Abstract

This study explores the potential of sugarcane (Saccharum officinarum L.) leaves (SCLs), a significant agricultural waste, for the sustainable production of carboxymethyl cellulose (CMC) utilizing an innovative approach of carboxymethylation with monochloroacetic acid and varying sodium hydroxide (NaOH) concentrations (ranging from 20 to 60 g/100 mL). The optimal carboxymethylation condition was identified as 40 g/100 mL NaOH, which yielded the highest degree of substitution (DS = 0.86). Furthermore, a higher ash content in the obtained CMC indicated significant carboxymethyl substitution within the structure. The chemical structure of cellulose and the resulting polymers were characterized using Fourier transform infrared spectroscopy (FTIR). The FTIR spectrum exhibited characteristic peaks of carboxymethyl groups and their salts at wavenumbers of 1588–1591 cm−1 and 1413–1415 cm−1, respectively. The analyses from X-ray diffraction (XRD) and field emission scanning electron microscopy (FE-SEM) revealed detailed insights into the crystallinity and morphology of carboxymethyl cellulose (CMC). The levels of heavy metals, including arsenic, lead, cadmium, and mercury, in the purified CMC were assessed using inductively coupled plasma mass spectrometry (ICP-MS) and were found to be within the recommended WHO/FAO limits, except for lead, which exceeded permissible levels. The prepared CMC demonstrated high purity at 99.34%, surpassing the 98.00% purity requirement for commercial-grade CMC. This product exhibits strong potential for diverse industrial applications, including paper coating, textile sizing and printing, ceramic glazing, and various uses in the oil industry.

1. Introduction

The proliferation of undesired agricultural waste products and byproducts resulting from agricultural activities and agro-based processing poses a critical environmental challenge, thereby leading to the genesis of pollution. A considerable portion of these agricultural residues primarily comprises cellulose originating from the intricate composition of plant cell walls [1]. Cellulose is the most abundant polymer on earth, making it the most common organic compound [2,3]. The photosynthetic process yields considerable cellulose production, with an estimated annual output of approximately 830 million metric tons. Notably, cellulose constitutes 40% of the dry weight of crops, thus accounting for an annual production of around 200 million tons. Within the plant kingdom, cellulose content varies, with plants typically containing approximately 33%, wood comprising around 50%, and cotton boasting an impressively high cellulose content of 90% [2,4].

Cellulose, a linear and high-molecular-weight polymer comprising glucose monosaccharide units interconnected through beta acetal linkages, exhibits unique characteristics due to the presence of hydrogen bonding in its molecular structure. So, cellulose displays limited solubility and resistance to melting in common solvents. These attributes render it less relevant for numerous industrial applications, with some notable exceptions including its usage in the construction of wood-based structures; the production of various paper products; as raw material for fabricating cotton, linen, and rayon textiles; incorporation in nitrocellulose explosives, and the synthesis of cellulose acetate films [5]; as well as use in food industries [6]. Cellulose’s inherent susceptibility to chemical derivatization enables its transformation into valuable chemical feedstock. Notably, etherification stands out as a pivotal pathway in the cellulose derivatization process [5,7,8]. The conversion of cellulose into high-value cellulose esters and ethers has garnered substantial attention within the realms of green and sustainable chemistry, thereby fostering the advancement of environmentally friendly technologies [9].

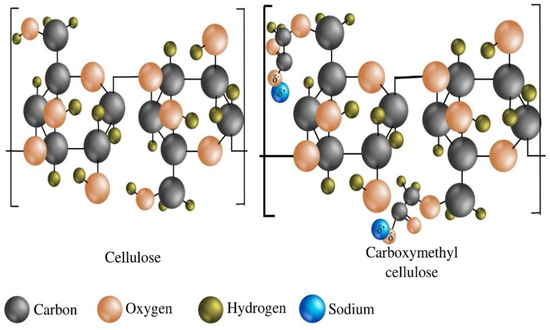

Carboxymethyl cellulose (CMC) is an anionic, water soluble derivative of cellulose, which is a linear polysaccharide composed of an anhydro glucose unit linked by -1,4-glycosidic bonds. At the molecular level, the major difference between CMC and cellulose is only some anionic carboxymethyl groups (i.e., –CH2COOH) in the CMC structure that replace the hydrogen atoms from some hydroxyl groups present in the pristine cellulose infrastructure [10]. CMC, a derivative of cellulose, is environmentally friendly due to its nontoxicity, biodegradability, and diverse uses. As a result, it has been used in numerous industrial applications, including paper, textile, pharmaceutical, food exploration, paint industries, biomedical, construction, plastics, cosmetics, and oil industries [5,10].

In the customary production of CMC, a two-step reaction process is employed involving alkalization and etherification. Initially, cellulose is activated by NaOH in an organic solvent, such as isopropanol (IPA), ethanol, or methanol, in a reaction depicted as shown in Equation (1). Subsequently, cellulose is subjected to etherification at hydroxyl groups using monochloroacetic acid (MCA) to yield CMC, as depicted in Equation (2) and Figure 1. The tandem of these two reactions is collectively referred to as the carboxymethylation reaction. Nevertheless, an additional side reaction, as depicted in Equation (3), may occur between the surplus NaOH and MCA [1,2,3,10,11].

Figure 1.

The fundamental structural difference between cellulose and carboxymethyl cellulose (CMC) [10].

The properties of cellulose derivatives are primarily evaluated based on their DS value. The DS value is technically defined as the average number of substitutes of the reactive group by other active molecules in the polymer chain. During the synthesis of CMC from cellulose, the value of DS is determined by the number of substituent groups (carboxymethyl) attached to each anhydro glucose unit [10,12]. A maximum DS of three can be achieved [13,14]. In commercial CMC, the most common DS obtained is usually lower which is from 0.4 to 1.4 [12]. The DS of CMC is dependent upon the reagent’s concentration, reaction time, solvent, and temperature [12,15].

Many CMC derivatives have been prepared through carboxymethylation reactions using diverse substances (i.e., corn husk [1,16], mimosa pigra [3], corn cobic [4], pistachio shells [17], sugarcane straw [9], cashew tree [12], brewer’s spent grain [7], sugar beet pulp [8], durian rind [18,19], cavendish banana pseudostem [20], lantana camara [21], sago palm [22], palm bunch [23,24], bagasse [23], palm kernel cake [25], and papaya peel [26,27]), as well as some waste materials (i.e., office wastepaper [2,11], carbon foam [28], and domestic matchstick waste [29]). These uses have attracted research interest for CMC producton. However, to date and to the best of our knowledge, there has been no prior research on the production of CMC from sugarcane (Saccharum officinarum L.) leaves (SCLs).

