The Triple-Level Proposal of the Circular Economy: Circular Performance, Case Studies and a Design Workshop

Abstract

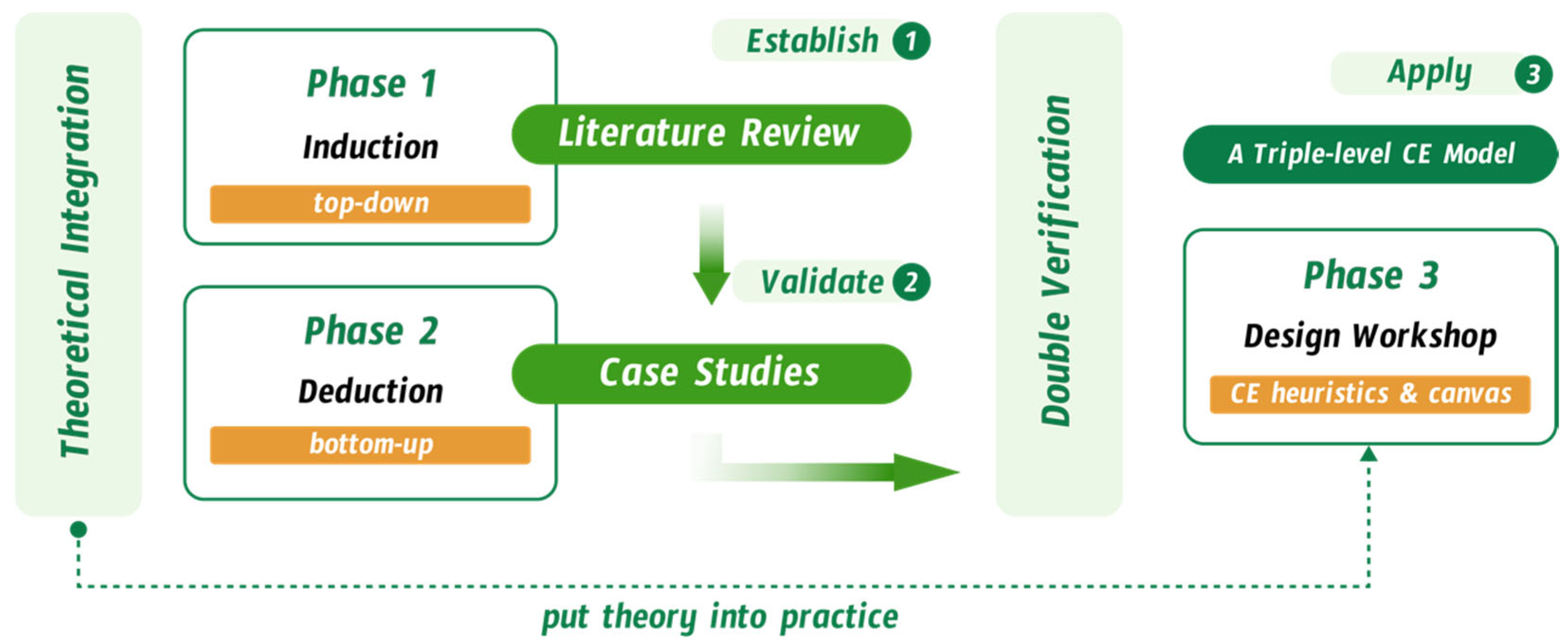

:1. Introduction

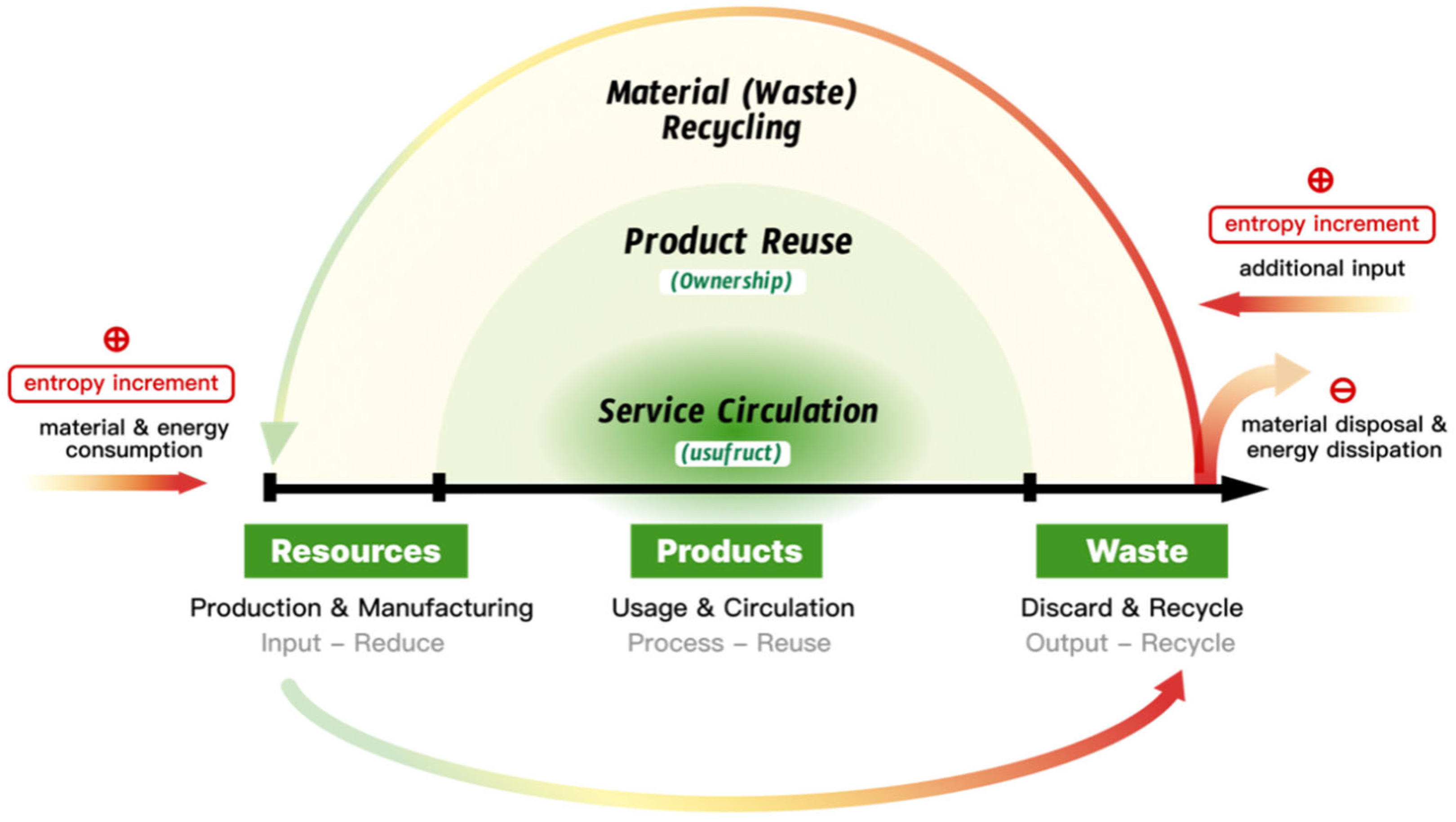

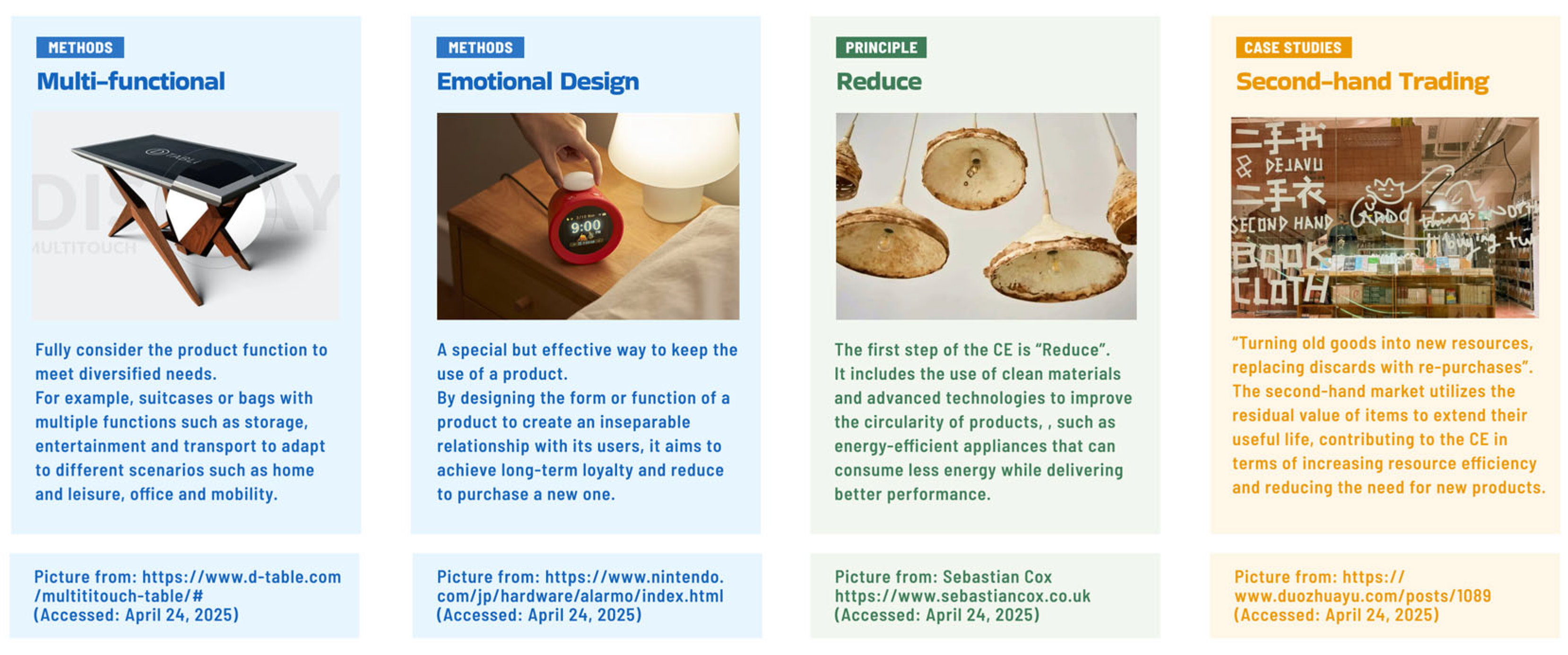

2. The Triple-Level Proposal of the CE

