Abstract

With respect to peak carbon and carbon neutrality, China’s economic structure is developing towards low carbonization, circulation, and cleanliness. There is an urgent need to expand the scope of cleaner production audits, improve cleaner production efficiency, and promote cleaner production through regional coordination. The 14th Five-Year National Cleaner Production Implementation Plan proposed selecting 100 parks or industrial clusters to conduct an overall cleaner production audit innovation pilot. To promote the coordinated development of cleaner production areas, this study constructed a set of cleaner production index systems for industrial parks, established an evaluation model based on the binary semantic evaluation method, and selected an industrial park in central China as an audit pilot. The binary group of the rating results was determined to be a cleaner production park. Based on the evaluation results, the clean production potential of the park was analyzed, and suggestions for clean production were put forward. Sixteen representative enterprises in the park were selected to build twenty-one ecological chains, providing reasonable suggestions for constructing a systematic and circular enterprise symbiosis network.

1. Introduction

The ‘Paris Agreement’ was adopted as a new climate agreement during the 21st Conference of the Parties (COP 21) at the United Nations Framework Convention on Climate Change (UNFCCC), held in Paris, France. The main objective of the Paris Agreement is to limit the global average temperature increase to well below 2 degrees Celsius above pre-industrial levels [1]. To achieve this goal, all countries are required to contribute by reducing their greenhouse gas emissions. Therefore, during the ‘14th Five-Year Plan’, China’s ecological civilization construction entered a critical period focusing on carbon reduction, realizing the improvement of ecological environment quality from quantitative change to qualitative aspects. At this new stage of development, the industrial sector remains a material pillar of China’s economic and social development. However, the industrial sector is a major source of energy, emitting large amounts of greenhouse gases and pollutants. Industrial energy consumption accounts for more than 65% of the country’s total energy consumption and emits more than 80% of the country’s carbon dioxide and more than 75% of atmospheric pollutants such as sulfur dioxide and particulate matter [2].Therefore, green and low-carbon transformation in the industrial field is key to the implementation of the Paris Agreement’s carbon reduction commitments and is also a significant way for China to achieve peak carbon, carbon neutrality, and the in-depth implementation of pollution prevention and control.

As the most effective means of promoting cleaner production (CP), a cleaner production audit allows enterprises to achieve energy savings, consumption reduction, emission reduction, and efficacy enhancement [3]. Cleaner production has been explored and practiced for more than 30 years. The research principally focuses on the enterprise and industry level, including the summary and evaluation of cleaner production technology, and the construction and evaluation of a cleaner production index system [4,5,6,7]. In recent years, the key enterprises, as the primary bodies conducting cleaner production audits, have achieved remarkable results; the number of participating enterprises has increased significantly, and the pollutant emission intensity has been decidedly reduced [8]. However, compared to the base of tens of millions of enterprises in China, the proportion of enterprises implementing cleaner production audits is low, and the promotion of green and low-carbon development in China’s industrial field is still very limited. According to statistics, as of April 2022, there are 2773 national and provincial industrial parks, including 663 national industrial parks and 2110 provincial industrial parks, and nearly 200,000 enterprises have settled in national and provincial industrial parks [9,10,11]. In contrast, industrial parks, as organizations of enterprise agglomeration, have significant advantages in expanding the scope of cleaner production audits and improving audit results [12].

The early research chiefly considered the cleaner production audit of enterprises in the park and promoted the ecological improvement of the park by improving the cleaner production level of the audited enterprises. Later, with the continuous innovation of the cleaner production audit mode of industrial parks in the national policy, more research broke through the original audit ideas and further expanded the audit implementation object and application scope to the industrial park level. For example, Liu Xiaoyu [9] et al. summarized the problems and suggestions for promoting cleaner production audits in industrial parks in China. Wei Yao et al. combined enterprise audits with park audits and proposed measures such as building an ecological chain, improving facilities, and optimizing cleaner production programs to promote cleaner production in industrial parks [13]. Liu, Zheng proposed the framework for promoting cleaner production in industrial parks under the new situation of environmental protection and put forward specific implementation plans from three perspectives: macro, medium, and micro, from the perspective of environmental elements [14]. At present, only Guangdong Province has promulgated the cleaner production index system for electroplating industrial parks in Guangdong Province. This index system is only for electroplating industrial parks and does not have universality. Environmental management in developed countries has been mostly carried out from the life cycle perspective, such as the European Union’s Waste Framework Directive. While in China, environmental management is more concerned with the production process, such as the CP audit system [15]. But the unformed audit methodology and the lack of effective practical exploration experience have hindered the development of cleaner production in industrial parks [16]. In this study, the evaluation index system of cleaner production audit in industrial parks, including carbon accounting indicators, was established. The binary semantic method was used to establish a cleaner production audit model for industrial parks. Case studies were carried out to optimize the industrial structure of industrial parks and the construction of ecological industrial chains. The hope is to provide a theoretical basis for the development of cleaner production in industrial parks, promote the sustainable development of industry, and achieve the goals of reducing pollution and carbon reduction.

The innovations of this study are reflected in the following aspects: (a) A set of industrial park cleaner production index systems was integrated through the comparison and analysis of existing indicator systems. (b) Indicators related to carbon emissions were considered in order to achieve the goal of carbon neutrality. (c) The two-tuple linguistic evaluation method was applied to the establishment of the rating model. (d) A case study of a cleaner production audit in industrial parks was performed to evaluate the overall cleaner production level of industrial parks and to build ecological cycle chains for it.

