Abstract

Fruits have a significant impact on human health due to the mineral substances and vitamins that they contain. Among agricultural activities globally and within Türkiye, fruit cultivation is of great importance. In this study, the energy analyses of wolfberries, grapes, pomegranates, and strawberries grown in different countries were evaluated, and the energy efficiency parameters were compared for different countries to improve berry fruit production. The energy parameters in fruit growing include transportation, water, organic fertilizer, farmyard manure, diesel oil/oil, agricultural machinery, animal labor, human labor, electricity, organic chemicals, biocides, chemical fertilizers, seeds, biochemicals, and plastics. Water use, one of the energy analysis parameters, was found to be highest in strawberries grown in greenhouses, with 24,353.30 MJ/ha and the lowest was found in pomegranates, with 35.80 MJ/ha. The highest diesel/oil parameter usage, with an amount of 805,178.20 MJ/ha, was in strawberries grown in greenhouses. The lowest amount was determined in pomegranates, with 1224.90 MJ/ha. The energy input for agricultural machinery was calculated as 18,384.03 MJ/ha in strawberry production in open fields, and the lowest was calculated as 130.48 MJ/ha for the same fruit. In the energy analysis, the highest human labor parameter with an amount of 35,338.86 MJ/ha was found for strawberries produced in greenhouses. The lowest amount was found in grape production, with 205.68 MJ/ha.

1. Introduction

One of the important agricultural production types globally and Türkiye is fruit production. Fruits play a crucial role in maintaining good health and wellbeing due to their rich nutritional content [1]. Due to its geographical location, Türkiye has a climate that is very suitable for all fruit types except for tropical garden plants. In this respect, Türkiye is the birthplace of horticulture and the homeland of many fruit species grown around the world [2]. The fruit production potential in Türkiye and globally is 23,019.7 and 662,987.8 thousand tonnes, respectively. The most produced fruits in Türkiye and globally are apples, grapes, watermelons, and bananas [3,4]. The fruits examined in this study are categorized as berry fruits, such as wolfberries, grapes, pomegranates, and strawberries.

Although the agricultural sector is not the largest energy consumer, there is a significant amount of energy consumption in this sector due to the fact that it includes many processes such as tillage, planting, weed control, irrigation, fertilization, harvesting, transportation, and drying [5]. As a result of the modernization of these processes, energy consumption increases in parallel [6]. It has been reported that energy consumption increases with the increase in agricultural production. Although energy consumption is slowly increasing to increase efficiency, energy use efficiency is constantly decreasing [7]. Beyond this, the effective use of energy in agricultural production is required in order to carry out agriculture in a sustainable manner, reduce air pollution, reduce the use of fossil fuels, and provide economic gains [8,9]. Therefore, research has focused on energy analysis in different branches of agricultural production to guide resource planning in ecosystems [10].

Energy analysis is a crucial process in fruit production since it addresses social, economic, and environmental factors. The effective use of resources like water, fertilizer, and pesticides is made possible by the comprehension of the energy inputs involved in fruit production. Sustainable agricultural methods depend on this optimization [11]. Farmers might find ways to lower production expenses by examining how much energy they consume. Fruit production can become more economically viable by implementing energy-efficient methods and technologies, which can result in cost savings. Agriculture’s overall sustainability is enhanced via energy analysis. Energy-efficient farming methods can be identified and promoted to help guarantee that farming systems are both environmentally benign and able to meet current requirements without endangering the capabilities of future generations [12]. The entire supply chain, from production to distribution, can be optimized with the use of energy analysis [13]. Areas with high energy consumption can be identified to aid in the development of policies that lessen pollution, cut carbon emissions, and support sustainable farming methods. Emissions of greenhouse gases are mostly caused by agriculture. Finding possible options for reducing emissions and implement climate-smart agricultural practices are two ways in which analyzing the energy footprint of fruit production might help alleviate climate change [6,14]. Data from energy analyses can be used by governments and decision makers to create efficient agricultural strategies. This could entail the creation of incentives to use energy-efficient technology, encouraging the use of renewable energy sources, and putting laws into place to reduce negative effects on the environment [15].

This study aims to compare the energy use efficiency of berry fruits (wolfberries, grapes, pomegranates, and strawberries) produced in Türkiye and other countries.

2. Materials and Methods

The material of this study consists of previous national and international studies and statistical data in the field of energy use efficiency in berry fruit production. Energy inputs used in fruit production were examined according to different energy forms, which are classified under the headings indirect/direct, renewable/non-renewable and commercial/non-commercial (Table 1).

Table 1.

Different types of energy inputs in berry fruit production [6,13].

Efficient use of energy is important in agricultural production processes. Appropriate mechanization must be provided for the enterprise through effective mechanization planning at the enterprise scale. In order to determine the energy use efficiency in agriculture, the indicators used were energy use efficiency, energy productivity, specific energy, and net energy [5,6,16]:

Information about input energy and crop yields obtained from the literature was inputted into the MS Excel program. Energy use efficiency, specific energy, energy productivity, and net energy values were obtained by using the necessary equations. Energy input and energy output values for berry fruits produced around the world and in Türkiye (wolfberries, grapes, pomegranates, and strawberries) were obtained from the studies.

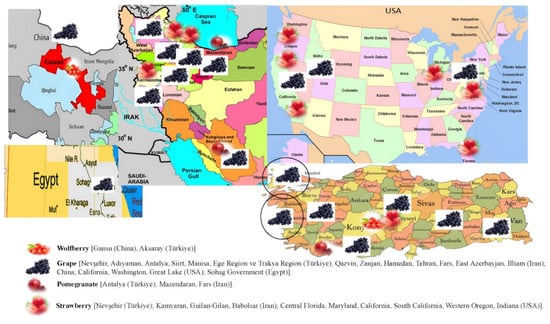

The countries where the four different berry fruits are cultivated are depicted in Figure 1. These countries are generally Türkiye, Iran, Egypt, USA, and China.

Figure 1.

The studied areas for all the berry fruits mentioned.

The energy input, output, and yield values of the fruits were taken from the references that are currently are published. The data are used to calculate energy use efficiency, energy productivity, specific energy, and net energy values. In addition, these data were used to calculate direct/indirect, renewable/non-renewable, and commercial/non-commercial energy amounts and their share in total input. These were all given as figures for each berry fruit.

3. Results

The study was carried out using data from studies in the literature on berry fruits such as wolfberries, grapes, pomegranates, and strawberries. The results of this study were evaluated separately for each fruit and are presented in the Figures and Tables below.

3.1. Wolfberry

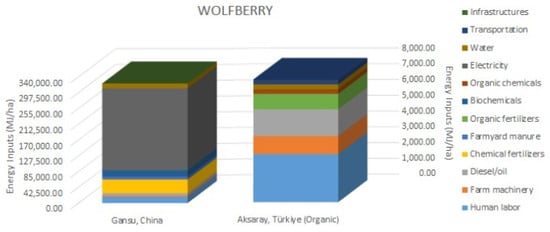

Goji (L. barbarum L.), which is also called wolfberry is a bushy, deciduous, perennial plant that is resistant to harsh climatic conditions. Goji berry fruits are bright red in color. The harvesting of fruits starts in June and continues until October-November. These fruits are known to have rich contents in terms of antioxidant capacity, and their total flavonoid content is high. Figure 2 shows the energy inputs needed to produce wolfberries in China and Türkiye. The total wolfberry production was determined using 12 energy input parameters. Figure 2 illustrates that China [17] had higher energy input values for goji berry production than Türkiye [18]. One study on wolfberries was carried out in Aksaray, Türkiye [18], while the other study was carried out in Gansu, China [17]. In Gansu, China, the highest energy input parameter for wolfberry production was electricity, with 220,500 MJ/ha [17]. The study conducted in Aksaray, Türkiye, documented the amount of electricity used [18]. While farmyard manure, biocides, and infrastructures were not used as input parameters in the study performed in Aksaray (Türkiye) [18], organic fertilizer, organic chemicals, and transportation were not counted as input parameters in Gansu (China) [17]. The amount of human labor energy input in Gansu (China) (16,614.00 MJ/ha) [17] was about 5.5 times higher than that in Aksaray (Türkiye) (3044.23 MJ/ha) [18].

