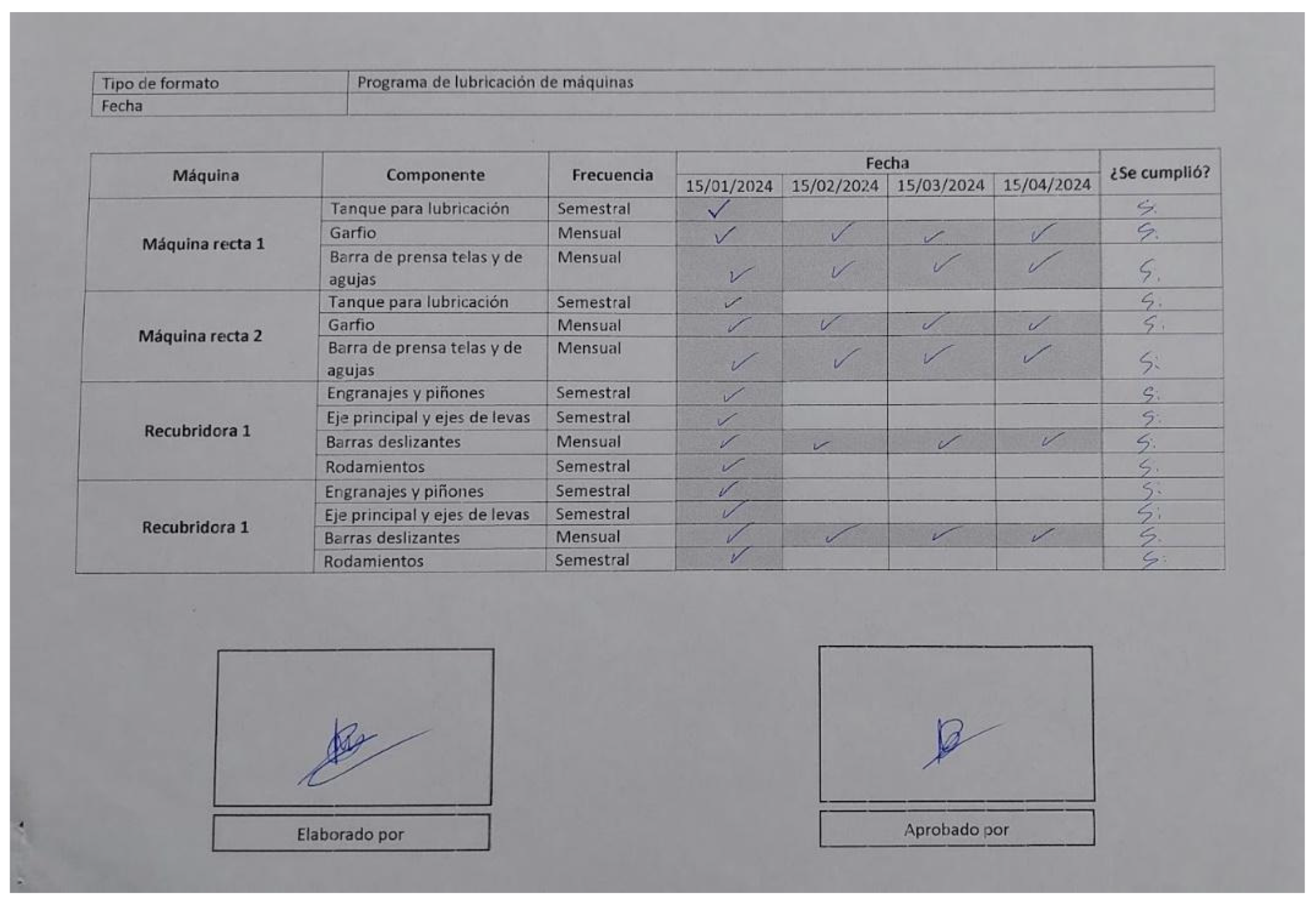

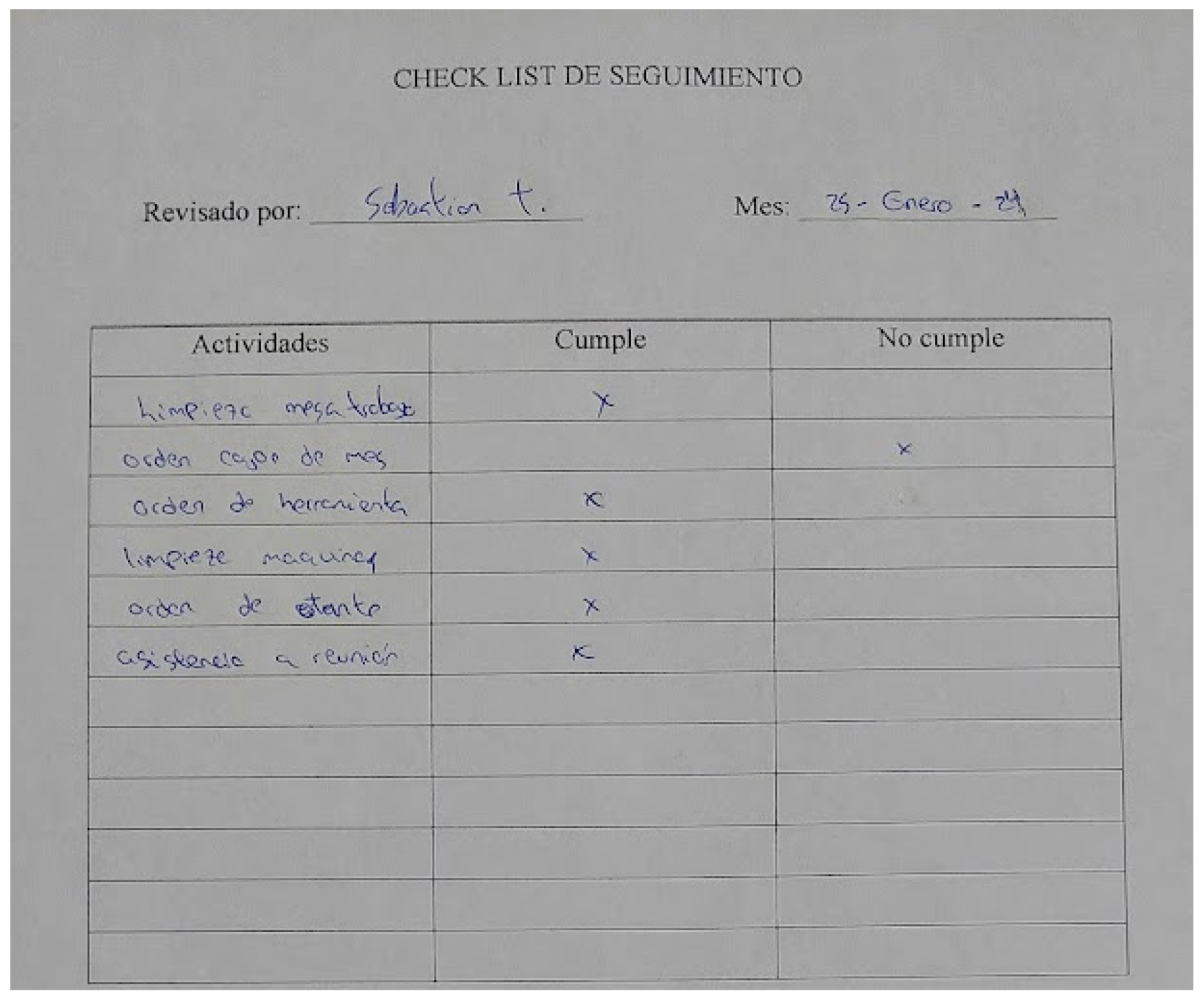

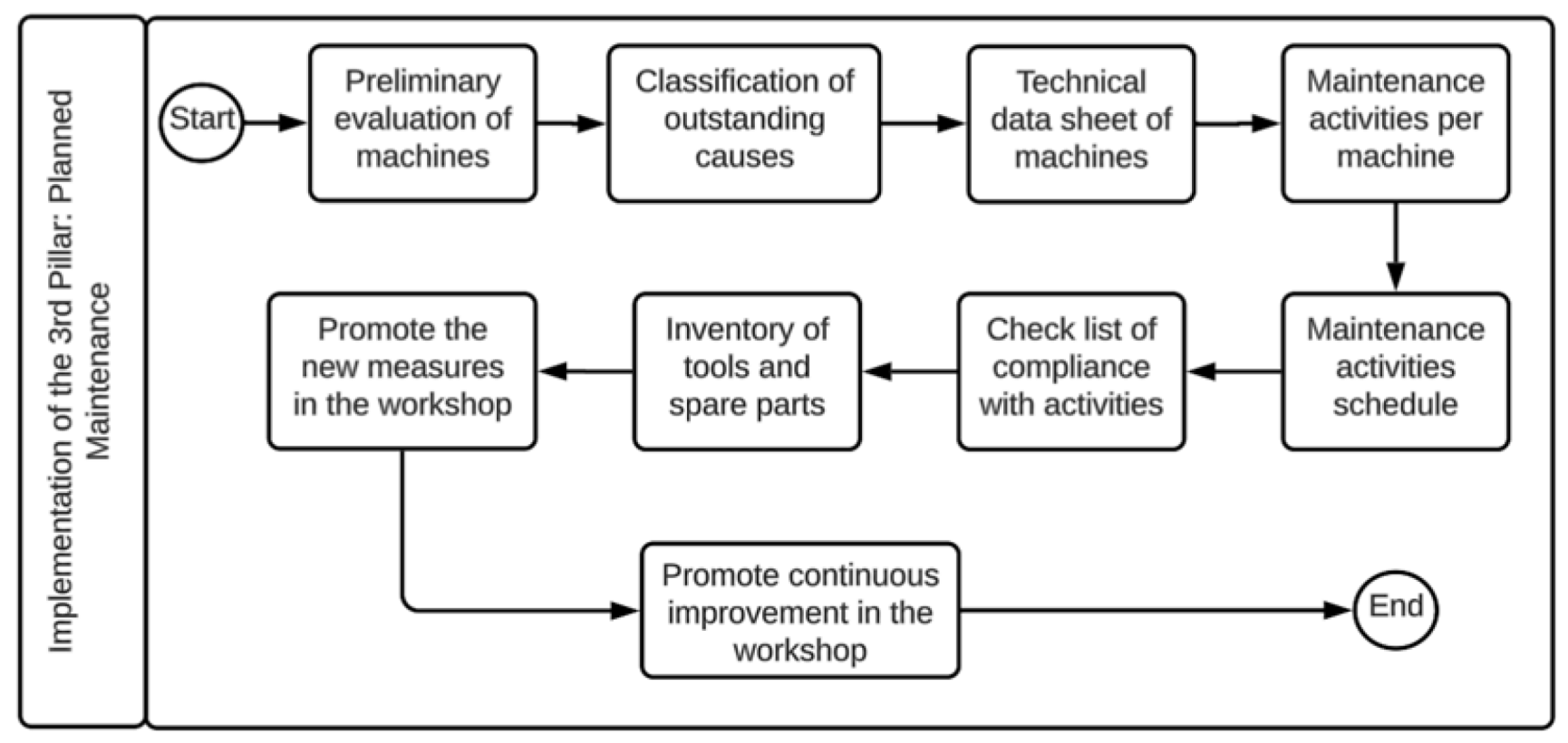

Following the 5S implementation, the model incorporates the Planned Maintenance (PM) pillar of Total Productive Maintenance (TPM) to address machine downtime. This involves identifying the sewing machines involved in production, analyzing the root causes of failures and stoppages, and developing a structured maintenance