Prioritizing Key Factors in Refrigerant Substitution for GHG Emission Reduction: An Integrated DEMATEL-ISM-MICMAC Approach

Abstract

1. Introduction

2. Literature Review

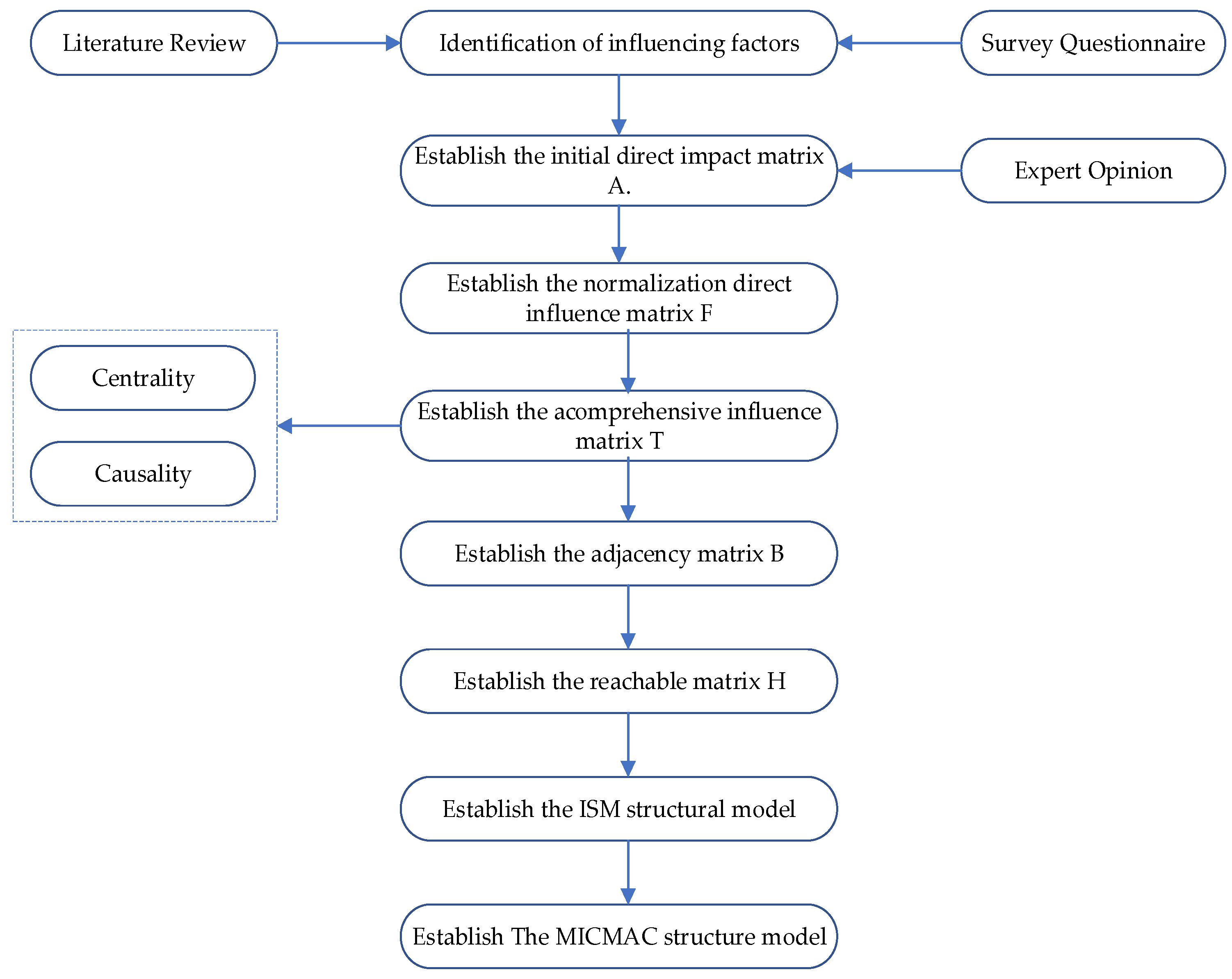

3. Research Method

4. Identification of Influencing Factors

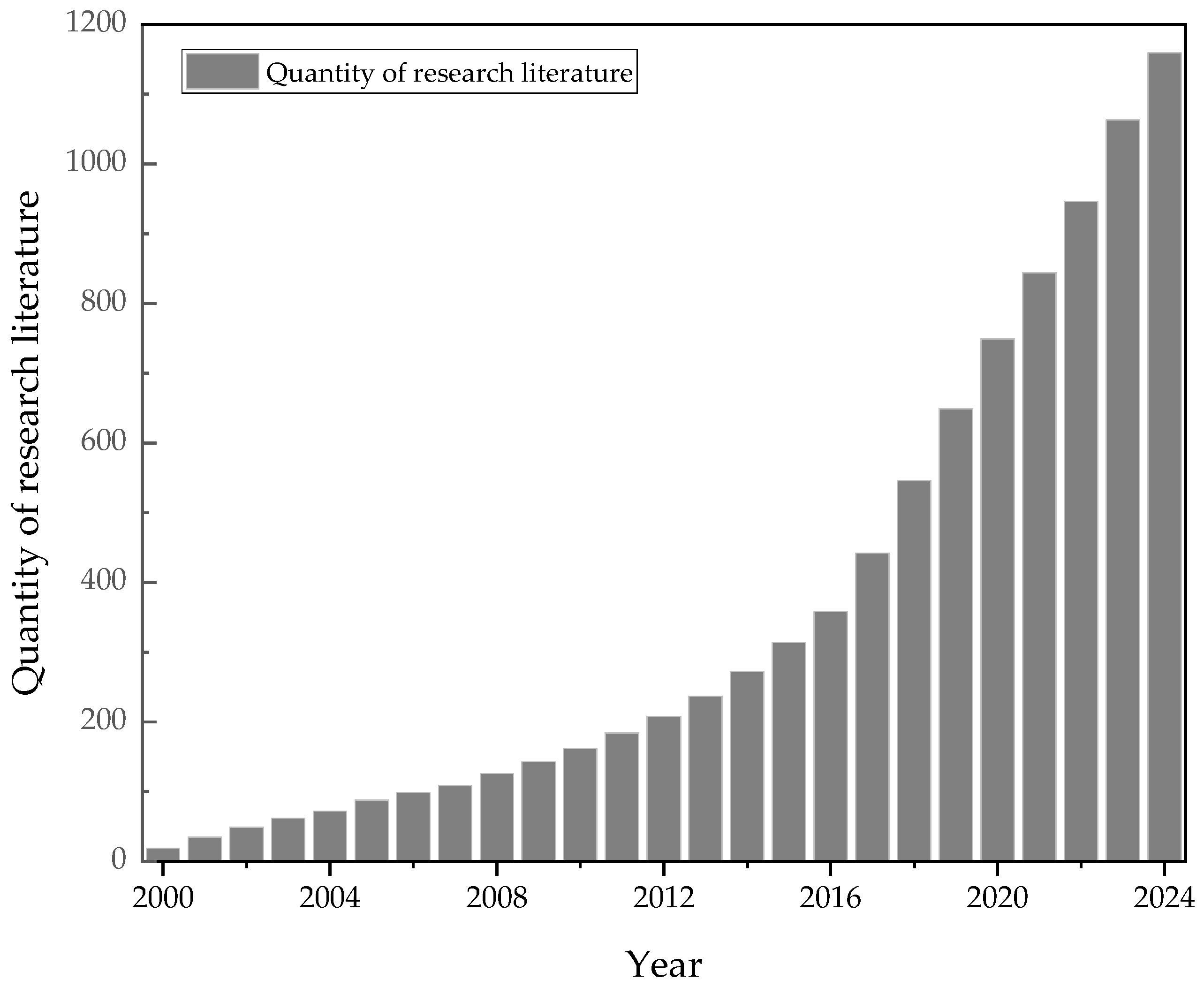

4.1. Comprehensive Collection and Analysis of Relevant Literature

