The Dynamic Relationships Among Green Technological Innovation, Government Policies, and the Low-Carbon Transformation of the Manufacturing Industry in the Yangtze River Economic Belt: An Analysis Based on the PVAR Model

Abstract

1. Introduction

2. Theoretical Analysis and Literature Review

2.1. Theoretical Analysis

2.2. Green Technological Innovation and the Low-Carbon Transformation of Manufacturing

2.3. Government Policies and Green Technological Innovation

2.4. Government Policies and the Low-Carbon Transformation of Manufacturing

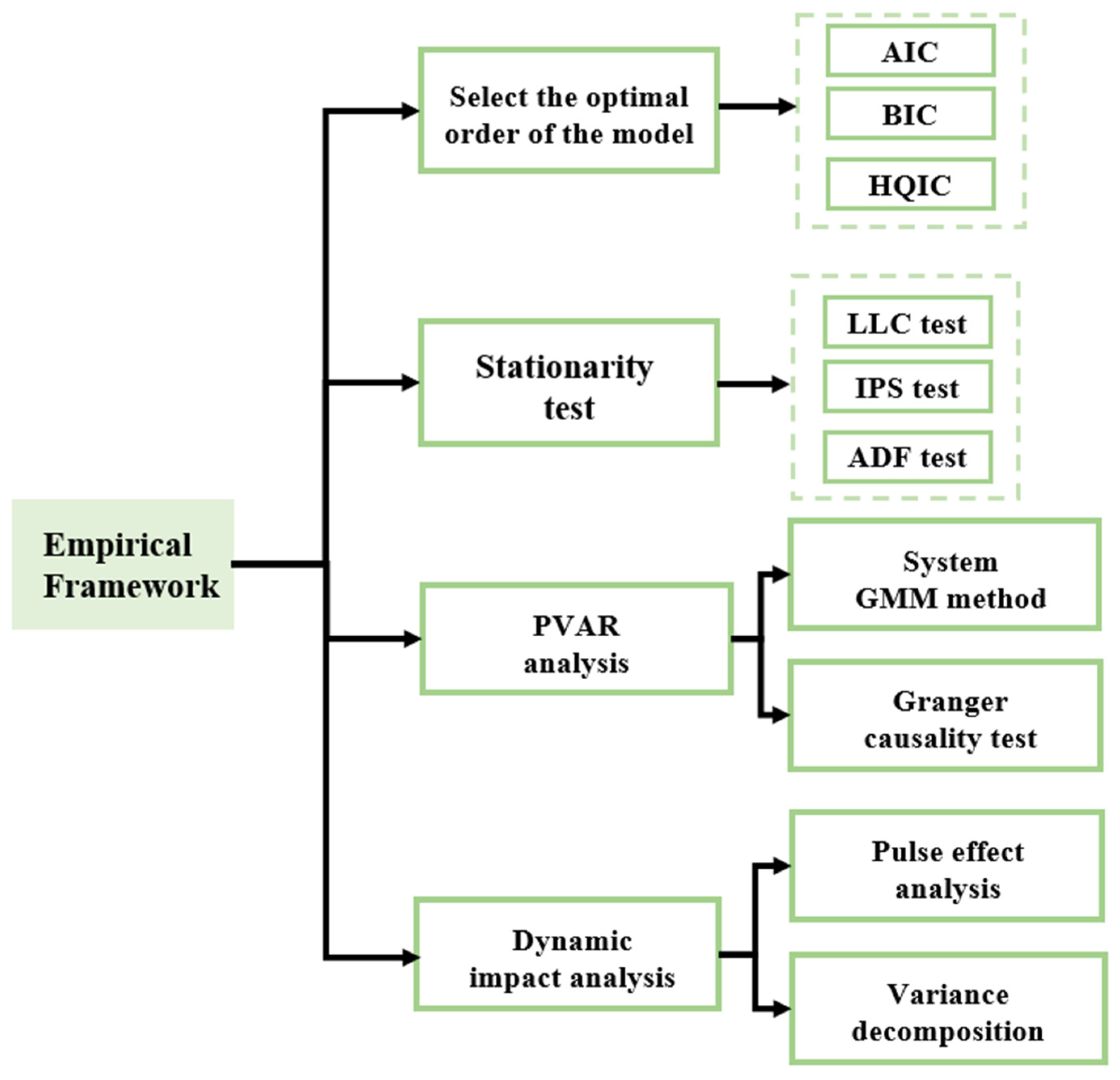

3. Data and Methods

3.1. Data and Processing

3.2. Variable Description

3.3. Method

3.3.1. Principal Component Analysis

3.3.2. PVAR Model

4. Empirical Results

4.1. BP-LM Test, Unit Root Test, and Cointegration Test Results

4.2. Panel Vector Autoregression Regression (PVAR) Analysis

4.3. Stability Test

4.4. Granger Causality Test

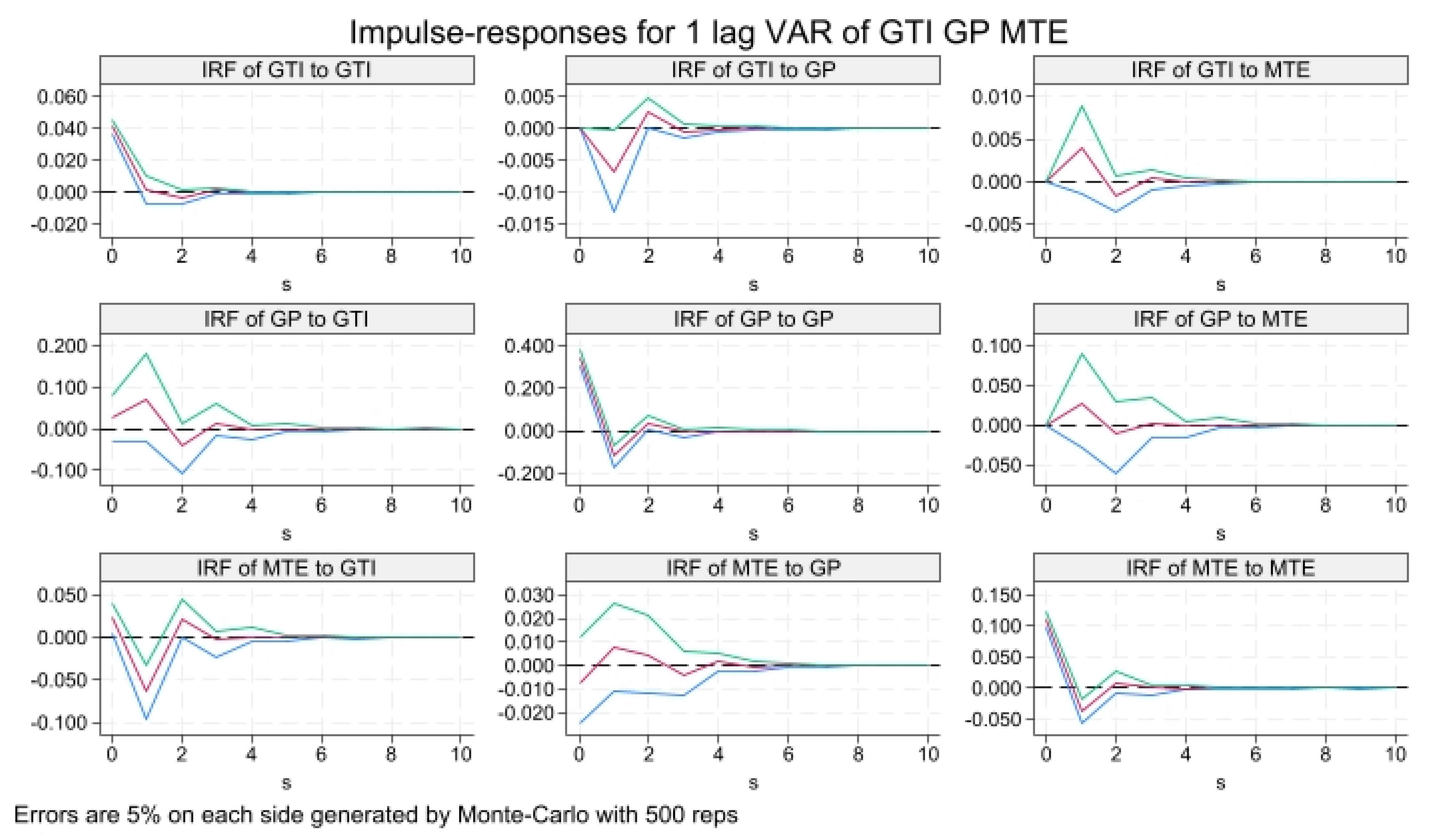

4.5. Impulse Response Analysis

4.6. Variance Decomposition

5. Conclusions and Suggestions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Lahouel, B.B.; Taleb, L.; Zaied, Y.B.; Managi, S. Does ICT change the relationship between total factor productivity and CO2 emissions? Evidence based on a nonlinear model. Energy Econ. 2021, 101, 105406. [Google Scholar] [CrossRef]