schedule. The schedule outlines essential tasks such as cleaning, lubrication, and repairs. To ensure compliance, checklists are employed to verify the timely execution of maintenance activities, thereby improving machine availability, reducing unplanned interruptions, and optimizing production time.

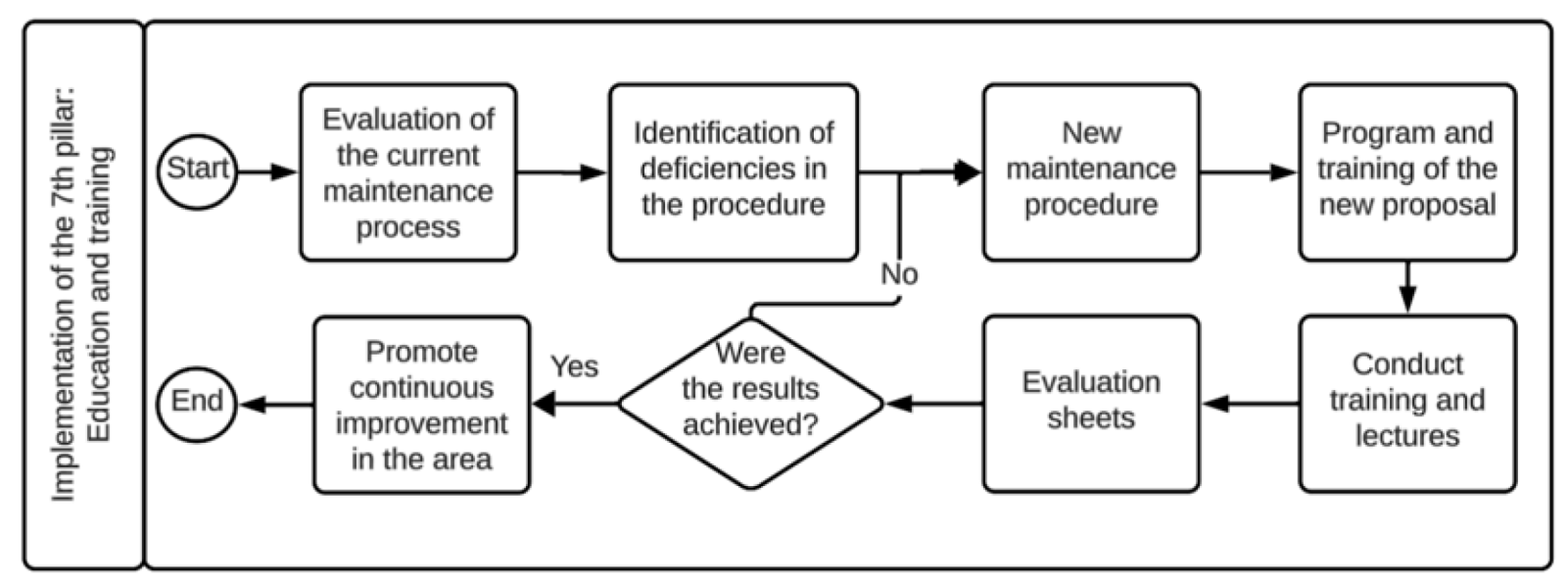

The model further integrates the Education and Training pillar of TPM, which plays a critical role in equipping operators with the necessary skills and knowledge for effective maintenance practices. This process begins with an evaluation of existing maintenance procedures, the identification of deficiencies, and the development of improved protocols. A comprehensive training program is then implemented to ensure that operators can competently apply the updated procedures, thereby minimizing downtime and enhancing overall productivity.

