Towards Human-Centric Manufacturing: Exploring the Role of Human Digital Twins in Industry 5.0

Abstract

1. Introduction

2. Research Context

2.1. Industry 5.0 and Human-Centric Manufacturing

2.2. The Role of Human Digital Twins in the Human-Centric Transition

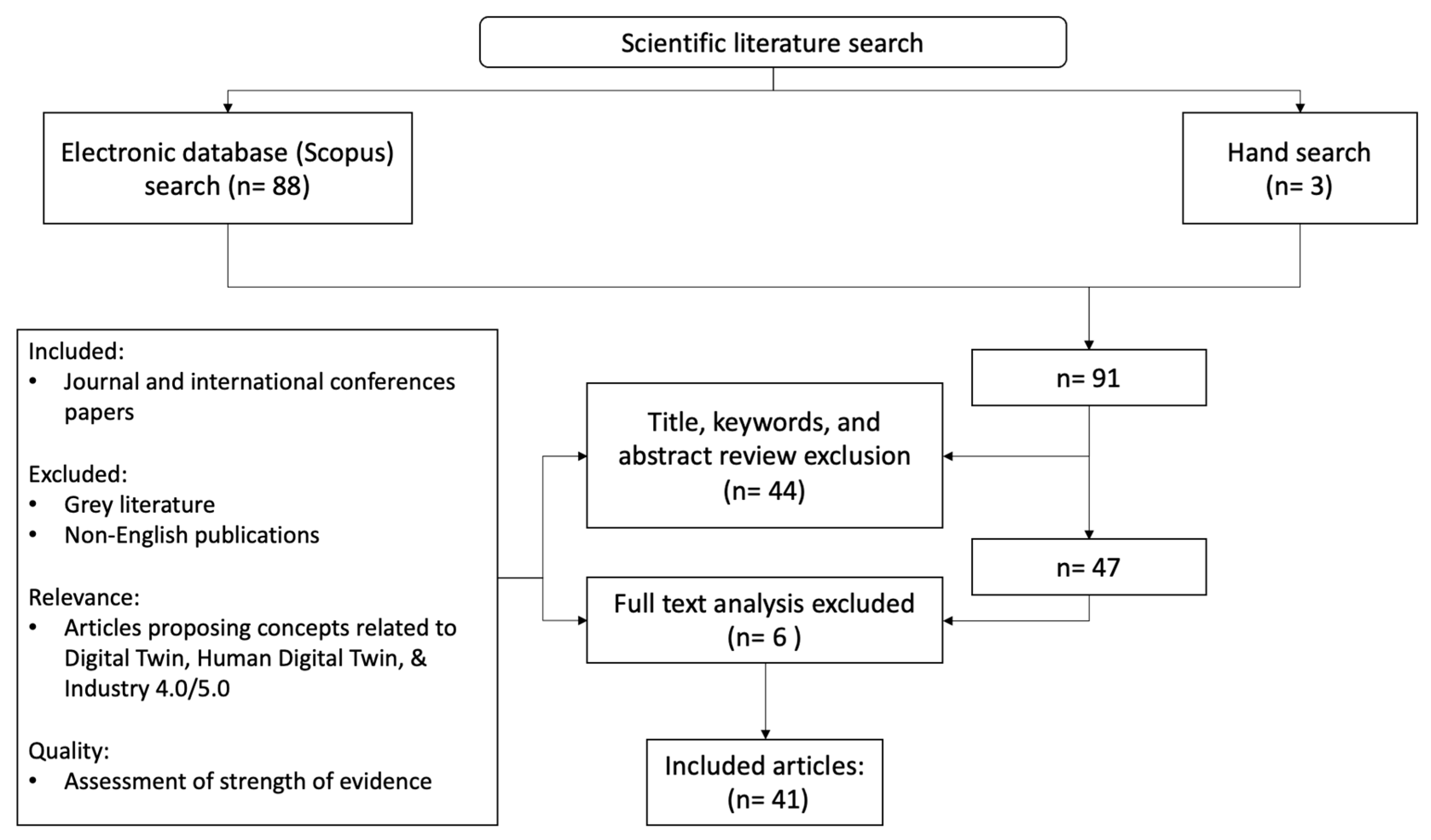

3. Research Methodology

4. Main Findings

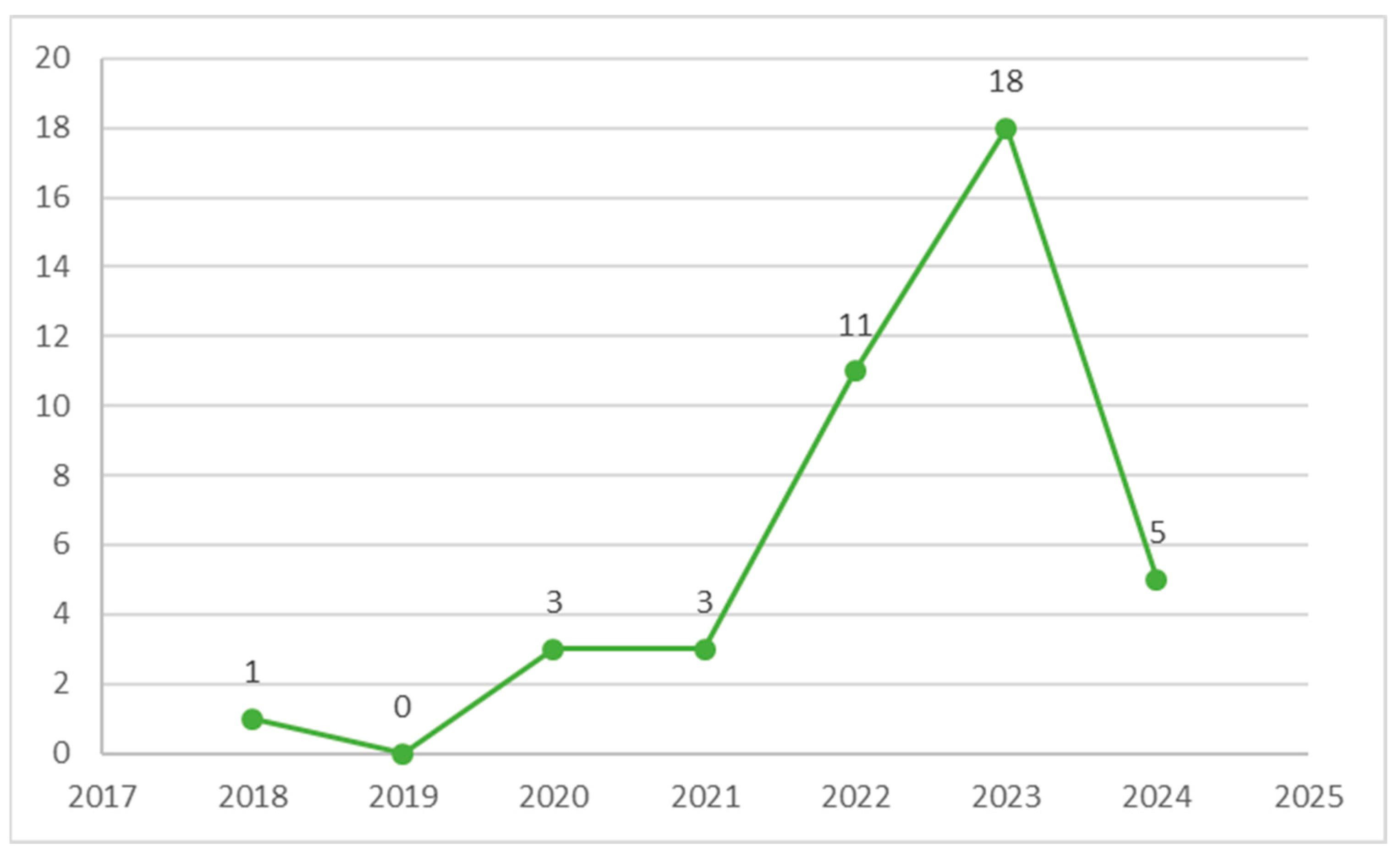

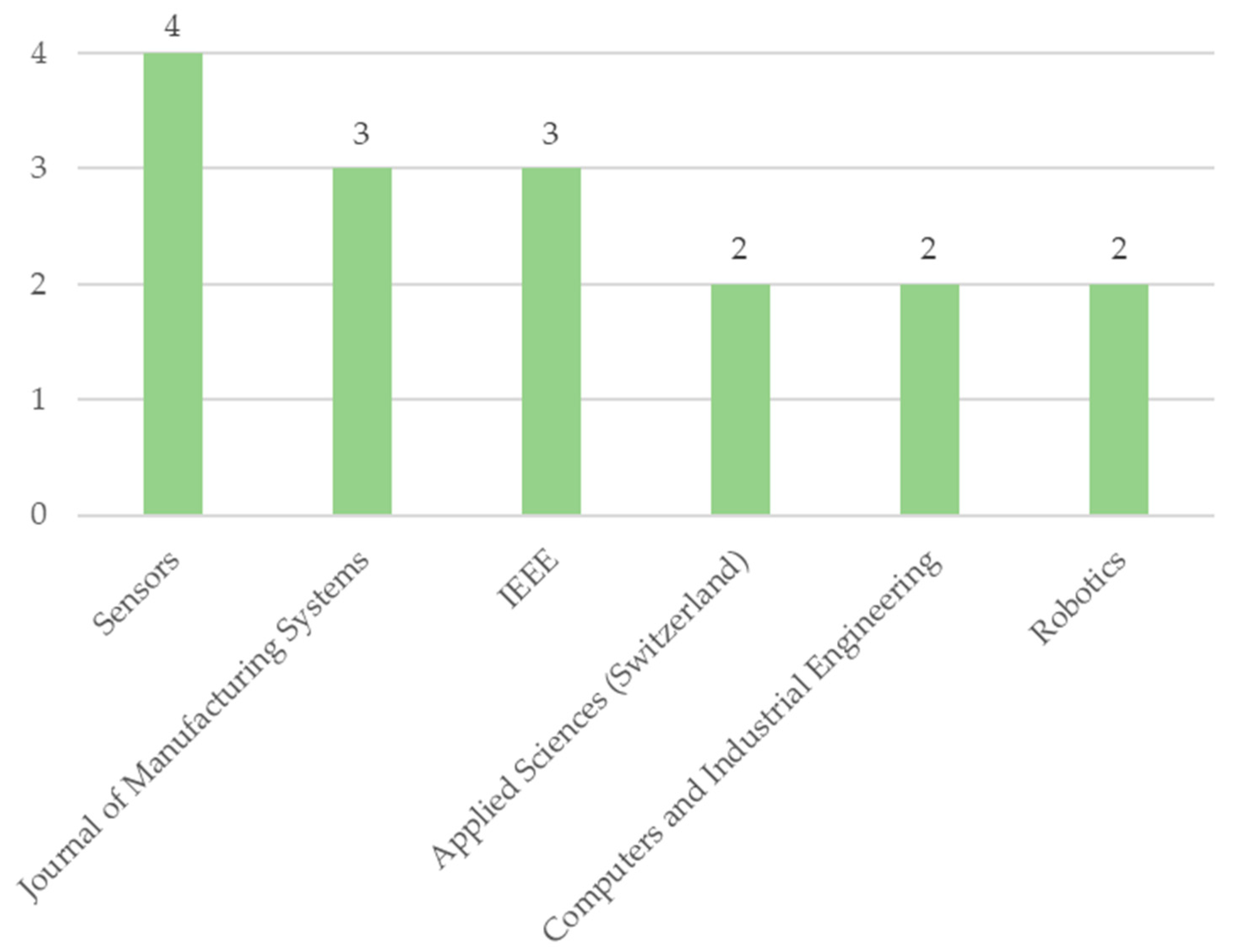