- Khan, M.K.; Khan, M.I.; Rehan, M. The relationship between energy consumption, economic growth and carbon dioxide emissions in Pakistan. Financ. Innov. 2020, 6, 1. [Google Scholar] [CrossRef]

- Shen, Y.; Zhang, X. Intelligent manufacturing, green technological innovation and environmental pollution. J. Innov. Knowl. 2023, 8, 100384. [Google Scholar] [CrossRef]

- Hao, Y.; Guo, Y.; Wu, H. The role of information and communication technology on green total factor energy efficiency: Does environmental regulation work? Bus. Strategy Environ. 2022, 31, 403–424. [Google Scholar] [CrossRef]

- Razzaq, A.; Sharif, A.; An, H.; Aloui, C. Testing the directional predictability between carbon trading and sectoral stocks in China: New insights using cross-quantilogram and rolling window causality approaches. Technol. Forecast. Soc. Change 2022, 182, 121846. [Google Scholar] [CrossRef]

- Wang, Y.; Duan, X.; Wang, L.; Zou, H. Spatial temporal patterns and driving factors of industrial pollution and structures in the Yangtze River Economic Belt. Chemosphere 2022, 303, 134996. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, S.; Huang, D.; Li, B.-L.; Liu, J.; Liu, W.; Ma, J.; Wang, F.; Wang, Y.; Wu, S. The development of China’s Yangtze River Economic Belt: How to make it in a green way. Sci. Bull. 2017, 62, 648–651. [Google Scholar] [CrossRef]

- Liu, J.; Diamond, J. China’s environment in a globalizing world. Nature 2005, 435, 52–53. [Google Scholar] [CrossRef]

