1. Introduction

Climate change is one of the global challenges that is now generating lots of concern. The US’s utility-scale power plants produced 4243 billion kWh, or over 4.24 trillion kWh, in 2022. Fuels source data in utility-scale power generation such as coal (19.5%), natural gas (39.8%), nuclear (18.2%), and renewable energy sources (21.5%) indicate that fossil fuels account for about 60% of the total electricity produced in the US [

1]. About 25% of all greenhouse gas (GHG) emissions in the US are emitted by the electricity sector as well as other end-use sectors like industries that utilize electricity [

2]. In less than 200 years, human activity has raised the atmospheric concentration of CO

2 by 50%, creating a new record for the global average atmospheric CO

2 concentration of 420 ppm [

3]. The US has set ambitious targets to mitigate the consequences of climate change, such as net-zero carbon emissions by 2050 [

4] and carbon-emission-free electricity by 2035 [

5].

In the US, coal is one of the primary fossil fuels used to produce electricity [

1]. However, coal has an adverse impact on the environment at all phases of production, including mining, transportation, stacking, processing, and combustion. For example, the mining of coal has the potential to damage nearby plants and contaminate the land, air, and water [

6]. The massive volumes of greenhouse gas emissions produced by burning coal are a major contributor to the phenomenon of global warming. On the other hand, the United States generates around 100 million tons of bituminous coal refuse, or 320 lbs., for every ton of coal sold [

7]. The utilization of readily available coal refuse (waste coal) for power generation can reduce the net CO

2 emissions because the mining process is not required. Additionally, the utilization of waste coal supports reclamation projects which will eliminate environmental problems such as acid mine drainage from the waste coal stockpiles and reclaim the land occupied by waste coal. Moreover, biomass-based power generation is expanding quickly due to its lower carbon footprint and ability to meet the net-zero carbon goal when carbon capture and storage (CCS) is implemented.

Several studies have been conducted on the performance and emission assessment of coal-fired, biomass-fired, and coal–biomass co-fired power plants. Dave et al. [

8] studied a black coal (Surat Basin)-fired power plant with a gross electrical output of 600 MW operating at an 85% capacity factor. The utilized higher heating value (HHV) of black coal was measured at 20.14 MJ/kg. The analysis revealed that the net plant efficiency was 36.7% in the absence of CCS implementation and 26.7% with CCS adoption for the subcritical range. The net plant efficiency for the supercritical range was determined to be 39.2% without CCS integration and 29.1% with CCS integration. Additionally, it was discovered that the implementation of CO

2 capture in these plants results in a decrease of around 10% in net plant efficiency and a more than twofold increase in the cost of electricity generation across all plants. Strube and Manfrida [

9] conducted a study on the efficiency of a 500 MW pulverized coal power plant that utilized monoethanolamine (MEA) and ammonia as chemical solvents for capturing CO

2 after combustion. The higher heating value (HHV) and lower heating value (LHV) of the coal were determined to be 27.06 MJ/kg and 25.87 MJ/kg, respectively. The study determined that the net plant efficiency of the plant, without integrating carbon capture technology, was 36.3%. The net plant efficiency for capture instances was determined to be 28.4% for MEA-based capture and 21.8% for ammonia-based capture. The study proposed that the most practical approach to upgrading current power plants is to implement the post-combustion capture method, as long as the levels of SO

X and NOx are decreased to the necessary thresholds to minimize the degradation of the solvent. Tramošljika et al. [

10] conducted a performance assessment of a potential advanced ultra-supercritical coal-fired power plant with a net plant capacity of 700 MW equipped with post-combustion CCS technology. They demonstrated that when the rate of CO

2 removal was set at 90%, the net efficiency of the advanced ultra-supercritical unit integrated with CCS was found to be 36.8%. The net efficiency loss incurred was 10.8%, and the penalty on power generation amounts to 362.3 kilowatt-hours per metric ton of CO

2 for the current state of CCS technology. The study also found that the absorption of CO

2 by a 30% weight MEA solution leads to net efficiency losses ranging from 9.7% to 13.4%, depending on the heating duty and temperature of the reboiler. Although coal-based power generation dominated the energy sector over the years, the push for a zero-carbon energy economy led to the deployment of advanced biomass-based power generation.

