Abstract

This study investigates the relationship between competence building, quality and reliability practices, and continuous quality improvement, and their impact on sustainable business performance in manufacturing enterprises. Data were collected through a questionnaire survey among Australian manufacturers. The analyses were conducted using a two-step approach involving exploratory and confirmatory factor analyses, followed by structural equation modelling (SEM). Statistical assessments ensured model fitness, reliability, validity, and examined hypothesized relationships. The findings highlight the significant influence of advanced manufacturing practices, such as product data management and manufacturing automation, on product quality, particularly emphasizing the role of competence-building facets. These practices optimize resources, reduce waste, and minimize environmental impact, contributing to sustainable performance improvement in manufacturing. The study underscores the importance of prioritizing quality and reliability evaluations embedded into business processes to minimize resource wastage and environmental impact. By aligning quality improvement initiatives with advanced manufacturing practices, the research highlights pathways for improving business outcomes. This research addresses a critical gap in the literature by presenting a comprehensive framework to evaluate the impact of various parameters on business performance in manufacturing enterprises. By pioneering an analysis of individual competence-building dimensions, it contributes to the existing body of knowledge and offers new directions for future research, particularly in advancing sustainable manufacturing practices.

1. Introduction

The global significance of the manufacturing sector as a driver of economic growth continues to increase, regardless of a nation’s development stage. The sector’s undeniable impact on worldwide economic progress is evident across major economies like China, Japan, Germany, India, Bangladesh, the United States, and France, where manufacturing contributes substantially to national output, up to 38% of GDP [1]. In recent years, the manufacturing landscape is undergoing profound transformations, introducing complex challenges that reverberate through the broader economy. Technological advancements and increased globalization have heightened global competition, subjecting manufacturers to pressures from foreign rivals, swift product introductions, shorter life cycles due to rapid innovation, shifting customer preferences, and advancements in manufacturing and information technology practices [2,3,4].

To remain competitive, manufacturing companies must effectively implement ongoing product and process innovation, superior manufacturing practices, continual quality improvement, and the consistent development of high-quality new products. In light of these dynamics, it is imperative to investigate the factors influencing manufacturing performance. Despite the manufacturing sector’s consistent and substantial contribution to global economic growth, the decline in its share of the GDP of many countries, including Australia, underscores the urgency of evaluating manufacturing business performance [1].

Attaining sustainable economic development stands as a paramount objective for nations worldwide, with the manufacturing sector’s contribution to GDP emerging as a pivotal driver for achieving enduring and robust economic growth. Unprecedented supply chain disruptions during the COVID-19 pandemic indicate that countries cannot entirely depend on the global supply of essential goods, and therefore, substantial local manufacturing is necessary [5]. However, the current literature exhibits ambiguity surrounding the correlations between business performance and factors such as competence building, quality and reliability practices, and quality improvement within the manufacturing domain. This lack of a comprehensive and unified theory impedes the ability of policymakers, governments, and relevant authorities to make well-informed decisions. Recognizing this gap in understanding, our study is driven by the aspiration to unravel the intricate connections among competence building, quality and reliability practices, quality improvement, and business performance. The notion of business performance lacks a universally accepted definition, rendering it a multifaceted term that varies across contexts and environments. Its interpretation hinges on specific circumstances, making generic factors affecting business performance unreliable. Context, country, culture, and size significantly shape the notion of business performance, making a standardized model ineffective. While some universally recognized factors influence business performance, their impact and relevance can vary across contexts. Nonetheless, competence building, quality and reliability practices, and quality improvement are widely acknowledged as factors impacting business performance. This study aims to explore how competence building, quality and reliability practices, and continuous quality improvement influence business performance within the manufacturing sector, gauging their magnitude and scope. Through an empirical exploration of these variables, our research seeks to illuminate their roles in shaping the business performance landscape of the manufacturing sector.

This research seeks to bridge gaps in understanding the complex relationships between organizational practices and sustainable business performance in manufacturing enterprises. Particularly, the aim of this study is to examine the relationships between various organizational factors and sustainable business performance in manufacturing enterprises. It is hypothesized that effective communication, improved customer relationships, employee empowerment, and effective supplier relationships positively influence key advanced manufacturing practices, including field feedback, failure analysis and prediction, advanced quality practices, and product data management. Furthermore, the selection of appropriate competitive advantages is expected to enhance quality practices, manufacturing automation, and product data management. The study also posits that advanced manufacturing practices contribute positively to product quality improvement, which in turn is expected to positively impact business performance. Finally, it is hypothesized that competence building, advanced manufacturing practices, and product quality improvements collectively contribute to enhanced business performance in the manufacturing sector.

The contribution of this research lies in its holistic investigation of the interconnectedness between the advanced manufacturing practices, their predecessors, and manufacturing performance. This research offers new insights into how practices such as product data management and manufacturing automation drive product quality, which in turn enhances long-term business outcomes. By examining the dimensions of competence building, the study addresses a key gap in the literature on sustainable manufacturing. Additionally, it underscores the importance of embedding quality improvement initiatives into core business processes to reduce waste, lower environmental impact, and boost operational efficiency. This research presents a novel framework for assessing the influence of organizational practices on performance, thereby supporting the development of more sustainable and competitive manufacturing strategies. The insights gleaned from this investigation hold the potential to furnish invaluable guidance to policymakers and investors, enhancing their comprehension of the interplay between these elements and fostering the formulation of effective strategies aimed at augmenting sustainable economic development. The remainder of this paper is organized as follows: the next section presents a comprehensive literature review, laying the foundation for understanding the current research landscape and developing the study’s hypotheses. Section 3 introduces the conceptual framework and outlines the associated hypotheses. Section 4 describes the model in detail, including its design and methodology. Finally, Section 5 discusses the results and implications, providing insights and interpretations based on the findings.

2. Literature Review and Hypotheses Formulation

2.1. Background

Researchers have made ongoing efforts to identify the key drivers of business success in the manufacturing sector. However, a definitive set of determinants that consistently contribute to or hinder business performance has yet to be established. Numerous empirical and theoretical studies have been conducted to explore the relationships between business performance and the factors that contribute to it. Although the body of research in this area continues to grow, a consensus has not yet been reached. Recent studies have yielded mixed results, with some finding a significant association between manufacturing business performance and competitive factors, while others have reported inconsistent outcomes. In the following subsections, we will review the findings of recent and relevant studies conducted in this domain. The rapid pace of new product development and evolving customer expectations have led to shorter product life cycles and a growing demand for high-quality, even more affordable products. To establish a strong and loyal customer base, companies must continuously enhance product quality. Successful companies like Apple have demonstrated that a loyal customer base, built on high-quality and functional products, is crucial for long-term success. Many research studies have explored the interrelationships between advanced production processes and quality improvement. The studies on quality management implementation and the interrelationships between its operational elements have provided valuable insights, but they also have revealed discrepancies in their findings. Additionally, the manufacturing strategy area lacks an adequate number of theoretical models compared to empirical studies. Most of the empirical research focuses on specific areas of improvement, such as customer focus or employee training. However, manufacturing encompasses a broad range of functional activities, including planning and design, procurement, production, inventory management, distribution, marketing, and sales. To develop a comprehensive improvement model, it is essential to consider the entire manufacturing system.