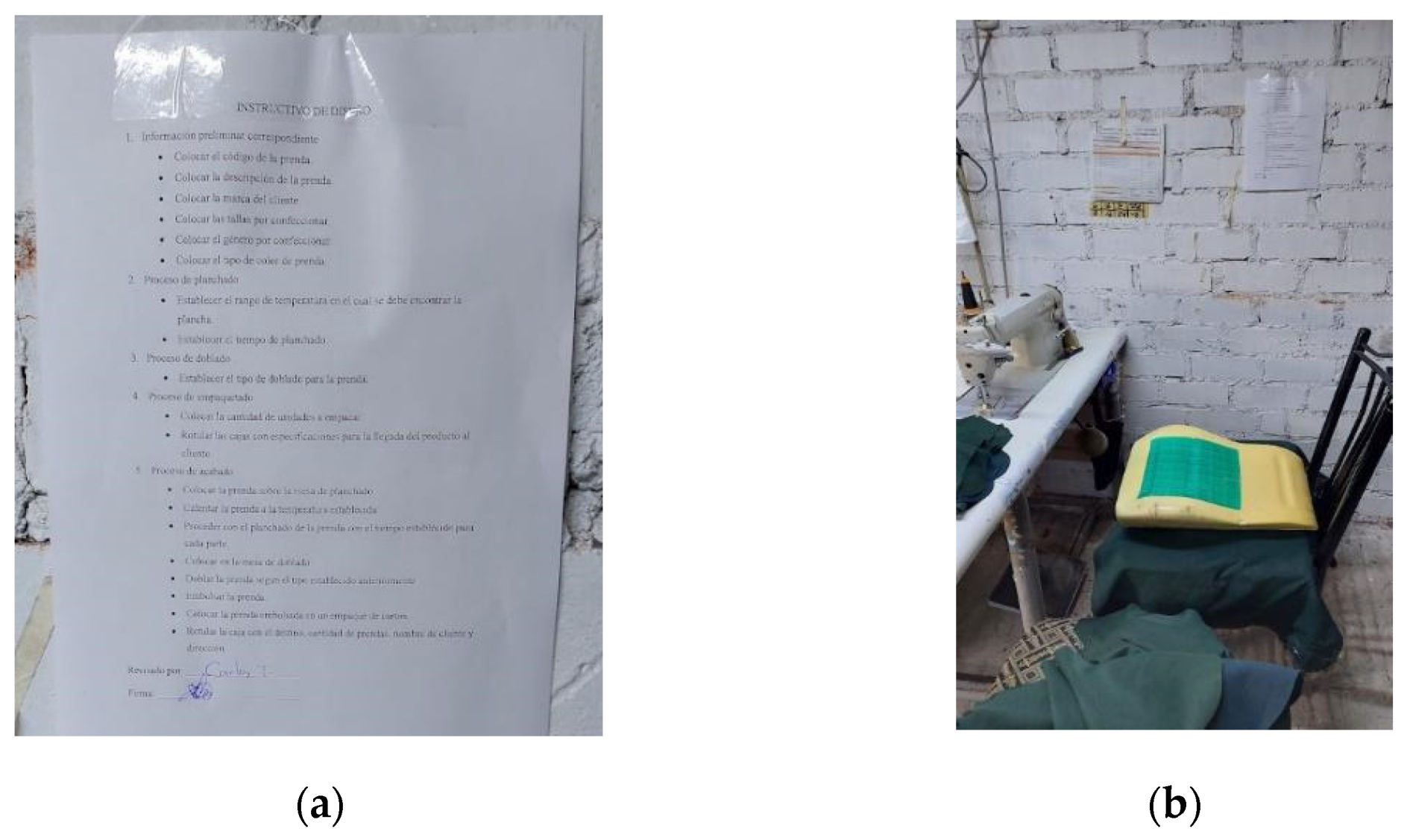

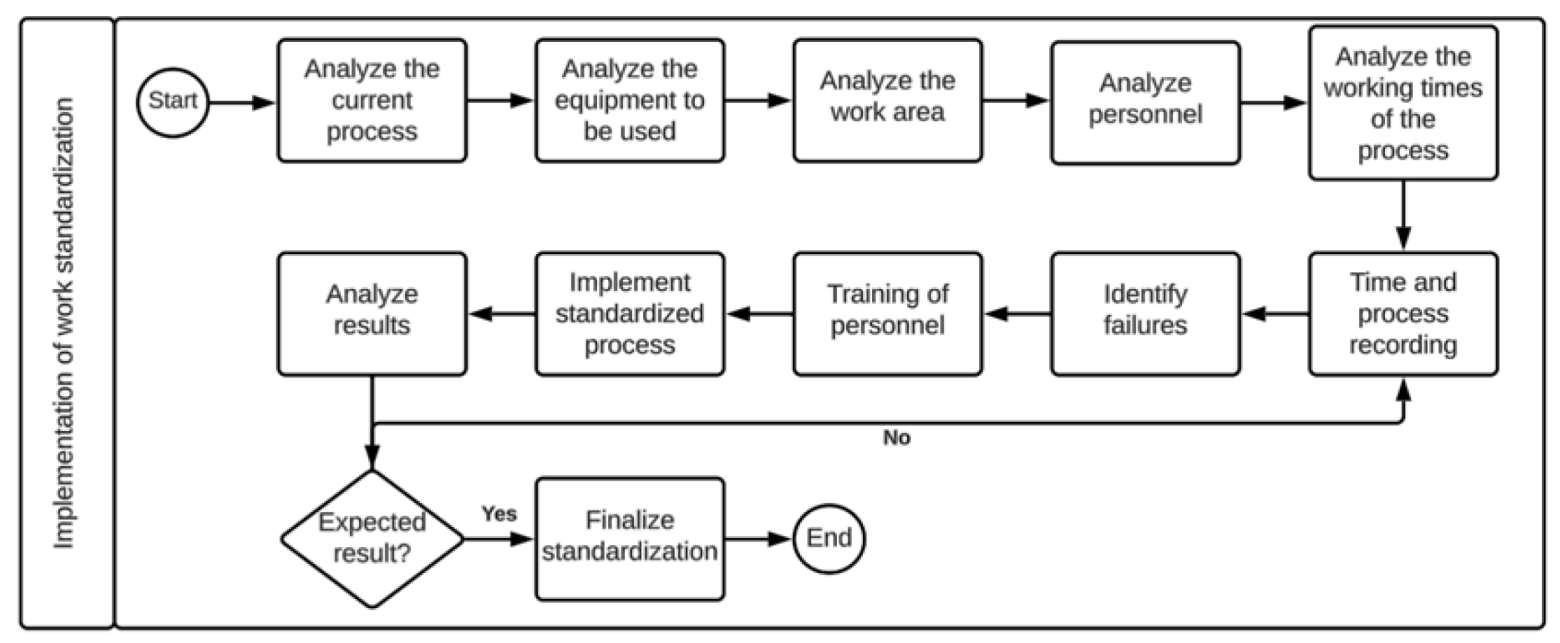

Finally, the Standardization component focuses on streamlining production processes by eliminating inefficiencies and ensuring uniformity in operational practices. This begins with a detailed analysis of current workflows to identify critical tasks and their sequence. Based on this analysis, an optimized activity diagram is developed, non-value-adding activities are eliminated, and best practices are incorporated. To support implementation, technical sheets and standardized instructions are provided to workers. Additionally, circular economy principles are embedded within this component to promote efficient material usage and minimize waste, reinforcing the model’s commitment to long-term sustainability.

3.2.1. 5S

The 5S methodology is implemented as the initial phase of the model, functioning as a foundational pillar upon which subsequent components are built. Its effective execution not only establishes the necessary organizational discipline but also facilitates the seamless integration of the tools and practices that follow.

Figure 3 illustrates the sequential implementation of the 5S methodology, outlining each stage from initiation to completion. The process begins with an initial audit aimed at identifying inefficiencies and deficiencies within the company’s operational environment. Following this, materials are systematically identified and classified using red tagging techniques. These items are then organized into designated containers and arranged based on their frequency of use to enhance accessibility. Subsequently, cleaning responsibilities are assigned to ensure a hygienic and orderly workspace. To sustain these improvements, formal measures and policies are established to guide the regular execution of organizational and cleaning tasks. The cycle concludes with a final audit, which serves to verify the effectiveness of the interventions and the degree of improvement achieved.

3.2.2. TPM—Planned Maintenance

The implementation of this pillar is intended to improve machine availability by systematically reducing the frequency of unplanned stoppages that have been disrupting operations.