- Zhang, S.; Li, H.; Zhang, Q.; Tian, X.; Shi, F. Uncovering the impacts of industrial transformation on low-carbon development in the Yangtze River Delta. Resour. Conserv. Recycl. 2019, 150, 104442. [Google Scholar] [CrossRef]

- Zhang, W.; Zhou, H.; Chen, J.; Fan, Z. An Empirical Analysis of the Impact of Digital Economy on Manufacturing Green and Low-Carbon Transformation under the Dual-Carbon Background in China. Int. J. Environ. Res Public Health 2022, 19, 13192. [Google Scholar] [CrossRef]

- Zhou, J. Digitalization and intelligentization of manufacturing industry. Adv. Manuf. 2013, 1, 1–7. [Google Scholar] [CrossRef]

- Chen, L.; Li, K.; Chen, S.; Wang, X.; Tang, L. Industrial activity, energy structure, and environmental pollution in China. Energy Econ. 2021, 104, 105633. [Google Scholar] [CrossRef]

- Kane, G. The technology fallacy: People are the real key to digital transformation. Res. -Technol. Manag. 2019, 62, 44–49. [Google Scholar] [CrossRef]

- Peng, H.; Lu, Y.; Gupta, S.; Wang, Q. Dynamic and heterogeneity assessment of carbon efficiency in the manufacturing industry in China: Implications for formulating carbon policies. Environ. Impact Assess. Rev. 2022, 97, 106885. [Google Scholar] [CrossRef]

- Rennings, K.; Ziegler, A.; Ankele, K.; Hoffmann, E. The influence of different characteristics of the EU environmental management and auditing scheme on technical environmental innovations and economic performance. Ecol. Econ. 2006, 57, 45–59. [Google Scholar] [CrossRef]