2. Methodology

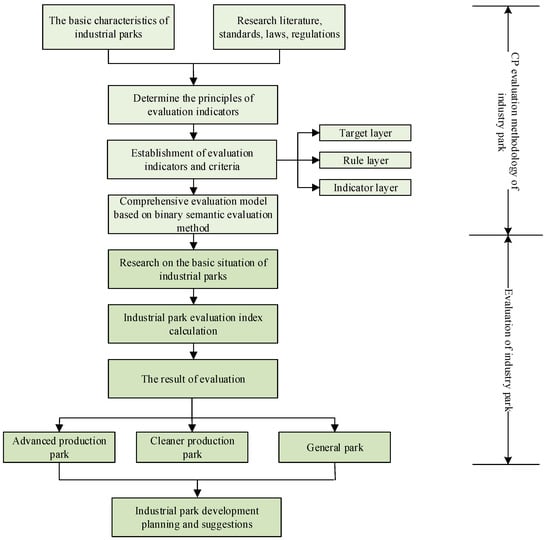

The CP evaluation system consisting of two parts was established, and the cleaner production level of the industrial park was evaluated [17]. The first part establishes the index framework and standards under certain principles along with an evaluation model according to the characteristics of the comprehensive industrial park [18]. The second part uses an evaluation system to evaluate the cleanliness level of the industrial park. The CP evaluation route for an industrial park is shown in Figure 1.

Figure 1.

CP evaluation route of industrial park.

2.1. Establish Index Framework and Standards

2.1.1. Principles for Determining Indicators

The construction of a cleaner production index system does not involve a simple random accumulation or combination of indicators [19]. Only a scientific, complete, and open index set that can adjust with changes in the economic and social environment and other conditions can objectively and truly reflect the index system of cleaner production levels. A relatively complete and reasonable index system can be established based on the following principles [19]:

(1) The integrity principle: The selected indicators should include an overall environmental assessment of the entire life cycle of an industrial park to reflect its complete environmental impact.

(2) The selected indicators should be in line with laws, regulations, and related industry standards, and can be adjusted according to the characteristics of industrial parks.

(3) Principle of easy quantification: When selecting indicators, we should highlight the key points and fully consider their operability.

(4) Pollution prevention: The possibility of resource utilization and conservation should be fully considered when selecting indicators.

(5) Principle of continuous improvement: The selected indicators should be adapted for the development of industrial parks to facilitate revision and improvement.

(6) Park planning principles: The selection of indicators not only puts forward requirements for the standards of the completed park, but also sets the threshold for the entry of enterprises into the park to prevent the entry of enterprises with high pollution and high energy consumption that are lower than the clean production standards, and it provides theoretical guidance for the park to be established.

2.1.2. Screening of System Indicators

(1) Screening according to relevant national laws and regulations:

The state has not yet issued clear regulations and standards for cleaner production evaluation in industrial parks; therefore, it is necessary to obtain a direct reference basis. However, all the aspects of industrial parks have been comprehensively evaluated. Since 2012, various parts of the country have successively proposed several assessment systems such as park recycling [20], eco-industrial parks [21], and green parks [22]. For example, in 2012, the National Development and Reform Commission and Ministry of Finance issued ‘Opinions on Promoting the Circular Transformation of the Park’, and the Ministry of Commerce issued the ‘Assessment and Evaluation Method for the Comprehensive Development Level of National Economic and Technological Development Zones (2021 Edition)’ in 2021. Indicators that met the evaluation objectives of cleaner production were selected from the relevant regulatory indicator system, and an alternative indicator library was established. Through the integration of regulations, the entire index eliminates unrelated indicators of cleaner production.

(2) Screening based on relevant research:

This research database was based on the instructions SU = industrial park/park + KY = index/index system retrieval. The relevant literature was retrieved, excluding domain-independent, low-quality, and incomplete literature, and effective studies were obtained. The index system was constructed by scholars in the literature by collecting indicators, excluding cleaner production indicators such as social factor evaluation and economic evaluation indicators, classifying the screened indicators according to six categories of the criterion layer, and calculating the frequency of its indicators.

2.1.3. Determination of Index Reference Value

Three methods were used to determine the reference values for each index. First, the development goal of the industrial park was considered as the benchmark value. Second, taking the indicators of demonstration parks established by countries or regions as reference values, the gap between general and advanced parks can be found to guide the evaluation of cleaner production. Third, considering the overall level of the industry as the evaluation standard and referring to big data released by the state, the benchmark value was determined. From a comparison between the current value of the park and the benchmark value, the overall positioning of the park can be understood and the potential for clean production can be determined.

2.2. Fuzzy Analytic Hierarchy Process Based on Two-Tuple Linguistics

2.2.1. Establishments of Weight

The subjective weight of each factor was determined based on the analytic hierarchy process. The steps of the analytic hierarchy process (AHP) method [19,23] are summarized as follows:

(1) Establishing the hierarchical structure of the problem.

(2) Constructing the comparison matrix.

(3) Calculating the importance ranking.

(4) Conducting a consistency test to determine whether there is a logical error in the weight distribution.

The objective weight of each factor is determined using the criteria importance through intercriteria correlation (CRITIC) method [24]. The specific steps are as follows:

(1) Constructing the original index data matrix.

