The Dynamics of Concrete Recycling in Circular Construction: A System-Dynamics Approach in Sydney, Australia

Abstract

1. Introduction

2. Methods

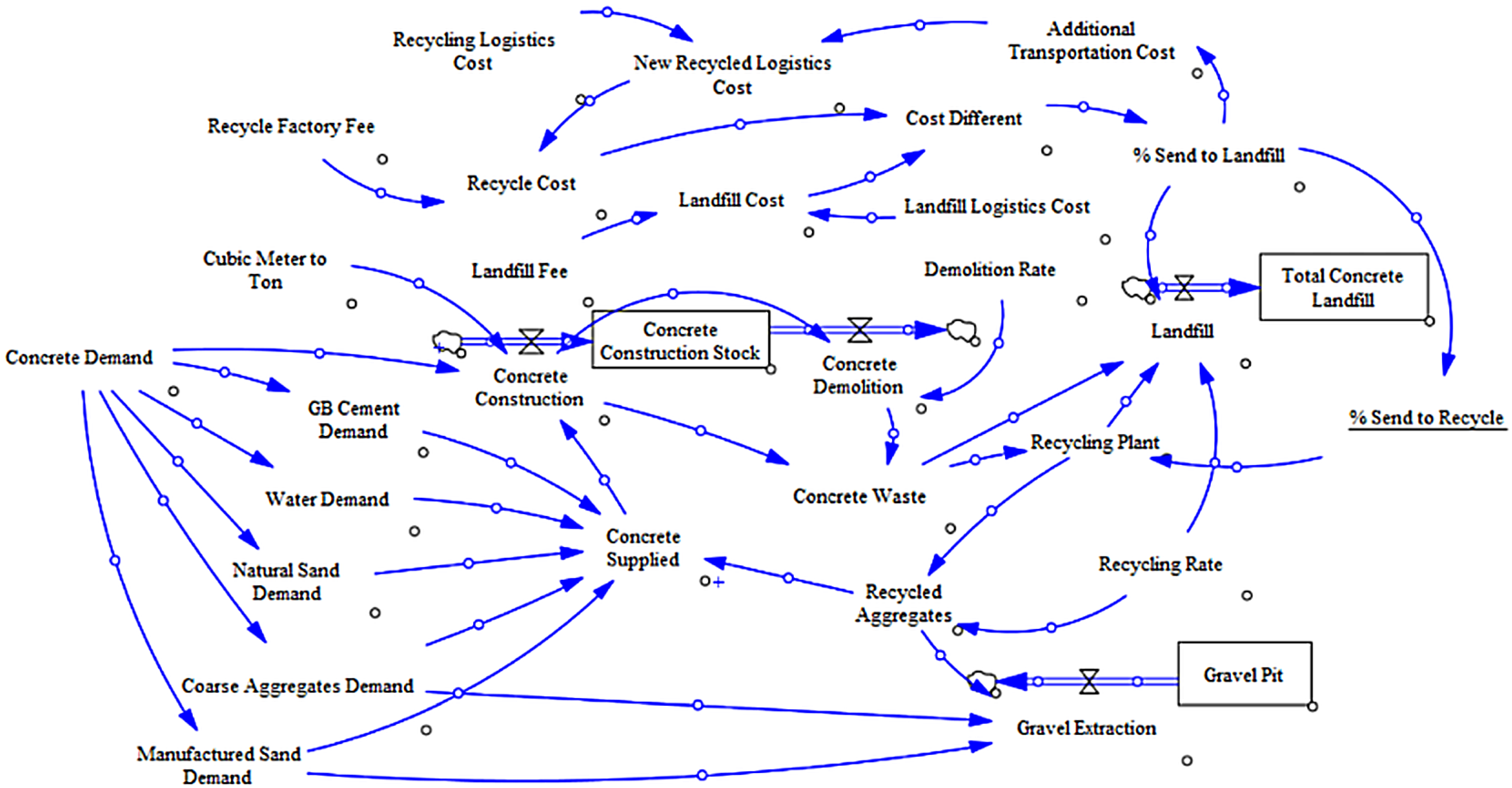

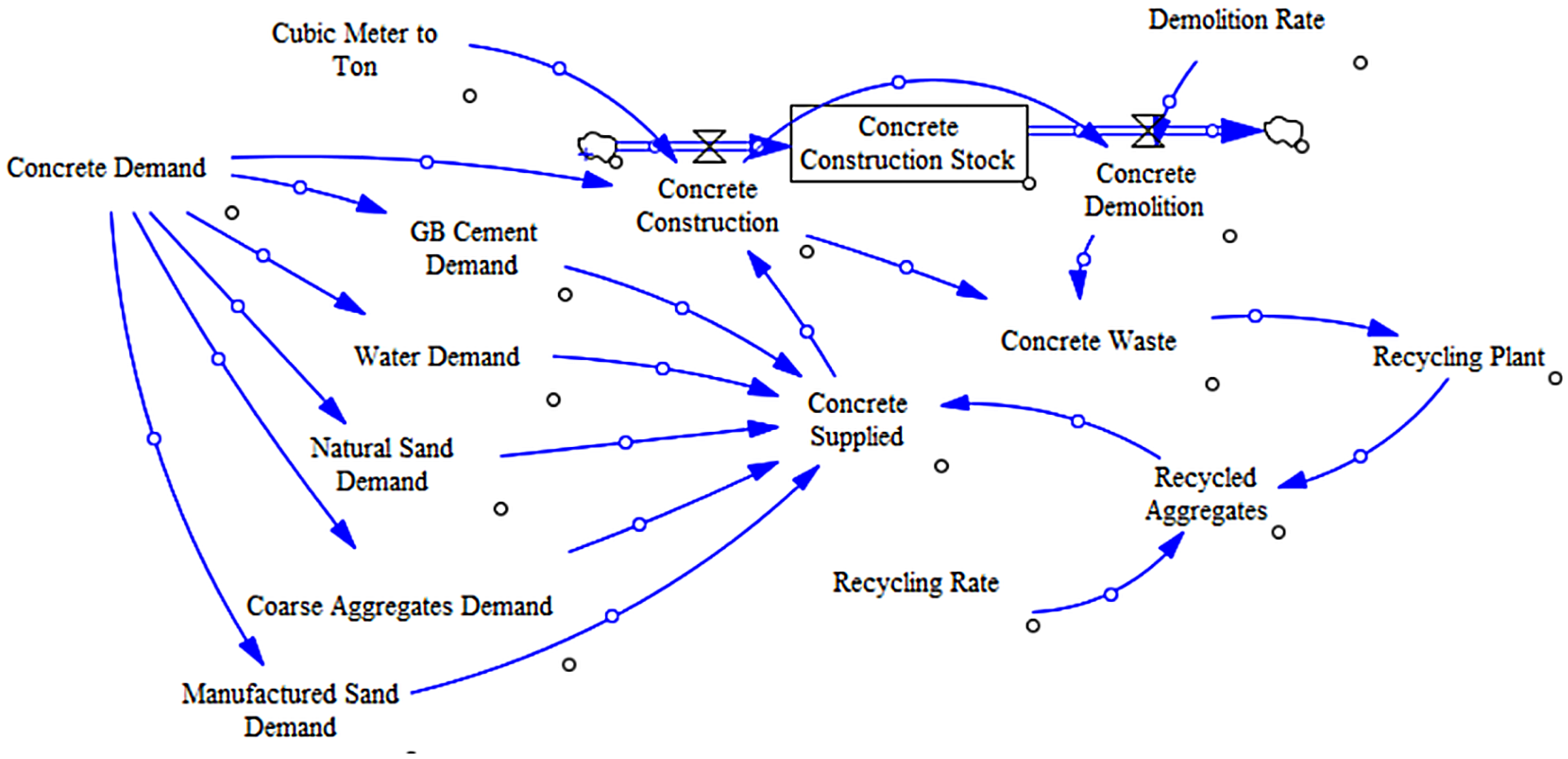

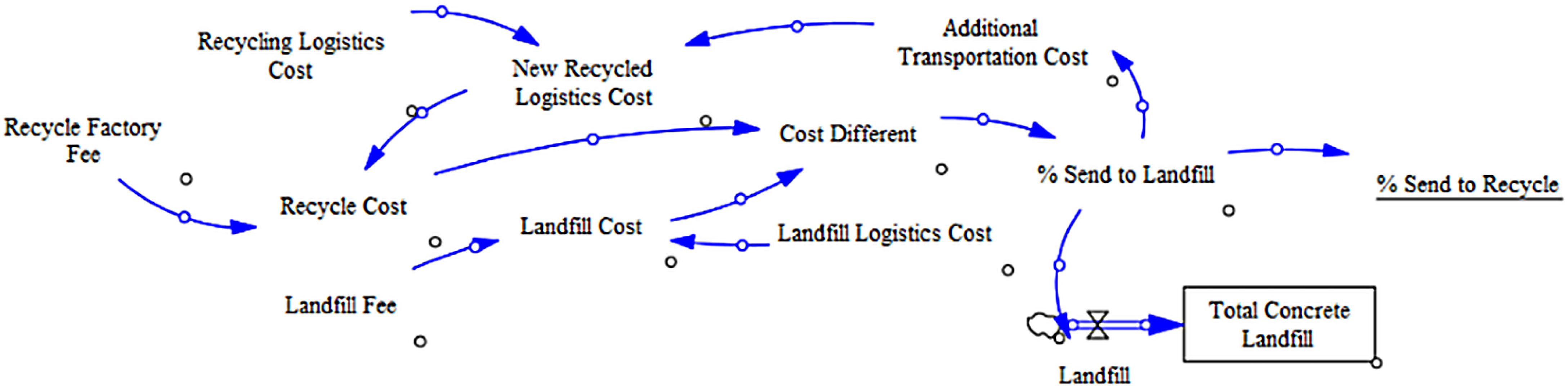

2.1. Development of the System-Dynamics Model for the Concrete Supply Chain

2.2. Model Formulation

2.2.1. Sydney Concrete Production Model

2.2.2. Sydney Concrete Recycling Choice Model

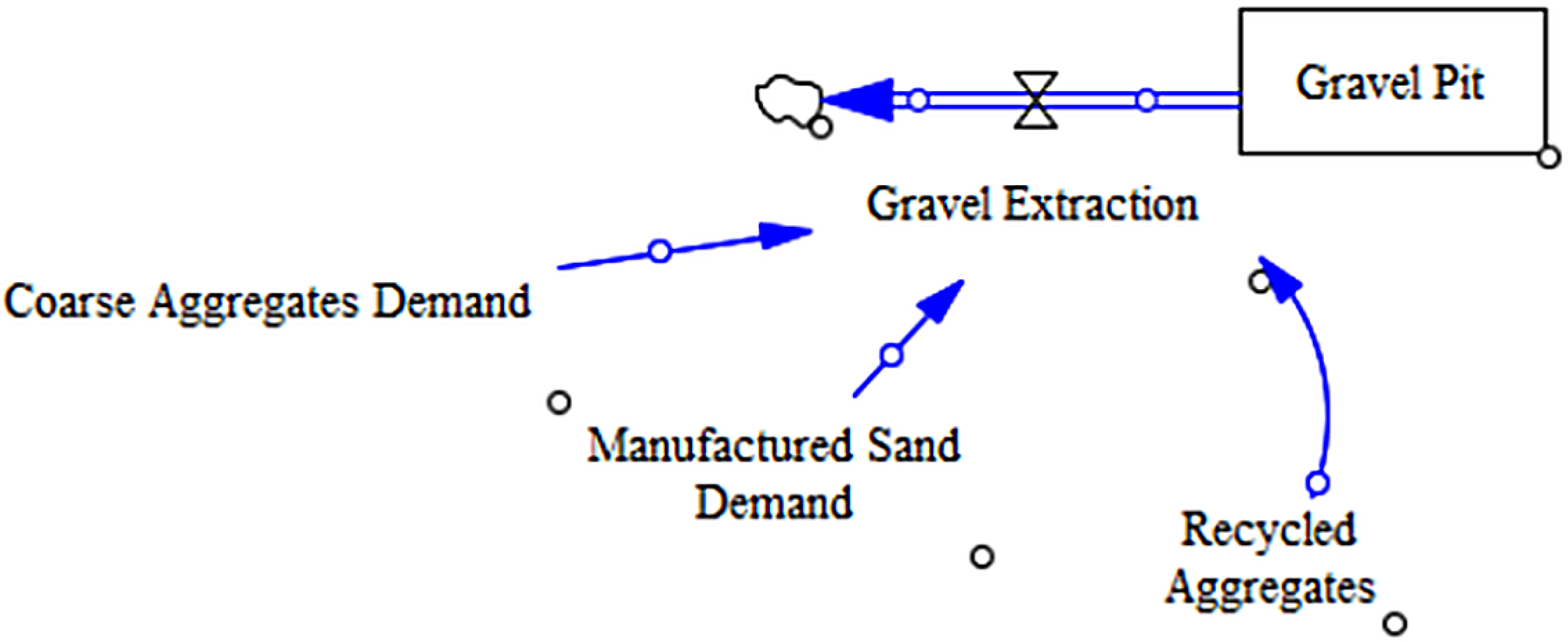

2.2.3. Integration of Sub-Models and Gravel Extraction Calculation

2.3. Model Validation and Empirical Grounding

- Data Calibration: Key model parameters were derived from authoritative sources, including official C&D waste statistics from New South Wales (2020–2021), infrastructure usage reports, and detailed interviews with local recycling contractors and plant operators. This ensures that the model reflects actual material flows and economic structures observed in the Sydney metropolitan context.

