Abstract

Volatile and semi-volatile compounds, such as petroleum hydrocarbons and equipment lubricating oils, often contaminate soil due to accidents, posing significant ecological and health risks. Traditional soil remediation methods, such as thermal desorption and bioremediation, are time-consuming and resource-intensive, prompting researchers to explore more efficient alternatives. This study investigates the effectiveness of an in situ reactor for microwave-assisted soil remediation, specifically focusing on the impact of soil type and moisture content on pollutant removal efficiency. The reactor, designed to operate within a modified household microwave oven, provides direct microwave irradiation to the soil surface, enabling precise control of heating conditions. Experiments were conducted using soil samples of varying particle sizes and moisture levels under standardized conditions (1000 W microwave power, 2.45 GHz frequency). The results show that moisture content plays a critical role in pollutant removal efficiency, with an optimal moisture content of 10 wt % enhancing microwave absorption and energy transfer, thus improving pollutant recovery. In comparison with traditional resistive heating, microwave heating achieved a faster temperature rise and higher final temperatures, significantly improving pollutant removal efficiency in a shorter time frame. This study highlights the advantages of microwave heating, including its superior energy efficiency, faster pollutant volatilization, and the potential for optimized soil remediation in real-world applications. These findings provide valuable insights for the development of more sustainable and efficient soil remediation technologies.

1. Introduction

Volatile and semi-volatile compounds, such as petroleum hydrocarbons, equipment lubricating oils, and mercury, frequently leak during various accidents. These compounds are challenging to degrade naturally, resulting in environmental pollution and significant harm to local ecosystems [1,2,3]. Additionally, pollutants like mineral oils found in transformers can cause severe ecological damage and health risks if not properly managed. Traditional soil remediation techniques, such as excavation, bioremediation, and chemical treatments, are often cost-prohibitive, time-consuming, and environmentally intrusive [4,5]. Consequently, there is growing interest in exploring more efficient and cost-effective soil purification methods. Recent studies have also shed light on the life cycle impacts of chemical spills on ecosystems. For instance, Cho et al. conducted a molecular-level analysis of soil contaminated by oil spilled during the Gulf War, revealing that in high-temperature, low-humidity environments, volatilization and oxidative degradation effects of the spilled oil were significant. However, even 30 years later, high-molecular-weight aromatic compounds showed incomplete chemical degradation, presenting challenges for ecosystem recovery [6]. With its unique ability to rapidly heat and volatilize pollutants, microwave heating has emerged as a promising soil remediation technology. Unlike conventional heating methods, microwaves can directly penetrate the soil, leading to volumetric heating. This process enhances pollutant desorption by uniformly and quickly increasing soil temperature, thereby reducing the time and energy required for effective remediation. Moreover, microwave heating can be precisely controlled, allowing for targeted treatment of contaminated areas [7,8].

Recently, microwave-assisted soil remediation has emerged as a promising alternative due to its energy efficiency and the potential for targeted heating, which accelerates the desorption of contaminants. For example, Falcoglia et al. [9] reported significant removal of diesel contaminants from sandy soil using microwave heating, achieving up to 95 wt % removal efficiency under optimized conditions. Similarly, Jiang et al. [10] highlighted the effectiveness of microwave heating in decomposing polycyclic aromatic hydrocarbons (PAHs) in clay, achieving rapid pollutant reduction with minimal energy consumption. A study by Zhang et al. [11] explored the use of microwave heating for remediating heavy metal-contaminated soil, demonstrating significant reductions in lead and cadmium concentrations while improving soil fertility. Chen et al. [12] provided a comprehensive review of thermal desorption for chlorinated organic pollutants in soil, emphasizing the potential of microwave heating in this domain. Additionally, Li et al. [13] investigated the combined effects of microwave heating and chemical reagents in degrading chlorinated hydrocarbons in agricultural soil, achieving a synergistic effect with higher degradation rates compared to traditional methods. The effectiveness of microwave heating for various other pollutants and soil size has also been evaluated. For instance, Robinson and Friedman [14] demonstrated that particle size distribution significantly affects the dielectric properties of soil, thereby influencing the efficiency of microwave heating. Liu et al. [15] demonstrated that microwave heating could effectively remove trichloroethylene (TCE) from loam soil, highlighting the potential of this technology for remediating volatile organic compounds (VOCs). Benitez et al. [16] conducted a comprehensive review of microwave-assisted remediation of hydrocarbon-contaminated soil, emphasizing the advantages of this technology in terms of efficiency and energy consumption. Recent advancements have further optimized microwave heating for soil remediation. For example, Chen et al. [17] explored the use of microwave heating combined with biochar to remediate PAH-contaminated soil, achieving enhanced degradation efficiency compared to microwave heating alone. Another study by Martinez et al. [18] investigated the effectiveness of microwave heating in the presence of various catalysts, such as iron oxides, demonstrating significant improvements in the decomposition of complex hydrocarbons. Furthermore, Tang et al. [19] emphasized the role of microwave heating in enhancing microbial degradation of pollutants, suggesting potential synergistic effects when combined with bioremediation techniques. Despite these advancements, the efficiency of microwave-assisted soil remediation is influenced by several factors, including soil type, moisture content, and the nature of the pollutants. Understanding these factors is crucial for optimizing the remediation process and achieving maximum pollutant removal. For instance, Smith et al. [20] demonstrated that higher moisture content in soil could enhance dielectric heating effects, thereby improving the efficiency of microwave-induced pollutant desorption. Similarly, Wang et al. [21] showed that different soil textures (sand, silt, clay) respond differently to microwave heating, affecting the overall remediation effectiveness. Lin et al. [22] found that microwave power and exposure time significantly influence the remediation efficiency of petroleum-contaminated soil, providing a basis for optimizing these parameters. Moreover, Luo et al. [23] demonstrated that combining microwave heating with chemical oxidation could effectively remediate PCB-contaminated soil, suggesting a synergistic approach for complex contaminant mixtures. Hu et al. [24] examined the effects of microwave heating on soil microbial communities and functions in petroleum-contaminated soil, revealing that microwave treatment could alter microbial dynamics and enhance biodegradation processes. Tan et al. [25] explored the use of microwave-induced vitrification for the remediation of heavy metal-contaminated soils, showing promising results in stabilizing and reducing metal mobility. Zhou et al. [26] applied microwave heating for the treatment of dioxin-contaminated soils, achieving significant contaminant reduction while maintaining soil quality. Xie et al. [27] investigated microwave-assisted soil vapor extraction for the removal of volatile organic compounds, demonstrating effective pollutant removal with potential for field-scale applications. However, existing studies on microwave-assisted soil remediation face certain limitations. Laboratory-based experiments often rely on expensive and complex instrumentation, which may not accurately reflect real-world conditions. On the other hand, field studies, though more representative of practical applications, are time-consuming and labor-intensive. Additionally, the presence of multiple variables in natural soils—such as different soil types, moisture contents, and pollutant characteristics—complicates the research process, making it challenging to draw clear conclusions regarding the optimal conditions for remediation.