Figure 2.

Energy inputs for wolfberry production in Türkiye [18] and China [17].

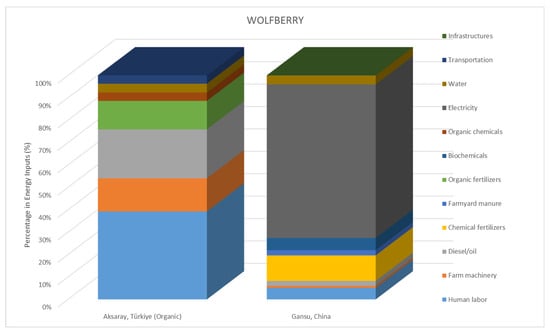

The percentage values of energy inputs in wolfberries produced in China and Türkiye are displayed in Figure 3. Chemical fertilizers were not used as an input in Aksaray (Türkiye), despite having an energy input percentage of 11.38% in Gansu (China) [17]. Figure 3 shows that, in contrast to Aksaray (Türkiye), where farmyard manure was not used [18], Gansu (China) had an energy input percentage of 2.33% [17]. In Aksaray, Türkiye, it was found that the percentage of energy used for transportation was 3.73% [18]. The transportation parameter was not an input in Gansu, China [17]. It is evident that the irrigation energy input percentages of both provinces were fairly similar to one another (Figure 3). The percentage of diesel/oil energy input was found to be 21.86% in Aksaray, Türkiye [18] and 2.18% in Gansu, China [17]. In comparison to Gansu (China) (2.18%) [17], Aksaray (Türkiye) (14.78%) [18] had a higher ratio of agricultural machinery use.

Figure 3.

Percentage of energy inputs in wolfberry production in Türkiye [18] and China [17].

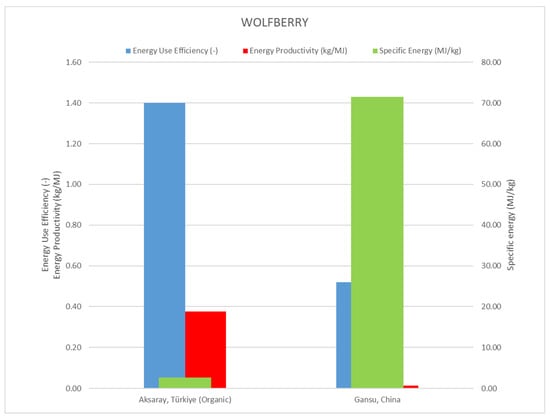

In Figure 4, specific energy values, energy productivity, and energy use efficiency in wolfberry production in Gansu, China, and Aksaray, Türkiye, are represented. While Aksaray, Türkiye [18] had an energy use efficiency of 1.40, Gansu, China [17] had a value of 0.52. Chemical fertilizer, farmyard manure, biocides, and electricity were not used in Aksaray (Türkiye). In particular, in Gansu (China), the high amount of energy input for electricity caused the energy efficiency rate to be low. The energy use efficiency in Aksaray (Türkiye) was calculated to be higher than that of Gansu (China), where it was found to be very low (0.01 kg/MJ) [17]. It is preferred that the specific energy be less than both the energy productivity and efficiency of use. Nonetheless, the figures in Aksaray, Türkiye [18] and Gansu, China [17] were determined to be 2.66 MJ/kg and 71.51 MJ/kg, respectively. In addition, the yield was very low in Türkiye when compared to China, and there was no use of pruning for wolfberries in Türkiye. The share of the total input energy used for human labor, diesel/oil, and farm machinery could be reduced. In China, the human energy use was about 5.5 times higher, the amount of diesel/oil was about 4.9 times higher, the FYM use was about 266 times higher, and the water use was about 42 times, so the energy input was very high. Reducing energy inputs with high yield would result in high energy use efficiency values.

Figure 4.

Energy use efficiency, energy productivity, and specific energy in wolfberry production in Türkiye [18] and China [17].

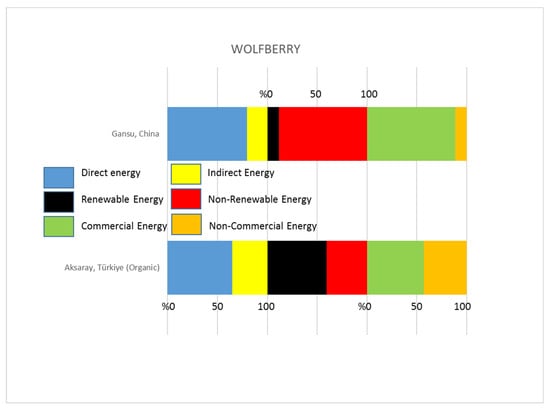

The various energy types used in China’s and Türkiye’s wolfberry production are depicted in Figure 5. Gansu, China [17] reported a direct energy input value of 79.86%, while Aksaray, Türkiye [18] reported a value of 65.07%. Indirect energy use was recorded in Gansu, China, at 20.14% [17] and Aksaray, Türkiye, at 34.93% [18]. Gansu, China, had a ratio of 11.48% for renewable energy resources, compared to Aksaray, Türkiye, where the ratio was 59.64% [17,18]. In terms of non-renewable energy resources, Aksaray (Türkiye) had 40.36% and Gansu (China) had 88.52% [17]. Sustainable agriculture is positively impacted by Aksaray (Türkiye) province’s growing use of renewable energy resources. In Aksaray (Türkiye), the percentage of energy used for commercial purposes was found to be 56.79%, while the percentage for non-commercial purposes was 43.21% [18]. In Gansu, China, 11.48% of energy came from non-commercial sources and 88.52% from commercial sources [17].

Figure 5.

Energy types in wolfberry production in Türkiye [18] and Gansu [17].

3.2. Grapes

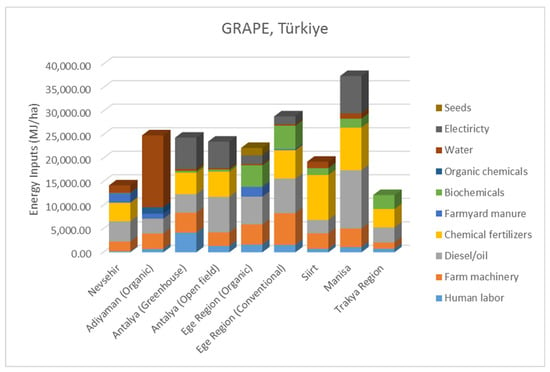

Plant production in Türkiye includes a significant amount of viticulture. The cultivation of viticulture holds significant value in utilizing barren land, preventing erosion, and generating revenue for the local population. It can be established on slopes where other crops, such as fruits and vegetables, cannot be grown [19]. Owing to its adaptability to a wide range of climates and soil conditions, ease of propagation, and versatility of applications, the grape is one of the most widely cultivated plants in the world [20]. Figure 6 lists various energy inputs used in Türkiye’s grape production. While grapes have become widely distributed throughout Türkiye, our research focused on Nevşehir, Adiyaman, Antalya, the Aegean Region, Siirt, Manisa, and the Thrace Region. In the process of producing grapes, the following resources were used: seed input parameters, water, electricity, diesel/oil, chemical fertilizer, farmyard manure, biochemicals, and organic chemicals. The amount of human labor energy input in grape production in greenhouses in Antalya (Türkiye) had the highest value, with 4175.98 MJ/ha [21]. The research conducted in Nevşehir yielded the lowest energy input value, 205.65 MJ/ha [22]. According to Figure 6, the Aegean Region (conventional) cultivation had the highest intensity of farm machinery use, with an energy input amount of 6746.52 MJ/ha [23]. In the Thrace Region, farm machinery had the lowest amount of energy input (1332.00 MJ/ha) [24]. Despite the fact that Manisa had the energy input value for farm machinery with 3944.12 MJ/ha, oil and diesel had the highest energy input with 12,388.20 MJ/ha [25]. The lowest diesel/oil energy input amount was calculated to be 2832.39 MJ/ha in Siirt, [26]. Chemical fertilizers were not used in the Aegean Region, where organic farming is practiced [23]. One of the highest levels of chemical fertilizer usage was recorded for Siirt, with 9568.22 MJ/ha [26] and Manisa, with 9077.80 MJ/ha [25]. The lowest energy input in chemical fertilizer was for Adiyaman, where organic farming is performed, with a value of 22.95 MJ/ha. Farmyard manure was not used in greenhouse agriculture and open areas in Antalya, Siirt, Manisa, or the Thrace Region. It can be seen in Figure 6 that organic farming took place in the Aegean Region, with an energy input amount of 2087.91 MJ/ha [23]. Biochemicals were not used in Adiyaman, where organic farming was practiced [27]. It had the highest energy input amount of 4979.70 MJ/ha in the Aegean Region, where conventional agriculture was undertaken [23]. Biochemicals were used only in Adiyaman (Türkiye) (1374.16 MJ/ha) [27].