Thailand, a predominantly agricultural nation with nearly half of its land area dedicated to cultivation, generates substantial agrarian residues or wastes. This encompassing array of agricultural byproducts comprises rice straws, rice husks, cane leaves and tops, bagasse, corn husks and stalks, cassava roots, palm trunks, palm leaves and branches, cashew nut shells, and other materials. Over the years, extensive efforts have been made to repurpose these waste materials, including their conversion into animal feeds, fertilizers, or bio-based energy sources [30]. Nevertheless, certain agricultural wastes remain challenging to employ in these conventional ways, thus leading to their disposal in landfills or incineration and resulting in deleterious environmental consequences, particularly air pollution. In 2018, an excess of 159.90 million tons of agricultural wastes remained unutilized even after secondary attempts at recycling [31]. SCLs represent a surplus biomass that remains in the fields following the sugar cane harvesting process, with an excess of 45.19 million tons remaining unutilized [31].

SCLs have been recognized for their substantial cellulose content in previous reports [32,33,34]. The isolation of cellulose materials from sugarcane leaves (SCLs) facilitates the synthesis of carboxymethyl cellulose (CMC) through etherification by utilizing an alkaline medium and an etherifying agent. This research aims to investigate the impact of varying sodium hydroxide (NaOH) concentrations on the synthesis process. The concentration of NaOH is crucial in etherification, thus significantly influencing the degree of substitution (DS), yield, purity, and the physicochemical properties of the resulting CMC. The study focuses on evaluating the properties of CMC derived from SCLs, including assessments of DS, yield percentage, purity, sodium chloride content, ash content, chemical structure, and crystallinity.

2. Materials and Methods

2.1. Materials

Sugarcane leaves (SCLs) were procured from sugarcane fields situated in the Satuek district (15.11° N, 103.33° E) of Buriram, Thailand for the purpose of this study. Currently, Thailand has a total sugarcane cultivation area of 17,635,756,800 m2. In the province of Buriram, the entire cultivated area for sugarcane amounts to 208,504,000 m2, which represents 1.18% of the nation’s total sugarcane cultivation area. Within Buriram province, Satuek district is recognized as an area with a sugarcane cultivation area of 29,123,200 m2, thus accounting for 13.97% of the entire sugarcane cultivation area in the province of Buriram [35]. The SCLs, amounting to an excess of 0.074 million tons, are left in the fields after the sugarcane harvesting process in Satuek district, Buriram, Thailand, without being utilized. The chemicals utilized in the experimental procedures included isopropyl alcohol, methyl alcohol, acetic acid, ethyl alcohol, monochloroacetic acid, sulfuric acid, hexyl alcohol, ammonium oxalate, sodium metabisulphite, sodium hydroxide, and sodium chlorite, all of which were acquired from Italmar, Thailand.

2.2. Preparation of Sample

The collected SCL samples underwent a rigorous washing process with water and were subsequently air-dried under ambient conditions over a period of seven consecutive days. Following this, the samples were sectioned into small pieces and subjected to further drying at a temperature of 105 ºC for a duration of 6 h. The resulting dried material was then finely powdered in a pin mill and subsequently sieved through a 70-mesh screen (size, 0.210 mm) to ensure uniform particle size distribution [18]. The finely powdered SCL sample was carefully stored in an airtight zip lock polybag at room temperature, minimizing moisture absorption, and preserved for subsequent characterization and experimental investigations.

2.3. Isolation of -Cellulose

A measured quantity of powdered SCL sample was treated with an 18% NaOH solution for a duration of 2 h, with intermittent stirring to maintain a solid-to-liquor ratio of 1:100 at room temperature [16]. Following the reaction, the cellulose residue was separated via filtration and subsequently subjected to thorough washing with 2% acetic acid, followed by rinsing with hot distilled water. Thereafter, the cellulose was stirred with n-hexane for 1 h at room temperature, followed by additional washing steps employing 95% ethanol. Following the initial filtration, the obtained cellulose was subjected to heating with a 0.7% NaClO2 solution buffered at pH 4 in a solid-to-liquor ratio of 1:50 at a temperature range of 90–95 °C for a duration of 90 min. Subsequently, the -cellulose was separated via filtration and underwent a series of washing steps with ethanol and distilled water. The isolated -cellulose was then treated with a 0.2% sodium metabisulphite solution for 15 min, followed by additional filtration and thorough washing with distilled water. Finally, the -cellulose was dried at 60 °C until reaching a constant weight [36]. The percentage yield of the alpha cellulose products was calculated using Equation (4).

where

W1 is the weight of alpha cellulose.

W0 is the weight of powdered SCLs.

2.4. Synthesis of Carboxymethyl Cellulose

In this study, carboxymethyl cellulose (CMC) was synthesized using cellulose derived from SCLs and various sodium hydroxide (NaOH) concentrations (20%, 30%, 40%, 50%, and 60% w/v of NaOH). The initial step in the CMC synthesis involved transferring 15.0 g of cellulose powder to 50 mL of sodium hydroxide at different concentrations (20%, 30%, 40%, 50%, and 60% w/v of NaOH) and stirring for 30 min. In the subsequent step, the solution was covered with aluminum foil and heated to a reaction temperature of 55 °C in an oven for 3.5 h. After heating, the solution separated into two phases: a liquid phase, which was removed, and a solid phase, which was suspended in 100 mL of methanol (70% v/v). The mixture was then neutralized with glacial acetic acid and filtered using a Buchner funnel. To eliminate undesirable byproducts, the solid was washed five times with ethanol (70% v/v) by suspending it in 300 mL for 10 min. Finally, it was washed with 300 mL of absolute methanol and dried in an oven at 55 °C overnight [18,23]. The percentage yield of the CMC products was calculated using Equation (5).

where

W1 is the weight of CMC.

W0 is the weight of alpha cellulose.