4.2. Preliminary Screening of Influencing Factors for Refrigerant Substitution

4.3. Identification of Key Influencing Factors for Refrigerant Substitution

5. DEMATEL-ISM-MICMAC Model Construction

5.1. DEMATAL Model Construction

5.2. ISM Model Construction

5.3. MICMAC Model Construction

6. Analysis Results

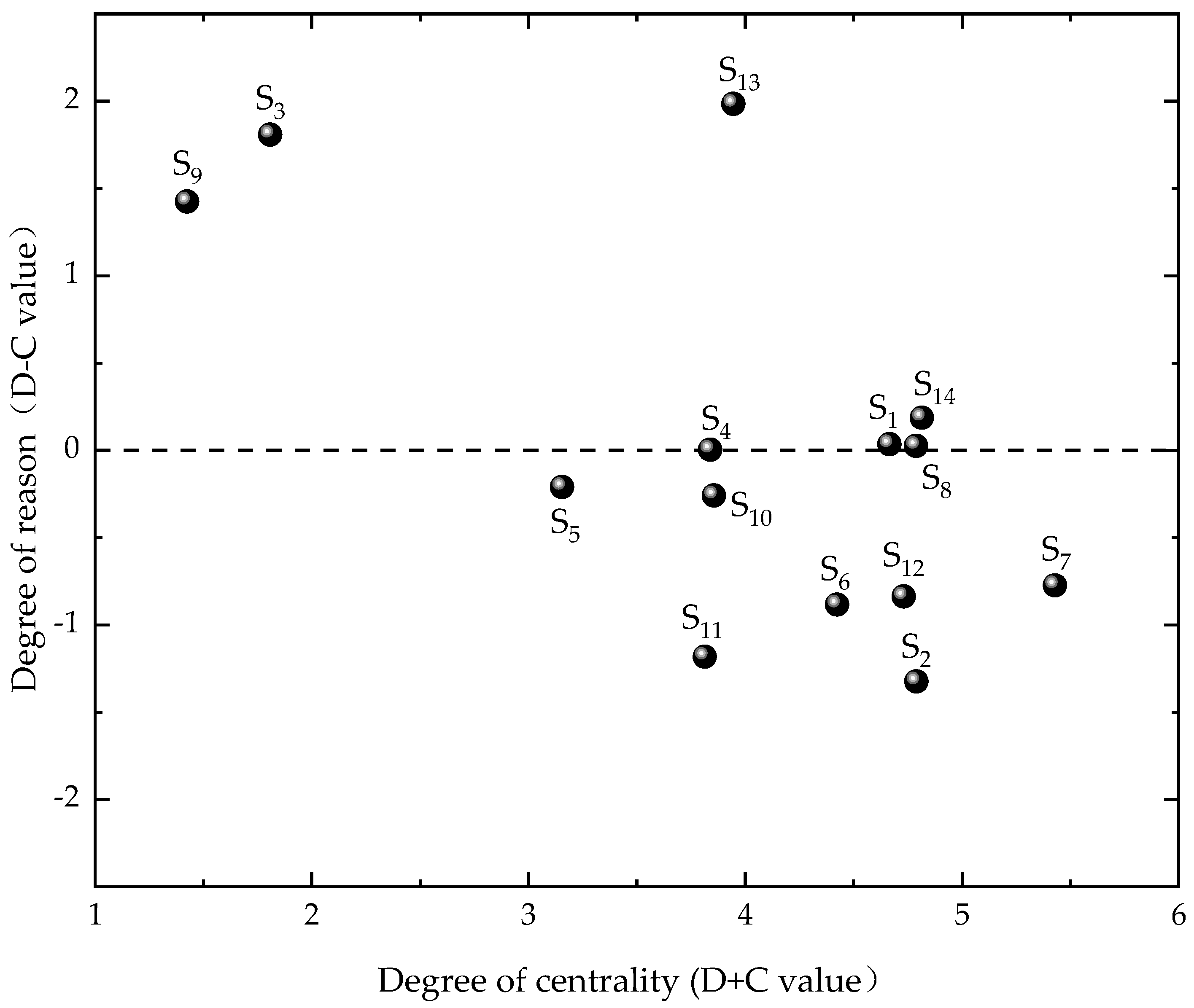

6.1. Analysis Utilizing the DEMATEL Method

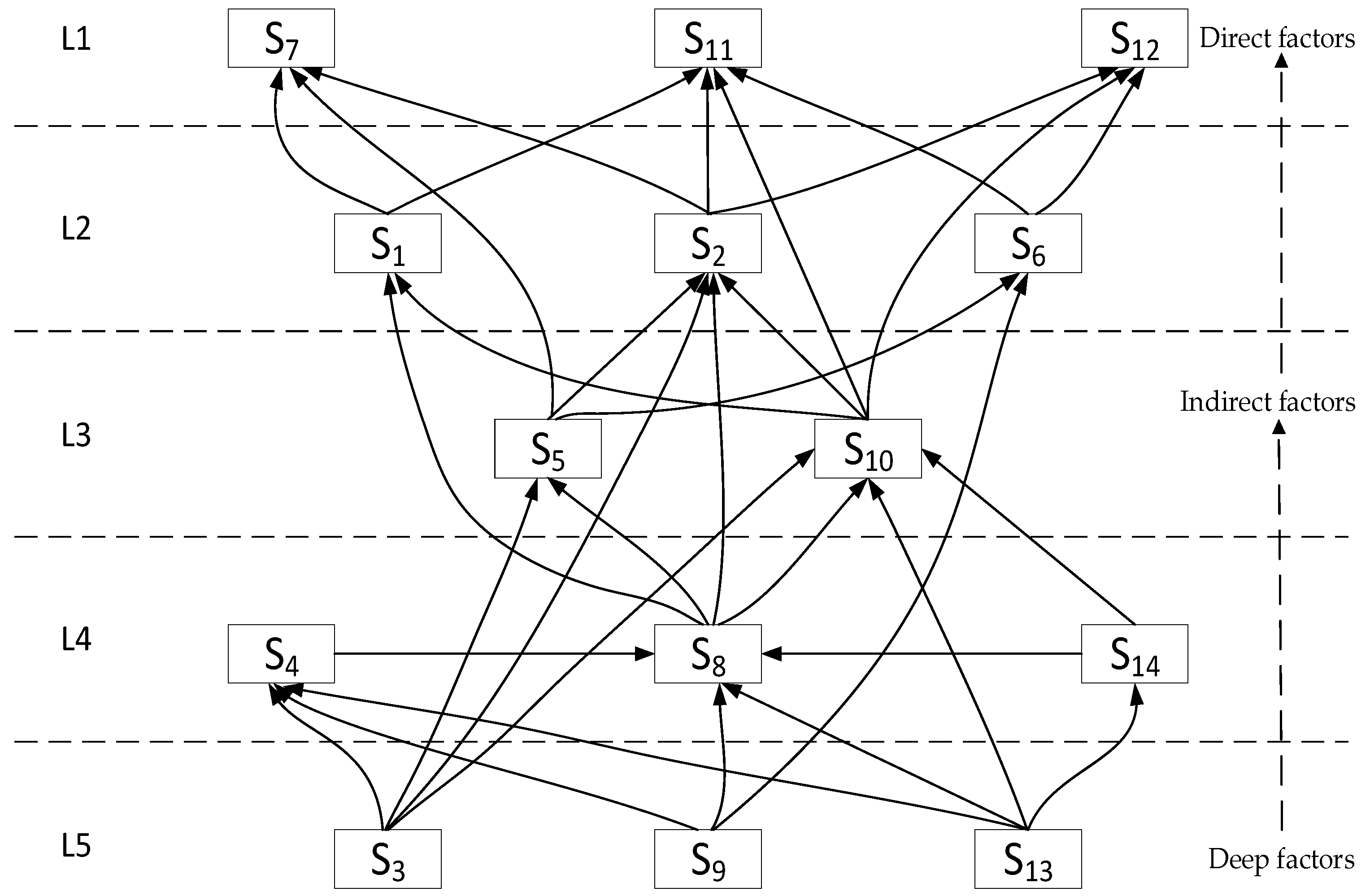

6.2. Analysis Utilizing the ISM Method