Figure 6.

Energy inputs in grape production in Nevsehir [22], Adiyaman (Organic) [27], Antalya (Greenhouse & Open Field) [21], Ege Region (Organic & Conventional) [23], Siirt [26], Manisa [25] and Trakya Region [24] in Türkiye.

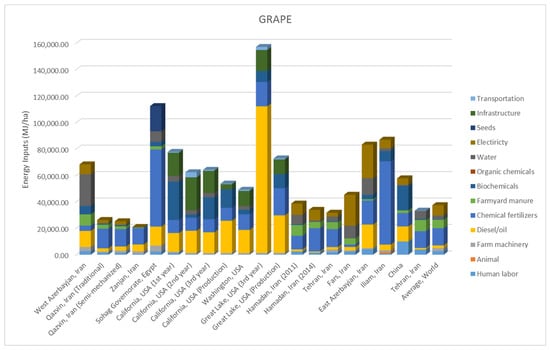

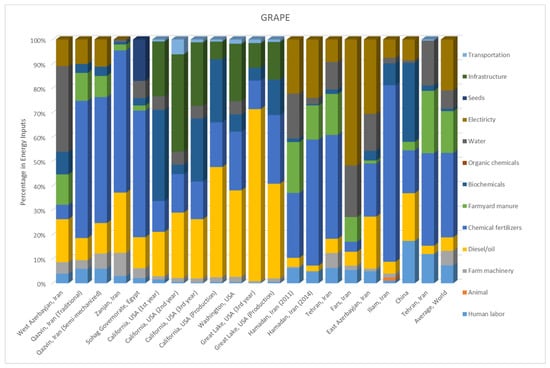

Figure 7 lists the energy inputs used in grape production across several nations. Human labor was used at two different levels: 10,033.55 MJ/ha in China [28] and 211.68 MJ/ha in California (USA) [8]. Animals were exclusively employed in Iliam, Iran [29]. With a maximum value of 4530.50 MJ/ha in the Sohag Governate (Egypt), farmyard manure was typically used in many locations [30]. The diesel/oil energy input reached 110,817.15 MJ/ha in Grate Lake, USA [8], compared to 788.34 MJ/ha in Hamadan, Iran [31]. All countries used chemical fertilizers, with the amount varying from 1856.30 MJ/ha in Fars (Iran) [32] to 62,937.60 MJ/ha in Iliam (Iran) [29]. Compared to biochemical usage, which was high in California (USA) at 29,056.12 MJ/ha [8], farmyard manure usage was high in Tehran (Iran), at 8513.70 MJ/ha [33]. In some countries, there were no water usage, but it reached its highest value, with 23,991.42 MJ/ha, in West Azerbeyjan (Iran) [34].

Figure 7.

Energy inputs in grape production in West Azerbayjan (Iran) [34], Qazvin (Iran) (Traditional) [35], Qazvin (Iran) (Semi-mechanized) [35], Zanjan (Iran) [36], Sohag Governorate (Egypt) [30], California (USA) (1st, 2nd, 3rd Year, Production) [8], Washington (USA) [8], Great Lake (3rd Year, Production) [8], Hamadan (Iran) (2011 [37] and 2014 [31]), Tehran (Iran) [38], Fars (Iran) [32], East Azarbayjan (Iran) [39], Illiam (Iran) [29], China [28], Tehran (Iran) [33], [Average (World) [40].

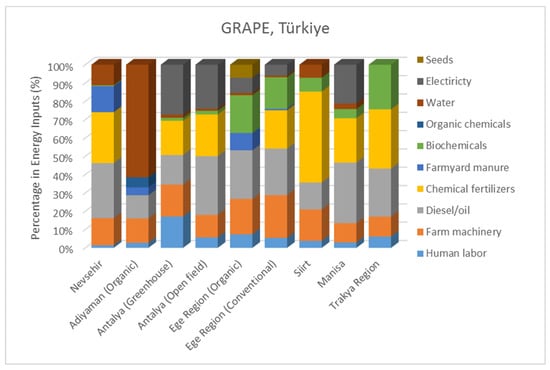

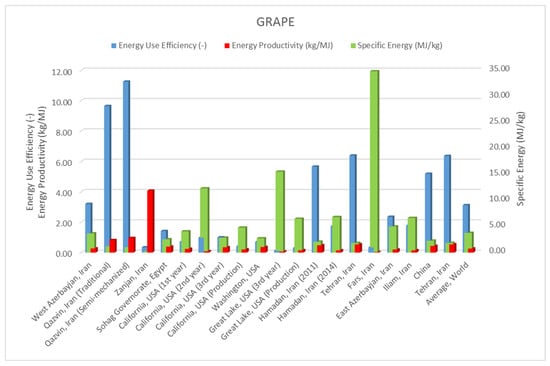

The energy input ratio for Turkish grape production is depicted in Figure 8. The human labor and farm machinery energy input in grape production at greenhouses in Antalya were close to each other and were 17.13% and 17.42%, respectively [21]. The highest percentage of energy input in farm machinery (23.34%) was in the Aegean region, where conventional agriculture is practiced [23]. The lowest ratio was in Manisa, with 10.52% [25]. Diesel/oil counted among the important inputs in agricultural production in recent years, with the highest energy input ratio in Manisa (33.04%) [25] and the lowest in Adiyaman (12.52%) [27]. It can be seen from Figure 8 that the energy input ratio in chemical fertilizer was 49.66% in Siirt [26]. Biochemical use was only seen in Adiyaman, and the energy input ratio was 5.52% [27]. The energy input ratio in water use was seen in Adiyaman and had the highest value (61.46%) [27].

Figure 8.

Percentages of energy inputs in grape production in Nevsehir [22], Adiyaman (Organic) [27], Antalya (Greenhouse & Open Field) [21], Ege Region (Organic & Conventional) [23], Siirt [26], Manisa [25] and Trakya Region [24] in Türkiye.

Figure 9 shows that the percentage of human labor in energy inputs varied from 0.22% for Great Lake (USA) [8] to 17.3% for China [28]. Out of all the literature sources that were reviewed, the highest percentage of diesel/oil usage in grape production, 70.52%, was found in Great Lake, USA [8]. In Iliam, Iran, the maximum percentage of fertilizers used comprised chemical ones (72.38%) [29], whereas in Tehran, Iran, farmyard manure usage was 25.59% [33]. The highest percentage of biochemicals was found in California (USA) [8], where it was 37.38%. While the highest percentage of electricity was used in Fars, Iran, at 51.69% [32], infrastructure was used in California, USA, at 39.94% [8].

Figure 9.

Percentages of energy inputs in grape production in West Azerbayjan (Iran) [34], Qazvin (Iran) (Traditional) [35], Qazvin (Iran) (Semi-mechanized) [35], Zanjan (Iran) [36], Sohag Governorate (Egypt) [30], California (USA) (1st, 2nd, 3rd Year, Production) [8], Washington (USA) [8], Great Lake (3rd Year, Production) [8], Hamadan (Iran) (2011 [37] and 2014 [31]), Tehran (Iran) [38], Fars (Iran) [32], East Azarbayjan (Iran) [39], Illiam (Iran) [29], China [28], Tehran (Iran) [33], [Average (World) [40].