(2) Dimensionless indexing.

(3) Calculating the index variability.

(4) Calculating the index conflict.

This study adopts the combination weighting method, which can not only overcome the multiplication effect caused by the unity of multiplication, but also abandon the subjective influence of linear weighting, and it has a good practical application effect. The formula used is as follows:

2.2.2. Fuzzy Comprehensive Evaluation

Fuzzy comprehensive evaluation (FCE), proposed by Zadeh in 1965, originates from the concept of the fuzzy algorithm in mathematics. The FCE combines fuzzy mathematics membership theory to transform quantitative and qualitative indicators into a quantitative evaluation of the same measurement scale [25,26]. The key steps are as follows:

(1) Determining the evaluation index hierarchy.

(2) Determining the membership degree and weight of the evaluation index.

(3) Determining the fuzzy matrix.

(4) Fuzzy matrix operation.

(5) Results.

The FCE method has been successfully applied to evaluate water [27,28,29] and soil environments [30]. In recent years, it has been widely used to evaluate cleaner production in logistics, mining, thermal power plants and other industries because it fits the characteristics of multi-attribute, multi-level, and random cleaner production. The evaluation results of the fuzzy hierarchy method are objective and scientific, making them the most widely used methods for cleaner production audit evaluations worldwide. In this research, the FCE method is employed to develop a cleaner production evaluation model for industrial parks. Initially, the index data is subjected to dimensionless processing, and the park’s final membership vector is determined using the fuzzy matrix calculation.

2.2.3. Two-Tuple Semantics

The binary semantic method uses elements in a pre-defined language evaluation set to represent the evaluation information, and the final evaluation result is directly expressed in the form of language [31]. The advantage of the two-tuple linguistic method is that it can avoid the loss and distortion of the linguistic information of the evaluation in the calculation process, resulting in more accurate results. In this study, a fuzzy mathematics evaluation was combined with an analytic hierarchy process and a two-tuple linguistic method to deal with inaccurate, uncertain, and fuzzy index data and complex data in the context of high nonlinearity and complexity [32]. The most concise and intuitive results are presented to solve the CP evaluation problem in industrial parks.

3. Cleaner Production Evaluation System for Industrial Park

3.1. Building Evaluation System

Evaluation Framework

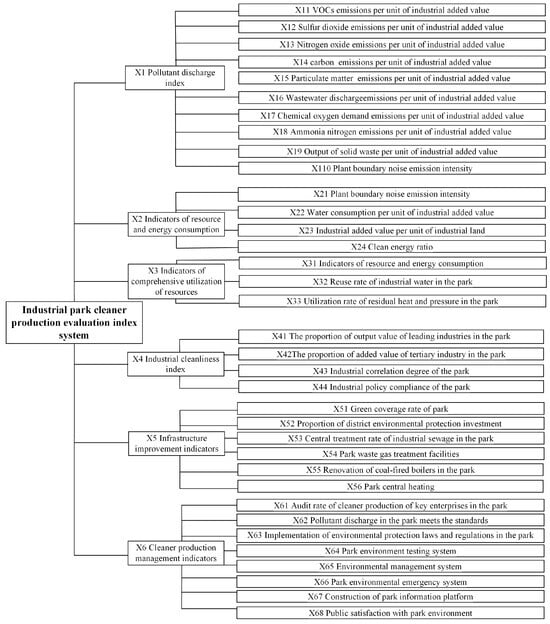

At present, the national cleaner production evaluation index system for key industries has matured and has successively issued the ‘General Principles for the Preparation of Cleaner Production Index System’ (trial version), as well as more than 80 industry cleaner production evaluation index systems with a standardized hierarchical structure. Based on the above standards and regulations, combined with the characteristics of cleaner production in industrial parks, this study divided the hierarchical structure of the index system into three levels, namely the target, criterion, and index layers. The target layer was an evaluation index system for cleaner production audits in industrial parks. The criterion layers included X1 pollutant generation index, X2 resource energy consumption index, X3 resource comprehensive utilization index, X4 industry cleanliness index, X5 infrastructure improvement index, and X6 cleaner production management index. Based on the principle of selection and a comprehensive understanding of the industrial park’s characteristics, an analysis of the relevant policies and regulations, scholarly research, and expert consultations was undertaken to establish an evaluation index framework (Figure 2). Finally, a cleaner production index system for industrial parks with 3 levels, 6 criteria, and 35 indicators was constructed.

Figure 2.

Evaluation index system for cleaner production in industrial park.

3.2. Fuzzy Hierarchy Evaluation Model Based on Two-Tuple Linguistics

3.2.1. Evaluation Grade and Classification Standard of Cleaner Production

The classification of cleaner production level in industrial parks principally includes resource utilization efficiency, waste emission control, environmental risk control, and environmental management level. If is used to represent the level of cleaner production, then the elements of set S must be set before the relevant calculations. In this study, cleaner production in industrial parks was divided into three levels: cleaner production in advanced production parks, cleaner production in general parks, and general parks, corresponding to . shows that clean production in the industrial park is at the leading level, and advanced clean production technology is adopted to minimize the generation of pollutants, maximize the utilization rate of resources, and realize the development of a low-carbon cycle. indicates that the cleaner production level of the park is in a good position, but there are still indicators to be improved. general park shows that the clean production level of the industrial park is poor, the technology needs to be improved, the environmental management needs to be strengthened, and each index is at a poor level.