Several studies have reported on the performance and emissions profiles of power plants that utilize biomass as a fuel source. Ghenai et al. [

11] performed an analysis of the performance of biomass-fired power plants with a capacity of 10 MW in West Palm Beach, Florida. Their study utilized various forms of biomasses, including bagasse, corn stover, forest residues, and urban wood residues. The investigation revealed that the thermal efficiency of the biomass-fueled power plant ranged from 26.51% to 27.75%. The heat rate was determined to be between 12.29 and 12.87 MMBtu/MWh, and the capacity factor ranged from 83.34 to 84.74. Another study carried out by Brown et al. [

12] evaluated the environmental performance of four newly constructed biomass plants situated in Altavista, Hopewell, Southampton, and Pittsylvania. The assessment was based on the estimated emissions of nitrogen oxides (NO

X), sulfur dioxide (SO

2), and carbon dioxide (CO

2) produced per megawatt-hour (MWh) of electricity generated. These power facilities have been transformed from coal plants to exclusively using biomass fuel, specifically woody biomass or wood waste, as their source of fuel. The study demonstrated a decrease in NO

X emissions by around 50–62% when comparing the emissions of NO

X per MWh in 2012 with their rate in 2014 in Hopewell and Southampton. In comparison to the statistics from 2010, the Altavista power plant witnessed a reduction of 37% in NO

X emissions in 2014 and a further reduction of 99% in 2016. Even though biomass-based power generation reduced GHG emissions significantly, storage and logistics are the major hurdles for large-scale advanced biomass-based power generation.

The co-firing of biomass and coal is a potential solution to decarbonize large-scale (typically > 300 MW) power plants. Numerous studies have focused on the modeling and performance of coal and biomass co-fired power plants with various boiler types and power plant capacities. To investigate important performance parameters like boiler efficiency, net plant efficiency, and combustion characteristics from the co-firing of different biomasses with two low-ranked coal samples based on an existing 500 MW pulverized coal-fired power plant, Mun et al. [

13] used a commercial process simulator in their study. The results quantitatively demonstrate that co-firing biomass with coal decreases the net plant efficiency because biomass has a lower heating value (LHV) than coal. However, among both biomass and low-rank coal co-firing, the plant efficiency of torrefied biomass co-firing was the highest because of the increased energy density and enhanced grindability of the torrefied biomass. D. Cebrucean et al. [

14] reported on a simplified form of a pulverized coal-fired power plant with biomass co-firing and integrated a post-combustion chemical absorption process for CO

2 collection. The main parts of the plant were a pulverized coal (PC) boiler and a flue gas desulfurization (FGD) section, where coal and biomass were co-fired and particulate matter, NOx, and SO

2 emissions were generated. These pollutants were removed using chemical absorption-based CCS technology. The study found that the net power plant efficiency of supercritical power plants was approximately 2.4% greater than that of conventional subcritical power plants. As a result, there was a roughly 6% decrease in CO

2 emissions compared to subcritical units. When accounting for the carbon neutrality of the biomass source, the addition of biomass to the feed in power plants resulted in a CO

2 emission reduction of around 28%. In a study by Andric et al. [

15], two methods were explored to address two important aspects of power production: the carbon footprint and an emergency evaluation of coal biomass co-firing. The study also showed that including around 20 percent biomass into the combustion mixture reduces CO

2 emissions by about 11–25 percent and energy flow by about 8–15 percent.

As discussed above, there have been several studies on the performance and emission characteristics of coal power plants [

8,

9,

10], biomass-based power plants [

11,

12], and coal and biomass co-fired power plants [

13,

14,

15]. To our knowledge, detailed assessments of waste coal (coal refuse) and pine biomass have not been reported in the literature. In addition, as discussed above, the major literature studies focused primarily on the effects of co-firing ratios of conventional coal and biomass on power plant performance. In this study, the effects of plant capacities (100 and 600 MW), boiler types (PC and CFB), fluid types (Subcritical and Supercritical), waste coal and biomass co-firing ratios (0:100, 20:80, 40:60, 60:40, 80:20, and 100:0), and CCS efficiencies (90, 95 and 97) on the performance of waste coal and pine biomass co-fired power plants are investigated.

