Techno-Economic Analysis of Combined Onshore Ocean Thermal Energy Conversion Technology and Seawater Air Conditioning in Small Island Developing States

Abstract

1. Introduction

- Develops a scalable onshore OTEC-SWAC system and assesses the feasibility of system integration across 32 SIDS using 20 years of region-specific data, identifying their potential for renewable energy generation and sustainable tourism.

- Analyzes key system parameters, such as pipeline length, pump sizing, and cooling requirements, and their influence on Levelized Cost of Energy (LCOE).

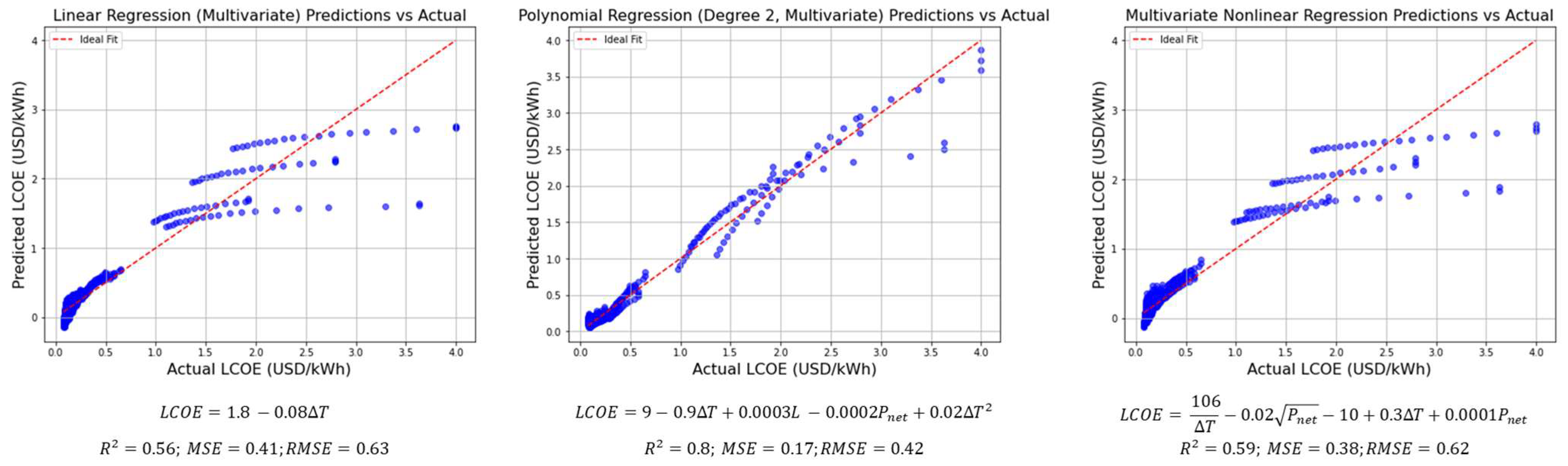

- Develops a reduced form of the cost estimation model, enabling adaptable cost predictions based on location-specific factors.

2. Literature Review

2.1. OTEC Technology and Technical Performance

2.2. OTEC Cost Drivers and Economic Performance

2.3. OTEC-SWAC Use in SIDS

3. Materials and Methods

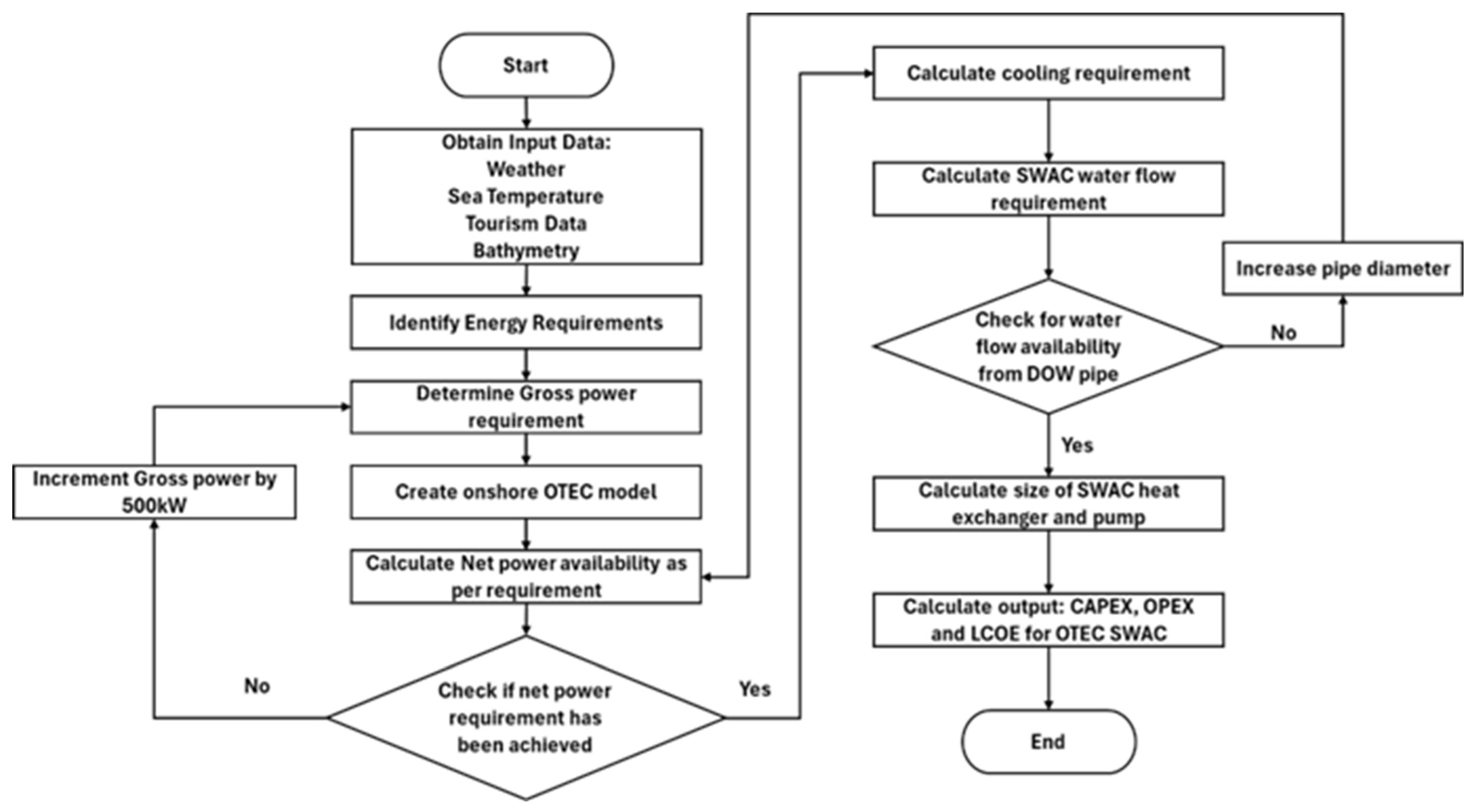

3.1. Onshore OTEC-SWAC System Design

3.2. SIDS Specific Parametrization

3.3. Techno-Economic Assessment

| Country | Tourism High Area | No. of Hotels | Depth 1000 m | Temperature (degC) | Oil Price (USD/L) [79] | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Source 1 [65] | Source 2 [66] | lat | lon | D 0 m | D 200 m | D 400 m | D 600 m | D 800 m | D 1000 m | |||

| American Samoa | Apia | 21 | 36 | −13.74 | −171.74 | 23.8 | 18.2 | 8.9 | 5.4 | 4.2 | 3.5 | 1.27 |

| Bahamas | Nassau | 97 | 103 | 25.13 | −77.36 | 22.1 | 17.4 | 14.1 | 10.9 | 7.4 | 4.9 | 1.41 |

| Belize | Belize city | 25 | 35 | 17.69 | −87.82 | 23.3 | 15.5 | 9.3 | 6.4 | 4.5 | 3.9 | 1.58 |

| Bermuda | Hamilton | 5 | 10 | 32.28 | −64.71 | 19.2 | 15.4 | 14.6 | 12.7 | 9.1 | 5.9 | 1.27 |

| Cabo Verde | Praia | 223 | 40 | 14.91 | −23.46 | 20.5 | 10.6 | 8.7 | 7.0 | 5.6 | 4.9 | 1.26 |

| The Cayman Islands | George Town | 52 | 33 | 19.30 | −81.42 | 23.2 | 17.9 | 12.7 | 8.7 | 5.9 | 4.3 | 1.47 |

| Cuba | Havana | 237 | 23.18 | −82.39 | 22.4 | 13.9 | 9.2 | 6.4 | 4.9 | 4.4 | 1.10 | |