2.5. Characterization

2.5.1. Degree of Substitution (DS)

The DS for CMC was determined following the D1439-03 Standard Test Methods for Sodium Carboxymethyl Cellulose. Initially, 5 g of CMC was introduced into a 200 mL solution of HNO3–methanol (1:1 v/v). This solution was agitated and left undisturbed for 3 h. Subsequently, the solution was rinsed with a 70% methanol solution (v/v) and dried in an oven until a constant weight was achieved. Next, 2 g of the dried sample was dissolved in 200 mL of distilled water and 30 mL of 1 N NaOH. The solution was then titrated with excess NaOH using 1 N HCl to a phenolphthalein endpoint. Titration was considered complete when the color transitioned from dark pink to colorless [8,9,37]. The DS was determined using Equations (6) and (7).

where

A is milliequivalents of acid consumed per gram of sample.

B is NaOH solution added (mL).

C is normality of the NaOH solution (N).

D is HCl required for titration of the excess NaOH (mL).

E is normality of the HCl (N).

F is acid carboxymethyl cellulose used (g).

The value 162 is gram molecular mass of the anhydro glucose unit of cellulose.

The value 584 is net increase in molecular mass of anhydro glucose unit for each carboxymethyl group substituted.

2.5.2. Purity

A quantity of 1.5 g of CMC was introduced into 100 mL of 80% methanol (v/v). This solution was subjected to stirring and allowed to stand for 10 min. Subsequently, the solution was filtered and rinsed with 100 mL of 80% methanol (v/v). To achieve a state of pure CMC, the sample was then dried at 100 °C until a consistent weight was attained [8,9]. The percentage of CMC purity was calculated using Equation (8).

where

W1 is the final weight.

W0 is the initial weight.

2.5.3. Sodium Chloride Content

A quantity of 2.0 g of CMC was placed into 250 mL of a 65% methanol solution (v/v). This solution was allowed to stand for 5 h, after which it separated into two distinct phases. A volume of 100 mL from the liquid phase was neutralized with diluted HNO3 and subjected to titration using a 0.1 N AgNO3 solution until a K2CrO4 endpoint was reached. The titration was considered complete when the color transitioned from red to orange brick [8]. The percentage of NaCl content in CMC was determined using Equation (9).

where

V is the amount of AgNO3 (mL).

m is the weight of dried sample (g).

2.5.4. Ash Content

The ash content of CMC was assessed in accordance with the D7582-15 Standard Test Methods for Proximate Analysis of Coal and Coke by Macro Thermogravimetric Analysis (Mettler Toledo, TGA/DSC 3+, Greifensee, Switzerland) [38]. The ash yield represents the residue that remains after subjecting the samples to heating.

2.5.5. Inductively Coupled Plasma Mass Spectrometer (ICP-MS)

The ICP-MS instrument utilized in this study was the NexION 350X provided by PerkinElmer, Waltham, MA, USA. Data analysis and instrument control were performed using SyngistixTM for ICP-MS version 1.0. Sample preparation involved microwave digestion, which is a technique facilitated by the Titan MPS instrument from PerkinElmer, Rodgau, Germany. In this process, microwave energy was used to break down the sample matrix and convert the elements of interest into their atomic form. Subsequently, the ions generated were introduced into the ICP-MS system, separated by their mass-to-charge ratio, and quantified [39].

2.5.6. Fourier Transform Infrared Spectroscopy (FTIR)

The functional groups of both -cellulose and carboxymethylcellulose were ascertained using an infrared spectrophotometer employing the KBr disc technique. This analysis was conducted utilizing a Nicolet iS50 model instrument from Thermo Scientific, Waltham, MA, USA, and the OMNIC software (version 9.12.1019). Pellets were prepared by grinding 0.2 mg of -cellulose and carboxymethylcellulose with 2 mg of KBr. Transmission measurements were performed across the wavenumber range of 4000–400 cm−1.

2.5.7. X-ray Diffractometry (XRD)

The X-ray diffraction patterns, used to assess the crystallinity of cellulose and CMC, were obtained using an X-ray diffractometer (Bruker AXS Model D8 Advance, Mannheim, Germany). The scattering angle (2) was scanned from 5° to 80° at a rate of 0.02° per step, with a duration of 0.2 s per step. The powder samples were exposed to X-ray beams with settings at 40 kV and 40 mA.

2.5.8. Field Emission Scanning Electron Microscopy (FE-SEM)

Morphological investigation of the cellulose and CMC samples was performed using field emission scanning electron microscopy or FESEM (JEOL, JSM 7800F, Tokyo, Japan). The samples were adhered to carbon tape containing a specimen stub and sputter-coated with a thin layer of gold using a sputter coater (QUORUM Q150R ES, Laughton, UK). The observation was run on a voltage of 2 kV with 500× magnification.

3. Results and Discussion

The compositional data of the SCLs sample, serving as the raw material, are meticulously presented within Table 1. It is noteworthy that Table 1 illustrates the -cellulose extracted, thereby quantifying 41.71 g per 100 g of dry biomass. These findings closely align with outcomes from similar studies, wherein corn husks were ascertained to harbor an -cellulose content of 45.13 g per 100 g dry biomass [1]. Additionally, investigations conducted by Suriyatem et al. [23] unveiled the -cellulose content of sugarcane bagasse to register at 42.5 g per 100 g of biomass. The diverse chemical composition evident in the original wood samples, even when derived from the same part and tree type, is attributed to an interplay of soil conditions, geographic locale, and prevailing climate factors [23].

Table 1.

The -cellulose content of the sample.

The -cellulose content refers to the portion of cellulosic materials that remains insoluble in a solution of sodium hydroxide of mercerizing strength under specific conditions and for a defined duration [40]. Through this process, certain components and impurities, such as wax, hemicellulose, and lignin, are dissolved, and subsequent filtration and washing steps yield a refined form of cellulose known as -cellulose [41]. This -cellulose is a white, odorless, and tasteless powder with insolubility in water. Widely utilized as a raw material, -cellulose finds applications in the manufacturing of propellants, paper, paperboards, fabrics, electrical cable insulators, cellulose derivatives, and various other products [42]. The visual characteristics of -cellulose and CMC obtained from SCLs are documented in Table 2.

Table 2.

Appearance of raw material, -cellulose, and CMC from SCLs in different conditions.