2.1. The Basic Level: Material Recycling to Reduce Consumption

2.2. The Intermediate Level: Product Reuse to Extend Lifecycle

2.3. The Superior Level: Service Circulation to Enhance the Utilization Intensity

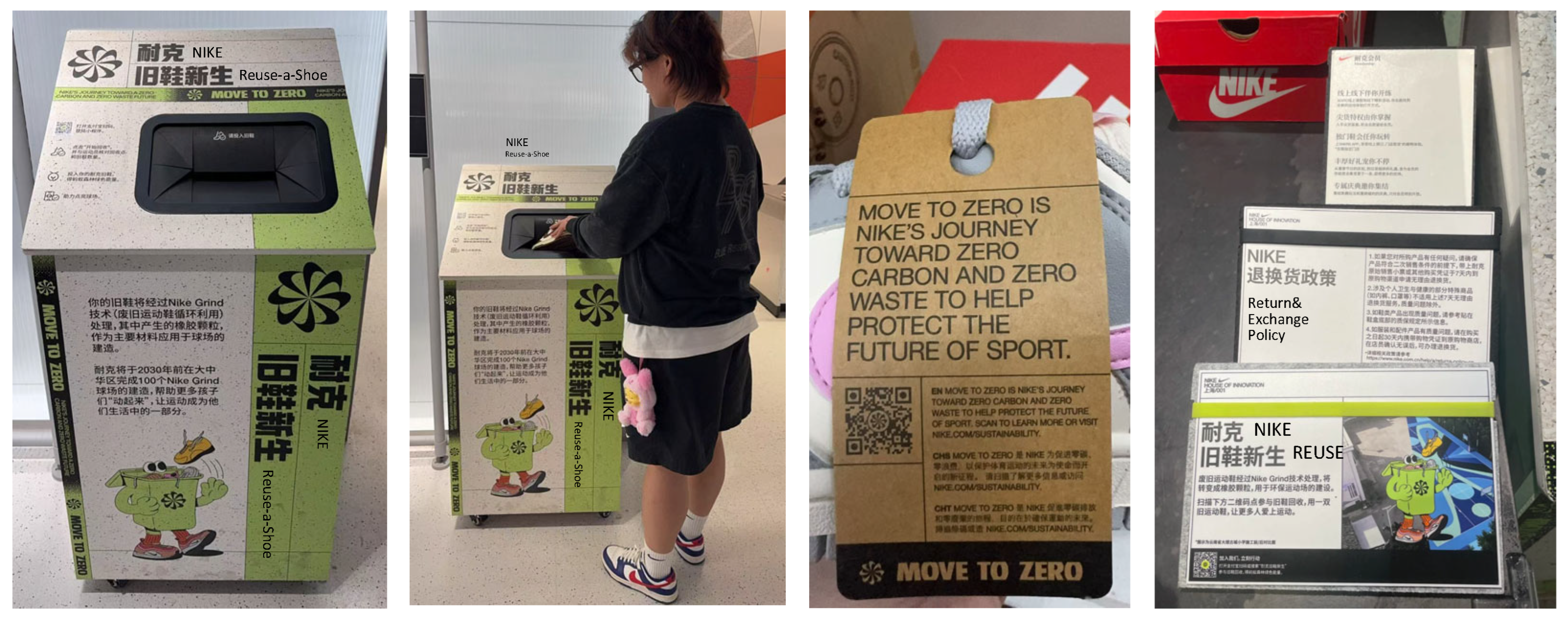

3. Case Studies

3.1. Material Recycling

3.2. Product Reuse

