Theoretical Framework for Virtual Logistics Centers Creation

Abstract

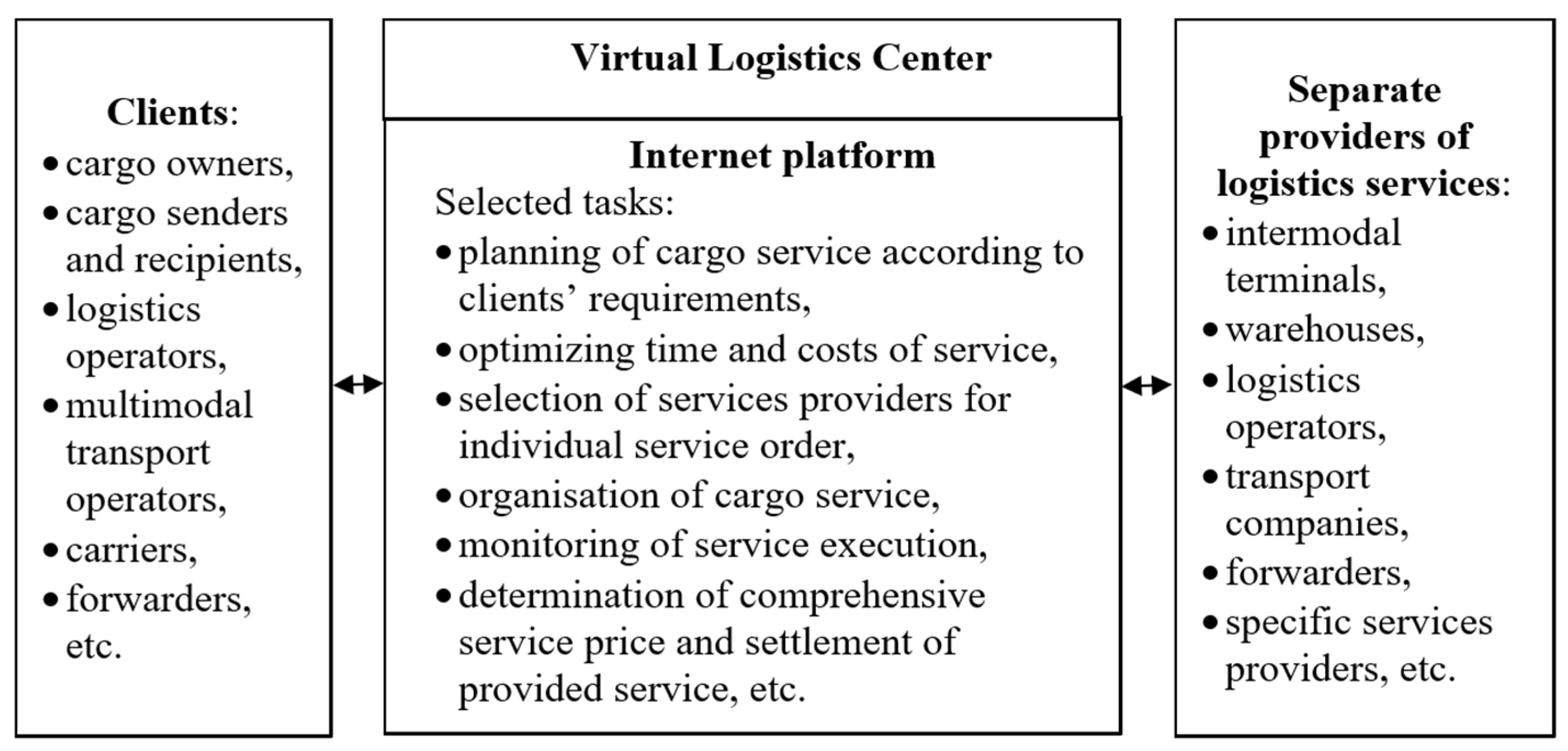

1. Introduction

2. Literature Review

- Flow of products or services;

- Flow of information regarding the products or services;

- Financial transactions related to the products or services.