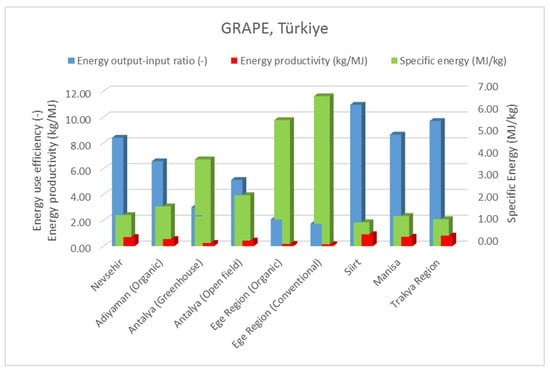

Figure 10 shows the energy use efficiency, energy productivity, and specific energy values in Türkiye. It can be seen in Figure 10 that the input for fuel/oil and chemical fertilizer, which were among the energy parameters in grapes produced in Türkiye, were high. In order for the energy efficiency to be high, the level of energy input must be low and output amounts must be high. The energy use efficiency was the highest in Siirt, at 10.94% [26]. With a ratio of 9.69%, the energy use efficiency in the Thrace Region was one of the highest values [24]. The lowest energy use efficiency was in the Aegean Region (1.74%), where traditional agriculture is practiced [23]. The highest energy use efficiency was in Siirt, with a value of 0.93 kg/MJ [26]. The amount of specific energy was the highest in the Aegean Region, where conventional agriculture is practiced (6.77 MJ/kg) [23].

Figure 10.

Energy use efficiency, energy productivity, and specific energy in grape production in Nevsehir [22], Adiyaman (Organic) [27], Antalya (Greenhouse & Open Field) [21], Ege Region (Organic & Conventional) [23], Siirt [26], Manisa [25] and Trakya Region [24] in Türkiye.

The energy use efficiency changed from 0.12 in Great Lake (USA) [8] to 11.26 in Qazvin (Iran) (semi-mechanized) [35] (Figure 11). In Great Lake, where the energy efficiency was the lowest, the high amount of fuel/oil energy input, one of the energy parameters, reduced energy efficiency. The energy productivity reached a minimum of 0.03 kg/MJ in Fars (Iran) [32] and a maximum of 4.07 kg/MJ in Zanjan (Iran) [36]. In contrast, while the minimum specific energy was 0.25 MJ/kg in Zanjan (Iran) [36], the maximum value was 34.84 MJ/kg in Fars (Iran) [32]. The yield of grapes was very high in Türkiye, but could be improved. The energy input value was very high in all of the countries, while the diesel/oil and chemical fertilizer usage was high. In addition, the diesel/oil, chemical fertilizer, and farm machinery energy was very high in Türkiye. Using pruning could also improve the energy efficiency in all the examined countries.

Figure 11.

Energy use efficiency, energy productivity, and specific energy in grape production in West Azerbayjan (Iran) [34], Qazvin (Iran) (Traditional) [35], Qazvin (Iran) (Semi-mechanized) [35], Zanjan (Iran) [36], Sohag Governorate (Egypt) [30], California (USA) (1st, 2nd, 3rd Year, Production) [8], Washington (USA) [8], Great Lake (3rd Year, Production) [8], Hamadan (Iran) (2011 [37] and 2014 [31]), Tehran (Iran) [38], Fars (Iran) [32], East Azarbayjan (Iran) [39], Illiam (Iran) [29], China [28], Tehran (Iran) [33], [Average (World) [40].

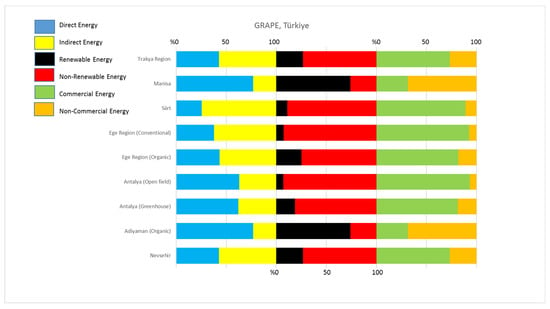

Figure 12 lists the various forms of energy used in Türkiye’s grape production. While Adiyaman and Manisa had the highest direct energy use (76.76%) [25,27], Figure 12 shows that the same provinces had the lowest indirect energy use (23.24%). Adiyaman and Manisa (74.10%) were the provinces that profited the most from renewable energy resources [25,27]. The provinces that use non-renewable energy resources the most are Antalya [21] and Nevşehir [22], with respective percentages of 93.13% and 94.01%. Nevşehir had the best commercial energy data, with a ratio of 94.01% [22]. According to Figure 12, Adiyaman and Manisa had a 68.58% ratio of non-commercial energy [25,27].

Figure 12.

Energy types in grape production in Nevsehir [22], Adiyaman (Organic) [27], Antalya (Greenhouse & Open Field) [21], Ege Region (Organic & Conventional) [23], Siirt [26], Manisa [25] and Trakya Region [24] in Türkiye.

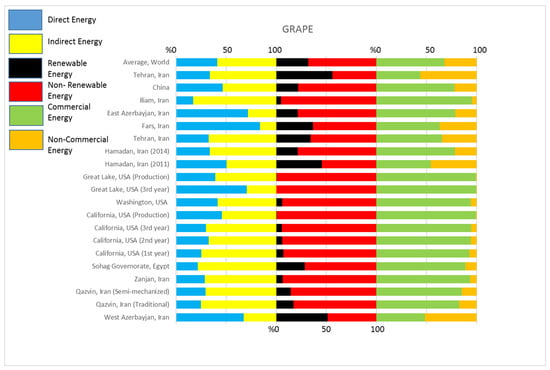

The use of direct energy sources in grape production was between 17.07% in Iliam (Iran) [29] and 84.04% in Fars (Iran) [32] (Figure 13). While the minimum renewable and non-commercial energy use was 0.22% in Great Lake (USA) [8], it reached its maximum amount with 56.02% for renewable energy use in Tehran (Iran) [33] and 99.78% for non-commercial energy use in Great Lake (USA) [8].

Figure 13.

Energy types in grape production in West Azerbayjan (Iran) [34], Qazvin (Iran) (Traditional) [35], Qazvin (Iran) (Semi-mechanized) [35], Zanjan (Iran) [36], Sohag Governorate (Egypt) [30], California (USA) (1st, 2nd, 3rd Year, Production) [8], Washington (USA) [8], Great Lake (3rd Year, Production) [8], Hamadan (Iran) (2011 [37] and 2014 [31]), Tehran (Iran) [38], Fars (Iran) [32], East Azarbayjan (Iran) [39], Illiam (Iran) [29], China [28], Tehran (Iran) [33], [Average (World) [40].

3.3. Pomegranates

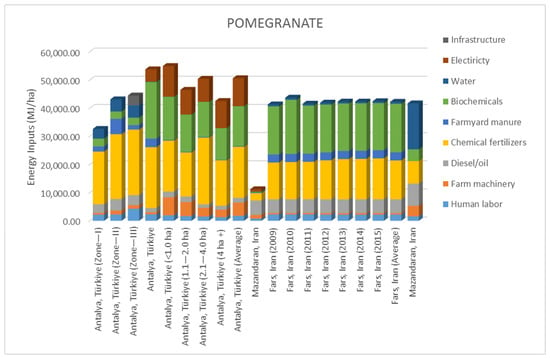

Despite being primarily associated with tropical and subtropical climates, pomegranates are becoming more and more frequently produced worldwide, especially in Türkiye. They can also grow to some extent in warm, temperate climates [41]. In Türkiye, pomegranate production involves various energy inputs, as shown in Figure 14. Pomegranate cultivation in Antalya (Zone—III) had the highest energy input from human labor (4293.00 MJ/ha) [42]. With a value of 790.57 MJ/ha, Mazandaran, Iran, had the lowest energy input for labor by humans [43]. At 6403.20 MJ/ha, Antalya (<1.0 ha) produced the most pomegranates with the highest energy input in farm machinery (Figure 14). Fars, Iran, had the lowest value with 482.63 MJ/ha [44]. The highest value for the diesel/oil energy input was recorded in Mazandaran, Iran, at 7887.00 MJ/ha [45]. The lowest amount was recorded in Antalya, Türkiye (2.1–4.0 ha) at 1224.90 MJ/ha [46]. Figure 14 illustrates that Mazandaran (Iran) had the highest energy input for water use, with 16,320.00 MJ/ha [45]. The lowest energy input value (35.80 MJ/ha) was found in the study carried out in Antalya, Türkiye [46]. Mazandaran, Iran, had the lowest energy input value, at 811.31 MJ/ha [43], while Antalya, Türkiye (<1.0 ha) had the highest, at 10,859.60 MJ/ha [46]. Only Antalya (Türkiye) (Zone—III) had an energy input for infrastructure use, with a value of 3484.20 MJ/ha [42].