3.3. Service Circulation

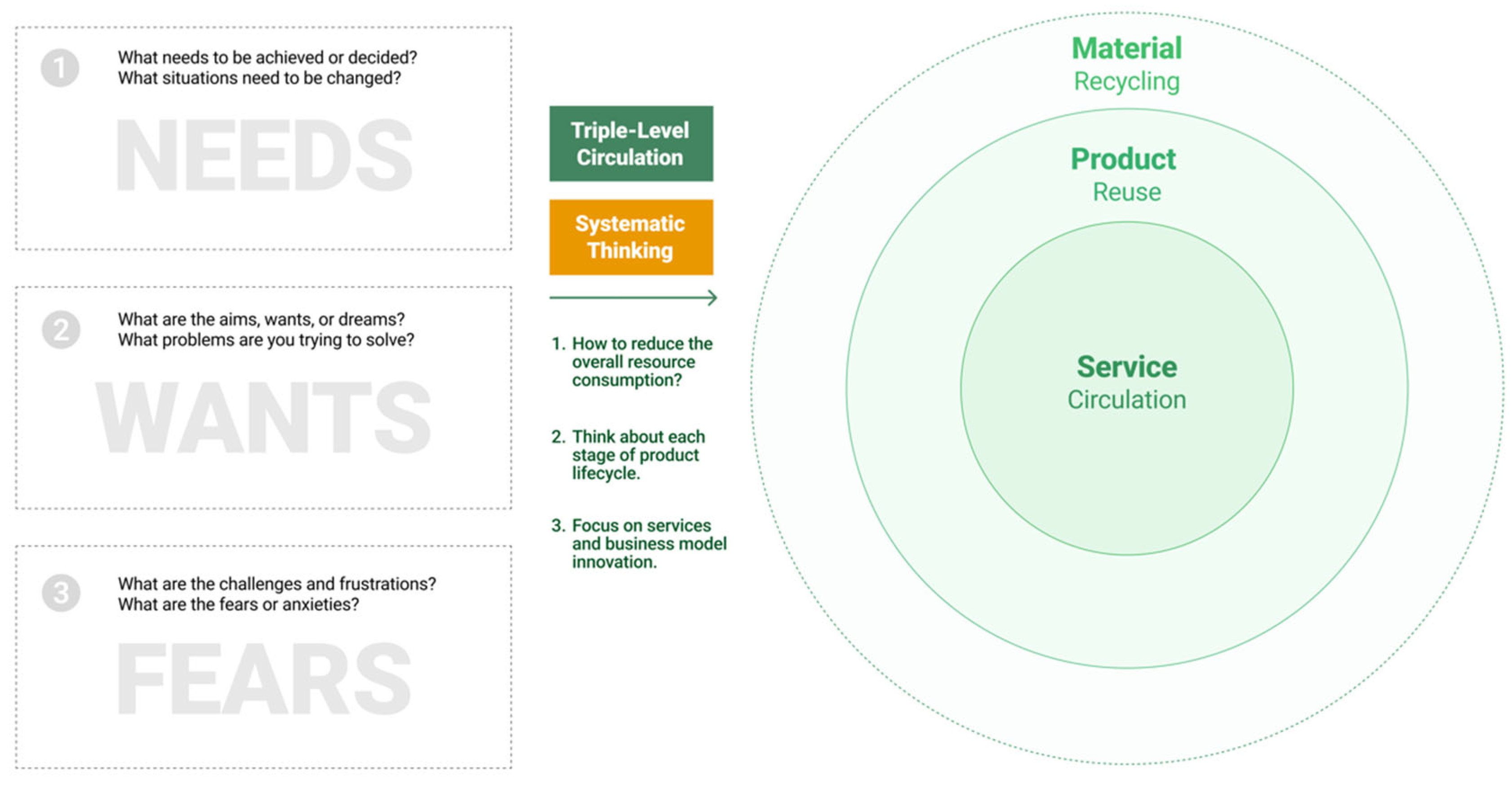

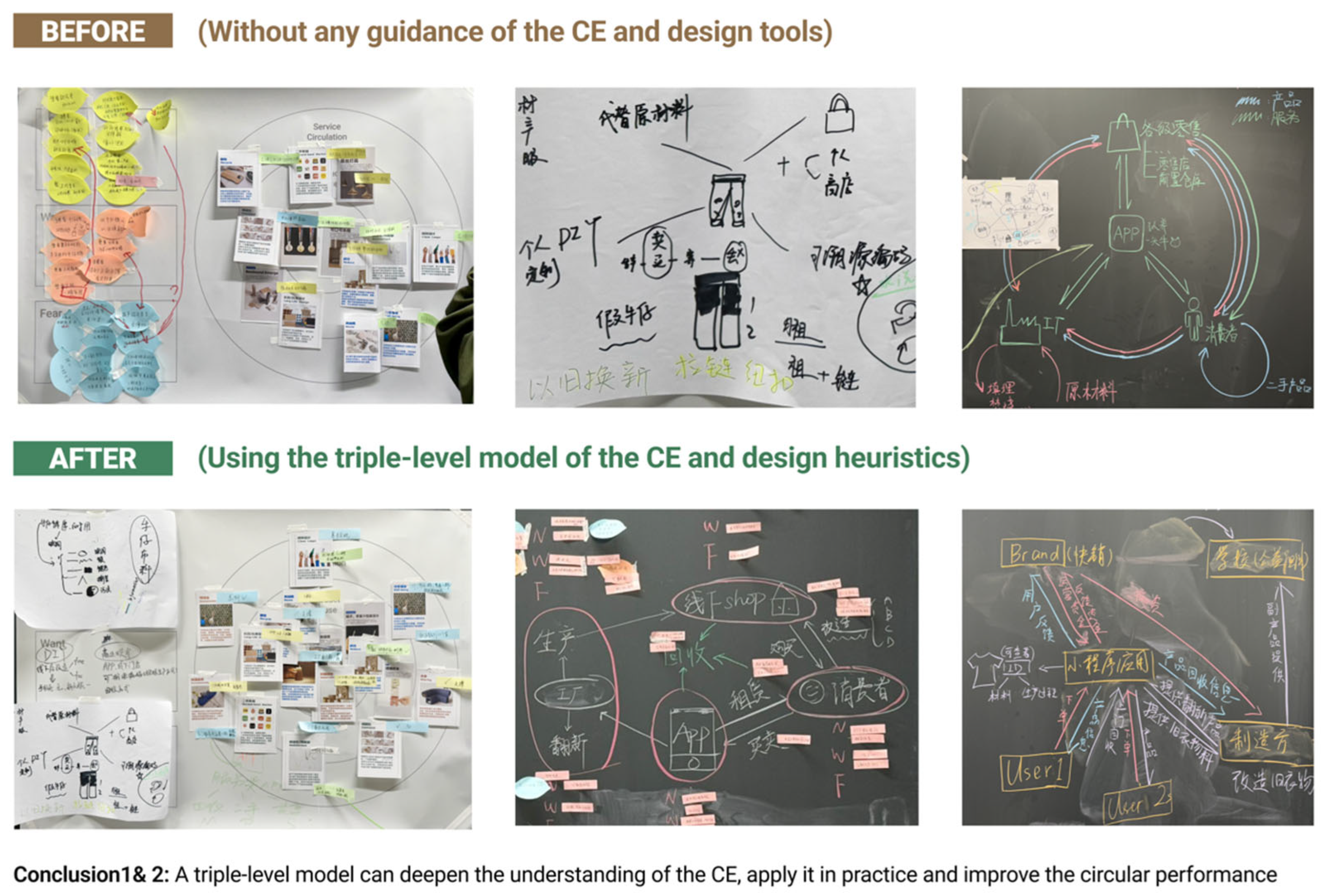

4. Design Workshop for the Triple-Level Proposal

5. Discussions and Policy Recommendations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CE | Circular Economy |

References

- United Nations Environment Programme. Global Resources Outlook 2024: Bend the Trend—Pathways to a Liveable Planet as Resource Use Spikes (R); International Resource Panel: Nairobi, Kenya, 2024; Available online: https://www.resourcepanel.org/reports/global-resources-outlook-2024 (accessed on 19 April 2025).