| Curacao | Willemstad | 382 | 224 | 12.12 | −69.04 | 22.7 | 14.3 | 8.8 | 6.2 | 4.8 | 4.1 | 1.01 |

| Dominica | Roseau | 68 | 27 | 15.28 | −61.42 | 22.8 | 15.8 | 10.1 | 6.9 | 5.1 | 4.4 | 1.09 |

| Dominican Republic | Santo Domingo | 420 | 334 | 18.31 | −69.91 | 22.9 | 17.3 | 12.1 | 8.0 | 5.5 | 4.4 | 0.99 |

| The Federated States of Micronesia | Kol onia | 1 | 1 | 6.99 | 158.10 | 24.0 | 10.8 | 7.1 | 5.8 | 4.6 | 3.7 | 1.27 |

| Fiji | Nadi | 108 | 71 | −17.89 | 177.16 | 22.8 | 17.7 | 10.6 | 5.8 | 4.3 | 3.4 | 1.20 |

| French Polynesia | Papeete | 105 | 82 | −17.51 | −149.58 | 22.9 | 18.3 | 9.9 | 5.4 | 4.1 | 3.3 | 1.27 |

| Guam | Tumon | 20 | 30 | 13.54 | 144.72 | 23.8 | 16.1 | 7.7 | 5.4 | 4.4 | 3.6 | 1.27 |

| Guinea-Bissau | Bissau | 6 | 8 | 11.86 | −17.39 | 21.1 | 11.0 | 8.9 | 6.5 | 5.0 | 4.4 | 1.27 |

| Guyana | George Town | 46 | 27 | 8.25 | −57.85 | 23.1 | 11.9 | 7.3 | 5.7 | 4.5 | 4.2 | 1.20 |

| Haiti | Port-au-Prince | 9 | 72 | 18.21 | −72.38 | 22.8 | 18.3 | 12.6 | 8.3 | 5.6 | 4.9 | 1.24 |

| Jamaica | Montego bay | 270 | 184 | 18.51 | −77.97 | 23.4 | 17.8 | 13.4 | 9.1 | 5.8 | 4.3 | 1.38 |

| Kiribati | South Tarawa | 2 | 1.31 | 172.96 | 24.0 | 13.6 | 8.0 | 5.8 | 4.6 | 3.8 | 1.27 | |

| The Maldives | Malé | 56 | 184 | 4.17 | 73.56 | 24.0 | 11.6 | 9.1 | 7.9 | 6.8 | 5.6 | 0.95 |

| The Marshall Islands | Majuro | 1 | 7.14 | 171.37 | 23.7 | 10.0 | 7.2 | 5.8 | 4.6 | 3.8 | 1.27 | |

| Mauritius | Port Louis | 27 | 10 | −20.13 | 57.45 | 21.5 | 16.5 | 11.4 | 8.9 | 6.2 | 4.3 | 1.39 |

| Papua New Guinea | Port Moresby | 15 | 22 | −9.56 | 147.11 | 22.8 | 15.9 | 10.2 | 6.6 | 4.9 | 3.7 | 1.27 |

| Puerto Rico | San Juan | 353 | 207 | 18.56 | −66.10 | 22.6 | 17.1 | 13.6 | 9.7 | 6.6 | 5.1 | 0.94 |

| The Seychelles | Victoria | 42 | 379 | −5.11 | 55.29 | 23.2 | 10.9 | 8.4 | 7.0 | 5.9 | 5.1 | 1.59 |

| The Solomon Islands | Honiara | 12 | 10 | −9.21 | 159.78 | 24.3 | 15.8 | 7.6 | 5.3 | 4.3 | 3.6 | 1.27 |

| St. Vincent and the Grenadines | Kingstown | 15 | 27 | 13.12 | −61.25 | 22.9 | 14.4 | 8.7 | 6.2 | 4.9 | 4.2 | 1.27 |

| Timor-Leste | Dili | 17 | 11 | −8.51 | 125.56 | 23.8 | 13.5 | 7.4 | 5.6 | 4.5 | 4.3 | 1.27 |

| Trinidad and Tobago | Port of Spain | 26 | 34 | 11.59 | −61.21 | 23.0 | 12.6 | 8.0 | 5.9 | 4.8 | 4.1 | 0.65 |

| Tuvalu | Funafuti | 2 | −8.54 | 179.22 | 24.3 | 17.9 | 7.9 | 5.5 | 4.4 | 3.7 | 1.27 | |

| The U.S. Virgin Islands | St. Thomas | 60 | 83 | 18.18 | −64.99 | 23.0 | 17.1 | 12.7 | 8.5 | 5.8 | 4.7 | 1.27 |

| Vanuatu | Port-Vila | 54 | 58 | −17.88 | 168.18 | 22.5 | 17.4 | 10.8 | 6.0 | 4.3 | 3.4 | 1.27 |