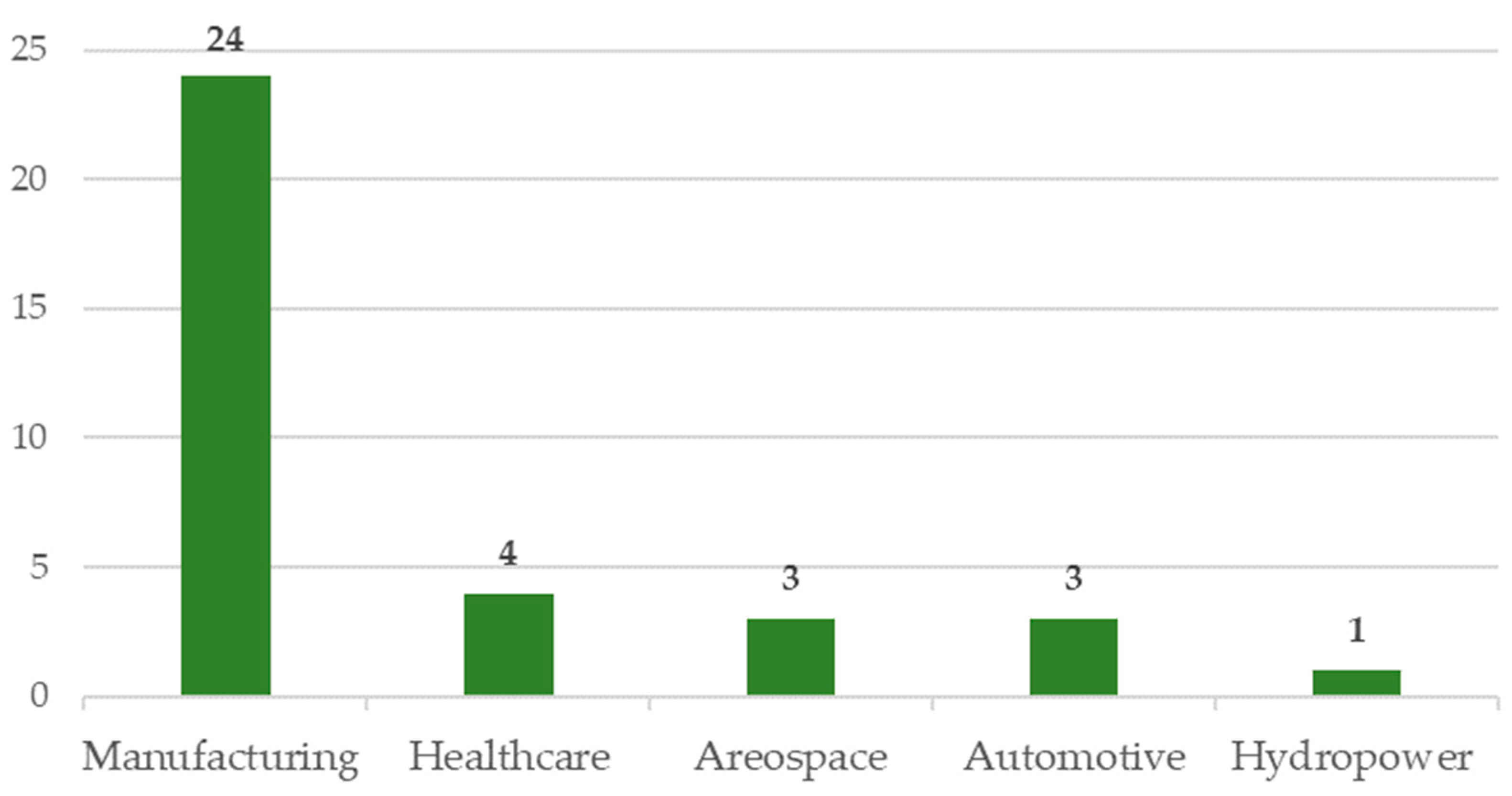

4.1. Descriptive Analysis

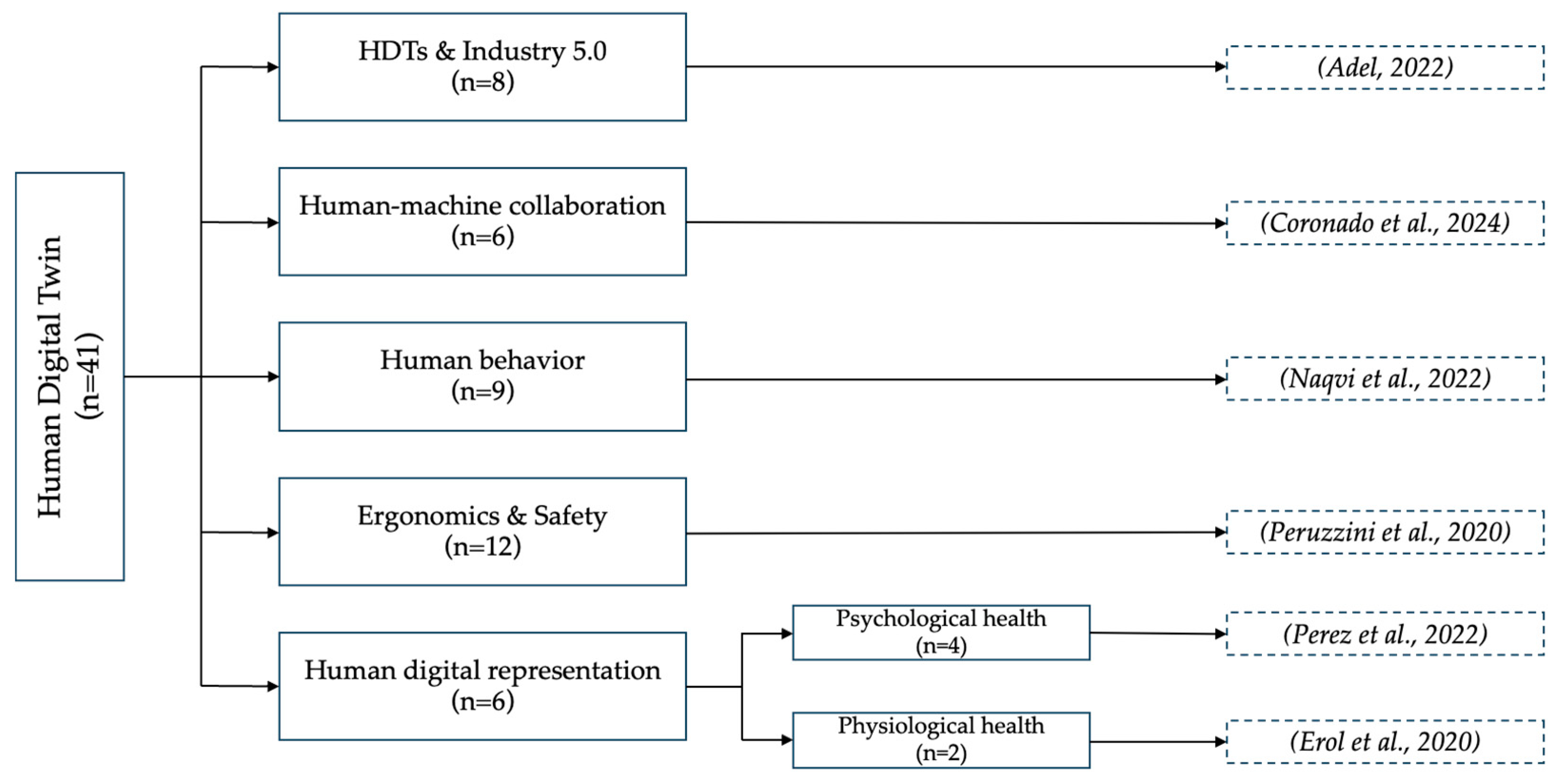

4.2. HDTs Thematic Classification Analysis

- HDTs and Industry 5.0 focuses on the introduction of the new I5.0 paradigm and DT technologies, emphasizing their integration with human-centric principles.

- Human-machine collaboration illustrates the features that ensure the correct collaboration between man and machine in industrial works.

- Human behavior relates to the inclusion of human behavior and skills that workers perform within the work process.

- Ergonomics and Safety is a fundamental aspect of HDT, as it most significantly characterizes of humans within the company.

- Human digital representation focuses on the digital representation of humans, particularly in two aspects: Psychological health and Physiological health of workers.