- Behavioral Realism: The logit-based routing function was calibrated to match observed waste-management behaviors, achieving an equilibrium where approximately 89% of waste is recycled—consistent with national C&D recycling performance data.

- Face Validity via Stakeholder Review: Model structures and simulation outputs were cross-validated through iterative consultation with industry stakeholders, providing qualitative feedback to align model assumptions with ground realities.

- Scenario Realism: Simulation scenarios were constructed using realistic ranges for landfill and recycling costs, informed by industry reports and local fee schedules. This ensures that policy insights derived from the model are implementable under plausible economic conditions.

3. Scenario Results and Discussion

3.1. Scenario Analysis

- Scenario: A brief description of the cost variation applied (e.g., “Landfill-logistics cost +10%” or “Both costs ”), with a base case included for reference.

- Recycling Cost: The total recycling cost in that scenario (including recycling facility fee plus recycling logistics cost, in $ per ton). This reflects how changes in recycling practices or policies alter the cost structure for recycling concrete waste.

- Landfill Cost: The total landfill disposal cost in that scenario (including landfill tipping fee plus landfill-logistics cost, in $ per ton). This shows the sensitivity of landfill expenses to changes in transport costs or fees.

- Cost Difference: The difference between the recycling cost and the landfill cost (Recycling minus Landfill, in $). This metric indicates the economic incentive or disincentive for choosing recycling over landfilling. A positive value means recycling is more expensive than landfilling (discouraging recycling), while a negative value means recycling is cheaper (encouraging recycling).