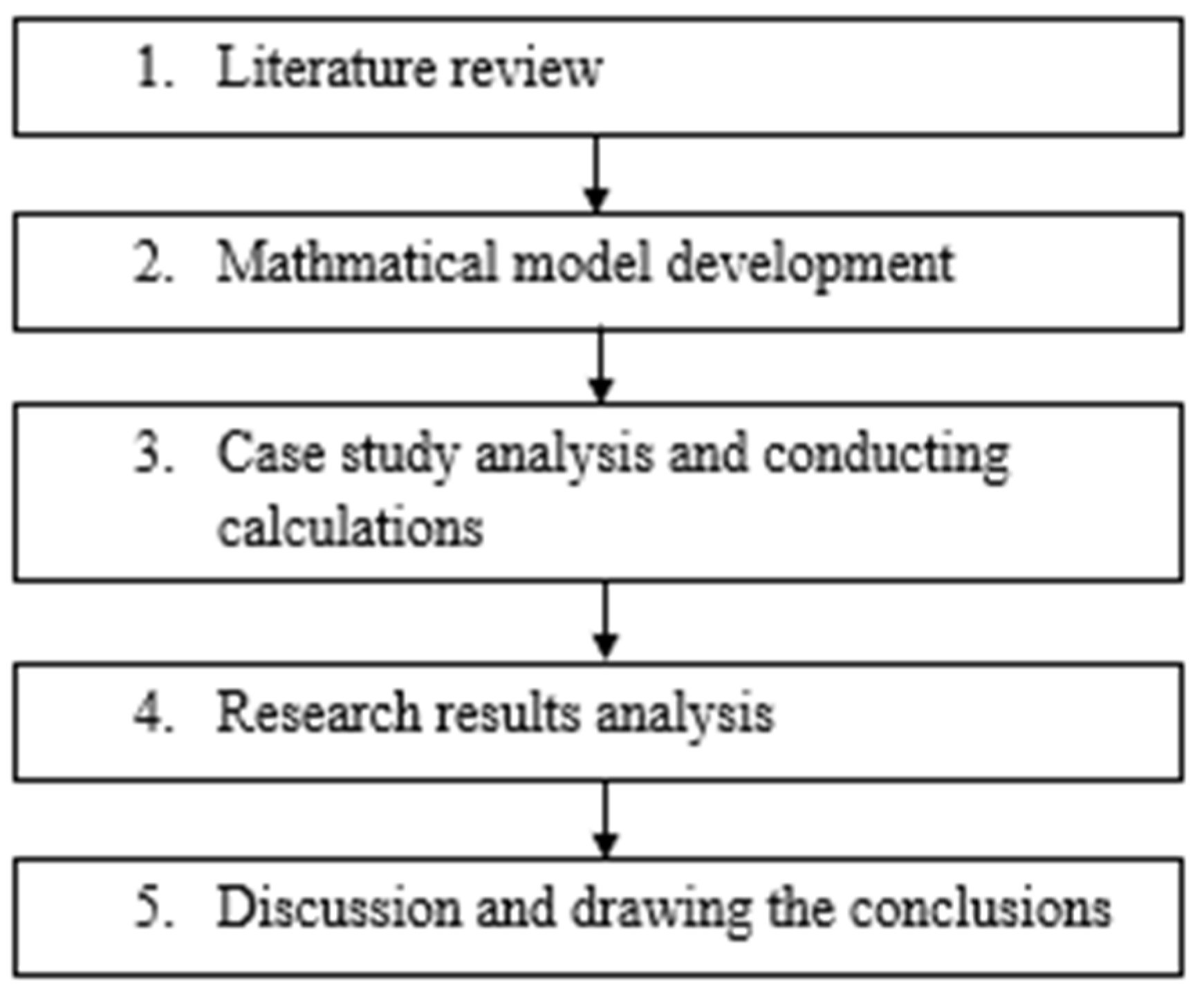

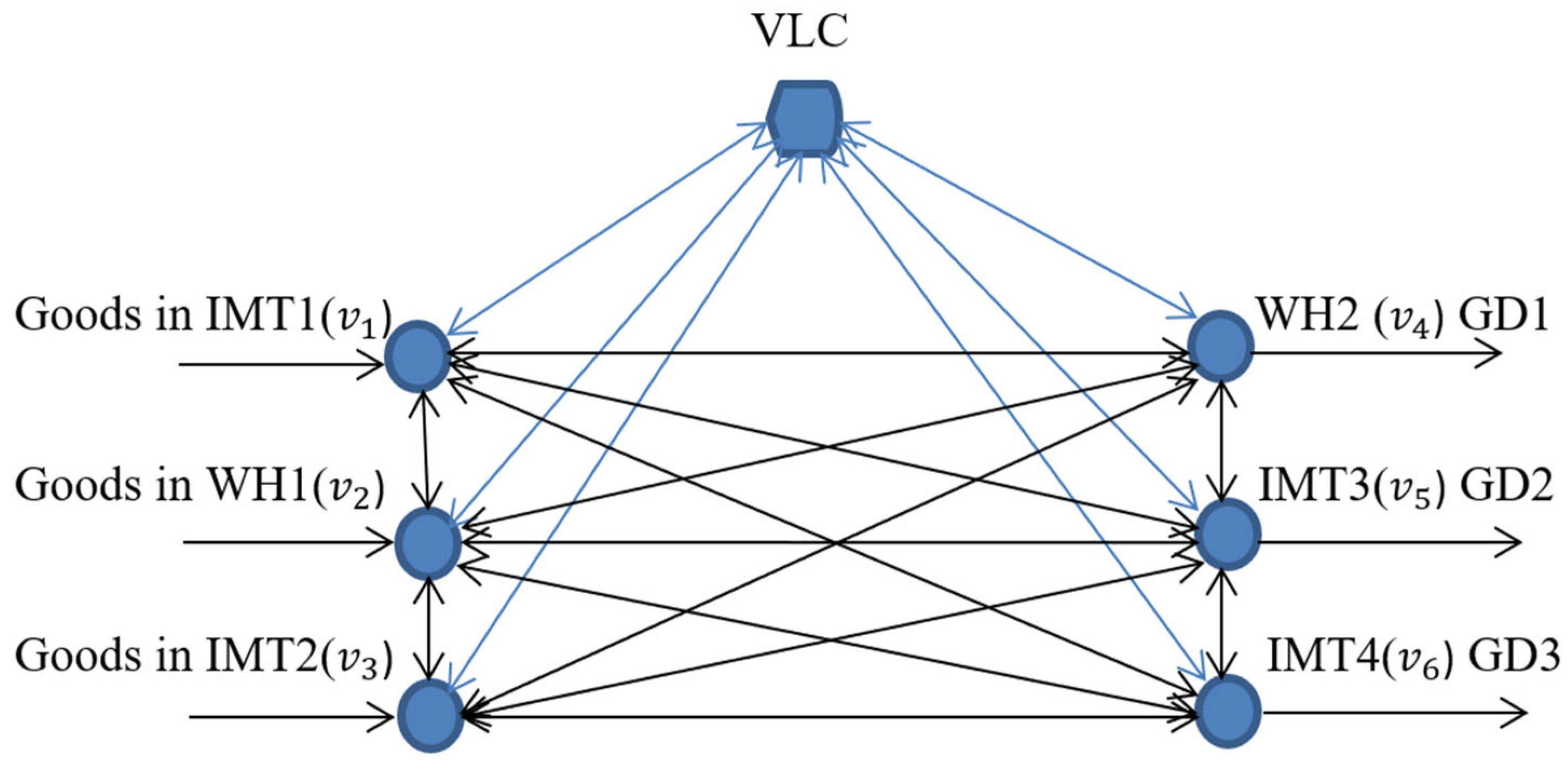

3. Materials and Methods

3.1. Steps of Research Methodology

3.2. Mathematical Model

- Identification of existing intermodal terminals and warehouses’ locations, as well as determining of logistics services that may be performed by a particular entity;

- Identification of senders’ and recipients’ locations and demand for services;

- Identification of possible cooperation schemes, assessing the technical possibilities to find the best solutions for the cases analyzed, and estimation of possible alternative logistics services.

- In order to assess possible cooperation solutions, the following criteria may be used:

- Time of logistics service;

- Price of logistics service;

- Possibility to re-address goods to another service provider while performing the logistics service;

- Energy demand while performing the service that impacts the environment and logistics costs.

