An Investigation into the Effects of Coke Dry Quenching Waste Heat Production on the Cost of the Steel Manufacturing Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Model Selection and Construction

2.1.1. Model Selection

2.1.2. Model Construction

2.2. Scenario Analysis

2.2.1. Scenario Analysis Method

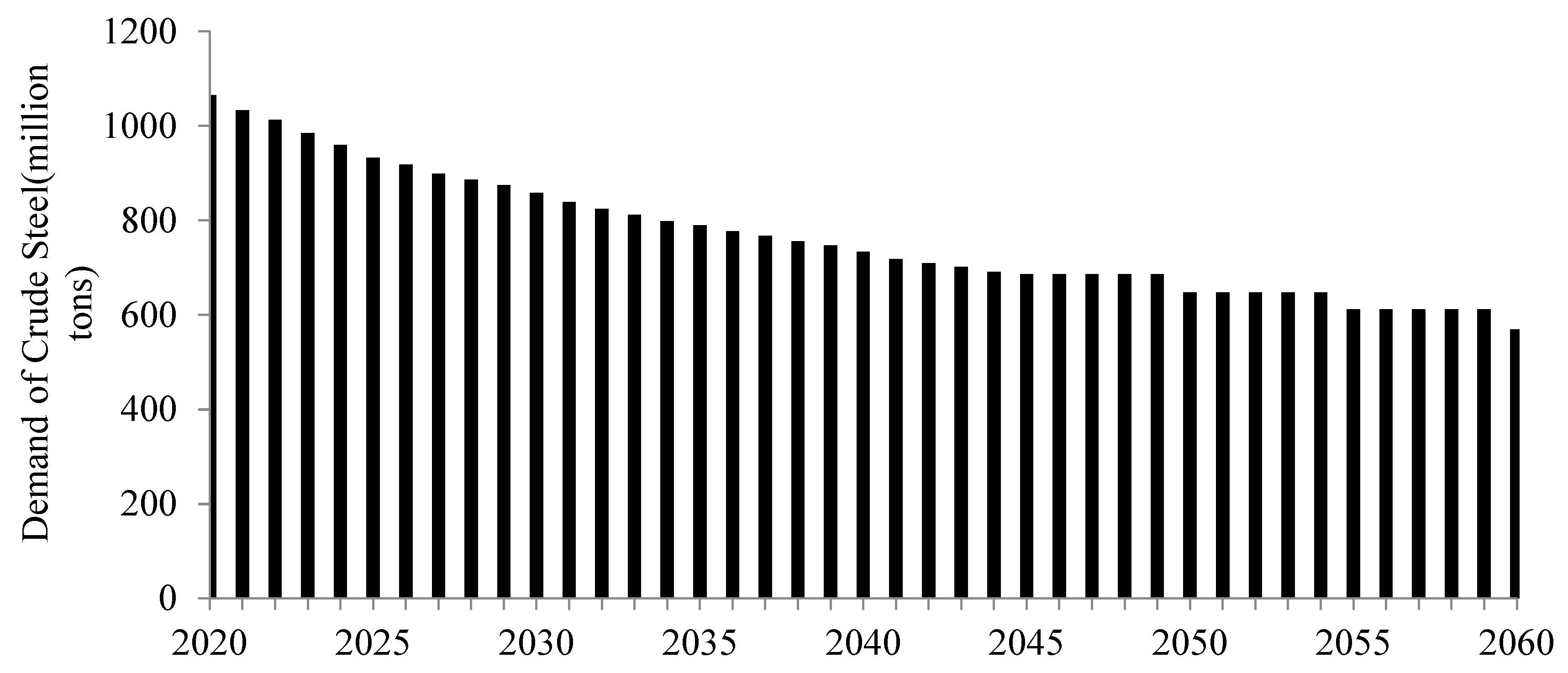

2.2.2. Reference (Baseline) Scenario Setting

2.2.3. Development of Hydrogen Metallurgy Scenario Setting

2.2.4. Development of the EAF Scrap Smelting Scenario Setting

2.3. Sources of Data

- (1)

- China’s crude steel demand and electricity demand data, as detailed in Section 2.1.2.

- (2)

- (3)

- (4)