Figure 4 presents the sequential implementation of the TPM—Planned Maintenance tool, illustrating each stage from initiation to completion. The process begins with the identification of sewing machines involved in production, followed by a systematic analysis of the root causes of equipment failures and operational stoppages. Based on these findings, a structured maintenance schedule is developed, detailing essential tasks such as cleaning, lubrication, and repairs. To ensure consistent execution and adherence to the plan, these activities are monitored and validated through standardized checklists, thereby promoting reliability, minimizing downtime, and enhancing Overall Equipment Effectiveness.

3.2.3. TPM—Education and Training

Figure 5 illustrates the sequential implementation of the TPM—Education and Training tool, detailing each stage from initiation to completion. The development of this pillar begins with the identification and evaluation of existing procedures for machine handling and maintenance, with particular emphasis on equipment associated with the highest levels of downtime. This phase involves diagnosing procedural shortcomings and formulating an improved, more effective protocol. Subsequently, a structured training program is introduced to ensure that operators acquire the necessary competencies to accurately and consistently apply the revised procedures, thereby enhancing operational reliability and minimizing disruptions.

3.2.4. Standardization

Figure 6 illustrates the sequential implementation of the standardization tool, detailing each phase from initiation to completion. The process begins with a comprehensive analysis of the current production workflow to identify individual activities and their operational sequence. Based on this assessment, an updated activity diagram is developed, outlining a streamlined and standardized process in which non-value-adding tasks are systematically eliminated. Subsequently, technical sheets and procedural instructions are introduced to guide workers in the accurate execution of the newly established process. This standardization effort is further reinforced by the integration of circular economy principles, ensuring the efficient use of materials and the minimization of waste throughout the production cycle.