| Item | Economic Value | Reference |

|---|---|---|

| Turbine capex | 328 USD/kWgross | [13] |

| Pumps capex | 1674 USD/kWpump | [55] |

| Seawater pipes capex | 42.5 USD/kgpipe | [75,77] |

| Seawater intake pit capex | 6128 USD/m3 | [75,77] |

| Heat exchangers capex | 215 USD/m2 | [55] |

| Project engineering capex | 3113 USD/kWgross | [55] |

| Extra cost | 3% of total CAPEX | [39] |

| OPEX | 3% of total CAPEX/year | [39] |

| LCOE calculation | ||

| Project lifetime | 30 years | [80] |

| Discount rate | 3% | [80] |

| Capacity factor | 96% | [81] |

| Fuel consumption | 0.286 L/kWh | [81] |

| Carbon emission | 2.8 kg/L | [82] |

| Carbon price | 130 USD/ton CO2 | [83] |

4. Results

4.1. Technical Analysis of the OTEC-SWAC System

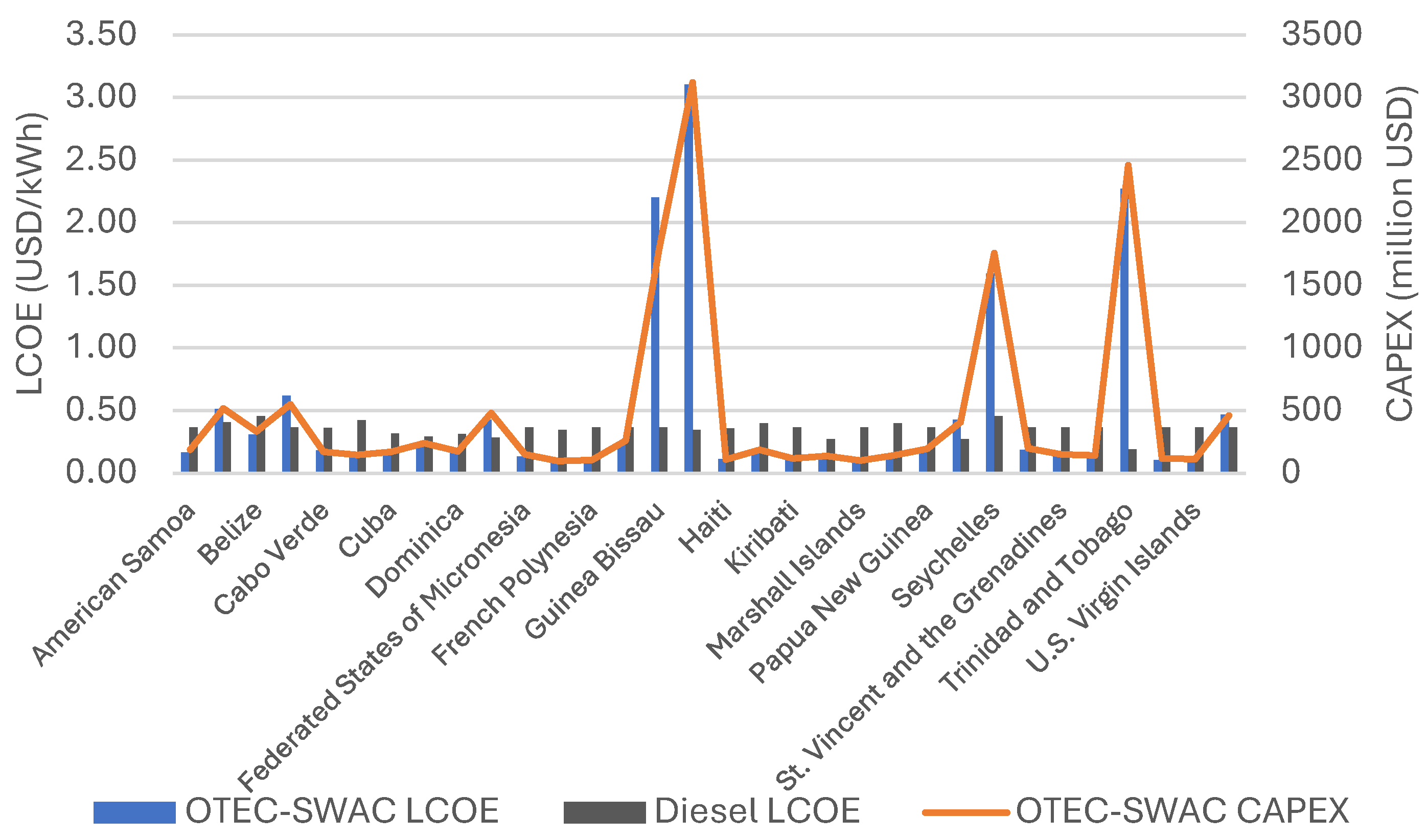

4.2. Economic Analysis of the OTEC-SWAC System

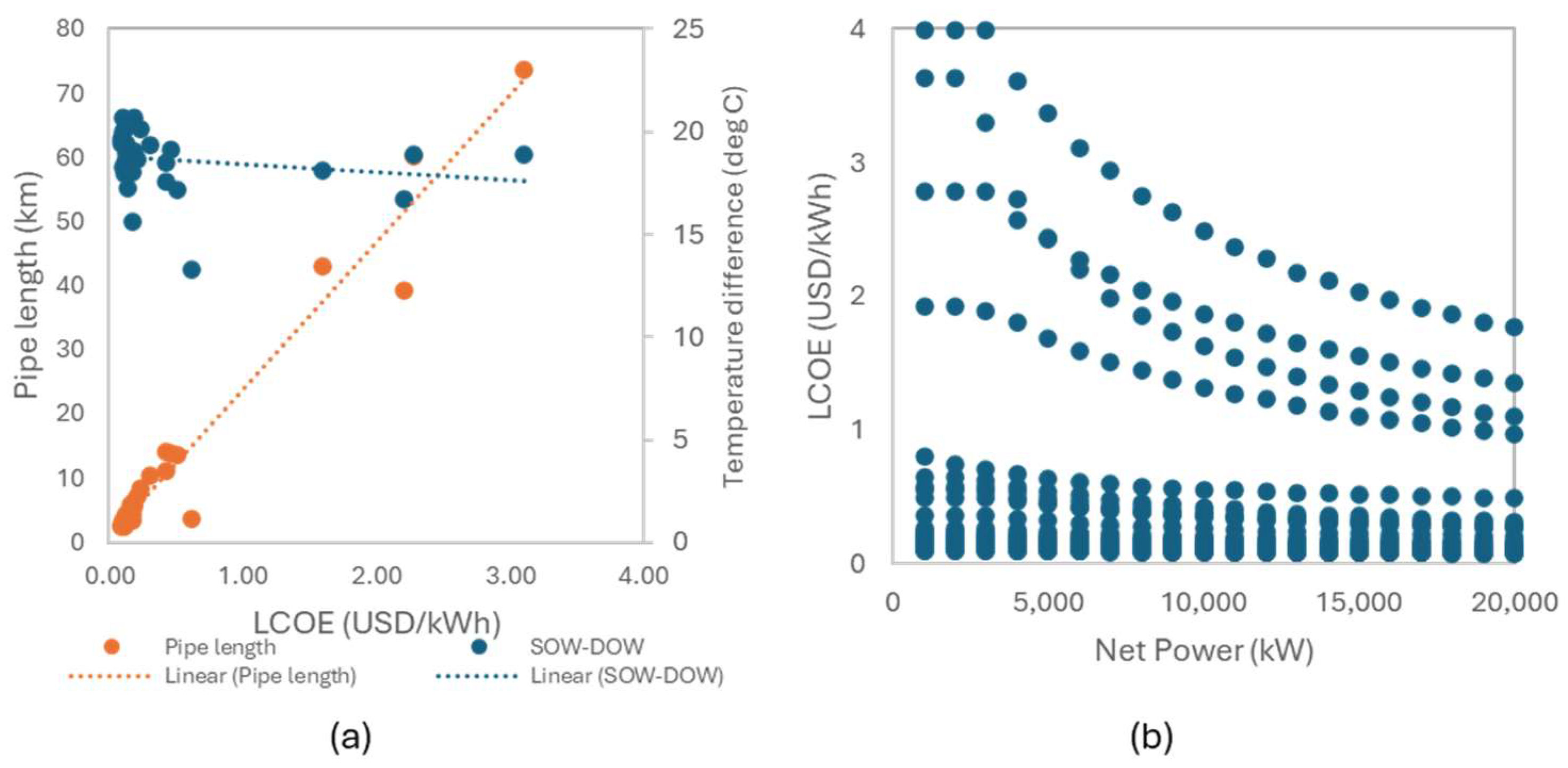

4.3. Simplification of the Model

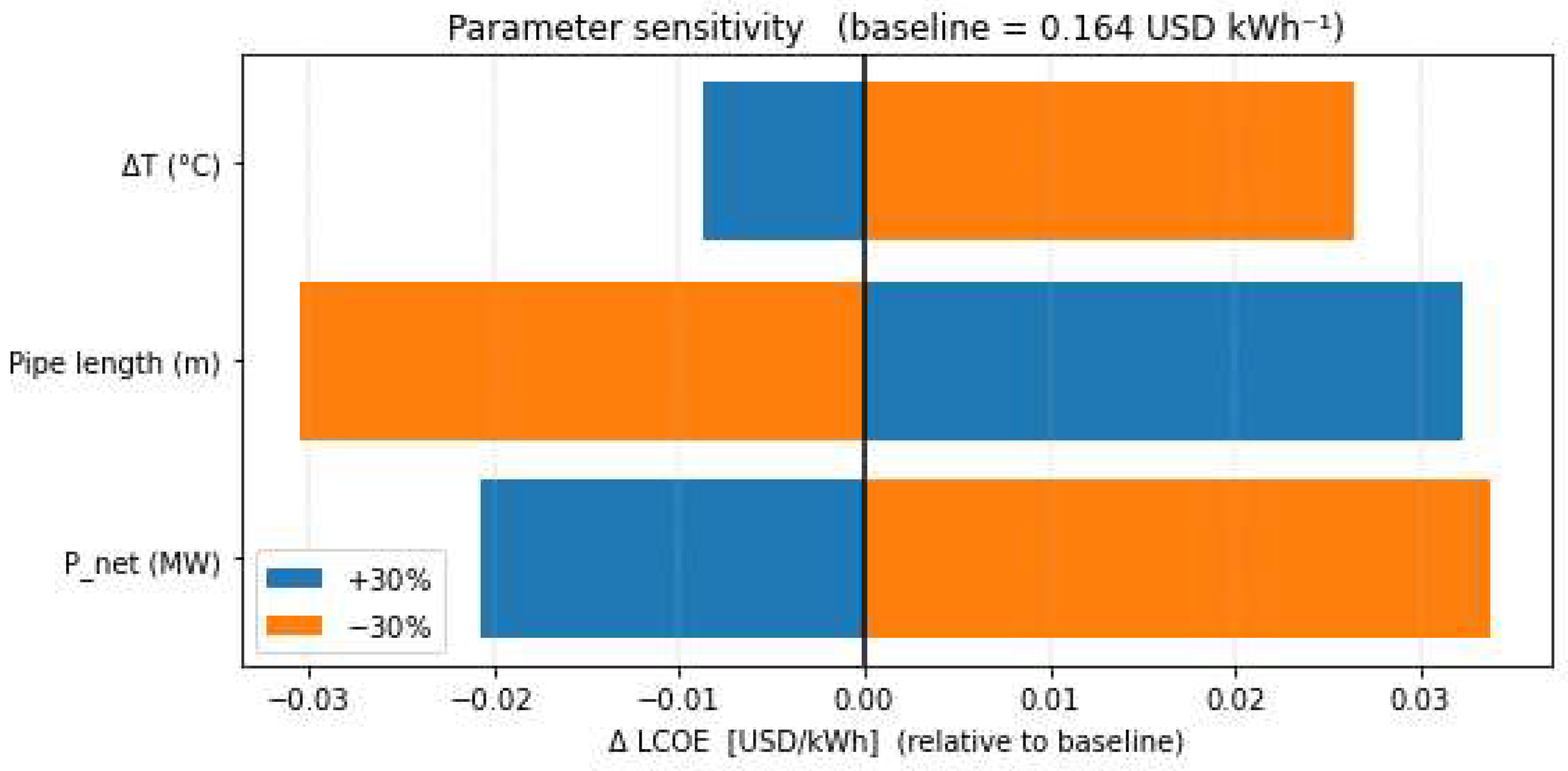

- The pipe length is the main factor for the geographically dependent cost variation.

- The temperature difference affects cost, albeit with a lower impact, and the relationship is inverse, i.e., a higher temperature difference lowers the LCOE.

- Net power and LCOE have a negative exponential relationship.