3. Results and Discussion

3.1. Analysis of the Outcomes Under the Reference Scenario

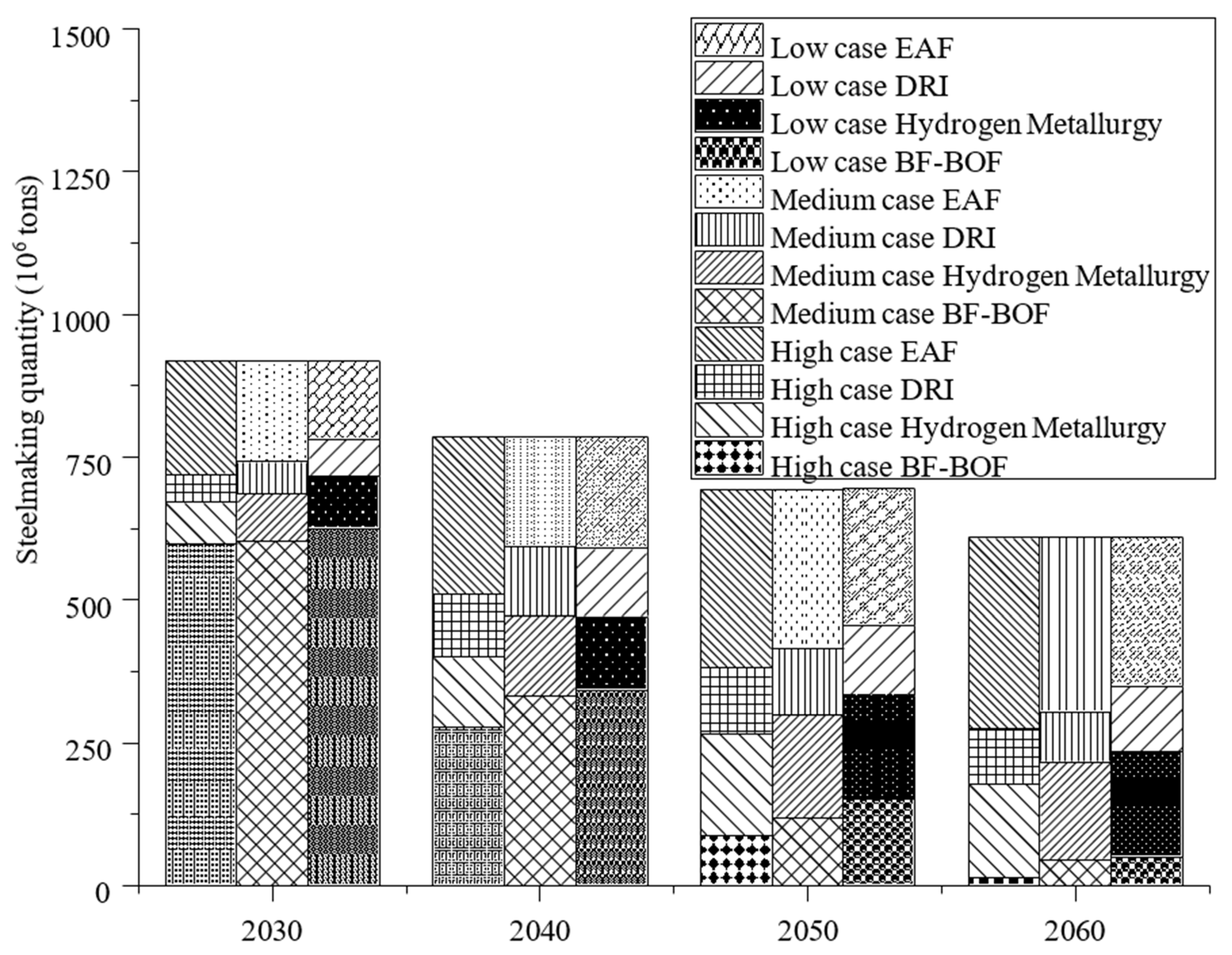

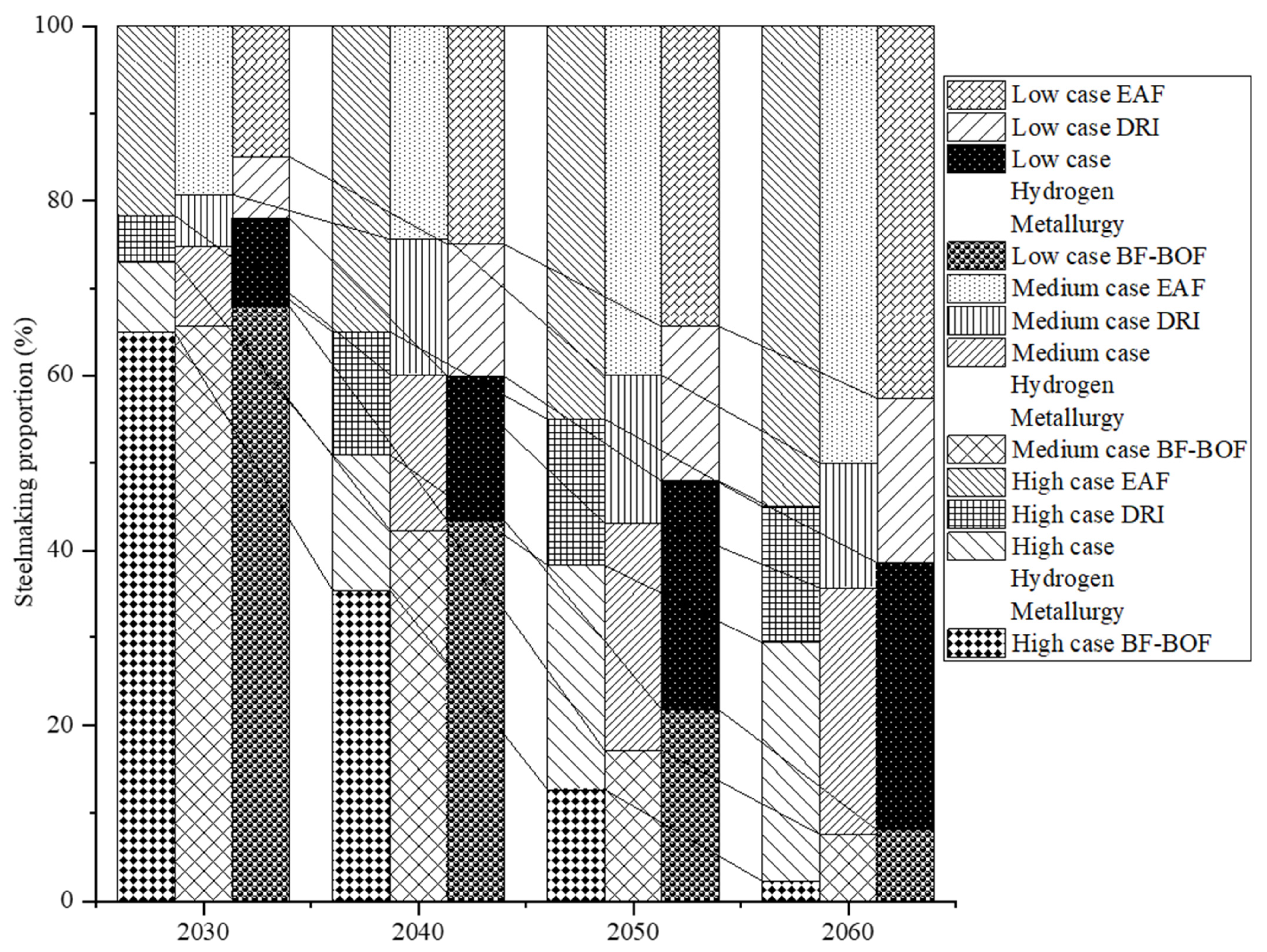

3.1.1. Analysis of the Steelmaking Structure Under the Reference Scenario

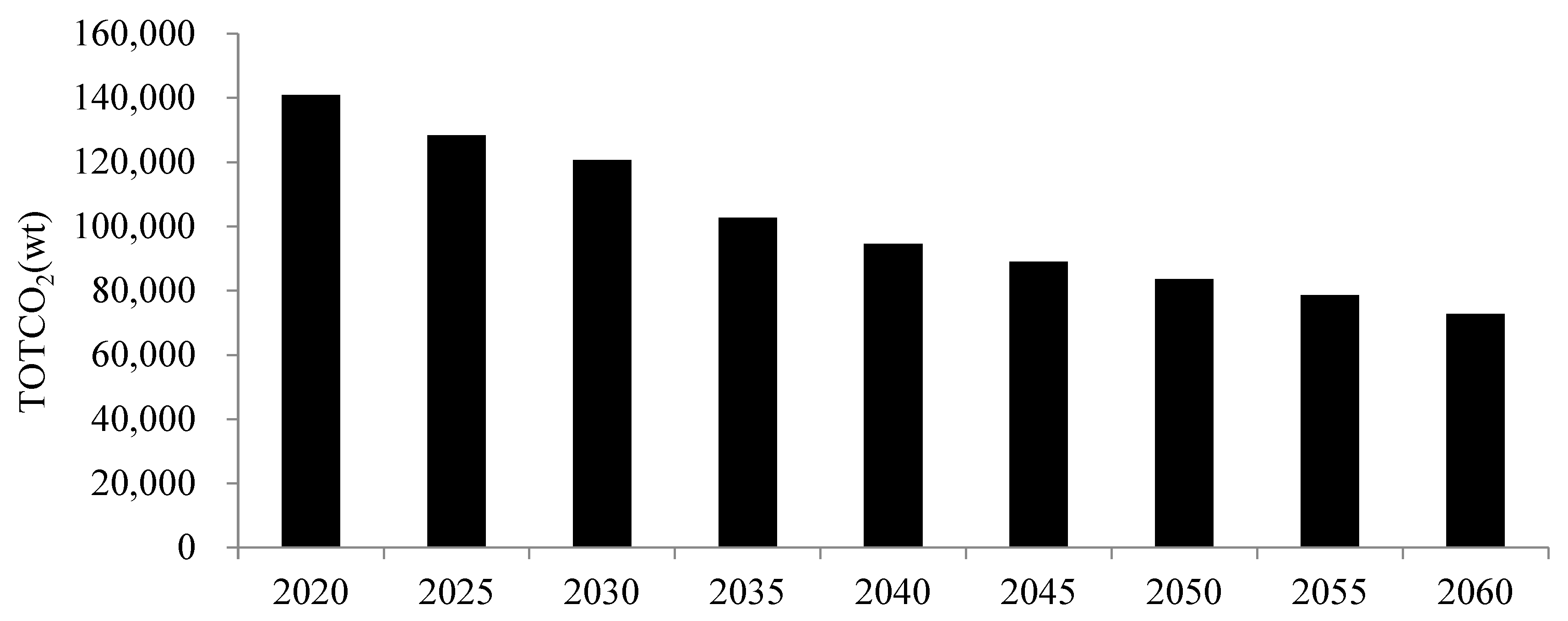

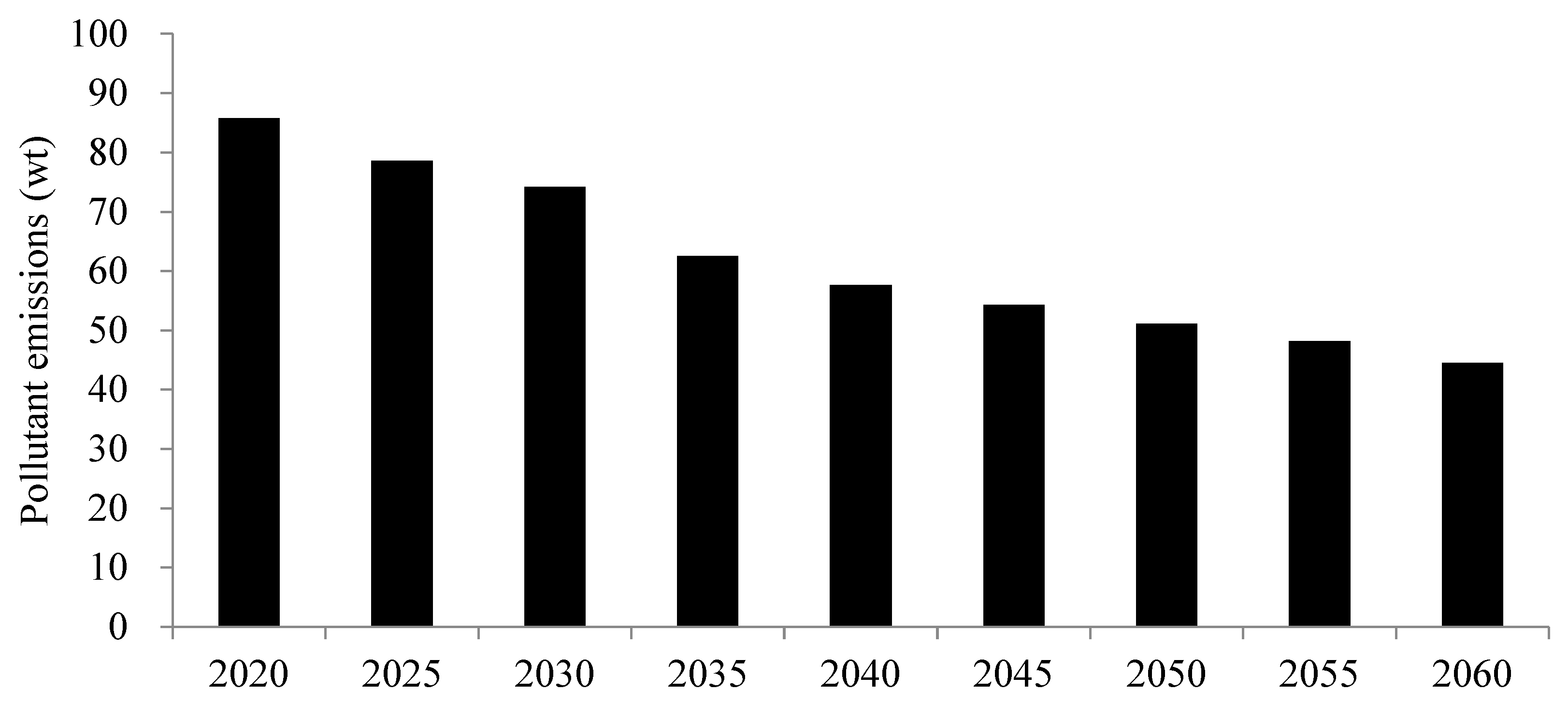

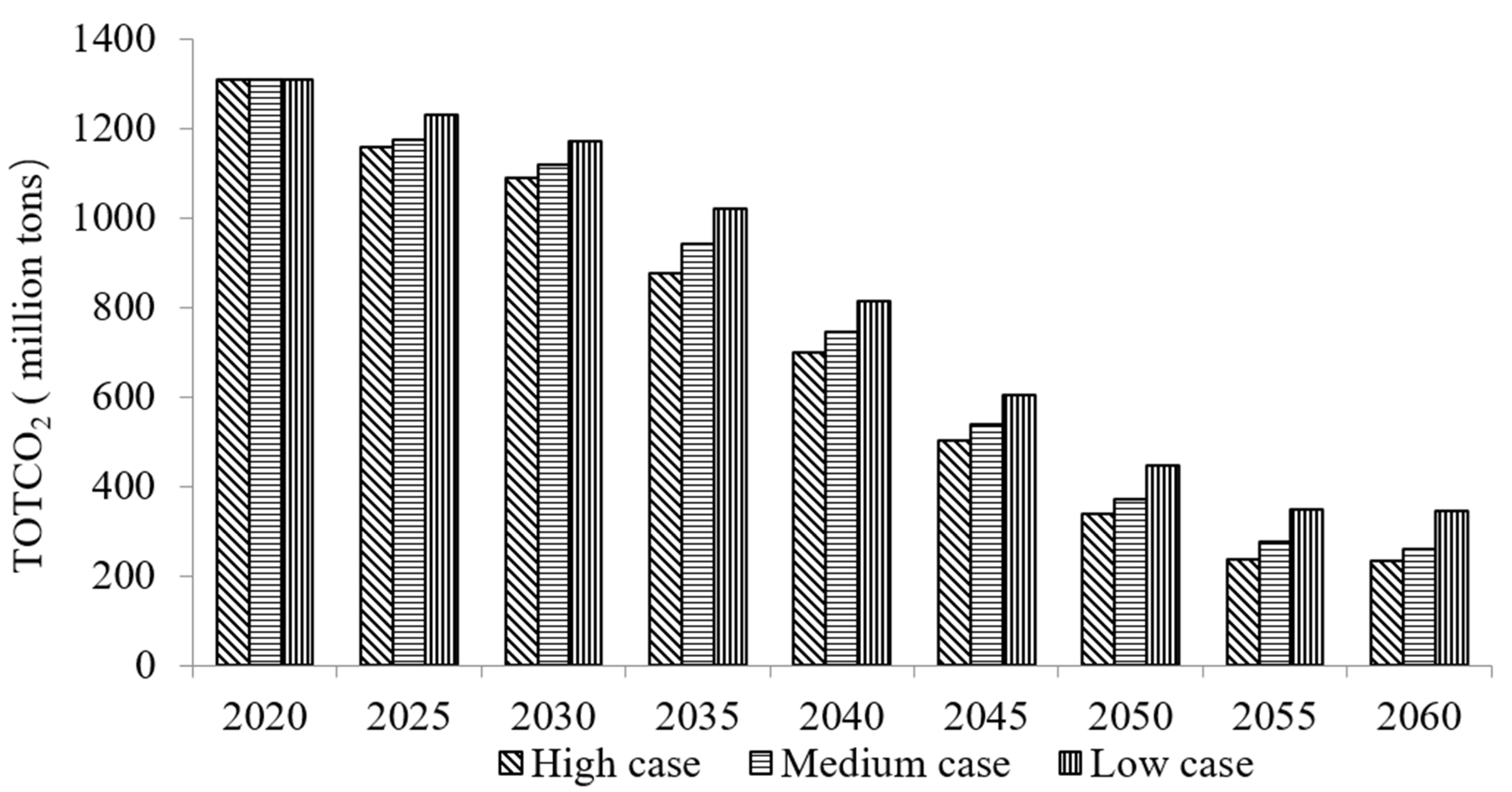

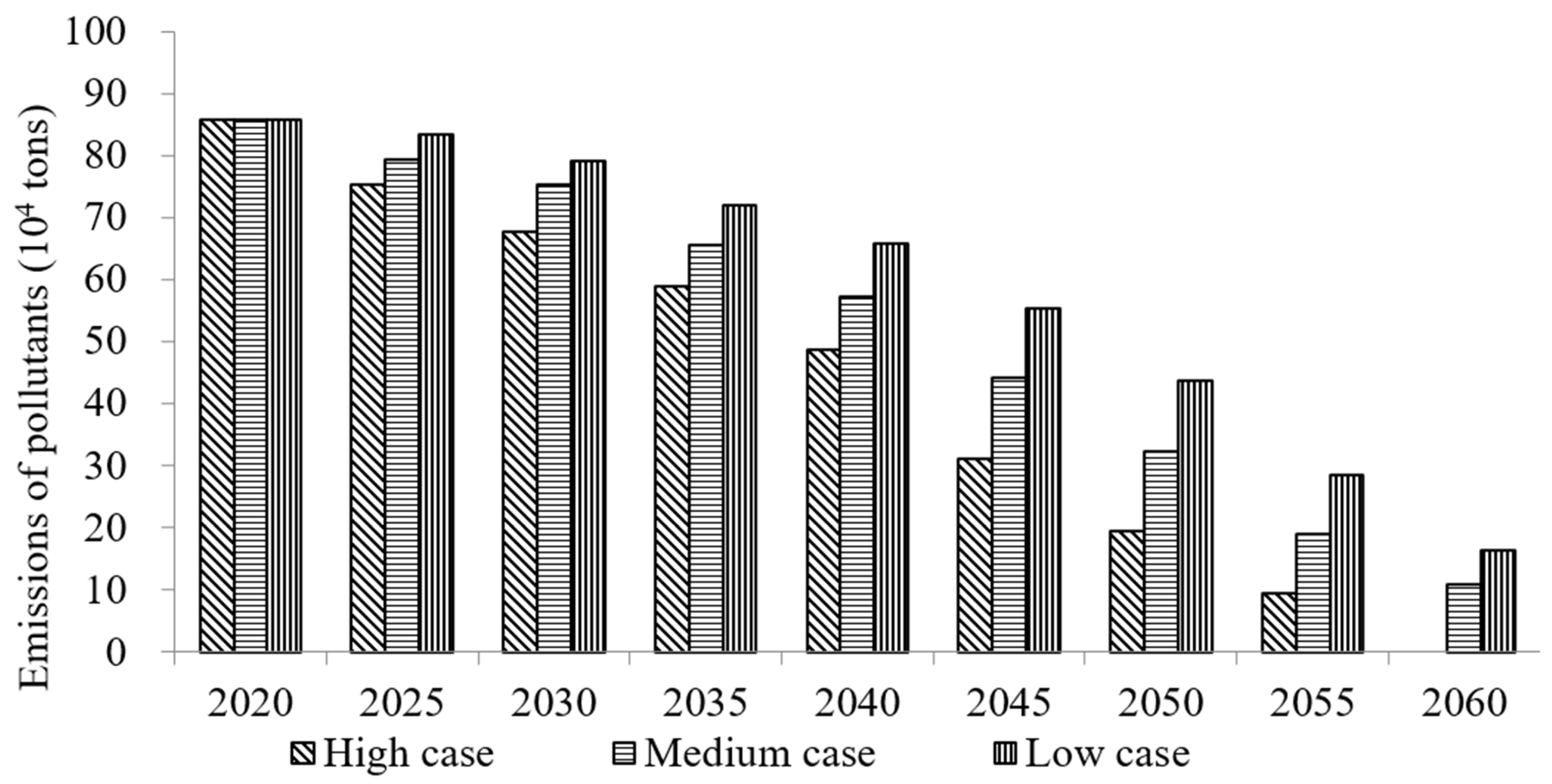

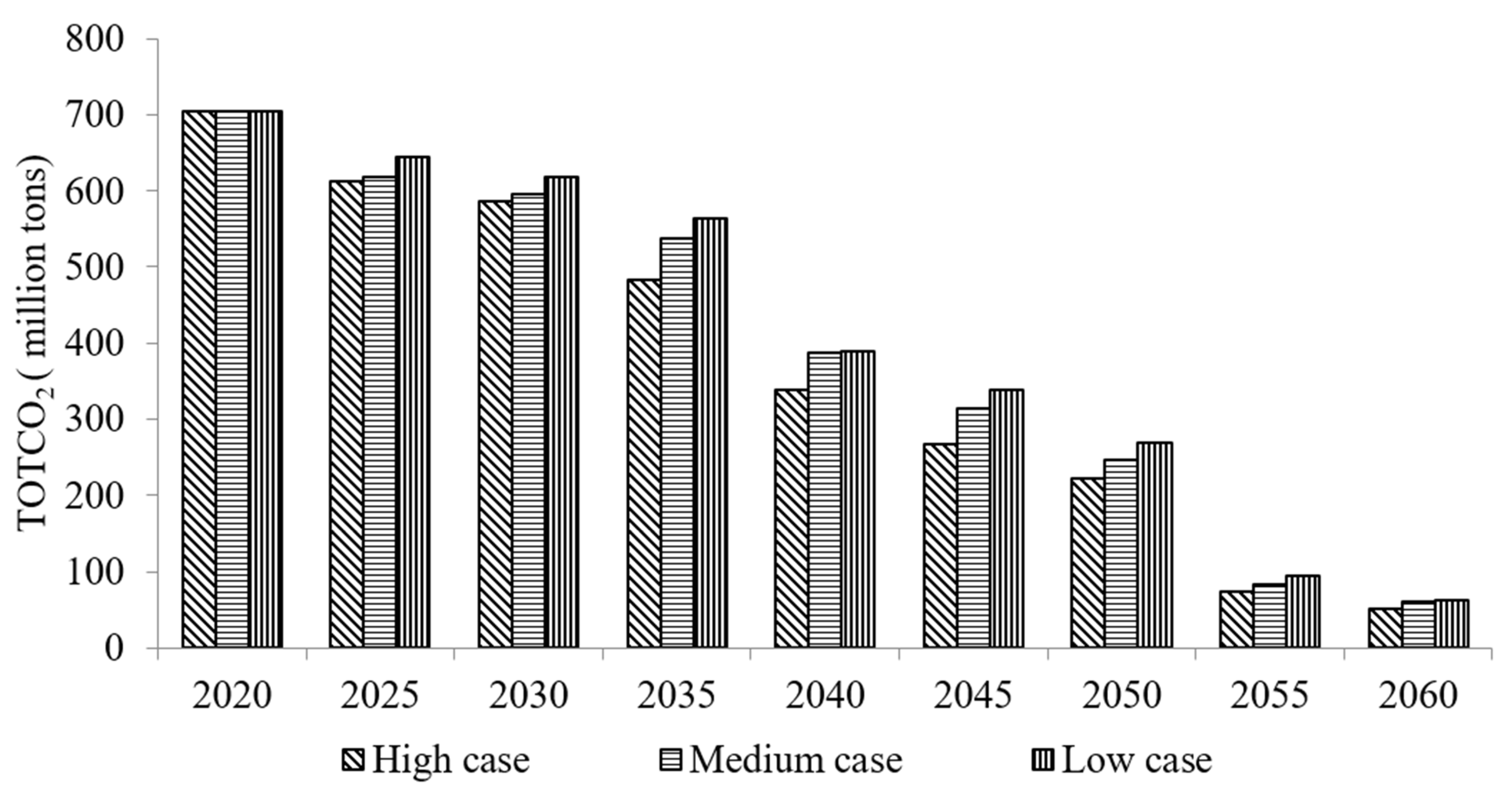

3.1.2. Analysis of the Pollution Emissions Under the Reference Scenario

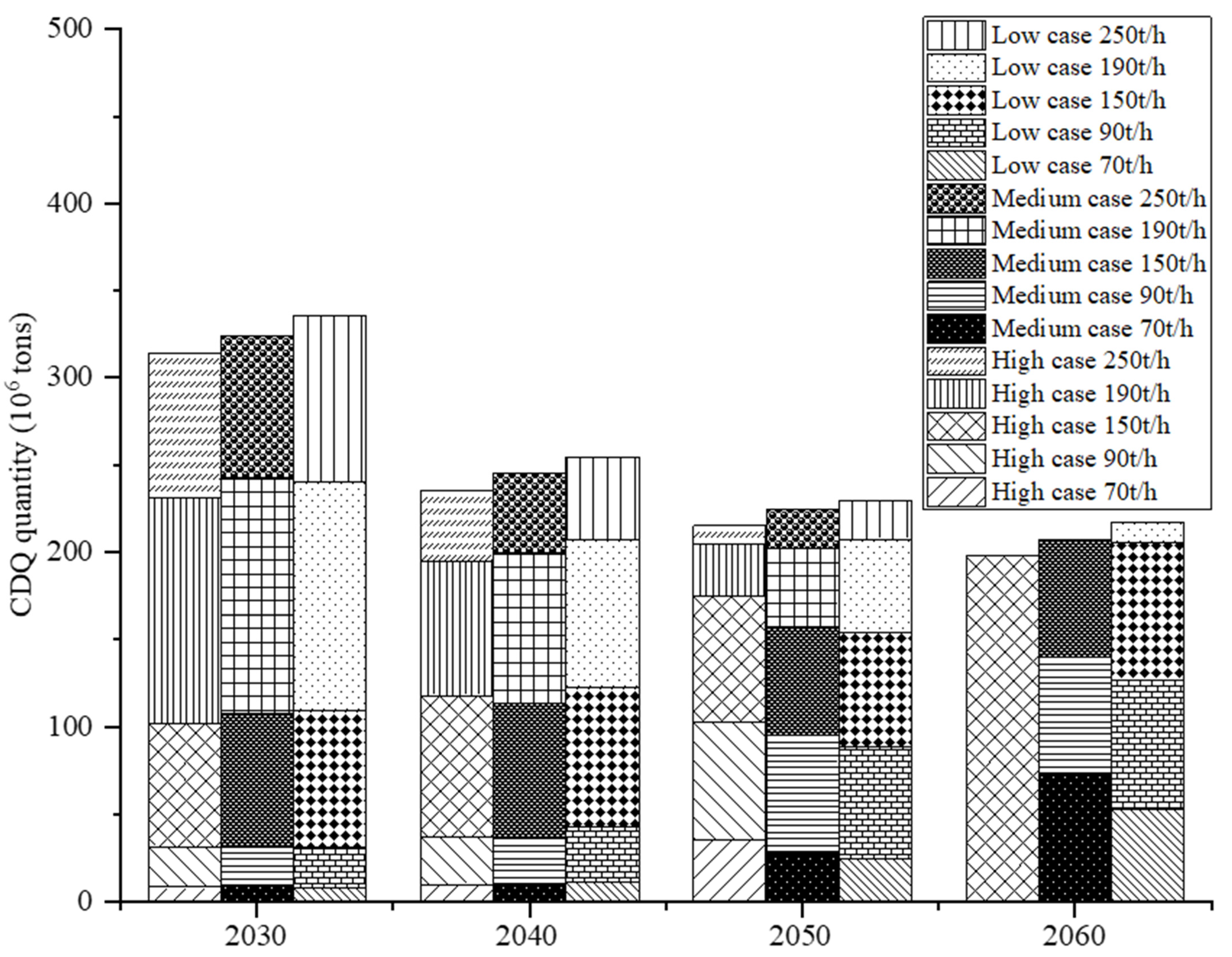

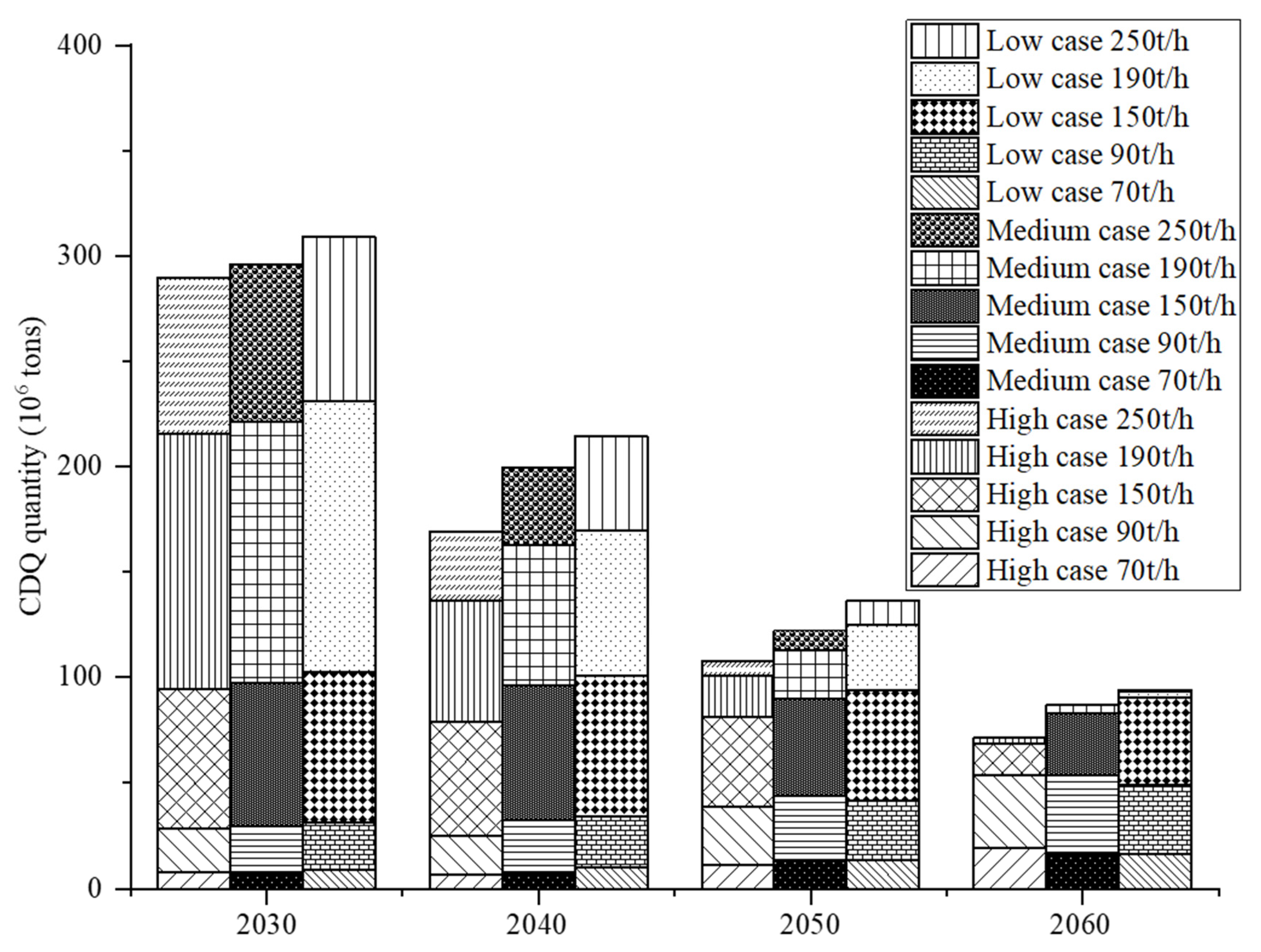