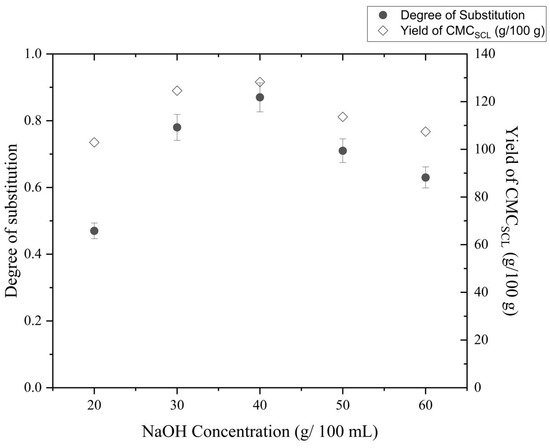

3.1. Degree of Substitution (DS) and Percent Yield of CMCSCL

The DS represents a critical property of CMC, thus significantly impacting not only its solubility but also its solution characteristics [43]. DS values falling within the range of 0.0 to 0.4 indicate that the CMC is insoluble but swellable, whereas values exceeding this range signify that the CMC is completely water soluble [23]. CMC derived from cellulose through alkalization and subsequent carboxymethylation employing monochloroacetic acid (MCA) generally falls within the range of 0.4–1.3 [15,18,20]. The DS values obtained in this study were well within the expected range, thus spanning from 0.46 to 0.86 (Figure 2).

Figure 2.

Effect of NaOH concentration on degree of substitution and percent yield of CMCSCL synthesized with various NaOH concentrations.

The degree of substitution (DS) values exhibited an increase with rising NaOH concentrations (20–40 g/100 mL), thus reaching a peak DS of 0.86 at 40 g/100 mL NaOH, followed by a significant decline. This behavior can be elucidated through the carboxymethylation process, wherein two competitive reactions occur simultaneously. The initial reaction involves the interaction of cellulose hydroxyl groups with monochloroacetic acid (MCA), thereby yielding CMCSCL, as demonstrated in Equation (2). The subsequent reaction, governed by NaOH and MCA, leads to the formation of sodium glycolate as a byproduct, as outlined in Equation (3).

The second reaction surpasses the first at higher alkaline concentrations. Excessive alkalinity leads to a predominant side reaction, thereby resulting in the formation of sodium glycolate as a byproduct and subsequently reducing the DS. Furthermore, the decrease in the DS observed at the elevated 40% NaOH concentration may also be attributed to the potential chain degradation of CMC polymers [3,4,44].

A similar trend has been noted in CMC derived from various cellulose sources, including corn cobs [4], sugar beet pulp [8], durian rind [18], cavendish banana pseudostems [20], lantana camara [21], and sago palm [22]. The DS values of CMC obtained from different cellulose sources are summarized in Table 3. Furthermore, the percentage yield of the CMCSCL exhibited a trend related to NaOH concentration that was similar to the DS results (Figure 2). This aligns with findings from previous studies [3,18,20].

Table 3.

The DS values of CMC obtained from different cellulose sources.

The DS in CMC is a crucial factor determining its properties and applicability in specific industrial contexts. Generally, as the DS increases, the water solubility of CMC improves, thus influencing its viscosity and dissolution kinetics [4,45]. This characteristic is particularly significant in applications requiring rapid dissolution, such as in pharmaceutical formulations or food products, where CMC serves as a widely used thickener and stabilizer in the food industry [46]. For food applications, DS typically falls within the range of 0.6–0.95 [47]. CMC with a high DS can enhance the electrostatic repulsion between protein particles, thus preventing phase separation in acidified milk drinks [46]. Additionally, the film-forming ability of CMC is influenced by the DS, with higher values contributing to improved film formation, thus making it suitable for applications in coatings and packaging materials [48].

3.2. Purity, NaCl, and Ash Contents Analysis

The purity of the CMC was assessed following multiple washes with 80% methanol, thereby effectively eliminating reaction byproducts such as sodium chloride and sodium glycolate. For CMC intended for human consumption, purification to a minimum level of 99.5% is essential. In contrast, CMC designated for commercial use in industries such as paper coating, textile sizing and printing, ceramic glazing, and oil drilling muds must meet a slightly lower purity threshold of 98.0%.

The CMC content and sodium chloride percentages in the prepared CMC were meticulously analyzed and then compared to the established standards for commercial and pharmaceutical grades of CMC. The results have been succinctly summarized in Table 4. Upon examination of the data in Table 4, it is evident that the CMC content achieved in this study fell within the anticipated range of 98.81–99.34%. While it is slightly below the 99.5% purity benchmark set for CMC standards in the food and pharmaceutical industry, it comfortably surpasses the requisite 98.0% purity level for standard CMC in commercial applications. Moreover, the sodium chloride content in the prepared CMC was found to be remarkably low at just 0.04%. Notably, the sodium salt content in food additives should not exceed 0.5%, either individually or in combination, thereby underscoring the suitability of the prepared CMC for use in various applications.

Table 4.

Determination of CMC, NaCl, and ash contents.

The results concerning the ash content of the prepared CMC are presented in Table 4. Notably, the ash content achieved in this study consistently fell within the expected range of 9.79–14.40%. The maximum ash content, 14.40%, was observed when utilizing a NaOH concentration of 40 g/100 mL. It is intriguing to observe that these results closely align with findings from analogous studies, where standard CMC samples were reported to contain an ash content of 14.23% [16]. This higher ash content suggests a greater degree of substitution (DS) in the CMC. It is conceivable that this phenomenon occurs because a higher number of hydroxyl groups are substituted by the sodium salts of carboxymethyl groups during the etherification reaction [11,16].

3.3. Heavy Metals of CMCSCL

Heavy metals are potential environmental contaminants, with the capability to cause human health problems due to their toxic effects, even at very low concentrations [16]. The toxic metal content in the prepared CMCSCL was determined and compared with the recommended values shown in Table 5. From the results in Table 5, it can be observed that the concentrations of As, Cd, and Hg were <0.04, <0.04, and <0.04 ppm, respectively. These values are within the World Health Organization’s (WHO) permissible limits for food additives and emulsifiers.

Table 5.

Concentration of heavy metals in the synthesized CMCSCL.

Conversely, the concentration of Pb in CMCSCL was 3.64 ppm, thus exceeding the permissible limits for food additives and emulsifiers set by the World Health Organization (WHO). When we consider the concentration of Pb in SCLs, which is <50 ppm, it is approximately 50 times the permissible limit. This underscores that during the processes of the isolation of -cellulose and the synthesis of carboxymethyl cellulose, specifically through the alkalization and etherification reactions, the concentration of Pb in CMCSCL decreases. The presence of Pb is a result of its deposition through the application of herbicides during the cultivation process [53].