This study develops a comprehensive theoretical framework by integrating the Resource-Based View (RBV) [6] and Stakeholder Theory [7] to explore the interplay between competence building, quality practices, and sustainable business performance in manufacturing enterprises. The RBV is widely recognized as a foundational theory for understanding how a firm’s internal resources and capabilities, when they are valuable, rare, inimitable, and non-substitutable (VRIN), can lead to sustained competitive advantage and long-term performance. Within the context of manufacturing, organizational competencies such as employee empowerment, strategic decision-making, and robust supplier and customer relationships are seen as core strategic assets that enhance innovation, operational efficiency, and adaptability. These capabilities facilitate the adoption of advanced manufacturing practices, including product data management (PDM), failure analysis and prediction (FAP), and advanced quality practices (AQP), all of which contribute to improved product quality and internal process excellence.

In parallel, Stakeholder Theory offers a broader socio-environmental perspective by emphasizing that sustainable performance is achieved when firms effectively balance and fulfill the expectations of various stakeholders, such as customers, employees, suppliers, communities, regulators, and investors. Managing these relationships responsibly not only builds trust and legitimacy but also supports continuous improvement, knowledge sharing, and innovation throughout the value chain. For instance, customer engagement drives feedback and quality enhancements, supplier collaboration fosters reliability and responsiveness, and employee empowerment promotes problem-solving and commitment to quality.

By integrating these two theoretical lenses, the framework proposed in this study explains how internal competence building and stakeholder engagement jointly drive the adoption of advanced manufacturing practices, which in turn enhance product quality and lead to sustainable business outcomes. The literature review supports this integrated model by synthesizing relevant empirical and theoretical insights. Moreover, the study contributes to the field by empirically testing this framework using Structural Equation Modeling (SEM), providing both academic value and practical guidance for manufacturing firms aiming to align internal capabilities with external expectations in the pursuit of long-term sustainability and performance.

The following sections will present a literature survey on the key dimensions of quality and reliability in relation to manufacturing practices, their precursors, and the outcomes in the manufacturing sector. The complexity of the quality management construct necessitates the identification of key elements that drive product quality improvement. From the literature, six dimensions associated with quality and reliability in advanced manufacturing practices, along with five dimensions of competence building (which act as precursors to quality and reliability in advanced manufacturing practices), have been identified [8,9,10]. The five dimensions of competence building encompass effective communication (EC), customer relationship (CR), supplier relationship (SR), employee empowerment (EE), and selection of competitive advantage (CA). The six dimensions of advanced manufacturing practices include the field feedback (FF) system, failure analysis and prediction (FAP), advanced quality practices, (AQP), product data management (PDM), manufacturing automation (MA), and incoming component management (ICM). Understanding and focusing on these dimensions can enable organizations to develop their competence in these areas and enhance product quality and reliability in their manufacturing practices.

Various models have been employed in the literature to examine the relationship between multiple factors and business performance. According to [11], these models are generally categorized into five types: SEM, regression analysis, qualitative analysis, correlation analysis, and ANOVA tests. Among these, SEM is the most frequently used method. SEM is a robust statistical technique for evaluating and estimating relationships among complex variables [12]. For example, ref. [13] employed SEM to investigate the relationship between quality practices and sustainable excellence performance within Vietnam’s manufacturing sector. Ref. [14] employed SEM using survey data from 2021 to 2023 to investigate the influence of operational, economic, and environmental factors on sustainable business performance in India’s manufacturing sector.

2.2. Hypotheses Formulation

This section formulates the research hypotheses based on a thorough review of the existing literature presented in the previous section. Specifically, it delineates the expected relationships between key organizational competencies—effective communication, customer relationships, employee empowerment, supplier relationships, and competitive advantage—and their influence on advanced manufacturing practices, product quality improvement, and sustainable business performance. Each subsection elaborates on these relationships, grounding the hypotheses in established theoretical insights and empirical evidence.

2.2.1. Effective Communication (EC), Manufacturing Practices, Quality Improvement, and Business Performance

Effective communication (EC), field feedback (FF), quality improvement (QI), and business performance (BP) are closely interconnected and significantly impact organizational success in manufacturing [15]. EC plays a vital role in facilitating FF by enabling the efficient collection and use of field data, which drives quality improvement initiatives [16,17,18]. Open communication channels allow real-time sharing of FF, ensuring timely updates on product performance, customer feedback, and operational challenges. Structured communication with field teams (e.g., service, sales, support) provides essential insights to quality control and research and development (R&D), creating a feedback loop that enables rapid responses to issues, boosts customer satisfaction, and prevents future failures. FF influences QI and business performance through several interconnected pathways. FF is essential for driving QI by identifying issues, refining processes, and enhancing products [18,19]. The continuous collection and analysis of FF provides real-time insights into product performance, customer experiences, and operational challenges, helping identify defects and inefficiencies. These data enable root cause analysis, allowing quality control and R&D teams to refine manufacturing processes and improve product designs. By implementing corrective and preventive actions based on FF, companies reduce defects, enhance product quality, increase product yield rate, foster timely delivery, and enhance overall business performance [20,21].

Effective internal communication significantly impacts failure analysis and prediction (FAP), enhancing organizational resilience and outcomes. Strong communication enables timely issue identification and resolution, reducing rework and cycle times, which boosts product throughput and schedule attainment [18,20,22]. This improves market responsiveness and competitiveness. Additionally, integrating communication with failure analysis fosters continuous improvement, enhancing product and service quality, customer satisfaction, and overall business performance [23]. Failure analysis and prediction (FAP) influence quality improvement (QI) and, ultimately, business performance through several key pathways. First, FAP involves identifying the root causes of product failures or defects, which helps organizations understand where and why quality issues arise. By analyzing failure patterns, companies can predict potential failures, allowing for proactive interventions before problems escalate. This predictive capability enables the refinement of manufacturing processes and product designs to prevent defects, reducing rework and scrap rates. Additionally, FAP helps optimize maintenance schedules, improving operational efficiency and reducing downtime. As a result, the company can produce higher-quality products with fewer defects, increase product yield, foster timely delivery, and enhance overall business outcomes. In this way, effective communication enables organizations to respond proactively to quality issues, adopt a forward-thinking approach to potential failures, and maintain a commitment to continuous quality improvement. This framework positions communication as a fundamental element of quality-focused practices, playing a crucial role in driving better production outcomes and enhancing sustainable business performance.

It is hypothesized that effective communication positively influences key advanced manufacturing practices, which subsequently lead to improved product quality. Enhanced product quality is, in turn, expected to have a positive impact on overall business performance. In general, it is proposed that competence building, advanced manufacturing practices, and product quality improvements collectively contribute to strengthening business performance in the manufacturing sector.