3.1.3. Analysis of the CDQ Quantity Under the Reference Scenario

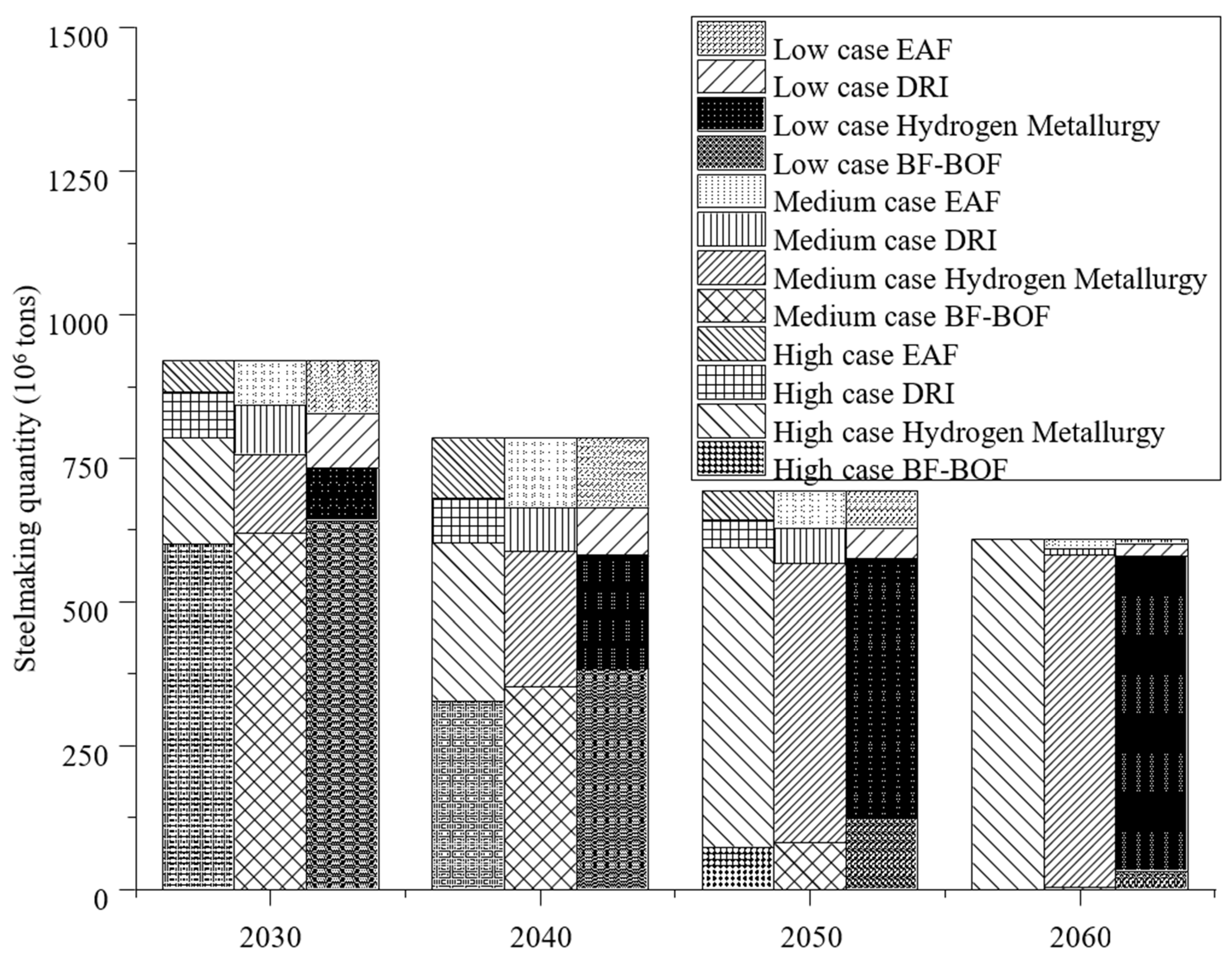

3.2. Analysis of the Outcomes Under the Hydrogen Metallurgy Scenario

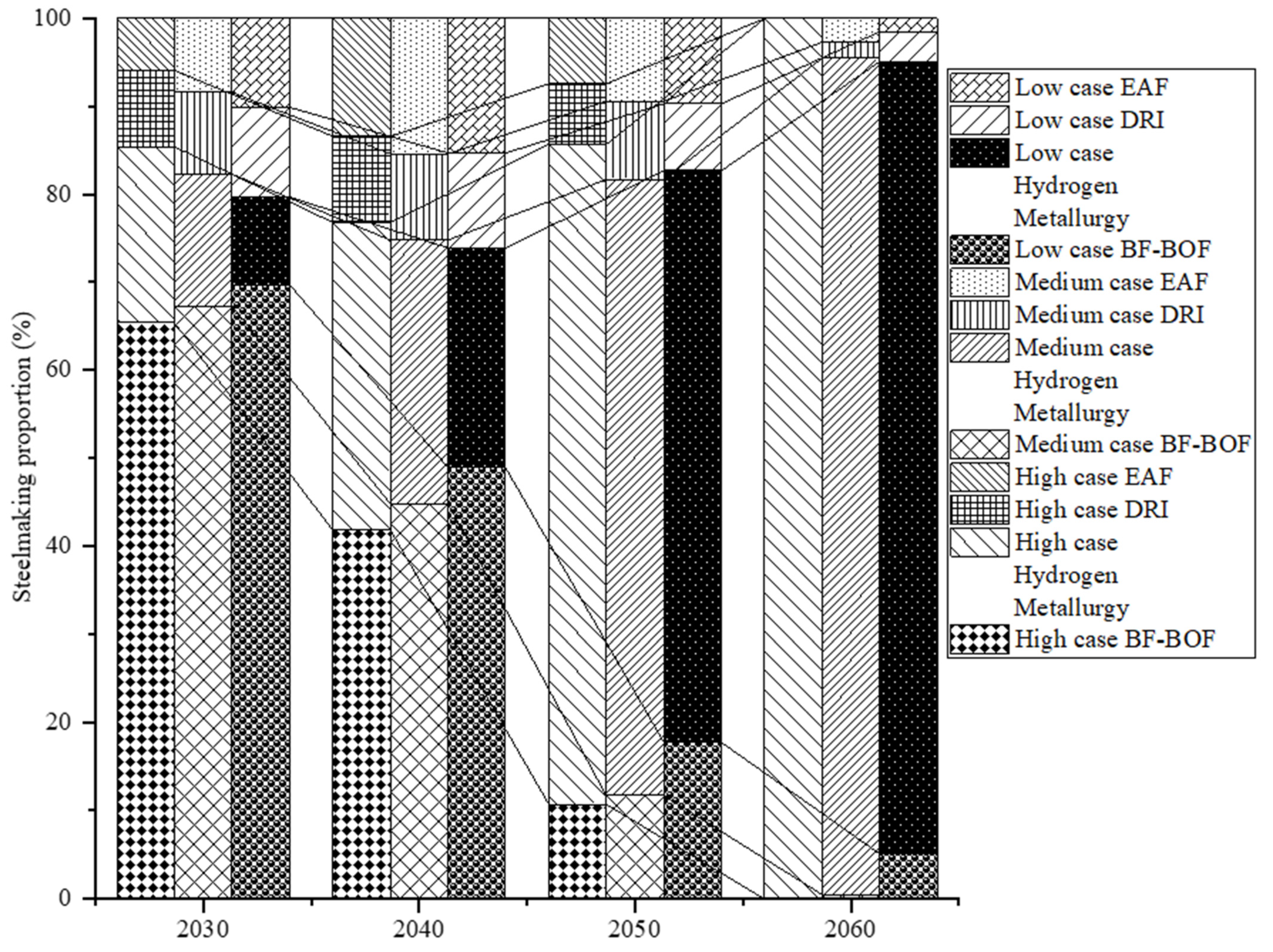

3.2.1. Analysis of the Steelmaking Structure Under the Hydrogen Metallurgy Scenario

3.2.2. Analysis of the Pollution Emissions Under the Hydrogen Metallurgy Scenario

3.2.3. Analysis of the CDQ Quantity Under the Hydrogen Metallurgy Scenario

3.3. Analysis of the Outcomes Under the EAF Scrap Smelting Scenario

3.3.1. Analysis of the Steelmaking Structure Under the EAF Scrap Smelting Scenario

3.3.2. Analysis of the Pollution Emissions Under the EAF Scrap Smelting Scenario

3.3.3. Analysis of the CDQ Quantity Under the EAF Scrap Smelting Scenario

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Basson, E. A Future Sustainable Steel Industry. In Proceedings of the 13th CSM Steel Congress, Chongqing, China, 22 September 2022. [Google Scholar]

- Holappa, L. Challenges and Prospects of Steelmaking towards the Year 2050. Metals 2021, 11, 1978. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Brooks, G.; Rhamdhani, M.A. Decarbonisation and hydrogen integration of steel industries: Recent development, challenges and technoeconomic analysis. J. Clean. Prod. 2023, 395, 136391. [Google Scholar] [CrossRef]

- Wang, J.G.; Xie, Z.; Yao, Y.; Yang, B.H.; Ma, S.W.; Liu, L.L. Soft sensor development for improving economic efficiency of the coke dry quenching process. J. Process Control 2019, 77, 20–28. [Google Scholar] [CrossRef]

- Yilmaz, C.; Wendelstorf, J.; Turek, T. Modeling and simulation of hydrogen injection into a blast furnace to reduce carbon dioxide emissions. J. Clean. Prod. 2017, 154, 488–501. [Google Scholar] [CrossRef]