- Abdullah, M.; Zailani, S.; Iranmanesh, M.; Jayaraman, K. Barriers to green innovation initiatives among manufacturers: The Malaysian case. Rev. Manag. Sci. 2016, 10, 683–709. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pujari, D.; Pontrandolfo, P. Green product innovation in manufacturing firms: A sustainability-oriented dynamic capability perspective. Bus. Strategy Environ. 2017, 26, 490–506. [Google Scholar] [CrossRef]

- Liao, B.; Li, L. Spatial division of labor, specialization of green technology innovation process and urban coordinated green development: Evidence from China. Sustain. Cities Soc. 2022, 80, 103778. [Google Scholar] [CrossRef]

- Xu, Y.; Ge, W.; Liu, G.; Su, X.; Zhu, J.; Yang, C.; Yang, X.; Ran, Q. The impact of local government competition and green technology innovation on economic low-carbon transition: New insights from China. Environ. Sci. Pollut. Res. 2023, 30, 23714–23735. [Google Scholar] [CrossRef]

- Ambec, S.; Cohen, M.A.; Elgie, S.; Lanoie, P. The Porter hypothesis at 20: Can environmental regulation enhance innovation and competitiveness? Rev. Environ. Econ. Policy 2013, 7, 2–22. [Google Scholar] [CrossRef]

- Sarkodie, S.A.; Strezov, V. A review on environmental Kuznets curve hypothesis using bibliometric and meta-analysis. Sci. Total Environ. 2019, 649, 128–145. [Google Scholar] [CrossRef]

- Zhou, P.; Ang, B.W.; Poh, K.L. A survey of data envelopment analysis in energy and environmental studies. Eur. J. Oper. Res. 2008, 189, 1–18. [Google Scholar] [CrossRef]

- Shi, Q.; Lai, X. Identifying the underpin of green and low carbon technology innovation research: A literature review from 1994 to 2010. Technol. Forecast. Soc. Change 2013, 80, 839–864. [Google Scholar] [CrossRef]

- Shi, R.; Cui, Y.; Zhao, M. Role of low-carbon technology innovation in environmental performance of manufacturing: Evidence from OECD countries. Environ. Sci. Pollut. Res. 2021, 28, 68572–68584. [Google Scholar] [CrossRef]

- Sun, L.; Feng, N. Research on fiscal policies supporting green and low-carbon transition to promote energy conservation and emission reduction in cities: Empirical evidence from China. J. Clean. Prod. 2023, 430, 139688. [Google Scholar] [CrossRef]

- Guo, L.; Tan, W. Analyzing the synergistic influence of green credit and green technology innovation in driving the Low-Carbon transition of the energy consumption structure. Sustain. Energy Technol. Assess. 2024, 63, 103633. [Google Scholar] [CrossRef]

- Tian, Y.; Song, W.; Liu, M. Assessment of how environmental policy affects urban innovation: Evidence from China’s low-carbon pilot cities program. Econ. Anal. Policy 2021, 71, 41–56. [Google Scholar] [CrossRef]

- Wang, T.; Song, Z.; Zhou, J.; Sun, H.; Liu, F. Low-carbon transition and green innovation: Evidence from pilot cities in China. Sustainability 2022, 14, 7264. [Google Scholar] [CrossRef]

- Yang, G.; Nie, Y.; Li, H.; Wang, H. Digital transformation and low-carbon technology innovation in manufacturing firms: The mediating role of dynamic capabilities. Int. J. Prod. Econ. 2023, 263, 108969. [Google Scholar] [CrossRef]

- Zeng, S.; Jin, G.; Tan, K.; Liu, X. Can low-carbon city construction reduce carbon intensity? Empirical evidence from low-carbon city pilot policy in China. J. Environ. Manag. 2023, 332, 117363. [Google Scholar] [CrossRef]

- Li, F.; Xu, X.; Li, Z.; Du, P.; Ye, J. Can low-carbon technological innovation truly improve enterprise performance? The case of Chinese manufacturing companies. J. Clean. Prod. 2021, 293, 125949. [Google Scholar] [CrossRef]

- Guo, Y.; Xia, X.; Zhang, S.; Zhang, D. Environmental regulation, government R&D funding and green technology innovation: Evidence from China provincial data. Sustainability 2018, 10, 940. [Google Scholar] [CrossRef]