Figure 14.

Energy inputs in pomegranate production in Antalya (Türkiye) (Zone—I, II & III) [42], Antalya (Türkiye) [47], Antalya (Türkiye) (<1.0 ha, 1.1–2.0 ha, 2.1–4.0 ha, 4 ha+, Average) [46], Mazandaran (Iran) [43], Fars (Iran) (2009, 2010, 2011, 2012, 2013, 2014, 2015 & Average) [44], Mazandaran (Iran) [45].

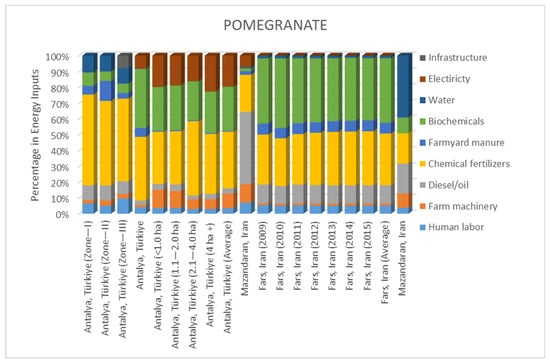

Figure 15 shows that the use of chemical fertilizers was greater than other energy input values, with Antalya (Zone—I) (Türkiye) having the highest energy input (57.40%) [42]. Mazandaran, Iran, had the lowest percentage, 19.18% [45]. Despite being used sparingly, farmyard manure has a 12.66% energy input in Antalya (Zone—III) (Türkiye). Iran made greater use of biochemicals. Mazandaran (Iran) had the lowest energy input ratio, with a value of 1.85% [43], while Fars (Iran) had the highest, with a value of 44.00% [44].

Figure 15.

Percentage of energy inputs in pomegranate production in Antalya (Türkiye) (Zone—I, II & III) [42], Antalya (Türkiye) [47], Antalya (Türkiye) (<1.0 ha, 1.1–2.0 ha, 2.1–4.0 ha, 4 ha+, Average) [46], Mazandaran (Iran) [43], Fars (Iran) (2009, 2010, 2011, 2012, 2013, 2014, 2015 & Average) [44], Mazandaran (Iran) [45].

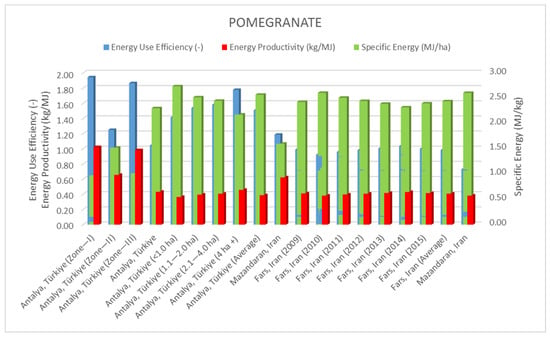

The energy use efficiency in pomegranate production in Antalya (Zone—I) (Türkiye) had the highest value, at 1.94% (Figure 16) [42]. In order to have a high energy efficiency in pomegranate production, high output values and low input parameters ensure that it reaches a balance state. For this reason, among the energy parameters, the high input amounts of chemical fertilizer affected the energy efficiency. Iran’s Mazandaran had the lowest percentage (0.73%) [45]. Figure 16 illustrates that the highest energy productivity (1.02 kg/MJ) [42] was recorded in Antalya (Zone—I) in Türkiye. With a yield of 0.37 kg/MJ, pomegranate production on less than 1 ha had the lowest energy productivity [46]. Antalya (Türkiye) (<1 ha) had the highest specific energy value in pomegranate production (2.74 MJ/kg) [46]. Antalya (Zone—I) (Türkiye) had the lowest specific energy, with 0.98 MJ/kg [42]. The energy input energy was very high in Türkiye, and had a high yield and thus a high output energy. The maximum energy use efficiency of 1.94% in Türkiye was higher than all other countries examined. The chemical fertilizer energy use was very high in Türkiye; the water and biochemical energy use was also high in some regions of Türkiye. In other studies, the chemical fertilizer, biochemical, and diesel/oil energy share in the total energy input was very high.

Figure 16.

Energy use efficiency, energy productivity, and specific energy in pomegranate production in Antalya (Türkiye) (Zone—I, II & III) [42], Antalya (Türkiye) [47], Antalya (Türkiye) (<1.0 ha, 1.1–2.0 ha, 2.1–4.0 ha, 4 ha+, Average) [46], Mazandaran (Iran) [43], Fars (Iran) (2009, 2010, 2011, 2012, 2013, 2014, 2015 & Average) [44], Mazandaran (Iran) [45].

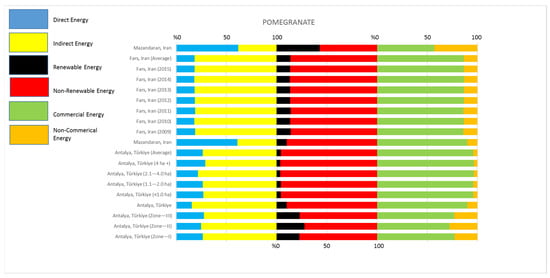

Figure 17 shows the different energy types in pomegranate production in Türkiye and in all of the countries studied. Among these energy types are the direct and indirect energy input parameters. The province with the highest direct energy value (61.82%) was Mazandaran (Iran) [45]. The indirect energy input parameters remained high. Figure 16 shows that the highest value was in Antalya (Türkiye), with 84.60% [47], while the lowest value was in Mazandaran (Iran) with 38.18% [45]. Other types of energy in pomegranate production include renewable and non-renewable energy. Non-renewable energy parameters are used more in pomegranate production (Figure 16). In Mazandaran (Iran), there is an almost equal use of renewable and non-renewable energy sources, and the energy input ratio in renewable energy sources was 42.90% [45]. It is seen in Figure 16 that the renewable energy input ratio in pomegranate production in areas between 2.1 and 4.0 ha in Antalya (Türkiye) was low (3.53%) [46]. The province with the highest energy input ratio in non-renewable energy resources was Antalya (Türkiye) in pomegranate production between 2.1 and 4.0 ha (96.47%) [46]. The lowest non-renewable energy input ratio was in Mazandaran (Iran) province, with 57.10% [45]. It can be seen in Figure 17 that among the commercial and non-commercial energy input ratio in pomegranate production, the highest energy input was for commercial energy. The highest commercial energy input was in Antalya (Türkiye), which produces pomegranates between 2.1 and 4.0 hectares, with a ratio of 96.47% [46], but the lowest was in Mazandaran (Iran), with a ratio of 57.10% [45]. The highest non-commercial energy input was in Mazandaran (Iran), with 42.90% [45]. The lowest was Antalya (Türkiye), with a ratio of 3.53% for 2.1–4.0 hectares [46].

Figure 17.

Energy types in pomegranate production in Antalya (Türkiye) (Zone—I, II & III) [42], Antalya (Türkiye) [47], Antalya (Türkiye) (<1.0 ha, 1.1–2.0 ha, 2.1–4.0 ha, 4 ha+, Average) [46], Mazandaran (Iran) [43], Fars (Iran) (2009, 2010, 2011, 2012, 2013, 2014, 2015 & Average) [44], Mazandaran (Iran) [45].

3.4. Strawberries

Among the berry-like fruits, strawberries can be consumed raw or cooked, and they have a worthy place on the table. The herbaceous structure of the strawberry, which is used in marmalade, jam, cake decorating, confectionery, and aromatic fruit, draws attention. Its superficial root structure sets it apart from other fruits. It can be grown both outside and indoors.