2.2.2. Customer Relationship (CR), Manufacturing Practices, Quality Improvement, and Business Performance

Customer relationships (CR) play a critical role in shaping manufacturing practices that lead to quality improvement and enhanced sustainable business performance through several key pathways. By fostering strong relationships, companies can collect comprehensive customer feedback, facilitating continuous product development and refinement. This feedback directly impacts quality performance by enhancing design quality, determining essential specifications, and identifying new features that align with customer preferences [24]. Accurate demand forecasting, supported by robust CR, allows for more effective production planning and waste reduction while enabling the customization of solutions that boost customer satisfaction. Strong customer relationships also contribute to fewer engineering change orders and reduced process variability, resulting in more efficient manufacturing designs and increased customer contentment. Understanding customer needs and feedback ensures that products meet expectations, thereby improving overall performance [25]. Customer input is vital for quality improvement and business success, as it offers insights into preferences and levels of satisfaction, allowing for strategic product adjustments [8]. Thus, integrating customer feedback is essential for achieving quality advancements and positive business outcomes [26].

Customer relationships inform failure analysis and prediction by leveraging customer insights for data-driven adjustments, early detection, and tailored quality improvements, ultimately supporting enhanced business performance. By identifying issues and trends, failure analysis addresses product weaknesses and aligns solutions with customer expectations to improve quality. Customer reviews provide crucial data that guide iterative improvements and help organizations adapt to evolving needs. Engaging customers in the design and development of new products is essential for ongoing quality improvement [27]. A customer-centered approach enhances both product quality and customer satisfaction [20]. Therefore, maintaining active engagement with customers and incorporating their feedback are key strategies for quality enhancement, increased satisfaction, and sustaining a competitive advantage.

Previous studies, such as those by [28], have highlighted that customer relationships positively impact quality management strategies. Customer Relationships (CRs) inform advanced quality practices by aligning product quality with customer expectations and driving continuous improvement through feedback integration. This approach enables proactive adjustments and iterative enhancements, leading to significant quality improvements that support sustainable business success. Ref. [29] demonstrated a positive relationship between advanced quality practices and both incremental and radical product and process innovation, contributing to sustainable business performance. CR fosters collaboration with customers during product development, embedding quality practices early in the process. It also enhances employee training focused on customer needs, cultivating a quality-first culture. Continuous after-sales feedback ensures ongoing quality assurance, boosting customer trust, loyalty, and overall business performance. Ultimately, CR supports sustained quality improvement, offering a competitive edge and driving long-term business success.

Customer relationship (CR) has emerged as a vital tool in fostering collaboration and trust between manufacturers and their suppliers, which in turn enhances the management of incoming components. Previous studies conducted by [30,31] suggested that collaborative CR practices build trust and accountability between manufacturers and suppliers, which in turn enhances the management of incoming components. This trust allows for proactive issue resolution, reducing delays and quality control issues, which positively impacted their incoming component management. They also stated that effective CR leads to improved communication and better forecasting, which optimizes procurement and can reduce the risk of defective components entering the manufacturing process, thereby improving product quality, which finally leads to enhanced overall business performance.

Ref. [32] highlights the positive relationship between customer relationships and PDM, which leads to higher product quality and improved business performance. By collecting customer data and maintaining them within the PDM system, companies can identify trends, underlying causes, and opportunities for improvement. This enables them to take corrective actions and implement preventative measures to enhance product quality. Product Data Management (PDM) systems offer significant benefits for manufacturing companies, ranging from efficient production processes to building stronger customer relationships [5]. With the exponential growth of manufacturing data, PDM systems provide an efficient and organized way to manage product information throughout the product lifecycle [33]. These systems help engineers and other stakeholders handle data and the product development process, enabling effective management of the vast amount of information required for designing, manufacturing, and maintaining products. Ref. [34] emphasizes that product failure is inevitable in manufacturing, but its occurrence can be minimized through proper failure analysis. PDM systems play a crucial role in this regard, offering benefits beyond engineering design by facilitating cost savings in manufacturing, reducing time to market, and enhancing product quality. However, it is worth noting that the existing literature often overlooks the effectiveness of utilizing historical data through a product data management system. Harnessing historical data and leveraging them within the PDM system can provide valuable insights and support decision-making processes for continuous improvement in product quality and overall business performance.

It is hypothesized that strong customer relationships positively influence key advanced manufacturing practices, which in turn enhance product quality, and improved product quality is expected to positively affect overall business performance. More broadly, it is proposed that competence building, advanced manufacturing practices, and product quality improvements collectively contribute to strengthening business performance within the manufacturing sector.

2.2.3. Competitive Advantage (CA), Manufacturing Practices, Quality Improvement, and Business Performance

Competitive advantage plays a crucial role in shaping Product Data Management (PDM) by influencing how companies collect, manage, and leverage product data to enhance performance and outperform competitors. A core element of competitive advantage is the ability to make data-driven decisions that improve product quality [35]. PDM is vital for modern business operations, allowing companies to centralize and analyze product data for better performance. By streamlining data across departments, PDM enhances communication, supports informed decision-making, and fosters collaboration [36]. Additionally, PDM helps ensure compliance with legal and industry standards, mitigating risks while maintaining high product quality. Studies have shown that effective PDM reduces lifecycle costs, accelerates time-to-market, and enhances product quality, all of which contribute to a competitive edge [37].

Advanced quality practices are key to competitiveness. Companies that integrate these practices see improvements in efficiency, quality, and cost reduction. Ref. [38] found that advanced quality practices lead to ongoing improvements and operational efficiency. Quality-related factors, such as product quality and design, significantly impact business performance [21], highlighting the importance of advanced quality practices for success.

Competitive advantage plays a pivotal role in driving the adoption and optimization of automation in business operations, offering benefits such as reduced human error, improved precision, standardized processes, enhanced product quality, faster production, better data analysis, and lower costs. These advantages contribute to a sustainable competitive edge. Ref. [39] highlights that automation ensures consistent product quality, while studies by [40,41] confirm that automation enhances efficiency, productivity, and profitability. Aligning automation with manufacturing strategies and competitive priorities leads to higher product quality and sustained business performance [42].

It is believed that competitive advantage has a positive effect on important advanced manufacturing practices, which then help improve product quality. Better product quality is expected to lead to stronger overall business performance. More generally, it is suggested that building employee skills, using advanced manufacturing practices, and improving product quality all work together to boost business performance in the manufacturing sector.

2.2.4. Supplier Relationship (SR), Manufacturing Practice, Quality Improvement, and Business Performance

Effective supplier relationships are essential for securing high-quality inputs and resources, which are pivotal for producing superior products. Integrating suppliers, warehouses, and production processes enhances strategic parameters such as quality and delivery time. Research underscores the importance of fostering strong supplier relationships. For instance, ref. [8,43] highlight the significant role that communication and information sharing play in performance evaluation. Ref. [44] found that effective communication with suppliers is a critical performance factor, while [8] linked supplier quality management to total quality management (TQM), which positively impacts business performance. Ref. [45] observed that strong supplier relationships facilitate field feedback and failure analysis, enabling swift resolution of issues. Moreover, ref. [46] demonstrated that robust supplier partnerships improve supply chain reliability and product quality. Empirical evidence from [47] further confirms that strong supplier relationships enhance overall performance, including quality, delivery, and company image by shaping PDM, facilitating field feedback and failure analysis, enhancing the management of incoming components, and embedding quality practices early in the process.

Failure analysis and prediction are essential for risk management and business continuity, helping organizations develop strategies to mitigate risks and maintain operations. Collaborating with suppliers to manage risks addresses supply chain vulnerabilities, boosting performance and resilience. Integrating product data management with supplier relationship management is crucial for maintaining product quality and performance, positively impacting customer satisfaction and company success [48]. Effective management in these areas leads to lower costs, faster deliveries, and improved satisfaction [44]. Proper documentation and traceability from product data management also help in quickly resolving quality issues, enhancing company resilience [5].