5. Discussion

6. Conclusions

- Feasibility assessment of OTEC-SWAC systems across 34 SIDS: The study conducted a comprehensive feasibility analysis of OTEC-SWAC integration across 32 SIDS, utilizing 20 years of geographically specific ocean and atmospheric data. The results show that 29 of the 32 analyzed SIDS meet thermal and geographic suitability criteria, confirming the viability of OTEC-SWAC systems for stable power generation and cooling in tourism-driven economies. The findings highlight significant regional variations, with longer pipeline distances and lower thermal gradients impacting system efficiency and costs in some locations.

- Analysis of key system parameters and their impact on Levelized Cost of Energy (LCOE): Techno-economic analysis reveals pipeline length as the main cost driver, with longer pipes leading to higher LCOE in countries like Guyana and Trinidad and Tobago. Most SIDS, however, achieve a competitive LCOE averaging 0.19 USD/kWh, presenting a cost-effective alternative to conventional diesel systems.

- Development of a scalable cost estimation model for onshore OTEC-SWAC deployment: Large-capacity onshore OTEC plants, in addition to power generation, provide economic benefits through deep-ocean water industries. The scalable model and the reduced form developed will enable policymakers, engineers, and stakeholders to quickly assess the economic viability of OTEC-SWAC projects at different locations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CDD | Cooling degree days |

| LCOE | Levelized cost of energy |

| OTEC | Ocean thermal energy conversion technology |

| SDG | Sustainable development goals |

| SIDS | Small island developing states |

| SWAC | Seawater air conditioning |

Appendix A

| Parameter | Formula |

|---|---|

| Calculation of pipe length | |

| Haversine formula (m) | R is the radius of the earth taken as 6371 m. |

| Length of pipe (m) | Assuming the shortest distance given by a right-angle triangle and a depth of 1000 m. |

| Calculation of pipe heat gain | |

| Dynamic viscosity of seawater | |

| Nusselt number | |

| Heat transfer coefficient | |

| Thermal resistance for pipe | |

| Overall heat transfer coefficient | |

| Calculation of OTEC technical system | |

| Evaporator saturation temperature (°C) | |

| Condensor saturation temperature (°C) | is the temperature of the deep-ocean water, and is the pinch point temperature assumed as 1.25. |

| Saturation pressure (bar) | |

| Enthalpy of liquid phase (kJ/kg) | |

| Enthalpy of vapor phase (kJ/kg) | |

| Isentropic quality of turbine outlet | is the electric efficiency of the turbine. |

| Mass flow of ammonia (kg/s) | is the gross power of the plant. |

| Ammonia pump power (kW) | |

| Evaporator heat in (kW) | |

| Mass flow of warm ocean water (kg/s) | is the specific heat capacity of the water taken at 4 kJ/kgK. |

| Evaporator area (m2) | |

| Condensation heat (kW) | |

| Mass flow of cold ocean water (kg/s) | |

| Condesor area (m2) | |

| Intake pit flow rate (m3/s) | |

| Area of intake pit (m2) | where is taken as 5 m |

| Diameter of siphon pipe (m) | where the equation is solved using an iteration method and is the diameter of the pipe. |

| Weight of pipe (kg) | |

| Dynamic viscosity (PaS) | |

| Reynolds number | is the density of deep-ocean water at 1027 kg/m3 is the density of surface ocean water at 1024 kg/m3. |

| Darcy friction factor | |

| Pressure drop (kPa) | |

| Pump power (kW) | |

| Thermal efficiency | |

| Calculation of SWAC technical system | |

| Mass of water required (kg) | |

| Velocity of water flow (m/s) | |

| Head loss | where is the friction factor, is, the length of pipe and is the diameter of pipe. |

| SWAC pump size (kW) | |

| SWAC heat exchanger area (m2) | is the heat transfer coefficient of a titanium heat exchanger in W/°Cm2. |

References

- Ghina, F. Sustainable development in small island developing states: The case of the Maldvies. Environ. Dev. Sustain. 2003, 5, 139–165. [Google Scholar] [CrossRef]

- Cadarso, M.; Gómez, N.; López, L.A.; Tobarra, M.-Á. Calculating tourism’s carbon footprint: Measuring the impact of investments. J. Clean. Prod. 2016, 111, 529–537. [Google Scholar] [CrossRef]

- McGillivray, M.; Naudé, W.; Santos-Paulino, A. Small island states development challenges: Introduction. J. Int. Dev. 2008, 20, 481–485. [Google Scholar] [CrossRef]

- Schubert, L.; Foley, W.; Savage, A.; Muriuki, G. Small Island Developing States, Climate Change, and Food and Nutrition Security. Adv. Sci. Lett. 2017, 23, 3389–3392. [Google Scholar] [CrossRef]

- Roudi, S.; Arasli, H.; Akadiri, S.S. New insights into an old issue—Examining the influence of tourism on economic growth: Evidence from selected small island developing states. Curr. Issues Tour. 2019, 22, 1280–1300. [Google Scholar] [CrossRef]

- Faizal, M.; Ahmed, M.R. Experimental studies on a closed cycle demonstration OTEC plant working on small temperature difference. Renew. Energy 2013, 51, 234–240. [Google Scholar] [CrossRef]

- Nihous, G. A Preliminary Investigation of the Effect of Ocean Thermal Energy Conversion (OTEC) Effluent Discharge Options on Global OTEC Resources. J. Mar. Sci. Eng. 2018, 6, 25. [Google Scholar] [CrossRef]

- Jia, Y.; Nihous, G.C.; Rajagopalan, K. An Evaluation of the Large-Scale Implementation of Ocean Thermal Energy Conversion (OTEC) Using an Ocean General Circulation Model with Low-Complexity Atmospheric Feedback Effects. J. Mar. Sci. Eng. 2018, 6, 12. [Google Scholar] [CrossRef]

- Hurtt, J.; Pellen, A.; Nagurny, N.J. OTEC Power Efficiency Challenges. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 3–6 May 2010; Volume 1, pp. 732–743. [Google Scholar] [CrossRef]

- Cooper, D.; Meyer, L.; Varley, R. OTEC Commercialization Challenges. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 4–7 May 2009; p. OTC-20170-MS. [Google Scholar] [CrossRef]

- Lu, B.; Liu, Y.; Zhai, X.; Zhang, L.; Chen, Y. Design and Experimental Study of 50 kW Ocean Thermal Energy Conversion Test Platform Based on Organic Rankine Cycle. J. Mar. Sci. Eng. 2024, 12, 463. [Google Scholar] [CrossRef]

- OES. White Paper on OTEC. 2021. Available online: https://www.ocean-energy-systems.org/publications/oes-position-papers/document/white-paper-on-otec/ (accessed on 31 January 2025).

- Martel, L.; Smith, P.; Rizea, S.; Van Ryzin, J.; Morgan, C.; Noland, G.; Pavlosky, R.; Thomas, M.; Halkyard, J. Ocean Thermal Energy Conversion Life Cycle Cost Assessment; Final Technical Report. 30 May 2012. Available online: https://www.osti.gov/servlets/purl/1045340/ (accessed on 20 June 2023).

- Richards, D.; George, J.F.; Seward, J.S. Design of 40-MW Grazing and Moored OTEC Pilot/Demonstration Plants. J. Energy 2012, 5, 224–230. [Google Scholar] [CrossRef]

- Srinivasan, N. A New Improved Ocean Thermal Energy Conversion System with Suitable Floating Vessel Design. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Honolulu, HI, USA, 31 May–5 June 2009; Volume 4, Part B. pp. 1119–1129. [Google Scholar] [CrossRef]

- Vega, L.A. Ocean Thermal Energy Conversion Primer. Mar. Technol. Soc. J. 2003, 36, 25–35. [Google Scholar] [CrossRef]

- George, J.F.; Richards, D.; Perini, L.L. Baseline Design of an OTEC Pilot Plantship. Volume A. Detailed Report. [Performance Analysis of OTEC Power Plant]. May 1979. Available online: https://www.osti.gov/servlets/purl/5672829/ (accessed on 20 June 2023).