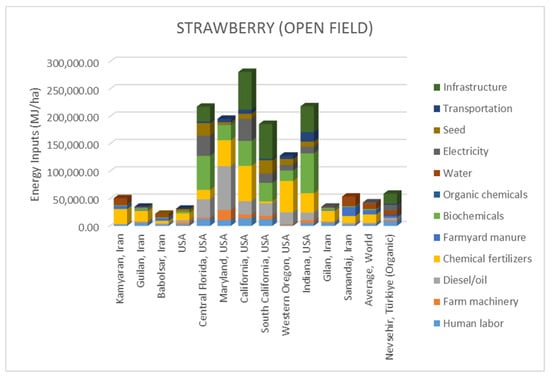

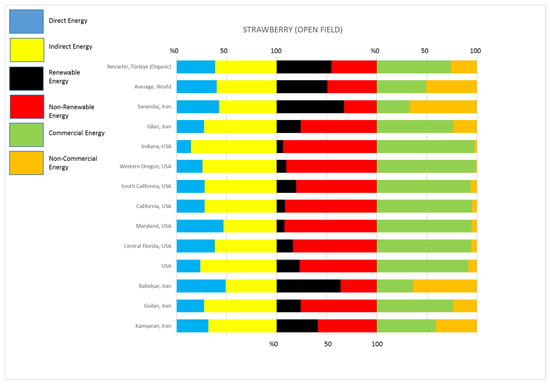

The various energy inputs used in open-field strawberry production in Türkiye are depicted in Figure 18. California (USA) had the largest human labor energy input, at 13,972.80 MJ/ha, while Western Oregon (USA) had the lowest, at 1691.48 MJ/ha [8]. By using 130.48 MJ/ha of farm machinery, Kamyaran (Iran) had the lowest energy input [48]. The highest amount was in Maryland (USA), with 18,384.03 MJ/ha [8]. Kamyaran, Iran, had the lowest value, 957.27 MJ/ha [48], while Maryland, USA, had the highest value, 80,073.14 MJ/ha [8], for the diesel/oil energy input parameter. The highest energy input amount was 17,689.00 MJ/ha in Sanandaj (Iran) [49], where farming uses water above the world average [40]. Figure 18 shows that no water was used for strawberry production at all in the USA [8]. It was in California, United States, where the amount of electricity used was roughly 26 times higher than the global average (1545.66 MJ/ha) [8].

Figure 18.

Energy inputs in open-field strawberry production in Türkiye [50] and Kamyaran (Iran) [48], Guilan (Iran) [51], Babolsar (Iran) [52], USA, Central Florida, Maryland, California, South California, Western Oregon & Indiana (USA) [8], Gilan (Iran) [53], Sanandaj (Iran) [49], Average (World) [40].

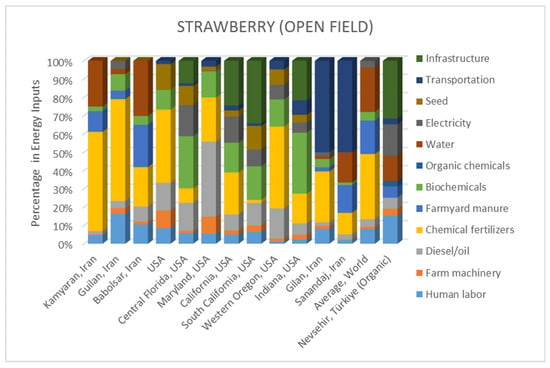

The energy inputs used in open-field strawberry production in Türkiye are displayed in Figure 19. Around the world, chemical fertilizers are frequently used. The greatest energy input ratio in chemical fertilizer was found to be 55.63% in research conducted in Guilan, Iran [51]. In Southern California (USA), the energy input ratio for chemical fertilizer was the lowest, at 1.72% [8]. Despite the low usage of farmyard manure, the province of Sanandaj (Iran) had the highest ratio of energy input (30.29%) [49]. Strawberry production did not involve the use of biochemicals. Figure 19 shows that the province of Kamyaran (Iran) had the lowest energy input ratio of biochemical use in strawberry production (2.51%) [48] and the state of Indiana (USA) had the highest (33.33%) [8]. The Central Province had the highest energy ratio, at 14.19%, out of all the states where seed use was documented [8]. In Southern California, the use of plastic in strawberry production required the most energy (34.16%) [8].

Figure 19.

Percentage of energy inputs in open-field strawberry production in Türkiye [50] and Kamyaran (Iran) [48], Guilan (Iran) [51], Babolsar (Iran) [52], USA, Central Florida, Maryland, California, South California, Western Oregon & Indiana (USA) [8], Gilan (Iran) [53], Sanandaj (Iran) [49], Average (World) [40].

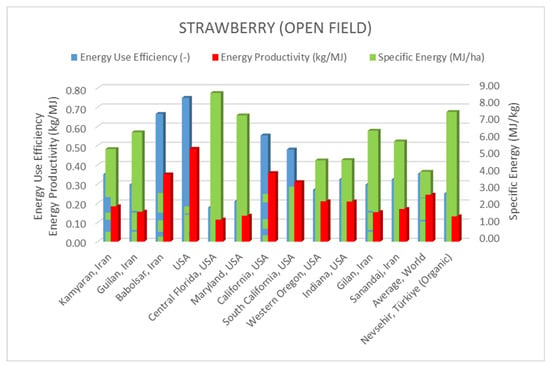

The energy productivity, energy use efficiency, and specific energy values in open-field strawberry production are depicted in Figure 20. With a 0.75 energy use efficiency, the USA led the world [8]. The high amounts of energy input for chemical fertilizers and biochemicals in strawberry production caused increases and decreases in energy efficiency. The USA had the highest value of energy productivity (0.48 kg/MJ). Figure 20 illustrates that Central Florida (USA) had the highest specific energy, measuring 8.71 MJ/kg [8]. There was only one study in Türkiye on strawberry production energy analysis; the energy input was high, but, on the contrary, the energy output was low. Therefore, some studies to improve strawberry yields are advised in order to improve energy use efficiency. In other countries besides Türkiye, the chemical fertilizer and biochemical energy usage was very high, so reducing these input amounts would improve the energy use efficiency.

Figure 20.

Energy use efficiency, energy productivity, and specific energy in open-field strawberry production in Türkiye [50] and Kamyaran (Iran) [48], Guilan (Iran) [51], Babolsar (Iran) [52], USA, Central Florida, Maryland, California, South California, Western Oregon & Indiana (USA) [8], Gilan (Iran) [53], Sanandaj (Iran) [49], Average (World) [40].

The different forms of energy used in open-field strawberry production in Türkiye and around the world are depicted in Figure 21. There was significant indirect energy consumption across all energy types from both direct and indirect energy sources. Indiana, USA, had the highest input ratio (85.64%) for indirect energy resources [8]. Babolsar, Iran, had the greatest input ratio for direct energy, 49.02% [52]. With a ratio of 67.32%, Sanandaj, Iran, had the highest value for renewable energy resources [49]. In Babolsar (Iran), the renewable energy inputs were equal (63.84%) [52]. The highest non-renewable energy input was in Indiana (USA), with 93.43% [8]. Figure 21 shows that the highest ratio in the use of commercial energy resources was in Western Oregon (USA), with 98.68% [8].

Figure 21.

Different energy types in open-field strawberry production in Türkiye [50] and Kamyaran (Iran) [48], Guilan (Iran) [51], Babolsar (Iran) [52], USA, Central Florida, Maryland, California, South California, Western Oregon & Indiana (USA) [8], Gilan (Iran) [53], Sanandaj (Iran) [49], Average (World) [40].