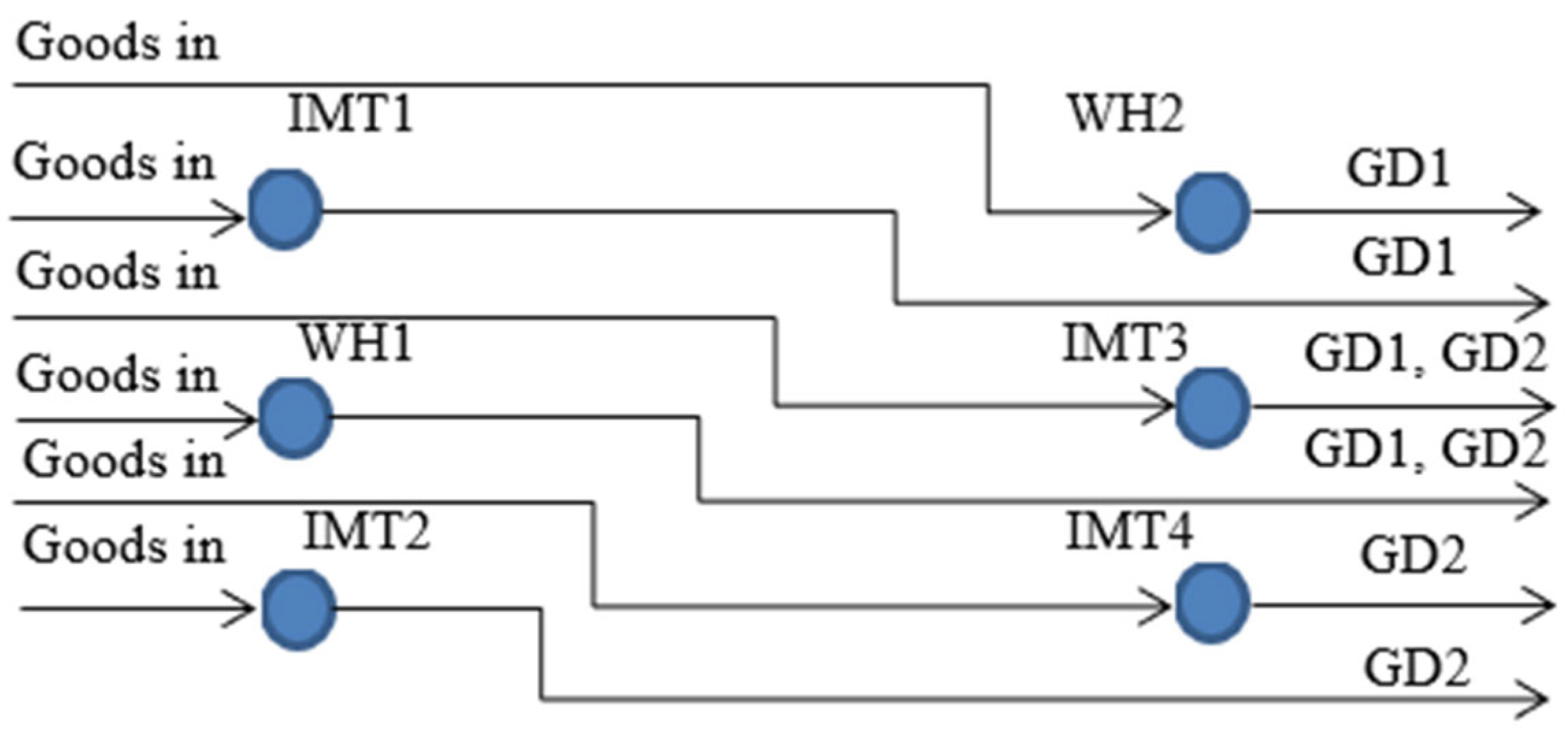

4. Results

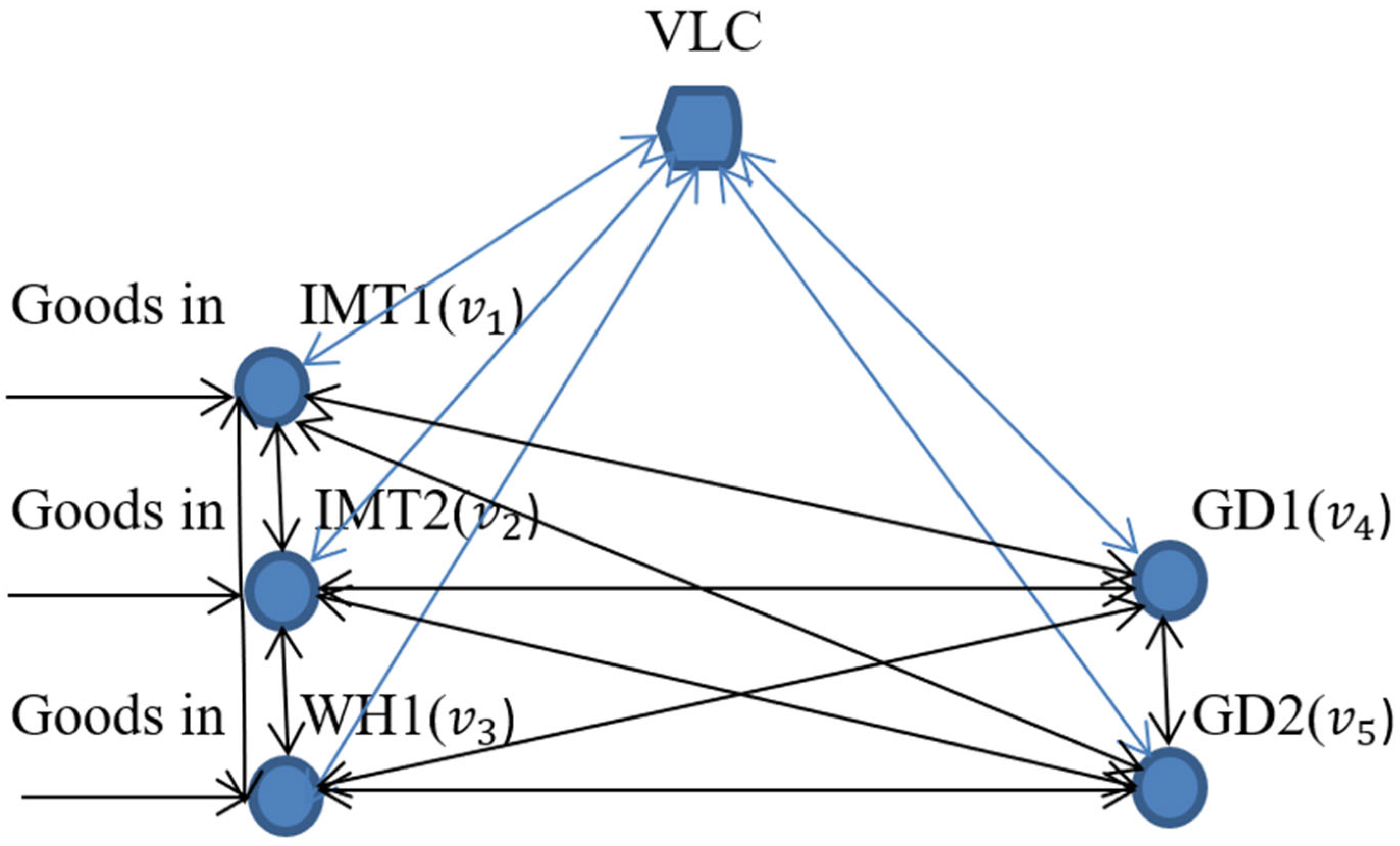

Practical Possibilities to Optimize Logistics Operations Performed Using Virtual Logistics Centers

- Through IMT1, 500 tons of goods are transported every week to GD1 (average 9.6 tons per week);

- Through WH1, 200 tons of goods are moved every week to GD1 (60%, 2.3 tons per week) and GD2 (40%, 1.5 tons per week);

- Through IMT2, 300 tons of goods are delivered every week to GD1 (30%, 1.7 tons per week) and to GD2 (70%, 4 tons per week).

5. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, X.; Walsh, J. Development of cross-border e-commerce in the context of China’s foreign trade strategy. City Univ. Res. J. 2019, 9, 776–787. [Google Scholar]

- Craighead, C.W.; Ketchen, D.J., Jr.; Darby, J.L. Pandemics and Supply Chain Management Research: Toward a Theoretical Toolbox. Decis. Sci. 2020, 51, 838–866. [Google Scholar] [CrossRef]

- Kostrzewski, M.; Filina-Dawidowicz, L.; Walusiak, S. Modern technologies development in logistics centers: The case study of Poland. Transp. Res. Procedia 2021, 55, 268–275. [Google Scholar] [CrossRef]

- Çavuşoğlu, D.; Zorba, Y.; Esmer, S. A Set of Criteria for Logistics Center Development: A Fuzzy Analytic Hierarchy Process. J. ETA Marit. Sci. 2022, 10, 47–60. [Google Scholar] [CrossRef]

