Adhesive-Coupled Polymer Multistage Modified Sustainable Alkali-Activated Materials: Barrier Performance and Microstructural Investigation Under Accelerated Curing Conditions

Abstract

1. Introduction

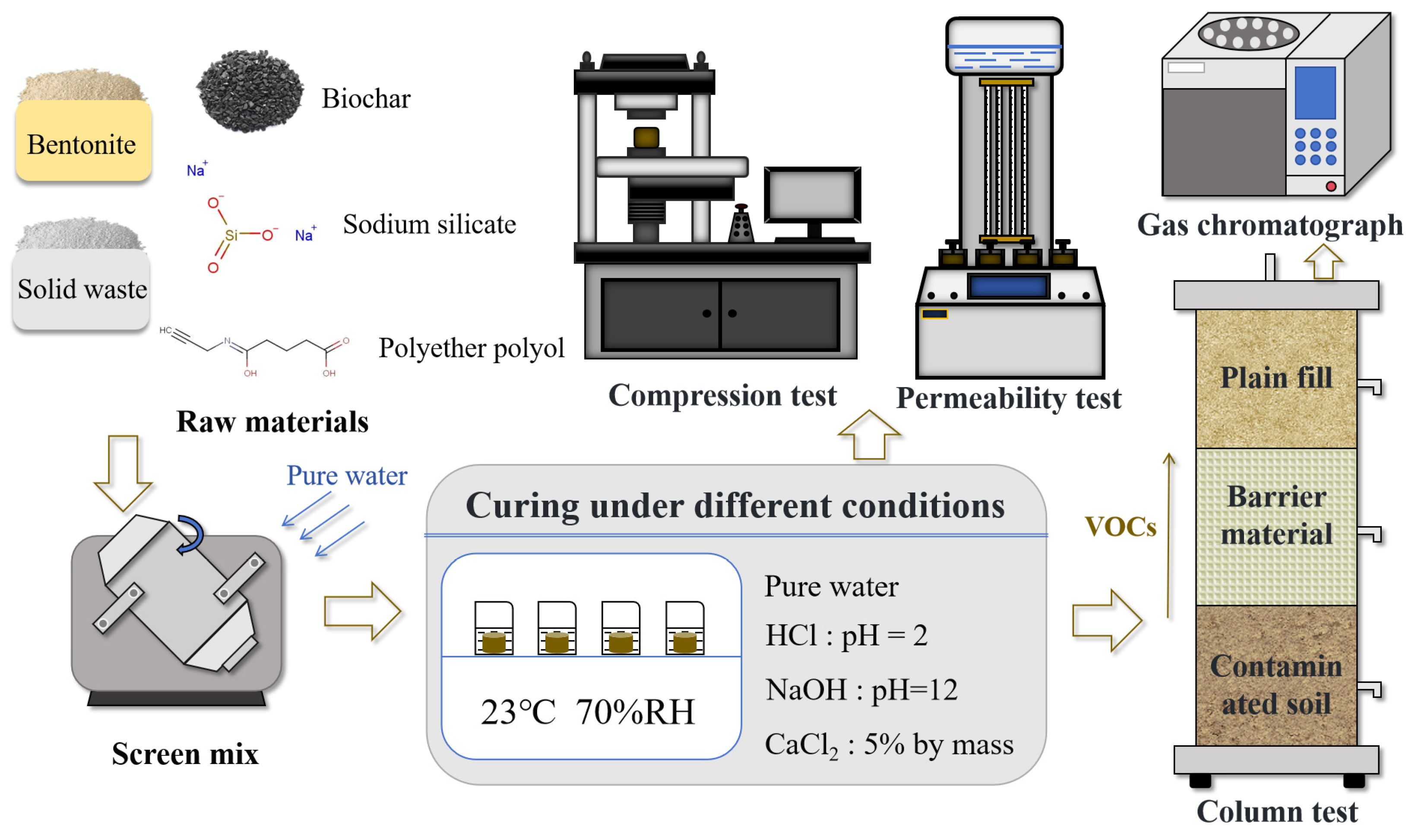

2. Materials and Methods

2.1. Raw Materials

2.2. Preparation and Analysis of Barrier Materials

2.3. Basic Physical Properties

2.4. Chemical Compatibility

2.5. Evaluation of VOC Barrier Effectiveness