It is believed that strong relationships with suppliers positively influence key advanced manufacturing practices, which in turn help improve product quality, and higher product quality is expected to enhance overall business performance. More broadly, it is suggested that developing employee skills, adopting advanced manufacturing practices, and improving product quality collectively contribute to better business performance in the manufacturing sector.

2.2.5. Employee Empowerment (EE), Manufacturing Practice, Quality Improvement, and Business Performance

Empowering employees is vital for effective failure analysis, as their frontline experience and expertise help identify patterns, root causes, and inefficiencies. Active employee involvement in data gathering and problem-solving enhances product quality [49]. Employee engagement in reporting and data collection is crucial. Ref. [50] show that employee empowerment, through training and support, is linked to advanced quality practices and responsiveness to customer feedback. Additionally, failure analysis based on field feedback positively impacts employees’ sense of meaning, competence, self-determination, and impact [51].

Empowering employees boosts job satisfaction, engagement, motivation, creativity, productivity, and overall performance [52]. A deep understanding of procedures and problem-solving is crucial for implementing advanced quality practices. Empowered employees contribute their expertise, enhancing quality improvement projects and efficiency [53]. Their collaboration in cross-functional teams and idea-sharing promotes superior quality outcomes. Employee empowerment significantly impacts company performance, with studies showing its importance in performance evaluations [54].

It is hypothesized that when employees are empowered, they can positively influence important advanced manufacturing practices, which then lead to better product quality. Better product quality is expected to improve overall business performance. Overall, it is suggested that providing employees with the right skills, using modern manufacturing methods, and focusing on product quality all work together to help businesses perform better in the manufacturing sector.

3. Conceptual Framework

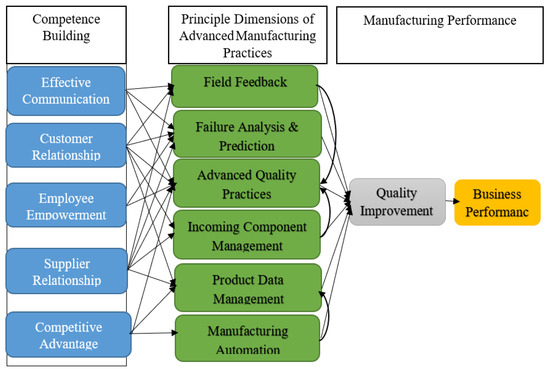

Based on the literature review presented above, the present study considers the following research framework (Figure 1) that depicts the hypothesized antecedents of sustainable business performance in the manufacturing sector. Here, competence building, advanced manufacturing practices, and product quality improvements are projected as the independent variables, and business performance is the dependent variable. The conceptual framework in the figure relates to the main concepts of competence building, advanced manufacturing practices, and manufacturing performance, with a view to answering the following questions.

Figure 1.

Framework for the proposed model (Source: figure created by authors).

- Do the attainments in competence building significantly affect advanced quality and reliability manufacturing practices?

- Do the advanced quality and reliability manufacturing practices significantly affect the attainment of manufacturing performance?

Based on the expected relationships, the following specific hypotheses are proposed for investigation.

H1a:

Effective communication has a positive relationship with field feedback, failure analysis and prediction, and advanced quality practices.

H1b:

Improved customer relationship has a positive relationship with field feedback, failure analysis and prediction, incoming component management, advanced quality practices, and product data management.

H1c:

Employee empowerment has a positive relationship with failure analysis and prediction and advanced quality practices.

H1d:

An effective supplier relationship has a positive association with field feedback, failure analysis and prediction, advanced quality practices, incoming component management, and product data management.

H1e:

The selection of appropriate competitive advantages (objectives) has a positive relationship with advanced quality practices, manufacturing automation, and product data management.

H2:

Advanced manufacturing practices (field feedback, failure analysis and prediction, advanced quality practices, incoming component management, product data management, and manufacturing automation) relate positively to product quality improvement.

H3:

Product quality improvement positively and significantly relates to business performance.

H4:

Competence building, advanced manufacturing practices, and product quality improvement are associated with manufacturing business performance.

4. Methodology

4.1. Sample and Procedure

Several scholars [55,56,57] have explored empirical research methods within the field of manufacturing operations. Ref. [55] outlined a structured process for conducting empirical investigations. Their model begins with establishing a theoretical foundation that clearly defines the research problem. Following this, a research design is selected that aligns with both the theoretical framework and the nature of the issue being investigated. While surveys are frequently utilized in empirical production and operations management research, other methodologies, such as single or multiple case studies [58], panel studies, and focus group discussions can also be employed based on the context of the research. Depending on the study’s requirements, researchers may adopt one or a combination of these approaches.

The subsequent phase involves choosing an appropriate sample and gathering data using methods such as analysis of historical records, direct or participant observation, interviews, surveys, and content analysis. Researchers may rely on one or a blend of these techniques, ensuring alignment with the overall research design. Once the data are collected, they are then processed and analyzed. The final step in this methodology involves compiling the findings and presenting them in a publishable format.

This study adopted Flynn’s empirical research framework. Typically, manufacturing research, hypotheses, or research problems are developed through an extensive review of existing literature. However, a limitation of this method is that such problems may be highly contextual, influenced by region, culture, and time. Consequently, issues identified in one geographical or temporal setting may not be transferable to others. In this research, initial problem statements were derived from the literature but were subsequently refined through a pilot study and an in-depth case analysis. A structured questionnaire survey was then conducted to test the formulated hypotheses.

Having designed the survey form, pilot testing was conducted with two manufacturers in Australia. These manufacturers were selected as the University already had non-disclosure agreements (NDA) with them. It was thought that as these manufacturers were protected, and therefore they would provide feedback without any reservation. The testing was used to assess the questionnaire for:

- Whether the questionnaire measures what it is supposed to measure,

- How easy the questionnaire is to complete, and which concepts are unclear or out of the respondents’ range of knowledge and responsibilities.

The pilot testing was carried out using face-to-face interviews with the managers involved in manufacturing and quality control of the selected manufacturers. Interviews took place in the respective manufacturing facilities. The researchers sent the questionnaire by email to the quality managers beforehand so that they had sufficient time to read and prepare for discussion. The duration of each interview was about one hour.

The final questionnaire incorporated various types of response formats, predominantly Likert scales (ranging from 1 to 5), and quantitative measures such as production capacity utilization, product yield, customer return rate, and on-time delivery. Participants were asked to provide current values for these metrics, often expressed as percentages.

To distribute the survey, a random sample of 1000 manufacturing firms was selected, with an effort made to exclude importers and to focus solely on true manufacturers, primarily those in the mechanical, electrical, and electronics sectors. Geographic diversity, in terms of selecting the number of manufacturers in each state in Australia, was also considered. The survey targeted quality managers, as they are generally responsible for managing quality and reliability-related concerns. Questions were designed to be straightforward, and participants were offered access to a summary of the survey findings if interested. Out of the 1000 questionnaires distributed, 40 were returned undelivered due to business closures or address changes. Some companies responded, indicating they had shifted from manufacturing to importing. Ultimately, the study received 165 valid responses, resulting in an effective response rate of 17.2%.