- Baublys, A. Model for distribution of warehouses in the commercial network in optimizing transportation of goods. Transport 2008, 23, 5–9. [Google Scholar] [CrossRef]

- Filina-Dawidowicz, L.; Kostrzewski, M. The Complexity of Logistics Services at Transshipment Terminals. Energies 2022, 15, 1435. [Google Scholar] [CrossRef]

- Shcherbakov, V.; Silkina, G. Supply Chain Management Open Innovation: Virtual Integration in the Network Logistics System. J. Open Innov. Technol. Mark. Complex. 2021, 7, 54. [Google Scholar] [CrossRef]

- Tamas, P.; Illes, B.; Banyai, T.; Toth, A.B.; Akylbek, U.; Skapinyecz, R. Intensifying Cross-border Logistics Collaboration Opportunities Using a Virtual Logistics Center. J. Eng. Res. Rep. 2020, 13, 1–7. [Google Scholar] [CrossRef]

- Dutta, P.; Choi, T.-M.; Somani, S.; Butala, R. Blockchain technology in supply chain operations: Applications, challenges and research opportunities. Transp. Res. Part E Logist. Transp. Rev. 2020, 142, 102067. [Google Scholar] [CrossRef]

- Modrák, V. Designing and effectiveness of virtual logistics centers. Adv. Logist. Syst. 2008, 2, 75–83. [Google Scholar]

- Li, W.; Zhong, Y.; Wang, X.; Cao, Y. Resource virtualization and service selection in cloud logistics. J. Netw. Comput. Appl. 2013, 36, 1696–1704. [Google Scholar] [CrossRef]