This research aims to fill the existing knowledge gaps by designing a low-cost, in situ reactor for the controlled investigation of the effects of soil type, moisture content, and particle size on microwave-assisted soil remediation. Unlike conventional laboratory setups, this reactor is designed for real-world applicability, making it a valuable tool for future remediation applications. By exploring the role of these factors, the study investigates how they influence the efficiency of pollutant removal, offering insights into optimizing microwave heating for soil decontamination. While temperature is a key factor in the volatilization of pollutants during microwave treatment, it is not the only determinant of success. The physicochemical properties of contaminants, along with soil characteristics, also play critical roles in the overall remediation effectiveness. Through a series of controlled experiments, we aim to identify optimal conditions that maximize pollutant removal. The findings from this research will contribute to the development of cost-effective and scalable soil remediation strategies, particularly for industrial and oil-contaminated sites. Ultimately, this study provides valuable evidence for implementing microwave heating as a viable, sustainable alternative for environmental cleanup, enhancing the efficiency of soil remediation efforts.

2. Materials and Methods

2.1. Materials

Using a checkerboard sampling method, soil samples were collected from the top 5–10 cm of the surface layer to ensure homogeneity and consistency across sampling sites. The sampling area covered approximately 10 m², with multiple points sampled and combined to create a representative composite sample. The relevant physical properties of the soil are shown in Table 1. After removing gravel and other debris, the samples were air-dried in a cool, shaded area. The dried soil samples were then crushed and sieved through 120, 60, and 30 mesh screens, respectively, and thoroughly mixed. The processed samples were stored in a dark place to avoid light exposure. The three different particle sizes of soil are referred to as fine sand, medium sand, and coarse sand. Kunlun KI40DX transformer oil was used to simulate oil leakage from a transformer under real-world conditions. In our study, we selected the transformer oil concentration based on typical contamination levels observed in environments where transformer oil spills occur (approximately 10 wt %). Specifically, we aimed to simulate realistic contamination scenarios that are commonly encountered in industrial settings.

Table 1.

Parameters of on-site polluted soil in a certain area of Hebei Province.

2.2. Experimental Apparatus and Method

2.2.1. Experimental Equipment

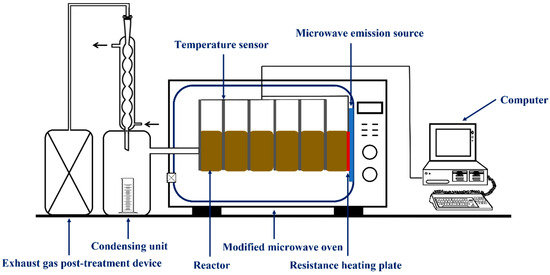

The experimental setup includes a modified household microwave oven (Midea Group, Foshan, China) as the microwave source, operating at a frequency of 2.45 GHz and a maximum power of 1000 W, with power levels adjustable for different experimental requirements [28]. A polytetrafluoroethylene (PTFE) reactor (30 cm length, 8 cm inner diameter) containing prepared soil samples, a power analyzer (WT-5000, Yokogawa Electric Corporation, Tokyo, Japan), a temperature controller (E5CC-800, Omron Corporation, Shanghai, China), and temperature sensors were used. Pollutant collection was facilitated using a spherical condenser and a graduated cylinder. To meet experimental needs, the oven cavity was modified by adding wave-absorbing materials to the inner walls to reduce reflection waves during the heating process. Two outlets were set on the left side of the cavity; one is equipped with a fan for ventilation, facilitating better temperature control inside the microwave oven. The other outlet connects to the reactor’s pipeline, equipped with a device to monitor the amount of gas evaporated from the soil during heating. This device comprises a spherical condenser, a graduated cylinder, and other components (Figure 1). Steam produced during heating condenses in the condenser and falls back into the graduated cylinder under gravity. Red dye powder, which is fully soluble in water but not in pollutants, is placed at the bottom of the graduated cylinder. This allows us to distinguish between the aqueous phase and the pollutant phase based on color changes and to calculate the liquid recovery rate during heating based on the known volumes of each phase. This design ensures effective recovery and analysis of the steam, enabling accurate assessment of water and pollutant recovery rates, thereby optimizing pollutant removal efficiency during the heating process.

Figure 1.

Schematic of microwave heating experimental setup.

Additionally, an outlet is set at the top of the oven cavity for signal line extraction. This modification ensures the safety and effectiveness of the experimental process while improving the efficiency and uniformity of microwave heating. With this setup, we can more precisely monitor and control the soil temperature, optimizing the pollutant removal process. The polytetrafluoroethylene (PTFE) reactor (soil column) is 30 cm in length with an inner diameter of 8 cm and an outer diameter of 8.5 cm. It is connected to the microwave oven cavity using screws, with the contact area being the microwave source (Figure 1, blue part). To facilitate more precise observation of the internal temperature changes in the reactor while ensuring the independence of compartments, the reactor is equally divided into six independent chambers, each 5 cm in length. A temperature sensor is inserted into the middle of each section, recording the temperature every 5 s. Additionally, sensors are placed inside the oven cavity to measure the internal temperature.