4. Conclusions

In this study, an energy analysis for fruits grown in different countries was performed. The fruits subject to research were the wolfberry, grape, strawberry, and pomegranate. The energy input parameters specified were human labor, animal, water, diesel/oil, electricity, biochemicals, farmyard manure, chemical fertilizers, organic chemicals, infrastructure, organic fertilizers, farm machinery, seeds, and transportation were used in all fruits. The water usage, which was among the energy input parameters, was highest in the production of mulberry fruits (75.34%) and lowest in the production of pomegranate fruits (0.07%). While the energy input in farmyard manure was used the most in open-field strawberry production (30.29%), the lowest was in pomegranate production (0.49%). A diesel/oil energy input was used more in pomegranate production (45.81%) than for other fruits. The lowest diesel/oil energy input was available in open-field strawberry production (1.90%). The fruit with the highest energy input in farm machinery was grapes (23.34%). The lowest energy input was in greenhouse strawberry production (0.08%). The energy input in the use of human labor in goji berry production was the highest (39.26%), and the lowest was in strawberry production in open fields (1.32%). The energy consumption for electricity was not used in mulberry production. The highest energy input rate was for goji berry production (68.52%), and the lowest was for strawberries produced in open fields (0.49%). Energy input values for organic chemicals were used only in wolfberries and grapes, and the highest was seen in grapes (5.52%). Among the input parameters, biocides occurred only in goji berries (5.45%). Chemical fertilizers were not used in mulberry and organic fig production. While the energy input in pomegranate production (57.40%) had the highest value, this was the lowest in grape production (0.09%).

A number of measures can be taken to ensure the effective use of energy in crop production systems and to adopt a more effective approach in terms of sustainability, the environment, and energy. These measures cover direct and indirect energy use, renewable and fossil energy use, and commercial and non-commercial energy use. In addition, re-planning should be performed to reduce the carbon footprint and water footprint of the inputs used. The use of modern technology and equipment should be encouraged to increase the energy efficiency of agricultural equipment, irrigation systems, and machinery used in other processes. Incentives and support should be provided to farmers to benefit from renewable energy sources, such as solar energy and wind energy. To reduce the use of chemical fertilizers, the use of organic fertilizers and alternative inputs (compost, green manure, balancing plants) should be encouraged. The use of water-saving methods such as drip irrigation should be encouraged. Water management systems, such as sensors that monitor soil moisture and modern irrigation technologies, should be used. To reduce carbon emissions, soil cultivation methods should be reviewed and low-carbon agricultural practices should be encouraged. The recycling of agricultural waste should be encouraged, and sustainable methods should be adopted for the management of waste generated in agricultural production processes.

Each type of fruit production mentioned in this study has its own unique energy input. The type of production (open field, organic, conventional, greenhouse) changes the energy use, and, subsequently, the energy parameters change. For this reason, precautions should be taken to increase energy use efficiency in each type of production (open field, organic, conventional, greenhouse).

Author Contributions

Conceptualization, C.E.; Methodology, C.E.; Investigation, C.E., A.C. and K.E.; Resources, A.C.; Data curation, C.E.; Writing—original draft, A.C.; Writing—review & editing, C.E. and K.E.; Supervision, K.E. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ağaoğlu, Y.S.; Çelik, H.; Çelik, M.; Fidan, Y.; Gülşen, Y.; Günay, A.; Halloran, N.; Köksal, A.İ.; Yanmaz, R. Genel Bahçe Bitkileri; T.C. A.Ü.Z.F. Eğitim, Araştırma ve Geliştirme Vakfı Yayınları No. 4: Ankara, Turkey, 1997. (In Turkish) [Google Scholar]

- Kılıç, O.; Eryılmaz, G.A.; Çakır, S. Konvansiyonel Meyve Yetiştiriciliği Yapan Üreticilerin Organik Tarım ve İyi Tarım Uygulamaları Konusundaki Görüşleri: Zonguldak İli Örneği, Türkiye. Türkiye Tarımsal Araştırmalar Derg. 2021, 8, 109–115. (In Turkish) [Google Scholar] [CrossRef]

- FAO. Dünyada ve Türkiye’de Narenciye Üretim Potansiyeli ve Verim Miktarları; Food and Agriculture Organization of the United Nations: Rome, Italy, 2022. (In Turkish) [Google Scholar]

- TUİK. 2023. Available online: https://www.tuik.gov.tr/ (accessed on 10 January 2024). (In Turkish)

- Öztürk, H.H. Bitkisel Üretimde Enerji Yönetimi; HASAD Yayıncılık: İstanbul, Turkey, 2021. (In Turkish) [Google Scholar]

- Ekinci, K.; Demircan, V.; Atasay, A.; Karamursel, D.; Sarica, D. Energy, economic and environmental analysis of organic and conventional apple production in Türkiye. Erwerbs-Obstbau 2020, 62, 1–12. [Google Scholar] [CrossRef]

- Akbolat, D.; Ekinci, K.; Demircan, V. Energy input-output and economic analysis of rose production in Türkiye. J. Agron. 2006, 5, 570–576. [Google Scholar]

- Pimentel, D. Handbook of Energy Utilization in Agriculture; CRC Press: Boca Raton, FL, USA, 1980; 487p, ISBN 9781315893419. [Google Scholar]

- Pervanchon, F.; Bockstaller, C.; Girardin, P. Assessment of energy use in arable farming systems by means of an agro-ecological indicator: The energy indicator. Agric. Syst. 2002, 72, 149–172. [Google Scholar] [CrossRef]

- Mandal, K.G.; Saha, K.P.; Ghosh, P.K.; Hati, K.M.; Bandyopadhyay, K.K. Bioenergy and economic analysis of soybean-based crop production systems in central India. Biomass Bioenergy 2002, 23, 337–345. [Google Scholar] [CrossRef]

- Taki, M.; Ajabshirchi, Y.; Ghasemi, H.M. Energy consumption input and eoutput relationship and cost analysis for greenhouse. Am. J. Exp. Agric. 2012, 2, 485–501. [Google Scholar]

- Taki, M.; Yildizhan, H. Evaluation the sustainable energy applications for fruit and vegetable productions processes; case study: Greenhouse cucumber production. J. Clean. Prod. 2018, 199, 164–172. [Google Scholar] [CrossRef]

- Barut, Z.B.; Ertekin, C.; Karaagac, H.A. Tillage effects on energy use for corn silage in Mediterranean Coastal of Türkiye. Energy 2011, 36, 5466–5475. [Google Scholar] [CrossRef]

- Demircan, V.; Ekinci, K.; Keener, H.M.; Akbolat, D.; Ekinci, C. Energy and economic analysis of sweet cherry production in Türkiye: A case study from Isparta province. Energy Convers. Manag. 2006, 47, 1761–1769. [Google Scholar] [CrossRef]

- Hatirli, S.A.; Ozkan, B.; Fert, C. An econometric analysis of energy input-output in Turkish agriculture. Renew. Sustain. Energy Rev. 2005, 9, 608–623. [Google Scholar] [CrossRef]

- Ertekin, C.; Canakci, M.; Kulcu, R.; Yaldız, O. Energy use pattern of some tuber plants cultivation over Turkey. In Proceedings of the XXXIV CIOSTA CIGR V Conference 2011, Efficient and Safe Production Processes in Sustainable Agriculture and Forestry, Vienna, Austria, 29 June–1 July 2011. [Google Scholar]

- Wang, Y.; Ma, Q.; Li, Y.; Sun, T.; Jin, H.; Zhao, C.; Milne, E.; Easter, M.; Paustian, K.; Yong, H.; et al. Energy Consumption, Carbon Emissions and Global Warming Potential of Wolfberry Production in Jingtai Oasis, Gansu Province, China. Environ. Manag. 2019, 64, 772–782. [Google Scholar] [CrossRef]

- Oguz, H.I.; Gokdogan, O.; Baran, M.F. Determination of energy balance in organic wolfberry (Lycium barbarum L.) production in Türkiye. Erwerbs-Obstbau 2019, 61, 61–66. [Google Scholar] [CrossRef]

- Gözener, B.; Kaya, Y.; Sayılı, M. Erzincan ili Üzümlü ilçesinde cimin üzümü üretimi ve pazarlama durumu. Gaziosmanpaşa Bilimsel Araştırma Derg. 2014, 9, 74–80. (In Turkish) [Google Scholar]

- Ataseven, Z.Y. Tarım Ürünleri Piyasaları: Üzüm; Tarımsal Ekonomi ve Politika Geliştirme Enstitüsü: Ankara, Turkey, 2021. (In Turkish) [Google Scholar]

- Ozkan, B.; Fert, C.; Karadeniz, C.F. Energy and cost analysis for greenhouse and open-field grape production. Energy 2007, 32, 1500–1504. [Google Scholar] [CrossRef]