- Etemadi, A.; Emdadi, A.; AsefAfshar, O.; Emami, Y. Electricity Generation by the Ocean Thermal Energy. Energy Procedia 2011, 12, 936–943. [Google Scholar] [CrossRef]

- Rahbar, K.; Mahmoud, S.; Al-Dadah, R.K.; Moazami, N.; Mirhadizadeh, S.A. Review of organic Rankine cycle for small-scale applications. Energy Convers. Manag. 2017, 134, 135–155. [Google Scholar] [CrossRef]

- Zhang, X.; He, M.; Zhang, Y. A review of research on the Kalina cycle. Renew. Sustain. Energy Rev. 2012, 16, 5309–5318. [Google Scholar] [CrossRef]

- Uehara, H.; Ikegami, Y. Optimization of a Closed-Cycle OTEC System. J. Sol. Energy Eng. 1990, 112, 247–256. [Google Scholar] [CrossRef]

- Guzović, Z.; Rašković, P.; Blatarić, Z. The comparision of a basic and a dual-pressure ORC (Organic Rankine Cycle): Geothermal Power Plant Velika Ciglena case study. Energy 2014, 76, 175–186. [Google Scholar] [CrossRef]

- Yamada, N.; Hoshi, A.; Ikegami, Y. Thermal efficiency enhancement of ocean thermal energy conversion (OTEC) using solar thermal energy. In Collection of Technical Papers—4th International Energy Conversion Engineering Conference, San Diego, CA, USA, 26–29 June 2006; AIAA: Reston, VA, USA, 2006; Volume 2, pp. 936–944. [Google Scholar] [CrossRef]

- Nemati, A.; Nami, H.; Ranjbar, F.; Yari, M. A comparative thermodynamic analysis of ORC and Kalina cycles for waste heat recovery: A case study for CGAM cogeneration system. Case Stud. Therm. Eng. 2017, 9, 1–13. [Google Scholar] [CrossRef]

- Kim, H.-J.; Lee, H.-S.; Lim, S.-T.; Petterson, M. The Suitability of the Pacific Islands for Harnessing Ocean Thermal Energy and the Feasibility of OTEC Plants for Onshore or Offshore Processing. Geosciences 2021, 11, 407. [Google Scholar] [CrossRef]

- Arias-Gaviria, J. Adoption of sea water air conditioning (SWAC) in the Caribbean: Individual vs regional effects. J. Clean. Prod. 2019, 227, 280–291. [Google Scholar] [CrossRef]

- Hunt, J.D.; Weber, N.d.A.B.; Zakeri, B.; Diaby, A.T.; Byrne, P.; Filho, W.L.; Schneider, P.S. Deep seawater cooling and desalination: Combining seawater air conditioning and desalination. Sustain. Cities Soc. 2021, 74, 103257. [Google Scholar] [CrossRef]

- War, J.C. Seawater Air Conditioning (SWAC) a renewable energy alternative. In Proceedings of the OCEANS’11—MTS/IEEE Kona, Waikoloa, HI, USA, 19–22 September 2011. Program Book. [Google Scholar] [CrossRef]

- Brecha, R.J.; Schoenenberger, K.; Ashtine, M.; Koon, R.K. Ocean Thermal Energy Conversion—Flexible Enabling Technology for Variable Renewable Energy Integration in the Caribbean. Energies 2021, 14, 2192. [Google Scholar] [CrossRef]

- Aresti, L.; Christodoulides, P.; Michailides, C.; Onoufriou, T. Reviewing the energy, environment, and economy prospects of Ocean Thermal Energy Conversion (OTEC) systems. Sustain. Energy Technol. Assess. 2023, 60, 103459. [Google Scholar] [CrossRef]

- Herrera, J.; Sierra, S.; Ibeas, A. Ocean Thermal Energy Conversion and Other Uses of Deep Sea Water: A Review. J. Mar. Sci. Eng. 2021, 9, 356. [Google Scholar] [CrossRef]

- Vega, L.; Martin, B. OES|Ocean Thermal Energy Conversion (OTEC) Economics: Updates and Strategies. 2024. Available online: https://www.ocean-energy-systems.org/publications/oes-technical-reports/document/ocean-thermal-energy-conversion-otec-economics-updates-and-strategies/ (accessed on 1 February 2025).

- Chan, N. “Large Ocean States”: Sovereignty, Small Islands, and Marine Protected Areas in Global Oceans Governance. Glob. Gov. A Rev. Multilater. Int. Organ. 2018, 24, 537–555. [Google Scholar] [CrossRef]

- Linus, M.; Jarett, G.; Fliss, J. Ocean Energy Technologies Patents Deployment Status and Outlook. 2014. Available online: https://www.irena.org/Publications/2014/Aug/Ocean-Energy-Technologies-Patents-Deployment-Status-and-Outlook (accessed on 15 April 2025).

- UNFCCC. COP 28: What Was Achieved and What Happens Next? Available online: https://unfccc.int/cop28/5-key-takeaways (accessed on 15 April 2025).

- Trimble, L.C.; Naef, F.E. Ocean Thermal Energy Conversion. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 4–7 May 1975; pp. 155–162. [Google Scholar] [CrossRef]

- Zhang, W.; Li, Y.; Wu, X.; Guo, S. Review of the applied mechanical problems in ocean thermal energy conversion. Renew. Sustain. Energy Rev. 2018, 93, 231–244. [Google Scholar] [CrossRef]

- Abu Husain, M.K.; Zaki, N.I.M.; Azman, N.U.; Sarip, S.; Jaafar, A.B.; Mukhlas, N.; Shah, M.S.A.; Umar, S.; Ng, C.T.; Yahaya, N.; et al. Feasibility Study of A Fixed Offshore OTEC Plant for Cost-Effective Power Generation In Malaysia. Malays. J. Civ. Eng. 2024, 36, 9–18. [Google Scholar] [CrossRef]

- Langer, J.; Blok, K. The global techno-economic potential of floating, closed-cycle ocean thermal energy conversion. J. Ocean Eng. Mar. Energy 2023, 10, 85–103. [Google Scholar] [CrossRef]

- Langer, J.; Quist, J.; Blok, K. Upscaling scenarios for ocean thermal energy conversion with technological learning in Indonesia and their global relevance. Renew. Sustain. Energy Rev. 2022, 158, 112086. [Google Scholar] [CrossRef]

- Olim, S.T.; Nickoloff, A.; Moffat, L.J.; Weaver, A.J.; Eby, M. Mitigating anthropogenic climate change with aqueous green energy. Sci. Rep. 2025, 15, 1700. [Google Scholar] [CrossRef]

- Osorio, A.F.; Arias-Gaviria, J.; Devis-Morales, A.; Acevedo, D.; Velasquez, H.I.; Arango-Aramburo, S. Beyond electricity: The potential of ocean thermal energy and ocean technology ecoparks in small tropical islands. Energy Policy 2016, 98, 713–724. [Google Scholar] [CrossRef]

- Ma, Q.; Zheng, Y.; Lu, H.; Li, J.; Wang, S.; Wang, C.; Wu, Z.; Shen, Y.; Liu, X. A Novel Ocean Thermal Energy Driven System for Sustainable Power and Fresh Water Supply. Membranes 2022, 12, 160. [Google Scholar] [CrossRef]

- Jin, Z.; Wang, H. Modelling and experiments on ocean thermal energy for desalination. Int. J. Sustain. Energy 2015, 34, 103–112. [Google Scholar] [CrossRef]

- Mutair, S.; Ikegami, Y. Design optimization of shore-based low temperature thermal desalination system utilizing the ocean thermal energy. J. Sol. Energy Eng. 2014, 136, 041005. [Google Scholar] [CrossRef]

- Pastor, J.; Liu, Y. Wave Climate Resource Analysis Based on a Revised Gamma Spectrum for Wave Energy Conversion Technology. Sustainability 2016, 8, 1321. [Google Scholar] [CrossRef]

- Guiberteau, K.L.; Liu, Y.; Lee, J.; Kozman, T.A. Investigation of Developing Wave Energy Technology In the Gulf of Mexico. Distrib. Gener. Altern. Energy J. 2012, 27, 36–52. [Google Scholar] [CrossRef]

- Sustainable Cooling: A Deep Dive into Seawater Air-Conditioning (SWAC) Solutions for the Caribbean. Available online: https://blogs.worldbank.org/en/latinamerica/sustainable-cooling--a-deep-dive-into-seawater-air-conditioning-?utm_source=chatgpt.com (accessed on 13 May 2025).

- Towards a Green Economy: Pathways to Sustainable Development and Poverty Eradication: Sustainable Development Knowledge Platform. Available online: https://sustainabledevelopment.un.org/index.php?page=view&type=400&nr=126&menu=35 (accessed on 2 May 2024).

- Sanjivy, K.; Marc, O.; Davies, N.; Lucas, F. Energy performance assessment of Sea Water Air Conditioning (SWAC) as a solution toward net zero carbon emissions: A case study in French Polynesia. Energy Rep. 2023, 9, 437–446. [Google Scholar] [CrossRef]

- Sanjivy, K.; Marc, O.; Lucas, F. Sea Water Air Conditioning (SWAC): A Resilient and Sustainable Cooling Solution for hot and humid climates-Energy Per-formance and Numerical Modeling. October 2023. Available online: https://hal.science/hal-04301115 (accessed on 19 January 2024).