- Franzo, S.; Urbinati, A.; Chiaroni, D.; Chiesa, V. Unravelling the Design Process of Business Models from Linear to Circular: An Empirical Investigation. Bus. Strateg. Environ. 2021, 30, 2758–2772. [Google Scholar] [CrossRef]

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. Business Model Innovation for Circular Economy and Sustainability: A Review of Approaches. J. Clean Prod. 2019, 215, 198–216. [Google Scholar] [CrossRef]

- Magnano, D.G.; Grimstad, S.M.F.; Glavee-Geo, R.; Anwar, F. Disentangling Circular Economy Practices and Firm’s Sustainability Performance: A Systematic Literature Review of Past Achievements and Future Promises. J. Environ. Manag. 2024, 353, 120138. [Google Scholar] [CrossRef] [PubMed]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and Its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Kimpimaki, J.P.; Ritala, P.; Konietzko, J. How Circular Are Large Corporations? Evidence from a Large-Scale Survey with Senior Leaders. Resour. Conserv. Recycl. 2025, 215, 108151. [Google Scholar] [CrossRef]

- Donaghy, K.P.A. Circular Economy Model of Economic Growth with Circular and Cumulative Causation and Trade. Net-Work. Spat. Econ. 2022, 22, 461–488. [Google Scholar] [CrossRef]

- Prieto-Sandoval, V.; Jaca, C.; Ormazabal, M. Towards a Consensus on the Circular Economy. J. Clean. Prod. 2018, 179, 605–615. [Google Scholar] [CrossRef]

- Simamindra, R.S.; Rajaonarivo, L. A Global Analysis of Circular Economy Initiatives: Weak or Strong Sustainability? J. Clean Prod. 2024, 467, 142830. [Google Scholar] [CrossRef]

- Buch-Hansen, H. Capitalist Diversity and De-Growth Trajectories to Steady-State Economies. Ecol. Econ. 2014, 106, 167–173. [Google Scholar] [CrossRef]

- Stahel, W.R. The Circular Economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef]

- Wuwung, L.; Croft, F.; Benzaken, D.; Azmi, K.; Goodman, C.; Rambourg, C.; Voyer, M. Global Blue Economy Governance—A Methodological Approach to Investigating Blue Economy Implementation. Front. Mar. Sci. 2022, 9, 1043881. [Google Scholar] [CrossRef]

- Giller, K.E.; Hijbeek, R.; Andersson, J.A.; Sumberg, J. Regenerative Agriculture: An Agronomic Perspective. Outlook Agric. 2021, 50, 13–25. [Google Scholar] [CrossRef] [PubMed]

- Ralph, N. A Conceptual Merging of Circular Economy, Degrowth and Conviviality Design Approaches Applied to Renewable Energy Technology. J. Clean. Prod. 2021, 319, 128549. [Google Scholar] [CrossRef]

- Hoang, K.-M.; Böckel, A. Cradle-to-Cradle Business Model Tool: Innovating Circular Business Models for Startups. J. Clean. Prod. 2024, 467, 142949. [Google Scholar] [CrossRef]

- Velenturf, A.P.M.; Archer, S.A.; Gomes, H.I.; Christgen, B.; Lag-Brotons, A.J.; Purnell, P. Circular Economy and the Matter of Integrated Resources. Sci. Total Environ. 2019, 689, 963–969. [Google Scholar] [CrossRef]

- Howard, K. TU Delft Library. In Encyclopedia of Libraries, Librarianship, and Information Science, 1st ed.; Baker, D., Ellis, L., Eds.; Academic Press: Oxford, UK, 2025; pp. 256–261. [Google Scholar] [CrossRef]

- Lin, Q.; Zhang, K.; Giguet- Covex, C.; Arnaud, F.; McGowan, S.; Gielly, L.; Capo, E.; Huang, S.; Ficetola, G.F.; Shen, J.; et al. Transient Social-Ecological Dynamics Reveal Signals of Decoupling in a Highly Disturbed Anthropocene Landscape. Proc. Natl. Acad. Sci. USA 2024, 121, e2321303121. [Google Scholar] [CrossRef]

- Baratsas, S.G.; Pistikopoulos, E.N.; Avraamidou, S. A Quantitative and Holistic Circular Economy Assessment Frame-work at the Micro Level. Comput. Chem. Eng. 2022, 160, 107697. [Google Scholar] [CrossRef]

- Drofenik, J.; Seljak, T.; Novak Pintarič, Z. A Multi-Level Approach to Circular Economy Progress: Linking National Targets with Corporate Implementation. J. Clean. Prod. 2025, 493, 144902. [Google Scholar] [CrossRef]

- Feng, J.; Liu, W.; Chen, F. Moving towards a Circular Economy: A Systematic Review of Barriers to Electric Vehicle Battery Recycling. Sustain. Prod. Consum. 2025, 54, 241–260. [Google Scholar] [CrossRef]