4.2.1. HDTs and Industry 5.0

4.2.2. Human–Machine Collaboration

4.2.3. Human Behavior

4.2.4. Ergonomics and Safety

4.2.5. Human Digital Representation

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Klingenberg, C.O.; Borges, M.A.V.; Antunes, J.A.V., Jr. Industry 4.0 as a Data-Driven Paradigm: A Systematic Literature Review on Technologies. J. Manuf. Technol. Manag. 2019, 32, 570–592. [Google Scholar] [CrossRef]

- Hazrat, M.A.; Hassan, N.M.S.; Chowdhury, A.A.; Rasul, M.G.; Taylor, B.A. Developing a Skilled Workforce for Future Industry Demand: The Potential of Digital Twin-Based Teaching and Learning Practices in Engineering Education. Sustainability 2023, 15, 16433. [Google Scholar] [CrossRef]

- Fani, V.; Bucci, I.; Rossi, M.; Bandinelli, R. Lean and Industry 4.0 Principles toward Industry 5.0: A Conceptual Framework and Empirical Insights from Fashion Industry. J. Manuf. Technol. Manag. 2024, 35, 122–141. [Google Scholar] [CrossRef]

- Mourtzis, D.; Wang, L. 3-Industry 5.0: Perspectives, Concepts, and Technologies. In Manufacturing from Industry 4.0 to Industry 5.0; Mourtzis, D., Ed.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 63–96. ISBN 978-0-443-13924-6. [Google Scholar]

- Ghobakhloo, M.; Iranmanesh, M.; Fathi, M.; Rejeb, A.; Foroughi, B.; Nikbin, D. Beyond Industry 4.0: A Systematic Review of Industry 5.0 Technologies and Implications for Social, Environmental and Economic Sustainability. Asia-Pac. J. Bus. Adm. 2024. ahead-of-print. [Google Scholar] [CrossRef]

- Breque, M.; De Nul, L.; Petridis, A. European Commission: Directorate-General for Research and Innovation. In Industry 5.0–Towards a Sustainable, Human-Centric and Resilient European Industry; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar]

- Peruzzini, M.; Prati, E.; Pelicciari, M. A Framework to Design Smart Manufacturing Systems for Industry 5.0 Based on the Human-Automation Symbiosis. Int. J. Comput. Integr. Manuf. 2023, 37, 1426–1443. [Google Scholar] [CrossRef]

- Fraga-Lamas, P.; Barros, D.; Lopes, S.I.; Fernández-Caramés, T.M. Mist and Edge Computing Cyber-Physical Human-Centered Systems for Industry 5.0: A Cost-Effective IoT Thermal Imaging Safety System. Sensors 2022, 22, 8500. [Google Scholar] [CrossRef]

- Fontes, C.; Carpentras, D.; Mahajan, S. Human Digital Twins Unlocking Society 5.0? Approaches, Emerging Risks and Disruptions. Ethics Inf. Technol. 2024, 26, 1–22. [Google Scholar] [CrossRef]

- Grego, G.; Nenna, F.; Gamberini, L. Enhancing Human-Machine Interactions: A Novel Framework for AR-Based Digital Twin Systems in Industrial Environments. In Proceedings of the 17th International Conference on PErvasive Technologies Related to Assistive Environments, Crete, Greece, 26–28 June 2024; Karim, E., Nikanfar, S., Pavel, H.R., Eds.; Association for Computing Machinery: New York, NY, USA, 2024; pp. 456–462. [Google Scholar]

- de la Torre, A.R.; Borregan, J.; Pikatza, N.; Maria Rio, R. Integrating Human-Centric Simulations in Educational Production Lines: Advancing Ergonomics for Industry 5.0 Applications. Int. J. Prod. Manag. Eng. 2024, 12, 141–157. [Google Scholar] [CrossRef]

- Krupas, M.; Kajati, E.; Liu, C.; Zolotova, I. Towards a Human-Centric Digital Twin for Human–Machine Collaboration: A Review on Enabling Technologies and Methods. Sensors 2024, 24, 2232. [Google Scholar] [CrossRef]

- He, Q.; Li, L.; Li, D.; Peng, T.; Zhang, X.; Cai, Y.; Zhang, X.; Tang, R. From Digital Human Modeling to Human Digital Twin: Framework and Perspectives in Human Factors. Chin. J. Mech. Eng. Engl. Ed. 2024, 37, 9. [Google Scholar] [CrossRef]

- Sachan, R.; Chauhan, K.; Agarwal, V. Outlook on Upskilling and Reskilling Capacities for Industry 5.0. In Humanizing Businesses for a Better World of Work; Shrivastava, R., Jain, K., Eds.; Emerald Publishing Limited: Leeds, UK, 2024; pp. 1–16. ISBN 978-1-83797-333-0. [Google Scholar]

- Narkhede, G.; Pasi, B.; Rajhans, N.; Kulkarni, A. Industry 5.0 and the Future of Sustainable Manufacturing: A Systematic Literature Review. Bus. Strategy Dev. 2023, 6, 704–723. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Mahdiraji, H.A.; Iranmanesh, M.; Jafari-Sadeghi, V. From Industry 4.0 Digital Manufacturing to Industry 5.0 Digital Society: A Roadmap Toward Human-Centric, Sustainable, and Resilient Production. Inf. Syst. Front. 2024. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Morales, M.E.; Nilashi, M.; Amran, A. Actions and Approaches for Enabling Industry 5.0-Driven Sustainable Industrial Transformation: A Strategy Roadmap. Corp. Soc. Responsib. Environ. Manag. 2023, 30, 1473–1494. [Google Scholar] [CrossRef]

- Ruiz-de-la-Torre-Acha, A.; Guevara-Ramirez, W.; Río-Belver, R.M.; Borregan-Alvarado, J. Industry 5.0. The Road to Sustainability. In Towards a Smart, Resilient and Sustainable Industry; Borgianni, Y., Matt, D.T., Molinaro, M., Orzes, G., Eds.; Springer Nature: Cham, Switzerland, 2023; pp. 247–257. [Google Scholar]

- Leng, J.; Zhong, Y.; Lin, Z.; Xu, K.; Mourtzis, D.; Zhou, X.; Zheng, P.; Liu, Q.; Zhao, J.L.; Shen, W. Towards Resilience in Industry 5.0: A Decentralized Autonomous Manufacturing Paradigm. J. Manuf. Syst. 2023, 71, 95–114. [Google Scholar] [CrossRef]

- Chabane, B.; Komljenovic, D.; Abdul-Nour, G. Converging on Human-Centred Industry, Resilient Processes, and Sustainable Outcomes in Asset Management Frameworks. Environ. Syst. Decis. 2023, 43, 663–679. [Google Scholar] [CrossRef]

- Ramírez-Gordillo, T.; Mora, H.; Pujol-Lopez, F.A.; Jimeno-Morenilla, A.; Maciá-Lillo, A. Industry 5.0: Towards Human Centered Design in Human Machine Interaction. In The International Research & Innovation Forum; Springer International Publishing: Cham, Switzerland, 2024; pp. 661–672. [Google Scholar]

- Turner, C.; Oyekan, J. Manufacturing in the Age of Human-Centric and Sustainable Industry 5.0: Application to Holonic, Flexible, Reconfigurable and Smart Manufacturing Systems. Sustainability 2023, 15, 10169. [Google Scholar] [CrossRef]

- Kokare, S.; Oliveira, J.P.; Godina, R. Life Cycle Assessment of Additive Manufacturing Processes: A Review. J. Manuf. Syst. 2023, 68, 536–559. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Z.; Zhou, G.; Chang, F.; Ma, D.; Jing, Y.; Cheng, W.; Ding, K.; Zhao, D. Towards New-Generation Human-Centric Smart Manufacturing in Industry 5.0: A Systematic Review. Adv. Eng. Inform. 2023, 57, 102121. [Google Scholar] [CrossRef]