5. Discussion

To assess the effectiveness of the improvement plan proposed in this case study, the outcomes were benchmarked against findings from prior research that addressed comparable challenges in the textile industry through the application of lean methodologies and maintenance strategies.

Saravanan et al. (2023) conducted a textile company specializing in the production of flame-resistant garments, tackling low productivity by implementing tools such as 5S, time studies, and preventive maintenance [

35]. This intervention led to a 20% increase in productivity, closely aligning with the 18% improvement observed in the present study. In terms of 5S implementation, efficiency rose from 42% to 88% in the referenced study, whereas in our case, it reached 90%, indicating a slightly superior outcome. Furthermore, machine availability, as measured by Overall Equipment Effectiveness (OEE), improved by 50% in the study [

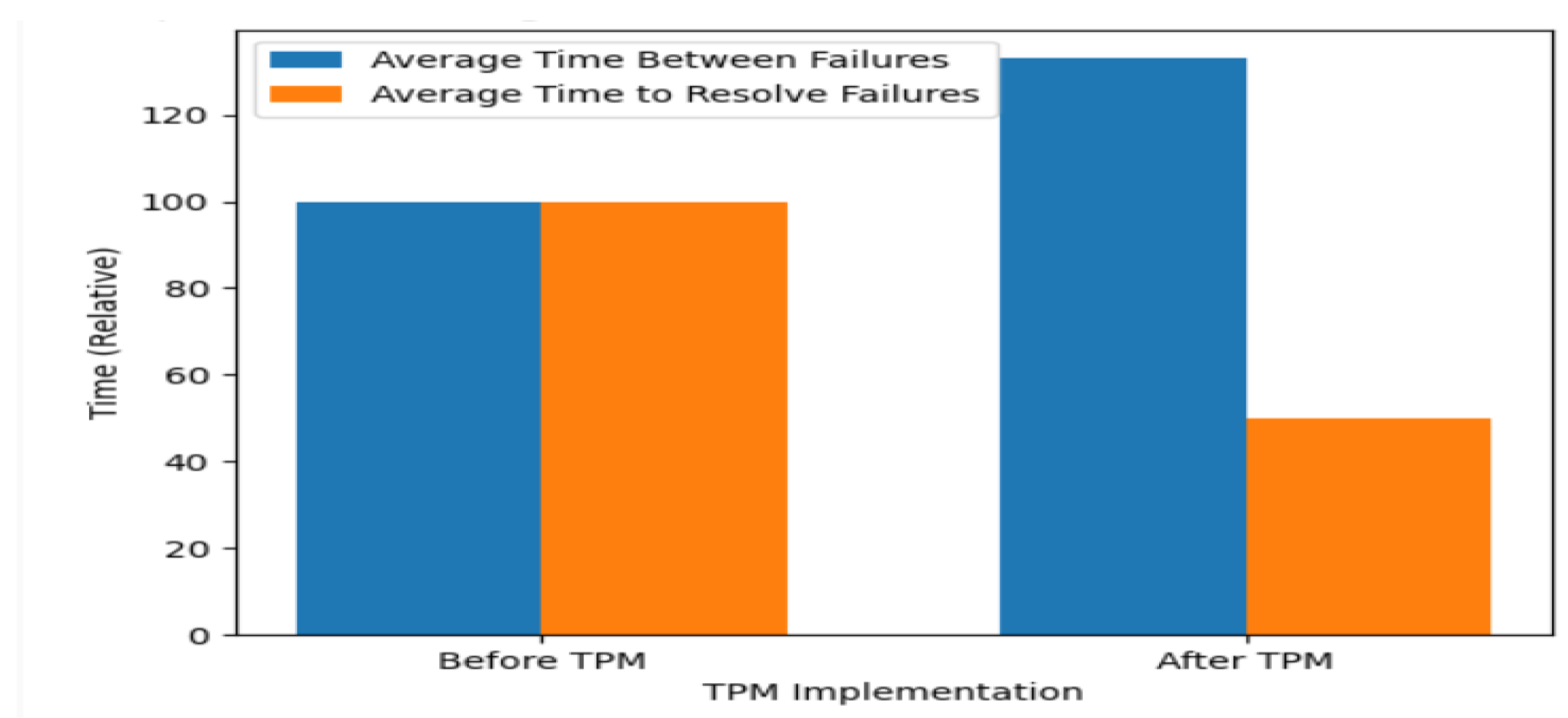

35]. In contrast, our study recorded a more substantial enhancement in equipment reliability, with the mean time between failures more than tripling.

Additionally, the same study employed Value Stream Mapping (VSM) and time studies to eliminate non-value-adding activities, resulting in a 57% increase in value-added time and a 14% rise in overall productivity. However, this improvement was accompanied by an increase in total production time—a divergence from the findings of our study, where productivity gains were achieved without extending operational hours.