An assessment was made to assess the extent to which the participating organizations were similar to the distribution of the manufacturing industry in the country. This was done by comparing the geographical locations of these participating organizations. Table 1 presents the geographical distribution of Australian manufacturing organizations responding to this study and a comparison with the geographical distribution of Australian manufacturers (ABS) [59].

Table 1.

Comparison of the geographical distribution of the respondents with that of Australian manufacturers.

From the table, it can be seen that the distribution of responding companies closely represents the distribution of manufacturing organizations in Australia.

4.2. Measures of the Constructs

We used existing scales extensively applied in prior research to assess the variables under examination. Six dimensions of quality and reliability-related advanced manufacturing practices and five dimensions of competence building (antecedents of quality and reliability-related advanced manufacturing practices) are identified from the literature [60,61,62]. The five dimensions of competence building are effective communications, customer relationship, supplier relationship, employee empowerment, and selection of competitive advantages. The six dimensions of advanced manufacturing practices are field feedback system, failure prediction and analysis, advanced quality practices, product data management, manufacturing automation, and incoming component management.

Although several studies addressing instruments for quality and reliability-related advanced manufacturing practices, competence building, product quality improvement, and manufacturing business performance measurement from various aspects have been conducted, the literature shows there are no common items for these constructs. In this study, we used a six-item scale to assess competitive advantage, a seven-item scale to assess advanced quality practices, a nine-item scale to assess supplier relationships, a three-item scale to assess product data management, a ten-item scale to assess field feedback, and a four-item manufacturing business performance developed by [63], as they confirmed the validity and reliability of items with the Cronbach’s coefficient >0.70. We also used in our survey a four-item scale to determine effective communication, a seven-item scale to determine customer relationships, a five-item scale to determine employee empowerment, a four-item scale to determine failure prediction and analysis, a five-item scale to determine manufacturing automation, a six-item scale to determine incoming components management, and a four-item scale to determine product quality improvement that we developed from a review of the literature.

4.3. Data Analysis

In this study, we first addressed the potential issue of common method variance (CMV) and then assessed the reliability and validity of the measurement model through confirmatory factor analysis (CFA) using AMOS 25. Model fitness was evaluated using various fit indices, including chi-square per degree of freedom (χ2/df), comparative fit index (CFI), normed fit index (NFI), Tucker–Lewis index (TLI), goodness-of-fit index (GFI) (the squared residuals from prediction compared with the actual data), adjusted goodness-of-fit index (AGFI), root mean square residual (RMR), and root mean error of approximation (RMSEA), with the fit criteria based on guidelines of [64,65]. The result is presented in Table 2. The study constructs’ reliability and validity were evaluated using multiple indicators. Internal consistency of variables was assessed using Cronbach’s alpha and composite reliability, while convergent validity was established through factor loading scores [66]. Finally, we tested our hypothesized research model using the structural equation model in AMOS 25, employing 5000 bootstrap samples with a 95% bootstrap confidence interval (CI) to examine the mediation model.

Table 2.

Goodness of fit of the measurement model (Source: table created by authors).

According to [11], these models can be categorized into five types: SEM, regression analysis, qualitative analysis, correlation analysis, and ANOVA tests, with SEM being the most commonly applied method. The SEM approach is particularly well-suited for this study for several reasons. Ref. [67] emphasized that SEM is more appropriate than other approaches when dealing with large sample sizes (n > 100). Additionally, SEM outperforms methods like regression analysis, qualitative analysis, correlation analysis, and ANOVA in hypothesis testing. This is because SEM can simultaneously address multiple dependent and independent variables, incorporate latent constructs, and assess both measurement and structural models. SEM offers a more holistic approach to hypothesis testing, utilizing fit indices such as CFI, RMSEA, and Chi-square tests to provide a comprehensive evaluation of how well the proposed model aligns with the data. It ensures proper specification of the measurement model before evaluating structural relationships and enables the comparison of multiple models. Unlike regression or ANOVA, SEM can model direct, indirect, and total effects while handling multiple equations, making it ideal for testing complex theories and drawing causal inferences. Furthermore, regression and correlation models are limited to observed variables and handle only one-directional effects.

5. Results

5.1. Common Method Variance

To mitigate potential common method variance (CMV), we took several preventive measures before conducting the survey. Firstly, we ensured respondent anonymity to minimize social desirability bias [68,69]. Secondly, we emphasized that participation in the survey was entirely voluntary [70,71,72]. Additionally, to further address CMV concerns, we strategically administered the survey in several different geographical locations in Australia at distinct time frames, as recommended by [73].

Furthermore, we employed four post hoc statistical remedies. Firstly, we explored a mediation model, which was expected to minimize CMV as it made it challenging for respondents to visualize the variables and their interactions, following the approach proposed by [69]. Secondly, we conducted the traditional Harman’s one-factor test using principal component analysis, which revealed that only 41% of the variance could be explained by a single factor, confirming that CMV did not significantly influence our data [73]. Thirdly, we utilized a five-step CFA marker technique in AMOS 25, employing a theoretically unrelated latent marker variable, and the results supported the absence of CMV in our data, as suggested by [74]. Lastly, we conducted a post hoc power analysis using Soper’s online SEM calculator to evaluate the adequacy of our sample size. Based on our model structure, which includes 13 latent constructs and 62 observed variables, and assuming a large effect size (f² = 0.35)—a standard assumption in SEM—the analysis indicated that a minimum sample size of 139 would be required to achieve a statistical power of 0.80 at a 0.05 significance level. Our actual sample size of 165 exceeds this threshold, confirming that the study is sufficiently powered to detect large effects, even in a complex SEM framework. This supports the statistical robustness and reliability of the results obtained from our model.

5.2. Measurement Model

After confirming that CMV was not a problem for our data, we proceeded to investigate the measurement model through CFA. The CFA of the measurement model suggests a good fit according to all relevant indices. The goodness-of-fit indices are shown in Table 2. It can be seen that there are no offending estimates. As can be seen in Table 2, χ2 value is 133.7, and the p-value of the χ2 is 0.000, which indicates a good fit. The RMR measure also indicated a good fit (0.018). All other fit indices are within the range of acceptable fit. Researchers have found it difficult to achieve the recommended fits for complex models like the present model. Ref. [65] found most of their indices between 0.80 and 0.90 and RMSEA value between 0.04 and 0.31. Ref. [75] also found many of the goodness-of-fit indices below 0.80 in his final models. In all these studies, path coefficient estimates were stable, and the lower value in some of them did not seem to affect substantive conclusions.

After that, we calculated the reliability and validity statistics. The results show that the measurement models meet all minimum requirements, as Table 3 shows. First, most indicator loadings are above 0.70, supporting the indicators’ reliability. Only six items show lower loadings, but as the corresponding constructs present satisfactory levels of internal consistency, reliability, and convergent validity, the analysis follows [64] and retains the items. Second, all composite reliabilities and Cronbach’s alpha are greater than 0.70, thus confirming the measures’ internal consistency reliability. In addition, all average variance extracted (AVE) values surpass the threshold of 0.50, supporting the construct measures’ convergent validity. Finally, the analysis confirms discriminant validity by comparing the square root of AVE to the constructs’ correlations, and we found that the square root of AVE in every latent construct is more than other correlation values among any pair of latent constructs. All these reliability and validity assessments demonstrate that the data are robust, and the conclusions drawn from the analysis are fair and reliable.