3.2.2. Grade Membership Function of Cleaner Production Evaluation Index

Each clean production index has different dimensions and cannot be directly compared or calculated. The information obtained can be preprocessed by establishing the membership function of the index [33,34]. Based on the evaluation index system for cleaner production in industrial parks and the actual situation, the following provisions are made for the grade membership degree. The evaluation indices for cleaner production can be divided into two categories: quantitative and qualitative. Qualitative indices are indices that cannot be expressed using data, and their membership functions are shown in Equation (2).

represents the degree of the index belonging to . When the membership value is one, it indicates that the requirement of is satisfied; otherwise, it is not satisfied. The index set of cleaner production is represented by X. Then, the index of the j index layer of the i criterion layer can be recorded as (i = 1, 2, 3, …, m, j = 1, 2, 3, …, n), whose corresponding benchmark value is recorded as (k = 1, 2, 3, …, h). The current value of the t industrial park indicator is , and the membership degree of the k-level benchmark value is .

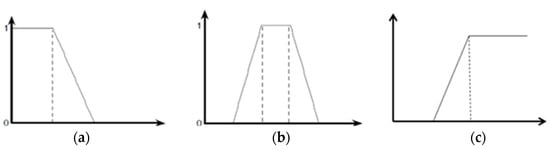

Quantitative indicators are evaluation indicators that can be expressed by data. The quantitative indicators can be divided into three categories: positive, reverse, and interval [35]. The membership function is expressed by Equations (4) and (5), and the membership function of the benefit index is shown in Figure 3.

Figure 3.

Membership function: (a) reverse type, (b) interval type, and (c) forward type.

For the reverse index, the calculation formula is:

For the positive index, the formula is:

For the interval index, the formula is:

3.3. Comprehensive Application of Fuzzy Weighted Comprehensive Evaluation Method and Two-Tuple Linguistic Method

After determining the membership function of the qualitative and quantitative evaluation indices according to the situation of cleaner production and industrial parks, the grade membership degree of industrial parks on the evaluation indices can be calculated using the formulas listed above. Usually, the grade membership matrix is expressed as , which is the basic indicator used in the cleaner production grade evaluation of industrial parks. In the subsequent first and second evaluation indices can be expressed as and , respectively.

3.3.1. Fuzzy Comprehensive Model and Method of Cleaner Production Grade Evaluation

Before the binary semantic method is used to evaluate an industrial park, the evaluation index must be preprocessed. Based on the hierarchical membership matrix determined above and the fuzzy linear weighted comprehensive evaluation method, a comprehensive membership vector can be obtained. The indices that can be preprocessed using the fuzzy linear weighted comprehensive evaluation method must satisfy the characteristics of strong complementarity [36]. The evaluation indices of cleaner production audits were satisfied when combined with the fuzzy linear weighted comprehensive evaluation method. The calculation of the fuzzy comprehensive method for cleaner production grade evaluation in industrial parks was divided into two steps.

The first step was to use the membership matrix of the second-level evaluation index, calculated using the membership function, to calculate the membership degree of each first-level evaluation index for grade (k = 1, 2, 3) in the industrial park to obtain the membership vector of the first-level index. The membership degree of the first-level evaluation index for grade was calculated as follows:

where is the kth column vector in the second-level membership matrix and , is the weight vector corresponding to each column vector.

The second step was to synthesize the membership vector of the first-level evaluation index to obtain the membership matrix of the first-level evaluation index of the industrial park. Combined with the weight vector of the index, the comprehensive membership degree of the industrial park to was calculated, and the comprehensive membership degree vector was obtained. The comprehensive membership degree of grade in industrial parks was calculated as follows:

where is the kth column vector in the first-level membership matrix and , is the weight vector corresponding to each column vector.

3.3.2. Binary Semantic Method of Cleaner Production Grade Evaluation

To transform the processed evaluation information into a two-tuple semantic group , a level eigenvalue is introduced, and the membership vector is further processed. The formula for the level eigenvalue is as follows (8):

From Equations (8) and (9), it can be seen that the level characteristic value is a dimensionless index, and its value lies between the first and h levels. For a cleaner production evaluation of industrial parks, the level characteristics will not be less than one and will not be greater than three. A two-tuple semantic method was introduced, and a cleaner production audit evaluation method based on two-tuple semantics was established as follows:

The level eigenvalue of the industrial park satisfies the following:

This indicates that the cleaner production level of the industrial park is p; that is, is equal to p in the binary semantic group of the evaluation object.

4. Case Study

4.1. Basic Situation of Industrial Park

4.1.1. Research on the Current Situation of Industrial Park

This study selected a park in central China (referred to as industrial park G) for the case analysis. The current value of the quantitative indicators was obtained through field research in industrial park G. A summary of these result is presented in Table 1.

Table 1.

Current value of each index of industrial park G.

The survey results of the quantitative indicators of industrial park G are as follows:

(1) The industrial policy compliance of X44 Industrial Park: It meets the requirements of national industrial policies such as the ‘Industrial Structure Adjustment Guidance Directory (2019 Edition)’, ‘Industrial Transfer Guidance Directory (2012 Edition)’, ‘Foreign Investment Industry Guidance Directory (2017 Revision)’, ‘Environmental Protection Comprehensive Directory (2017 Edition)’, and ‘Negative List of Market Access (2018)’.