- Zou, Y.C.; Yang, L.Z.; Li, B.; Yan, Z.F.; Li, Z.H.; Wang, S.; Guo, Y.F. Prediction Model of End-Point Phosphorus Content in EAF Steelmaking Based on BP Neural Network with Periodical Data Optimization. Metals 2022, 12, 1519. [Google Scholar] [CrossRef]

- Hu, H.; Yang, L.Z.; Zou, Y.C.; Xue, B.T.; Chen, F.; Wang, S.; Guo, Y.F. Mathematical modelling and techno-economic analysis of electric arc furnace steelmaking process with hot metal charging in China. Ironmak. Steelmak. 2024, 51, 411–426. [Google Scholar] [CrossRef]

- Wei, Z.C.; Liu, X.M.; Hu, G.W.; Xue, K.; Wu, Y.F. Research Progress on Iron- and Steelmaking Iste Slag-Based Glass-Ceramics: Preparation and GHG Emission Reduction Potentials. Sustainability 2023, 15, 16925. [Google Scholar] [CrossRef]

- Li, Z.; Hanaoka, T. Plant-level mitigation strategies could enable carbon neutrality by 2060 and reduce non-CO2 emissions in China’s iron and steel sector. One Earth 2022, 5, 932–943. [Google Scholar] [CrossRef]

- Pauna, H.; Ernst, D.; Zarl, M.; Aula, M.; Schenk, J.; Huttula, M.; Fabritius, T. Hydrogen plasma smelting reduction process monitoring with optical emission spectroscopy-Establishing the basis for the method. J. Clean. Prod. 2022, 372, 133755. [Google Scholar] [CrossRef]

- Venkataraman, M.; Csereklyei, Z.; Aisbett, E.; Rahbari, A.; Jotzo, F.; Lord, M.; Pye, J. Zero-carbon steel production: The opportunities and role for Australia. Energy Policy 2022, 163, 112811. [Google Scholar] [CrossRef]

- Stopar, K.; Kovacic, M.; Kitak, P.; Pihler, J. Electric arc modeling of the EAF using differential evolution algorithm. Mater. Manuf. Process. 2017, 32, 1189–1200. [Google Scholar] [CrossRef]

- Chen, Y.; Ryan, S.; Silaen, A.K.; Zhou, C.Q. Simulation of Scrap Melting Process in an AC Electric Arc Furnace: CFD Model Development and Experimental Validation. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2022, 53, 2675–2694. [Google Scholar] [CrossRef]

- Sambandam, M.; Nurni, V.N.; Jayaraj, S.P. Sustainable Production of Steel-Carbon Neutrality and Low Life Cycle Emission. J. Indian Inst. Sci. 2022, 102, 117–126. [Google Scholar] [CrossRef]

- Zhang, F.C.; Hong, L.K.; Xu, Y. Prospects for green steelmaking technology with low carbon emissions in China. Carbon Energy 2024, 6, 456. [Google Scholar]

- Lu, L.; Yao, X.L.; Yan, Z.P.; Liu, L. Life cycle cost of coke dry quenching waste heat recovery-mediated power generation. J. Clean. Prod. 2024, 446, 141161. [Google Scholar] [CrossRef]

- Arens, M.; Worrell, E. Diffusion of energy efficient technologies in the German steel industry and their impact on energy consumption. Energy 2014, 73, 968–977. [Google Scholar] [CrossRef]

- Utlu, Z.; Onal, B.S. Thermodynamic analysis of thermophotovoltaic systems used in waste heat recovery systems: An application. Int. J. Low-Carbon Technol. 2018, 13, 52–60. [Google Scholar] [CrossRef]

- Fumoto, K.; Yamagami, K.; Ishi, K. Fundamental study on heat transport device for effective utilization of unused heat. Tetsu-Hagane/J. Iron Steel Inst. Jpn. 2020, 106, 571–580. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, X.R.; Lai, N.C.; Jiang, Z.Y.; Li, J.Z. A novel process for coke wastewater gasification quenching: Energy and exergy analysis. Appl. Therm. Eng. 2021, 191, 116863. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, X.R.; Jiang, Z.Y.; Wu, L.; Lai, N.C. Bi-objective optimization and thermal economy analysis of a novel coke quenching process with wastewater gasification. Appl. Therm. Eng. 2023, 219, 119473. [Google Scholar] [CrossRef]

- Qin, S.Y.; Chang, S.Y.; Yao, Q. Modeling, thermodynamic and techno-economic analysis of coke production process with waste heat recovery. Energy 2017, 141, 435–450. [Google Scholar] [CrossRef]

- Sun, K.; Tseng, C.T.; Shan-Hill, W.D.; Shieh, S.S.; Jang, S.S.; Kang, J.L.; Hsieh, W.D. Model predictive control for improving waste heat recovery in coke dry quenching processes. Energy 2015, 80, 275–283. [Google Scholar] [CrossRef]

- Yang, W.H.; Xu, T.; Chen, G.; Guo, Y.J.; Jia, L.Y.; Li, W. Coke dry quenching and utilization of its waste heat for electricity in iron and steel industry. In Proceedings of the 2009 2nd Conference on Power Electronics and Intelligent Transportation System, Shenzhen, China, 19–20 December 2009. [Google Scholar]

- Ozcan, H.; Kayabasi, E. Thermodynamic and economic analysis of a synthetic fuel production plant via CO2 hydrogenation using waste heat from an iron-steel facility. Energy Convers. Manag. 2021, 236, 114074. [Google Scholar] [CrossRef]

- Jouhara, H.; Khordehgah, N.; Almahmoud, S.; Delpech, B.; Chauhan, A.; Tassou, S.A. Waste heat recovery technologies and applications. Therm. Sci. Eng. Prog. 2018, 6, 268–289. [Google Scholar] [CrossRef]

- Pili, R.; Garcia, M.L.; Wieland, C.; Spliethoff, H. Techno-economic potential of waste heat recovery from German energy-intensive industry with Organic Rankine Cycle technology. Renew. Sustain. Energy Rev. 2020, 134, 110324. [Google Scholar] [CrossRef]

- Chaimongkol, N.P.; Deethayat, T.; Wang, D.; Kiatsiriroat, T. Waste heat harvesting from continuous blowdown for power generation via organic Rankine cycle network: Case study of a coal-fired power plant. Results Eng. 2023, 20, 101543. [Google Scholar] [CrossRef]

- Ishaq, H.; Dincer, I.; Naterer, G.F. Exergy and cost analyses of waste heat recovery from furnace cement slag for clean hydrogen production. Energy 2019, 172, 1243–1253. [Google Scholar] [CrossRef]

- Chen, Y.F.; Li, C.H.; Zeng, Z.Y. Proposal and comprehensive analysis of an innovative steam generation system by deep recovery of low-grade waste heat. J. Clean. Prod. 2021, 310, 127509. [Google Scholar] [CrossRef]

- Zhang, L.; Zhai, H.X.; He, J.Y.; Yang, F.; Wang, S.L. Application of Exergy Analysis in Flue Gas Condensation Waste Heat Recovery System Evaluation. Energies 2022, 15, 7525. [Google Scholar] [CrossRef]

- Wang, J.G.; Zhao, J.H.; Shen, T.; Ma, S.W.; Yao, Y.; Chen, T.; Shen, B.; Wu, Y.P. Deep learning-based soft-sensing method for operation optimization of coke dry quenching process. In Proceedings of the 35th Chinese Control Conference, Chengdu, China, 27–29 July 2016. [Google Scholar]

- Besevli, B.; Kayabasi, E.; Akroot, A.; Talal, W.; Alfaris, A.; Assaf, Y.H. Technoeconomic Analysis of Oxygen Supported Combined Systems for Recovering Waste Heat in an Iron-Steel Facility. Appl. Sci. 2024, 14, 2563. [Google Scholar] [CrossRef]

- Zhu, Q.D.; Wei, G.L.; Mu, J.W.; Yang, G. Study on alloying of high manganese pig iron in 50 t oxygen top-blown converter. Steelmaking 2018, 34, 14–18. (In Chinese) [Google Scholar]

- Jiang, T.F.; Zhu, L.; Liu, F.G.; Zhao, X.D.; Luo, Y.Z. Recycling of desulfurization slag in pretreatment of hot metal. Iron Steel 2017, 52, 24–27+32. [Google Scholar]

- Meng, Y.; Zhu, X.H.; Zhang, Y.Y.; Su, Y.L.; Qu, F.L.; Poon, C.S.; Yan, J.H.; Tsang, D.C.W. Valorizing inherent resources from waste streams for in-situ CO2 capture and sequestration in the steel industry. J. Clean. Prod. 2024, 458, 142486. [Google Scholar] [CrossRef]

- Han, B.C.; Gao, C.L.; Li, Y.Q.; Liu, D.; Wei, G.S.; Zhu, R. Energy saving analysis for CO2-O2 mixed injection technology in converter steelmaking. J. Iron Steel Res. Int. 2024, 31, 1095–1103. [Google Scholar] [CrossRef]

- Sun, H.; Yang, J.; Zhang, R.H. Influence of the Basicity on Phosphorus Enrichment Properties of Decarbonization Slag in Low-Carbon Double Slag Converter Steelmaking Process with Industrial Experiments, Mineralogy, and Ion-molecule Coexistence Theory. Steel Res. Int. 2024, 95, 853. [Google Scholar] [CrossRef]

- Wang, S.L.; Gao, L.W. Production practice of steelmaking with low cost. China Metall. 2018, 28, 71–74. [Google Scholar]