- Adel, A. Future of Industry 5.0 in Society: Human-Centric Solutions, Challenges and Prospective Research Areas. J. Cloud Comput. 2022, 11, 40. [Google Scholar] [CrossRef]

- Asad, U.; Khan, M.; Khalid, A.; Lughmani, W.A. Human-Centric Digital Twins in Industry: A Comprehensive Review of Enabling Technologies and Implementation Strategies. Sensors 2023, 23, 3938. [Google Scholar] [CrossRef]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.d.S.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M.J. Industry 4. 0: The Future of Productivity and Growth in Manufacturing Industries April 09. Boston Consult. Group 2016, 9, 54–89. [Google Scholar]

- Galli, E.; Fani, V.; Bandinelli, R.; Lacroix, S.; Le Duigou, J.; Eynard, B.; Godart, X. Literature Review and Comparison of Digital Twin Frameworks in Manufacturing. Proc. Eur. Counc. Model. Simul. ECMS 2023, 2023, 428–434. [Google Scholar] [CrossRef]

- Corallo, A.; Del Vecchio, V.; Lezzi, M.; Morciano, P. Shop Floor Digital Twin in Smart Manufacturing: A Systematic Literature Review. Sustainability 2021, 13, 12987. [Google Scholar] [CrossRef]

- Lago Alvarez, A.; Mohammed, W.M.; Vu, T.; Ahmadi, S.; Martinez Lastra, J.L. Enhancing Digital Twins of Semi-Automatic Production Lines by Digitizing Operator Skills. Appl. Sci. 2023, 13, 1637. [Google Scholar] [CrossRef]

- Davila-Gonzalez, S.; Martin, S. Human Digital Twin in Industry 5.0: A Holistic Approach to Worker Safety and Well-Being through Advanced AI and Emotional Analytics. Sensors 2024, 24, 655. [Google Scholar] [CrossRef]

- Domínguez, L.G.I. Digital Twins in Industry 5.0—A Systematic Literatura Review. Eur. Public Soc. Innov. Rev. 2024, 9, 1–21. [Google Scholar] [CrossRef]

- Kim, G.-Y.; Kim, D.; Do Noh, S.; Han, H.K.; Kim, N.G.; Kang, Y.-S.; Choi, S.H.; Go, D.H.; Song, J.; Lee, D.Y.; et al. Human Digital Twin System for Operator Safety and Work Management. In IFIP Advances in Information and Communication Technology; Kim, D.Y., von Cieminski, G., Romero, D., Eds.; Springer Science and Business Media Deutschland GmbH: New York, NY, USA, 2022; Volume 664, pp. 529–536. [Google Scholar]

- Grego, G.; Nenna, F.; Gamberini, L. XR-Based Digital Twin for Industry 5.0: A Usability and User Experience Evaluation. In Proceedings of Lecture Notes in Computer Science; De Paolis, L.T., Arpaia, P., Sacco, M., Eds.; Springer Science and Business Media Deutschland GmbH: New York, NY, USA, 2024; Volume 15027, pp. 387–403. [Google Scholar]

- Naudet, Y.; Baudet, A.; Risse, M. Human Digital Twin in Industry 4.0: Concept and Preliminary Model. In Proceedings of the 2nd International Conference on Innovative Intelligent Industrial Production and Logistics, Online, 25–27 October 2021; pp. 137–144. [Google Scholar]

- Denyer, D.; Tranfield, D. Producing a Systematic Review. In The Sage Handbook of Organizational Research Methods; Sage Publications Ltd.: London, UK, 2009. [Google Scholar]

- Smart, P.; Hemel, S.; Lettice, F.; Adams, R.; Evans, S. Pre-Paradigmatic Status of Industrial Sustainability: A Systematic Review. Int. J. Oper. Amp. Prod. Manag. 2017, 37, 1425–1450. [Google Scholar] [CrossRef]

- Ren, S.; Zhang, Y.; Liu, Y.; Sakao, T.; Huisingh, D.; Almeida, C.M.V.B. A Comprehensive Review of Big Data Analytics throughout Product Lifecycle to Support Sustainable Smart Manufacturing: A Framework, Challenges and Future Research Directions. J. Clean. Prod. 2019, 210, 1343–1365. [Google Scholar] [CrossRef]

- Maeda, J. The Laws of Simplicity; MIT Press: Cambridge, MA, USA, 2006. [Google Scholar]

- Taddei, E.; Sassanelli, C.; Rosa, P.; Terzi, S. Circular Supply Chains in the Era of Industry 4.0: A Systematic Literature Review. Comput. Ind. Eng. 2022, 170, 108268. [Google Scholar] [CrossRef]

- Alimam, H.; Mazzuto, G.; Tozzi, N.; Emanuele Ciarapica, F.; Bevilacqua, M. The Resurrection of Digital Triplet: A Cognitive Pillar of Human-Machine Integration at the Dawn of Industry 5.0. J. King Saud Univ. Comput. Inform. Sci. 2023, 35, 101846. [Google Scholar] [CrossRef]

- Bécue, A.; Maia, E.; Feeken, L.; Borchers, P.; Praça, I. A New Concept of Digital Twin Supporting Optimization and Resilience of Factories of the Future. Appl. Sci. 2020, 10, 4482. [Google Scholar] [CrossRef]

- Berti, N.; Finco, S.; Guidolin, M.; Battini, D. Towards Human Digital Twins to Enhance Workers’ Safety and Production System Resilience. IFAC-Pap. 2023, 56, 11062–11067. [Google Scholar] [CrossRef]

- Borck, C.; Schmitt, R.; Berger, U.; Hentschel, C. IIoT and Smart Sensors in Human-Centered Manufacturing. In The Future of Smart Production for SMEs: A Methodological and Practical Approach Towards Digitalization in SMEs; Springer International Publishing: Cham, Switzerland, 2022; pp. 213–224. ISBN 978-303115428-7. [Google Scholar]

- Tang, C.; Yi, W.; Occhipinti, E.; Dai, Y.; Gao, S.; Occhipinti, L. A Roadmap for the Development of Human Body Digital Twins. Nat. Rev. Electr. Eng. 2024, 1, 199–207. [Google Scholar] [CrossRef]

- Coronado, E.; Ueshiba, T.; Ramirez-Alpizar, I.G. A Path to Industry 5.0 Digital Twins for Human–Robot Collaboration by Bridging NEP+ and ROS. Robotics 2024, 13, 28. [Google Scholar] [CrossRef]

- Cutrona, V.; Bonomi, N.; Montini, E.; Ruppert, T.; Delinavelli, G.; Pedrazzoli, P. Extending Factory Digital Twins through Human Characterisation in Asset Administration Shell. Int. J. Comput. Integr. Manuf. 2023, 37, 1214–1231. [Google Scholar] [CrossRef]