Table 3.

Reliability and Validity Test (Source: table created by authors).

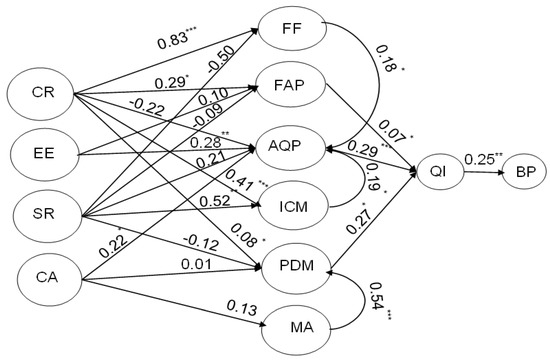

5.3. Structural Equation Model and Hypotheses Tests

By utilizing AMOS, we performed the structural equation model that provided a satisfactory fit for our hypothesized mediation model according to all relevant fit indices (see Table 1). The relationship between the constructs of the model and their statistical significance levels is shown in Table 4 and Figure 2. As can be seen, thirteen relationships are statistically very significant, and the remaining are statistically insignificant. The empirical results show that SR positively and significantly (p ≤ 0.001) relates to advanced manufacturing practices through ICM. Furthermore, advanced manufacturing practices namely FF (p ≤ 0.001), ICM (p ≤ 0.001), FAP (p ≤ 0.05), and PDM (p ≤ 0.05) are clearly and significantly influenced by CR. The study results also show that CA and EE dimensions of the competence-building scale directly and significantly (p ≤ 0.05, p ≤ 0.01, respectively) influence the main dimension of advanced manufacturing practices. Most notably, competence building’s customer relationship, competitive advantage, employee empowerment, and supplier relationship dimensions positively and significantly influence advanced manufacturing practices. More precisely, while the customer relationship dimension plays a vital role in driving field feedback and incoming component management, the supplier relationship dimension strongly plays a role in influencing incoming component management. Moreover, advanced quality practices are significantly relying on field feedback (p ≤ 0.05) and incoming component management (p ≤ 0.05). However, contrary to the hypotheses, effective communication plays no role in driving advanced manufacturing practices, as this EC dimension does not affect either of the advanced manufacturing practices dimensions. Moreover, advanced quality practices, failure analysis and prediction, and product data management positively and significantly affect product quality improvement with significant levels at p ≤ 0.001, p ≤ 0.05, and p ≤ 0.05, respectively. Finally, we found that product quality improvement positively and significantly (p ≤ 0.01) influences manufacturing business performance. The significant paths in the structural model also establish the nomological validity of the constructs. The competence-building constructs have nomological validity as they are directly linked to advanced manufacturing practices and indirectly to manufacturing performance, as hypothesized. Advanced manufacturing practices exhibit nomological validity via their strong link to product quality improvement. In other words, competence-building capabilities lead to the development of valuable resources, which in turn lead to superior manufacturing practices and eventually higher manufacturing business performance. These competencies and acquired knowledge are idiosyncratic and difficult for competitors to imitate.

Table 4.

Relationship between constructs of the model (Source: table created by authors).

Figure 2.

Structural model estimate (Source: figure created by authors). ***, **, and * indicate significance at 0.001, 0.01, and 0.05 levels, respectively.

6. Discussion

The conceptual model in Figure 2 highlights the key mediating mechanisms through which competence building influences sustainable business performance. Specifically, advanced manufacturing practices (AMP) and product quality improvement serve as central mediators. Competence building, through initiatives like employee empowerment, supplier and customer integration, and internal capability development, enhances the adoption of AMP, including tools such as product data management, failure analysis, and advanced quality systems. These practices, in turn, improve internal process efficiency and product reliability. Product quality further acts as a mediator by translating these improvements into tangible sustainability outcomes, such as customer satisfaction, reduced waste, and long-term competitiveness. Together, AMP and product quality form a sequential pathway through which competence building contributes to sustainable business performance. In addition to the mediating effects, the model incorporates institutional pressures as a moderating variable. Drawing from Institutional Theory, the model suggests that coercive (regulatory), mimetic (competitive), and normative (industry standard) pressures influence the strength of the relationship between AMP and sustainable performance. In environments with strong institutional expectations, the implementation of advanced practices is more likely to result in significant sustainability gains, as firms align with external demands for compliance, quality, and operational excellence. This moderation highlights the contextual nature of the proposed relationships and strengthens the theoretical contribution by accounting for the interaction between internal capabilities and external institutional forces. Sustainable business performance in manufacturing is fundamentally tied to practices that not only improve operational efficiency but also minimize environmental impact and optimize resource use. Several key factors identified in the study directly contribute to enhancing sustainability within manufacturing enterprises, ensuring long-term business success. A detailed explanation of this pathway is provided below.

The study’s findings led to the rejection of Hypothesis H1a, which posited a positive correlation between effective communication and field feedback (FF), failure analysis and prediction (FAP), and advanced quality practices (AQP). Due to the misalignment between these relationships and the proposed model, the construct of ‘effective communication’ was subsequently excluded. In the context of the Australian manufacturing sector, effective communication may not consistently yield positive outcomes in relation to FF, FAP, and AQP due to several underlying factors. These include structural challenges such as communication silos [63], poorly designed feedback loops [76], resistance to organizational change [77,78]), the inherent complexity of technical communication [79], and a lack of integration of communication strategies across hierarchical levels [9]. Furthermore, these challenges are closely linked to specific characteristics of the Australian manufacturing sector. Despite the emphasis on effective communication, its impact on field feedback, failure analysis, and advanced quality practices remains limited due to structural and cultural barriers. The industry’s fragmentation, dominated by small and medium-sized enterprises (SMEs) operating across diverse subsectors, fosters operational silos that restrict information flow. Hierarchical organizational structures further impede the upward movement of critical frontline insights. A prevailing culture of siloed communication weakens cross-functional collaboration, while limited integration systems and a short-term business focus prevent valuable feedback from being systematically utilized. Collectively, these contextual factors sustain communication gaps and undermine initiatives aimed at cohesive quality improvement and sustainable business practices. Consequently, even when communication occurs, it seldom translates into coordinated, data-driven improvements in quality management or failure prediction.

Furthermore, another plausible explanation for the lack of a distinct effect could be that the function of ‘effective communication’ is already embedded within other exogenous constructs, such as ‘supplier relationship’, ‘customer relationship’, and ‘employee empowerment’. Prior studies by [80,81] suggest that effective communication plays a pivotal role in nurturing supplier relationships, which, in turn, enhance overall business performance.