(2) X54 Industrial Park waste gas treatment facilities: According to the survey, the production process of some enterprises in industrial park G is accompanied by VOCs, but the VOC treatment facilities are not perfect; some enterprises involved in the unorganized emission of pellets have no corresponding collection and treatment facilities; the storage and transportation of solid waste in some enterprises are not strictly in accordance with the relevant regulations.

(3) Transformation of coal-fired boilers in X55 Industrial Park: According to the survey, industrial park G completed the elimination of small coal-fired boilers and the clean energy transformation of coal-fired boilers in the area by the end of 2016, and all coal-fired boilers below 10 steam tons have been eliminated.

(4) Central heating in X56 Park: Central heating facilities are under construction, and central heating has not yet been realized.

(5) X62 Park pollutant discharge standard: The major air and water pollutant emissions did not exceed the total amount and concentration control index, and all types of solid waste were properly disposed of.

(6) Implementation of environmental laws and regulations in X63 Industrial Park: The new renovation and expansion projects of industrial park G strictly implement an environmental impact assessment system with an implementation rate of 100%. Simultaneously, the ‘three simultaneous’ system is strictly implemented. The status quo is in line with national industrial policy. Processes, equipment, and construction projects use coal and heavy oil as fuel.

(7) X64 Park environmental monitoring system: At present, the routine monitoring of environmental quality in industrial park G relies on local environmental protection departments.

4.1.2. Industrial Park Index Status Value

Based on the previous research on industrial park G, the current values of each index were calculated according to the description requirements of the index. The results are shown in Table 2.

Table 2.

Current value of each index of industrial park G.

4.2. Evaluation of Cleaner Production Level in Industrial Park

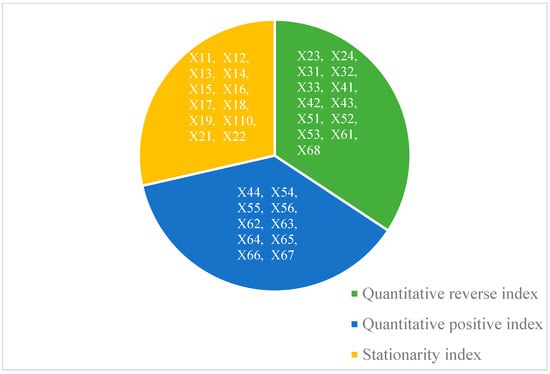

(1) Non-dimensionalities of indicators

To determine the membership matrix of an index, its properties must first be divided. According to the characteristics of this index system, the indicators were divided into quantitative, quantitative, and qualitative. This classification is illustrated in Figure 4. The yellow plate is the quantitative reverse index, the green plate is the quantitative positive index, and the blue is the stationarity index.

Figure 4.

Index classification.

r1~r6 are expressed in the form of a matrix, and the specific data are shown in the Supplementary Materials.

(2) One-level fuzzy operation

According to Table 2, and can be calculated, respectively, and are expressed below in the form of a matrix. Because the park does not involve the utilization of waste heat and pressure, the weight value of the utilization rate of waste heat and pressure in X33 Park is transferred to other indicators.

According to Equation (6), the membership degree of criterion layer X1 with respect to Sk = (S1, S2, S3) can be calculated as follows:

The membership vectors of X1 with respect to Sk = (S1, S2, S3) are T11 = (0.3657, 0.2138, 0.4205).

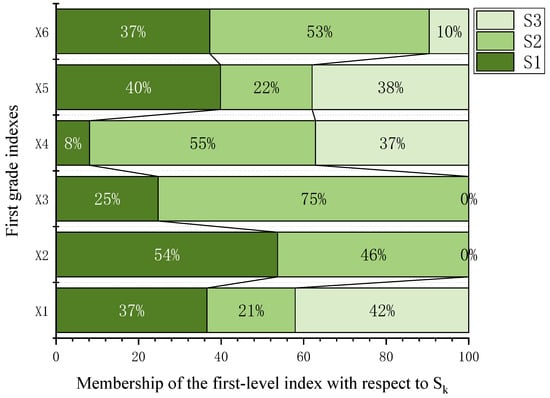

Similarly, T12 = (0.5367, 0.4633, 0.0000), T13 = (0.2475, 0.7525, 0.0000), T14 = (0.0811, 0.5475, 0.3714), T15 = (0.3984, 0.2220, 0.3796), and T16 = (0.3725, 0.5315, 0.0960) can be calculated. The second-level fuzzy judgment matrix T1 of the industrial park is obtained in the Supplementary Materials.

(3) Two-level fuzzy operation

According to Equation (7), the second-level fuzzy operation is performed, and the cleaner production grade membership degree S1i of the park with respect to the target layer Sk = (S1, S2, S3) can be obtained.

S11 = 0.3524; S12 = 0.4036; S13 = 0.2440.