- Fan, C.; Chen, Y. Design Optimization of Ocean Thermal Energy Conversion (OTEC) Considering the Off-Design Condition. J. Therm. Sci. 2023, 32, 2126–2143. [Google Scholar] [CrossRef]

- Xiao, C.; Hu, Z.; Chen, Y.; Zhang, C. Thermodynamic, economic, exergoeconomic analysis of an integrated ocean thermal energy conversion system. Renew. Energy 2024, 225, 120194. [Google Scholar] [CrossRef]

- Langer, J.; Ferreira, C.I.; Quist, J. Is bigger always better? Designing economically feasible ocean thermal energy conversion systems using spatiotemporal resource data. Appl. Energy 2022, 309, 118414. [Google Scholar] [CrossRef]

- Upshaw, C. Thermodynamic and Economic Feasibility Analysis of a 20 MW Ocean Thermal Energy Conversion (OTEC) Power Plant. 2012. Available online: https://repositories.lib.utexas.edu/items/5c400cb5-55fd-4517-ac94-c291c7c710c7 (accessed on 30 April 2024).

- Samsuri, N.; Sazali, N.; Jamaludin, A.S.; Razali, M.N.M. Techno-economic efficiencies and environmental criteria of Ocean Thermal Energy Conversion closed Rankine cycle using different working fluids. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1062, 012042. [Google Scholar] [CrossRef]

- Oko, C.O.C.; Obeneme, W.B. Thermo-economic analysis of an ocean thermal power plant for a Nigerian coastal region. Int. J. Ambient. Energy 2018, 39, 562–572. [Google Scholar] [CrossRef]

- Adiputra, R.; Utsunomiya, T.; Koto, J.; Yasunaga, T.; Ikegami, Y. Preliminary design of a 100 MW-net ocean thermal energy conversion (OTEC) power plant study case: Mentawai island, Indonesia. J. Mar. Sci. Technol. 2020, 25, 48–68. [Google Scholar] [CrossRef]

- Patterson, S.E.; Spalding, M.A. Molecular Design of High Density Polyethylene for Pipes. In Pipelines 2012: Innovations in Design, Construction, Operations, and Maintenance—Doing More with Less—Proceedings of the Pipelines 2012 Conference; ASCE: Reston, VA, USA, 2012; pp. 964–973. [Google Scholar] [CrossRef]

- Keesmaat, K. Installation Limits of Large Diameter Cold Water Pipes in Deep Water for Land-Based OTEC Plants. Master’s Thesis, TU Delft, Delft, The Netherlands, 5 August 2015. Available online: https://repository.tudelft.nl/file/File_378943bf-4dca-4cd2-9ce8-571df916eaaf?preview=1 (accessed on 12 April 2025).

- Energy, Resources, and Technology Division, Department of Business, Economic Development & Tourism, State of Hawaii. Sea Water District Cooling Feasibility Analysis; Hawaii.gov: Honolulu, HI, USA, 2002.

- Santamouris, M. Cooling the buildings—Past, present and future. Energy Build. 2016, 128, 617–638. [Google Scholar] [CrossRef]

- Sivak, M. Potential energy demand for cooling in the 50 largest metropolitan areas of the world: Implications for developing countries. Energy Policy 2009, 37, 1382–1384. [Google Scholar] [CrossRef]

- ASHRAE Store. ASHRAE 55-2017. Available online: https://store.accuristech.com/ashrae/standards/ashrae-55-2017?product_id=1994974 (accessed on 26 April 2024).

- Booking.com|Official Site. The Best Hotels, Flights, Car Rentals & Accommodations. Available online: https://www.booking.com/index.en-gb.html?label=gen173nr-1DCAEoggI46AdIM1gEaHWIAQGYAQm4ARfIAQzYAQPoAQGIAgGoAgO4As-2tLgGwAIB0gIkMDNlOTU0NWYtNDI4Yi00YjRlLTgyZGQtYjg4MzVjNzhkZWQx2AIE4AIB&sid=99618c5d612900ed31600db56e741787&keep_landing=1&sb_price_type=total& (accessed on 14 October 2024).

- Trip.com Official Site. Travel Deals and Promotions. Available online: https://us.trip.com/?locale=en-us (accessed on 14 October 2024).

- GEBCO. Gridded Bathymetry Data. Available online: https://www.gebco.net/data_and_products/gridded_bathymetry_data/ (accessed on 28 April 2024).

- Copernicus Marine Service. Global Ocean Physics Analysis and Forecast. Available online: https://data.marine.copernicus.eu/product/GLOBAL_ANALYSISFORECAST_PHY_001_024/description (accessed on 28 April 2024).

- National Centers for Environmental Information (NCEI). Past Weather. Available online: https://www.ncei.noaa.gov/access/past-weather/22.16799201091221,-94.84984515217047,16.93260562480587,-84.65998763121615 (accessed on 26 April 2024).

- World Tourism Organization. UNWTO Briefing Note—Tourism and COVID-19, Issue 2. Tourism in SIDS—The Challenge of Sustaining Livelihoods in Times of COVID-19; UNWTO: Madrid, Spain, 2020. [Google Scholar] [CrossRef]

- Renewable Energy Opportunities for Island Tourism. Available online: https://www.irena.org/publications/2014/Aug/Renewable-Energy-Opportunities-for-Island-Tourism (accessed on 2 May 2024).

- Lockheed Martin Final Report on Ocean Thermal Energy Conversion—Google Search. Available online: https://www.google.com/search?q=lockheed+martin+final+report+on+ocean+thermal+energy+conversion&rlz=1C1JCYX_jaJP1082JP1082&oq=lockheed+martin+final+report+on+ocean+thermal+ener&gs_lcrp=EgZjaHJvbWUqCQgBECEYChigATIGCAAQRRg5MgkIARAhGAoYoAEyCQgCECEYChigATIJCAMQIRgKGKAB0gEJMTE1NjhqMGo3qAIAsAIA&sourceid=chrome&ie=UTF-8 (accessed on 30 April 2024).

- Giostri, A.; Romei, A.; Binotti, M. Off-design performance of closed OTEC cycles for power generation. Renew. Energy 2021, 170, 1353–1366. [Google Scholar] [CrossRef]

- Bernardoni, C.; Binotti, M.; Giostri, A. Techno-economic analysis of closed OTEC cycles for power generation. Renew. Energy 2019, 132, 1018–1033. [Google Scholar] [CrossRef]

- Green Decentralization Reform Promotion Project. Kumejima Deep Sea Water Composite Use Basic Survey Report. Kumejima Town, Okinawa Prefecture. Available online: http://www.gosea.info/en/infomation/dswusefs/ (accessed on 15 February 2024).

- Martin, B.; Okamura, S.; Nakamura, Y.; Yasunaga, T.; Ikegami, Y. Status of the “Kumejima Model” for advanced deep seawater utilization. In Proceedings of the Techno-Ocean 2016: Return to the Oceans, Kobe, Japan, 6–8 October 2016; pp. 211–216. [Google Scholar] [CrossRef]

- Report on the Feasibility Study of Using Deep Seawater to Revitalize Remote Islands. Cabinet Office Okinawa General Bureau, Economy, Trade and Industry Department: Naha, Japan. Available online: http://www.gosea.info/en/infomation/dswusefs/ (accessed on 15 October 2024).

- Ministry of Earth Sciences|Technology|Lakshadweep. Explainer/Low Temperature Thermal Desalination (LTTD) Technology. Available online: https://www.manoramayearbook.in/current-affairs/india/2022/07/23/low-temperature-thermal-desalination-lttd-technology.html (accessed on 3 April 2025).

- GlobalPetrolPrices.com. Diesel Prices Around the World, 22-Apr-2024. Available online: https://www.globalpetrolprices.com/diesel_prices/ (accessed on 30 April 2024).

- Keiner, D.; Salcedo-Puerto, O.; Immonen, E.; van Sark, W.G.; Nizam, Y.; Shadiya, F.; Duval, J.; Delahaye, T.; Gulagi, A.; Breyer, C. Powering an island energy system by offshore floating technologies towards 100% renewables: A case for the Maldives. Appl. Energy 2022, 308, 118360. [Google Scholar] [CrossRef]

- Salameh, T.; Ghenai, C.; Merabet, A.; Alkasrawi, M. Techno-economical optimization of an integrated stand-alone hybrid solar PV tracking and diesel generator power system in Khorfakkan, United Arab Emirates. Energy 2020, 190, 116475. [Google Scholar] [CrossRef]

- Why Does Burning 1 Litre of Fuel Create over 2kg of Carbon Dioxide? Available online: https://www.driverknowledgetests.com/resources/why-does-burning-1-litre-of-fuel-create-over-2kg-of-carbon-dioxide/ (accessed on 18 July 2024).