2.6. Characterization and Detection Methods

3. Results and Discussion

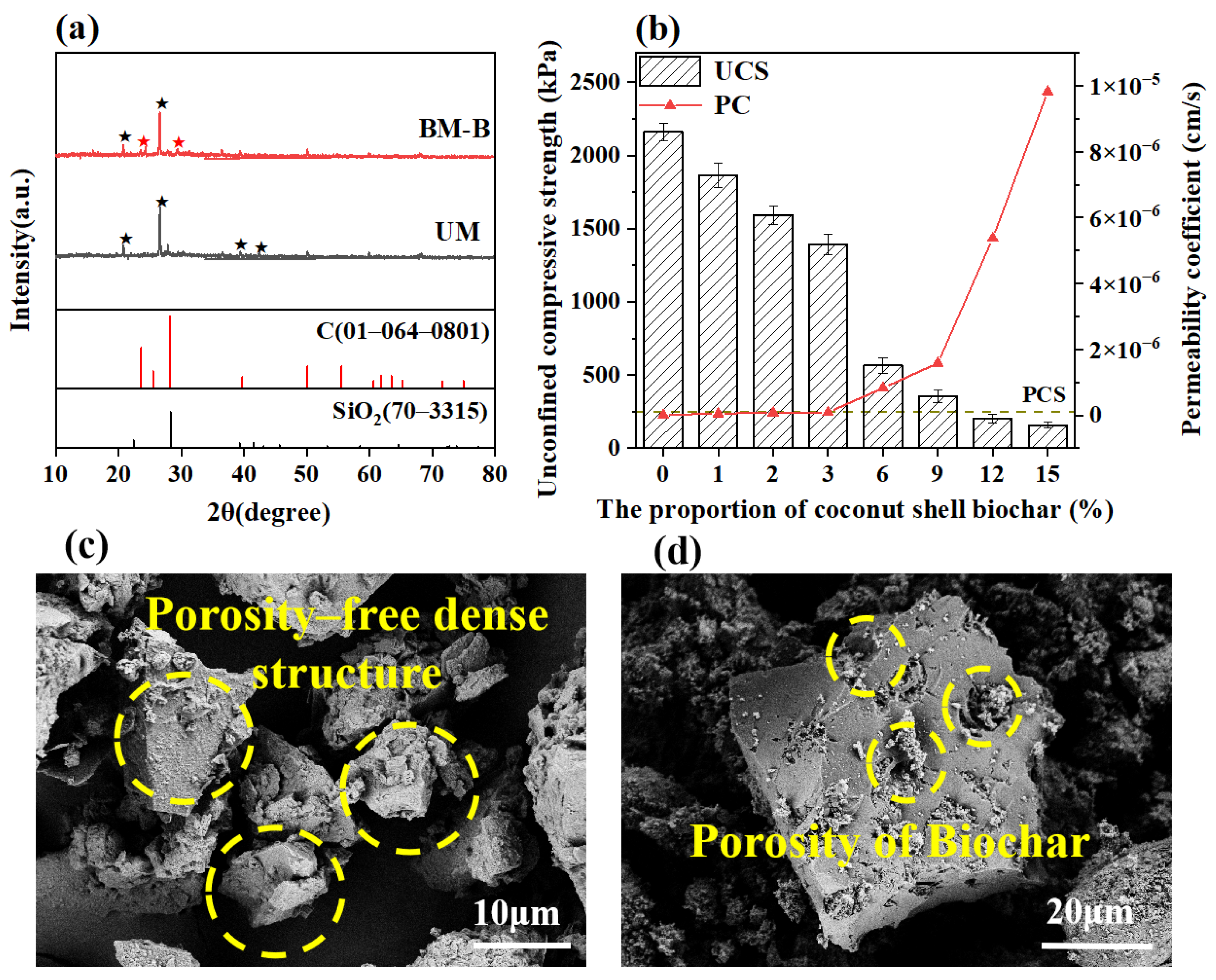

3.1. Physical Properties of Barrier Materials Prepared from Multiple Solid Wastes

3.2. Effects of Biochar on Compressive and Permeability Properties

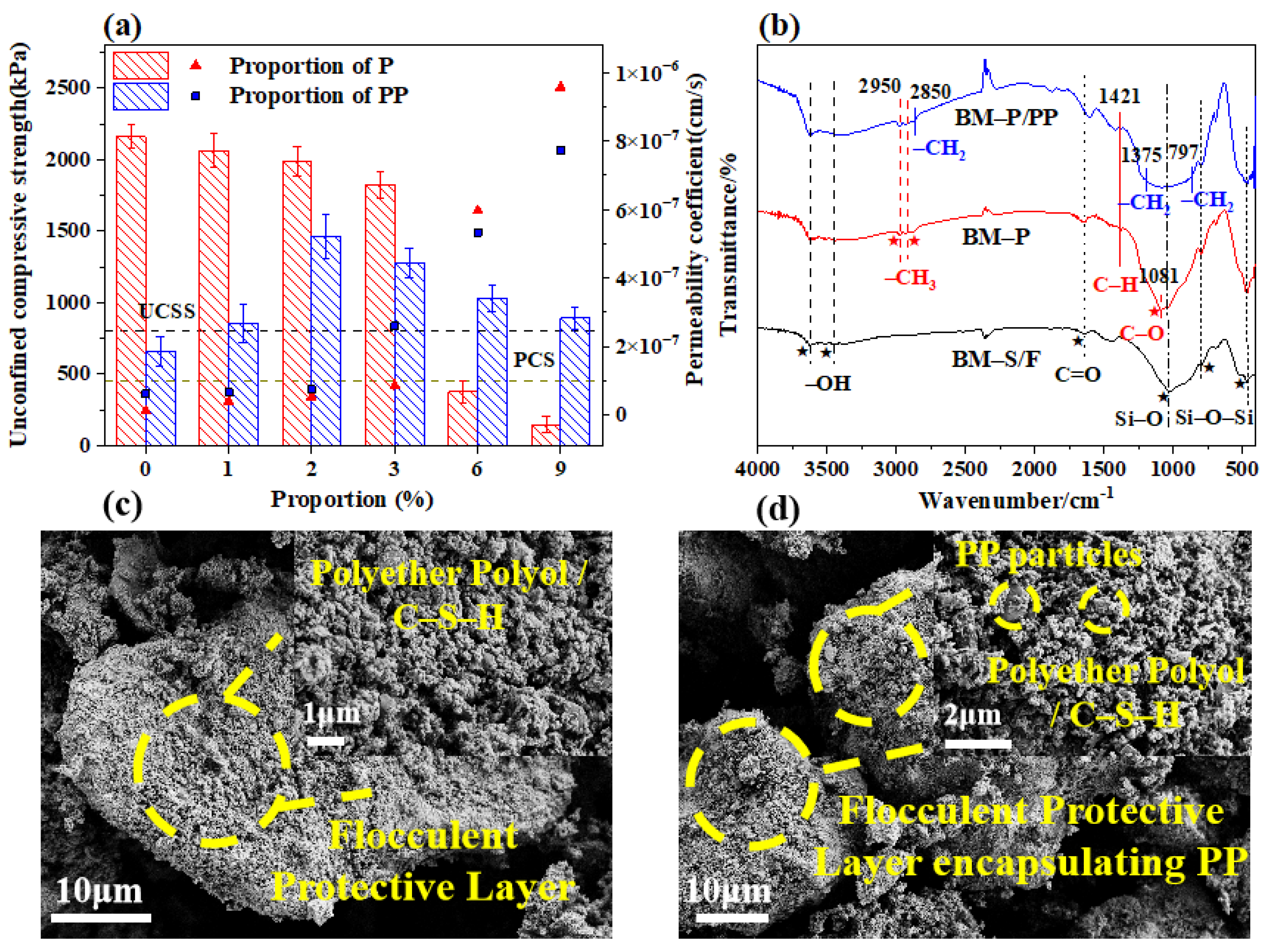

3.3. Effects of Adhesives on Material Molding Rate

3.4. Effects of Polymers on Material Chemical Compatibility

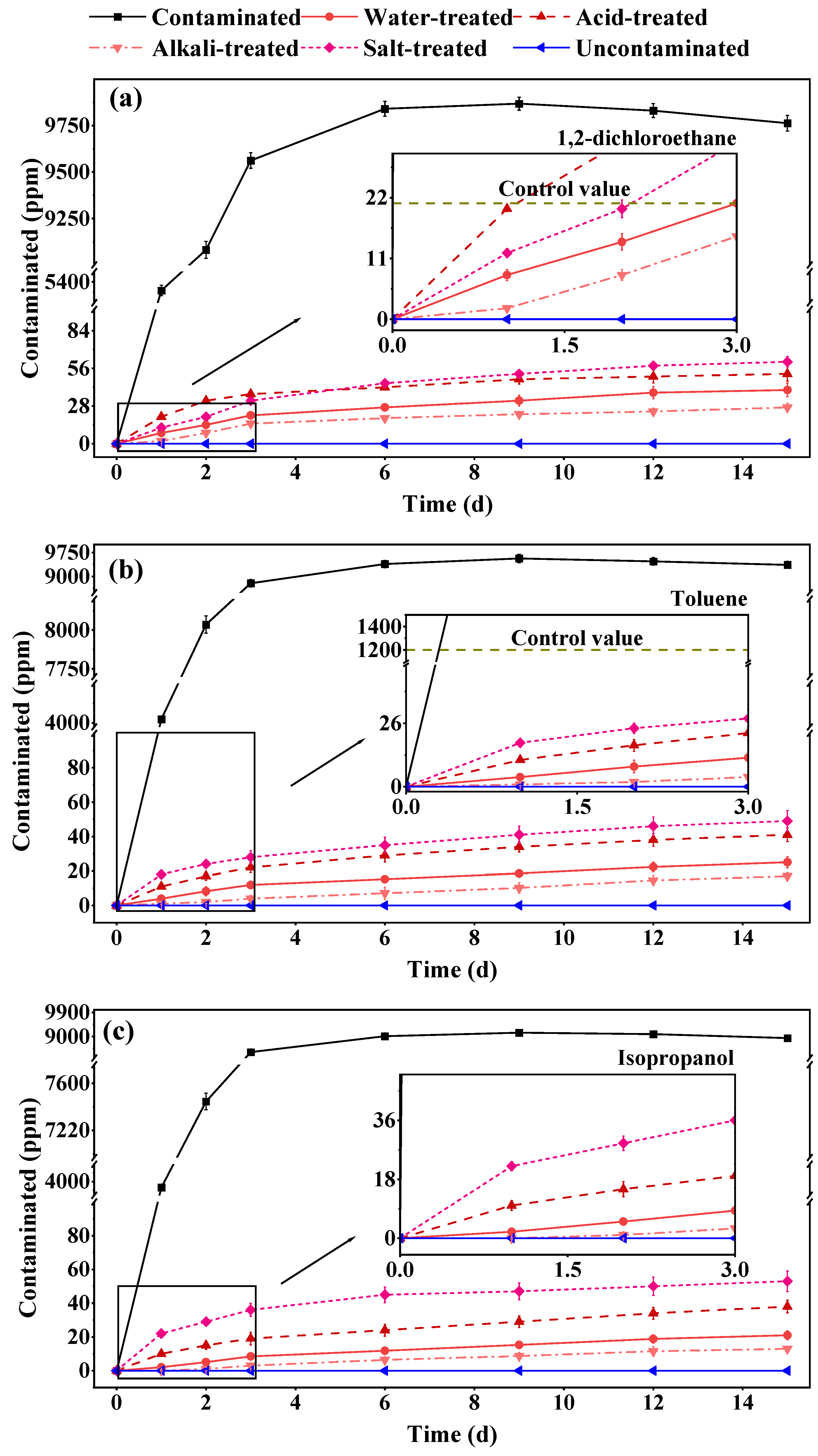

3.5. VOC Barrier Effectiveness of Modified Materials

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Declaration of Generative AI and Al-Assisted Technologies in the Writing Process

References

- Carvalho, S.-Z.; Vernilli, F.; Almeida, B.; Demarco, M.; Silva, S.-N. The Recycling Effect of BOF Slag in the Portland Cement Properties. Resour. Conserv. Recycl. 2017, 127, 216–220. [Google Scholar] [CrossRef]

- Zhang, M.-T.; Yang, C.-H.; Zhao, M.; Yu, L.-W.; Yang, K.; Zhu, X.-H.; Jiang, X. Immobilization of Cr(VI) by Hydrated Portland Cement Pastes with and without Calcium Sulfate. J. Hazard. Mater. 2018, 342, 242–251. [Google Scholar] [CrossRef] [PubMed]

- Moon, D.-H.; Grubb, D.-G.; Reilly, T.L. Stabilization/Solidification of Selenium-Impacted Soils Using Portland Cement and Cement Kiln Dust. J. Hazard. Mater. 2009, 168, 944–951. [Google Scholar] [CrossRef]