- Dallel, M.; Havard, V.; Dupuis, Y.; Baudry, D. Digital Twin of an Industrial Workstation: A Novel Method of an Auto-Labeled Data Generator Using Virtual Reality for Human Action Recognition in the Context of Human–Robot Collaboration. Eng. Appl. Artif. Intell. 2023, 118, 105655. [Google Scholar] [CrossRef]

- De Marchi, J.A.; Baalbergen, E.H. Towards a Human-Centric Digital Twin Architecture for Industry 5.0: Aiding Skilled Operators with Composites Production Automation. J. Phys. Conf. Ser. Inst. Phys. 2023, 2526, 012047. [Google Scholar] [CrossRef]

- Dobaj, J.; Riel, A.; Macher, G.; Egretzberger, M. Towards DevOps for Cyber-Physical Systems (CPSs): Resilient Self-Adaptive Software for Sustainable Human-Centric Smart CPS Facilitated by Digital Twins. Machines 2023, 11, 973. [Google Scholar] [CrossRef]

- Franciosi, C.; Miranda, S.; Veneroso, C.R.; Riemma, S. Investigating Human Factors Integration into DT-Based Joint Production and Maintenance Scheduling. In IFIP Advances in Information and Communication Technology; Alfnes, E., Romsdal, A., Strandhagen, J.O., von Cieminski, G., Romero, D., Eds.; Springer Science and Business Media Deutschland GmbH: New York, NY, USA, 2023; Volume 689, pp. 633–648. [Google Scholar]

- Gallego-García, S.; García-García, M. Human Needs Evolution and Organizational Development: A Case Study Analysis towards the Fifth Industrial Revolution. Adv. Sci. Technol. 2023, 132, 453–463. [Google Scholar]

- Han, B.; Schotten, H.D. Multi-Sensory HMI for Human-Centric Industrial Digital Twins: A 6G Vision of Future Industry. In Proceedings of the 2022 IEEE Symposium on Computers and Communications, Rhodes, Greece, 30 June–3 July 2022; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2022; Volume 2022. [Google Scholar]

- Jeong, Y.; Flores-García, E.; Piontek, S.; Wiktorsson, M. Implementing Transmission of Data for Digital Twins in Human-Centered Cyber-Physical Systems. Procedia CIRP 2023, 120, 992–997. [Google Scholar] [CrossRef]

- Kober, C.; Fette, M.; Wulfsberg, J.P. Challenges of Digital Twin Application in Manufacturing. In Proceedings of the 2022 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Kuala Lumpur, Malaysia, 7–10 December 2022; IEEE Computer Society: Los Alamitos, CA, USA; Volume 2022, pp. 162–168. [Google Scholar]

- Kolesnikov, M.V.; Atmojo, U.D.; Vyatkin, V. Data-Driven Human Factors Enabled Digital Twin. In Proceedings of the IECON 2023—49th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 16–19 October 2023. [Google Scholar]

- Kuts, V.; Marvel, J.A.; Aksu, M.; Pizzagalli, S.L.; Sarkans, M.; Bondarenko, Y.; Otto, T. Digital Twin as Industrial Robots Manipulation Validation Tool. Robotics 2022, 11, 113. [Google Scholar] [CrossRef]

- Lam, W.S.; Lam, W.H.; Lee, P.F. A Bibliometric Analysis of Digital Twin in the Supply Chain. Mathematics 2023, 11, 3350. [Google Scholar] [CrossRef]

- Lonsdale, H.; Gray, G.M.; Ahumada, L.M.; Yates, H.M.; Varughese, A.; Rehman, M.A. The Perioperative Human Digital Twin. Anesth. Analg. 2022, 134, 885–892. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Gutiérrez, A.; Díez-González, J.; Perez, H.; Araújo, M. Towards Industry 5.0 through Metaverse. Rob. Comput. Integr. Manuf. 2024, 89, 102764. [Google Scholar] [CrossRef]

- Modoni, G.E.; Sacco, M. A Human Digital-Twin-Based Framework Driving Human Centricity towards Industry 5.0. Sensors 2023, 23, 6054. [Google Scholar] [CrossRef]

- Naqvi, S.M.R.; Ghufran, M.; Meraghni, S.; Varnier, C.; Nicod, J.-M.; Zerhouni, N. Human Knowledge Centered Maintenance Decision Support in Digital Twin Environment. J. Manuf. Syst. 2022, 65, 528–537. [Google Scholar] [CrossRef]

- Pang, J.; Zheng, P. An MBD-Enabled Digital Twin Modeling Method for Cognition Assistance in Human-Centric Smart Assembly. In Proceedings of the 2023 IEEE 19th International Conference on Automation Science and Engineering (CASE), Auckland, New Zealand, 26–30 August 2023; Volume 2023. [Google Scholar]

- Paul, G.; Briceno, L. A Conceptual Framework of DHM Enablers for Ergonomics 4.0. In Lecture Notes Networks Systems; Black, N.L., Neumann, W.P., Noy, I., Eds.; Springer Science and Business Media Deutschland GmbH: New York, NY, USA, 2022; Volume 223, pp. 403–406. [Google Scholar]

- Perez, M.-J.; Meza, S.-M.; Bravo, F.-A.; Trentesaux, D.; Jimenez, J.-F. Evolution of the Human Digital Representation in Manufacturing Production Systems. In Service Oriented, Holonic and Multi-Agent Manufacturing Systems for Industry of the Future; Borangiu, T., Trentesaux, D., Leitão, P., Cardin, O., Joblot, L., Eds.; Springer Science and Business Media Deutschland GmbH: New York, NY, USA, 2022; Volume 1034, pp. 201–211. [Google Scholar]

- Peruzzini, M.; Grandi, F.; Pellicciari, M. Exploring the Potential of Operator 4.0 Interface and Monitoring. Comput. Ind. Eng. 2020, 139, 105600. [Google Scholar] [CrossRef]

- Erol, T.; Mendi, A.F.; Doğan, D. The Digital Twin Revolution in Healthcare. In Proceedings of the 2020 4th International Symposium on Multidisciplinary Studies and Innovative Technologies (ISMSIT), Istanbul, Turkey, 22–24 October 2020; pp. 1–7. [Google Scholar]

- Tu, X.; Autiosalo, J.; Ala-Laurinaho, R.; Yang, C.; Salminen, P.; Tammi, K. TwinXR: Method for Using Digital Twin Descriptions in Industrial eXtended Reality Applications. Front. Virtual Real. 2023, 4, 1019080. [Google Scholar] [CrossRef]

- Wang, H.; Lv, L.; Li, X.; Li, H.; Leng, J.; Zhang, Y.; Thomson, V.; Liu, G.; Wen, X.; Sun, C.; et al. A Safety Management Approach for Industry 5.0′s Human-Centered Manufacturing Based on Digital Twin. J. Manuf. Syst. 2023, 66, 1–12. [Google Scholar] [CrossRef]

- Shengli, W. Is Human Digital Twin Possible? Comput. Methods Programs Biomed. Update 2021, 1, 100014. [Google Scholar] [CrossRef]