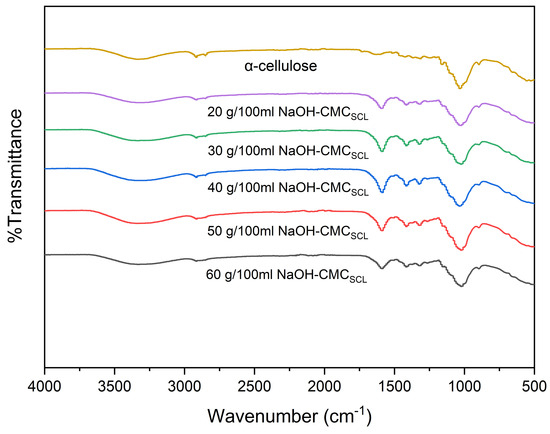

3.4. FTIR Analysis

The identification of the produced -cellulose and CMCSCL was conducted through Fourier Transform Infrared (FTIR) spectroscopy. The FTIR spectra of the synthesized CMC samples and -cellulose are depicted in Figure 3. As observed in Figure 3, the spectra exhibited characteristic absorptions related to the cellulose backbone and the presence of the carboxymethyl ether group, notably at 1588–1591 cm−1.

Figure 3.

FTIR spectra of -cellulose and CMCSCL synthesized with various NaOH concentrations.

The broad band within the range of 3200–3600 cm−1 corresponds to O-H stretching, while the band between 2800 and 3100 cm−1 is attributed to C-H stretching vibrations. The band at approximately 1600 cm−1 represents C=O stretching, and the bands around 1420 and 1320 cm−1 are associated with -CH2 scissoring and -OH bending vibrations, respectively. The band spanning from 1000 to 1200 cm−1 is linked to -O- stretching, while the band at around 1030 cm−1 corresponds to -CH-O-CH2 stretching. Additionally, a wavelength near 890 cm−1 is indicative of the 1,4- glycoside linkage of cellulose [1,5,18,22,23,54].

The absorbance bands in the CMCSCL spectra exhibited consistency across different NaOH concentrations but displayed variations from those of -cellulose. Notably, the emergence of a new and robust absorption band at 1588–1591 cm−1 provides clear evidence of stretching vibrations associated with the carboxyl group (COO-), whereas the band at 1413–1415 cm−1 can be attributed to carboxyl groups in the sample salts [1,18,20]. A comprehensive dataset of FTIR spectra for the -cellulose and CMCSCL, synthesized with varying NaOH concentrations, are presented in Table 6. These results substantiate the occurrence of carboxymethylation within the cellulose molecules, thus aligning with prior findings [1,3,4,18,20,22,23].

Table 6.

FTIR spectra data of -cellulose and CMCSCL synthesized with various NaOH concentrations.

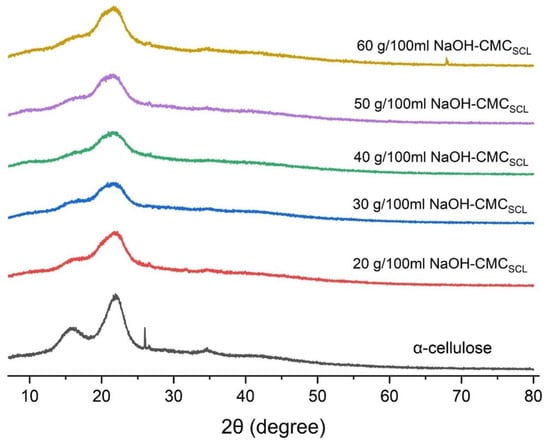

3.5. XRD Analysis

X-ray diffraction (XRD) analysis serves as a pivotal method for determining the crystallinity levels in polymers, with cellulose characterized by its inherent semicrystalline nature [16]. This study presents XRD patterns for -cellulose and carboxymethyl cellulose sodium salt (CMCSCL) synthesized at varying sodium hydroxide (NaOH) concentrations, as depicted in Figure 4. The crystallinity index (CI) was computed based on the ratio between the intensity of the 002 peak (I002) and the minimum intensity (IAM) observed between the 002 and 101 peaks [55]. Notably, the XRD patterns revealed prominent crystalline peaks at diffraction angles (2 ) of 15.89° (101), 18.00° (IAM), and 22.05° (I002). The calculated CI values for -cellulose and CMCSCL, across a range of NaOH concentrations from 20% to 60% w/v, were found to be 67.62%, 50.50%, 44.39%, 45.03%, 49.92%, and 43.37%, respectively. These findings indicate a decline in CI for CMCSCL synthesized with increasing NaOH concentrations, thus suggesting a decrease in crystallinity. This observed reduction in crystallinity can be attributed to the disruption of hydrogen bonds during NaOH treatment [11,20], which is consistent with previous studies reporting similar effects in carboxymethyl cellulose (CMC) derived from various cellulose sources such as durian rind [18], corn husk [1], and brewer’s spent grain [7], all of which demonstrated diminished crystallinity following alkaline processing.

Figure 4.

XRD patterns of -cellulose and CMCSCL synthesized with various NaOH concentrations.