- Wang, C.; Engels, A.; Wang, Z.-H. Overview of Research on China’s Transition to Low-Carbon Development: The Role of Cities, Technologies, Industries, and the Energy System. Renew. Sustain. Energy Rev. 2018, 81 Pt 1, 1350–1364. [Google Scholar] [CrossRef]

- Zou, H.; Cui, S.-T.; Zhao, K.; Cheng, J.-S.; Zheng, Z.-J.; Li, S.-J.; Zhang, Y.-L. Dynamic Mechanical Properties and Microstructure of Ultrafine Slag Powder Cement Paste Utilizing Solid Waste Industrial Tailings Powder and Fly Ash. Process Saf. Environ. Prot. 2024, 191, 813–827. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, D. Transforming Waste into Sustainable Solution: Physicochemical and Geotechnical Evaluation of Cement Stabilized Municipal Solid Waste Incinerator Bottom Ash for Geoenvironmental Applications. Process Saf. Environ. Prot. 2023, 176, 685–695. [Google Scholar] [CrossRef]

- Adesina, A. Synthesis, Characterization, and Efficacy of Alkali-Activated Materials from Mine Tailings: A Review. Waste Manag. 2025, 191, 23–46. [Google Scholar] [CrossRef] [PubMed]

- Fan, C.-C.; Wang, B.-M.; Ai, H.-M.; Qi, Y.; Liu, Z. A Comparative Study on Solidification/Stabilization Characteristics of Coal Fly Ash-Based Geopolymer and Portland Cement on Heavy Metals in MSWI Fly Ash. J. Clean. Prod. 2021, 319, 128790. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Cristelo, N.; Miranda, T.; Palomo, Á. Sustainable Alkali Activated Materials: Precursor and Activator Derived from Industrial Wastes. J. Clean. Prod. 2017, 162, 1200–1209. [Google Scholar] [CrossRef]

- Sadegh, F.; Sadegh, N.; Wongniramaikul, W.; Apiratikul, R.; Choodum, A. Adsorption of Volatile Organic Compounds on Biochar: A Review. Process Saf. Environ. Prot. 2024, 182, 559–578. [Google Scholar] [CrossRef]

- Saludung, A.; Azeyanagi, T.; Ogawa, Y.; Kawai, K. Effect of Silica Fume on Efflorescence Formation and Alkali Leaching of Alkali-Activated Slag. J. Clean. Prod. 2021, 315, 128210. [Google Scholar] [CrossRef]

- Tang, W.; Ye, C.-W.; Zhang, Q.; Li, J.; Ao, F.; Zheng, B.; Luo, Y. Study on the Carbon Sequestration Performance and Barrier Mechanism of Biochar Cement-Based Vertical Cutoff Walls for Phenol Pollution in Groundwater. J. Environ. Chem. Eng. 2024, 12, 114560. [Google Scholar] [CrossRef]

- Zhao, Z.; El-Naggar, A.; Kau, J.; Olson, C.; Tomlinson, D.; Chang, S.X. Biochar Affects Compressive Strength of Portland Cement Composites: A Meta-Analysis. Biochar 2024, 6, 21. [Google Scholar] [CrossRef]

- Matinfar, M.; Nychka, J.-A. A Review of Sodium Silicate Solutions: Structure, Gelation, and Syneresis. Adv. Colloid Interface Sci. 2023, 322, 103036. [Google Scholar] [CrossRef]

- Li, B.; Trueman, B.F.; Munoz, S.; Locsin, J.M.; Gagnon, G.A. Impact of Sodium Silicate on Lead Release and Colloid Size Distributions in Drinking Water. Water Res. 2021, 190, 116709. [Google Scholar] [CrossRef]

- Sun, N.; Di, M.; Liu, Y. Lignin-Containing Polyurethane Elastomers with Enhanced Mechanical Properties via Hydrogen Bond Interactions. Int. J. Biol. Macromol. 2021, 184, 1–8. [Google Scholar] [CrossRef]

- Fang, C.-Q.; Pan, S.-F.; Wang, Z.; Zhou, X.; Lei, W.-Q.; Cheng, Y.-L. Synthesis of Waterborne Polyurethane Using Snow as Dispersant: Structures and Properties Controlled by Polyols Utilization. J. Mater. Sci. Technol. 2019, 35, 1491–1498. [Google Scholar] [CrossRef]