- Clarke, M.P. Virtual logistics: An introduction and overview of the concepts. Int. J. Phys. Distrib. Logist. Manag. 1998, 28, 486–507. [Google Scholar] [CrossRef]

- Foulard, C.; Sandoval, V. Virtual Manufacturing Spaces and Logistics. IFAC Proc. Vol. 2000, 33, 137–140. [Google Scholar] [CrossRef]

- Rehman Khan, S.A.; Yu, Z. Future trends in supply chain. In Strategic Supply Chain Management; EAI/Springer Innovations in Communication and Computing; Springer: Cham, Switzerland, 2019; pp. 261–270. [Google Scholar] [CrossRef]

- Maggi, E.; Borruso, G. A theoretical framework of the new approach to logistics: Supply chain management. Eur. Transp./Trasp. Eur. 2001, 7, 16–24. [Google Scholar]

- Van Baalen, P.J.; Zuidwijk, R.; van Nunen, J. Port Inter-Organizational Information Systems: Capabilities to Service Global Supply Chains. Found. Trends Technol. Inf. Oper. Manag. 2009, 2, 81–241. [Google Scholar] [CrossRef]

- Demirova, S. Role of new technologies in logistics processes and expansion of logistics activity with virtual components. In Proceedings of the 13th International Scientific Conference Business and Management 2023, Vilnius, Lithuania, 11–12 May 2023. [Google Scholar]

- Van Oosterhout, M. Organizations and flows in the network. In Port Inter-Organizational Information Systems. Capabilities to service Global Supply Chains; Now Publisher: Delft, The Netherlands, 2008; Volume 2, pp. 176–185. [Google Scholar]

- Li, S. Structure Optimization of e-Commerce Platform Based on Artificial Intelligence and Blockchain Technology. Wirel. Commun. Mob. Comput. 2020, 2020, 8825825. [Google Scholar] [CrossRef]

- Szymonik, A. Logistics and Supply Chain Management; Technical University of Lodz Press: Lodz, Poland, 2012; pp. 308–352. Available online: https://www.researchgate.net/profile/Andrzej-Szymonik (accessed on 25 August 2023).

- Lu, L.; Reardon, T. An economic model of the evolution of food retail and supply chains from traditional shops to supermarkets to e-commerce. Am. J. Agric. Econ. 2018, 100, 1320–1335. [Google Scholar] [CrossRef]

- Pehlivanis, K.; Papagianni, M.; Styliadis, A. Virtual reality & logistics. In Proceedings of the International Conference on Theory and Applications of Mathematics and Informatics-ICTAMI, Thessaloniki, Greece, 16–18 September 2004; pp. 377–384. Available online: http://www.kurims.kyoto-u.ac.jp/EMIS/journals/AUA/acta8/Pehlivanis-Papagianni-Styliadis.pdf (accessed on 20 August 2023).

- Sayed, A.M.; Afia, N. An NPV Optimization Model for Closed-Loop Supply Chain Network Design and Planning. Am. J. Eng. Appl. Sci. 2017, 10, 114–125. [Google Scholar] [CrossRef]

- Hong, S.; Mao, B. An interactive logistics centre information integration system using virtual reality. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2018, XLII-3, 523–526. [Google Scholar] [CrossRef]

- Zhang, H.; Ge, H.; Yang, J.; Su, S.; Tong, Y. Combining affinity propagation with differential evolution for three-echelon logistics distribution optimization. Appl. Soft Comput. 2022, 131, 109787. [Google Scholar] [CrossRef]

- Wang, K. Application of Virtual Reality Technology in Higher Vocational Smart Logistics Teaching. J. Phys. Conf. Ser. 2021, 1881, 032041. [Google Scholar] [CrossRef]

- Lee, K.L.; Huang, W.C.; Kuo, M.S.; Lin, S.C. Competitiveness model of international DISTRI-PARK using the virtual value chain analysis. J. East. Asia Soc. Transp. Stud. 2001, 4, 313–325. [Google Scholar]

- Önden, I.; Acar, A.Z.; Eldemir, F. Evaluation of the logistics center locations using a multi-criteria spatial approach. Transport 2018, 33, 322–334. [Google Scholar] [CrossRef]

- Allen, J.; Browne, M.; Woodburn, A.; Leonardi, J. The Role of Urban Consolidation Centres in Sustainable Freight Transport. Transp. Rev. 2012, 32, 473–490. [Google Scholar] [CrossRef]

- Bolumole, Y.A.; Frankel, R.; Naslund, D. Developing a Theoretical Framework for Logistics Outsourcing. Transp. J. 2007, 46, 35–54. [Google Scholar] [CrossRef]