2.2.2. Experimental Methods

In our study, we focused on monitoring temperature changes during microwave heating to evaluate its impact on pollutant volatilization. Clean soil samples were placed in an oven at 100 °C for 24 h and allowed to cool to room temperature inside the oven. Subsequently, the dried soil was mixed with water, followed by mixing with transformer oil to prepare the required soil samples. The pollutant concentration in the soil used in the experiments was 10% (mass concentration), which was chosen based on prior studies and the typical pollutant levels encountered in contaminated sites. First, distilled water was gradually added to the dried soil samples in a predetermined ratio, stirring thoroughly until the desired moisture level was achieved. Next, transformer oil was gradually added to the moistened soil in the required proportion and stirred continuously to ensure thorough mixing until the sample was homogeneous. Finally, the treated soil samples were placed in clean, sealed containers to prevent evaporation and external contamination. These steps ensured that the prepared soil samples were uniform and met experimental requirements, simulating actual contamination scenarios and providing a reliable basis for subsequent experiments. Next, the prepared soil was filled into the reactor chambers, and the reactor was placed into the oven cavity to begin heating. Once heating starts, temperature sensors begin recording data, and the power analyzer is turned on. The maximum heating duration is 170 min. The microwave oven parameters remain constant across all experiments: power at 1000 W and frequency at 2.45 GHz. After heating, the reactor was cooled to room temperature before proceeding with subsequent processing to avoid further evaporation during sampling. Firstly, any foreign matter was removed from the sample. Approximately 10 g of the sample (accurate to 0.01 g) was weighed and placed in a mortar, adding an appropriate amount of anhydrous sodium sulfate to absorb moisture. Then, the prepared sample was transferred to a thimble, and the thimble was placed into a Soxhlet extractor. An amount of 100 mL of n-hexane was added as the extraction solvent, and the extraction was performed for 16–18 h with a reflux rate of 8–10 cycles per hour. After extraction, all the extract was cooled down, collected, transferred to a concentration apparatus, and concentrated to 1 mL. Finally, the concentrated extract was purified and analyzed using gas chromatography with a flame ionization detector (GC-FID). The removal efficiency can be calculated using Equation (1):

where X0 is the initial concentration of the contaminant in the soil, and Xi is the concentration of the contaminant in the soil after treatment. Additionally, we compared the effects of microwave heating and conductive heating under identical conditions. The specific experimental conditions and parameters are detailed in Table 2 [9,29].

Table 2.

Summary of the experiments conducted in the reactor.

3. Results and Discussion

3.1. Temperature Variation and Phase Transitions During Microwave Heating

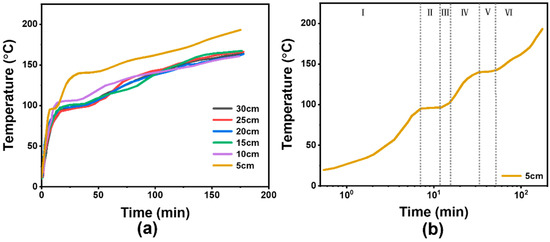

Figure 2a illustrates the temperature variation at different positions within the reactor during microwave heating under conditions of a certain soil oil content (10 wt %), soil moisture content (10 wt %), and medium-sized soil particles (medium sand). From the figure, it could be observed that the temperature at the position 5 cm away from the microwave source rose the fastest and reached the highest value. The temperature rose rapidly in the initial stage of heating and gradually leveled off after 50 min, eventually stabilizing between 150 °C and 200 °C. This indicated that the temperature distribution during microwave heating was uneven, mainly due to the complex behavior of the three-phase flow (water, gas, and pollutants) within the reactor [30]. To minimize the influence of these complex factors, we uniformly selected the temperature probe closest to the microwave source (5 cm from the heat source) for the study of temperature variation parameters. This approach helped to analyze the fluctuations and changes in temperature more precisely during microwave heating. Figure 2b shows the temperature variation in the first temperature sensor located 5 cm from the heat source. Based on the temperature variation trend, the temperature changes in the soil inside the reactor were divided into six distinct stages [9,11,14]:

Figure 2.

Soil temperature variation during microwave heating: (a) Temperature variations at different distances from the microwave source. (b) Temperature variation at 5 cm distance from the microwave source.

- Initial Heating Stage: During this stage, the temperature rise rate was the highest.

- Transition Stage: As the temperature approached the boiling point of water, it briefly stabilized just below 100 °C due to impurities present in the soil. The temperature then stabilized around 100 °C until most of the water in the soil evaporated. During this phase, the temperature did not exceed 100 °C.

- Stable Transition Stage Related to the Latent Heat of Vaporization of Water: The stabilization of temperature was associated with the latent heat of vaporization of water. This phenomenon was accompanied by an increase in pressure within the soil column, releasing a mixture of water vapor and pollutants.

- Drying and Heating Stage: After the water in the soil had completely evaporated, the temperature began to rise above 100 °C. At this stage, only mineral oil vapor was released from the reactor outlet.

- Pollutant Evaporation Stage: The second stable transition zone was related to the latent heat of vaporization of the mineral oil. During this stage, the temperature did not exceed 150 °C until most of the mineral oil in the soil had evaporated.

- Final Heating Stage: When there was no water or pollutants left in the soil, the temperature rose again but at a slower rate.