4.3. Analysis and Suggestions for the Evaluation Results of Industrial Park G

4.3.1. Evaluation Results of Industrial Park G

The two-tuple semantic group of the target layer of industrial park G is , It is determined that the industrial park belongs to the S2 level and is identified as a cleaner production park. The deviation value shows that the cleaner production level of industrial park G is better than the lowest level of the S2 level, but there is still clean production potential that can be tapped. Figure 5 shows the membership degrees of the six first-level indicators of Sk. The greater the proportion of X index Sk in the figure, the closer the status of this index in the industrial park is to the level. It can be seen from the graph analysis that the X2 resource and energy consumption index and the X3 resource comprehensive utilization index of industrial parks have the highest contribution to the evaluation results, and both the X1 pollutant emissions and the X4 industrial cleanliness indexes have great clean production potential. The low contribution of the X1 index to the evaluation results is primarily due to the poor control effect of volatile organic compounds and carbon emissions. Most of the enterprises involved in volatile organic compound (VOC) emissions in the park have not set up VOC collection and treatment facilities. However, sulfur dioxide, ammonia nitrogen, and particulate matter emissions had better control effects. In terms of wastewater pollutants, the total amount of wastewater was well controlled, but the leading enterprises in the park included food and beverage processing, textiles and garments, wood processing, and furniture manufacturing, resulting in a large amount of chemical oxygen demand and ammonia nitrogen. In terms of X4 industrial cleanliness indicators, the output value of machinery manufacturing, electronic manufacturing, food and beverage processing, textiles and garments, wood processing, and furniture manufacturing dominate the park, accounting for more than 80%. The industrial concentration is high, a good industrial chain has not been formed, and the industrial correlation degree is low.

Figure 5.

Membership of the first-level index with respect to Sk.

4.3.2. Cleaner Production Recommendations

(1) Improvement in VOC collection and treatment facilities.

As one of the key air pollution indicators during the 14th Five-Year Plan, it is particularly important to control the generation and emission of VOCs at the park level. According to the survey, industrial park G is primarily focused on machinery manufacturing, electronics manufacturing, food and beverage processing, textiles and garments, wood processing, and furniture manufacturing, as well as a small number of chemical raw material manufacturing, printing, and building material enterprises. Although there are a few waste-gas-polluting enterprises, most of the enterprises involved in VOC emissions in the park have not set up VOC collection and treatment facilities, resulting in VOC emissions per industrial unit added value of the park reaching 1.9838 kg/10,000 yuan. Therefore, parks should focus on the control of VOCs, do a good job in VOC collection and treatment, encourage enterprises to use low-VOC raw materials, and further control their generation from the source.

(2) Reducing carbon emissions from parks

Currently, the carbon emissions from industrial park G are relatively high. Currently, energy consumption is the major source of carbon emissions from parks. In the future development process, parks can promote waste incineration capacity and cogeneration technology upgrades, which will have significant emission reduction potential and synergistic environmental and economic benefits. Simultaneously, attention should be paid to the elimination of high-energy-consuming equipment in enterprises within the park, and the carbon emission reduction task within the park should be completed by eliminating or replacing backward production capacity and improving energy efficiency, waste heat recovery, and utilization [37,38].

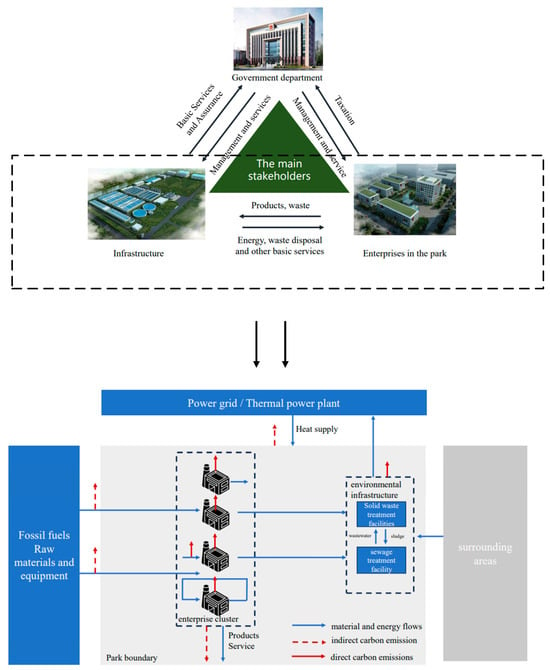

4.3.3. Industrial Park Green Low Carbon Cycle Development Plan

Within the park, the stakeholders include government departments, infrastructure, and manufacturing and service industries. Infrastructure and manufacturing are the primary components of most parks and are also the focus of current park carbon emissions. A complex material and energy flow network exists among the enterprises in the park [39]. The upstream and downstream supply chains among enterprises, industrial clusters composed of the same enterprises in the industrial sector, and recycling industry symbiosis formed among some enterprises to reduce waste constitute the material and energy exchange model of the park, which further increases the complexity of carbon emissions accounting in the park. Figure 6 shows the possible modes of energy and material exchange within the park. With the continuous deepening of the industrial integration development of the park, to realize the low-carbon development of the park, in addition to strengthening the relationship among the major bodies of activities and establishing a solid triangular relationship, we must also tap the potential of the material and energy flow networks between enterprises. By maintaining and strengthening the balance of the ecosystem of the industrial park, it can realize the efficient recycling of resources and energy, reduce waste emissions, and achieve harmony, economic efficiency, and a virtuous ecological circle.

Figure 6.

Composition of industrial parks and the possible forms of energy and material flows.