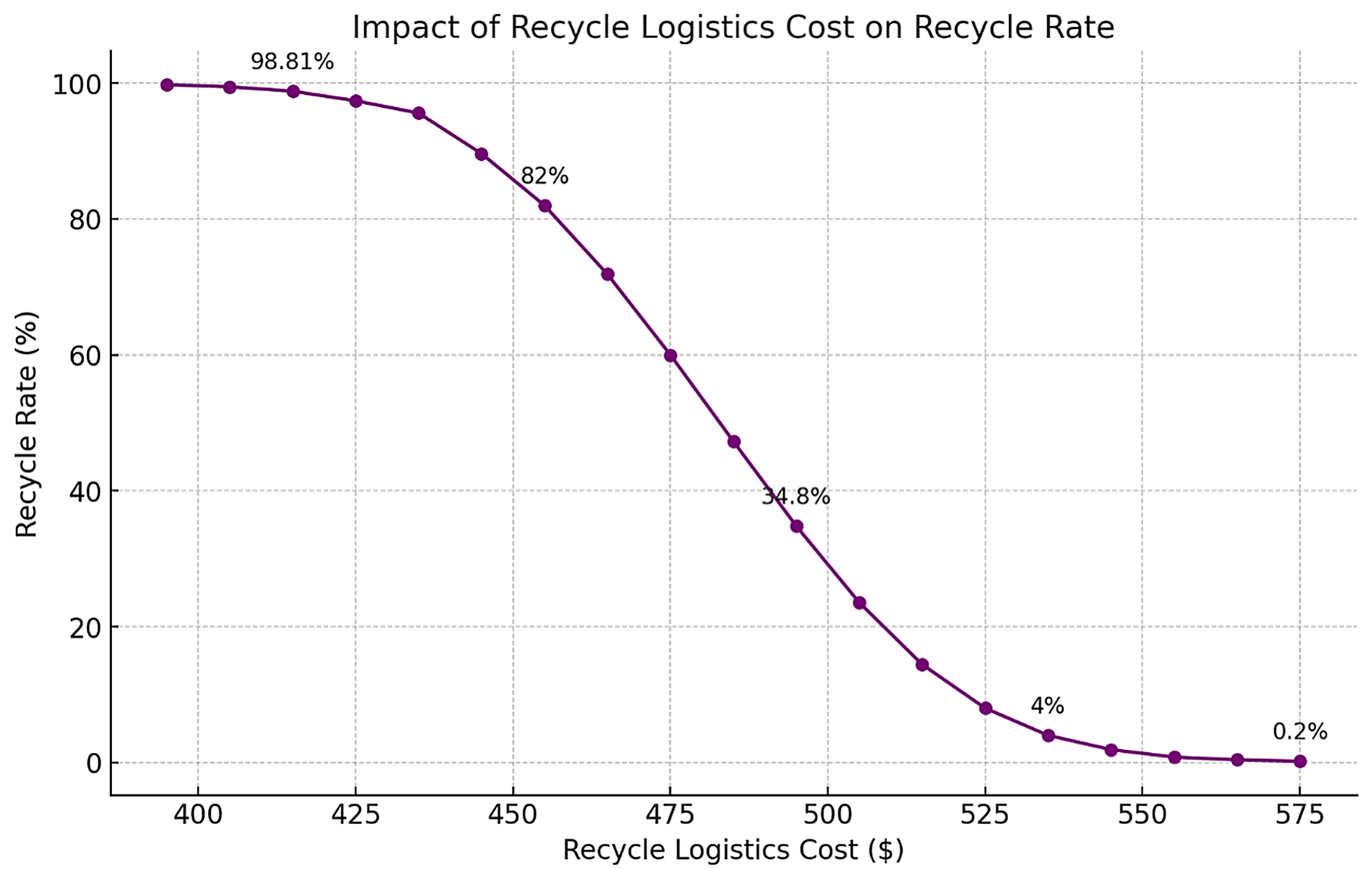

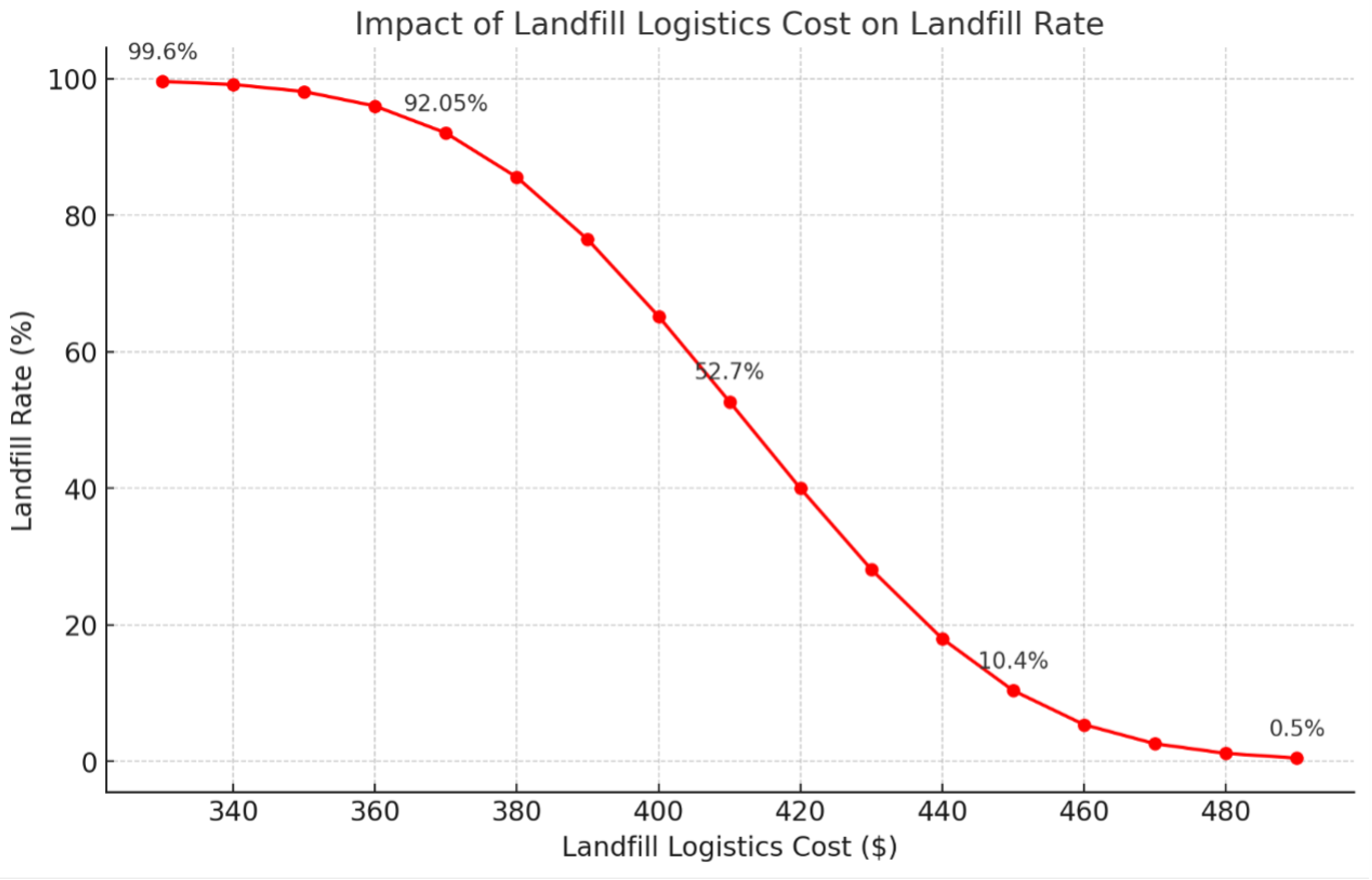

- % Sent to Recycle: The percentage of concrete waste directed to recycling facilities under the scenario. The logit choice model determines this and indicates how responsive the recycling uptake is to the cost difference.

- % Sent to Landfill: The percentage of concrete waste sent to landfills in the scenario. (Since all waste must go either to recycling or landfill, this value is essentially minus the above recycling percentage).