- Feng, X.-M.; Wang, B.; Wang, X.; Wen, P.-Y.; Cai, W.; Hu, Y.; Liew, K.M. Molybdenum Disulfide Nanosheets as Barrier Enhancing Nanofillers in Thermal Decomposition of Polypropylene Composites. Chem. Eng. J. 2016, 295, 278–287. [Google Scholar] [CrossRef]

- Zielińska, D.; Siwińska-Ciesielczyk, K.; Bula, K.; Peplińska, B.; Jesionowski, T.; Borysiak, S. Advanced Nanocellulose Hybrid Fillers for Sustainable Polypropylene Biomaterials with Enhanced Oxygen Barrier Properties. Appl. Mater. Today 2023, 34, 101897. [Google Scholar] [CrossRef]

- JTG E40-2007; Highway Geotechnical Test Procedures. China Communications Press: Beijing, China, 2007.

- JTG E40-2007; Highway Engineering Geotechnical Test Procedures. China Communications Press: Beijing, China, 2007.

- Hu, Y.; Huan, Q.; Lai, J.-H.; Yao, X.-Y.; Song, C.-Y.; Song, M. Modification of Multi-Source Industrial Solid Waste with Porous Materials to Produce Highly Polymerized Silica Gel: Microstructure Optimization and CO2 Mineralization Enhancement Mechanism. Sep. Purif. Technol. 2024, 336, 126225. [Google Scholar] [CrossRef]

- Yao, X.-Y.; Song, B.; Huan, Q.; Hu, Y.; Song, M. Ambient pressure carbonation curing of cold-bonded fly ash lightweight aggregate using coal-fired flue gas for properties enhancement and CO2 sequestration. J. Environ. Chem. Eng. 2024, 12, 114208. [Google Scholar] [CrossRef]

- Wei, H.; Song, B.; Huan, Q.; Song, C.-Y.; Wang, S.-F.; Song, M. Preparation of iron tailings-based porous ceramsite and its application to lead adsorption: Characteristic and mechanism. Sep. Purif. Technol. 2024, 342, 126839. [Google Scholar] [CrossRef]

- Zhang, X.; Xiao, Y.; Wang, T.; Xia, J.-L.; Lu, M.-X.; Xue, Y.-J. Kill two birds with one stone: Contribution of steel slag on enhancing the performance of coal gangue-based cementitious materials and simultaneous sulfur fixation. J. Environ. Chem. Eng. 2023, 11, 111169. [Google Scholar] [CrossRef]

- Palankar, N.; Ravi Shankar, A.-U.; Mithun, B.-M. Durability studies on eco-friendly concrete mixes incorporating steel slag as coarse aggregates. J. Clean. Prod. 2016, 129, 437–448. [Google Scholar] [CrossRef]

- Yang, P.; Liu, L.; Suo, Y.-L.; Zhu, M.-B.; Xie, G.; Deng, S.-C. Mechanical properties, pore characteristics and microstructure of modified magnesium slag cemented coal-based solid waste backfill materials: Affected by fly ash addition and curing temperature. Process Saf. Environ. Prot. 2023, 176, 1007–1020. [Google Scholar] [CrossRef]

- Vieira, C.-S.; Pereira, P.-M.; Lopes, M.d.L. Recycled construction and demolition wastes as filling material for geosynthetic reinforced structures: Interface properties. J. Clean. Prod. 2016, 124, 299–311. [Google Scholar] [CrossRef]

- Poinot, T.; Laracy, M.E.; Aponte, C.; Jennings, H.M.; Ochsendorf, J.A.; Olivetti, E.A. Beneficial use of boiler ash in alkali-activated bricks. Resour. Conserv. Recycl. 2018, 128, 1–10. [Google Scholar] [CrossRef]

- Fu, Q.; Bu, M.; Zhang, Z.-R.; Xu, W.-R.; Yuan, Q.; Niu, D. Hydration characteristics and microstructure of alkali-activated slag concrete: A review. Engineering 2023, 20, 162–179. [Google Scholar] [CrossRef]

- Lin, M.; Li, F.; Li, X.; Rong, X.; Oh, K. Biochar-Clay, Biochar-Microorganism, and Biochar-Enzyme Composites for Environmental Remediation: A Review. Environ. Chem. Lett. 2023, 21, 1837–1862. [Google Scholar] [CrossRef]