- Su, P.F.; Zhou, Y.; Wu, J.Z. Multi-objective scheduling of a steelmaking plant integrated with renewable energy sources and energy storage systems: Balancing costs, emissions and make-span. J. Clean. Prod. 2023, 428, 139350. [Google Scholar] [CrossRef]

- Zang, G.Y.; Sun, P.P.; Elgowainy, A.; Bobba, P.; McMillan, C.; Ma, O.; Podkaminer, K.; Rustagi, N.; Melaina, M.; Koleva, M. Cost and life cycle analysis for deep CO2 emissions reduction of steelmaking: Blast furnace-basic oxygen furnace and electric arc furnace technologies. Int. J. Greenh. Gas Control 2023, 128, 103958. [Google Scholar] [CrossRef]

- Son, M.; Bin, Y.; Lee, I.B.; Lee, S.Y. Multi-Objective Optimization Model for the Energy System of Electric Arc Furnace Steelmaking Considering the Cost and Carbon Dioxide Emission under Uncertainty: Process Systems Engineering and Safety. J. Chem. Eng. Jpn. 2020, 53, 546–554. [Google Scholar] [CrossRef]

- Wei, L.; Chen, W.; Yang, Y. Decision-making on iron and steel enterprise considering carbon emission regulations and demand updating. Comput. Integr. Manuf. Syst. 2022, 28, 1199–1210. [Google Scholar]

- Geng, C.M.; Shi, Z.Y.; Chen, X.H.; Sun, Z.W.; Jin, Y.W.; Shi, T.; Wu, X. Stochastic Capacity Optimization of an Integrated BFGCC-MSHS-Wind-Solar Energy System for the Decarbonization of a Steelmaking Plant. Energies 2024, 17, 2994. [Google Scholar] [CrossRef]

- Badea, D.O.; Trifu, A.; Darabont, D.C. A comparative study on the effectiveness of pollutants control measures adopted in the steel industry to reduce workplace and environmental exposure: A case study. Sci. Rep. 2024, 14, 9916. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.G.; Zuo, H.B.; Wang, J.S.; Xue, Q.G.; Ren, B.L.; Yang, F. The production and application of hydrogen in steel industry. Int. J. Hydrogen Energy 2021, 46, 10548–10569. [Google Scholar] [CrossRef]

- Dawood, F.; Anda, M.; Shafiullah, G.M. Hydrogen production for energy: An overview. Int. J. Hydrogen Energy 2020, 45, 3847–3869. [Google Scholar] [CrossRef]

- Tang, J.; Chu, M.S.; Li, F.; Feng, C.; Liu, Z.G.; Zhou, Y.S. Development and progress on hydrogen metallurgy. Int. J. Miner. Metall. Mater. 2020, 27, 713–723. [Google Scholar] [CrossRef]

- Zhao, Z.G.; Yu, X.B.; Li, Y.T.; Zhu, J.M.; Shen, Y.S. CFD study of hydrogen co-injection through tuyere and shaft of an ironmaking blast furnace. Fuel 2023, 348, 128641. [Google Scholar] [CrossRef]

- Li, S.; Zhang, H.L.; Nie, J.P.; Dewil, R.; Baeyens, J.; Deng, Y.M. The Direct Reduction of Iron Ore with Hydrogen. Sustainability 2021, 13, 8866. [Google Scholar] [CrossRef]

- Liu, Z.J.; Lu, S.F.; Wang, Y.Z.; Zhang, J.L.; Cheng, Q.; Song, X.R. Optimization of Hydrogen-Based Shaft Furnace Raw Material Parameters Based on Numerical Simulation and Rist Operation Diagram. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2023, 54, 2121–2136. [Google Scholar] [CrossRef]

- Chen, S.Y.; Zhang, J.L.; Wang, Y.Z.; Wang, T.F.; Li, Y.; Liu, Z.J. Thermodynamic Study of H2-FeO Based on the Principle of Minimum Gibbs Free Energy. Metals 2023, 13, 225. [Google Scholar] [CrossRef]

- Li, H.F.; Chen, J.R.; Luo, Z.; Wang, X.; Cavaliere, P.; Roca, A. Development of Mass-Energy Balance Model Based on a New Process of RSF with Hy-O-CR. Metals 2024, 14, 127. [Google Scholar] [CrossRef]

- Ma, G.; Zhu, R.; Dong, K.; Li, Z.; Liu, R.; Yang, L.; Wei, G. Development and application of electric arc furnace combined blowing technology. Ironmak. Steelmak. 2016, 43, 594–599. [Google Scholar] [CrossRef]

- Yang, L.Z.; Hu, H.; Yang, S.; Wang, S.; Chen, F.; Guo, Y.F. Life cycle carbon footprint of electric arc furnace steelmaking processes under different smelting modes in China. Sustain. Mater. Technol. 2023, 35, e00564. [Google Scholar] [CrossRef]

- Hu, S.; Zhu, R.; Dong, K.; Liu, R. Numerical Simulation and Industrial Experimental Research on the Coherent Jet with “CH4 + N2” Mixed Fuel Gas. Metall. Mater. Trans. B 2018, 49, 2584–2598. [Google Scholar] [CrossRef]

- Wei, G.; Zhu, R.; Cheng, T.; Dong, K.; Liu, R. Modelling on the penetration depth of the coherent supersonic jet in EAF steelmaking. Ironmak. Steelmak. 2018, 45, 828–838. [Google Scholar] [CrossRef]

- Kumar, B.; Roy, G.G.; Sen, P.K. Exergy and CO2 emission analysis of rotary hearth furnace-electric arc furnace routes of steelmaking. Int. J. Exergy 2021, 36, 280–297. [Google Scholar] [CrossRef]

- Hernández, J.D.; Onofri, L.; Engell, S. Energy optimization of the electric arc furnace for operations at a fixed electrical power level. IFAC-Pap. 2022, 55, 144–149. [Google Scholar] [CrossRef]

- Salimbeni, A.; Bianca, M.D.; Rizzo, A.M.; Chiaramonti, D. Activated Carbon and P-Rich Fertilizer Production from Industrial Sludge by Application of an Integrated Thermo-Chemical Treatment. Sustainability 2023, 15, 14620. [Google Scholar] [CrossRef]

- Dock, J.; Kienberger, T. Techno-economic case study on Oxyfuel technology implementation in EAF steel mills–Concepts for waste heat recovery and carbon dioxide utilization. Clean. Eng. Technol. 2022, 9, 100525. [Google Scholar] [CrossRef]

- Yang, X.; Pang, J.; Teng, F.; Gong, R.; Springer, C. The environmental co-benefit and economic impact of China’s low-carbon pathways: Evidence from linking bottom-up and top-down models. Renew. Sustain. Energy Rev. 2021, 136, 110438. [Google Scholar] [CrossRef]

- Sun, J. Carbon Emission Reduction Effect of Regional Technological Innovation in China: Based on Regional-macro Econometric Simulation Analysis. J. Technol. Econ. 2018, 37, 107–116. (In Chinese) [Google Scholar]

- Hong, J.K.; Huang, H.; Wang, X.Z. The effect of economic structural transformation on carbon emission reduction. Resour. Sci. 2023, 45, 2103–2116. (In Chinese) [Google Scholar]

- Nishiura, O.; Krey, V.; Fricko, O.; van Ruijven, B.; Fujimori, S. Integration of energy system and computable general equilibrium models: An approach complementing energy and economic representations for mitigation analysis. Energy 2024, 296, 131039. [Google Scholar] [CrossRef]

- Younis, A.; Benders, R.; Delgado, R.; Lap, T.; Gonzalez-Salazar, M.; Cadena, A.; Faaij, A. System analysis of the bio-based economy in Colombia: A bottom-up energy system model and scenario analysis. Biofuels Bioprod. Biorefining 2020, 15, 481–501. [Google Scholar] [CrossRef]

- Colucci, G.; Lerede, D.; Nicoli, M.; Savoldi, L. A dynamic accounting method for CO2 emissions to assess the penetration of low-carbon fuels: Application to the TEMOA-Italy energy system optimization model. Appl. Energy 2023, 352, 121951. [Google Scholar] [CrossRef]

- Rehman, S.A.; Cai, Y.; Mirjat, N.H.; Walasai, G.D.; Nafees, M. Energy-environment-economy nexus in Pakistan: Lessons from a PAK-TIMES model. Energy Policy 2019, 126, 200–211. [Google Scholar] [CrossRef]

- Wan, F.; Li, J.Z.; Han, Y.F.; Yao, X.L. Research of the Impact of Hydrogen Metallurgy Technology on the Reduction of the Chinese Steel Industry’s Carbon Dioxide Emissions. Sustainability 2024, 16, 1814. [Google Scholar] [CrossRef]

- Christos, S.I.; Hana, G.; Ali, B.; Sesil, K.; Nikolaos, K. Strategic Planning for Carbon Capture and Storage Implementation in the Electricity Sector of Greece: A TIMES Based Analysis. Processes 2021, 9, 1913. [Google Scholar] [CrossRef]

- Andrea, M.; Ilkka, K.; Daniele, L.; Laura, S. Role of technology learning in the decarbonization of the iron and steel sector: An energy system approach using a global-scale optimization model. Energy 2023, 274, 127339. [Google Scholar]

- The Chinese Academy of Engineering. Research on the Strategic Path of Green and Low-Carbon Innovative Development of China’s Coal-Coke Hydrogen Iron Industry Chain Under the Goal of “Double Carbon”; The Chinese Academy of Engineering: Beijing, China, 2023. [Google Scholar]

- National Development and Reform Commission. The 14th Five-Year Plan for the Development of Renewable Energy. Available online: http://www.china-cer.com.cn/guwen/2022060118955.html (accessed on 20 October 2024).