- Gao, S.; Meng, W. Development of a Personalized Recommendation System for E-Commerce Products for Distributed Storage Systems. Comput. Intell. Neurosci. 2022, 2022, 4752981. [Google Scholar] [CrossRef] [PubMed]

- Trojanowski, P.; Filina-Dawidowicz, L. Diagnostic and repair centers locating methodology for vehicles carrying sensitive cargo. Transp. Res. Procedia 2021, 55, 410–417. [Google Scholar] [CrossRef]

- Schodl, R.; Eitler, S. Virtual Urban Consolidation Center. Lect. Notes Netw. Syst. 2023, 687, 616–620. [Google Scholar] [CrossRef]

- Fechner, I. Logistics Centers in Europe. Polish Logistics Congress “Logistics 2004—Logistics networks on the integrated European market”, Poznań 19–21 May 2004. (In Polish). Available online: https://www.logistyka.net.pl/bank-wiedzy/item/6072-centra-logistyczne-w-europie (accessed on 20 August 2023).

- Probierz, J. Logistics centers in Europe. Virtual Logistics Center in Turku. Zesz. Naukowe. Organ. I Zarządzanie/Politech. Śląska 2007, 41, 297–307. (In Polish) [Google Scholar]

- Cichosz, M.; Nowicka, K.; Ocicka, B. Collaborative Outsourcing for Sustainable Transport Management. In International Business, Trade and Institutional Sustainability; Leal Filho, W., Borges de Brito, P., Frankenberger, F., Eds.; World Sustainability Series; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Rezaei, S.; Behnamian, J. Benders decomposition-based particle swarm optimization for competitive supply networks with a sustainable multi-agent platform and virtual alliances. Appl. Soft Comput. 2022, 114, 107985. [Google Scholar] [CrossRef]

- Ji, Y.; Yang, H.; Zhang, Y.; Zhong, W. Location optimization model of regional express distribution center. Procedia Soc. Behav. Sci. 2013, 96, 1008–1013. [Google Scholar] [CrossRef][Green Version]

- Krstić, M.; Tadić, S.; Elia, V.; Massari, S.; Farooq, M.U. Intermodal Terminal Subsystem Technology Selection Using Integrated Fuzzy MCDM Model. Sustainability 2023, 15, 3427. [Google Scholar] [CrossRef]

- Silva e Sousa, R.; Pinho, T.; Simões, D. How Can Customer Experience Improve Retail Operations Sustainability; Springer Proceedings in Business and Economics; Springer: Cham, Switzerland, 2023; pp. 337–346. [Google Scholar] [CrossRef]

- Liu, F. Research on the construction of agricultural product virtual logistics enterprise. J. Shanghai Jiaotong Univ. 2016, 21, 63–68. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, R.K.; Murtaza, Q. Disposition decisions in reverse logistics: Graph theory and matrix approach. J. Clean. Prod. 2016, 137, 93–104. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, R.K.; Murtaza, Q. Outsourcing decisions in reverse logistics: Sustainable balanced scorecard and graph theoretic approach. Resour. Conserv. Recycl. 2016, 108, 41–53. [Google Scholar] [CrossRef]

- Šakalys, R.; Batarlienė, N. Research on intermodal terminal interaction in international transport corridors. Procedia Eng. 2017, 187, 281–288. [Google Scholar] [CrossRef]

- Paulauskas, V.; Henesey, L.; Placiene, B.; Jonkus, M.; Paulauskas, D.; Barzdžiukas, R.; Kaulitzky, A.; Simutis, M. Optimizing Transportation between Sea Ports and Regions by Road Transport and Rail and Inland Waterway Transport Means Including “Last Mile” Solutions. Appl. Sci. 2022, 12, 10652. [Google Scholar] [CrossRef]

- Ypsilantis, P.; Zuidwijk, R. Collaborative fleet deployment and routing for sustainable transport. Sustainability 2019, 11, 5666. [Google Scholar] [CrossRef]

- Matuliauskas, K. Graph Theory; Vilnius University Publish House: Vilnius, Lithuania, 2010; 21p. (In Lithuanian) [Google Scholar]

- Andreae, T. On independent cycles and edges in graphs. Discret. Math. 1996, 149, 291–297. [Google Scholar] [CrossRef][Green Version]

- Bondy, J.A.; Chvatal, V. A method in graph theory. Discret. Math. 1976, 15, 111–135. [Google Scholar] [CrossRef]

- Curtis, A.; Izurieta, C.; Joeris, B.; Lundberg, S.; McConnell, R. An implicit representation of chordal comparability graphs in linear time. Discret. Appl. Math. 2010, 158, 869–875. [Google Scholar] [CrossRef]

- Fujita, S. Recent results on disjoint cycles in graphs. Electron. Notes Discret. Math. 2005, 22, 409–412. [Google Scholar] [CrossRef]

- Eurostat. Freight Transport in the EU-28 Modal Split of Inland Transport Modes. 2017. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=File:Freight_transport_in_the_EU-28_modal_split_of_inland_transport_modes_(%25_of_total_tonne-kilometres).png&oldid=336869 (accessed on 12 August 2023).