- Lee, Y.-W.; Park, J.-W.; Choung, J.-H.; Choi, D.-K. Adsorption characteristics of SO2 on activated carbon prepared from coconut shell with potassium hydroxide activation. Environ. Sci. Technol. 2002, 36, 1086–1092. [Google Scholar] [CrossRef]

- Xu, W.-J.; Zhang, Y.-Y.; Li, M.; Qu, F.; Poon, C.-S.; Zhu, X.-H.; Tsang, D.C.W. Durability and micromechanical properties of biochar in biochar-cement composites under marine environment. J. Clean. Prod. 2024, 450, 141842. [Google Scholar] [CrossRef]

- Ni, J.; Zhou, J.-S.; Wang, Y.; Guo, H. Gas permeability and emission in unsaturated vegetated landfill cover with biochar addition. Biochar 2023, 5, 47. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, X.-Y. Hydration, strength, durability, and workability of biochar-cement binary blends. J. Build. Eng. 2021, 42, 103064. [Google Scholar] [CrossRef]

- Su, Y.; Wen, Y.; Yang, W.; Zhang, X.; Xia, M.; Zhou, N.; Xiong, Y.; Zhou, Z. The mechanism transformation of ramie biochar’s cadmium adsorption by aging. Bioresour. Technol. 2021, 330, 124947. [Google Scholar] [CrossRef]

- Komljenović, M.; Baščarević, Z.; Bradić, V. Mechanical and microstructural properties of alkali-activated fly ash geopolymers. J. Hazard. Mater. 2010, 181, 35–42. [Google Scholar] [CrossRef]

- Luo, J.; Chang, H.; Wang, P.-H.; Moon, R.J.; Kumar, S. Cellulose nanocrystals effect on the stabilization of polyacrylonitrile composite films. Carbon 2018, 134, 92–102. [Google Scholar] [CrossRef]

- Li, S.; Liu, Z.; Hou, L.; Chen, Y.; Xu, T. Effect of polyether/polyester polyol ratio on properties of waterborne two-component polyurethane coatings. Prog. Org. Coat. 2020, 141, 105545. [Google Scholar] [CrossRef]

- Li, X.; Cai, T.; Chung, T.-S. Anti-fouling behavior of hyperbranched polyglycerol-grafted poly(ether sulfone) hollow fiber membranes for osmotic power generation. Environ. Sci. Technol. 2014, 48, 9898–9907. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Q.; Cheng, Y.; Song, F.; Ding, Y.; Shao, M. Self-reinforced composites based on polypropylene fiber and graphene nano-platelets/polypropylene film. Carbon 2022, 189, 586–595. [Google Scholar] [CrossRef]

- Sunder, A.; Mülhaupt, R.; Haag, R.; Frey, H. Hyperbranched Polyether Polyols: A Modular Approach to Complex Polymer Architectures. Adv. Mater. 2000, 12, 235–239. [Google Scholar] [CrossRef]

- Wang, X.-T.; Liang, Y.-F.; Pu, Z.-C.; He, J.; Yang, S.-Q. Transforming waste to treasure: Superhydrophobic coatings from recycled polypropylene for high-value application. Prog. Org. Coat. 2024, 188, 108248. [Google Scholar] [CrossRef]

- Xie, G.; Liu, L.; Suo, Y.-L.; Yang, P.; Zhang, C.-X.; Qu, H.-S.; Lv, Y. Hydration mechanism of calcium chloride modified coal gasification slag-based backfill materials. Process Saf. Environ. Prot. 2024, 182, 127–138. [Google Scholar] [CrossRef]

- Qu, R.-J.; Wang, Y.; Li, D.; Wang, L.-J. Rheological behavior of nanocellulose gels at various calcium chloride concentrations. Carbohydr. Polym. 2021, 274, 118660. [Google Scholar] [CrossRef] [PubMed]

- Huan, Q.; Wibowo, H.; Yan, M.; Song, M. A review of CO2 mineral storage: Current processes, typical applications, and life cycle assessment. J. Environ. Chem. Eng. 2024, 12, 114785. [Google Scholar] [CrossRef]

- Xing, J.; Dong, W.; Liang, N.; Huang, Y.; Wu, M.; Zhang, L.-J.; Chen, Q. Sorption of organic contaminants by biochars with multiple porous structures: Experiments and molecular dynamics simulations mediated by three-dimensional models. J. Hazard. Mater. 2023, 458, 131953. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Zhang, B.; Xia, B.; Liu, Z.-H.; Tan, C.-Q.; Song, C.-Y.; Fujii, M.; Ma, L.; Song, M. Defect engineering boosted peroxydisulfate activation of dual-vacancy Cu–Fe spinel oxides for soil organics decontamination. ACS ES&T Eng. 2024, 4, 2025–2035. [Google Scholar] [CrossRef]