- D’Urzo, M.; Campagnaro, C. Design-Led Repair & Reuse: An Approach for an Equitable, Bottom-up, Innovation-Driven Circular Economy. J. Clean. Prod. 2023, 387, 135724. [Google Scholar] [CrossRef]

- Metic, J.; Guzzo, D.; Kopainsky, B.; McAloone, T.C.; Pigosso, D.C.A. A Simulation-Based Approach for Investigating the Dynamics of Rebound Effects in the Circular Economy: A Case of Use-Oriented Product/Service System. J. Environ. Manag. 2024, 365, 121627. [Google Scholar] [CrossRef] [PubMed]

- Stahel, W. The Performance Economy, 2nd ed.; Palgrave Macmillan: London, UK, 2010. [Google Scholar] [CrossRef]

- Chen, H.; Yang, Y.; Dong, Z. The Effect of Product Design on Recycling Efficiency of Lithium-Ion Batteries through Structural Equation Modeling and Life Cycle Assessment. Sci. Rep. 2025, 15, 12352. [Google Scholar] [CrossRef]

- Minoja, M.; Romano, G. Effective Stakeholder Governance in Circular Economy: Insights from Italian Companies. J. Clean. Prod. 2024, 474, 143584. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Pieroni, M.P.P.; Pigosso, D.C.A.; Soufani, K. Circular Business Models: A Review. J. Clean. Prod. 2020, 277, 123741. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product Design and Business Model Strategies for a Circular Economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Stahel, W.R. Product of Life Factor. 1982. Available online: https://www.mendeley.com/catalogue/97a964ef-fd74-3324-b6c4-753e67af51b7/ (accessed on 19 April 2025).

- Yan, X. Research on the Action Mechanism of Circular Economy Development and Green Finance Based on Entropy Method and Big Data. J. Enterp. Inf. Manag. 2021, 35, 988–1010. [Google Scholar] [CrossRef]

- Agliardi, E.; Kasioumi, M. Closing the Loop in a Duopolistic Circular Economy Model. Int. J. Prod. Econ. 2023, 262, 108927. [Google Scholar] [CrossRef]

- Salehi, N.; Amir, S.; Roci, M.; Shoaib-ul-Hasan, S.; Asif, F.M.A.; Mihelič, A.; Sweet, S.; Rashid, A. Towards Circular Manufacturing Systems Implementation: An Integrated Analysis Framework for Circular Supply Chains. Sustain. Prod. Consum. 2024, 51, 169–198. [Google Scholar] [CrossRef]

- Robaina, M.; Murillo, K.; Rocha, E.; Villar, J. Circular Economy in Plastic Waste—Efficiency Analysis of European Countries. Sci. Total Environ. 2020, 730, 139038. [Google Scholar] [CrossRef]

- Schmidt, S.; Laner, D.; Van Eygen, E.; Stanisavljevic, N. Material Efficiency to Measure the Environmental Performance of Waste Management Systems: A Case Study on PET Bottle Recycling in Austria, Germany and Serbia. Waste Manag. 2020, 110, 74–86. [Google Scholar] [CrossRef]

- Arun, M.; Barik, D.; Chandran, S.S.R. Exploration of Material Recovery Framework from Waste—A Revolutionary Move towards Clean Environment. Chem. Eng. J. Adv. 2024, 18, 100589. [Google Scholar] [CrossRef]

- Velenturf, A.P.M.; Purnell, P. Principles for a Sustainable Circular Economy. Sustain. Prod. Consum. 2021, 27, 1437–1457. [Google Scholar] [CrossRef]

- Nudurupati, S.S.; Budhwar, P.; Pappu, R.P.; Chowdhury, S.; Kondala, M.; Chakraborty, A.; Ghosh, S.K. Transforming Sustainability of Indian Small and Medium-Sized Enterprises through Circular Economy Adoption. J. Bus. Res. 2022, 149, 250–269. [Google Scholar] [CrossRef]

- Okumura, S. Reuse-Efficiency Model for Evaluating Circularity of End-of-Life Products. Comput. Ind. Eng. 2022, 171, 108232. [Google Scholar] [CrossRef]

- Konietzko, J.; Baldassarre, B.; Brown, P.; Bocken, N.; Hultink, E.J. Circular Business Model Experimentation: Demystifying Assumptions. J. Clean. Prod. 2020, 277, 122596. [Google Scholar] [CrossRef]

- Fadeyi, J.A.; Monplaisir, L. Instilling Lifecycle Costs into Modular Product Development for Improved Remanufacturing-Product Service System Enterprise. Int. J. Prod. Econ. 2022, 246, 108404. [Google Scholar] [CrossRef]

- Aguiar, M.F.; Mesa, J.A.; Jugend, D.; Pinheiro, M.A.P.; Fiorini, P.D.C. Circular Product Design: Strategies, Challenges and Relationships with New Product Development. Manag. Environ. Qual. Int. J. 2022, 33, 300–329. [Google Scholar] [CrossRef]

- van Loon, P.; Diener, D.; Harris, S. Circular Products and Business Models and Environmental Impact Reductions: Current Knowledge and Knowledge Gaps. J. Clean. Prod. 2021, 288, 125627. [Google Scholar] [CrossRef]

- Cappelletti, F.; Rossi, M.; Germani, M. How De-Manufacturing Supports Circular Economy Linking Design and EoL- a Literture Review. J. Manuf. Syst. 2022, 63, 118–133. [Google Scholar] [CrossRef]

- Linder, M.; Williander, M. Circular Business Model Innovation: Inherent Uncertainties. Bus. Strategy Environ. 2017, 26, 182–196. [Google Scholar] [CrossRef]