- Natural Resources Defense Council. Research on Development Strategy for Hydrogen Metallurgy Towards Carbon Neutrality-Executive Summary. Available online: https://www.doc88.com/p-73273252906628.html (accessed on 20 October 2024).

- Chang, Y.F.; Wan, F.; Li, J.Z.; Liu, N.; Yao, X.L. The impact of cautious coal power phase-out on decarbonization of China’s iron and steel industry. J. Clean. Prod. 2023, 397, 136447. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, W.; Wang, J. The policy effects of demand-pull and technology-push on the diffusion of wind power: A scenario analysis based on system dynamics approach. Energy 2022, 261, 125224. [Google Scholar]

- Du, Y.Y.; Huang, H.; Liu, H.B.; Zhao, J.Y.; Yang, Q.Z. Life Cycle Assessment of Abandonment of Onshore Wind Power for Hydrogen Production in China. Sustainability 2024, 16, 5772. [Google Scholar] [CrossRef]

- Rocky Mountain Institute. China’s Zero-Carbon Steel Path Under the Carbon Neutral Goal. Available online: https://rmi.org.cn/wp-content/uploads/2021/09/202109290934514586.pdf (accessed on 20 October 2024).

- Central Committee of the Communist Party of China and the State Council. “14th Five-Year Plan” Comprehensive Work Plan for Energy Conservation and Emission Reduction. Available online: https://www.gov.cn/zhengce/content/2022-01/24/content_5670202.htm (accessed on 20 October 2024).

- China Iron and Steel Association. Research Report on the Progress of Short-Process Steelmaking in China’s Electric Furnace: Current Trends, Carbon Emission Reduction Potential, and Development Prospects. Available online: https://zhuanlan.zhihu.com/p/656341012 (accessed on 20 October 2024).

- Li, F.; Chu, M.S.; Tang, J.; Liu, Z.G.; Wang, J.X.; Li, S.K. Life-cycle assessment of the coal gasification-shaft furnace-electric furnace steel production process. J. Clean. Prod. 2020, 287, 125075. [Google Scholar] [CrossRef]

- Li, H.Y.; Wang, Z.Y.; Zhou, J.J. Energy saving calculation and analysis of independent coke dry quenching waste heat power generation project. Henan Chem. Ind. 2020, 37, 29–32. (In Chinese) [Google Scholar]

- Ren, M.; Lu, P.T.; Liu, X.R.; Hossain, M.S.; Fang, Y.R.; Hanaoka, T.; O’Gallachoir, B.; Glynn, J.; Dai, H. Decarbonizing China’s iron and steel industry from the supply and demand sides for carbon neutrality. Appl. Energy 2021, 298, 117209. [Google Scholar] [CrossRef]

- Lopez, G.; Galimova, T.; Fasihi, M.; Bogdanov, D.; Breyer, C. Towards defossilised steel: Supply chain options for a green European steel industry. Energy 2023, 273, 127236. [Google Scholar] [CrossRef]

- National Bureau of Statistics. The China Iron and Steel Industry Yearbook. 2021. Available online: https://www.zgtjnj.org/navipage-n3023062108000101.html (accessed on 19 February 2024).

- The China Media Research Institute. The China Energy Big Data Report. Available online: https://www.dx2025.com/archives/25854.html (accessed on 15 March 2022).

- Zhang, Y.F.; Gao, Q.; Wei, J.P.; Shi, X.P.; Zhou, D.Q. Can China’s energy-consumption permit trading scheme achieve the “Porter” effect? Evidence from an estimated DSGE model. Energy Policy 2023, 180, 113671. [Google Scholar] [CrossRef]

- Yang, L.Z.; Hu, H.; Wang, M.X.; Chen, F.; Wang, S.; Guo, Y.F.; Yang, S.; Jiang, T. Comparative life cycle assessment and techno-economic analysis of electric arc furnace steelmaking processes integrated with solar energy system. J. Clean. Prod. 2023, 425, 138868. [Google Scholar] [CrossRef]

| Variables | Variables Description |

|---|---|

| OBJ(z) | the comprehensive cost of the system |

| R | the set of regions |

| years | the set of years |

| refy | the base year |

| ACT(r, t, p, s) | Operational Intensity of Technology p in Sub-Period s of Period t within Region r |

| NCAP(r, t, p) | Newly Commissioned Capacity of Technology p in Period t within Region r |

| CAP(r, t, p) | Total Installed Capacity of Technology p in Period t within Region r |

| CAPT(r, t, p, s) | Aggregate Installed Capacity of Technology p in Sub-Period s of Period t within Region r |

| ANNcost(r, y) | Annual Total Expenditure of Technology Pathway in Region r during Year y, including technology investment cost, annual operation and maintenance cost, variable cost, and associated tax subsidies |

| ACT_COST(r, t, p) | Variable Operational Cost Associated with Technology p in Period t within Region r |

| FLO_EMIS | Emission Factor per Unit Process or Activity |

| FLOW(r, t, p, c, s) | Production or Consumption Volume of Product c by Technology p in Sub-Period s of Period t within Region r |

| UC_CAP(uc_n, side, r, y, p) | Coefficient of Activity Variables in User-Defined Constraints |

| DEM(r, t, p) | Vector of Final Crude Steel Demand |

| dr,y | the discount rate |

| Salv(z) | the residual value of assets when the technical device is phased out |

| Scenario Setting | 2030 | 2035 | 2040 | 2045 | 2050 | 2055 | 2060 |

|---|---|---|---|---|---|---|---|

| High scenarios | 20% | 25% | 65% | 55% | 75% | 95% | 100% |

| Medium scenarios | 15% | 20% | 30% | 50% | 70% | 90% | 95% |

| Low scenarios | 10% | 15% | 55% | 45% | 65% | 85% | 90% |

| Scenario Setting | 2030 | 2035 | 2040 | 2045 | 2050 | 2055 | 2060 |

|---|---|---|---|---|---|---|---|

| High scenarios | 25% | 30% | 35% | 40% | 45% | 50% | 55% |

| Medium scenarios | 20% | 25% | 30% | 35% | 40% | 45% | 50% |

| Low scenarios | 15% | 20% | 25% | 30% | 35% | 40% | 45% |

| 2020 | 2025 | 2030 | 2035 | 2040 | 2045 | 2050 | 2055 | 2060 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| BF-BOF | proportion | 64.20% | 67.70% | 69.60% | 62.80% | 61.90% | 61.90% | 60.50% | 59.10% | 59.00% |

| output | 733 | 722 | 676 | 640 | 531 | 486 | 455 | 420 | 387 | |

| Hydrogen Metallurgy | proportion | 11.10% | 11.10% | 11.10% | 11.20% | 11.50% | 12.00% | 13.40% | 14.70% | 14.3% |

| output | 127 | 124 | 111 | 102 | 95 | 90 | 88 | 93 | 96 | |

| DRI | proportion | 8.80% | 8.90% | 8.90% | 9.60% | 10.20% | 11.30% | 10.80% | 11.60% | 12% |

| output | 100 | 98 | 89 | 82 | 81 | 80 | 83 | 75 | 76 | |

| EAF | proportion | 15.90% | 12.30% | 10.40% | 16.40% | 16.40% | 14.80% | 15.30% | 14.60% | 14.70% |

| output | 182 | 169 | 123 | 96 | 139 | 129 | 109 | 106 | 96 |

| 2020 | 2025 | 2030 | 2035 | 2040 | 2045 | 2050 | 2055 | 2060 | |

|---|---|---|---|---|---|---|---|---|---|

| 70 t/h | 943 | 848 | 811 | 803 | 1024 | 1214 | 1334 | 1551 | 1752 |

| 90 t/h | 2560 | 2304 | 2353 | 2562 | 2783 | 3061 | 3460 | 3983 | 6638 |

| 150 t/h | 7770 | 7397 | 7271 | 6318 | 6209 | 6171 | 6384 | 6565 | 6866 |

| 190 t/h | 15,372 | 14,028 | 13,743 | 10,996 | 8347 | 7711 | 7017 | 6493 | 3337 |

| 250 t/h | 10,321 | 9289 | 7762 | 6218 | 6406 | 5178 | 3769 | 2095 | 523 |

| CDQ quantity | 36,966 | 33,867 | 31,940 | 26,897 | 24,769 | 23,334 | 21,964 | 20,687 | 19,116 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, L.; Yan, Z.; Yao, X.; Han, Y. An Investigation into the Effects of Coke Dry Quenching Waste Heat Production on the Cost of the Steel Manufacturing Process. Sustainability 2025, 17, 4402. https://doi.org/10.3390/su17104402

Lu L, Yan Z, Yao X, Han Y. An Investigation into the Effects of Coke Dry Quenching Waste Heat Production on the Cost of the Steel Manufacturing Process. Sustainability. 2025; 17(10):4402. https://doi.org/10.3390/su17104402

Chicago/Turabian StyleLu, Lin, Zhipeng Yan, Xilong Yao, and Yunfei Han. 2025. "An Investigation into the Effects of Coke Dry Quenching Waste Heat Production on the Cost of the Steel Manufacturing Process" Sustainability 17, no. 10: 4402. https://doi.org/10.3390/su17104402

APA StyleLu, L., Yan, Z., Yao, X., & Han, Y. (2025). An Investigation into the Effects of Coke Dry Quenching Waste Heat Production on the Cost of the Steel Manufacturing Process. Sustainability, 17(10), 4402. https://doi.org/10.3390/su17104402