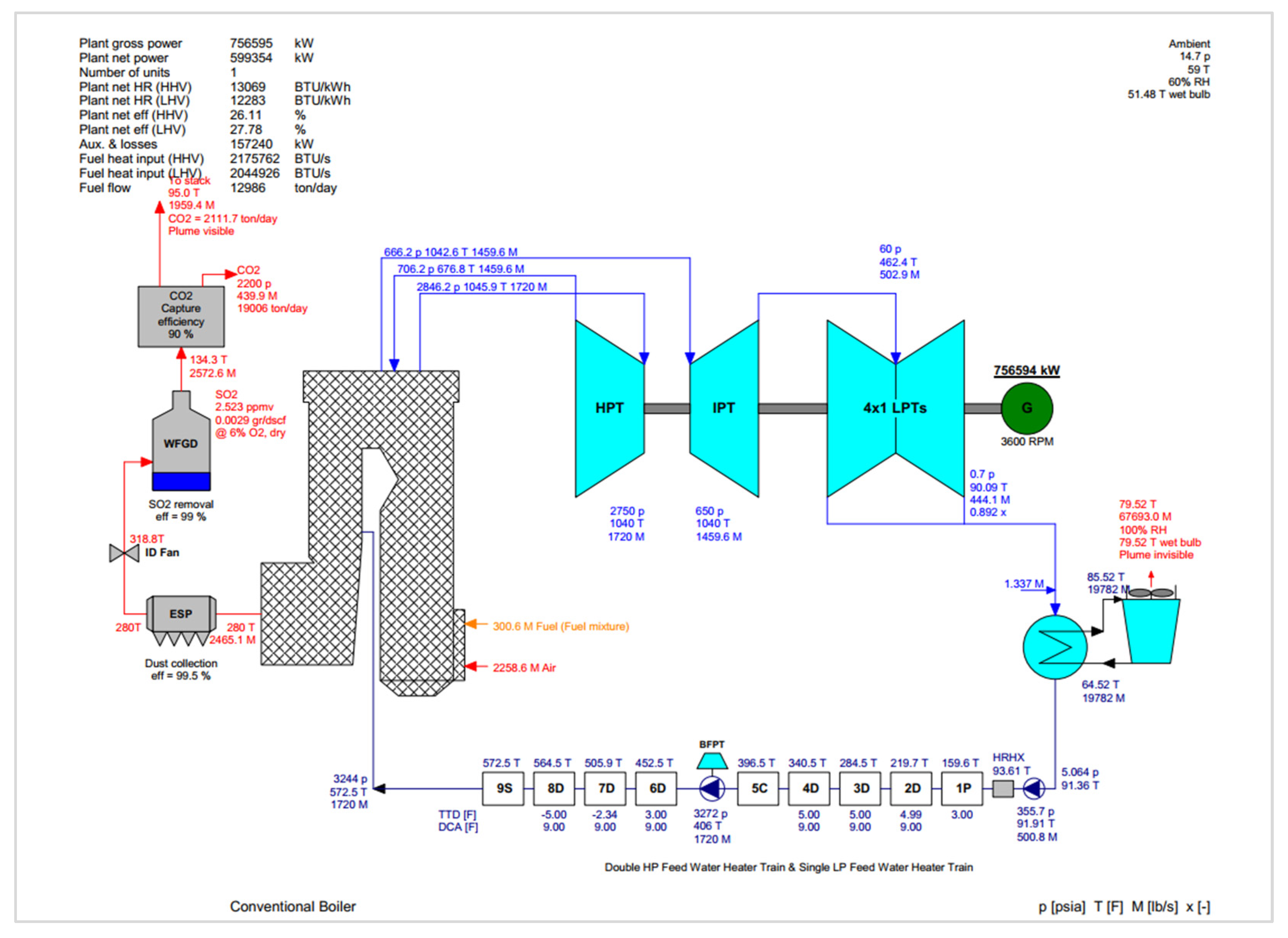

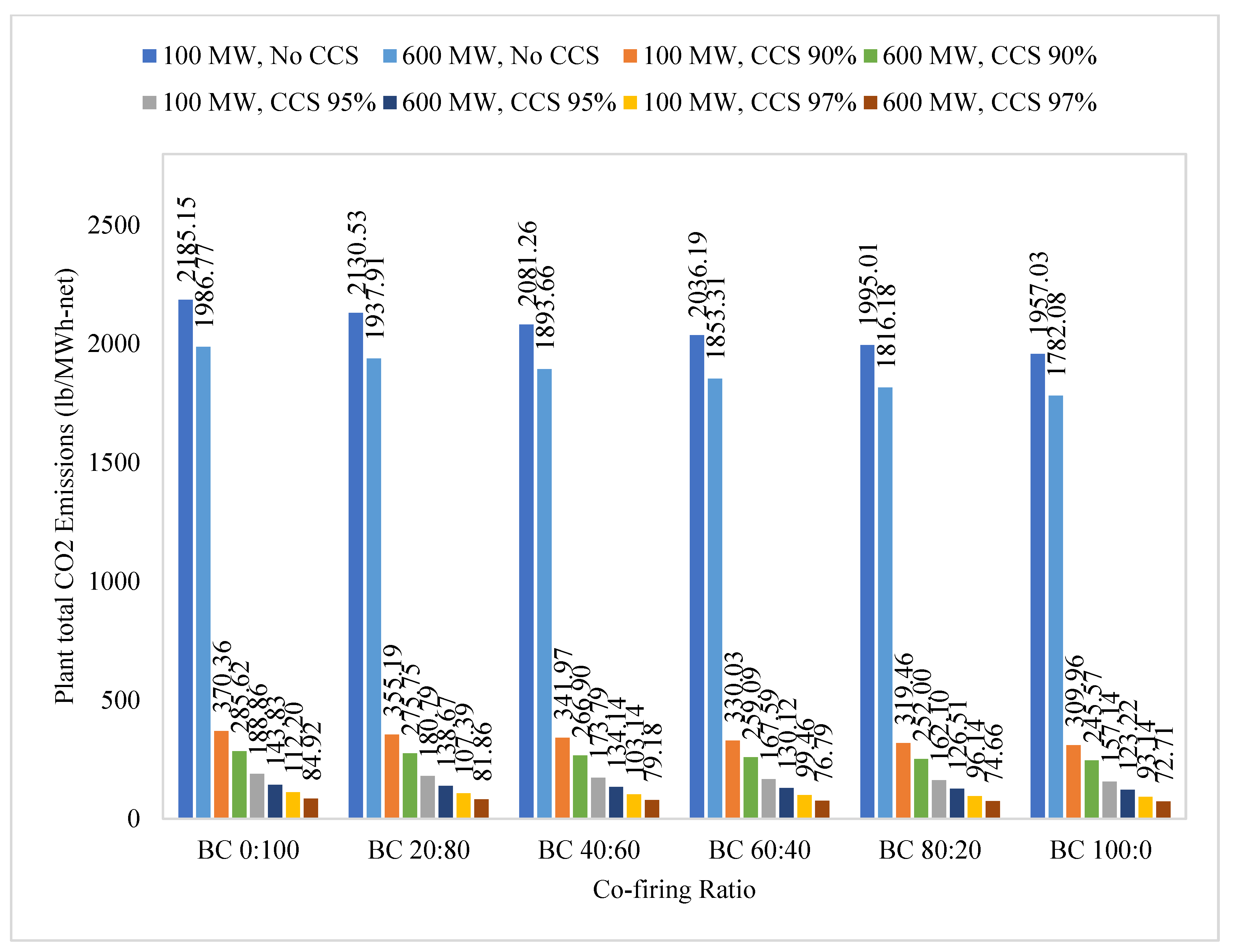

The objective of this study is to evaluate the performances of waste coal and biomass co-fired circulating fluidized bed (CFB)- and pulverized coal (PC)-fired power plants with net plant capacities of 100 MW and 600 MW. For 100 MW co-fired power plants, only subcritical phases have been considered, whereas both the subcritical and supercritical phases have been considered for the co-fired power plant with 600 MW net plant capacity. The key performance parameters considered for this study were gross power output, the net plant LHV/HHV heat rate, auxiliary and transformer losses, and net plant LHV/HHV efficiency. Additionally, important power plant emissions such as plant total CO2, particulate matter, and SO2 emissions were also considered and compared with different co-firing cases. The performance of the co-fired power plants was examined at biomass waste coal co-firing ratios of 0:100, 20:80, 40:60, 60:40, 80:20, and 100:0. Overall, the impacts of co-firing ratios, PC and CFB boiler types, CCS technology implementation, plant capacity, and subcritical and supercritical fluid types were taken into consideration when comparing the performance and emission characteristics of the co-fired power plants.