- Zhu, Q.; Huang, S.; Wang, G.; Moghaddam, S.K.; Lu, Y.; Yan, Y. Dynamic Reconfiguration Optimization of Intelligent Manufacturing System with Human-Robot Collaboration Based on Digital Twin. J. Manuf. Syst. 2022, 65, 330–338. [Google Scholar] [CrossRef]

| Ref. | Type | Main Objective | Category |

|---|---|---|---|

| [25] | Review | Discusses I5.0 opportunities, challenges, and prospects. Focuses on human–machine collaboration, emerging technologies, and their applications. | HDT and Industry 5.0 |

| [41] | Framework | Proposes a hierarchical framework for digital triplets integrating human intuition, knowledge, and creativity into cyberspace, enhancing human–machine interaction. | Human- machine collaboration |

| [26] | Review | Reviews enabling technologies for HDTs and provides guidelines for their development and application. | Ergonomics and Safety |

| [42] | Framework | Introduces a holistic DT approach integrating human behavior and full manufacturing process dependencies to improve resilience and optimization. | Human– machine collaboration |

| [43] | Framework | Proposes a real-time monitoring system architecture using HDTs to improve worker safety and system resilience. | Ergonomics and Safety |

| [44] | Guideline | Provides recommendations for using IIoT and smart sensors to support human-centered manufacturing, particularly in SMEs. | Human behavior |

| [45] | Framework | Proposes a five-level roadmap for developing Human Body DTs for healthcare applications, addressing ethical and technical challenges. | Ergonomics and Safety |

| [46] | Framework | Proposes bridging NEP (a human-centered development framework intended to assist users and developers with diverse backgrounds and resources in constructing interactive human–machine systems) + and Robot Operating System (ROS) frameworks for developing human-centered systems in I5.0 applications. | Human- machine collaboration |

| [47] | Methodology | Extends DTs by integrating human characterization into Asset Administration Shell for improved operator well-being and resilience. | Human behavior |

| [48] | Methodology | Develops a method for generating auto-labeled datasets using DTs and Virtual Reality (VR) for human action recognition in human-robot collaboration. | Human behavior |

| [49] | Framework | Proposes an operator-centric DT architecture for composites production, emphasizing decision-making support. | HDT and Industry 5.0 |

| [50] | Methodology | Proposes self-adaptive software for CPSs using DTs to manage resilience and enable dynamic reconfiguration. | HDT and Industry 5.0 |

| [8] | Guideline | Describes a cost-effective IIoT thermal imaging system for enhancing safety in human-centered manufacturing. | HDT and Industry 5.0 |

| [51] | Framework | Proposes a framework integrating human factors into DT-based scheduling to improve safety, well-being, and productivity. | Human behavior |

| [52] | Model | Develops an HDT model to integrate human needs and decision-making into organizational environments. | Human behavior |

| [53] | Review | Explores the role of multi-sensory Human–Machine Interfaces (HMIs) in enabling human-centric DTs within the 6G industrial revolution. | Ergonomics and Safety |

| [13] | Framework | Proposes a unified HDT framework integrating physical and virtual twins to advance ergonomic analysis and real-time monitoring. | Ergonomics and Safety |

| [54] | Model | Proposes a model for bi-directional data transmission in human-centered Cyber-Physical Systems (CPS) for enhanced DT functionality. | HDT and Industry 5.0 |

| [33] | Model | Proposes an HDT system to improve worker safety and work management through real-time analysis. | Ergonomics and Safety |

| [55] | Review | Identifies technical, organizational, and methodological challenges in DT applications in manufacturing and proposes measures to enhance their effectiveness. | HDT and Industry 5.0 |

| [56] | Methodology | Develops a methodology to incorporate human factors data into DTs, enabling real-time task scheduling and ergonomic improvements. | Ergonomics and Safety |

| [12] | Review | Analyzes enabling technologies and methods for human-centric DTs, emphasizing human–machine collaboration in I5.0. | Human– machine collaboration |

| [57] | Methodology | Explores the use of VR-based interfaces in DTs to improve robot manipulation validation and user interaction in collaborative systems. | Ergonomics and Safety |

| [30] | Methodology | Introduces a methodology to digitize operator skills for integration into DTs, improving job rotation and performance management. | Human behavior |

| [58] | Review | Conducts a bibliometric analysis of DT applications in supply chains, highlighting trends and integration of AI and human-centric systems. | HDT and Industry 5.0 |

| [59] | Framework | Explores the concept of perioperative HDTs for individualized precision medicine, focusing on digital biomarkers and AI-driven care. | Human digital representation |

| [60] | Framework | Proposes a framework integrating DTs, VR, and IIoT into a human-centered industrial metaverse for collaboration and training. | Human– machine collaboration |

| [61] | Framework | Develops a DT framework emphasizing human–machine harmonization and real-time interaction to enhance manufacturing systems. | Human behavior |

| [62] | Methodology | Proposes an intelligent maintenance support system leveraging past maintenance data and DT technology for smart manufacturing. | Human behavior |

| [35] | Model | Introduces the concept and preliminary model of HDTs to integrate human elements into I4.0 systems. | Human digital representation |

| [63] | Methodology | Develops a Model-Based Definition (MBD) enabled DT modeling method to assist cognition in manual assembly processes for small-batch manufacturing. | HDT and Industry 5.0 |

| [64] | Framework | Proposes a framework for Ergonomics 4.0, integrating Digital Human Modelling (DHM) with I4.0 concepts for improved ergonomics. | Ergonomics and Safety |

| [65] | Review | Reviews the evolution of human representation in manufacturing systems, focusing on synchronization and well-being in advanced environments. | Human digital representation |

| [66] | Framework | Develops a framework for integrating human factors into smart factories, using monitoring systems to improve ergonomics and performance. | Ergonomics and Safety |

| [21] | Model | Proposes an AI-based model to enhance human-robot interaction, prioritizing safety, reliability, and human-centered design principles. | Human digital representation |

| [67] | Review | Explores the transformative potential of DTs in healthcare for personalized medicine, diagnostics, and treatment planning. | Human digital representation |

| [68] | Methodology | Introduces a method integrating DTs and XR for scalable industrial applications and system interoperation. | Ergonomics and Safety |

| [69] | Methodology | Proposes a semantic reasoning method using DTs for addressing safety challenges in human-centered manufacturing. | Ergonomics and Safety |

| [70] | Framework | Explores the concept and feasibility of HDTs for lifecycle health management, proposing a system architecture and implementation approach. | Human behavior |

| [24] | Review | Reviews advancements and challenges in human-centric smart manufacturing, focusing on the integration of I5.0 principles. | Human digital representation |

| [71] | Methodology | Proposes a method for dynamic task allocation between humans and robots to optimize production efficiency in intelligent manufacturing systems. | Human– machine collaboration |

| I4.0 Technologies | [8] | [25] | [49] | [50] | [54] | [55] | [58] | [63] | Tot |