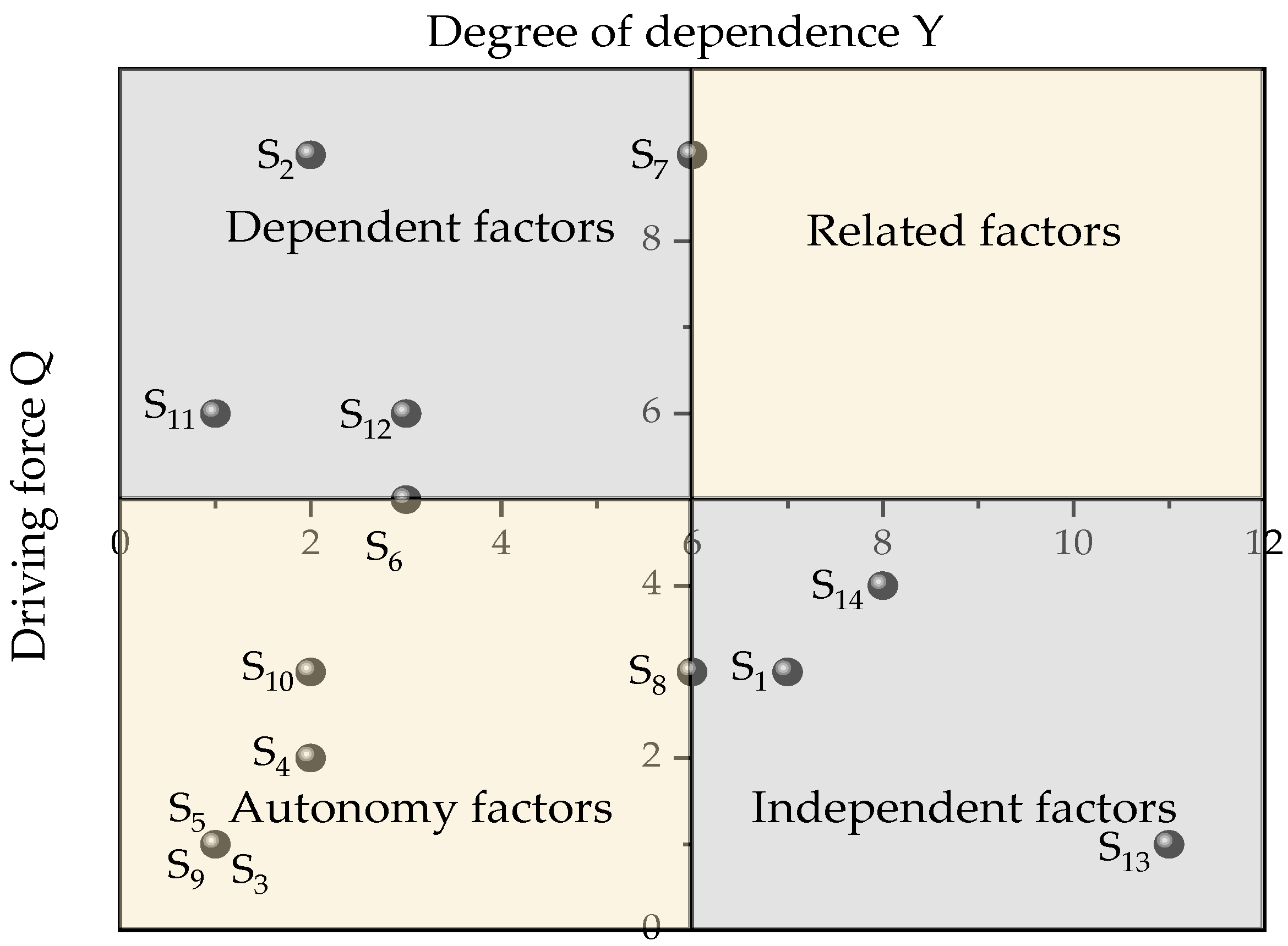

6.3. Analysis Utilizing the MICMAC Method

7. Discussion

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1

| S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 | S10 | S11 | S12 | S13 | S14 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 0.000 | 3.083 | 0.000 | 1.583 | 0.417 | 2.917 | 3.500 | 2.000 | 0.000 | 2.250 | 3.083 | 2.917 | 0.000 | 3.417 |