- World Bank. State and Trends of Carbon Pricing 2024. In State and Trends 2024; World Bank: Washington, DC, USA, 2024. [Google Scholar] [CrossRef]

- Elantary, A.R. Energy Consumption Patterns in Residential Buildings: A Comparative Study of Air Conditioning Systems. Yanbu J. Eng. Sci. 2025, 22, 2–12. [Google Scholar] [CrossRef]

- Electric Prices by Country|Doing Business. World Bank Group Archives: Washington, DC, USA, 2023. Available online: https://databank.worldbank.org/embed/Electric-Prices-by-Country/id/7b12e700 (accessed on 14 May 2025).

- Islam, M.A.; Chowdhury, R.I. Generalized Linear Models. In Analysis of Repeated Measures Data; Springer: Singapore, 2017. [Google Scholar] [CrossRef]

- Dou, Y.; Liu, Y.; Whittington, W.; Miller, J. Experimental Calibration of ISV Damage Model Constants for Pure Copper for High-Speed Impact Simulation. In Proceedings of the ASME 2016 International Mechanical Engineering Congress and Exposition, Phoenix, AZ, USA, 11–17 November 2016. [Google Scholar] [CrossRef]

- Prataviera, F.; Batista, A.M.; Ortega, E.M.M.; Cordeiro, G.M.; Silva, B.M. The Logit Exponentiated Power Exponential Regression with Applications. Ann. Data Sci. 2023, 10, 713–735. [Google Scholar] [CrossRef]

- Surroop, D.; Raghoo, P. Renewable energy to improve energy situation in African island states. Renew. Sustain. Energy Rev. 2018, 88, 176–183. [Google Scholar] [CrossRef]

- Boccaletti, C.; Fabbri, G.; Marco, L.J.; Santini, E. An overview on renewable energy technologies for developing countries: The case of Guinea Bissau. Renew. Energy Power Qual. J. 2008, 6, 343–348. [Google Scholar] [CrossRef]

- Anderson, J.H. Ocean thermal power—The coming energy revolution. Sol. Wind. Technol. 1985, 2, 25–40. [Google Scholar] [CrossRef]

- Water Intake System Agricultural Industry Operation Platform. Available online: https://agri.nais.net.cn/patentdetails/26A84DC6-61D0-4A4F-A37A-13D4192F2829.html (accessed on 13 April 2025).

- Vega, L.A. Economics of ocean thermal energy conversion (OTEC): An update. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 2010; Available online: https://onepetro.org/OTCONF/proceedings-abstract/10OTC/All-10OTC/36399 (accessed on 30 April 2024).

- Atalah, A.; Kariuki, J. Cost Comparison between Horizontal Directional Drilling and Open-Cut Construction Methods in Nairobi, Kenya. In Proceedings of the International Conference on Pipelines and Trenchless Technology 2009, ICPTT 2009: Advances and Expe-riences with Pipelines and Trenchless Technology for Water, Sewer, Gas, and Oil Applications, Shanghai, China, 18–21 October 2009; Volume 361, pp. 1369–1378. [Google Scholar] [CrossRef]

- Ocean Thermal Energy Conversion: Technology Brief. 2014. Available online: https://www.irena.org/Publications/2014/Jun/Ocean-Thermal-Energy-Conversion (accessed on 31 January 2025).

- Martin, B.; Okamura, S.; Yasunaga, T.; Ikegami, Y.; Ota, N. OTEC and Advanced Deep Ocean Water Use for Kumejima: An Introduction. In Proceedings of the Oceans Conference Record (IEEE), Chennai, India, 20 February 2022. [Google Scholar] [CrossRef]

- Langer, J.; Quist, J.; Blok, K. Recent progress in the economics of ocean thermal energy conversion: Critical review and research agenda. Renew. Sustain. Energy Rev. 2020, 130, 109960. [Google Scholar] [CrossRef]

- Gomes, C.S.F.; Fernandes, J.V.; Fernandes, F.V.; Silva, J.B.P. Salt Mineral Water and Thalassotherapy. In Minerals latu sensu and Human Health: Benefits, Toxicity and Pathologies; Springer: Cham, Switzerland, 2021; pp. 631–656. [Google Scholar] [CrossRef]

- Liu, C.C. Ocean thermal energy conversion and open ocean mariculture: The prospect of Mainland-Taiwan collaborative research and development. Sustain. Environ. Res. 2018, 28, 267–273. [Google Scholar] [CrossRef]

| Plant Type | Size | Capital Cost (Millions USD) | Cost per kW (USD) |

|---|---|---|---|

| Closed-Cycle OTEC | 10 MW | 286.3 | 21,606–27,012 |

| Closed-Cycle OTEC | 50 MW | 886.9 | 11,223–16,578 |

| Open-Cycle OTEC | 10 MW | 378.4 | 33,962–35,697 |

| Open-Cycle OTEC | 50 MW | 1308.6 | 22,722–24,459 |

| Onshore Open-Cycle OTEC | 1.36 MW | 42.8 | 31,471 |

| Country | DOW Pipe Length (km) | DOW Pipe Dia (m) | SOW Pipe Dia (m) | DOW Pipe Temp Inc. (%) | DOW Pump (MW) | SOW Pump (MW) | Evap Area (m2) | Cond Area (m2) | Gross OTEC Power (MW) | Net Therm. Eff | Avg CDD/day | Cooling Req (kWh/day) | SWAC Pump (kW) | SWAC Heat EX (m2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| American Samoa | 6 | 2 | 1 | 2% | 2 | 1 | 12,983 | 15,402 | 10 | 2.16% | 7.8 | 54,674 | 521 | 57 |

| Bahamas | 14 | 3 | 1 | 3% | 3 | 2 | 22,811 | 27,350 | 13 | 1.23% | 5.1 | 35,491 | 143 | 52 |

| Belize | 10 | 2 | 1 | 2% | 2 | 1 | 14,939 | 17,781 | 11 | 1.88% | 7.0 | 49,152 | 379 | 56 |

| Bermuda | 4 | 6 | 3 | 1% | 40 | 30 | 307,982 | 374,032 | 85 | 0.09% | 2.4 | 16,582 | 15 | 34 |

| Cabo Verde | 3 | 2 | 1 | 1% | 5 | 3 | 35,001 | 42,173 | 16 | 0.79% | 3.2 | 22,273 | 35 | 32 |

| The Cayman Islands | 4 | 2 | 1 | 2% | 2 | 2 | 16,260 | 19,377 | 11 | 1.77% | 6.5 | 45,535 | 301 | 56 |

| Cuba | 5 | 2 | 1 | 1% | 2 | 2 | 18,846 | 22,529 | 12 | 1.49% | 4.2 | 29,440 | 81 | 37 |

| Curacao | 7 | 2 | 1 | 2% | 2 | 2 | 16,807 | 20,049 | 11 | 1.68% | 7.8 | 54,674 | 521 | 65 |

| Dominica | 5 | 2 | 1 | 1% | 2 | 2 | 17,157 | 20,480 | 11 | 1.62% | 6.1 | 42,299 | 241 | 53 |

| Dominican Republic | 14 | 2 | 1 | 3% | 2 | 2 | 17,188 | 20,519 | 11 | 1.62% | 8.4 | 58,531 | 639 | 75 |

| The Federated States of Micronesia | 5 | 2 | 1 | 1% | 2 | 1 | 13,017 | 15,445 | 10 | 2.16% | 7.9 | 55,335 | 540 | 60 |

| Fiji | 2 | 2 | 1 | 1% | 2 | 1 | 14,796 | 17,604 | 11 | 1.91% | 5.1 | 35,652 | 144 | 36 |

| French Polynesia | 3 | 2 | 1 | 2% | 2 | 1 | 14,461 | 17,193 | 11 | 1.98% | 6.7 | 46,580 | 322 | 47 |

| Guam | 8 | 2 | 1 | 2% | 2 | 1 | 13,252 | 15,734 | 10 | 2.10% | 7.7 | 54,097 | 505 | 58 |

| Guinea-Bissau | 39 | 3 | 1 | 2% | 3 | 2 | 25,214 | 30,277 | 13 | 1.10% | 0.2 | 1530 | 0.011 | 2 |

| Guyana | 74 | 3 | 1 | 2% | 2 | 2 | 16,486 | 19,654 | 11 | 1.73% | 4.7 | 33,016 | 115 | 40 |

| Haiti | 2 | 2 | 1 | 1% | 2 | 2 | 18,981 | 22,695 | 12 | 1.48% | 3.2 | 22,273 | 35 | 32 |

| Jamaica | 5 | 2 | 1 | 2% | 2 | 2 | 16,143 | 19,233 | 11 | 1.79% | 7.3 | 51,280 | 430 | 64 |

| Kiribati | 3 | 2 | 1 | 1% | 2 | 1 | 13,157 | 15,616 | 10 | 2.12% | 4.6 | 32,053 | 105 | 35 |

| The Maldives | 4 | 2 | 1 | 1% | 2 | 2 | 17,255 | 20,601 | 11 | 1.61% | 8.8 | 61,488 | 741 | 111 |

