A Study on Carbon-Reduction Strategies for Rural Residential Buildings Based on Economic Benefits in the Gannan Tibetan Area, China

Abstract

1. Introduction

2. Literature Review

3. Research Method

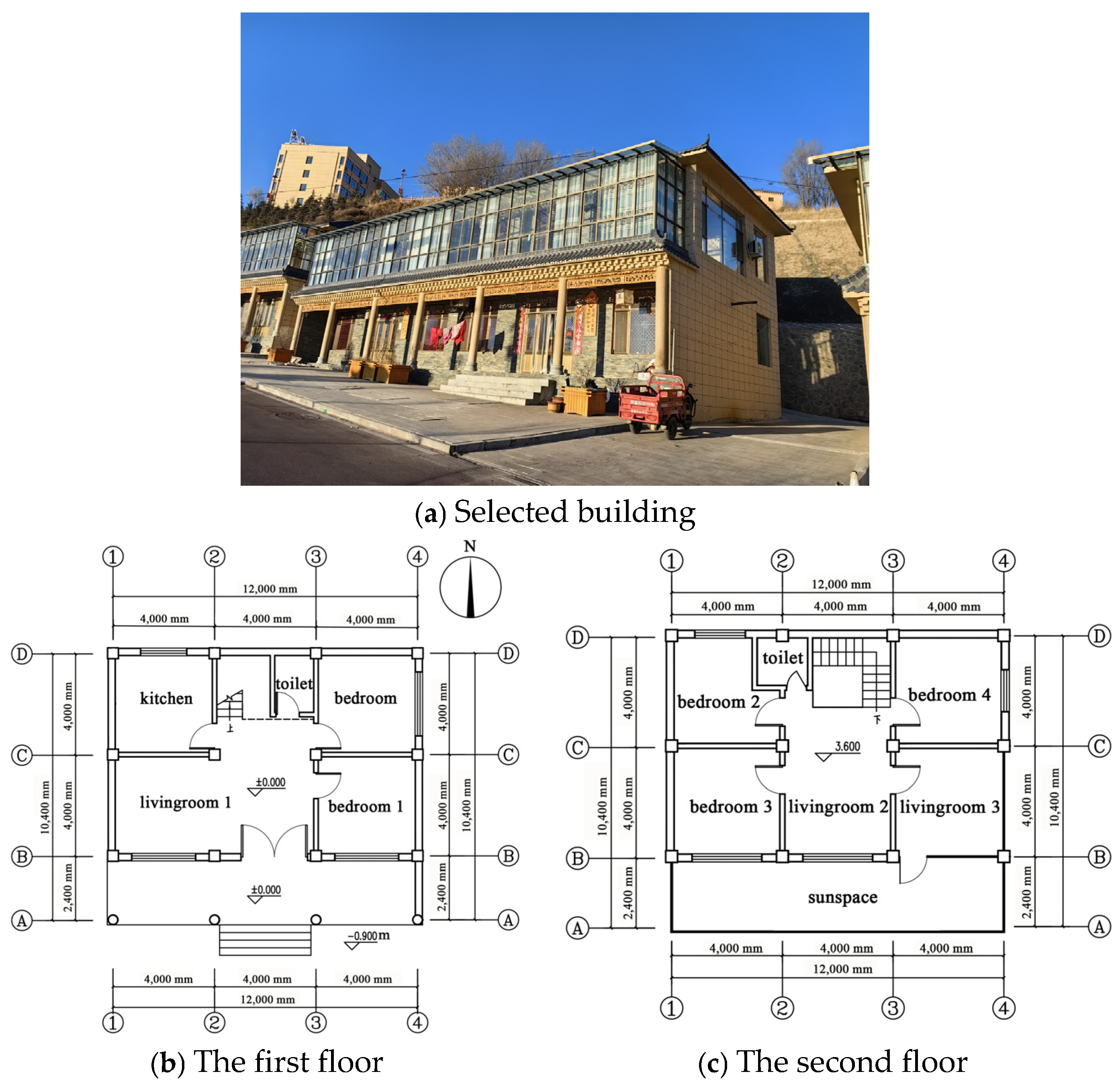

3.1. Field Investigation

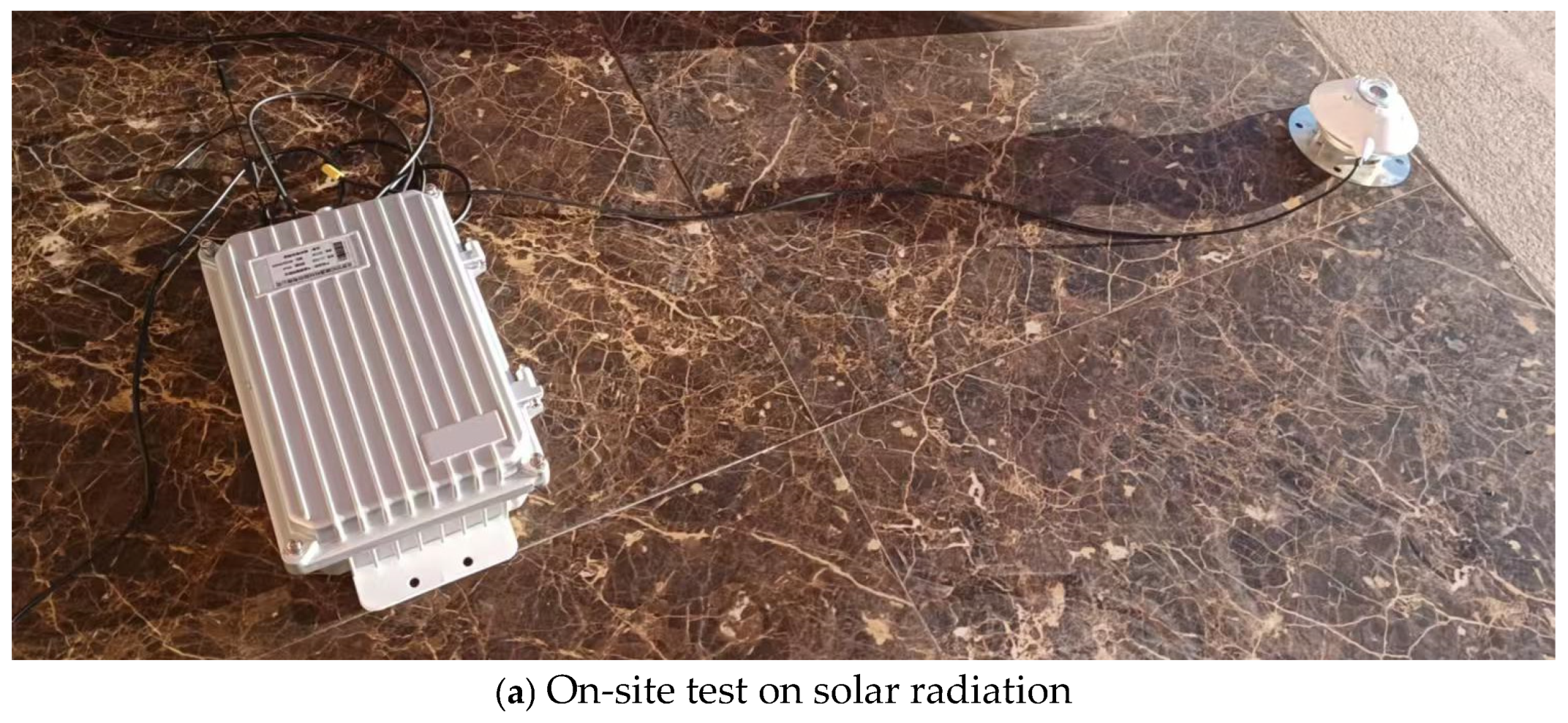

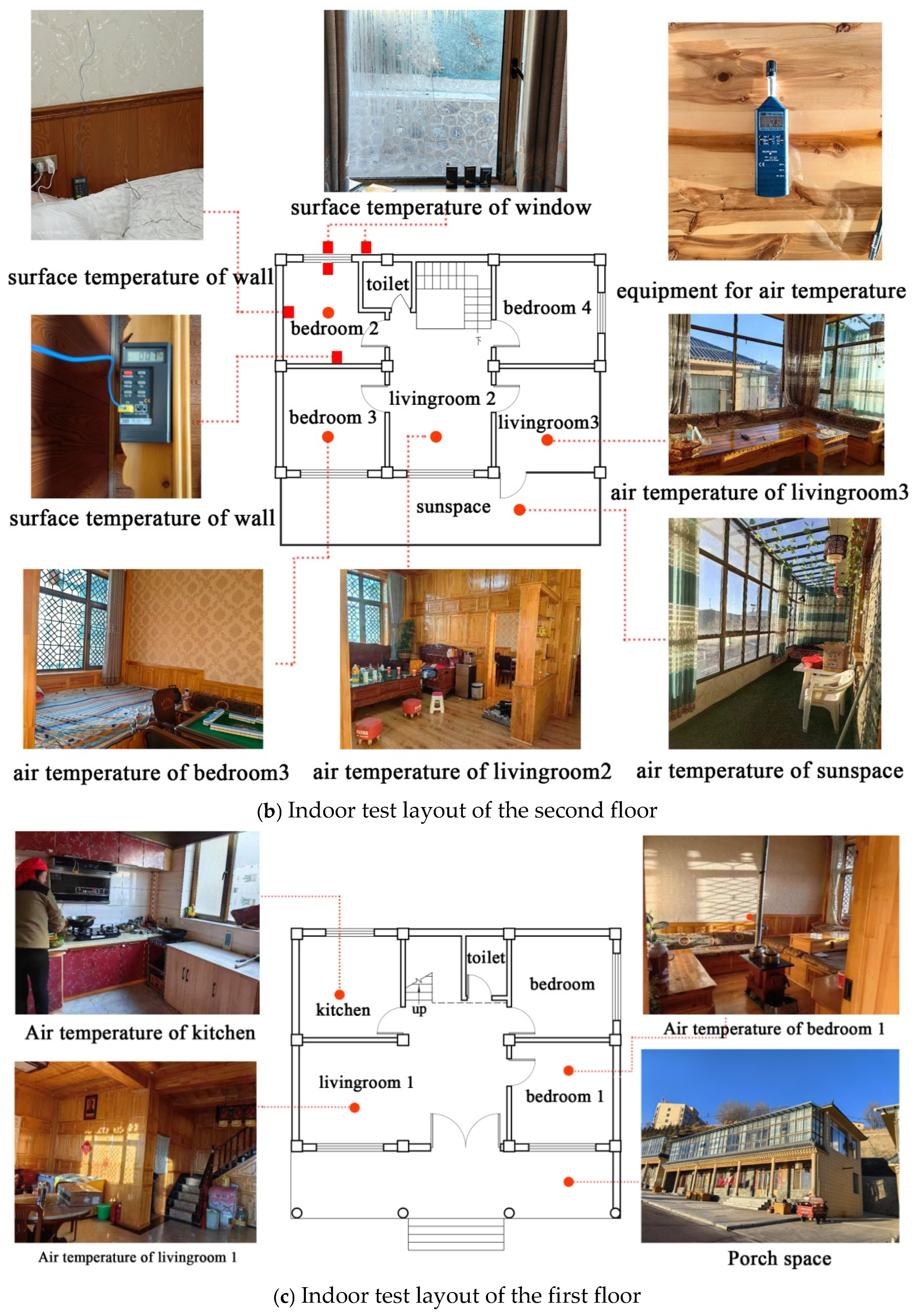

3.2. Thermal Environment Test

3.3. Numerical Calculation of Building Carbon Emissions

3.3.1. Building Material Production and Transportation

- (1)

- Building material production

- (2)

- Building material transportation

3.3.2. Construction and Demolition

- (1)

- Building construction

- (2)

- Building demolition

3.3.3. Building Operation Stage

- (1)

- Heating

- (2)

- Domestic hot water

- (3)

- Building lighting

4. Results

4.1. On-Site Surveys

4.1.1. Heating Conditions

- (1)

- Heating mode

- (2)

- Heating fees

- (3)

- Heating temperature and factors influencing heating optimization

4.1.2. Thermal Environment

- (1)

- Solar radiation

- (2)

- Outdoor air temperature

- (3)

- Indoor air temperature

4.2. Carbon-Reduction Strategies

4.2.1. Analysis of Carbon Emissions of Reference Building

- (1)

- Building energy consumption

- (2)

- Carbon emissions of the reference building

4.2.2. Carbon-Reduction Effects of Different Optimization Strategies

- (1)

- Building envelopes

- (2)