- Zhao, X.; Huang, X.-F.; Wang, Z.; Peng, K.-M.; Lu, L.-J.; Liu, J. Composite-polymer modified bentonite enhances anti-seepage and barrier performance under high-concentration heavy-metal solution. J. Clean. Prod. 2022, 376, 134253. [Google Scholar] [CrossRef]

- Souza, R.-F.C.; Pejon, O.-J. Pore size distribution and swelling behavior of compacted bentonite/claystone and bentonite/sand mixtures. Eng. Geol. 2020, 275, 105738. [Google Scholar] [CrossRef]

- Bawn, C. High Polymers. Nature 1957, 180, 672–673. [Google Scholar] [CrossRef]

- Wang, Z.-G.; Luo, X.-F.; Song, Z.-J.; Lu, K.; Zhu, S.-W.; Yang, Y.-S.; Zhang, Y.-T.; Fang, W.-X.; Jin, J. Microporous polymer adsorptive membranes with high processing capacity for molecular separation. Nat. Commun. 2022, 13, 4169. [Google Scholar] [CrossRef]

| Material | CaO | SiO2 | Al2O3 | Fe2O3 | Na2O | TiO2 | MgO |

|---|---|---|---|---|---|---|---|

| FA | 15.31 | 30.49 | 18.96 | 3.91 | 0.531 | 0.863 | 7.24 |

| GGBS | 40.54 | 38.34 | 12.52 | 1.21 | 0.244 | 0.576 | 4.57 |

| SS | 25.57 | 16.19 | 7.33 | 33.83 | 0.191 | 0.480 | 4.53 |

| Material ID | Soil/% | GGBS/% | Bentonite/% | Biochar/% | Na2SiO3/% | Na2SiF6/% | Polyether Polyols/% | PP/% |

|---|---|---|---|---|---|---|---|---|

| UM | 50 | 41.7 | 8.3 | / | / | / | / | / |

| BM-B | 48.5 | 40.4 | 8.2 | 2.9 | / | / | / | / |

| BM-S | 38.2 | 31.9 | 6.4 | 2.3 | 21.2 | / | / | / |

| BM-S/F | 37 | 30.9 | 6.2 | 2.2 | 20.6 | 3.1 | / | / |

| BM-P | 36.3 | 30.2 | 6 | 2.2 | 20.1 | 3 | 2.2 | / |

| BM-P/PP | 35.6 | 29.8 | 6 | 2.2 | 19.8 | 3 | 2.2 | 1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Huan, Q.; Hu, Y.; Cao, X.; Wang, S.; Wang, Z.; Hui, Y.; Song, M. Adhesive-Coupled Polymer Multistage Modified Sustainable Alkali-Activated Materials: Barrier Performance and Microstructural Investigation Under Accelerated Curing Conditions. Sustainability 2025, 17, 4344. https://doi.org/10.3390/su17104344

Guo Y, Huan Q, Hu Y, Cao X, Wang S, Wang Z, Hui Y, Song M. Adhesive-Coupled Polymer Multistage Modified Sustainable Alkali-Activated Materials: Barrier Performance and Microstructural Investigation Under Accelerated Curing Conditions. Sustainability. 2025; 17(10):4344. https://doi.org/10.3390/su17104344

Chicago/Turabian StyleGuo, Yantao, Qun Huan, Yue Hu, Xian Cao, Shaofeng Wang, Ziye Wang, Yue Hui, and Min Song. 2025. "Adhesive-Coupled Polymer Multistage Modified Sustainable Alkali-Activated Materials: Barrier Performance and Microstructural Investigation Under Accelerated Curing Conditions" Sustainability 17, no. 10: 4344. https://doi.org/10.3390/su17104344

APA StyleGuo, Y., Huan, Q., Hu, Y., Cao, X., Wang, S., Wang, Z., Hui, Y., & Song, M. (2025). Adhesive-Coupled Polymer Multistage Modified Sustainable Alkali-Activated Materials: Barrier Performance and Microstructural Investigation Under Accelerated Curing Conditions. Sustainability, 17(10), 4344. https://doi.org/10.3390/su17104344