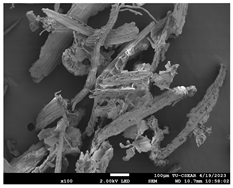

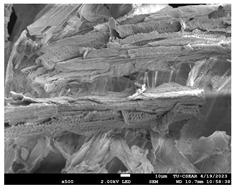

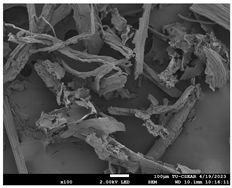

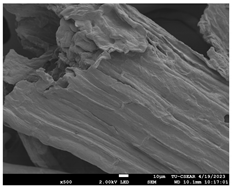

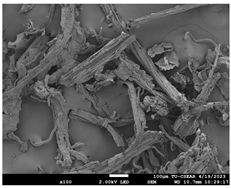

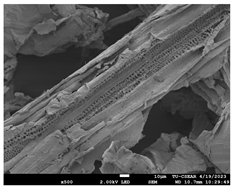

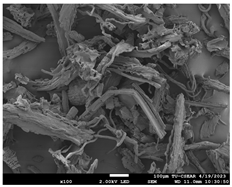

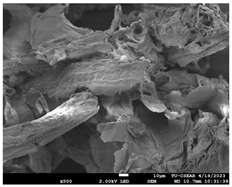

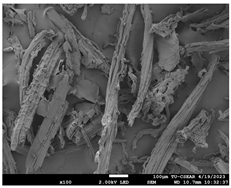

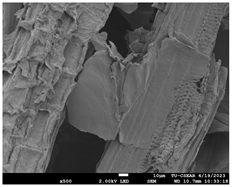

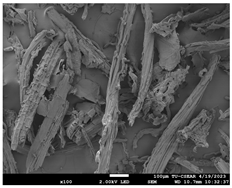

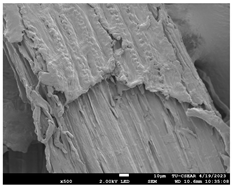

3.6. Morphology of -Cellulose and CMCSCL Analysis

Field emission scanning electron microscopy (FE-SEM) is a sophisticated technique employed for imaging the microstructure of materials. In this study, FE-SEM analysis was utilized to assess the morphologies of -cellulose and CMCSCL synthesized with various NaOH concentrations. Table 7 presents the morphological characteristics of the -cellulose and CMCSCL synthesized using different NaOH concentrations. After alkali treatment, the surface of the SCL fibers became rougher, with diameters ranging from 80 to 150 µm. Prior to cellulose extraction, the fiber surfaces appeared to be covered by substances, possibly lignin and hemicellulose encrusting the cellulose within [23]. Following extraction with varying NaOH concentrations (20–60% w/v of NaOH), the FE-SEM images of the SCL cellulose demonstrated the removal of these encrusting substances from the fiber surfaces. In the case of the CMCSCL synthesized with different NaOH concentrations, the resulting molecules exhibited a rod-like or ribbon-shaped structure, thereby suggesting the presence of some degree of crystallinity within the material. This structure aligns with images of typical CMC molecules as reported in previous studies [16,29].

Table 7.

Morphological characteristics of -cellulose and CMCSCL synthesized using different NaOH concentrations.

4. Conclusions

In Thailand, surplus sugarcane leaves (SCLs) often end up as biomass waste left in the fields after the sugar cane harvesting process. Unfortunately, traditional methods of utilizing these SCL wastes are limited, and their disposal in landfills or through incineration leads to significant environmental issues, particularly air pollution. However, the innovative approach of using them as a chemical feedstock for large-scale production offers a more contemporary solution. This concept holds promise for mitigating pollution problems. This study demonstrates the successful isolation of cellulose from SCLs. Chemical treatments involving alkali and sodium chlorite effectively removed noncellulosic constituents, thus resulting in fibers with a high -cellulose content making them suitable for CMC production. The carboxymethylation of cellulose was achieved successfully, thereby generating samples with different average degrees of substitution (0.46–0.86) based on the reaction conditions. The highest DS achieved was 0.86 using 40 g/100 mL NaOH. Characterization techniques such as FTIR, XRD, FE-SEM, and ICP-MS provided a comprehensive understanding of the CMC’s chemical structure, crystallinity, morphology, and purity level (99.34%), alongside an assessment of the heavy metal content within permissible limits. This process allowed for the production of high-purity CMC suitable for various industrial applications, including paper coating, textile sizing and printing, ceramic glazing, and oil-related uses. This research exemplifies a sustainable approach to utilizing agricultural waste, thereby potentially reducing environmental pollution and offering a pathway to diverse industrial applications of CMC.

Author Contributions

Conceptualization, H.P.; Methodology, T.C.; Supervision, P.U. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Thammasat University.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

We extend our gratitude to Thammasat University for their generous provision of financial support and essential research equipment, which greatly facilitated this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yeasmin, M.S.; Mondal, M.I.H. Synthesis of highly substituted carboxymethyl cellulose depending on cellulose particle size. Int. J. Biol. Macromol. 2015, 80, 725–731. [Google Scholar] [CrossRef]

- Joshi, G.; Naithani, S.; Varshney, V.K.; Bisht, S.S.; Rana, V.; Gupta, P.K. Synthesis and characterization of carboxymethyl cellulose from office waste paper: A greener approach towards waste management. Waste Manag. 2015, 38, 33–40. [Google Scholar] [CrossRef]

- Rachtanapun, P.; Rattanapanone, N. Synthesis and characterization of carboxymethyl cellulose powder and films from Mimosa pigra. J. Appl. Polym. Sci. 2011, 122, 3218–3226. [Google Scholar] [CrossRef]

- Singh, R.K.; Singh, A.K. Optimization of reaction conditions for preparing carboxymethyl cellulose from corn cobic agricultural waste. Waste Biomass Valorization 2013, 4, 129–137. [Google Scholar] [CrossRef]

- Singh, R.K.; Khatri, O.P. A scanning electron microscope based new method for determining degree of substitution of sodium carboxymethyl cellulose. J. Microsc. 2012, 246, 43–52. [Google Scholar] [CrossRef] [PubMed]

- Baranwal, J.; Barse, B.; Fais, A.; Delogu, G.L.; Kumar, A. Biopolymer: A Sustainable Material for Food and Medical Applications. Polymers 2022, 14, 983. [Google Scholar] [CrossRef] [PubMed]

- Dos Santos, D.M.; De Lacerda Bukzem, A.; Ascheri, D.P.R.; Signini, R.; de Aquino, G.L.B. Microwave-assisted carboxymethylation of cellulose extracted from brewer’s spent grain. Carbohydr. Polym. 2015, 131, 125–133. [Google Scholar] [CrossRef] [PubMed]

- Togrul, H. Production of carboxymethyl cellulose from sugar beet pulp cellulose and rheological behaviour of carboxymethyl cellulose. Carbohydr. Polym. 2003, 54, 73–82. [Google Scholar] [CrossRef]

- Candido, R.G.; Gonçalves, A.R. Synthesis of cellulose acetate and carboxymethylcellulose from sugarcane straw. Carbohydr. Polym. 2016, 152, 679–686. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.S.; Hasan, M.S.; Nitai, A.S.; Nam, S.; Karmakar, A.K.; Ahsan, M.S.; Shiddiky, M.J.A.; Ahmed, M.B. Recent Developments of Carboxymethyl Cellulose. Polymers 2021, 13, 1345. [Google Scholar] [CrossRef]