| S2 | 2.500 | 0.000 | 0.000 | 1.250 | 0.333 | 1.083 | 2.667 | 2.167 | 0.000 | 1.333 | 2.333 | 2.000 | 0.000 | 2.250 |

| S3 | 0.583 | 1.000 | 0.000 | 2.000 | 2.833 | 2.250 | 1.167 | 0.750 | 0.000 | 2.667 | 0.083 | 1.667 | 2.583 | 1.250 |

| S4 | 2.167 | 2.917 | 0.000 | 0.000 | 3.500 | 3.000 | 2.000 | 2.000 | 0.000 | 0.917 | 1.250 | 0.917 | 1.000 | 0.917 |

| S5 | 1.083 | 2.333 | 0.000 | 2.333 | 0.000 | 3.000 | 2.083 | 1.583 | 0.000 | 1.000 | 0.750 | 0.917 | 0.000 | 0.583 |

| S6 | 1.750 | 3.500 | 0.000 | 1.667 | 1.417 | 0.000 | 2.667 | 2.250 | 0.000 | 0.917 | 1.583 | 1.583 | 0.667 | 0.667 |

| S7 | 1.750 | 3.583 | 0.000 | 0.667 | 1.250 | 1.667 | 0.000 | 2.250 | 0.000 | 3.333 | 3.500 | 3.667 | 1.000 | 2.500 |

| S8 | 1.500 | 3.667 | 0.000 | 2.500 | 2.833 | 3.333 | 2.833 | 0.000 | 0.000 | 2.250 | 2.583 | 2.917 | 0.500 | 1.583 |

| S9 | 0.833 | 1.750 | 0.000 | 2.583 | 2.583 | 2.333 | 1.833 | 2.000 | 0.000 | 0.333 | 0.500 | 0.667 | 0.000 | 0.083 |

| S10 | 1.667 | 1.500 | 0.000 | 0.583 | 0.333 | 1.000 | 2.500 | 1.000 | 0.000 | 0.000 | 0.833 | 2.667 | 2.917 | 2.583 |

| S11 | 1.750 | 0.667 | 0.000 | 0.667 | 0.333 | 0.667 | 2.083 | 1.000 | 0.000 | 0.750 | 0.000 | 2.500 | 0.667 | 2.000 |

| S12 | 1.333 | 2.250 | 0.000 | 1.167 | 1.250 | 2.333 | 2.333 | 2.250 | 0.000 | 1.333 | 2.667 | 0.000 | 0.750 | 2.833 |

| S13 | 3.000 | 2.750 | 0.000 | 4.083 | 2.500 | 3.167 | 3.500 | 3.167 | 0.000 | 3.167 | 2.500 | 2.000 | 0.000 | 1.917 |

| S14 | 3.583 | 2.583 | 0.000 | 1.750 | 1.000 | 3.083 | 3.500 | 2.583 | 0.000 | 1.667 | 2.083 | 3.500 | 1.000 | 0.000 |

Appendix A.2

| S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 | S10 | S11 | S12 | S13 | S14 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 0.000 | 0.097 | 0.000 | 0.050 | 0.013 | 0.092 | 0.110 | 0.063 | 0.000 | 0.071 | 0.097 | 0.092 | 0.000 | 0.108 |

| S2 | 0.079 | 0.000 | 0.000 | 0.039 | 0.010 | 0.034 | 0.084 | 0.068 | 0.000 | 0.042 | 0.073 | 0.063 | 0.000 | 0.071 |

| S3 | 0.018 | 0.031 | 0.000 | 0.063 | 0.089 | 0.071 | 0.037 | 0.024 | 0.000 | 0.084 | 0.003 | 0.052 | 0.081 | 0.039 |

| S4 | 0.068 | 0.092 | 0.000 | 0.000 | 0.110 | 0.094 | 0.063 | 0.063 | 0.000 | 0.029 | 0.039 | 0.029 | 0.031 | 0.029 |

| S5 | 0.034 | 0.073 | 0.000 | 0.073 | 0.000 | 0.094 | 0.066 | 0.050 | 0.000 | 0.031 | 0.024 | 0.029 | 0.000 | 0.018 |

| S6 | 0.055 | 0.110 | 0.000 | 0.052 | 0.045 | 0.000 | 0.084 | 0.071 | 0.000 | 0.029 | 0.050 | 0.050 | 0.021 | 0.021 |

| S7 | 0.055 | 0.113 | 0.000 | 0.021 | 0.039 | 0.052 | 0.000 | 0.071 | 0.000 | 0.105 | 0.110 | 0.115 | 0.031 | 0.079 |

| S8 | 0.047 | 0.115 | 0.000 | 0.079 | 0.089 | 0.105 | 0.089 | 0.000 | 0.000 | 0.071 | 0.081 | 0.092 | 0.016 | 0.050 |

| S9 | 0.026 | 0.055 | 0.000 | 0.081 | 0.081 | 0.073 | 0.058 | 0.063 | 0.000 | 0.010 | 0.016 | 0.021 | 0.000 | 0.003 |

| S10 | 0.052 | 0.047 | 0.000 | 0.018 | 0.010 | 0.031 | 0.079 | 0.031 | 0.000 | 0.000 | 0.026 | 0.084 | 0.092 | 0.081 |

| S11 | 0.055 | 0.021 | 0.000 | 0.021 | 0.010 | 0.021 | 0.066 | 0.031 | 0.000 | 0.024 | 0.000 | 0.079 | 0.021 | 0.063 |

| S12 | 0.042 | 0.071 | 0.000 | 0.037 | 0.039 | 0.073 | 0.073 | 0.071 | 0.000 | 0.042 | 0.084 | 0.000 | 0.024 | 0.089 |

| S13 | 0.094 | 0.087 | 0.000 | 0.129 | 0.079 | 0.100 | 0.110 | 0.100 | 0.000 | 0.100 | 0.079 | 0.063 | 0.000 | 0.060 |

| S14 | 0.113 | 0.081 | 0.000 | 0.055 | 0.031 | 0.097 | 0.110 | 0.081 | 0.000 | 0.052 | 0.066 | 0.110 | 0.031 | 0.000 |

Appendix A.3

| S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 | S10 | S11 | S12 | S13 | S14 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 0.139 | 0.268 | 0.000 | 0.147 | 0.100 | 0.232 | 0.283 | 0.198 | 0.000 | 0.185 | 0.244 | 0.256 | 0.057 | 0.241 |

| S2 | 0.175 | 0.133 | 0.000 | 0.112 | 0.075 | 0.144 | 0.213 | 0.166 | 0.000 | 0.129 | 0.184 | 0.187 | 0.041 | 0.173 |

| S3 | 0.123 | 0.169 | 0.000 | 0.147 | 0.159 | 0.186 | 0.174 | 0.130 | 0.000 | 0.171 | 0.113 | 0.171 | 0.124 | 0.140 |

| S4 | 0.174 | 0.235 | 0.000 | 0.088 | 0.177 | 0.212 | 0.208 | 0.173 | 0.000 | 0.124 | 0.160 | 0.161 | 0.071 | 0.138 |

| S5 | 0.118 | 0.185 | 0.000 | 0.134 | 0.059 | 0.182 | 0.174 | 0.134 | 0.000 | 0.103 | 0.117 | 0.130 | 0.034 | 0.103 |

| S6 | 0.155 | 0.238 | 0.000 | 0.128 | 0.110 | 0.112 | 0.214 | 0.171 | 0.000 | 0.119 | 0.164 | 0.173 | 0.059 | 0.127 |

| S7 | 0.189 | 0.276 | 0.000 | 0.122 | 0.121 | 0.195 | 0.181 | 0.202 | 0.000 | 0.214 | 0.252 | 0.273 | 0.087 | 0.216 |

| S8 | 0.184 | 0.289 | 0.000 | 0.179 | 0.174 | 0.248 | 0.267 | 0.141 | 0.000 | 0.185 | 0.229 | 0.252 | 0.071 | 0.188 |

| S9 | 0.105 | 0.164 | 0.000 | 0.143 | 0.138 | 0.163 | 0.161 | 0.143 | 0.000 | 0.080 | 0.104 | 0.115 | 0.030 | 0.080 |

| S10 | 0.159 | 0.184 | 0.000 | 0.102 | 0.080 | 0.148 | 0.216 | 0.141 | 0.000 | 0.096 | 0.146 | 0.209 | 0.130 | 0.187 |

| S11 | 0.130 | 0.122 | 0.000 | 0.079 | 0.060 | 0.106 | 0.165 | 0.110 | 0.000 | 0.092 | 0.089 | 0.170 | 0.051 | 0.141 |

| S12 | 0.156 | 0.215 | 0.000 | 0.122 | 0.111 | 0.193 | 0.220 | 0.181 | 0.000 | 0.138 | 0.205 | 0.140 | 0.068 | 0.198 |

| S13 | 0.260 | 0.309 | 0.000 | 0.252 | 0.191 | 0.283 | 0.330 | 0.267 | 0.000 | 0.243 | 0.263 | 0.267 | 0.070 | 0.231 |

| S14 | 0.249 | 0.269 | 0.000 | 0.162 | 0.125 | 0.250 | 0.296 | 0.224 | 0.000 | 0.178 | 0.227 | 0.281 | 0.087 | 0.152 |

Appendix B

Appendix B.1

| S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 | S10 | S11 | S12 | S13 | S14 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 1.139 | 0.268 | 0.000 | 0.147 | 0.100 | 0.232 | 0.283 | 0.198 | 0.000 | 0.185 | 0.244 | 0.256 | 0.057 | 0.241 |