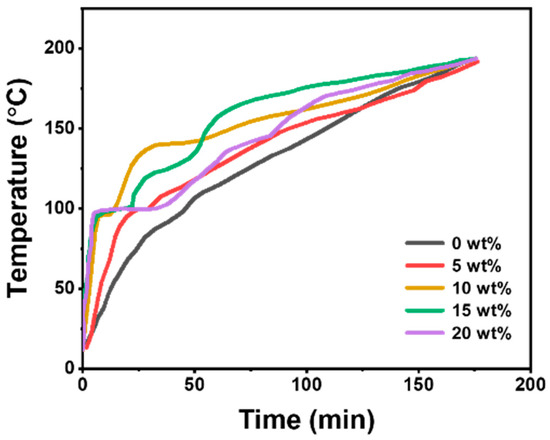

3.2. Effect of Soil Moisture Content

To study the effect of moisture content on the removal rate of soil pollutants, the same medium sand soil was used, with moisture content adjusted to 0 wt %, 5 wt %, 10 wt %, 15 wt %, and 20 wt %. Meanwhile, the mineral oil content was fixed at 10 wt %, and the heating duration was set at 170 min. Figure 3 shows the soil temperature variation at 5 cm from the microwave source under different moisture contents. It was observed that increasing the water content led to a higher heating rate of up to 100 °C. However, as the water content continued to increase (greater than 10 wt %), the soil heating rate tended to stabilize. For example, samples with more than 10 wt % moisture content reached 100 °C in 7 min, while samples with 0 wt % and 5 wt % moisture content took 46 min and 25 min, respectively, to reach 100 °C. By the end of the experiment, all temperature curves converged, approaching 175 °C. The enhanced heating efficiency in soils with higher moisture content can be attributed to the interaction between microwaves and water molecules. Microwaves induce the rotation of polar water molecules, generating heat through dipole friction. This process increases the dielectric loss factor of the soil, allowing it to absorb microwave energy more effectively. At higher moisture levels, the soil exhibits greater dielectric loss, resulting in rapid heating up to the boiling point of water. However, beyond a certain moisture threshold, excessive water reduces pore space, leading to steam transmission inefficiency and a temporary temperature plateau due to energy consumption in water evaporation rather than heating contaminants [11,12,13,14,15,16,17,18,19]. Increasing the water saturation from 10% to 20% led to a longer temperature stabilization time at 100 °C. This stabilization occurred because, at the boiling point of water, all the microwave energy was used for the phase change process rather than for increasing the temperature, resulting in a temperature plateau. Another reason was that higher water content filled more soil pore spaces, reducing steam transmission efficiency and evaporation. In contrast, dry medium particle soil did not exhibit a temperature plateau at 100 °C. Hydrocarbons also interact with microwaves, albeit less directly than water. The heat generated within the soil matrix aids in breaking intermolecular bonds in hydrocarbons, enhancing their volatilization. Moreover, the steam-driving effect from water evaporation promotes the movement of hydrocarbons toward the soil surface for extraction [29,31].

Figure 3.

Temperature variation during microwave heating of soils with different moisture contents.

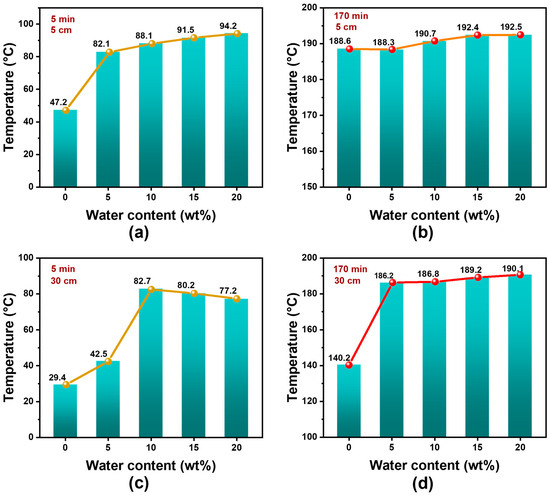

To further investigate the relationship between moisture content and temperature variation within the soil column, Figure 4 depicts the relationship between different heating times (5 min and 170 min) and the distance from the microwave heat source for soils with varying moisture content. At 5 cm from the microwave heat source (Figure 4a,b), in a short heating time, the temperature increased more significantly with increasing moisture content. However, for longer heating durations, the influence of moisture content on temperature variation was less pronounced. Compared to the contaminated soil with 0 wt % moisture content, the temperature distribution of contaminated soils with more than 10 wt % moisture content was more uniform at the end of the heating process. For soil with 20 wt % moisture content, the first section of the reactor reached 94.2 °C within just 5 min. For soil samples located further from the microwave heat source (30 cm) (Figure 4c,d), the soil temperature peaked at 10 wt % moisture content and then started to decline. This was because higher moisture content enhanced microwave absorption by the soil, leading to significant microwave absorption by water. Consequently, the transmission rate of microwaves was relatively lower, and the heat transfer (convection) of steam within the pores was reduced. However, for longer heating durations, the temperature curve for 20 wt % moisture content showed higher temperatures [7,14]. By comparing Figure 4b,d, it can be observed that when the moisture content is 0%, the temperature at 30 cm from the microwave heat source after 170 min of exposure is only around 140 °C. In contrast, in Figure 4b, the temperature at 5 cm from the microwave heat source reaches approximately 188 °C after 170 min of exposure. This indicates that during the microwave heating process, the radiation intensity decreases sharply with distance. According to the inverse square law of microwave radiation, the intensity of radiation is inversely proportional to the square of the distance. Therefore, the farther the distance from the microwave source, the less energy is received. The significant difference in radiation intensity between the 5 cm and 30 cm positions directly results in the observed temperature difference. Furthermore, in this study, when the sample’s moisture content is 0%, the absorption capacity of hydrocarbons is relatively low. Compared to water molecules, hydrocarbons lack distinct polarity, and as a result, their absorption efficiency of microwave radiation is much lower, leading to insufficient heat absorption by the sample. This explains why the temperature remains relatively low (around 140 °C) after 170 min of exposure at 30 cm, while at 5 cm, the temperature reaches approximately 188 °C.

Figure 4.

Relationship between soil moisture content and distance from the microwave heat source at different heating times. Subfigures: (a) 5 min, 6 cm; (b) 170 min, 6 cm; (c) 5 min, 30 cm; (d) 170 min, 30 cm.