The model robustly upheld hypothesis H1b, highlighting the pivotal role of customer relationships as the driving force behind five distinct advanced manufacturing practices: field feedback, product data management, failure analysis and prediction, incoming component management, and advanced quality practices. This cascade of relationships subsequently leads to enhanced product quality, which in turn has a positive influence on overall business performance. Although a direct link between customer relationships and advanced quality practices (AQP) was not evident, a closer examination of Table 3 and Figure 2 illustrates a connection between customer relationships and AQP through the pathways of field feedback (FF) and incoming component management (ICM). This outcome finds substantial support in prior works such as [20,82,83] Notably, ref. [82] underscored the significance of customer feedback, intrinsically tied to customer relationships, in amplifying product quality and effecting adjustments in line with customer preferences. Harnessing customer relationships emerges as a strategic approach to ensuring the efficacy of manufacturing practices, encompassing facets like incoming part quality, field feedback, product data management, and the integration of advanced quality and reliability practices.

Product quality improvement and the implementation of advanced quality practices are integral to business sustainability, as they foster long-term growth, customer loyalty, and environmental responsibility. Advanced quality practices, such as awareness of customer requirements and priorities, effective communication during the design of a new product, emphasis on quality during design, use of field failure and manufacturing data during design, and Q&R estimation during the design, promote continuous improvement and process optimization, which minimize defects and resource consumption and operational costs [84]. Thus, these practices contribute to business sustainability by reducing waste, lowering operational costs, and improving customer satisfaction, which in turn strengthens market competitiveness and long-term profitability [85]. Furthermore, integrating sustainability-oriented quality management aligns with environmental and social responsibility, ensuring compliance with regulations and meeting stakeholder expectations [86]. Empirical studies suggest that firms adopting advanced quality practices achieve superior sustainability performance by balancing economic efficiency with ecological and social considerations [84]. Therefore, product quality improvement through advanced quality practices serves as a strategic enabler of sustainable business growth.

Similarly, customer relationships are essential in creating demand-driven improvements that enhance product quality and market adaptability. Effective communication channels with customers allow businesses to gather valuable insights into consumer preferences, facilitating product innovation and customization [87]. Actively valuing customer feedback fosters trust, loyalty, and brand equity, which are key to sustaining competitive advantage in dynamic markets. Moreover, understanding customer expectations helps companies align their quality practices with market trends and sustainability requirements, such as eco-friendly product designs and reduced environmental footprints [88].

Drawing lessons from past oversight remains a cornerstone of continuous product quality enhancement, contingent on the systematic and structured recording of valuable manufacturing and field failure data. In this realm, the role of product data management emerges as crucial, given the complexity of modern manufacturing databases due to multifarious processes, equipment arrays, and nonlinear process flow. Negotiating the voluminous data alongside accelerated ‘time-to-market expectations’ poses a formidable challenge in swiftly identifying and rectifying issues.

The study’s outcomes provided partial validation for hypotheses spanning from H1c to H1e, signifying links between supplier relationships, competitive advantages, and employee empowerment with advanced manufacturing practices. The findings align robustly with conclusions drawn from the research conducted by [53,89]. The assertions of these earlier studies offer substantial support to the results obtained in the present study. For instance, as highlighted by [89] businesses adeptly utilize effective supplier relationships to bolster various manufacturing objectives encompassing flexibility, cost-effectiveness, quality, and punctual delivery. The caliber of incoming supply quality and the organization’s long-term supplier management strategies are indicative of its commitment to enhancing manufacturing quality. Consequently, in the contemporary manufacturing landscape, the significance of cultivating strong supplier relationships is paramount. Furthermore, ref. [53] posit that when employees experience empowerment, they are more inclined to contribute their expertise and insights toward embracing advanced quality practices. This inclination translates into enhanced quality improvement initiatives and heightened efficiency across processes, ultimately enhancing overall business performance. Ref. [38] further accentuate the pivotal role of advanced quality practices in gaining competitive advantages. These advantages, in turn, cascade into heightened product quality, thus exerting a positive impact on overall business performance.

Effective Supplier relationships (SR) play a pivotal role in nurturing sustainable supply chains and contributing to the long-term success of businesses. Strong supplier relationships based on transparency, continuous feedback, and collaborative quality improvement efforts enable organizations to ensure consistent material and component standards. By addressing quality issues at the source, businesses can minimize defects, reduce production waste, and optimize operational efficiency, aligning with sustainability goals [21]. Collaborative partnerships with suppliers also encourage the adoption of environmentally friendly practices, such as resource-efficient production methods and the use of sustainable materials.

Employee empowerment is also a foundational element that significantly contributes to business performance and further strengthens sustainability efforts by fostering a culture of ownership, accountability, and continuous improvement, which enhances organizational adaptability and stakeholder engagement. When employees are empowered to participate in decision-making and sustainability initiatives, they contribute to more ethical, efficient, and environmentally conscious practices. Thus, the integration of strategic supplier partnerships, core competencies, and engaged human capital plays a crucial role in achieving and maintaining sustainable business performance.

By integrating robust SR and EP strategies within businesses can achieve a balance between operational excellence, market responsiveness, and environmental responsibility. These collaborative relationships not only strengthen the supply chain but also position organizations as socially responsible entities committed to long-term sustainability.

The study’s findings provide robust support for the second hypothesized relationship, revealing that three distinct dimensions of advanced manufacturing practices, namely, product data management, failure analysis and prediction, and advanced quality practices, stand as pivotal drivers of enhanced product quality. These findings resonate strongly with previous research endeavors by [32,38]. Ref. [38], for instance, underscore the company’s achievement of sustained quality enhancement and competitive edge through the integration of product data management, failure analysis, and advanced quality practices into daily operations. Such practices enable companies to pinpoint inefficiencies, streamline operations, and curtail costs linked to defects, rework, and customer dissatisfaction. However, the dimensions of field feedback, incoming component management, and manufacturing automation reveal no significant direct impact on product quality improvement. It is important to note that this outcome does not negate the importance of these dimensions; rather, it suggests their comparatively lesser significance in relation to the other dimensions. Notably, the positive and significant relationships between these dimensions and advanced quality practices do imply an indirect link with product quality improvement through the intermediary of advanced quality practices and product data management. This underscores the intrinsic significance of these dimensions in the context of enhancing product quality.

In this study, quality improvement serves as a crucial mediating variable that links advanced manufacturing practices to enhanced business performance. The mechanisms underlying this mediation operate through several pathways. First, advanced manufacturing practices, such as product data management (PDM), failure analysis and prediction (FAP), and advanced quality practices (AQP), enable organizations to systematically collect, analyze, and act upon operational and customer feedback data. Specifically, practices such as Failure Analysis and Prediction (FAP) enable the early identification and prevention of defects, thereby reducing operational waste and improving product reliability. PDM acts as a critical mediator by providing a centralized repository for quality-related data, enabling manufacturers to identify patterns and trends in product performance. Specifically, the integration of field failure data with design specifications within the PDM system allows for rapid identification of root causes and facilitates targeted design modifications to improve product reliability. Advanced Quality Practices (AQP), including techniques like failure mode and effect analysis (FMEA) and statistical process control (SPC), institutionalize proactive quality assurance across all stages of production. Collectively, these practices lead to the identification and elimination of process inefficiencies, reduction of product defects, and enhancement of product reliability and consistency. Second, by improving internal manufacturing processes and embedding continuous improvement cultures, these practices enhance operational agility, reduce costs associated with waste and rework, and strengthen responsiveness to customer needs. As a result, improved product quality directly contributes to higher customer satisfaction, better market reputation, and increased productivity, all of which are critical components of sustainable business performance. Thus, quality improvement acts as a dynamic conduit that translates the technical and strategic benefits of advanced manufacturing practices into tangible business outcomes.