| S2 | 0.175 | 1.133 | 0.000 | 0.112 | 0.075 | 0.144 | 0.213 | 0.166 | 0.000 | 0.129 | 0.184 | 0.187 | 0.041 | 0.173 |

| S3 | 0.123 | 0.169 | 1.000 | 0.147 | 0.159 | 0.186 | 0.174 | 0.130 | 0.000 | 0.171 | 0.113 | 0.171 | 0.124 | 0.140 |

| S4 | 0.174 | 0.235 | 0.000 | 1.088 | 0.177 | 0.212 | 0.208 | 0.173 | 0.000 | 0.124 | 0.160 | 0.161 | 0.071 | 0.138 |

| S5 | 0.118 | 0.185 | 0.000 | 0.134 | 1.059 | 0.182 | 0.174 | 0.134 | 0.000 | 0.103 | 0.117 | 0.130 | 0.034 | 0.103 |

| S6 | 0.155 | 0.238 | 0.000 | 0.128 | 0.110 | 1.112 | 0.214 | 0.171 | 0.000 | 0.119 | 0.164 | 0.173 | 0.059 | 0.127 |

| S7 | 0.189 | 0.276 | 0.000 | 0.122 | 0.121 | 0.195 | 1.181 | 0.202 | 0.000 | 0.214 | 0.252 | 0.273 | 0.087 | 0.216 |

| S8 | 0.184 | 0.289 | 0.000 | 0.179 | 0.174 | 0.248 | 0.267 | 1.141 | 0.000 | 0.185 | 0.229 | 0.252 | 0.071 | 0.188 |

| S9 | 0.105 | 0.164 | 0.000 | 0.143 | 0.138 | 0.163 | 0.161 | 0.143 | 1.000 | 0.080 | 0.104 | 0.115 | 0.030 | 0.080 |

| S10 | 0.159 | 0.184 | 0.000 | 0.102 | 0.080 | 0.148 | 0.216 | 0.141 | 0.000 | 1.096 | 0.146 | 0.209 | 0.130 | 0.187 |

| S11 | 0.13 | 0.122 | 0.000 | 0.079 | 0.060 | 0.106 | 0.165 | 0.110 | 0.000 | 0.092 | 1.089 | 0.170 | 0.051 | 0.141 |

| S12 | 0.156 | 0.215 | 0.000 | 0.122 | 0.111 | 0.193 | 0.220 | 0.181 | 0.000 | 0.138 | 0.205 | 1.140 | 0.068 | 0.198 |

| S13 | 0.26 | 0.309 | 0.000 | 0.252 | 0.191 | 0.283 | 0.330 | 0.267 | 0.000 | 0.243 | 0.263 | 0.267 | 1.070 | 0.231 |

| S14 | 0.249 | 0.269 | 0.000 | 0.162 | 0.125 | 0.250 | 0.296 | 0.224 | 0.000 | 0.178 | 0.227 | 0.281 | 0.087 | 1.152 |

Appendix B.2

| Factor | S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 | S10 | S11 | S12 | S13 | S14 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 |

| S2 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 1 |

| S3 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 0 |

| S4 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 0 |

| S5 | 0 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S6 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 0 |

| S7 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 |

| S8 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 |

| S9 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 |

| S10 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 |

| S11 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 |

| S12 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 1 |

| S13 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 |

| S14 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 |

References

- Wu, J.; Liu, G.; Marson, A.; Fedele, A.; Scipioni, A.; Manzardo, A. Mitigating environmental burden of the refrigerated transportation sector: Carbon footprint comparisons of commonly used refrigeration systems and alternative cold storage systems. J. Clean. Prod. 2022, 372, 133514. [Google Scholar] [CrossRef]

- Wang, F.; You, T. Comparative Analysis on the Life Cycle Climate Performance of Ground Source Heat Pump Using Alternative Refrigerants. Case Stud. Therm. Eng. 2023, 42, 102761. [Google Scholar] [CrossRef]

- Xu, C.; Ma, H.; Yu, X. Comprehensive performance evaluation method of working fluids for high temperature heat pump based on multi-objective optimization. Appl. Therm. Eng. 2024, 247, 123102. [Google Scholar] [CrossRef]

- Sagia, Z.; Rakopoulos, C. Alternative refrigerants for the heat pump of a ground source heat pump system. Appl. Therm. Eng. 2016, 100, 768–774. [Google Scholar] [CrossRef]

- Cai, D.; Hao, Z.; Xu, H.; He, G. Research on flammability of R290/R134a, R600a/R134a and R600a/R290 refrigerant mixtures. Int. J. Refrig. 2022, 137, 137. [Google Scholar] [CrossRef]

- Paurine, A.; Maidment, G.G.; Rodway, M.; Yebiyo, M. Understanding the market need for skills in alternative refrigerants with low global warming potential in the EU region—A comprehensive survey on Refrigerant Emissions And Leakage (REAL) alternatives programme. Int. J. Refrig. 2021, 122, 11–20. [Google Scholar] [CrossRef]

- You, T.; Wang, F. Green ground source heat pump using various low-global-warming-potential refrigerants: Thermal imbalance and long-term performance. Renew. Energy 2023, 210, 159–173. [Google Scholar] [CrossRef]

- Li, Y.; Cui, Y.; Song, Z.; Zhao, X.; Li, J.; Shen, C. Eco-economic performance and application potential of a novel dual-source heat pump heating system. Energy 2023, 283, 128478. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, B.; Shi, W.; Li, X. Numerical Research on R32/R1234ze(E) Air Source Heat Pump under Variable Mass Concentration. Int. J. Refrig. 2017, 82, 1–10. [Google Scholar] [CrossRef]

- Sieres, J.; Ortega, I.; Cerdeira, F.; Alvarez, E. Drop-in performance of the low-GWP alternative refrigerants R452B and R454B in an R410A liquid-to-water heat pump. Appl. Therm. Eng. 2021, 182, 116049. [Google Scholar] [CrossRef]

- Nawaz, K.; Elatar, A.F.; Shen, B.; Baxter, V.D.; Abdelaziz, O.A. Hydrocarbons as natural refrigerants for heat pump water heating applications. In Proceedings of the 25th IIR International Congress of Refrigeration, Montréal, QC, Canada, 24–30 August 2019. [Google Scholar] [CrossRef]

- Alabdulkarem, A.; Eldeeb, R.; Hwang, H.; Aute, V.; Radermacher, R. Testing, simulation and soft-optimization of R410A low-GWP alternatives in heat pump system. Int. J. Refrig. 2015, 60, 106–117. [Google Scholar] [CrossRef]

- Roberts Mark, W. Finishing the job: The Montreal Protocol moves to phase down hydrofluorocarbons. Rev. Eur. 2017, 26, 220–230. [Google Scholar] [CrossRef]

- Kosmadakis, G.; Arpagaus, C.; Neofytou, P.; Bertsch, S. Techno-economic analysis of high-temperature heat pumps with low-global warming potential refrigerants for upgrading waste heat up to 150 °C. Energy Convers. Manag. 2020, 226, 113488. [Google Scholar] [CrossRef]

- Wang, R.; Yan, H.; Wu, D.; Jiang, J.; Dong, Y. High temperature heat pumps for industrial heating processes using water as refrigerant. Energy 2024, 313, 133847. [Google Scholar] [CrossRef]