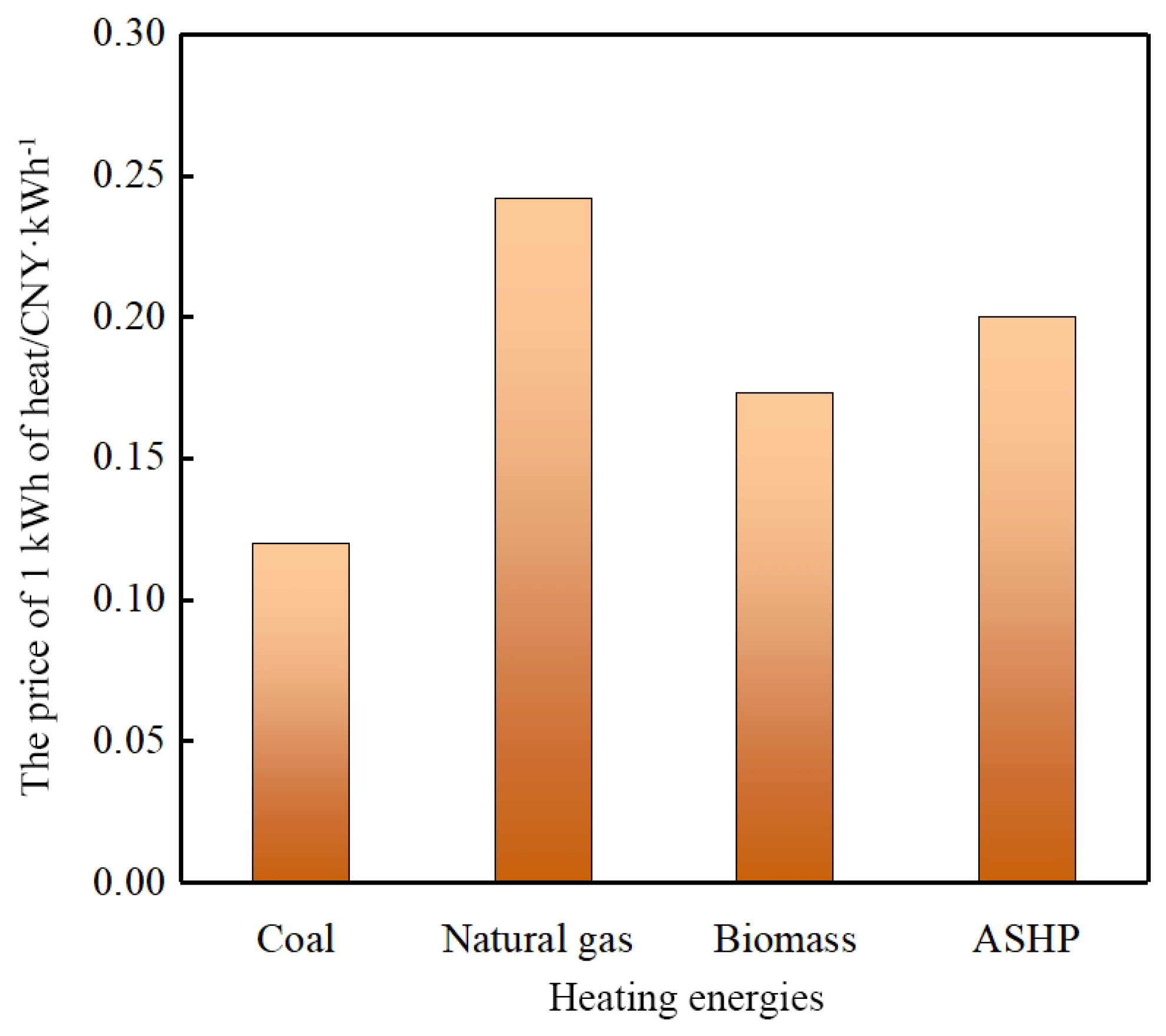

- Heating modes and heating efficiency optimization

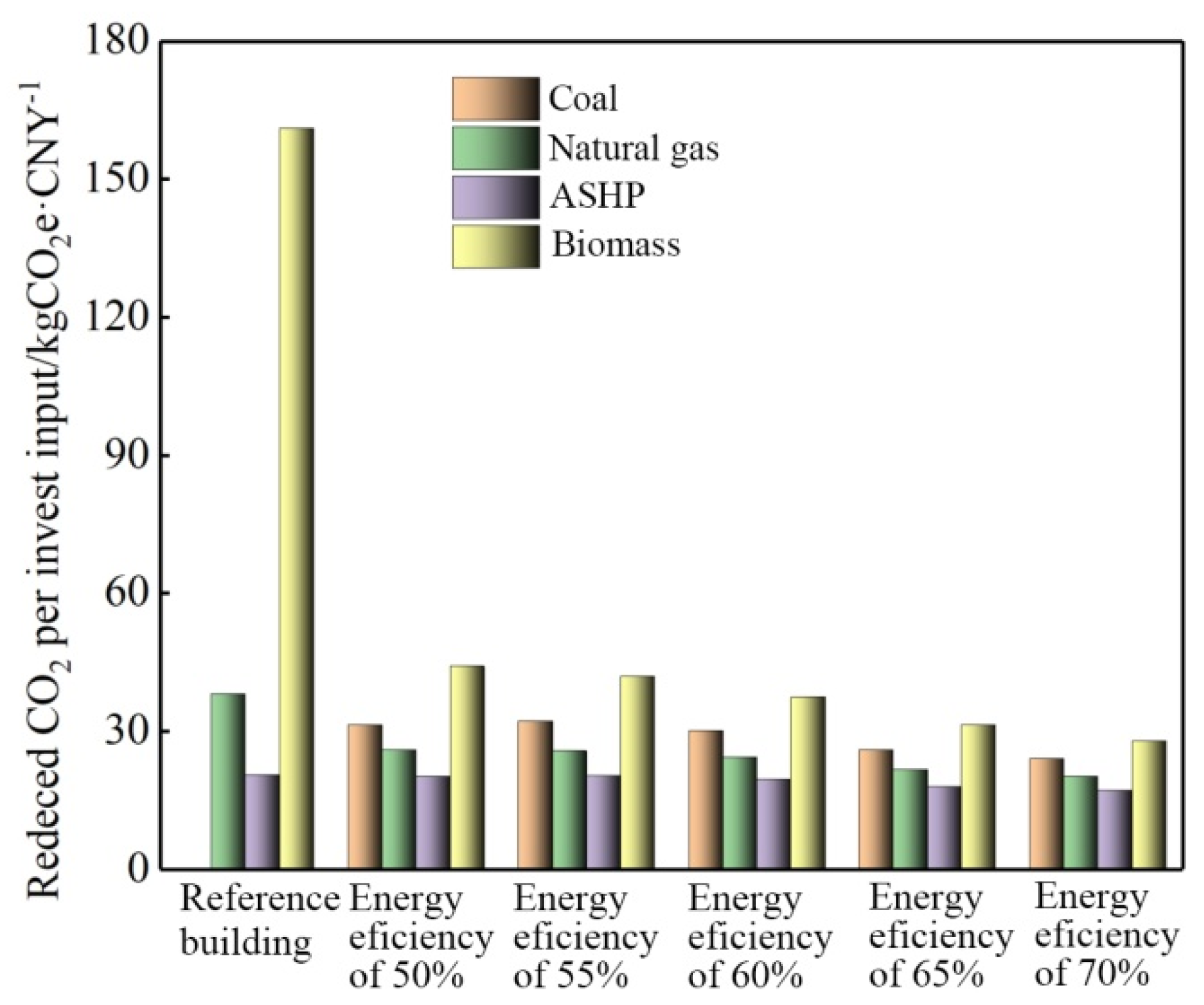

- (a)

- The carbon emissions generated by biomass energy were the lowest, followed by natural gas, ASHPs, and traditional coal.

- (b)

- The annual heating fees of natural gas were the highest, followed by ASHPs, biomass, and coal when supplying the same heat for buildings.

- (c)

- Biomass was the most economical way to reduce carbon emissions due to the low initial cost input and low carbon emission of biomass, followed by thermal insulation design, natural gas for heating, and ASHPs used for heating. The initial investment in natural gas was large with pipeline layouts.

5. Conclusions and Discussions

- (1)

- Increasing building thermal insulation could effectively reduce carbon emissions. The optimum energy efficiency was 55% in Gannan, with 30 mm thermal insulation of walls and 50 mm thermal insulation of the roof. It was not economical to blindly increase building insulation to reduce BCEs. In addition, it was an economic way to reduce carbon emissions. RCEs of thermal insulation reached 32.31 kgCO2e·CNY−1 with an energy efficiency of 55%.

- (2)

- Traditional coal produced the maximum carbon emissions by supplying the same amount of energy, but it was the most commonly used heating source due to its availability and low heating costs. It takes some time to eliminate the use of coal in rural areas; therefore, optimizing coal’s burning efficiency needs further study.

- (3)

- Biomass was the most economical way to reduce carbon emissions due to the low initial investments. RCEs of biomass reached 44.19 kgCO2e·CNY−1 with energy efficiency of 50%. Carbon emissions generated by biomass were 12.4% and 24% of those caused by coal and natural gas when supplying the same energy.

- (4)

- The maximum RCEs of natural gas reached 26.08 kgCO2e·CNY−1 with relatively high pipeline layout and maintenance costs. The government investment was an important factor in popularizing natural gas in rural areas.