|---|---|---|---|---|---|---|---|---|---|

| Additive manufacturing | - | ||||||||

| AR | - | ||||||||

| Autonomous robots | x | 1 | |||||||

| BDA | x | x | x | x | x | x | 6 | ||

| Cybersecurity | x | 1 | |||||||

| H/V system integration | x | x | x | 3 | |||||

| Simulation | x | x | x | x | x | x | x | x | 8 |

| The cloud | x | x | 2 | ||||||

| The IIoT | x | x | x | x | x | 5 |

| I4.0 Technologies | [12] | [41] | [42] | [46] | [60] | [71] | Tot |

|---|---|---|---|---|---|---|---|

| Additive manufacturing | - | ||||||

| AR | x | x | x | x | 4 | ||

| Autonomous robots | x | x | x | 3 | |||

| BDA | x | x | x | x | 4 | ||

| Cybersecurity | x | 1 | |||||

| H/V system integration | x | x | x | 3 | |||

| Simulation | x | x | x | x | x | x | 6 |

| The cloud | - | ||||||

| The IIoT | x | x | x | x | x | 5 |

| I4.0 Technologies | [30] | [44] | [47] | [48] | [51] | [52] | [61] | [62] | [70] | Tot |

|---|---|---|---|---|---|---|---|---|---|---|

| Additive manufacturing | - | |||||||||

| AR | x | x | x | x | 4 | |||||

| Autonomous robots | x | x | x | 3 | ||||||

| BDA | x | x | x | x | x | x | x | 7 | ||

| Cybersecurity | - | |||||||||

| H/V system integration | - | |||||||||

| Simulation | x | x | x | x | x | x | x | x | x | 9 |

| The cloud | x | 1 | ||||||||

| The IIoT | x | x | x | x | x | x | x | 7 |

| I4.0 Technologies | [13] | [26] | [33] | [43] | [45] | [53] | [56] | [57] | [64] | [66] | [68] | [69] | Tot |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Additive manufacturing | - | ||||||||||||

| AR | x | x | x | x | x | x | x | x | x | x | 10 | ||

| Autonomous robots | x | x | x | x | x | 5 | |||||||

| BDA | x | x | x | x | x | x | x | x | x | x | x | 11 | |

| Cybersecurity | x | 1 | |||||||||||

| H/V system integration | - | ||||||||||||

| Simulation | x | x | x | x | x | x | x | x | x | x | x | x | 12 |

| The cloud | x | x | x | 3 | |||||||||

| The IIoT | x | x | x | x | x | x | x | x | x | 9 |

| Psychological Health | Physiological Health | ||||||

|---|---|---|---|---|---|---|---|

| I4.0 Technologies | [21] | [24] | [35] | [65] | [59] | [67] | Tot |

| Additive manufacturing | - | ||||||

| AR | x | x | x | x | 4 | ||

| Autonomous robots | x | x | 2 | ||||

| BDA | x | x | x | x | x | 5 | |

| Cybersecurity | - | ||||||

| H/V system integration | - | ||||||

| Simulation | x | x | x | x | x | x | 6 |

| The cloud | x | 1 | |||||

| The IIoT | x | x | x | x | x | 5 | |

| HDT and Industry 5.0 | Human- Machine Collaboration | Human Behavior | Ergonomics and Safety | Human Digital Representation | Tot | |

|---|---|---|---|---|---|---|

| Type | ||||||

| Framework | 1 | 4 | 3 | 5 | 1 | 14 |

| Guideline | 1 | - | 1 | - | - | 2 |

| Methodology | 2 | 1 | 4 | 4 | - | 11 |

| Model | 1 | - | 1 | 1 | 2 | 5 |

| Review | 3 | 1 | - | 2 | 3 | 9 |

| I4.0 Technologies | ||||||

| Additive manufacturing | - | - | - | - | - | 0 |

| AR | - | 4 | 4 | 10 | 4 | 21 |

| Autonomous Robot | 1 | 3 | 3 | 5 | 2 | 14 |

| BDA | 6 | 4 | 7 | 11 | 5 | 32 |

| Cybersecurity | 1 | 1 | - | 1 | - | 3 |

| H/V system integration | 3 | 3 | - | - | - | 6 |

| Simulation | 8 | 6 | 9 | 12 | 6 | 41 |

| The cloud | 2 | - | 1 | 3 | 1 | 7 |

| The IIoT | 5 | 5 | 7 | 9 | 5 | 30 |

| Industry | ||||||

| Aerospace | 3 | - | - | - | - | 3 |

| Automotive | 2 | - | - | 1 | - | 3 |

| Healthcare | - | - | 1 | 1 | 2 | 4 |

| Hydropower | 1 | - | - | - | - | 1 |

| Manufacturing | 3 | 6 | 4 | 7 | 3 | 24 |

| Total articles | 8 | 6 | 9 | 12 | 6 | 41 |

| Top Industries | Relevant Literature | Type | I4.0 Technologies | |

|---|---|---|---|---|

| HDTs and Industry 5.0 | Aerospace, Automotive, Manufacturing | Literature discusses methodology integrating I5.0 principles into DTs, emphasizing operator decision-making [49,55]. | Review, Methodology | Simulation, IIoT, BDA |

| Human- machine collaboration | Manufacturing | Studies propose frameworks for immersive collaboration [60] and AR-based solutions for assembly and monitoring [46,71] | Framework, Methodology | Simulation, IIoT, AR |

| Human behavior | Manufacturing, Healthcare | Literature highlights methodologies for integrating IIoT and behavioral modeling [30,47,51] | Methodology, Framework | Simulation, IIoT, BDA |

| Ergonomics and Safety | Manufacturing, Automotive | Literature focuses on methodologies for integrating VR/AR to monitor safety and mitigate ergonomic risks [13,26,43] | Framework, Methodology | Simulation, BDA, AR |

| Human digital representation | Healthcare, Manufacturing | Studies address psychological and physiological HDTs for mental health and personalized care [35,59,65] | Review, Model | Simulation, BDA, AR |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bucci, I.; Fani, V.; Bandinelli, R. Towards Human-Centric Manufacturing: Exploring the Role of Human Digital Twins in Industry 5.0. Sustainability 2025, 17, 129. https://doi.org/10.3390/su17010129

Bucci I, Fani V, Bandinelli R. Towards Human-Centric Manufacturing: Exploring the Role of Human Digital Twins in Industry 5.0. Sustainability. 2025; 17(1):129. https://doi.org/10.3390/su17010129

Chicago/Turabian StyleBucci, Ilaria, Virginia Fani, and Romeo Bandinelli. 2025. "Towards Human-Centric Manufacturing: Exploring the Role of Human Digital Twins in Industry 5.0" Sustainability 17, no. 1: 129. https://doi.org/10.3390/su17010129

APA StyleBucci, I., Fani, V., & Bandinelli, R. (2025). Towards Human-Centric Manufacturing: Exploring the Role of Human Digital Twins in Industry 5.0. Sustainability, 17(1), 129. https://doi.org/10.3390/su17010129