Figure 5 illustrates the remediation efficiency of microwave thermal desorption under different heating times and soil moisture contents, calculated using Equation (1). It is evident from the figure that increasing soil moisture content significantly enhanced pollutant recovery efficiency. For medium-grain soil samples, the removal rates at 0% and 10% water saturation were 36.1% and 91.3%, respectively, highlighting the positive impact of moisture on microwave-assisted remediation. These findings align with those of Falciglia et al. [9], which indicated that increasing the moisture content from 10 wt % to 20 wt % improved the pollutant recovery rate. However, the increase became marginal beyond 10%, suggesting diminishing returns with higher moisture levels. This phenomenon can be attributed to the different temperature-dependent processes of water vaporization and pollutant volatilization. As moisture content increased, more water was converted into steam during heating, which facilitated the volatilization and removal of contaminants. Water vaporization occurs first, around 100 °C, where it absorbs heat and slows down the temperature increase. Pollutants, on the other hand, begin to volatilize at higher temperatures, typically around 150 °C. Therefore, the effect of water content on pollutant removal is primarily observed after the water has fully vaporized. Once the water has evaporated, the temperature can rise further, allowing for more efficient pollutant volatilization.

Figure 5.

The relationship between the removal rate of soil pollutants with different moisture contents and heating times.

However, excessively high moisture content did not significantly enhance the removal efficiency, even though water occupies the soil pores and evaporates after approximately 20 min of heating, exposing the pores. This phenomenon can be attributed to several factors. While the water evaporates relatively quickly, the energy provided by microwave heating is primarily consumed in the evaporation process, causing a temporary stabilization of temperature around 100 °C. During this period, the temperature is not high enough to efficiently volatilize pollutants, which typically requires temperatures around 150 °C. Once the water has vaporized, the pores are indeed exposed. However, the excess water in the pores during the initial stages of heating has already caused a delay in the heating of the soil and the pollutants. This results in a slower temperature rise, which affects the overall volatilization process. Additionally, when the water content is too high, the steam generated during evaporation may create excessive pressure in the pores, further hindering the effective volatilization and removal of contaminants. Therefore, although the pores are exposed after the water evaporates, the delayed heating and the early consumption of energy by water evaporation still negatively impact the final pollutant removal efficiency. The effect of high moisture content is most pronounced when the water has not yet fully evaporated, as it impedes the temperature increase necessary for effective pollutant volatilization.

3.3. The Influence of Soil Size

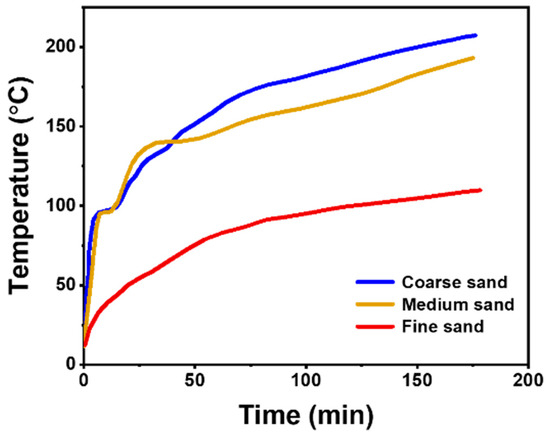

In this experiment, different soil sizes (fine sand, medium sand, and coarse sand) were tested under fixed conditions of 10 wt % water content and 10 wt % mineral oil content. During the experiment, the soil moisture content at 5 cm from the microwave source was kept constant, and the temperature variations for different soil sizes were observed. Figure 6 shows the temperature variations for different soil sizes (fine sand, medium sand, and coarse sand). Particle size significantly impacts microwave heating efficiency. Larger soil particles increase pore size and permeability, facilitating the escape of steam and hydrocarbons. Additionally, larger particles generally exhibit higher thermal capacity and dielectric constant, allowing more efficient absorption and retention of microwave energy. In contrast, finer particles tend to trap steam and contaminants due to higher capillary pressure, reducing the efficiency of contaminant desorption [32,33]. Consequently, the transition zone was longer in smaller particle soils. Under the same conditions, it was found that microwave heating was more effective in coarse sand than in medium sand and fine sand, indicating that the coarser the grains, the higher the efficiency of microwave heating. Additionally, increasing soil particle size improved its relative dielectric constant.

Figure 6.

Temperature variation during microwave heating of soils with different soil sizes.

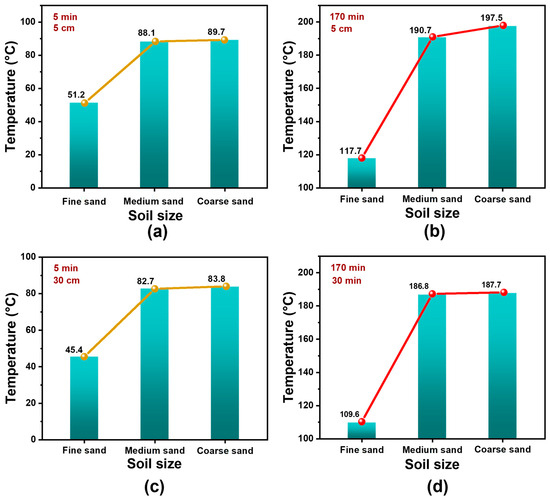

Figure 7 demonstrates the characteristics of temperature variation in different soil sizes at various heating times. The results indicated that at t = 5 min, the temperature increased with the soil particle size, and this trend remained consistent after heating for 170 min. Larger soil particles achieved higher temperatures during the heating process regardless of whether the heating duration was short (5 min) or long (170 min). This was likely because larger soil particles had a higher thermal capacity, allowing them to absorb and retain more heat. Instead, the enhanced absorption of microwave energy by smaller particles, the improved heat transfer within the soil, and surface volatilization all contribute to the removal process [34,35]. Therefore, soil particle size significantly impacted temperature rise, and this effect was consistent across different heating durations.

Figure 7.

Relationship between soil size and distance from the microwave heat source at different heating times. Subfigures: (a) 5 min, 6 cm; (b) 170 min, 6 cm; (c) 5 min, 30 cm; (d) 170 min, 30 cm.