- Kwon, H.; Park, J.; Koo, B. 4E analysis for a novel cryogenic hydrogen liquefaction process using various refrigerants: Energy, exergy, economic, and environment. J. Clean. Prod. 2024, 469, 14. [Google Scholar] [CrossRef]

- Hosseinnia, S.M.; Amiri, L.; Nesreddine, H.; Monney, D.; Poncet, S. Thermodynamic analysis of high temperature cascade heat pump with R718 (high stage) and six different low-GWP refrigerants (low stage). Case Stud. Therm. Eng. 2024, 53, 103812. [Google Scholar] [CrossRef]

- Duarte, W.M.; Paulino, T.F.; Pabon, J.J.G.; Sawalha, S.; Machado, L. Refrigerants selection for a direct expansion solar assisted heat pump for domestic hot water. Sol. Energy 2019, 184, 527–538. [Google Scholar] [CrossRef]

- Kong, X.; Zhang, Y.; Nie, J. A New Mixture Refrigerant for Space Heating Air Source Heat Pump: Theoretical Modelling and Performance Analysis. Appl. Sci. 2018, 8, 622. [Google Scholar] [CrossRef]

- Shen, B.; Nawaz, K.; Elatar, A.; Baxter, V.; Abdelaziz, O. R290 (propane) and R600a (isobutane) as natural refrigerants for residential heat pump water heaters. Appl. Therm. Eng. 2017, 127, 870–883. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, N.; Cai, L. Natural refrigerant matching optimization and characteristic analysis of two-stage Rankine cycle for LNG cold power generation process. Appl. Therm. Eng. 2025, 258, 124655. [Google Scholar] [CrossRef]

- Kim, B.; Lee, S.H.; Lee, D.; Kim, Y. Performance comparison of heat pumps using low global warming potential refrigerants with optimized heat exchanger designs. Appl. Therm. Eng. 2020, 171, 114990. [Google Scholar] [CrossRef]

- Nawaz, K.; Shen, B.; Elatar, A.; Baxter, V.; Abdelaziz, O. R1234yf and R1234ze(E) as low-GWP refrigerants for residential heat pump water heaters. Int. J. Refrig. 2017, 82, 348–365. [Google Scholar] [CrossRef]

- Chae, J.H.; Choi, J.M. Evaluation of the impacts of high stage refrigerant charge on cascade heat pump performance. Renew. Energy 2015, 79, 66–71. [Google Scholar] [CrossRef]

- Konrad, M.E.; Macdonald, B.D. Cold climate air source heat pumps: Industry progress and thermodynamic analysis of market-available residential units. Renew. Sustain. Energy Rev. 2023, 188, 113739. [Google Scholar] [CrossRef]

- Adamo, A.; Helena Martin, H.; Hoz, J.D.L.; Rubio, J.; Valero, J. Regulatory framework for the promotion of heat pumps in the European Union. Energy Rep. 2024, 12, 5909–5930. [Google Scholar] [CrossRef]

- Sanguri, K.; Ganguly, K.; Pandey, A. Modelling the barriers to low global warming potential refrigerants adoption in developing countries: A case of Indian refrigeration industry. J. Clean. Prod. 2021, 280, 124357. [Google Scholar] [CrossRef]

- Fu, X.; Yan, X.; Liu, Z. Coupling thermodynamics and economics of liquid CO2 energy storage system with refrigerant additives. Energy 2023, 284, 128642. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, S.; Nian, V.; Li, X.; Yuan, J. Life cycle cost-benefit analysis of refrigerant replacement based on experience from a supermarket project. Energy 2019, 187, 115918. [Google Scholar] [CrossRef]

- Devotta, S.; Asthana, S.; Joshi, R. Challenges in recovery and recycling of refrigerants from Indian refrigeration and air-conditioning service sector. Atmos. Environ. 2004, 38, 845–854. [Google Scholar] [CrossRef]

- Navarro-Esbrí, J.; Fernández-Moreno, A.; Mota-Babiloni, A. Modelling and evaluation of a high-temperature heat pump two-stage cascade with refrigerant mixtures as a fossil fuel boiler alternative for industry decarbonization. Energy 2022, 254, 124308. [Google Scholar] [CrossRef]

- Zhou, M.; Liu, H.; Peng, L.; Qin, Y.; Chen, D.; Zhang, L.; Mauzerall, D.L. Environmental benefits and household costs of clean heating options in northern China. Nat. Sustain. 2022, 5, 329–338. [Google Scholar] [CrossRef]

- Kulcar, B.; Goricanec, D.; Krope, J. Economy of replacing a refrigerant in a cooling system for preparing chilled water. Int. J. Refrig. 2010, 33, 989–994. [Google Scholar] [CrossRef]

- Dreepaul, R.K. A study of alternative refrigerants for the refrigeration and air conditioning sector in Mauritius. IOP Conf. Ser. Earth Environ. Sci. 2017, 93, 012054. [Google Scholar] [CrossRef]

- Alkhatib, I.I.; Albà, C.G.; Llovell, F.; Vega, L. Delicate balance between energy, exergy, cost and environmental impact in Finding sustainable cooling systems: Alternative refrigerants and advanced cycles. Appl. Therm. Eng. 2025, 262, 125316. [Google Scholar] [CrossRef]

- Saif, A.; Elhedhli, S. Cold supply chain design with environmental considerations: A simulation-optimization approach. Eur. J. Oper. Res. 2016, 251, 274–287. [Google Scholar] [CrossRef]

- Gao, E.; Zhang, Z.; Deng, Q.; Jing, H.; Wang, X.; Zhang, X. Techno-economic and Environmental Analysis of Low-GWP Alternative Refrigerants in Cold Storage Unit under Year-round Working Conditions. Int. J. Refrig. 2021, 134, 197–206. [Google Scholar] [CrossRef]

- Tassou, S.A.; Grace, I.N. Fault diagnosis and refrigerant leak detection in vapour compression refrigeration systems. Int. J. Refrig. 2005, 28, 680–688. [Google Scholar] [CrossRef]

- Valeria, P.; Giuseppe, E.; Frazzica, A. Analysis of the Potential of Solar-Assisted Heat Pumps: Technical, Market, and Social Acceptance Aspects. Solar RRL 2022, 6, 2200037. [Google Scholar] [CrossRef]

- Thakkar, J.J. Decision-Making Trial and Evaluation Laboratory (DEMATEL). In Multi-Criteria Decision Making; Springer: Berlin/Heidelberg, Germany, 2021; Volume 336. [Google Scholar] [CrossRef]

- Sushil. Interpreting the Interpretive Structural Model. Glob. J. Flex. Syst. Manag. 2012, 13, 87–106. [Google Scholar] [CrossRef]

- Villacorta, P.J.; Masegosa, A.D.; Castellanos, D.; Lamata, M.T. A new fuzzy linguistic approach to qualitative Cross Impact Analysis. Appl. Soft Comput. 2014, 24, 19–30. [Google Scholar] [CrossRef]

- Chauhan, A.; Singh, A.; Jharkharia, S. An interpretive structural modeling (ISM) and decision-making trail and evaluation laboratory (DEMATEL) method approach for the analysis of barriers of waste recycling in India. J. Air Waste Manag. Assoc. 2018, 68, 100–110. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Yang, Z.; Zhang, S.Y. Impact pathways of emerging ITs to mitigate supply chain vulnerability: A novel DEMATEL-ISM approach based on grounded theory. Expert. Syst. Appl. 2024, 239, 122398. [Google Scholar] [CrossRef]