- (5)

- Carbon emissions and heating fees of AHSP were relatively high. Reducing the carbon emissions and costs of the electricity generation process further improved the economic benefits of electric heating.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ke, Y.; Zhou, L.; Zhu, M. Scenario Prediction of Carbon Emission Peak of Urban Residential Buildings in China’s Coastal Region: A Case of Fujian Province. Sustainability 2023, 15, 2456. [Google Scholar] [CrossRef]

- Nie, Y.; Deng, M.; Shan, M.; Yang, X. Clean and low-carbon heating in the building sector of China: 10-Year development review and policy implications. Energy Policy 2013, 179, 113659. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Deng, B. Emission reduction analysis of China’s building operations from provincial perspective: Factor decomposition and peak prediction. Energy Build. 2023, 296, 113366. [Google Scholar] [CrossRef]

- Gao, Y.; Luo, S.; Jiang, J. Environmental-thermal-economic performance trade-off for rural residence retrofiting in the Beijing–Tianjin–Hebei region, Northern China: A multi-objective optimization framework under different scenarios. Energy Build. 2023, 286, 112910. [Google Scholar] [CrossRef]

- Wu, S.; Zheng, X.; You, C. Household energy consumption in rural China: Historical development, present pattern and policy implication. J. Clean. Prod. 2019, 211, 981–991. [Google Scholar] [CrossRef]

- Wang, J.; Xue, D.; Wang, M. Influencing Factors and Mechanism of Rural Carbon Emissions in Ecologically Fragile Energy Areas—Taking Ejin Horo Banner in Inner Mongolia as an Example. Sustainability 2022, 14, 7126. [Google Scholar] [CrossRef]

- Fan, J.; Ran, A.; Li, X. A Study on the factors affecting China’s direct household carbon emission and comparison of regional differences. Sustainability 2019, 11, 4919. [Google Scholar] [CrossRef]

- Guan, X.; Guo, S.; Xiong, J. Energy-related CO2 emissions of urban and rural residential buildings in China: A provincial analysis based on end-use activities. J. Build. Eng. 2023, 64, 105686. [Google Scholar] [CrossRef]

- GB/T 51366; Standard for Building Carbon Emission Calculation. Ministry of Housing and Urban-Urban Development of the People’s Republic of China, China Building Industry Press: Beijing, China, 2019. (In Chinese)

- Xu, X. Study on Life Cycle Carbon Emission of Straw Bale Buildings Based on Hybrid-LCA Model. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2019. (In Chinese). [Google Scholar]

- Liu, Y.; Zhang, J.; Xu, J. Carbon emission-based life cycle assessment of rural residential buildings constructed with engineering bamboo: A case study in China. J. Build. Eng. 2023, 76, 107182. [Google Scholar] [CrossRef]

- Li, H.; Luo, Z.; Xu, X. Assessing the embodied carbon reduction potential of straw bale rural houses by hybrid life cycle assessment: A four-case study. J. Clean. Prod. 2021, 303, 127002. [Google Scholar] [CrossRef]

- Chen, P. Assessment on Electric Heating in Rural Area of Beijing. Master’s Thesis, North China Electric Power University, Beijing, China, 2020. (In Chinese). [Google Scholar]

- Deng, M.; Ma, R.; Lu, F. Techno-economic performances of clean heating solutions to replace raw coal for heating in Northern rural China. Energy Build. 2021, 240, 110881. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, G.; Zhou, D. Experimental study and performance evaluation of an air source heat pump (ASHP) system with a frost-free evaporator. J. Clean. Prod. 2024, 448, 141469. [Google Scholar] [CrossRef]

- Wu, X.; Li, J. Experimental study on optical operation about solar energy assisted air source heat pump heating system in severe cold area. J. Eng. Thermophys. 2019, 40, 900–906. (In Chinese) [Google Scholar]

- Zeng, H. Research on Technical Economic Analysis and Policy of Electric Energy Replacement on Rural Areas of Beijing–Tianjin–Hebei. Master’s Thesis, North China Electric Power University, Beijing, China, 2017. (In Chinese). [Google Scholar]

- Zhou, Q.; He, Q.; He, D. Assessment model of electrical energy replacement based on cost utility analysis. Electr. Energy 2018, 39, 538–543+555. (In Chinese) [Google Scholar]

- Chen, J. Research on Cost Management of Rural “Coal to Electricity” Project in Certain Area in Beijing. Master’s Thesis, North China Electric Power University, Beijing, China, 2017. (In Chinese). [Google Scholar]

- Zhang, R. Research and Analysis of Rural Heating Mode Under the Background of “No Coalification” Transformation in Tianjin and Hebei. Master’s Thesis, North China Electric Power University, Beijing, China, 2018. (In Chinese). [Google Scholar]

- He, L. Comparative Study on Energy Supply of Rural Construction in Beijing. Ph.D. Thesis, Beijing University of Civil Engineering and Architecture, Beijing, China, 2018. (In Chinese). [Google Scholar]