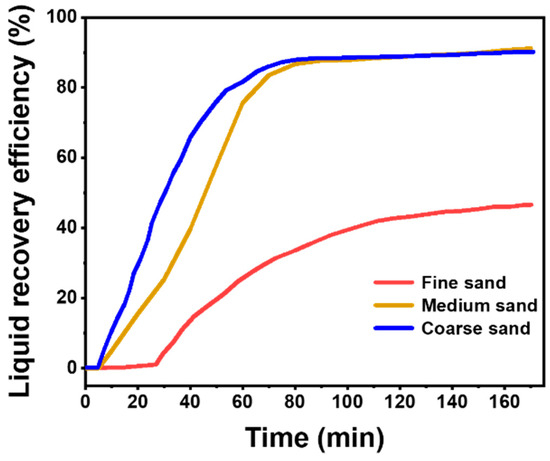

Figure 8 illustrates the impact of particle size on pollutant removal efficiency. While the boiling point of the pollutants is around 138–142 °C, the temperature in fine sand, as shown in Figure 7, only reaches about 100 °C. Despite this, approximately 40% of the pollutants are still removed. This can be attributed to several factors beyond just temperature. Smaller soil particles have a higher surface area-to-volume ratio, which leads to more efficient absorption of microwave energy, resulting in greater energy transfer to the soil and pollutants. This increased energy can create localized hotspots that are sufficient to volatilize some pollutants, even if the average temperature is below their boiling point. Additionally, the smaller particle size improves the heat transfer efficiency within the soil, allowing for effective heat distribution, which aids in pollutant volatilization at temperatures lower than their boiling point. Fine sand’s larger surface area also facilitates surface volatilization, where pollutants can desorb or evaporate from the particle surfaces, contributing to the overall pollutant removal efficiency. Therefore, the removal of pollutants in fine sand is not solely dependent on reaching the boiling point of the pollutants; instead, it is driven by a combination of enhanced microwave energy absorption, improved heat transfer, and surface volatilization, allowing for significant pollutant removal even at lower temperatures.

Figure 8.

Liquid recovery rate of soils of different sizes.

3.4. Recovery Efficiency

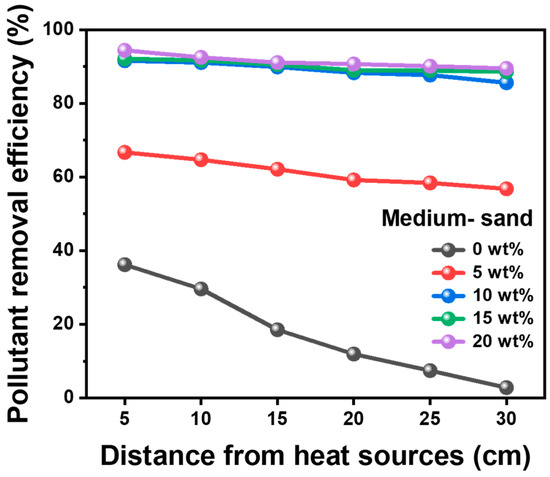

Figure 9 shows the removal efficiency of different soil samples with varying moisture contents and distances from the microwave source after 170 min of heating. It was evident that the pollutant removal rate decreased with increasing distance from the heat source for all samples. There was a significant difference in efficiency between moist and dry samples. Soil with 10 wt % moisture content still had a removal rate of 85.2% at 30 cm from the microwave source, while soil with 0 wt % moisture content had only 2.8%. This low efficiency in dry soil samples was primarily due to two reasons: there was no liquid water at the outlet to help push the pollutants out, and the reactor temperature was just below the boiling point of the pollutants (138–142 °C). In the absence of a pressure gradient, pollutant vapor was transported only through a slow diffusion mechanism, requiring longer heating times to improve efficiency [36]. Despite these factors, they did not affect the overall trend or our analysis of how parameters influenced temperature distribution and efficiency. These results still provided important insights into soil remediation efficiency and temperature distribution during microwave heating.

Figure 9.

Removal efficiency of medium sand-contaminated soil with different moisture contents after heating for 170 min.

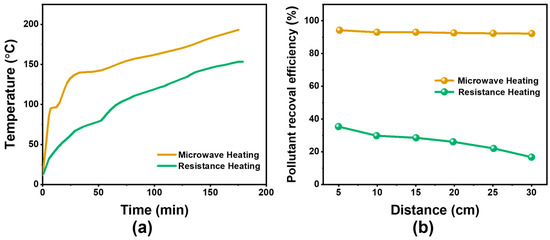

3.5. Comparison Between Microwave Heating and Resistance Heating

We compared the effects of microwave heating and conductive heating at 5 cm from the heat source on medium-grained soil with 10 wt % moisture content and 10 wt % pollutant content. The soil samples were subjected to microwave heating and resistive heating, with the resistance wire set at 200 °C for 170 min. As shown in Figure 10a, under the same conditions, microwave heating resulted in a faster temperature rise and higher final temperatures after 170 min of heating. However, the significantly higher pollutant removal efficiency observed in microwave heating, despite the similar temperature values, suggests that temperature alone is not the sole factor influencing pollutant removal. Microwave heating operates through dielectric heating, where the electromagnetic field interacts with polar molecules, such as water, causing them to rotate and generate heat throughout the entire sample. This volumetric heating allows the soil to heat uniformly and rapidly. In contrast, resistive heating relies on heat conduction, transferring heat from the surface to the inner layers, resulting in slower and more uneven heating. Although the temperature in both methods might be similar, the uneven temperature distribution in resistive heating reduces its effectiveness, especially in deeper layers where the temperature remains lower, hindering the volatilization and removal of contaminants. The superior performance of microwave heating is due to its ability to directly heat water and other polar molecules, leading to more effective pollutant desorption and volatilization. This high energy transfer efficiency ensures that more energy is directed toward the contaminants, improving their removal even at similar temperatures compared to resistive heating. Therefore, the significantly higher pollutant removal efficiency in microwave heating is not solely due to higher temperature but is largely attributed to the uniform heating and efficient energy transfer that facilitates more effective volatilization of pollutants [31,37,38].

Figure 10.

(a) Temperature variations at different heating methods. (b) Removal efficiency of soil contaminated with different heating methods after heating for 170 min.