- Kumar, D.; Mangla, S.; Gandhi, S. A combined approach using AHP and DEMATEL for evaluating success factors in implementation of green supply chain management in Indian manufacturing industries. Int. J. Logist. Res. Appl. 2016, 19, 537–561. [Google Scholar] [CrossRef]

- Zhu, C.; Zhu, N.; Zheng, S.; Zou, L.; Wang, X. Analyzing critical success factors for green supplier selection: A combined DEMATEL-ISM approach and convolutional neural network based consensus model. Appl. Soft Comput. 2025, 171, 112760. [Google Scholar] [CrossRef]

- Kumar, S.S.; Kumar, M.S.; Sunil, L.; Zahran, A. Mobile wallet inhibitors: Developing a comprehensive theory using an integrated mode. J. Retail. Consum. Serv. 2018, 45, 52–63. [Google Scholar] [CrossRef]

- Ebadi Torkayesh, A.; Hendiani, S.; Walther, G.; Venghaus, S. Fueling the future: Overcoming the barriers to market development of renewable fuels in Germany using a novel analytical approach. Eur. J. Oper. Res. 2024, 316, 1012–1033. [Google Scholar] [CrossRef]

- Vonglao, P. Application of fuzzy logic to improve the Likert scale to measure latent variables. Kasetsart J. Soc. Sci. 2017, 38, 337–344. [Google Scholar] [CrossRef]

- Sheykhan, S.; Boozary, P.; Ghorbantanhaei, H.; Behzadi, S.; Rahmani, F.; Rabiee, M. Creating a fuzzy DEMATEL-ISM-MICMAC -fuzzy BWM model for the organization’s sustainable competitive advantage, incorporating green marketing, social responsibility, brand equity and green brand image. Sustain. Futures 2024, 8, 100280. [Google Scholar] [CrossRef]

- Si, S.-L.; You, X.-Y.; Liu, H.-C.; Zhang, P. DEMATEL Technique: A Systematic Review of the State-of-the-Art Literature on Methodologies and Applications. Math. Probl. Eng. 2018, 2018, 1–33. [Google Scholar] [CrossRef]

- Han, W.; Sun, Y.; Xie, H.; Che, Z. Hesitant Fuzzy Linguistic Group DEMATEL Method with Multi-granular Evaluation Scales. Int. J. Fuzzy Syst. 2018, 20, 2187–2201. [Google Scholar] [CrossRef]

- Jadhav, J.R.; Mantha, S.S.; Rane, S.B. Development of framework for sustainable Lean implementation: An ISM approach. J. Ind. Eng. Int. 2014, 10, 72. [Google Scholar] [CrossRef]

- Sindhwani, R.; Malhotra, V. Modelling and analysis of agile manufacturing system by ISM and MICMAC analysis. Int. J. Syst. Assur. Eng. Manag. 2017, 8, 253–263. [Google Scholar] [CrossRef]

- Xie, J.H.; Tian, F.J.; Li, X.Y.; Chen, Y.Q.; Li, S.Y. A study on the influencing factors and related paths of farmer’s participation in food safety governance—Based on DEMATEL-ISM-MICMAC model. Sci. Rep. 2023, 13, 11372. [Google Scholar] [CrossRef] [PubMed]

- Bianco, D.; Godinho Filho, M.; Osiro, L.; Ganga, G.M.D.; Tortorella, G.L. The driving and dependence power between Lean leadership competencies: An integrated ISM/fuzzy MICMAC approach. Prod. Plan. Control. 2021, 34, 1037–1061. [Google Scholar] [CrossRef]

| Serial Numbers | Influencing Factors | Literature Sources |

|---|---|---|

| 1 | The level of market demand for refrigerants | [8,39] |

| 2 | Awareness of social environmental protection | [39] |

| 3 | Awareness of consumer health | [32] |

| 4 | Consumers’ willingness to adopt environmentally friendly refrigerants | [39] |

| 5 | Implement the government’s supportive policies for environmental protection of refrigerants | [6,9,10,21,25,34] |

| 6 | Greenhouse gas emissions from equipment utilizing environmentally friendly refrigerants | [1,2,29,38] |

| 7 | Refrigerants ozone depletion potential (ODP) | [19,34] |

| 8 | Refrigerant global warming potential (GWP) | [2,19,22,34,38] |

| 9 | Specific climatic conditions | [1,2,11,12,18,19,31] |

| 10 | Thermal characteristics of refrigerants | [2,3,4,9,10,18,31] |

| 11 | The market price of environmentally friendly refrigerants | [20,25,33,34] |

| 12 | The amount of refrigerant charged | [1,5,16,17,21] |

| 13 | The amount of refrigerant leakage | [2,37] |

| 14 | The flammability of refrigerants | [3,5,23,34] |

| 15 | The toxicity of refrigerants | [3,25,28,34] |

| 16 | The cost of equipment transformation for environmental protection and refrigerant replacement | [3,21,23,25,29,34] |

| 17 | Technological innovation in refrigerant substitution | [25] |

| 18 | The Stability of the Supply Chain for Environmentally Friendly Refrigerants | [35] |

| 19 | System Performance Evaluation of Equipment Utilizing Environmentally Friendly Refrigerants (COP) | [2,4,11,12,20,23,25] |

| 20 | Full Life-Cycle Cost Analysis of Equipment Using Environmentally Friendly Refrigerants | [29] |

| 21 | Optimization of Key Equipment Components Utilizing Environmentally Friendly Refrigerants | [10,20,22,23,25] |

| Serial Numbers | Influencing Factors | Mean Score |

|---|---|---|

| 1 | Refrigerant global warming potential (GWP) | 2.4 |

| 2 | Refrigerants ozone depletion potential (ODP) | 2.5 |

| 3 | The amount of refrigerant leakage | 2.7 |

| 4 | The amount of refrigerant charged | 2.7 |

| 5 | The flammability of refrigerants | 2.7 |

| 6 | Thermal characteristics of refrigerants | 2.7 |

| 7 | The toxicity of refrigerants | 2.8 |

| 8 | Implement the government’s supportive policies for environmental protection of refrigerants | 3.0 |

| 9 | Awareness of consumer health | 3.0 |

| 10 | Awareness of social environmental protection | 3.0 |

| 11 | The Stability of the Supply Chain for Environmentally Friendly Refrigerants | 3.1 |

| 12 | Consumers’ willingness to adopt environmentally friendly refrigerants | 3.1 |

| 13 | System Performance Evaluation of Equipment Utilizing Environmentally Friendly Refrigerants (COP) | 3.1 |

| 14 | Technological innovation in refrigerant substitution | 3.1 |

| 15 | Optimization of Key Equipment Components Utilizing Environmentally Friendly Refrigerants | 3.2 |

| 16 | The cost of equipment transformation for environmental protection and refrigerant replacement | 3.5 |

| 17 | Greenhouse gas emissions from equipment utilizing environmentally friendly refrigerants | 3.5 |

| 18 | System Performance Evaluation of Equipment Utilizing Environmentally Friendly Refrigerants (COP) | 3.6 |

| 19 | Full Life-Cycle Cost Analysis of Equipment Using Environmentally Friendly Refrigerants | 3.6 |

| 20 | The market price of environmentally friendly refrigerants | 3.6 |

| 21 | Specific climatic conditions | 3.6 |

| Serial Numbers | Influencing Factors | Instructions |

|---|---|---|

| S1 | The market price of environmentally friendly refrigerants | Market retail price of environmentally friendly refrigerants. |