- Mouschoutzi, M.; Ponis, S.T. A comprehensive literature review on spare parts logistics management in the maritime industry. Asian J. Shipp. Logist. 2022, 38, 71–83. [Google Scholar] [CrossRef]

- Gao, S.; Liu, N. Improving the Resilience of Port–Hinterland Container Logistics Transportation Systems: A Bi-Level Programming Approach. Sustainability 2022, 14, 180. [Google Scholar] [CrossRef]

- Martins, V.; Correia, C.; Cunha-Lopes, I.; Faria, T.; Diapouli, E.; Manousakas, M.I.; Eleftheriadis, K.; Almeida, S.M. Chemical characterisation of particulate matter in urban transport modes. J. Environ. Sci. 2021, 100, 51–61. [Google Scholar] [CrossRef] [PubMed]

- Heinrich, L.; Koschinsky, A.; Markus, T.; Singh, P. Quantifying the fuel consumption, greenhouse gas emissions and air pollution of a potential commercial manganese nodule mining operation. Mar. Policy 2020, 114, 103678. [Google Scholar] [CrossRef]

- Behdani, B.; Fan, Y.; Wiegmans, B.; Zuidwijk, R. Multimodal Schedule Design for Synchromodal Freight Transport Systems. Eur. J. Transp. Infrastruct. Res. 2016, 16, 424–444. [Google Scholar] [CrossRef]

- Iheonu, N.O.; Inyama, S.C. On the Optimization of Transportation Problem. Br. J. Math. Comput. Sci. 2016, 13, 1–11. [Google Scholar] [CrossRef]

- Castaneda, J.; Ghorbani, E.; Ammouriova, M.; Panadero, J.; Juan, A.A. Optimizing Transport Logistics under Uncertainty with Simheuristics: Concepts, Review and Trends. Logistics 2022, 6, 42. [Google Scholar] [CrossRef]

| Service Group | Service Example |

|---|---|

| Basic |

|

| Additional |

|

| Other services, including value added services |

|

| Factors | Separate Work System | Virtual Logistics Center | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Separate Work System (SWS) | VLC Work System (VLC) | |||||||||

| , EUR/t | 6.2 | 0.5 | 0.35 | 0.2 | 0.64 | 3.7 | 0.3 | 0.43 | 0.2 | 0.512 |

| , h/t | 1.8 | 0.2 | 0.35 | 0.1 | 0.27 | 1.0 | 0.1 | 0.43 | 0.1 | 0.186 |

| , EUR/t | 0.5 | 0.5 | 0.35 | 0.1 | 0.57 | 0.7 | 0.2 | 0.43 | 0.1 | 0.286 |

| , kg/t | 7.4 | 0.5 | 0.35 | 0.2 | 0.64 | 4.1 | 0.3 | 0.43 | 0.2 | 0.472 |

| , EUR/t | 0.2 | 0.05 | 0.35 | 0.2 | 0.19 | 0.4 | 0.1 | 0.43 | 0.1 | 0.184 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paulauskas, V.; Filina-Dawidowicz, L.; Senčila, V.; Paulauskas, D.; Plačienė, B. Theoretical Framework for Virtual Logistics Centers Creation. Sustainability 2024, 16, 3680. https://doi.org/10.3390/su16093680

Paulauskas V, Filina-Dawidowicz L, Senčila V, Paulauskas D, Plačienė B. Theoretical Framework for Virtual Logistics Centers Creation. Sustainability. 2024; 16(9):3680. https://doi.org/10.3390/su16093680

Chicago/Turabian StylePaulauskas, Vytautas, Ludmiła Filina-Dawidowicz, Viktoras Senčila, Donatas Paulauskas, and Birutė Plačienė. 2024. "Theoretical Framework for Virtual Logistics Centers Creation" Sustainability 16, no. 9: 3680. https://doi.org/10.3390/su16093680

APA StylePaulauskas, V., Filina-Dawidowicz, L., Senčila, V., Paulauskas, D., & Plačienė, B. (2024). Theoretical Framework for Virtual Logistics Centers Creation. Sustainability, 16(9), 3680. https://doi.org/10.3390/su16093680