| The Marshall Islands | 3 | 2 | 1 | 1% | 2 | 1 | 13,390 | 15,904 | 10 | 2.07% | 4.3 | 30,341 | 89 | 33 |

| Mauritius | 3 | 2 | 1 | 1% | 3 | 2 | 22,455 | 26,911 | 13 | 1.27% | 4.2 | 29,600 | 83 | 37 |

| Papua New Guinea | 6 | 2 | 1 | 2% | 2 | 2 | 16,131 | 19,219 | 11 | 1.79% | 6.0 | 42,253 | 241 | 46 |

| Puerto Rico | 11 | 3 | 1 | 2% | 3 | 2 | 20,936 | 25,072 | 12 | 1.34% | 3.8 | 26,479 | 59 | 41 |

| The Seychelles | 43 | 3 | 1 | 2% | 2 | 2 | 18,749 | 22,410 | 12 | 1.51% | 7.5 | 52,244 | 455 | 81 |

| The Solomon Islands | 7 | 2 | 1 | 2% | 2 | 1 | 12,566 | 14,889 | 10 | 2.27% | 6.5 | 45,535 | 301 | 49 |

| St. Vincent and the Grenadines | 4 | 2 | 1 | 1% | 2 | 2 | 16,746 | 19,974 | 11 | 1.69% | 7.3 | 51,280 | 430 | 62 |

| Timor-Leste | 4 | 2 | 1 | 1% | 2 | 1 | 14,812 | 17,624 | 11 | 1.91% | 6.8 | 47,836 | 349 | 59 |

| Trinidad and Tobago | 60 | 3 | 1 | 3% | 2 | 2 | 16,459 | 19,621 | 11 | 1.74% | 6.7 | 46,590 | 322 | 55 |

| Tuvalu | 3 | 2 | 1 | 2% | 2 | 1 | 12,601 | 14,933 | 10 | 2.26% | 8.4 | 58,611 | 642 | 63 |

| The U.S. Virgin Islands | 3 | 2 | 1 | 1% | 2 | 2 | 18,328 | 21,892 | 12 | 1.57% | 7.1 | 49,868 | 395 | 68 |

| Vanuatu | 14 | 2 | 1 | 3% | 2 | 2 | 15,363 | 18,302 | 11 | 1.80% | 4.7 | 33,016 | 115 | 34 |

| Country | OTEC LCOE (USD/kWh) | Electricity Tariff USD/kWh [85] | Gross Revenue (USD/year) | ROI | Simple Payback Period |

|---|---|---|---|---|---|

| Cabo Verde | 0.18 | 0.263 | $13,270,349 | 5% | 20 |

| Dominica | 0.17 | 0.368 | $18,568,397 | 8% | 13 |

| The Federated States of Micronesia | 0.13 | 0.414 | $20,889,446 | 11% | 9 |

| Fiji | 0.09 | 0.218 | $10,999,757 | 9% | 12 |

| Haiti | 0.11 | 0.211 | $10,646,554 | 7% | 14 |

| Jamaica | 0.17 | 0.264 | $13,320,806 | 4% | 24 |

| Kiribati | 0.12 | 0.413 | $20,838,989 | 15% | 7 |

| The Maldives | 0.12 | 0.394 | $19,880,294 | 12% | 9 |

| The Marshall Islands | 0.10 | 0.406 | $20,485,786 | 18% | 6 |

| Mauritius | 0.14 | 0.205 | $10,343,808 | 5% | 22 |

| Papua New Guinea | 0.18 | 0.289 | $14,582,246 | 5% | 22 |

| The Solomon Islands | 0.18 | 0.716 | $36,127,642 | 15% | 7 |

| St. Vincent and the Grenadines | 0.13 | 0.346 | $17,458,330 | 9% | 11 |

| Timor-Leste | 0.13 | 0.234 | $11,807,078 | 5% | 19 |

| Component | Fitted Form | R Square | Standard Error | p-Value | |

|---|---|---|---|---|---|

| Location-dependent components (million USD) | 93% | 16% | Intercept | ||

| 0 | |||||

| Seawater intake system (million USD) | 99% | 9.3% | Intercept | 0 | |

| 0 | |||||

| Location-independent components (million USD) | 70% | 34% | Intercept | ||

| OPEX | 3% of per year, where | ||||

| LCOE function (USD/kWh) | |||||

| Group | SIDS | Main Explanatory Factor | Recommended Actions |

|---|---|---|---|

| Techno economically feasible | American Samoa Belize Cabo Verde The Cayman Islands Cuba Curacao Dominica The Federated States of Micronesia Fiji French Polynesia Guam Haiti Jamaica Kiribati The Maldives The Marshall Islands Mauritius Papua New Guinea The Solomon Islands St. Vincent and Grenadins Timor Leste Tuvalu The US Virgin Islands | Steep near-shore bathymetry results in short intake pipes (≤10 km), keeping capital cost below ≈200 M USD. Diesel tariffs > 0.30 USD/kWh yield large LCOE savings (≥0.15 USD/kWh). High ambient cooling loads monetize the SWAC stream, driving additional revenue. In Cabo Verde, the is 16 °C; however, the short pipe length of 3 km gives an OTEC LCOE of 0.18 USD/kWh, much lower than the diesel LCOE (0.36 USD/kWh). | Technical: adopt modular 6–10 MW onshore units; use bundled HDPE pipes and aluminum plate-fin heat exchangers for lower CAPEX. Financial: leverage concessional climate finance and blended debt at <3% to keep LCOE < 0.15 USD/kWh. Structure power-purchase agreements that bundle electricity and chilled-water services. Institutional: fast-track marine zoning and environmental permits; create “OTEC eco-park” special-purpose zones that collocate desalination, aquaculture, and tourism cooling to diversify revenue. |

| Technically feasible but economically constrained | Dominican Republic Guyana The Seychelles Trinidad and Tobago Vanuatu | Adequate temperature difference is available °C, pipe lengths > 10 km, and capital cost > 250 million USD. This, combined with diesel LCOE ≤ 0.30 USD/kWh, narrows the economic margin, as diesel LCOE is less than OTEC LCOE. Trinidad and Tobago is additionally penalized by very low diesel costs (0.65 USD/l). | Technical: deploy higher-efficiency hybrid cycles or floating offshore plants to reduce pipe length; pilot solar-boosted hybrid OTEC to raise net efficiency where is weak. Financial: introduce green-bond frameworks, viability gap grants, or carbon offset revenues; reform fuel-subsidy structures so tariffs reflect import parity pricing. Institutional: Establish regional OTEC development funds (e.g., CARICOM green window); engage multilateral insurers to de-risk first-of-a-kind assets. |

| Unsuitable under current conditions | Bahamas Bermuda Guinea-Bissau Puerto Rico | Extremely low and long intake pipes (>40 km) drive capital costs above 1 billion USD, giving high OTEC LCOE higher than the diesel LCOE by 1 USD/kWh. | Technical: shift focus to offshore OTEC platforms or hybrid floating desalination to shorten pipe length; invest in R&D on flexible HDPE risers and deep-water moorings. Financial: pursue grant-funded resource assessments and small-scale demonstrators rather than utility projects; explore blue-carbon credits to improve project economics. Institutional: prioritise alternative renewables (PV + storage, wind) in near-term energy plans; maintain a strategic watch on OTEC cost-learning curves for future re-entry. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saadha, A.; Ishihara, K.N.; Ogawa, T.; Basu, S.; Okumura, H. Techno-Economic Analysis of Combined Onshore Ocean Thermal Energy Conversion Technology and Seawater Air Conditioning in Small Island Developing States. Sustainability 2025, 17, 4724. https://doi.org/10.3390/su17104724

Saadha A, Ishihara KN, Ogawa T, Basu S, Okumura H. Techno-Economic Analysis of Combined Onshore Ocean Thermal Energy Conversion Technology and Seawater Air Conditioning in Small Island Developing States. Sustainability. 2025; 17(10):4724. https://doi.org/10.3390/su17104724

Chicago/Turabian StyleSaadha, Aminath, Keiichi N. Ishihara, Takaya Ogawa, Soumya Basu, and Hideyuki Okumura. 2025. "Techno-Economic Analysis of Combined Onshore Ocean Thermal Energy Conversion Technology and Seawater Air Conditioning in Small Island Developing States" Sustainability 17, no. 10: 4724. https://doi.org/10.3390/su17104724

APA StyleSaadha, A., Ishihara, K. N., Ogawa, T., Basu, S., & Okumura, H. (2025). Techno-Economic Analysis of Combined Onshore Ocean Thermal Energy Conversion Technology and Seawater Air Conditioning in Small Island Developing States. Sustainability, 17(10), 4724. https://doi.org/10.3390/su17104724