This study furnishes compelling evidence supporting the positive correlations between product quality improvement and business performance within the manufacturing sector, thereby affirming the premises laid out in the third hypothesis. In the current landscape of fierce competition, companies that excel in delivering quality products invariably reap benefits such as enhanced reputations, heightened customer satisfaction, and amplified productivity. It follows, then, that elevating product quality stands as a pivotal driver of overall business performance. This discovery finds substantial resonance in the existing body of literature, as underscored by studies by [20,53,63]. As aptly stated by [63], the augmentation of product quality across the product lifecycle exerts a positive influence on product performance, customer satisfaction, and reputation—a collective impact that inevitably shapes a company’s success. Notably, this particular study also ascertained that product quality enhancement represents the chief determinant of success within Australian industries.

The study contributes valuable insights into the role of customer and supplier relationships and employee empowerment in driving advanced manufacturing practices and achieving sustainability. It underscores the significance of product data management, failure analysis, and advanced quality practices as key drivers of enhanced product quality, which positively impacts business performance. By showing that effective communication is integrated within other constructs, the research refines existing models and informs strategic focus on customer feedback and structured data for quality enhancement. This study aids practitioners in prioritizing relationships and data management for sustainable competitive advantage and operational excellence.

7. Practical Implications

The findings of this study offer several detailed and actionable practical implications for manufacturing firms striving to achieve sustainable business performance. One of the most significant insights is the critical role of competence building, especially through customer relationships, supplier partnerships, employee empowerment, and the strategic selection of competitive advantages. These elements were found to significantly influence the adoption and success of advanced manufacturing practices such as field feedback systems, failure analysis and prediction, advanced quality practices (AQP), product data management (PDM), incoming component management (ICM), and manufacturing automation. For practitioners, manufacturing firms can cultivate strong customer relationships through structured feedback mechanisms like surveys, focus groups, and service channels, integrating insights into product development via cross-functional teams. This proactive approach not only strengthens trust and loyalty but also positions the firm for sustained growth and competitive advantage. Supplier relationships can be enhanced through evaluations, performance scorecards, and joint reviews, fostering transparency, accountability, and continuous improvement. By fostering transparency and aligning supplier capabilities with organizational goals, firms can enhance product quality, reduce operational risks, and drive sustainable business performance. Similarly, manufacturing firms should establish a structured feedback system where employees regularly share insights on processes and improvements. Feedback must be systematically collected, reviewed in cross-functional teams, and visibly acted upon. Providing training on problem-solving and failure analysis will enhance employee contributions. Recognizing and implementing valuable suggestions fosters empowerment, improves quality practices, and boosts overall performance. Transparent communication and leadership commitment are essential to sustaining an empowered, feedback-driven culture. Furthermore, systematically integrating feedback into strategic planning supports firms in adapting more quickly to market shifts, thereby reinforcing competitive advantage. A feedback-driven culture not only enhances trust and collaboration among stakeholders but also drives continuous quality improvement and sustainable business performance.

Manufacturing firms can also strengthen customer relations, supplier partnerships, employee empowerment, and competitive advantage by adopting a systematic failure analysis mechanism. This proactive approach identifies, predicts, and prevents product and process failures, improving quality and reliability. By analyzing failures, firms gather critical feedback and field data to enhance design and swiftly resolve defects, building customer trust. Collaborating on root-cause analysis deepens supplier integration and drives joint problem-solving. Empowering employees to engage in failure detection fosters ownership, motivation, and informed decision-making. Finally, failure insights guide firms in selecting strategic advantages, whether quality leadership, innovation, or operational efficiency, thereby driving sustainable performance and market competitiveness.

The study further emphasizes the strategic importance of data management systems, particularly PDM, as essential tools for organizing, analyzing, and leveraging complex manufacturing and quality data to inform continuous improvement efforts. While effective communication did not show a direct influence in the model, its role is embedded within other constructs, suggesting that communication practices should be integrated into relationship-building and collaborative strategies rather than treated as standalone initiatives. Additionally, product quality improvement was shown to be a direct and significant driver of business performance, reinforcing the need for organizations to embed quality practices into every stage of product development and operations. Continuous quality improvement not only enhances productivity and customer satisfaction but also contributes to waste reduction, cost efficiency, and environmental sustainability. For policymakers and industry leaders, these findings suggest the need to support initiatives that promote capability development, supplier collaboration, and digital transformation in manufacturing. Overall, the study provides a comprehensive framework for firms to align internal capabilities with external demands, adopt data-driven practices, and build resilient, high-performing, and sustainable manufacturing systems.

8. Conclusions, Limitations, and Future Research

A conceptual framework was introduced to examine the intricate connections between advanced manufacturing practices, their enabling competencies, and enhancements in product quality as well as business performance. Given the intricate nature of the model, a two-step approach involving SEM analysis was employed. The initial phase encompassed an exploratory factor analysis, affirming the suitability of measurement items for the constructs. Subsequently, confirmatory factor analysis was rigorously employed to assess all measurement models, each of which exhibited fit indices surpassing conventional acceptability thresholds.

The comprehensive structural equation model was subsequently deployed to estimate anticipated parameters and relationships. Statistical assessments of the outcomes validated a majority of the hypothesized relationships, demonstrating the statistical significance of numerous links postulated in the theoretical framework. Notably, the vast majority of relationships posited in the theoretical model were found to be statistically significant, affirming the substantial impact of advanced manufacturing practices on bolstering product quality. Furthermore, the findings lent robust support to the influence of competence-building facets in fostering advanced manufacturing practices and, consequently, elevating product quality, a factor intricately tied to enhanced business performance. This discernible connection ought to galvanize enterprises to embrace pivotal practices like prioritizing competence development and ensuring quality and reliability evaluations prior to manufacturing. Although existing literature implies a favorable correlation between competence building, advanced manufacturing practices, and business performance, a comprehensive examination of these connections within a single empirical framework has been notably absent. For example, to date, no study has systematically examined how the synergies between customer relationship management and incoming component management, customer relationship management and field feedback management, supplier relationship management and incoming component management, supplier relationship management and field feedback management, and competitive advantage strategy and manufacturing automation collectively influence advanced quality practices within the Australian manufacturing context. Previous research has typically treated these practices in isolation, thereby overlooking the combined impact they have in shaping a pathway toward sustainable performance.

This research not only fills this gap by pioneering an analysis that investigates the impact of individual competence-building dimensions on both advanced manufacturing practices and the overall performance of manufacturing businesses. But also uniquely identifies the synergistic effect of customer relationship management and incoming component management, customer relationship management and field feedback management, supplier relationship management and incoming component management, supplier relationship management and field feedback management, and competitive advantage strategy and manufacturing automation on advanced quality practices within the context of Australian manufacturing, revealing a pathway to sustainable performance. As the first of its kind, this study makes a valuable contribution to the existing body of knowledge.

This research presents a comprehensive framework for evaluating the impact of various parameters on business performance. Our objective was to provide an in-depth understanding of the topic within a specific national context, using Australia as a case study. Despite the geographic limitation, we believe the findings are both valid and meaningful for several reasons.