- Shao, Y.; Chen, Z. Can government subsidies promote the green technology innovation transformation? Evidence from Chinese listed companies. Econ. Anal. Policy 2022, 74, 716–727. [Google Scholar] [CrossRef]

- Wang, P.; Dong, C.; Chen, N.; Qi, M.; Yang, S.; Nnenna, A.B.; Li, W. Environmental regulation, government subsidies, and green technology innovation—A provincial panel data analysis from China. Int. J. Environ. Res. Public Health 2021, 18, 11991. [Google Scholar] [CrossRef]

- Yi, M.; Fang, X.; Wen, L.; Guang, F.; Zhang, Y. The heterogeneous effects of different environmental policy instruments on green technology innovation. Int. J. Environ. Res. Public Health 2019, 16, 4660. [Google Scholar] [CrossRef]

- Zhang, N.; Deng, J.; Ahmad, F.; Draz, M.U.; Abid, N. The dynamic association between public environmental demands, government environmental governance, and green technology innovation in China: Evidence from panel VAR model. Environ. Dev. Sustain. 2023, 25, 9851–9875. [Google Scholar] [CrossRef]

- Wu, G.; Xu, Q.; Niu, X.; Tao, L. How does government policy improve green technology innovation: An empirical study in China. Front. Environ. Sci. 2022, 9, 799794. [Google Scholar] [CrossRef]

- Guo, Q.; Zhou, M.; Liu, N.; Wang, Y. Spatial effects of environmental regulation and green credits on green technology innovation under low-carbon economy background conditions. Int. J. Environ. Res. Public Health 2019, 16, 3027. [Google Scholar] [CrossRef]

- Wu, H.; Hu, S. The impact of synergy effect between government subsidies and slack resources on green technology innovation. J. Clean. Prod. 2020, 274, 122682. [Google Scholar] [CrossRef]

- Barbera, A.J.; McConnell, V.D. The impact of environmental regulations on industry productivity: Direct and indirect effects. J. Environ. Econ. Manag. 1990, 18, 50–65. [Google Scholar] [CrossRef]

- Lanjouw, J.O.; Mody, A. Innovation and the international diffusion of environmentally responsive technology. Res. Policy 1996, 25, 549–571. [Google Scholar] [CrossRef]

- Wang, L.; Long, Y.; Li, C. Research on the impact mechanism of heterogeneous environmental regulation on enterprise green technology innovation. J. Environ. Manag. 2022, 322, 116127. [Google Scholar] [CrossRef]

- Wei, L.; Zhang, H. How environmental regulations affect the efficiency of green technology innovation? Am. J. Ind. Bus. Manag. 2020, 10, 507–521. [Google Scholar] [CrossRef]

- Deng, Y.; You, D.; Wang, J. Optimal strategy for enterprises’ green technology innovation from the perspective of political competition. J. Clean. Prod. 2019, 235, 930–942. [Google Scholar] [CrossRef]

- Ouyang, X.; Li, Q.; Du, K. How does environmental regulation promote technological innovations in the industrial sector? Evidence from Chinese provincial panel data. Energy Policy 2020, 139, 111310. [Google Scholar] [CrossRef]

- Busch, J.; Foxon, T.J.; Taylor, P.G. Designing industrial strategy for a low carbon transformation. Environ. Innov. Soc. Transit. 2018, 29, 114–125. [Google Scholar] [CrossRef]

- Feng, N.; Ge, J. How does fiscal policy affect the green low-carbon transition from the perspective of the evolutionary game? Energy Econ. 2024, 134, 107578. [Google Scholar] [CrossRef]

- Liu, M.; Li, S.; Li, Y.; Shi, J.; Bai, J. Evaluating the synergistic effects of digital economy and government governance on urban low-carbon transition. Sustain. Cities Soc. 2024, 105, 105337. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, L.; An, H.; Peng, L.; Zhou, H.; Hu, F. Has China’s low-carbon strategy pushed forward the digital transformation of manufacturing enterprises? Evidence from the low-carbon city pilot policy. Environ. Impact Assess. Rev. 2023, 102, 107184. [Google Scholar] [CrossRef]

- Pingkuo, L.; Huan, P. What drives the green and low-carbon energy transition in China?: An empirical analysis based on a novel framework. Energy 2022, 239, 122450. [Google Scholar] [CrossRef]