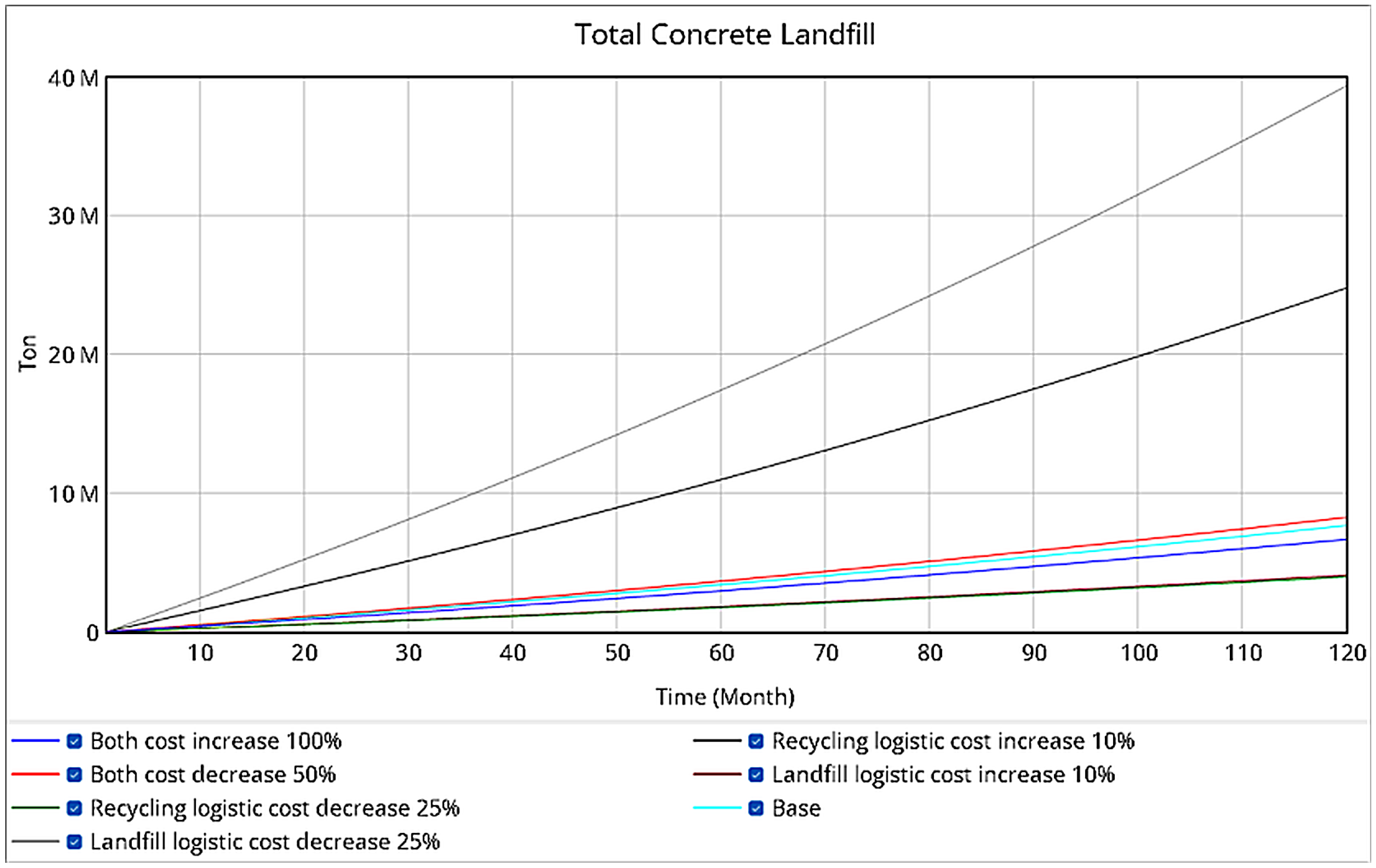

- Total Landfill (Million tons): The cumulative quantity of concrete waste (in million tons) that has been landfilled over the 120-time steps simulation. This provides a measure of the long-term landfill burden under each scenario.

- Total Landfill / Base: The total landfilled waste normalized to the base scenario (unitless ratio). A value below 1 indicates less landfill accumulation than the baseline, while a value above 1 indicates more.