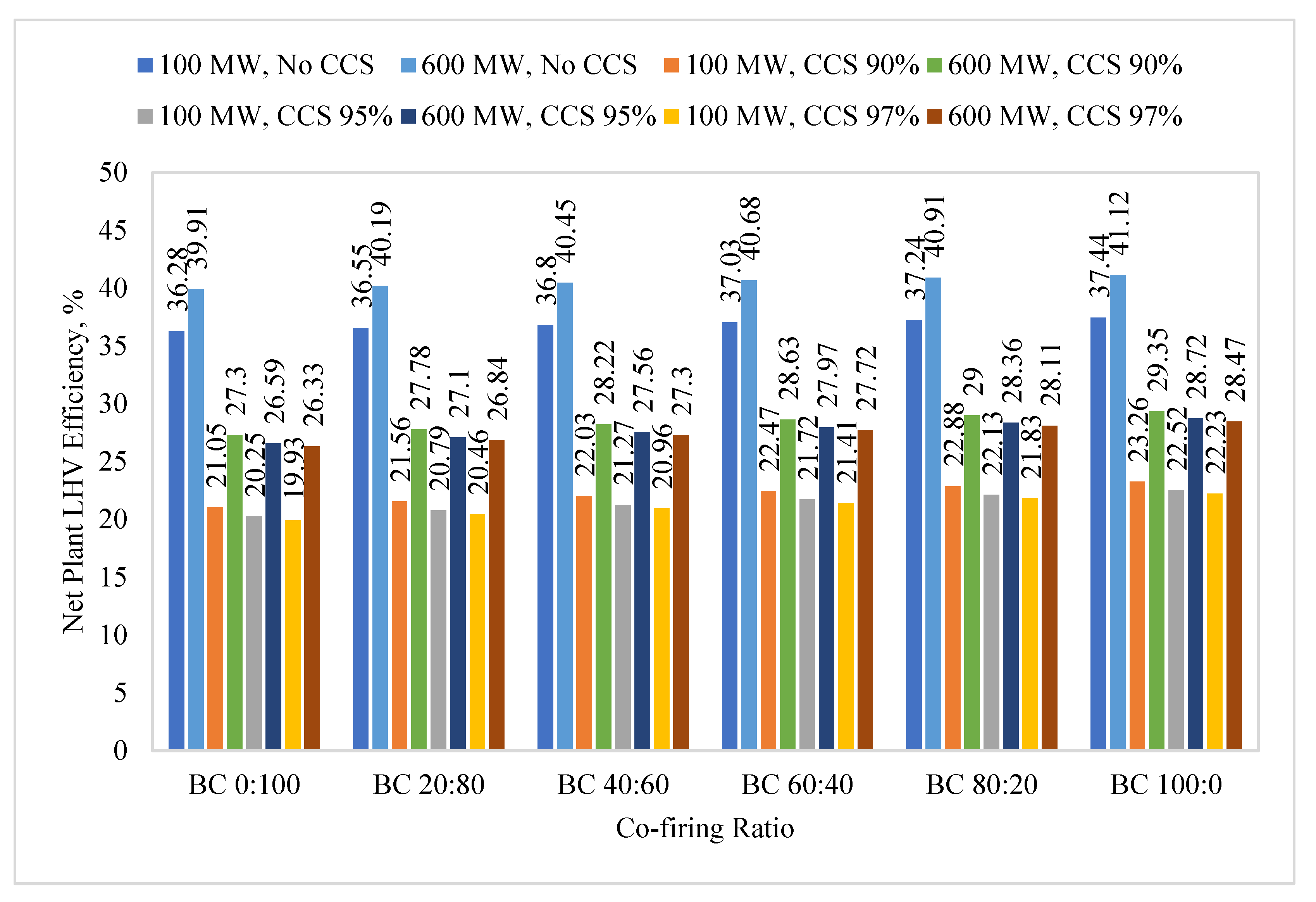

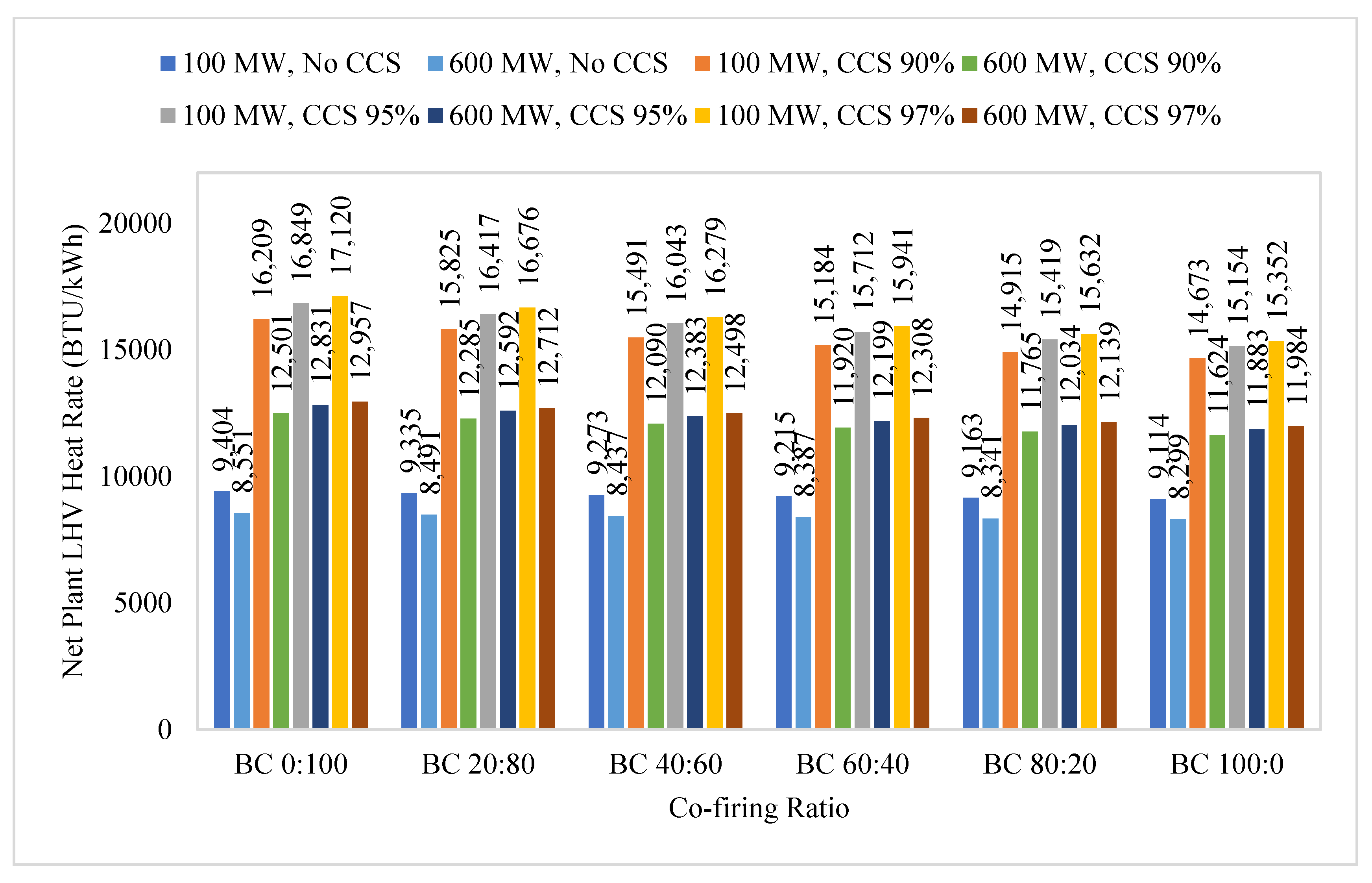

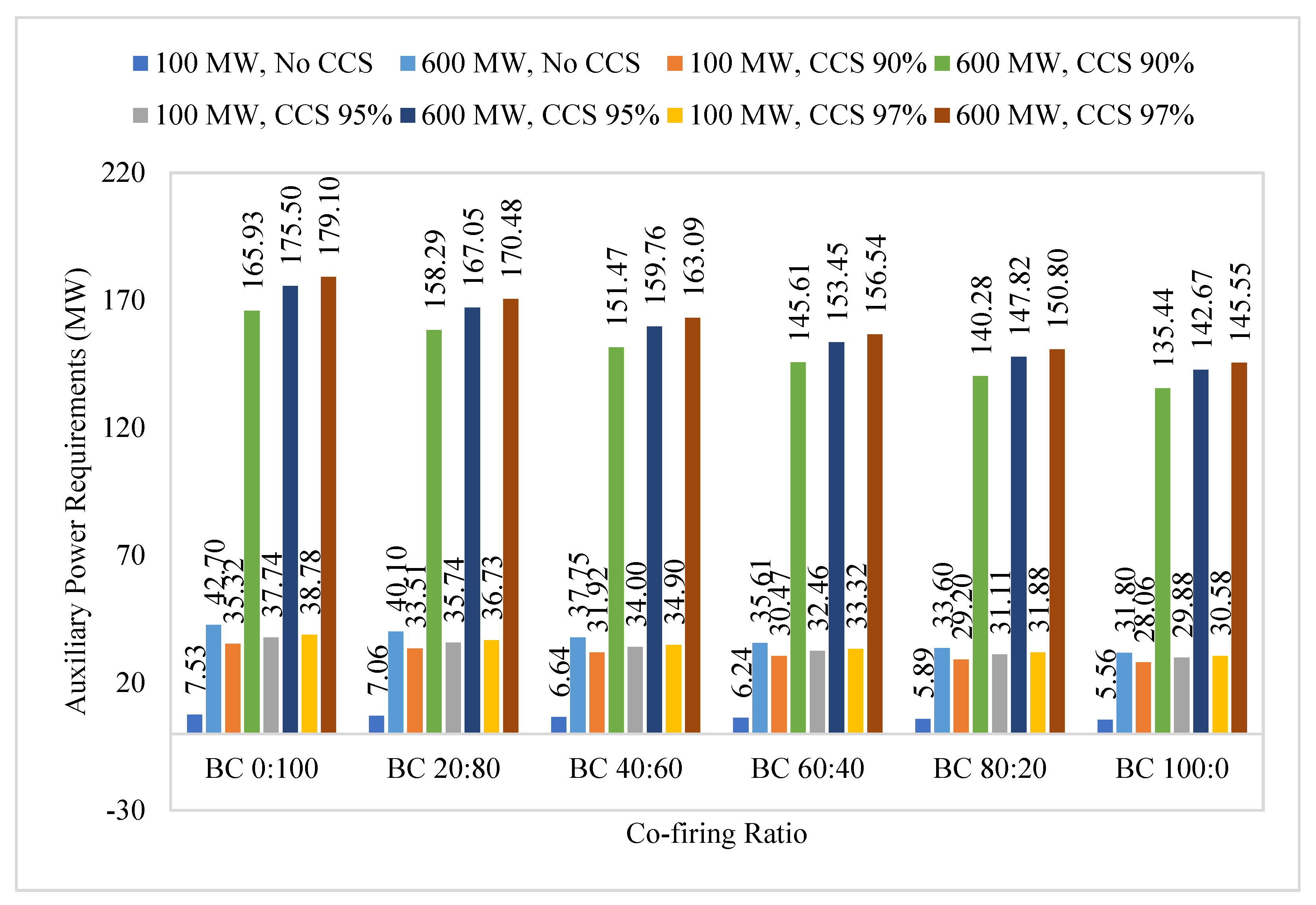

4. Conclusions

This study assessed the performance metrics and environmental impact of power plants that simultaneously co-fire anthracite waste coal and loblolly pine biomass. The power plants were assessed for a net plant capacity of 100 MW and 600 MW. Both subcritical and supercritical power plants, utilizing CFB (circulating fluidized bed) and PC (pulverized coal) combustion techniques, have been analyzed. Various combinations of pine biomass and waste coal co-firing such as 0:100, 20:80, 40:60, 60:40, 80:20, and 100:0 have been assessed, along with the incorporation of CCS technology at varying degrees of capture efficiencies (90%, 95%, and 97%). This study demonstrated an increase in efficiency of around 3–8% as the biomass fraction in the power plant increases from 0% to 100% due to the superior LHV of pine biomass over anthracite waste coal. The auxiliary power requirements