Figure 10b compares the pollutant removal efficiency and energy consumption of microwave and resistive heating methods. The results demonstrate that microwave heating achieves a significantly higher removal efficiency (approximately 96%) compared to resistive heating (around 65%) under identical conditions. Moreover, the energy consumption per unit of pollutant removed is considerably lower for microwave heating (15 Wh) than for resistive heating (23 Wh). This highlights the superior energy efficiency of microwave-assisted remediation. Traditional resistive heating has been widely used for thermal desorption but suffers from inefficiencies such as uneven heating, extended treatment durations, and significant energy consumption. Our previous study demonstrated that microwave-assisted thermal desorption offers superior performance, achieving higher removal rates of mineral oil at lower temperatures and shorter durations. Additionally, microwave heating preserved soil’s organic matter and cation exchange capacity better than resistive heating, highlighting its potential as a more energy-efficient and environmentally friendly alternative [37].

4. Conclusions

This study presents a comprehensive investigation into the application of microwave-assisted soil remediation using a newly designed in situ reactor. The key findings and contributions of this research are summarized as follows:

- (1)

- Design of an In Situ Reactor: A novel in situ reactor was designed and implemented to investigate the effects of microwave heating on soil contamination. This reactor, integrated with a modified household microwave oven, allows for precise control of microwave energy and direct heating of soil samples, making it a valuable tool for future remediation applications in real-world environments.

- (2)

- Impact of Soil Moisture Content on Contamination Removal: The study demonstrates that soil moisture content significantly influences the efficiency of pollutant removal. An optimal moisture content of 10 wt % was identified, which enhances microwave absorption and energy transfer, leading to higher pollutant recovery rates. Excessive moisture, however, beyond 20 wt %, resulted in diminished returns, as excess water reduced the effectiveness of pollutant volatilization.

- (3)

- Influence of Soil Particle Size: Soil particle size was found to have a substantial impact on the heating efficiency and the removal of contaminants. Larger soil particles with higher thermal capacity and dielectric constant exhibited better absorption of microwave energy, facilitating faster volatilization and improved pollutant removal. In contrast, smaller particles, although they had a higher surface area for absorption, exhibited less efficient heat retention, leading to reduced pollutant volatilization.

- (4)

- Comparison with Conventional Resistance Heating: A direct comparison between microwave heating and traditional resistance heating revealed significant differences in performance. Microwave heating not only achieved a faster temperature rise but also resulted in higher final temperatures and greater overall pollutant removal efficiency. The uniformity and rapid heating capability of microwave energy make it a superior alternative to resistance heating, which suffers from slower, less uniform heat transfer.

This study highlights the potential of microwave-assisted remediation as a highly efficient, sustainable, and cost-effective method for soil decontamination. The findings provide valuable insights into optimizing microwave heating parameters for real-world applications, paving the way for future research on large-scale environmental cleanup using microwave technology.

Author Contributions

Writing—original draft, J.X.; Writing—review & editing, S.L. and C.C. All authors have read and agreed to the published version of the manuscript.

Funding

Science and Technology Project of State Grid (5204DY1900A).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Gao, H.; Wu, M.; Liu, H.; Xu, Y.; Liu, Z. Effect of petroleum hydrocarbon pollution levels on the soil microecosystem and ecological function. Environ. Pollut. 2022, 293, 118511. [Google Scholar] [CrossRef] [PubMed]

- Darwesh, O.M.; Shalaby, M.A.; Gharieb, M.M.; Matter, I.A. Application of the novel Cu-resistant fungus Aspergillus niger A3 in bioremoval of Cu-NPs from its aqueous solutions. OpenNano 2023, 14, 100187. [Google Scholar] [CrossRef]

- Pabón, R.E.C.; de Souza Filho, C.R.; de Oliveira, W.J. Reflectance and imaging spectroscopy applied to detection of petroleum hydrocarbon pollution in bare soils. Sci. Total Environ. 2019, 649, 1224–1236. [Google Scholar] [CrossRef] [PubMed]

- Darwesh, O.M.; Li, H.; Matter, I.A. Nano-bioremediation of textile industry wastewater using immobilized CuO-NPs myco-synthesized by a novel Cu-resistant Fusarium oxysporum OSF18. Environ. Sci. Pollut. Res. 2023, 30, 16694–16706. [Google Scholar] [CrossRef]

- Abdelhameed, R.M.; Darwesh, O.M.; El-Shahat, M. Titanium-based metal-organic framework capsulated with magnetic nanoparticles: Antimicrobial and photocatalytic degradation of pesticides. Microporous Mesoporous Mater. 2023, 354, 112543. [Google Scholar] [CrossRef]

- Cho, E.; Park, M.; Hur, M.; Kang, G.; Kim, Y.H.; Kim, S. Molecular-level investigation of soils contaminated by oil spilled during the Gulf War. J. Hazard. Mater. 2019, 373, 271–277. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wei, M.; Yu, B.; Liu, L.; Xue, Q. Thermal desorption optimization for the remediation of hydrocarbon-contaminated soils by a self-built sustainability evaluation tool. J. Hazard. Mater. 2022, 436, 129156. [Google Scholar] [CrossRef] [PubMed]

- O’Brien, P.L.; DeSutter, T.M.; Casey, F.X.; Khan, E.; Wick, A.F. Thermal remediation alters soil properties—A review. J. Environ. Manag. 2018, 206, 826–835. [Google Scholar] [CrossRef] [PubMed]

- Falciglia, P.P.; Urso, G.; Vagliasindi, F.G. Microwave heating remediation of soils contaminated with diesel fuel. J. Soils Sediments 2013, 13, 1396–1407. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, Z.; Wang, Q.; Li, Y. Decomposition of polycyclic aromatic hydrocarbons in clay soils using microwave heating. Environ. Sci. Technol. 2020, 54, 7421–7429. [Google Scholar]

- Zhang, H.; Wang, J.; Sun, Y. Application of microwave heating for the remediation of heavy metal-contaminated soils. J. Hazard. Mater. 2022, 422, 126838. [Google Scholar]