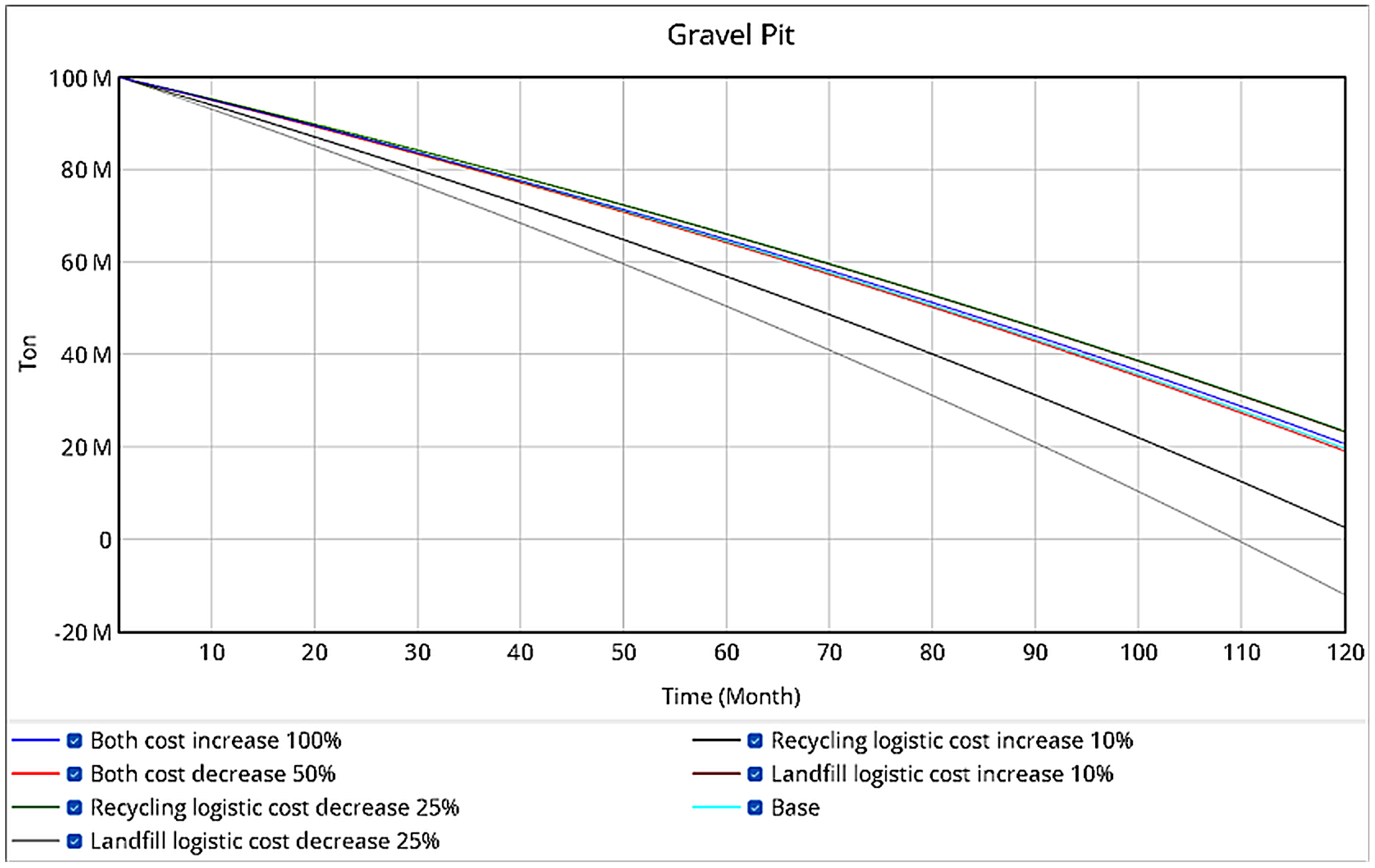

- Gravel Pit Balance (Million tons): The remaining gravel resource in pits at the end of the simulation. This reflects how much virgin gravel has been conserved or depleted relative to the initial amount, highlighting the linkage between recycling rates and the consumption of natural aggregates.

- Total Gravel Extraction (Million tons): The total amount of virgin gravel extracted over the 120 time steps. This is inversely related to the use of recycled aggregate—higher recycling of aggregate leads to lower gravel extraction.

- Total Gravel Extraction / Base: The gravel extraction amount normalized to the base scenario (unitless). This helps compare how each scenario increases or decreases the reliance on virgin materials relative to the baseline.

3.2. Results

3.2.1. Effects of Recycling and Landfill Cost Changes

Individual Cost Variations

Combined Cost Variations

3.2.2. Impacts of Logistics Costs on Recycling, Landfilling, and Gravel Extraction

3.3. Discussion and Implications

4. Limitations and Future Research

5. Conclusions

- Cost tipping points. A 10% increase in landfill-logistics costs or a 25% decrease in recycling logistics costs diverts more than 95% of concrete waste to recycling, cutting cumulative landfill mass by almost one-half and lowering virgin gravel extraction by 56%.

- Leverage for policy and industry. Aligning landfill levies, recycling subsidies, and facility-siting decisions with these thresholds offers a near-term, evidence-based pathway to accelerate circular construction goals without large infrastructure outlays.

- Robustness and limitations. While qualitative patterns are stable, absolute magnitudes depend on spatial variability in transport distances and on contractors’ price responsiveness; parameter refinement remains a priority.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Babbitt, C.W.; Gaustad, G.; Fisher, A.; Chen, W.Q.; Liu, G. Closing the loop on circular economy research: From theory to practice and back again. Resour. Conserv. Recycl. 2018, 135, 1–2. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Bao, Z. Developing circularity of construction waste for a sustainable built environment in emerging economies: New insights from China. Dev. Built Environ. 2023, 13, 100107. [Google Scholar] [CrossRef]

- Ding, Z.; Zhu, M.; Tam, V.W.Y.; Yi, G.; Tran, C.N.N. A system dynamics-based environmental benefit assessment model of construction waste reduction management at the design and construction stages. J. Clean. Prod. 2018, 176, 676–692. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K.; Sarkis, J.; Tseng, M.L. Resources melioration and the circular economy: Sustainability potentials for mineral, mining and extraction sector in emerging economies. Resour. Policy 2022, 77, 102652. [Google Scholar] [CrossRef]

- Neuhold, M. Why the Circular Economy Is Transforming Traditional Logistics; EY: London, UK, 2022. [Google Scholar]

- Ryfan. Construction Conundrum; Ryfan: Spruce Grove, AB, Canada, 2018. [Google Scholar]

- Yarra City Council. Raw Material Consumption in Construction. 2020. Available online: https://www.yarracity.vic.gov.au/residents/bins-waste-recycling-and-cleaning/recycling-and-rubbish/what-to-put-your-bins/what-you-can-recycle#:~:text=Recycling%20through%20your%20kerbside%20bins,lime%2Dgreen%20lidded%20FOGO%20bin (accessed on 4 March 2025).