- Nie, Y.; Deng, M.; Shan, M.; Yang, X. Is there interaction between forestry residue and crop residue in co-pyrolysis? Evidence from wood sawdust and peanut shell. J. Therm. Anal. Calorim. 2023, 148, 2467–2481. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, X.; Qi, J. Characterization of fine particulate matter generated in a large woody biomass-firing circulating fluid bed boiler. J. Energy Inst. 2021, 96, 11–18. (In Chinese) [Google Scholar] [CrossRef]

- Tian, H.; Ma, L.; Li, Q. Energy saving retrofit of rural house based on the joint utilization of solar collector and attached sunspace. Energy Build. 2023, 299, 113591. [Google Scholar] [CrossRef]

- Padovani, F.; Sommerfeldt, N.; Longobardi, F. Decarbonizing rural residential buildings in cold climates: A techno-economic analysis of heating electrification. Energy Build. 2021, 250, 111284. [Google Scholar] [CrossRef]

- Tahsildoost, M.; Zomorodian, Z. Energy, carbon, and cost analysis of rural housing retrofit in different climates. J. Build. Eng. 2020, 30, 101277. [Google Scholar] [CrossRef]

- Meteorological Information Center of China Meteorological Administration. Special Meteorological Data for Building Thermal Environment Analysis in China; China Building Industry Press: Beijing, China, 2005. (In Chinese) [Google Scholar]

- GB 50176; Code for Thermal Design of Civil Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China, China Building Industry Press: Beijing, China, 2016. (In Chinese)

- Ministry of Housing and Urban-Rural Development of Jiangsu Province. Guidelines for Carbon Emission Calculation of Civil Buildings in Jiangsu Province; Ministry of Housing and Urban-Rural Development of Jiangsu Province: Nanjing, China, 2023. (In Chinese) [Google Scholar]

- Zhang, S.; Liu, Y.; Hou, L. Comparative study on energy efficiency calculation methods of residential buildings in central heating areas of Northern China. J. Harbin Inst. Technol. 2019, 51, 178–185. (In Chinese) [Google Scholar]

- JGJ 26; Design Standards for Energy Efficiency of Residential Buildings in Severe Cold and COLD Areas. Ministry of Housing and Urban-Rural Development of the People’s Republic of China, China Building Industry Press: Beijing, China, 2019. (In Chinese)

- GB50555; Standard for Water Saving Design in Civil Building. Ministry of Housing and Urban-Rural Development of the People’s Republic of China, China Building Industry Press: Beijing, China, 2010. (In Chinese)

- GB/T 50824; Design Standard for Energy Efficiency of Rural Residential Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China, China Building Industry Press: Beijing, China, 2013. (In Chinese)

- DB62/T 3151; Design Standards for Energy Efficiency of Residential Buildings in Severe Cold and Cold Areas (75%). Ministry of Housing and Urban-Rural Development of Gansu Province, China Building Industry Press: Beijing, China, 2018. (In Chinese)

- Song, B.; Yang, L. Analysis of influence factors and economic efficiency of energy consumption of rural dwellings in cold regions. Build. Sci. 2020, 36, 33–38. (In Chinese) [Google Scholar]

- Zhang, M.; Yang, Z.; Ma, J. Standard rating conditions based on two-side multi-grade method: Summary and analysis on the Chinese standards for air source heat pumps. Int. J. Refrig. 2021, 131, 394–406. [Google Scholar] [CrossRef]

| Building Envelopes | Structures | K-Values/W·m−2·K−1 | ||

|---|---|---|---|---|

| Thickness | Materials | Thermal Conductivity λ /W·m−1·K−1 | ||

| Wall | 20 mm | cement plaster | 0.93 | 1.68 |

| 300 mm | fly ash block | 0.74 | ||

| 20 mm | cement plaster | 0.93 | ||

| 5 mm | limestone | 1.16 | ||

| Roof | 10 mm | cement tile | 0.74 | 1.70 |

| / | waterproof | / | ||

| 120 mm | reinforced concrete floor | 1.74 | ||

| 100 mm | air | 0.28 | ||

| 10 mm | wooden ceiling | 0.17 | ||

| Ground | / | Compacted plain soil | / | 0.13 (non-surrounding ground) 0.34 (surrounding ground) |