- Hina, M.; Chauhan, C.; Sharma, R.; Dhir, A. Circular Economy Business Models as Pillars of Sustainability: Where Are We Now, and Where Are We Heading? Bus. Strategy Environ. 2023, 32, 6182–6209. [Google Scholar] [CrossRef]

- Geyer, R.; Kuczenski, B.; Zink, T.; Henderson, A. Common Misconceptions about Recycling. J. Ind. Ecol. 2016, 20, 1010–1017. [Google Scholar] [CrossRef]

- Genc, T.S.A. Circular Economy with Tax Policy: Using Collection Channels and Returns to Mitigate Distortions in Steel Production and Recycling. J. Clean. Prod. 2024, 451, 142120. [Google Scholar] [CrossRef]

- Group, F.O.C. Encina and BASF Establish Long-Term Partnership for Supply of Circular Raw Materials. Focus Catal. 2024, 2024, 1. [Google Scholar] [CrossRef]

- Al Nuaimi, A.H.; Williams, L.G. Radioactive Waste Management in the UAE: Proposal for an Inventory Management System. Prog. Nucl. Energy 2022, 146, 104140. [Google Scholar] [CrossRef]

- Camargo, T.A.d.; Alves, L.A.; Mendes, I.C.; Gasques, L.R.; Oliveira, L.G.S.d.; Pires, G.C.; Almeida, T.O.; Carvalho, P.C.d.F.; Souza, E.D.d. Enhancing Soil Quality and Grain Yields through Fertilization Strategies in Integrated Crop-Livestock System under No-till in Brazilian Cerrado. Eur. J. Soil Biol. 2024, 121, 103613. [Google Scholar] [CrossRef]

- Sushandoyo, D.; Tisyadi, N.A.-L.; Damar, M.R.; Prasetio, E.A.; Permana, M.Y.; Matsuura, Y. Overcoming Knowledge Asymmetry through Knowledge Transfer in Technology Adoption Process. Knowl. Manag. Res. Pract. 2024, 23, 188–204. [Google Scholar] [CrossRef]

- Abdelmeguid, A.; Tsironis, G.; Afy-Shararah, M.; Tsagarakis, K.P.; Salonitis, K. Insights into Sustainability and Circular Economy Trends in Luxury Fashion: A LinkedIn Topic Modelling Study. Clean. Responsible Consum. 2024, 15, 100228. [Google Scholar] [CrossRef]

- Kumar, H.; Kimta, N.; Guleria, S.; Cimler, R.; Sethi, N.; Dhanjal, D.S.; Singh, R.; Duggal, S.; Verma, R.; Prerna, P.; et al. Valorization of Non-Edible Fruit Seeds into Valuable Products: A Sustainable Approach towards Circular Bioeconomy. Sci. Total Environ. 2024, 922, 171142. [Google Scholar] [CrossRef]

- Sahu, P.; Prabu, V. Techno-Economic Analysis on Oxy-Fuel Based Steam Turbine Power System Using Municipal Solid Waste and Coals with Ultrasonicator Sulfur Removal. Waste Dispos. Sustain. Energy 2022, 4, 131–147. [Google Scholar] [CrossRef]

- Carneiro, M.L.N.M.; Gomes, M.S.P. Energy, Exergy, Environmental and Economic Analysis of Hybrid Waste-to-Energy Plants. Energy Conv. Manag. 2019, 179, 397–417. [Google Scholar] [CrossRef]

- Kamp Albæk, J.; Shahbazi, S.; McAloone, T.C.; Pigosso, D.C.A. Circularity Evaluation of Alternative Concepts During Early Product Design and Development. Sustainability 2020, 12, 9353. [Google Scholar] [CrossRef]

- Griffiths, P.; Cayzer, S. Design of Indicators for Measuring Product Performance in the Circular Economy. In Sustainable Design and Manufacturing 2016; Setchi, R., Howlett, R.J., Liu, Y., Theobald, P., Eds.; Springer International Publisher: Cham, Switzerland, 2016; pp. 307–321. [Google Scholar] [CrossRef]

- Kjaer, L.L.; Pigosso, D.C.A.; Niero, M.; Bech, N.M.; McAloone, T.C. Product/Service-Systems for a Circular Economy: The Route to Decoupling Economic Growth from Resource Consumption? J. Ind. Ecol. 2019, 23, 22–35. [Google Scholar] [CrossRef]

- Alzaydi, A. Balancing Creativity and Longevity: The Ambiguous Role of Obsolescence in Product Design. J. Clean. Prod. 2024, 445, 141239. [Google Scholar] [CrossRef]

- Yao, L.; Gao, Z.-H. A Study on Sustainable Design’s Contribution to Fashionable Brands Growth. In Textile Bioengi-Neering and Informatics Symposium (TBIS) Proceedings; Li, Y., Zhang, K., Pan, Z., Li, G., Eds.; Textile Bioengineering and Informatics Symposium Proceedings; Textile Bioengineering & Informatics Society Ltd.: Hong Kong SAR, China, 2019; pp. 519–524. [Google Scholar]

- Alange, S.; Clancy, G.; Marmgren, M. Naturalizing Sustainability in Product Development: A Comparative Analysis of IKEA and SCA. J. Clean Prod. 2016, 135, 1009–1022. [Google Scholar] [CrossRef]

- Cullen, U.A.; De Angelis, R. Circular Entrepreneurship: A Business Model Perspective. Resour. Conserv. Recycl. 2021, 168, 105300. [Google Scholar] [CrossRef]