- Wongvitvichot, W.; Pithakratanayothin, S.; Wongkasemjit, S.; Chaisuwan, T. Fast and practical synthesis of carboxymethyl cellulose from office paper waste by ultrasonic-assisted technique at ambient temperature. Polym. Degrad. Stab. 2021, 184, 109473. [Google Scholar] [CrossRef]

- Silva, D.A.; de Paula, R.C.M.; Feitosa, J.P.A.; de Brito, A.C.F.; Maciel, J.S.; Paula, H.C.B. Carboxymethylation of cashew tree exudate polysaccharide. Carbohydr. Polym. 2004, 58, 163–171. [Google Scholar] [CrossRef]

- Salmi, T.; Valtakari, D.; Paatero, E.; Holmbom, B.; Sjoholm, R. Kinetic study of the carboxymethylation of cellulose. Ind. Eng. Chem. Res. 1994, 33, 1454–1459. [Google Scholar] [CrossRef]

- JECFA. Compendium of Food Additive Specifications. In FAO Food and Nutrition Paper Add 10; Issue 52, 59th Session; JECFA: Geneva, Switzerland, 2002; p. 15. [Google Scholar]

- Waring, M.J.; Parsons, D. Physico-chemical characterisation of carboxymethylated spun cellulose fibres. Biomaterials 2001, 22, 903–912. [Google Scholar] [CrossRef] [PubMed]

- Mondal, M.I.H.; Yeasmin, M.S.; Rahman, M.S. Preparation of food grade carboxymethyl cellulose from corn husk agrowaste. Int. J. Biol. Macromol. 2015, 79, 144–150. [Google Scholar] [CrossRef] [PubMed]

- Melis, T.; Emre, U.; Caglagul, T.; Hasanferdi, G. Synthesis And Characterization of Carboxymethyl Cellulose Film from Pistachio Shells. Int. J. Adv. Sci. Eng. Technol. (IJASEAT) 2016, 4, 153–155. [Google Scholar]

- Rachtanapun, P.; Luangkamin, S.; Tanprasert, K.; Suriyatem, R. Carboxymethyl cellulose film from durian rind. LWT—Food Sci. Technol. 2012, 48, 52–58. [Google Scholar] [CrossRef]

- Penjumras, P.; Rahman, R.B.A.; Talib, R.A.; Abdan, K. Extraction and Characterization of Cellulose from Durian Rind. Agric. Agric. Sci. Procedia 2014, 2, 237–243. [Google Scholar] [CrossRef]

- Adinugraha, M.P.; Marseno, D.W.; Haryadi. Synthesis and characterization of sodium carboxymethylcellulose from cavendish banana pseudo stem (Musa Cavendishii LAMBERT). Carbohydr. Polym. 2005, 62, 164–169. [Google Scholar] [CrossRef]

- Varshney, V.K.; Gupta, P.K.; Naithani, S.; Khullar, R.; Bhatt, A.; Soni, P.L. Carboxymethylation of α-cellulose isolated from Lantana Camara Respect Degree Substit. Rheol. Behavior. Carbohydr. Polym. 2006, 63, 40–45. [Google Scholar] [CrossRef]

- Pushpamalar, V.; Langford, S.J.; Ahmad, M.; Lim, Y.Y. Optimization of reaction conditions for preparing carboxymethyl cellulose from sago waste. Carbohydr. Polym. 2006, 64, 312–318. [Google Scholar] [CrossRef]

- Suriyatem, R.; Noikang, N.; Kankam, T.; Jantanasakulwong, K.; Leksawasdi, N.; Phimolsiripol, Y.; Insomphun, C.; Seesuriyachan, P.; Chaiyaso, T.; Jantrawut, P.; et al. Physical Properties of Carboxymethyl Cellulose from Palm Bunch and Bagasse Agricultural Wastes: Effect of Delignification with Hydrogen Peroxide. Polymers 2020, 12, 1505. [Google Scholar] [CrossRef] [PubMed]

- Ab Rasid, N.S.; Zainol, M.M.; Amin, N.A.S. Synthesis and characterization of carboxymethyl cellulose derived from empty fruit bunch. Sains Malays. 2021, 50, 2523–2535. [Google Scholar] [CrossRef]

- Bono, A.; Ying, P.H.; Yan, F.Y.; Muei, C.L.; Sarbatly, R.; Krishnaiah, D. Synthesis and characterization of carboxymethyl cellulose from palm kernel cake. Adv. Nat. Appl. Sci. 2009, 3, 5–12. [Google Scholar]

- Rachtanapun, P.; Eitssayeam, S.; Pengpat, K. Study of Carboxymethyl Cellulose from Papaya Peels as Binder in Ceramics. Adv. Mater. Res. 2010, 93–94, 17–21. [Google Scholar] [CrossRef]

- Rachtanapun, P. Blended films of carboxymethyl cellulose from papaya peel (CMCp) and corn starch. Agric. Nat. Resour. 2009, 43, 259–266. [Google Scholar]

- Kim, H.G.; Kwac, L.K.; Kim, Y.-S.; Shin, H.K.; Rhee, K.-Y. Synthesis and characterization of eco-friendly carboxymethyl cellulose based carbon foam using electron beam irradiation. Compos. Part B Eng. 2018, 151, 154–160. [Google Scholar] [CrossRef]

- Maida, A.; Maliha, U. Evaluating the Impact of Cellulose Extraction via Traditional and Ionosolv Pretreatments from Domestic Matchstick Waste on the Properties of Carboxymethyl Cellulose. ACS Omega 2023, 8, 8722–8731. [Google Scholar]

- Phungrassami, H.; Usubharatana, P. Life cycle assessment of bio-based thermal insulation materials formed by different methods. Environ. Eng. Manag. J. 2019, 18, 1471–1486. [Google Scholar] [CrossRef]

- DAEDE. Department of Alternative Energy Development and Efficiency, Ministry of Energy (Thailand), Alternative Energy Development Plan 2018–2037. Available online: https://policy.asiapacificenergy.org/node/4351 (accessed on 1 December 2023).