- Liu, X.-m.; Zhang, Y.-q. Study on the impact of intelligent city pilot on green and low-carbon development. Environ. Sci. Pollut. Res. 2023, 30, 57882–57897. [Google Scholar] [CrossRef] [PubMed]

- Pan, J.; Chen, X.; Luo, X.; Zeng, X.; Liu, Z.; Lai, W.; Xu, Y.; Lu, C. Analysis of the impact of China’s energy industry on social development from the perspective of low-carbon policy. Energy Rep. 2022, 8, 14–27. [Google Scholar] [CrossRef]

- Wang, Z.; Liang, F.; Li, C.; Xiong, W.; Chen, Y.; Xie, F. Does China’s low-carbon city pilot policy promote green development? Evidence from the digital industry. J. Innov. Knowl. 2023, 8, 100339. [Google Scholar] [CrossRef]

- Zhou, Z.; Ma, Z.; Lin, X. Carbon emissions trading policy and green transformation of China’s manufacturing industry: Mechanism assessment and policy implications. Front. Environ. Sci. 2022, 10, 984612. [Google Scholar] [CrossRef]

- Xie, R.H.; Yuan, Y.J.; Huang, J.J. Different types of environmental regulations and heterogeneous influence on “green” productivity: Evidence from China. Ecol. Econ. 2017, 132, 104–112. [Google Scholar] [CrossRef]

- Li, B.; Wu, S. Effects of local and civil environmental regulation on green total factor productivity in China: A spatial Durbin econometric analysis. J. Clean. Prod. 2017, 153, 342–353. [Google Scholar] [CrossRef]

- Wang, Q.; Su, M. A preliminary assessment of the impact of COVID-19 on environment–A case study of China. Sci. Total Environ. 2020, 728, 138915. [Google Scholar] [CrossRef]

- Horbach, J.; Rammer, C.; Rennings, K. Determinants of eco-innovations by type of environmental impact—The role of regulatory push/pull, technology push and market pull. Ecol. Econ. 2012, 78, 112–122. [Google Scholar] [CrossRef]

- Testa, F.; Annunziata, E.; Iraldo, F.; Frey, M. Drawbacks and opportunities of green public procurement: An effective tool for sustainable production. J. Clean. Prod. 2016, 112, 1893–1900. [Google Scholar] [CrossRef]

- Kivimaa, P.; Kern, F. Creative destruction or mere niche support? Innovation policy mixes for sustainability transitions. Res. Policy 2016, 45, 205–217. [Google Scholar] [CrossRef]

- Chen, Z.; Niu, X.; Gao, X.; Chen, H. How does environmental regulation affect green innovation? A perspective from the heterogeneity in environmental regulations and pollutants. Front. Energy Res. 2022, 10, 885525. [Google Scholar] [CrossRef]

- Ren, S.; Li, X.; Yuan, B.; Li, D.; Chen, X. The effects of three types of environmental regulation on eco-efficiency: A cross-region analysis in China. J. Clean. Prod. 2018, 173, 245–255. [Google Scholar] [CrossRef]

- Holtz-Eakin, D.; Newey, W.; Rosen, H.S. Estimating Vector Autoregressions with Panel Data. Econometrica 1988, 56, 1371–1395. [Google Scholar] [CrossRef]

- Love, I.; Zicchino, L. Financial development and dynamic investment behavior: Evidence from panel VAR. Q. Rev. Econ. Financ. 2006, 46, 190–210. [Google Scholar] [CrossRef]

- Pesaran, M.H. Estimation and inference in large heterogeneous panels with a multifactor error structure. Econometrica 2006, 74, 967–1012. [Google Scholar] [CrossRef]