| 120 mm | crushed stone concrete | 1.51 | ||

| 10 mm | wooden floor | 0.17 | ||

| Window 1 | 6 mm | glass | / | 2.70 |

| / | wood | / | ||

| 6 mm | glass | / | ||

| / | wooden frame | / | ||

| Window 2 | 6 mm | glass | / | 4.70 |

| / | aluminum alloy frame | / | ||

| Instrument Devices | Parameters | Specifications | Accuracies |

|---|---|---|---|

| Temperature recorder | Air temperature | −20–60 °C | ±0.1 °C |

| Thermocouple temperature recorder | Surface temperature | −20–85 °C | ±0.1 °C |

| Solar radiation recorder | Solar radiation | 0–2000 W/m2 | ≤±2% |

| Spaces | Lighting Density/W·m−2 | Monthly Lighting Time/h |

|---|---|---|

| Living room | 6 | 165 |

| Bedroom | 6 | 135 |

| Dining room | 6 | 75 |

| Kitchen | 6 | 96 |

| Building Envelope | Net Heat Loss/W | Percentage |

|---|---|---|

| Walls | 5599.97 | 46.93% |

| Roof | 2719.17 | 22.79% |

| Ground | 436.40 | 3.66% |

| Windows | 1794.93 | 15.04% |

| Infiltration | 582.04 | 4.88% |

| Door | 490.68 | 4.11% |

| Balcony | 310.42 | 2.59% |

| Sum | 11,933.61 | 100.00% |

| Various Stages | Carbon Emissions/kgCO2e⋅m−2 | Percentage | |||

|---|---|---|---|---|---|

| Material production + transportation | Production | 486.94 | 96.86% | 502.72 | 7.36% |

| Transportation | 15.78 | 3.14% | |||

| Construction + demolition | Construction | 3.59 | 52.63% | 6.82 | 0.11% |

| Demolition | 3.23 | 47.36% | |||

| Operation | Hot water | 552.75 | 8.75% | 6318.11 | 92.53% |

| Heating | 5743.28 | 90.90% | |||

| Lighting | 22.07 | 0.35% | |||

| Sum | 6827.64 | 100.00% | |||

| Energy Efficiency | Envelope | Thermal Insulation Thickness | K-Value/W·m−2·K−1 |

|---|---|---|---|

| 50% | Wall | 30 mm | 0.73 |

| Roof | 50 mm | 0.54 | |

| Window | / | 3.00 | |

| 55% | Wall | 40 mm | 0.61 |

| Roof | 60 mm | 0.47 | |

| Window | / | 3.00 | |

| 60% | Wall | 50 mm | 0.53 |

| Roof | 60 mm | 0.47 | |

| Window | / | 2.70 | |

| 65% | Wall | 60 mm | 0.47 |

| Roof | 80 mm | 0.38 | |

| Window | / | 2.40 | |

| 70% | Wall | 100 mm | 0.32 |

| Roof | 100 mm | 0.32 | |

| Window | / | 2.40 |

| Heating Energy | Heating Efficiency | Calorific Value | Operating Cost | Carbon Emission Factor/kgCO2e·Unit−1 |

|---|---|---|---|---|

| Coal | 0.75 | 29,307 J·g−1 | 700 CNY·t−1 | 89 tCO2e·TJ−1 |

| Natural gas | 0.91 | 38,931 k J·m−3 | 2.4 CNY·m−3 | 55.54 tCO2e·TJ−1 |

| Biomass | 0.75 | 16,368 J·g−1 | 590 CNY·t−1 | 180 kgCO2e·t−1 |

| Air-source heat pump | 2.5 | 3600 kJ·kwh−1 | 0.5 CNY·kWh−1 | 0.66 kgCO2e·kWh−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Zhang, X. A Study on Carbon-Reduction Strategies for Rural Residential Buildings Based on Economic Benefits in the Gannan Tibetan Area, China. Sustainability 2025, 17, 131. https://doi.org/10.3390/su17010131

Yang J, Zhang X. A Study on Carbon-Reduction Strategies for Rural Residential Buildings Based on Economic Benefits in the Gannan Tibetan Area, China. Sustainability. 2025; 17(1):131. https://doi.org/10.3390/su17010131

Chicago/Turabian StyleYang, Jingjing, and Xilong Zhang. 2025. "A Study on Carbon-Reduction Strategies for Rural Residential Buildings Based on Economic Benefits in the Gannan Tibetan Area, China" Sustainability 17, no. 1: 131. https://doi.org/10.3390/su17010131

APA StyleYang, J., & Zhang, X. (2025). A Study on Carbon-Reduction Strategies for Rural Residential Buildings Based on Economic Benefits in the Gannan Tibetan Area, China. Sustainability, 17(1), 131. https://doi.org/10.3390/su17010131