decreased by around 26% as the proportion of biomass increased from 0% to 100%. The net plant heat rate of the power plants decreased by around 3–8% as the biomass ratio in the power plant increased from 0% to 100%. Furthermore, the supercritical co-fired power plants exhibited a higher net plant efficiency of around 6% compared to subcritical power plants, underscoring the significance of incorporating supercritical power plants to improve overall plant performance, particularly on a larger scale. It has been shown that by increasing the proportion of biomass from 0% to 100%, the plant total CO2 emissions from the plant are lowered by around 10–16%. Additionally, the implementation of carbon capture technology with 90% efficiency resulted in a substantial 83% decrease in plant total CO2 emissions for the same co-firing ratio of pine biomass and waste coal. This reduction could be further enhanced by improving the efficiency of carbon capture. The plant total emissions of sulfur dioxide (SO2) from the co-fired power plants decrease significantly as the proportion of biomass in the power plant feed grows and eventually become negligible when 100% biomass is utilized. By increasing the proportion of biomass in co-fired power plants, the plant total emissions of particulate matter (PM) are reduced in all configurations. When 100% biomass is used in these power plants, the plant total SO2 and PM emissions are approximately negligible. Overall, the highest thermal efficiency of 41.12% and the lowest heat rate of 8299 BTU/kWh are observed at the 600 MW CFB subcritical power plant at the 100% biomass ratio. However, logistics and transportation of feedstock, i.e., biomass, are the major challenges for a large-scale biomass-fired power plant. Therefore, the co-firing of 20 to 40% biomass is a recommended approach to mitigate GHG emissions in large-scale modern power plants. In this study, for non-CCS cases, the biomass and waste coal co-firing ratios of 20:80 and 40:60 provided efficiencies in the range of 36.55–36.8% and 40.19–40.45% and net plant LHV heat rates in the range of 9273–9335 BTU/kWh and 8437–8491 BTU/kWh, respectively, for the 100 and 600 MW CFB subcritical plants. For the CCS cases, using a combination of 20% biomass and 80% waste coal or 40% biomass and 60% waste coal resulted in efficiencies ranging from 20.46% to 22.03% and 26.84% to 28.22%, respectively, for the 100 MW and 600 MW plants. The net plant LHV heat rate for the 100 MW and 600 MW CFB subcritical plants varied between 15,491–16,676 BTU/kWh and 12,090–12,172 BTU/kWh, respectively, for the 100 MW and 600 MW plants. These values were dependent on the carbon capture efficiency of the CCS employed, which ranged from 90% to 97% carbon capture efficiency. These data are useful for developing new designs or retrofitting designs of waste coal and pine biomass-based commercial-scale co-fired power plants. In addition, these data provide basic information for evaluating the economic and environmental assessment of waste coal and biomass co-fired power plants.