- Dickey, D.A.; Fuller, W.A. Distribution of the Estimators for Autoregressive Time Series With a Unit Root. J. Am. Stat. Assoc. 1979, 74, 427–431. [Google Scholar] [CrossRef]

| Index | Symbol | Description |

|---|---|---|

| Labor input | LI | Manufacturing employment per thousands of people |

| R&D investment | RI | Hundred million yuan of internal expenditure of R&D funds |

| Capital input | CI | Hundred million yuan of the net fixed assets of manufacturing enterprises above designated size |

| Energy input | EI | Tons of standard coal in total energy consumption in manufacturing |

| Earnings output | FO | Manufacturing new product sales revenue per ten thousand yuan |

| Innovation output | IO | A unit of green invention patents granted |

| Industrial wastewater discharge | IWE | Ten thousand tons of industrial wastewater discharge |

| Industrial sulfur dioxide emissions | ISDE | Ten thousand tons of industrial sulfur dioxide emissions |

| Industrial smoke and dust emissions | ISAD | Ten thousand tons of industrial smoke and dust emissions |

| Generating capacity | PG | Hundreds of millions of kilowatt-hours of renewable energy generation |

| Manufacturing value added | MVA | Hundred million yuan of manufacturing value added |

| Carbon emission | CE | Ten thousand tons of carbon dioxide emissions |

| Government policy | GP | Percentage of keyword frequency |

| Green technology innovation | GTI | Green technology innovation efficiency value |

| Low-carbon transformation in manufacturing | MTE | Efficiency value of low-carbon transition in manufacturing industry |