- Simsek, E.; Oguz, H.I.; Gokdogan, O. Energy Use Efficiency of Grape Production in Vineyard Areas of Nevsehir Province in Türkiye. Erwerbs-Obstbau 2022, 64, 113–118. [Google Scholar] [CrossRef]

- Gundogmus, E.; Bayramoglu, Z. Energy Input Use on Organic Farming: A Comparative Analysis on Organic versus Conventional Farms in Türkiye. J. Agron. 2006, 5, 16–22. [Google Scholar] [CrossRef]

- Akdemir, S. Determination of Energy Balance in Grape Production for Wine in Thrace Region. Erwerbs-Obstbau 2022, 64, 103–111. [Google Scholar] [CrossRef]

- Kocturk, O.M.; Engindeniz, S. Energy and cost analysis of sultana grape growing: A case study of Manisa, west Türkiye. Afr. J. Agric. Res. 2009, 4, 938–943. [Google Scholar]

- Uzun, T.; Baran, M.F. Energy Input–Output Analysis of Grape (Vitis vinifera L.) Production in Türkiye, A Case Study from Siirt Province. Erwerbs-Obstbau 2022, 64, 95–102. [Google Scholar] [CrossRef]

- Baran, M.F.; Lule, F.; Gokdogan, O. Energy input-output analysis of organic grape production: A case study from Adiyaman Province. Erwerbs-Obstbau 2017, 59, 275–279. [Google Scholar] [CrossRef]

- Tian, D.; Wang, J.; Feng, J. Analysis of energy consumption for protected grape production system in China. Adv. Mater. Res. 2015, 1073–1076, 2468–2472. [Google Scholar] [CrossRef]

- Kamari, F.; Ghamary, B.; Azizpanah, A. Determination and Evaluation of energy consumption for grape production in Eyvan county (Ilam province). Agric. Eng. Int. CIGR J. 2021, 23, 173. [Google Scholar]

- Abdelkader, M.; Zargar, M.; Murtazova, K.M.S.; Nakhaev, M.R. Life Cycle Assessment of the Cultivation Processes for the Main Vegetable Crops in Southern Egypt. Agronomy 2022, 12, 1527. [Google Scholar] [CrossRef]

- Rasouli, M.; Namdari, M.; Mousavi-Avval, S.H. Modeling and analysis of energy efficiency in grape production of Iran. J. Agric. Technol. 2014, 10, 517–532. [Google Scholar]

- Khoshroo, A.R.; Emrouznejad, A.; Ghaffarizadeh, A.; Kasraei, M.; Omid, M. Sensitivity analysis of energy inputs in crop production using artificial neural networks. J. Clean. Prod. 2018, 197, 992–998. [Google Scholar] [CrossRef]

- Mohseni, P.; Borghei, A.M.; Khanali, M. Coupled life cycle assessment and data envelopment analysis for mitigation of environmental impacts and enhancement of energy efficiency in grape production. J. Clean. Prod. 2018, 197, 937–947. [Google Scholar] [CrossRef]

- Mardani, A.; Taghavifar, H. An overview on energy inputs and environmental emissions of grape production in West Azerbayjan of İran. Renew. Sustain. Energy Rev. 2016, 54, 918–924. [Google Scholar] [CrossRef]

- Rahmani, A.; Parashkoohi, M.G.; Zamani, D.M. Sustainability of environmental impacts and life cycle energy and economic analysis for different methods of grape and olive production. Energy Rep. 2022, 8, 2778–2792. [Google Scholar] [CrossRef]

- Alizadeh, H.H.A.; Taromi, K. An Investigation of Energy Use Efficiency and CO2 Emissions for Grape Production in Zanjan Province of Iran. Int. J. Adv. Biol. Biom. Res. 2014, 2, 2249–2258. [Google Scholar]

- Hamedani, S.R.; Keyhani, A.R.; Alimardani, R. Energy use patterns and econometric models of grape production in Hamadan province of Iran. Energy 2011, 36, 6345–6351. [Google Scholar] [CrossRef]

- Karimi, M.; Moghaddam, H. On-farm energy flow in grape orchards. J. Saudi Soc. Agric. Sci. 2018, 17, 191–194. [Google Scholar] [CrossRef]

- Sattari-Yuzbashkandi, S.; Khalilian, S.; Mortazavi, S.A. Energy efficiency for open-field grape production in Iran using Data Envelopment Analysis (DEA) approach. Int. J. Farming Allied Sci. 2014, 3–6, 637–646. [Google Scholar]

- Elsoragaby, S.; Yahya, A.; Mahadi, M.R.; Nawi, N.M.; Mairghany, M. Energy utilization in major crop cultivation. Energy 2019, 173, 1285–1303. [Google Scholar] [CrossRef]

- Şahin, A. Nar Yetiştiriciliği. T.C.; Tarım ve Orman Bakanlığı Tarımsal Araştırmalar ve Politikalar Genel Müdürlüğü Batı Akdeniz Tarımsal Araştırma Enstitüsü: Antalya, Turkey, 2020. Available online: https://arastirma.tarimorman.gov.tr/batem/Belgeler/Kutuphane/Teknik%20Bilgiler/Nar%20Yeti%C5%9Ftiricili%C4%9Fi.pdf (accessed on 10 January 2024). (In Turkish)

- Canakci, M. Energy use pattern and economic analyses of pomegranate cultivation in Türkiye. Afr. J. Agric. Res. 2010, 5, 491–499. [Google Scholar]

- Troujeni, M.E.; Khojastehpour, M.; Vahedi, A.; Emadi, B. Sensitivity analysis of energy inputs and economic evaluation of pomegranate production in Iran. Inf. Process. Agric. 2018, 5, 114–123. [Google Scholar] [CrossRef]

- Houshyar, E.; Mahmoodi-Eshkaftaki, M.; Azadi, H. Impacts of technological change on energy use efficiency and GHG mitigation of pomegranate: Application of dynamic data envelopment analysis models. J. Clean. Prod. 2017, 162, 1180–1191. [Google Scholar] [CrossRef]

- Nouri-Khjebelagh, R.; Sefidkouhi, M.A.G.; Khoshravesh, M. Evaluation of energy indices and greenhouse gas emissions in major horticultural crops and paddy crops in Tajan plain. Appl. Water Sci. 2023, 13, 39. [Google Scholar] [CrossRef]

- Ozalp, A.; Yilmaz, S.; Ertekin, C.; Yilmaz, I. Energy Analysis and Emissions of Greenhouse Gases of Pomegranate Production in Antalya Province of Türkiye. Erwerbs-Obstbau 2018, 60, 321–329. [Google Scholar] [CrossRef]

- Akcaoz, H.; Ozcatalbas, O.; Kizilay, H. Analysis of energy use for pomegranate production in Türkiye. J. Food Agric. Environ. 2009, 7, 475–480. [Google Scholar]

- Salami, P.; Ahmadi, H.; Keyhani, A. Estimating the Energy İndices and Profitability of Strawberry Production in Kamyaran Zone of İran. Energy Res. J. 2010, 1, 32–35. [Google Scholar] [CrossRef]

- Salami, P.; Ahmadi, H.; Keyhani, A.R. Energy use and economic analysis of strawberry production in Sanandaj zone of Iran. Biotechnol. Agron. Soc. Environ. 2010, 14, 653–658. [Google Scholar]

- Baran, M.F.; Oguz, H.I.; Gokdogan, O. Determination of energy input-output analysis in organic strawberry production. Fresenius Environ. Bull. 2017, 26, 2076–2081. [Google Scholar]

- Khoshnevisan, B.; Rafiee, S.; Omid, M.; Mousazadeh, H. Developing an Artificial Neural Networks Model for Predicting Output Energy and GHG Emission of Strawberry Production. İnt. J. Appl. Oper. Res. 2013, 3, 43–54. [Google Scholar]

- Loghmanpor, R.; Tabatabaekoloor, R.; Akram, A. Input-Output Energy and Economic Analysis of Strawberry Production in Iran. Am. J. Eng. Res. AJER 2013, 2, 173–177. [Google Scholar]

- Khoshnevisan, B.; Shariati, H.M.; Rafiee, S.; Mousazadeh, H. Comparison of energy consumption and GHG emissions of open field and greenhouse strawberry production. Renew. Sustain. Energy Rev. 2014, 29, 316–324. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).