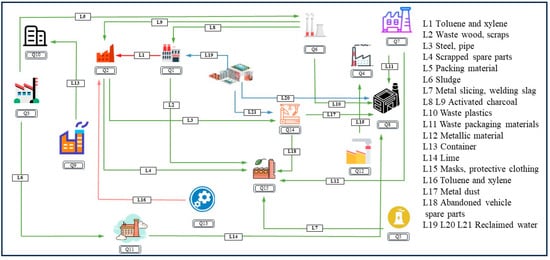

Cleaner production only involves material and energy flow analyses within an enterprise, which is not conducive to material recycling. The construction of the industrial chain considers recycled materials as the major body, processes as the means, and equipment as the carrier, and has gradually become core of the integration of industrial park development. To improve the level of cleaner production in industrial parks and enterprises in development zones, combined with the nature of the mainstream enterprises in the park and data from enterprises in the development zone, 16 representative enterprises with clean production potential in the park were selected to build the ecological chain of the park, as shown in Figure 7. Q stands for different enterprises in the industrial park. The green lines, blue lines, and red lines in Figure 7 denote the transport pathways of particulate matter, liquid substances, and gaseous compounds within the industrial park. This visualization helps to analyze and manage the environmental impacts associated with industrial activities in the park.

Figure 7.

Twenty-one ecological chains that can exist among sixteen enterprises in the industrial park.

The enterprises in industrial park G are primarily machinery manufacturing, electronic manufacturing, food and beverage processing, textiles and garments, wood processing, and furniture manufacturing, accounting for more than 80%, and the industry is concentrated downstream of the industrial chain. During the construction of the industrial chain, the material flow chain was found to be relatively singular, and the sustainable development of the park was inadequate. In the later construction of the park, chemical raw material enterprises, polyester processing enterprises, and other enterprises could be introduced to ‘supplement’ the existing industrial and material chain of the industrial park. Simultaneously, the park can also introduce hazardous waste treatment enterprises to conduct the centralized management, recovery, and treatment of hazardous waste generated by enterprises within the park. This can not only reduce the environmental risk of hazardous waste storage, but also reduce the energy consumption for the long-distance transportation of hazardous waste. It also aids in building a symbiotic, systematic, and circular enterprise network in the park to maximize the utilization of resources, improve the level of cleaner production in the park, and build a sustainable park.

5. Discussion

This study establishes an industrial park cleaner production index system and evaluation model based on the background of peak carbon and carbon neutralization. Although the cleaner production index system of industrial parks does not contain complete carbon-trading system indicators and does not explore the relationship between greenhouse gas management and emission trading from quantitative or qualitative perspectives [40], the carbon emission indicators of the industrial parks covered need the parks to account for their own carbon emissions, which helps to promote the establishment and improvement of the carbon-trading system in the industrial field. The application of the established index system and evaluation model has verified its feasibility in practice. However, it must be admitted that the proposed model and index system may have limitations and incompleteness, for example, regarding how to promote the local consumption of renewable energy from the perspective of index construction [16], how to realize the deep low-carbonization of industrial parks, and how to conduct the model energy-based analysis of time series carbon emissions data at the park level [41], etc., all of which require more in-depth research and more case practice. If this study is fortunate enough to be published, then we hope that this method can be adopted by more industrial parks and provide insight.

In addition, when Chinese enterprises conduct cleaner audits, the last and most important stage deals with sustainable cleaner production. It includes the formulation of long-term pollution reduction and consumption reduction targets and the promotion of sustainability education for enterprise employees. The concept and measures of cleaner production are of great significance to promote the sustainable development of enterprises and industrial parks [42]. From the industrial level, the promotion of sustainable education can achieve wider and faster dissemination. At the same time, it can also promote the construction of ecological parks and cleaner production parks. Therefore, when promoting cleaner production at the industrial park level, more attention should be paid to sustainable education, incorporating it into the audit process.

6. Conclusions

Based on an extensive study of laws and regulations issued in recent years and the available literature, this study proposes a set of cleaner production index systems for industrial parks, establishes an evaluation model based on a binary semantic evaluation method, and applies it to industrial park G, which can provide theoretical support for the country to promote regional collaborative audits.

The conclusions can be summarized as follows:

(1) Summarizing the evaluation index system of cleaner production in the industry, the relevant evaluation standards of various parks, and the research results of scholars, the relevant indicators of cleaner production in industrial parks were screened. A cleaner production index system for industrial parks with 3 levels, 6 criteria, and 35 indicators was constructed.

(2) A fuzzy mathematics evaluation model of cleaner production based on the two-tuple linguistic evaluation method was constructed. The establishment of the evaluation model has realized the innovation of a cleaner production audit method system, and accelerated the formation of cleaner production technology methods and evaluation rules in industrial parks.

(3) Through empirical research on industrial park G, this study analyzes the potential for cleaner production in the industrial park, proposes suggestions for cleaner production, builds an ecological chain, and drafts reasonable suggestions for the future planning of the park to promote ecological priority, and the economical and intensive green and sustainable low-carbon development of industrial parks.

This study aims to shatter the traditional cleaner production audit mode, breach the limitations of a single enterprise as the audit object, satisfy the practical needs of quickly and effectively improving the overall cleaner production level of the park, effectively support the key industries and key areas to reduce pollution and carbon reduction by industrial upgrading, and promote the sustainable development of the industry.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su16062330/s1.