Conversely, Galvez and Zamora conducted a Micro and Small Enterprise in the textile sector, employing tools such as 5S, standardized work, and Kaizen, resulting in a 27% increase in labor productivity and a 25% reduction in cycle time [

33]. While these outcomes represent a substantial improvement in workforce efficiency, the present study achieved complementary advancements, including a 50% reduction in failure response time and a 33% enhancement in machine reliability. These findings suggest that the integration of lean methodologies with Total Productive Maintenance (TPM) yields a more holistic impact, simultaneously enhancing personnel performance and equipment dependability.

Furthermore, Jiménez et al. (2021) reported a 20% increase in productivity following the implementation of 5S and preventive maintenance in a textile manufacturing context [

8]. This reinforces the consistency of the results observed in the present study, where the combined application of 5S and TPM similarly produced significant gains in operational efficiency and a marked reduction in equipment failures.

Taken together, the reviewed studies demonstrate that lean tools such as 5S, Kaizen, standardized work, VSM, and TPM can generate significant improvements in productivity and efficiency, especially when properly applied. However, while some approaches focused on the isolated application of these tools, the approach adopted in the present study allowed for the simultaneous addressing of multiple dimensions of operational performance: process efficiency, equipment reliability, resource utilization, and staff engagement.

An important contribution of this study is that it shows how the integration of lean tools with maintenance strategies can generate more robust and sustainable results than their isolated application. It also highlights the importance of key factors that are often underestimated in the literature, such as staff training, regular internal audits, and the existence of continuous feedback mechanisms. It is also emphasized that the success of methodologies such as 5S and TPM largely depends on the active commitment of workers.From a socioeconomic perspective, the improvements achieved in this case, such as the reduction of rework, more efficient use of resources, and the decrease in downtime, translate into significant savings, increased profitability, and improved company competitiveness. In turn, these advances may support the creation of more stable jobs and contribute to the economic development of the region.

6. Conclusions

This study presents a comprehensive analysis of productivity enhancement within a textile manufacturing context, emphasizing the integrated application of lean methodologies and maintenance strategies, including 5S, Total Productive Maintenance (TPM), and process standardization. By synthesizing these tools into a unified improvement framework, the study achieves demonstrable outcomes, highlighting substantial gains in operational efficiency, resource utilization, and overall productivity. The results not only advance practical implementation within the textile sector but also offer valuable contributions to the broader discipline of operations management, particularly in the context of Small and Medium-Sized Enterprises (SMEs).

The principal findings indicate that the pilot implementation of the proposed framework, conducted over a four-month period in a textile production environment, yielded quantifiable improvements across multiple operational dimensions. Notably, the Mean Time between Failures (MTFs) of machinery increased to more than three times its initial value, signifying a marked enhancement in equipment reliability. Concurrently, the Mean Time to Repair (MTR) was reduced by over 50%, underscoring the effectiveness of the TPM approach in minimizing downtime and accelerating response to equipment malfunctions.