- Chen, Z.; Chen, Z.; Li, Y.; Zhang, R.; Liu, Y.; Hui, A.; Cao, W.; Liu, J.; Bai, H.; Song, J. A review on remediation of chlorinated organic contaminants in soils by thermal desorption. J. Ind. Eng. Chem. 2023, 133, 112–121. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Xu, J. Synergistic effects of microwave heating and chemical agents on the degradation of chlorinated hydrocarbons in agricultural soils. Chemosphere 2021, 273, 128545. [Google Scholar]

- Robinson, D.A.; Friedman, S.P. Effect of particle size distribution on the effective dielectric permittivity of saturated granular media. Water Resour. Res. 2001, 37, 33–40. [Google Scholar] [CrossRef]

- Liu, C.; Xu, X.; Wu, D. Microwave remediation of trichloroethylene-contaminated loamy soils. Environ. Pollut. 2019, 254, 113027. [Google Scholar]

- Benitez, J.; Real, M.; Garcia, A. Microwave-assisted remediation of hydrocarbon-contaminated soils: A review. J. Environ. Chem. Eng. 2018, 6, 895–908. [Google Scholar]

- Chen, X.; Wang, Y.; Tang, Z. Enhanced degradation of PAHs in soil using microwave heating combined with biochar. Environ. Res. 2023, 216, 114320. [Google Scholar]

- Martinez, J.A.; Lopez, M.; Green, P. Catalytic effects of iron oxides on microwave-assisted remediation of hydrocarbon-contaminated soils. J. Hazard. Mater. 2021, 414, 125522. [Google Scholar]

- Tang, J.; Yang, H.; Zhang, H. Synergistic effects of microwave heating and microbial degradation for the remediation of petroleum-contaminated soil. Sci. Total Environ. 2020, 722, 137873. [Google Scholar]

- Smith, S.E.; Taylor, R.; Jones, D. Impact of soil moisture on microwave remediation efficiency. J. Environ. Manag. 2017, 203, 1008–1015. [Google Scholar]

- Wang, Q.; Jiang, Y.; Li, Z. Influence of soil texture on the efficiency of microwave heating for soil remediation. J. Environ. Sci. 2020, 95, 160–169. [Google Scholar]

- Lin, D.; Li, S.; Zhou, Y. Influence of microwave power and exposure time on the remediation efficiency of petroleum-contaminated soil. Environ. Pollut. 2020, 258, 113662. [Google Scholar]

- Luo, L.; Zhang, M.; Wu, J. Microwave heating combined with chemical oxidation for the remediation of PCB-contaminated soil. Chemosphere 2019, 235, 517–525. [Google Scholar]

- Hu, X.; Tang, J.; Zhou, X. Effects of microwave heating on soil microbial community and function in petroleum-contaminated soil. J. Hazard. Mater. 2020, 385, 121551. [Google Scholar]

- Tan, Z.; Qin, Z.; Li, Y. Remediation of heavy metal-contaminated soil by microwave-induced vitrification. J. Environ. Sci. 2019, 85, 140–148. [Google Scholar]

- Zhou, W.; Zhang, C.; Li, S. Application of microwave heating for the treatment of dioxin-contaminated soils. J. Hazard. Mater. 2022, 428, 128295. [Google Scholar]

- Xie, Y.; Li, H.; Wang, M. Microwave-assisted soil vapor extraction for volatile organic compound removal. J. Environ. Chem. Eng. 2021, 9, 106224. [Google Scholar]

- Dong, Y.; McCartney, J.S.; Lu, N. Critical review of thermal conductivity models for unsaturated soils. Geotech. Geol. Eng. 2015, 33, 207–221. [Google Scholar] [CrossRef]

- Davarzani, H.; Cochennec, M.; Djigo, O.A.; Menard, Y.; Colombano, S. Influence of water saturation and soil properties on the removal of organic pollutants using microwave heating. J. Contam. Hydrol. 2022, 251, 104095. [Google Scholar] [CrossRef] [PubMed]

- Kok, L.P.; Boon, M.E.; Smid, H.M. The problem of hot spots in microwave equipment used for preparatory techniques—Theory and practice. Scanning 1993, 15, 100–109. [Google Scholar] [CrossRef]

- Lee, J.Y.; Lee, H.M.; Kim, B.J. Facile microwave treatment of activated carbons and its effects on hydrocarbon adsorption/desorption behaviors. Carbon Lett. 2023, 33, 1105–1114. [Google Scholar] [CrossRef]

- Messai, S.; Sghaier, J.; El Ganaoui, M.; Chrusciel, L.; Gabsi, S. Low-pressure superheated steam drying of a porous media. Dry. Technol. 2015, 33, 103–110. [Google Scholar] [CrossRef]

- Verma, A.K. Effects of Phase Transformation of Steam-Water Relative Permeabilities. 1986. Available online: https://escholarship.org/uc/item/34k479v4 (accessed on 1 November 2024).

- Farouki, O.; Farouki, O. Thermal Properties of Soils; US Army Corps of Engineers, Cold Regions Research and Engineering Laboratory: Hanover, NH, USA, 1981; Volume 81.

- Li, H.; Zhao, Z.; Xiouras, C.; Stefanidis, G.D.; Li, X.; Gao, X. Fundamentals and applications of microwave heating to chemicals separation processes. Renew. Sustain. Energy Rev. 2019, 114, 109316. [Google Scholar] [CrossRef]

- Xu, J.; Liu, S.; Chen, C. A Comparative Study of Microwave and Resistance Heating for the Efficient Thermal Desorption of Mineral Oil from Contaminated Soils. Sustainability 2024, 16, 8222. [Google Scholar] [CrossRef]

- Falciglia, P.P.; Roccaro, P.; Bonanno, L.; De Guidi, G.; Vagliasindi, F.G.; Romano, S. A review on the microwave heating as a sustainable technique for environmental remediation/detoxification applications. Renew. Sustain. Energy Rev. 2018, 95, 147–170. [Google Scholar] [CrossRef]

- Jones, D.A.; Lelyveld, T.P.; Mavrofidis, S.D.; Kingman, S.W.; Miles, N.J. Microwave heating applications in environmental engineering—A review. Resour. Conserv. Recycl. 2002, 34, 75–90. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).