| S2 | The level of market demand for refrigerants | The total refrigerant demand from potential buyers in the market and its intensity level. |

| S3 | Specific climatic conditions | General overview of the multi-year weather characteristics in the region where environmentally friendly refrigerant equipment is utilized. |

| S4 | Awareness of consumer health | The extent to which consumers prioritize their own health, along with the attitudes, beliefs, and actions they adopt to maintain and enhance it. |

| S5 | Awareness of social environmental protection | Individual and societal awareness and understanding of the critical importance of environmental protection. |

| S6 | Consumers’ willingness to adopt environmentally friendly refrigerants | The tendency or willingness of consumers to choose environmentally friendly refrigerants when purchasing and utilizing refrigeration equipment. |

| S7 | Technological innovation in refrigerant substitution | New technologies and methods have been developed, applied, and continuously improved to replace traditional refrigerants, such as HFCs, in the refrigeration and air conditioning industry. |

| S8 | Implement the government’s supportive policies for environmental protection of refrigerants | The government has implemented specific policies aimed at facilitating the replacement of refrigerants. |

| S9 | Greenhouse gas emissions from equipment utilizing environmentally friendly refrigerants | Greenhouse gas emissions, either directly or indirectly resulting from the use of environmentally friendly refrigerants in the operation of refrigeration equipment, encompass gases released during refrigerant leakage as well as those associated with equipment manufacturing, transportation, installation, maintenance, and disposal. |

| S10 | Optimization of Key Equipment Components Utilizing Environmentally Friendly Refrigerants | Improve or upgrade key components that directly influence the cooling performance and energy efficiency of equipment by utilizing environmentally friendly refrigerants, thereby enhancing the overall performance and efficiency of the equipment. |

| S11 | The Stability of the Supply Chain for Environmentally Friendly Refrigerants | All links in the supply chain can ensure stable and continuous operation when providing environmentally friendly refrigerants and are less susceptible to internal and external interference or changes. |

| S12 | The cost of equipment transformation for environmental protection and refrigerant replacement | The total cost of replacing conventional refrigerants (e.g., R22, R134a, etc.) with environmentally friendly alternatives (e.g., R410A, R32, R1234yf, etc.) in existing refrigeration and air conditioning systems includes several factors. Retrofit costs are influenced by the type and size of the equipment, the compatibility of existing systems, and the specific choice of environmentally friendly refrigerants. |

| S13 | Eco-friendly refrigerant system performance (COP) | The ratio of heat output by the equipment to the electricity consumed during operation when using environmentally friendly refrigerants is defined as the coefficient of performance (COP). A higher COP value indicates better energy efficiency of the refrigeration equipment. |

| S14 | Full Life-Cycle Cost Analysis of Equipment Using Environmentally Friendly Refrigerants | From equipment planning, design, manufacturing, procurement, installation, operation, maintenance, renovation, and updating to eventual scrapping, all related costs throughout the entire life-cycle should be considered. |

| Degree of Influence (D Value) | Degree of Affected (C Value) | Degree of Centrality (D + C Value) | Degree of Reason (D-C Value) | |

|---|---|---|---|---|

| S1 | 2.350 | 2.315 | 4.665 | 0.035 |

| S2 | 1.733 | 3.057 | 4.790 | −1.324 |

| S3 | 1.808 | 0.000 | 1.808 | 1.808 |

| S4 | 1.921 | 1.917 | 3.838 | 0.004 |

| S5 | 1.472 | 1.683 | 3.155 | −0.210 |

| S6 | 1.770 | 2.654 | 4.424 | −0.883 |

| S7 | 2.328 | 3.101 | 5.429 | −0.773 |

| S8 | 2.407 | 2.381 | 4.788 | 0.026 |

| S9 | 1.425 | 0.000 | 1.425 | 1.425 |

| S10 | 1.799 | 2.057 | 3.856 | −0.259 |

| S11 | 1.315 | 2.498 | 3.813 | −1.182 |

| S12 | 1.947 | 2.784 | 4.731 | −0.837 |

| S13 | 2.965 | 0.980 | 3.945 | 1.985 |

| S14 | 2.501 | 2.314 | 4.815 | 0.187 |

| Si | Reachable Set R (Si) | Antecedent Set A (Sj) | Intersection C (Si) |

|---|---|---|---|

| S1 | 1,2,4,6,7,8,10,11,12,14 | 1,2,4,6,7,8,10,12,13,14 | 1,2,4,6,7,8,10,12,14 |

| S2 | 1,2,6,7,8,11,12,14 | 1,2,3,4,5,6,7,8,9,10,12,13,14 | 1,2,6,7,8,12,14 |

| S3 | 2,3,4,5,6,7,10,12 | 3 | 3 |

| S4 | 1,2,4,5,6,7,8,11,12 | 1,3,4,8,9,13,14 | 8,1,4 |

| S5 | 2,5,6,7 | 3,4,5,8,13 | 5 |

| S6 | 1,2,6,7,8,11,12 | 1,2,3,4,5,6,7,8,9,10,12,13,14 | 1,2,6,7,8,12 |

| S7 | 1,2,6,7,8,10,11,12,14 | 1,2,3,4,5,6,7,8,9,10,11,12,13,14 | 1,2,6,7,8,10,11,12,14 |

| S8 | 1,2,4,5,6,7,8,10,11,12,14 | 1,2,4,6,7,8,9,12,13,14 | 1,2,4,6,7,8,12,14 |

| S9 | 2,4,6,7,8,9 | 9 | 9 |

| S10 | 1,2,6,7,10,11,12,14 | 1,3,7,8,10,13,14 | 1,10,14,7 |

| S11 | 7,11,12 | 1,2,4,6,7,8,10,11,12,13,14 | 11,12,7 |

| S12 | 1,2,6,7,8,11,12,14 | 1,2,3,4,6,7,8,10,11,12,13,14 | 1,2,6,7,8,11,12,14 |

| S13 | 1,2,4,5,6,7,8,10,11,12,13,14 | 13 | 13 |

| S14 | 1,2,4,6,7,8,10,11,12,14 | 1,2,7,8,10,12,13,14 | 1,2,7,8,10,12,14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Huang, S.; Li, L.; Ouyang, S. Prioritizing Key Factors in Refrigerant Substitution for GHG Emission Reduction: An Integrated DEMATEL-ISM-MICMAC Approach. Sustainability 2025, 17, 5155. https://doi.org/10.3390/su17115155

Zhang H, Huang S, Li L, Ouyang S. Prioritizing Key Factors in Refrigerant Substitution for GHG Emission Reduction: An Integrated DEMATEL-ISM-MICMAC Approach. Sustainability. 2025; 17(11):5155. https://doi.org/10.3390/su17115155

Chicago/Turabian StyleZhang, Hui, Shengzhong Huang, Longhui Li, and Shuang Ouyang. 2025. "Prioritizing Key Factors in Refrigerant Substitution for GHG Emission Reduction: An Integrated DEMATEL-ISM-MICMAC Approach" Sustainability 17, no. 11: 5155. https://doi.org/10.3390/su17115155

APA StyleZhang, H., Huang, S., Li, L., & Ouyang, S. (2025). Prioritizing Key Factors in Refrigerant Substitution for GHG Emission Reduction: An Integrated DEMATEL-ISM-MICMAC Approach. Sustainability, 17(11), 5155. https://doi.org/10.3390/su17115155