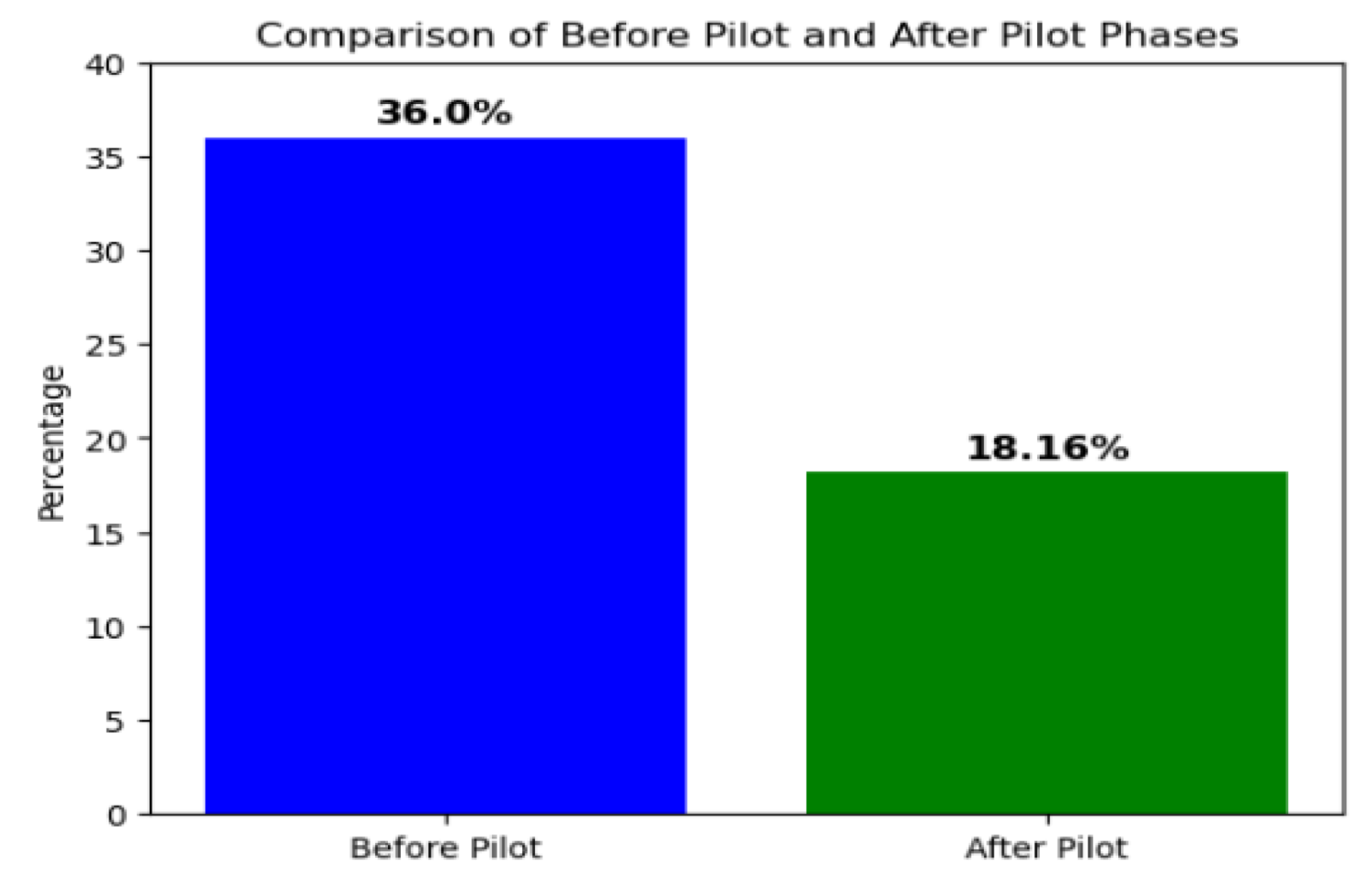

One of the most salient findings of the study was the marked reduction in the proportion of poles requiring reprocessing. Prior to the pilot implementation, 36% of the total production necessitated rework; this figure was reduced to 18.16% post-intervention. This improvement reflects a more efficient utilization of resources, as fewer units required corrective processing, thereby yielding time savings and enhancing resource allocation. The reduction in rework not only contributed to cost efficiency but also significantly bolstered overall production performance—an essential factor for sustaining competitiveness in the textile manufacturing sector.

Furthermore, the deployment of the 5S methodology across multiple operational zones, including the sewing area, led to a notable enhancement in workplace organization and cleanliness culture. The final 5S audit yielded a score of 18 out of 20, indicating substantial progress from the baseline condition. Although the ideal 5S state was not fully attained, the improvements observed signify a clear transition toward heightened organizational discipline, more effective resource management, and increased employee engagement in maintaining a clean and efficient work environment. The successful implementation of 5S was underpinned by periodic audits and targeted training sessions, which emphasized the importance of orderliness, cleanliness, and the continuous responsibility of personnel in sustaining these standards.

Process standardization also emerged as a critical factor in enhancing productivity. The implementation of technical sheets and standardized operating procedures for key stages—such as spinning, sewing, and finishing—ensured procedural consistency across the workforce. This uniformity led to a reduction in process variability, improved control over production activities, and a measurable increase in overall operational efficiency. The training sessions conducted during the standardization phase played a pivotal role in equipping employees with the requisite skills and knowledge to consistently apply the new procedures. This, in turn, contributed to the observed decline in reprocessing rates and the overall improvement in production output.

7. Limitations of the Study

While this study offers significant insights into the effectiveness of lean manufacturing practices, it was conducted within a specific contextual framework. The four-month duration of the pilot phase enabled the observation of short-term impacts, providing a valuable foundation for understanding the initial outcomes of the implemented interventions. Nevertheless, to more comprehensively assess the long-term sustainability of these improvements, future research is encouraged to incorporate extended monitoring periods.

Moreover, the study’s focus on a single textile manufacturing facility allowed for an in-depth case analysis and facilitated a detailed examination of context-specific factors. This approach enhanced the internal validity of the findings. However, comparative analyses across different sectors could further strengthen the generalizability of the results. Accordingly, future studies incorporating multiple case studies from diverse industrial settings may contribute to a broader and more nuanced understanding within the existing literature body.

Recommendations for Future Research

Future research should systematically investigate the integration of lean manufacturing practices with emerging digital technologies. Advanced tools such as Artificial Intelligence (AI), data analytics, and the Internet of Things (IoT) offer significant potential to enhance real-time monitoring, predictive maintenance, and resource optimization. Exploring how these technologies can augment the effectiveness of lean systems may yield critical insights into the digital transformation of operational excellence frameworks.

In addition, future studies should adopt a multidimensional approach by examining the broader organizational impacts of lean and maintenance strategies. Beyond productivity and equipment reliability, it is essential to assess their influence on product quality, employee engagement, and customer satisfaction. Such comprehensive evaluations would contribute to a more holistic understanding of how lean practices support organizational sustainability.

Finally, longitudinal research is needed to assess the long-term viability of lean and maintenance interventions. By tracking performance over extended periods, scholars can identify patterns of institutional learning, resistance, and adaptation. These insights are vital for developing evidence-based strategies that ensure the sustained momentum of continuous improvement initiatives, particularly in digitally evolving production environments.