- Weber, S.; Weber, O.; Habib, K.; Dias, G.M. Textile Waste in Ontario, Canada: Opportunities for Reuse and Recycling. Resour. Conserv. Recycl. 2023, 190, 106835. [Google Scholar] [CrossRef]

- Bürklin, N. Worn Wear: Better than New—How Patagonia’s Social Marketing Campaign Enhances Consumers’ Responsible Behavior. In Social Marketing in Action; Basil, D.Z., Diaz-Meneses, G., Basil, M.D., Eds.; Springer Texts in Business and Eco-nomics; Springer International Publisher: Cham, Switzerland, 2019; pp. 187–201. [Google Scholar] [CrossRef]

- da Silva, S.B.G.; Barros, M.V.; Radicchi, J.Â.Z.; Puglieri, F.N.; Piekarski, C.M. Opportunities and Challenges to Increase Circularity in the Product’s Use Phase. Sustain. Futures 2024, 8, 100297. [Google Scholar] [CrossRef]

- Selvefors, A.; Rexfelt, O.; Renström, S.; Strömberg, H. Use to Use—A User Perspective on Product Circularity. J. Clean. Prod. 2019, 223, 1014–1028. [Google Scholar] [CrossRef]

- Balatsas-Lekkas, A.; Luomala, H.; Pennanen, K. Factors Associated with Finnish, German and UK Consumers’ Intentions to Test, Buy and Recommend Reusable Fast-Moving Consumer Goods Packaging. Sustain. Prod. Consum. 2024, 52, 210–227. [Google Scholar] [CrossRef]

- Werrel, M.; Klar, M.; Aurich, J.C. Circularity Assessment of Product-Service Systems Using System Dynamics Modeling. Sustain. Prod. Consum. 2024, 52, 124–135. [Google Scholar] [CrossRef]

- Porter, M.E.; Kramer, M.R. Creating Shared Value. In Managing Sustainable Business: An Executive Education Case and Textbook; Lenssen, G.G., Smith, N.C., Eds.; Springer: Dordrecht, The Netherlands, 2019; pp. 323–346. [Google Scholar] [CrossRef]

- Dokter, G.; Thuvander, L.; Rahe, U. How Circular Is Current Design Practice? Investigating Perspectives across Industrial Design and Architecture in the Transition towards a Circular Economy. Sustain. Prod. Consum. 2021, 26, 692–708. [Google Scholar] [CrossRef]

- Pan, A.Q.; Martin, E.W.; Shaheen, S.A. Is Access Enough? A Spatial and Demographic Analysis of One-Way Carsharing Policies and Practice. Transp. Policy 2022, 127, 103–115. [Google Scholar] [CrossRef]

- White, C.; Swan, L.G. Pack-Level Performance of Electric Vehicle Batteries in Second-Life Electricity Grid Energy Services. J. Energy Storage 2023, 57, 106265. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Y. New-Arrival or Second-Hand? A Direct-to-Consumer Business Model for Electric Vehicles in the Sus-tainable Transportation. Energy Rep. 2023, 10, 3035–3038. [Google Scholar] [CrossRef]

- Mohammadian, N.; Fatahi Valilai, O.; Schlüter, A. Sustainable Design and Repair: Leveraging Circular Economy and Ma-chine Learning for Product Development. J. Open Innov. Technol. Mark. Complex. 2025, 11, 100469. [Google Scholar] [CrossRef]

- Rexfelt, O.; Selvefors, A. Mapping the Landscape of Circular Design Tools. Resour. Conserv. Recycl. 2024, 209, 107783. [Google Scholar] [CrossRef]

- den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product Design in a Circular Economy Development of a Typology of Key Concepts and Terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- Cao, X.; Hsu, Y.; Lu, H. Design Heuristics Cards for Circular Economy to Support Generating Ideas. Des. J. 2024, 27, 111–132. [Google Scholar] [CrossRef]

- Kremer, G.; Peters, I.; Bingoel, B.; Stark, R. Better Design through Shared Knowledge via Design Heuristics. Procedia CIRP 2023, 119, 957–962. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy: A New Sustainability Paradigm? J. Clean Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a Circular Economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Cagno, E.; Morioka, S.N.; Neri, A.; de Souza, E.L. Understanding How Circular Economy Practices and Digital Technolo-gies Are Adopted and Interrelated: A Broad Empirical Study in the Manufacturing Sector. Resour. Conserv. Recycl. 2025, 216, 108172. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Han, Y.; Zhu, D. The Triple-Level Proposal of the Circular Economy: Circular Performance, Case Studies and a Design Workshop. Sustainability 2025, 17, 4945. https://doi.org/10.3390/su17114945

Zhang S, Han Y, Zhu D. The Triple-Level Proposal of the Circular Economy: Circular Performance, Case Studies and a Design Workshop. Sustainability. 2025; 17(11):4945. https://doi.org/10.3390/su17114945

Chicago/Turabian StyleZhang, Shuai, Yicheng Han, and Dajian Zhu. 2025. "The Triple-Level Proposal of the Circular Economy: Circular Performance, Case Studies and a Design Workshop" Sustainability 17, no. 11: 4945. https://doi.org/10.3390/su17114945

APA StyleZhang, S., Han, Y., & Zhu, D. (2025). The Triple-Level Proposal of the Circular Economy: Circular Performance, Case Studies and a Design Workshop. Sustainability, 17(11), 4945. https://doi.org/10.3390/su17114945