- Ar, M.; Sabbarwal, S.; Mishra, P.K.; Upadhyay, S.N. Thermal Degradation Kinetics of Sugarcane Leaves (Saccharum officinarum L.) using Thermo-gravimetric and Differential Scanning Calorimetric Studies. Bioresour. Technol. 2019. [Google Scholar] [CrossRef]

- Rahul, A.P.; Umesh, B.D. Dry Sugarcane Leaves: Renewable Biomass resources for Making Briquettes. Int. J. Eng. Res. Technol. 2017, 10, 232–235. [Google Scholar]

- Tiwary, K.N.; Kulkarni, A.Y. Sugar cane leaf-a potential raw material for cheap grades of paper and board. Part ii. IPPTA 1980, 17, 27–30. [Google Scholar]

- OCSB. Office of The Cane and Sugar Board (Thailand), Report on the Sugarcane Cultivation Situation for the Production Year 2021–2022. Available online: https://old.ocsb.go.th/upload/journal/fileupload/13813-1585.pdf (accessed on 15 January 2023).

- Mondal, M.I.H.; Haque, M.M.-U. Effect of grafting methacrylate monomers onto jute constituents with a potassium persulfate initiator catalyzed by Fe(II). J. Appl. Polym. Sci. 2006, 103, 2369–2375. [Google Scholar] [CrossRef]

- ASTM D1439-03; Standard Test Methods for Sodium Carboxymethylcellulose. ASTM: West Conshohocken, PA, USA, 2003.

- ASTM D7582-15; Standard Test Methods for Proximate Analysis of Coal and Coke by Macro Thermogravimetric Analysis. ASTM: West Conshohocken, PA, USA, 2015.

- Ammann, A.A. Inductively coupled plasma mass spectrometry (ICP MS): A versatile tool. J. Mass Spectrom. 2007, 42, 419–427. [Google Scholar] [CrossRef] [PubMed]

- John, O.B.; Royal, H.R. The Determination of the Alpha-Cellulose Content and Copper Number of Paper. Bur. Stand. J. Res. 1931, 6, 603–619. [Google Scholar]

- Rivai, H.; Hamdani, A.S.; Ramdani, R.; Lalfari, R.S.; Andayani, R.; Armin, F.; Djamaan, A. Production and Characterization of Alpha Cellulose Derived from Rice Straw (Oryza Sativa L.). Int. J. Pharm. Sci. Rev. Res. 2018, 52, 45–48. [Google Scholar]

- Adeleye, O.A.; Bamiro, O.A.; Albalawi, D.A.; Alotaibi, A.S.; Iqbal, H.; Sanyaolu, S.; Femi-Oyewo, M.N.; Sodeinde, K.O.; Yahaya, Z.S.; Thiripuranathar, G.; et al. Characterizations of Alpha-Cellulose and Microcrystalline Cellulose Isolated from Cocoa Pod Husk as a Potential Pharmaceutical Excipient. Materials 2022, 15, 5992. [Google Scholar] [CrossRef]

- Stigsson, V.; Kloow, g.; Germgård, U.; Andersson, N. The Influence of Cobalt (II) in Carboxymethyl Cellulose Processing. Cellulose 2005, 12, 395–401. [Google Scholar] [CrossRef]

- Kirk, R.E.; Othmer, D.F. Cellulose Encyclopedia of Chemical Technology, 2nd ed.; Wiley: New York, NY, USA, 1967; Volume 4, pp. 593–683. [Google Scholar]

- Kamide, K.; Okajima, K.; Kowsaka, K.; Matsui, T.; Nomura, S.; Hikichi, K. Effect of the Distribution of Substitution of the Sodium Salt of Carboxymethylcellulose on Its Absorbency toward Aqueous Liquid. Polym. J. 1985, 17, 909–918. [Google Scholar] [CrossRef][Green Version]

- Xin, C.; Nie, L.; Chen, H.; Li, J.; Li, B. Effect of Degree of Substitution of Carboxymethyl Cellulose Sodium on the State of Water, Rheological and Baking Performance of Frozen Bread Dough. Food Hydrocoll. 2018, 80, 8–14. [Google Scholar] [CrossRef]

- Coffey, D.G.; Bell, D.A.; Henderson, A. Cellulose and Cellulose Derivatives. In Food Polysaccharides and Their Applications; Stephen, A.M., Phillips, G.O., Williams, P.A., Eds.; CRC Press: Abingdon, UK, 2006; pp. 147–180. [Google Scholar]

- Macieja, S.; Środa, B.; Zielińska, B.; Roy, S.; Bartkowiak, A.; Łopusiewicz, Ł. Bioactive Carboxymethyl Cellulose (CMC)-Based Films Modified with Melanin and Silver Nanoparticles (AgNPs)—The Effect of the Degree of CMC Substitution on the In Situ Synthesis of AgNPs and Films’ Functional Properties. Int. J. Mol. Sci. 2022, 23, 15560. [Google Scholar] [CrossRef] [PubMed]

- S International Trade Commission. Purified Carboxymethyl Cellulose from Finland, Mexico, Netherlands, and Sweden, Invs. Nos. 731-TA-1084-1087 (Final); USITC Publication 3787; US International Trade Commission: Washington, DC, USA, 2005; p. 15.

- JECFA. Compendium of Food Additive Specifications. In FAO Food and Nutrition Paper, Add 5; Issue 52, 59th Session; JECFA: Rome, Italy, 1997; p. 160. [Google Scholar]

- JECFA. Specifications for the Identity and Purity of Food Additives and Their Toxicological Evaluation: Some Emulsifiers and Stabilizers and Certain Other Substances; World Health Organization Technical Report Series 10, No. 373; WHO: Geneva, Switzerland, 1967; p. 11. [Google Scholar]

- JECFA. Evaluation of Certain Food Additives and Contaminants; WHO Technical Report Series 53, No. 896; WHO: Geneva, Switzerland, 2000; p. 11f. [Google Scholar]

- Kladsomboon, S.; Jaiyen, C.; Choprathumma, C.; Tusai, T.; Apilux, A. Heavy metals contamination in soil, surface water, crops, and resident blood in Uthai District, Phra Nakhon Si Ayutthaya, Thailand. Environ. Geochem. Health 2019. [Google Scholar] [CrossRef] [PubMed]

- Kondo, T. The assignment of IR absorption bands due to free hydroxyl groups in cellulose. Cellulose 1997, 4, 281–292. [Google Scholar] [CrossRef]

- Park, S.; Baker, J.O.; Himmel, M.E.; Parilla, P.A.; Johnson, D.K. Cellulose Crystallinity Index: Measurement Techniques and Their Impact on Interpreting Cellulase Performance. Biotechnol. Biofuels 2010, 3, 1–10. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).