| Number | Minimum | Median | Maximum | Standard | Kurtosis | Skewness | |

|---|---|---|---|---|---|---|---|

| LI | 143 | 0 | 0.44 | 1 | 0.34 | 1.59 | 0.06 |

| RI | 143 | 0 | 0.34 | 1 | 0.32 | 1.84 | 0.42 |

| CI | 143 | 0 | 0.48 | 1 | 0.32 | 1.71 | 0.06 |

| EI | 143 | 0 | 0.52 | 1 | 0.34 | 1.60 | −0.04 |

| FO | 143 | 0 | 0.44 | 1 | 0.32 | 1.84 | 0.27 |

| IO | 143 | 0 | 0.32 | 1 | 0.33 | 1.88 | 0.46 |

| IWE | 143 | 0 | 0.14 | 1 | 0.35 | 3.02 | 1.31 |

| ISDE | 143 | 0 | 0.24 | 1 | 0.40 | 1.29 | 0.33 |

| ISAD | 143 | 0 | 0.45 | 1 | 0.32 | 1.79 | 0.11 |

| PG | 143 | 0 | 0.48 | 1 | 0.32 | 1.84 | 0.00 |

| MVA | 143 | 0 | 0.44 | 1 | 0.33 | 1.79 | 0.22 |

| CE | 143 | 0 | 0.43 | 1 | 0.30 | 1.97 | 0.20 |

| GP | 143 | 0 | 0.46 | 1 | 0.29 | 2.25 | 0.13 |

| Primary Index | Secondary Index | Tertiary Indicators | PCA Weigh |

|---|---|---|---|

| Input index | Labor input | 3.9884% | |

| R&investment | 13.9260% | ||

| Capital input | 39.9493% | ||

| Energy input | 1.2823% | ||

| Expected output | Earnings output | 9.1987% | |

| Innovation output | 12.7295% | ||

| Undesirable output | Industrial wastewater | 3.5649% | |

| Industrial sulfur dioxide | 10.5885% | ||

| Industrial smoke dust | 4.7723% |

| Lags | AIC | BIC | HQIC |

|---|---|---|---|

| 1 | −3.59434 * | −2.56325 * | −3.17613 * |

| 2 | −3.02473 | −1.68785 | −2.48382 |

| 3 | 2.41974 | 4.10883 | 3.10023 |

| 4 | −1.67542 | 0.424874 | −0.83532 |

| Variables | Chibar2 | Prob > Chibar2 |

|---|---|---|

| GTI | 0.00 | 1.0000 |

| GP | 0.00 | 1.0000 |

| MTE | 0.00 | 1.0000 |

| Variables | Statistic | Value | p-Value |

|---|---|---|---|

| GTI | Z | −7.5812 | 0.0000 |

| L | −8.6700 | 0.0000 | |

| Pm | 12.3570 | 0.0000 | |

| GP | Z | −13.0053 | 0.0000 |

| L | −20.3904 | 0.0000 | |

| Pm | 33.3665 | 0.0000 | |

| MTE | Z | −9.2009 | 0.0000 |

| L | −13.0292 | 0.0000 | |

| Pm | 20.4018 | 0.0000 |

| Variables | Statistic | Value | p-Value |

|---|---|---|---|

| GTI | Modified P–P | 2.9775 | 0.0015 |

| P–P | −3.1629 | 0.0008 | |

| ADF | −3.3287 | 0.0004 | |

| GP | Modified P–P | 1.7423 | 0.0407 |

| P–P | −9.0185 | 0.0000 | |

| ADF | −9.5261 | 0.0000 | |

| MTE | Modified P–P | 2.5044 | 0.0061 |

| P–P | −6.5321 | 0.0000 | |

| ADF | −3.6446 | 0.0001 |

| Explained Variable | Explanatory Variable | Lags | Regression Coefficient | p Value |

|---|---|---|---|---|

| GTI | GTI | 1 | 0.0164 | 0.892 |

| GP | 1 | −0.0190 | 0.068 | |

| MTE | 1 | 0.0349 | 0.022 | |

| GP | GTI | 1 | 1.7716 | 0.239 |

| GP | 1 | −0.3415 | 0.000 | |

| MTE | 1 | 0.2483 | 0.436 | |

| MTE | GTI | 1 | 1.3660 | 0.003 |

| GP | 1 | 0.0164 | 0.582 | |

| MTE | 1 | −0.3209 | 0.004 |

| Eigenvalue | Modulus | |

|---|---|---|

| Real | Imaginary | |

| −0.2931 | −0.1992 | 0.3544 |

| −0.2931 | 0.1992 | 0.3544 |

| −0.2458 | 0.0000 | 0.2458 |

| Independent Variable–Dependent Variable | chi2 | df | Prob > chi2 |

|---|---|---|---|

| GTI→GP | 3.330 | 1 | 0.068 |

| GTI→MTE | 5.231 | 1 | 0.022 |

| GP→GTI | 1.384 | 1 | 0.239 |

| GP→MTE | 0.599 | 1 | 0.436 |

| MTE→GMI | 8.761 | 1 | 0.003 |

| MTE→GP | 0.303 | 1 | 0.582 |

| Response Variable | Number of Periods | Shock Variable | ||

|---|---|---|---|---|

| GTI | GP | MTE | ||

| GTI | 1 | 1.000 | 0.000 | 0.000 |

| 5 | 0.961 | 0.029 | 0.010 | |

| 10 | 0.961 | 0.029 | 0.010 | |

| GP | 1 | 0.007 | 0.993 | 0.000 |

| 5 | 0.050 | 0.943 | 0.006 | |

| 10 | 0.050 | 0.943 | 0.006 | |

| MTE | 1 | 0.040 | 0.005 | 0.955 |

| 5 | 0.263 | 0.009 | 0.728 | |

| 10 | 0.263 | 0.009 | 0.728 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shangguan, J.; Xiong, P.; Ye, Z.; Wang, J. The Dynamic Relationships Among Green Technological Innovation, Government Policies, and the Low-Carbon Transformation of the Manufacturing Industry in the Yangtze River Economic Belt: An Analysis Based on the PVAR Model. Sustainability 2025, 17, 4544. https://doi.org/10.3390/su17104544

Shangguan J, Xiong P, Ye Z, Wang J. The Dynamic Relationships Among Green Technological Innovation, Government Policies, and the Low-Carbon Transformation of the Manufacturing Industry in the Yangtze River Economic Belt: An Analysis Based on the PVAR Model. Sustainability. 2025; 17(10):4544. https://doi.org/10.3390/su17104544

Chicago/Turabian StyleShangguan, Jiawei, Pingping Xiong, Zhexuan Ye, and Jie Wang. 2025. "The Dynamic Relationships Among Green Technological Innovation, Government Policies, and the Low-Carbon Transformation of the Manufacturing Industry in the Yangtze River Economic Belt: An Analysis Based on the PVAR Model" Sustainability 17, no. 10: 4544. https://doi.org/10.3390/su17104544

APA StyleShangguan, J., Xiong, P., Ye, Z., & Wang, J. (2025). The Dynamic Relationships Among Green Technological Innovation, Government Policies, and the Low-Carbon Transformation of the Manufacturing Industry in the Yangtze River Economic Belt: An Analysis Based on the PVAR Model. Sustainability, 17(10), 4544. https://doi.org/10.3390/su17104544