- United Nations Environment Programme. 2021 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient, and Resilient Buildings and Construction Sector; Technical Report; United Nations Environment Programme: Nairobi, Kenya, 2021. [Google Scholar]

- Norouzi, M.; Chàfer, M.; Cabeza, L.; Jiménez, L.; Boer, D. Circular economy in the building and construction sector: A scientific evolution analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Gasik-Kowalska, N.; Koper, A. Green Concrete Production Technology with the Addition of Recycled Ceramic Aggregate. Sustainability 2025, 17, 3028. [Google Scholar] [CrossRef]

- Wu, J.; Ye, X.; Cui, H. Recycled Materials in Construction: Trends, Status, and Future of Research. Sustainability 2025, 17, 2636. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to circular construction: An integrated management of construction and demolition waste for resource recovery. J. Clean. Prod. 2020, 244, 118710. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Rios, F.C.; Grau, D.; Bilec, M. Barriers and Enablers to Circular Building Design in the US: An Empirical Study. J. Constr. Eng. Manag. 2021, 147, 1–17. [Google Scholar] [CrossRef]

- Friedman, A. Housing Design for Circular Economy and Sustainability. Sustainability 2025, 17, 2921. [Google Scholar] [CrossRef]

- Shooshtarian, S.; Maqsood, T.; Caldera, S.; Ryley, T. Transformation towards a circular economy in the Australian construction and demolition waste management system. Sustain. Prod. Consum. 2022, 30, 89–106. [Google Scholar] [CrossRef]

- Gonz, A.; Sendra, C.; Herena, A.; Rosquillas, M.; Vaz, D. Resources, Conservation & Recycling Advances Methodology to assess the circularity in building construction and refurbishment activities. Resour. Conserv. Recycl. Adv. 2021, 12, 200051. [Google Scholar] [CrossRef]

- Grupe, V.; Tollin, N.; Andreas, P.; Birkved, M.; Holmboe, T. What are the challenges in assessing circular economy for the built environment? A literature review on integrating LCA, LCC and S-LCA in life cycle sustainability assessment, LCSA. J. Build. Eng. 2022, 50, 104203. [Google Scholar] [CrossRef]

- McNeil-Ayuk, N.; Jrade, A. Integrating Building Information Modeling and Life Cycle Assessment to Enhance the Decisions Related to Selecting Construction Methods at the Conceptual Design Stage of Buildings. Sustainability 2025, 17, 2877. [Google Scholar] [CrossRef]

- Dahlbo, H.; Bachér, J.; Lähtinen, K.; Jouttijärvi, T.; Suoheimo, P.; Mattila, T.; Sironen, S.; Myllymaa, T.; Saramäki, K. Construction and demolition waste management—A holistic evaluation of environmental performance. J. Clean. Prod. 2015, 107, 333–341. [Google Scholar] [CrossRef]

- Ellingsen, E. Designing buildings, using biology. Scientist 2007, 3, 97–107. [Google Scholar]

- Australian Government Department of Climate Change Energy the Environment and Water. Waste and Resource Recovery Data Hub—National Waste Data Viewer; DCCEEW: Parramatta, NSW, Australia, 2022. [Google Scholar]

- Cement Concrete & Aggregates Australia. Concrete Overview; Cement Concrete & Aggregates Australia: Mascot, Australia, 2023. [Google Scholar]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Ohemeng, E.A.; Ekolu, S.O. Comparative analysis on costs and benefits of producing natural and recycled concrete aggregates: A South African case study. Case Stud. Constr. Mater. 2020, 13, e00450. [Google Scholar] [CrossRef]

- Zhao, Y.; Goulias, D.; Tefa, L.; Bassani, M. Life cycle economic and environmental impacts of cdw recycled aggregates in roadway construction and rehabilitation. Sustainability 2021, 13, 8611. [Google Scholar] [CrossRef]

- Hameed, M.; Chini, A.R. Impact of Transportation on Cost, Energy, and Particulate Emissions for Recycled Concrete Aggregate; Technical Report; University of Florida: Gainesville, FL, USA, 2013. [Google Scholar]

- Marinković, S.; Dragaš, J.; Ignjatović, I.; Tošić, N. Environmental assessment of green concretes for structural use. J. Clean. Prod. 2017, 154, 633–649. [Google Scholar] [CrossRef]

- Shooshtarian, S.; Caldera, S.; Maqsood, T.; Ryley, T. Using recycled construction and demolition waste products: A review of stakeholders’ perceptions, decisions, and motivations. Recycling 2020, 5, 31. [Google Scholar] [CrossRef]

- Tam, V.W.Y. Comparing the implementation of concrete recycling in the Australian and Japanese construction industries. J. Clean. Prod. 2009, 17, 688–702. [Google Scholar] [CrossRef]

- Alsheyab, M.A.T. Recycling of construction and demolition waste and its impact on climate change and sustainable development. Int. J. Environ. Sci. Technol. 2022, 19, 2129–2138. [Google Scholar] [CrossRef]

- European Environment Agency. Construction and Demolition Waste: Challenges and Opportunities in a Circular Economy; European Environment Agency: Copenhagen, Denmark, 2019. [Google Scholar] [CrossRef]

- Hua, C.; Liu, C.; Chen, J.; Yang, C.; Chen, L. Promoting construction and demolition waste recycling by using incentive policies in China. Environ. Sci. Pollut. Res. 2022, 29, 53844–53859. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Liu, Y.; Wang, X. An environmental assessment model of construction and demolition waste based on system dynamics: A case study in Guangzhou. Environ. Sci. Pollut. Res. 2020, 27, 37237–37259. [Google Scholar] [CrossRef]

- Hao, J.; Yuan, H.; Liu, J.; Chin, C.S.; Lu, W. A model for assessing the economic performance of construction waste reduction. J. Clean. Prod. 2019, 232, 427–440. [Google Scholar] [CrossRef]

- Mak, T.M.W.; Chen, P.C.; Wang, L.; Tsang, D.C.W.; Hsu, S.C.; Poon, C.S. A system dynamics approach to determine construction waste disposal charge in Hong Kong. J. Clean. Prod. 2019, 241, 118309. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A Comprehensive Review on Recycled Aggregate and Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- He, L.; Yuan, H.; Wu, H. Collaborative mechanism for promoting the cross-regional management of construction and demolition waste. J. Clean. Prod. 2022, 372, 133706. [Google Scholar] [CrossRef]

- Forrester, J.W. System dynamics, systems thinking, and soft OR. Syst. Dyn. Rev. 1994, 10, 245–256. [Google Scholar] [CrossRef]

- Li, X.; Wang, C.; Kassem, M.; Liu, Y.; Ali, K. Study on Green Building Promotion Incentive Strategy Based on Evolutionary Game between Government and Construction Unit. Sustainability 2022, 14, 10155. [Google Scholar] [CrossRef]

- Jones, L. Vensim and the development of system dynamics. In Discrete-Event Simulation and System Dynamics for Management Decision Making; Wiley Blackwell: Hoboken, NJ, USA, 2014; Volume 9781118349, pp. 215–247. [Google Scholar] [CrossRef]

- Jia, S.; Liu, X.; Yan, G. Dynamic analysis of construction and demolition waste management model based on system dynamics and grey model approach. Clean Technol. Environ. Policy 2018, 20, 2089–2107. [Google Scholar] [CrossRef]

- Staff Writer. Demand for Concrete Expected to Rise over Next Five Years—Report. Roads & Infrastructure Magazine, 12 June 2018. [Google Scholar]

- Mohammadi, J.; South, W. Life cycle assessment (LCA) of benchmark concrete products in Australia. Int. J. Life Cycle Assess. 2017, 22, 1588–1608. [Google Scholar] [CrossRef]

| Variables | Type | Unit | Equations |

|---|---|---|---|

| Concrete Demand | Data | m3 | / |

| GB Cement Demand | Auxiliary | Ton | |

| Water Demand | Auxiliary | Ton | |

| Natural Sand Demand | Auxiliary | Ton | |

| Coarse Aggregates Demand | Auxiliary | Ton | |

| Manufactured Sand Demand | Auxiliary | Ton | |

| Concrete Supplied | Auxiliary | m3 | |

| Concrete Construction | Auxiliary | Ton | |

| Cubic Meter to Ton | Constant | ||

| Concrete Construction Stock | Level | Ton | |

| Concrete Demolition | Auxiliary | Ton | |

| Demolition Rate | Auxiliary | ||

| Concrete Waste | Auxiliary | Ton | |

| Recycling Plant | Auxiliary | Ton | % Send to Recycle |

| Recycled Aggregates | Auxiliary | Ton | |

| Recycling Rate | Constant | ||

| Gravel Extraction | Auxiliary | Ton | |

| Gravel Pit | Level | Ton | |

| Recycle Factory Fee | Constant | $ | 80 |

| Recycling Logistics Cost | Constant | $ | 445 |

| Recycle Cost | Auxiliary | $ | |

| New Recycled Logistics Cost | Auxiliary | $ | |

| Additional Transportation Cost | Auxiliary | $ | |

| Landfill Fee | Constant | $ | 147 |

| Landfill Cost | Auxiliary | $ | |

| Landfill-Logistics Cost | Constant | $ | 450 |

| Cost Different | Auxiliary | $ | |

| % Send to Landfill | Auxiliary | ||

| % Send to Recycle | Auxiliary | ||

| Landfill | Auxiliary | ||

| Total Concrete Landfill | Level | Landfill |

| Scenarios | Recycling Cost ($/t) | Landfill Cost ($/t) | Recycling Rate (%) | Landfill Rate (%) |

|---|---|---|---|---|

| Landfill logistic +10% | 445 | 495 | 99.60 | 0.40 |

| Recycling logistic +10% | 489.5 | 450 | 41.58 | 58.42 |

| Landfill logistic −25% | 445 | 337.5 | 0.70 | 99.30 |

| Recycling logistic −25% | 333.8 | 450 | 100.0 | 0.00 |

| Both cost −50% | 222.5 | 225 | 87.97 | 12.03 |

| Both cost +100% | 890 | 900 | 92.42 | 7.58 |

| Base case | 445 | 450 | 89.64 | 10.36 |

| Scenarios | Total Landfill (Mt) | Landfill vs. Base (ratio) | Gravel Pit Balance (Mt) | Gravel Ext. vs. Base (ratio) |

|---|---|---|---|---|

| Landfill logistic +10% | 4.09 | 0.53 | 23.26 | 0.956 |

| Recycling logistic +10% | 24.78 | 3.23 | 2.56 | 1.213 |

| Landfill logistic −25% | 39.35 | 5.14 | −12.00 | 1.394 |

| Recycling logistic −25% | 4.09 | 0.53 | 23.38 | 0.954 |

| Both cost −50% | 8.25 | 1.08 | 19.09 | 1.007 |

| Both cost +100% | 6.66 | 0.87 | 20.68 | 0.988 |

| Base case | 7.66 | 1.00 | 19.68 | 1.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Bell, M.G.H.; Bhattacharjya, J.; Geers, G. The Dynamics of Concrete Recycling in Circular Construction: A System-Dynamics Approach in Sydney, Australia. Sustainability 2025, 17, 4282. https://doi.org/10.3390/su17104282

Wang Z, Bell MGH, Bhattacharjya J, Geers G. The Dynamics of Concrete Recycling in Circular Construction: A System-Dynamics Approach in Sydney, Australia. Sustainability. 2025; 17(10):4282. https://doi.org/10.3390/su17104282

Chicago/Turabian StyleWang, Ze, Michael G. H. Bell, Jyotirmoyee Bhattacharjya, and Glenn Geers. 2025. "The Dynamics of Concrete Recycling in Circular Construction: A System-Dynamics Approach in Sydney, Australia" Sustainability 17, no. 10: 4282. https://doi.org/10.3390/su17104282

APA StyleWang, Z., Bell, M. G. H., Bhattacharjya, J., & Geers, G. (2025). The Dynamics of Concrete Recycling in Circular Construction: A System-Dynamics Approach in Sydney, Australia. Sustainability, 17(10), 4282. https://doi.org/10.3390/su17104282