Author Contributions

Conceptualization, T.T.; Validation, S.W.; Writing—original draft, J.D.; Writing—review & editing, Z.L.; Project administration, K.P.; Funding acquisition, W.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article and Supplementary Materials.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kim, T.-H.; Jeong, Y.-S. Analysis of Energy-Related Greenhouse Gas Emission in the Korea’s Building Sector: Use National Energy Statistics. Energies 2018, 11, 855. [Google Scholar] [CrossRef]

- Shan, Y.; Huang, Q.; Guan, D.; Hubacek, K. China CO2 emission accounts 2016–2017. Sci. Data 2020, 7, 54. [Google Scholar] [CrossRef] [PubMed]

- Yuan, X.; Jin, S.; Zhang, H. Optimal Green Technology Choice for Firms under an Emission Trading Scheme: End-of-Pipe vs. Cleaner Production. Sustainability 2023, 15, 16311. [Google Scholar] [CrossRef]

- Lopes, J.; Medeiros, D.L.; Kiperstok, A. Combining cleaner production and life cycle assessment for reducing the environmental impacts of irrigated carrot production in Brazilian semi-arid region. J. Clean. Prod. 2018, 170, 924–939. [Google Scholar] [CrossRef]

- Xiong, W.; Liu, L.; Xiong, M. Application of gray correlation analysis for cleaner production. Clean Technol. Environ. Policy 2010, 12, 401–405. [Google Scholar] [CrossRef]

- Fresner, J.; Jantschgi, J.; Birkel, S.; Baernthaler, J.; Krenn, C. The theory of inventive problem solving (TRIZ) as option generation tool within cleaner production projects. J. Clean. Prod. 2010, 18, 128–136. [Google Scholar] [CrossRef]

- Zhang, P.; Duan, N.; Dan, Z.; Shi, F.; Wang, H. An understandable and practicable cleaner production assessment model. J. Clean. Prod. 2018, 187, 1094–1102. [Google Scholar] [CrossRef]

- Li, Y.; Ma, C. Circular economy of a papermaking park in China: A case study. J. Clean. Prod. 2015, 92, 65–74. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, C.; Ren, H.; Wang, X.; Zhong, L.; Li, N. Progress and Suggestions of Promoting Cleaner Production Audit in Industrial Parks. Chin. J. Environ. Manag. 2022, 3, 30–37. [Google Scholar] [CrossRef]

- Kim, H. Changes in Policies and Studies in Relation to Industrial Parks in China. J. Int. Area Stud. 2022, 26, 203–226. [Google Scholar] [CrossRef]

- Ye, C.; Li, S.; Zhuang, L.; Zhu, X. A comparison and case analysis between domestic and overseas industrial parks of China since the Belt and Road Initiative. J. Geogr. Sci. 2020, 30, 1266–1282. [Google Scholar] [CrossRef]

- He, Y.; Zhu, Z.; Xie, H.; Zhang, X.; Sheng, M. A case study in China of the influence mechanism of industrial park efficiency using DEA. Environ. Dev. Sustain. 2023, 25, 7261–7280. [Google Scholar] [CrossRef]

- Yao, W.; Bin, L.; Bo, Z.; Ling, X.; Lei, J.; Xia, M.X. Framework and Key Points of Industrial Park Cleaner Production Audit. Sichuan Environ. 2017, 36, 17–21. (In Chinese) [Google Scholar] [CrossRef]

- Liu, Z.; Dang, C.G.; Li, Z.; Wang, P.; Yuan, Y.; Liu, J.; Zhou, Q.; Zhou, C. Analysis on the Framework of Cleaner Production in Industrial Parks under the New Situation of Environmental Protection. Environ. Prot. 2017, 45, 60–65. (In Chinese) [Google Scholar] [CrossRef]

- Cong, W.; Shi, L. Heterogeneity of industrial development and evolution of cleaner production: Bibliometric analysis based on JCLP. J. Clean. Prod. 2019, 212, 822–836. [Google Scholar] [CrossRef]

- Guo, Y.; Tian, J.; Chen, L. Managing energy infrastructure to decarbonize industrial parks in China. Nat. Commun. 2020, 11, 981. [Google Scholar] [CrossRef] [PubMed]

- Bai, S.-W.; Zhang, J.-S.; Wang, Z. A methodology for evaluating cleaner production in the stone processing industry: Case study of a Shandong stone processing firm. J. Clean. Prod. 2015, 102, 461–476. [Google Scholar] [CrossRef]

- Timmerman, J.; Vandevelde, L.; Van Eetvelde, G. Towards low carbon business park energy systems: Classification of techno-economic energy models. Energy 2014, 75, 68–80. [Google Scholar] [CrossRef]

- Bao, J.; Zhang, J.; Shi, S.; Johansson, J. Cleaner production assessment of group company based on improved AHP and grey relational analysis. J. Intell. Fuzzy Syst. 2018, 35, 439–444. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, H.; Guo, S. Evaluating the comprehensive benefit of eco-industrial parks by employing multi -criteria decision making approach for circular economy. J. Clean. Prod. 2017, 142, 2262–2276. [Google Scholar] [CrossRef]

- Hong, H.; Gasparatos, A. Eco-industrial parks in China: Key institutional aspects, sustainability impacts, and implementation challenges. J. Clean. Prod. 2020, 274, 122853. [Google Scholar] [CrossRef]

- Wu, W.; Ding, K. Optimization Strategy for Parks and Green Spaces in Shenyang City: Improving the Supply Quality and Accessibility. Int. J. Environ. Res. Public Health 2022, 19, 4443. [Google Scholar] [CrossRef] [PubMed]

- Song, Z.; Gao, H.; Liu, W.; Li, L.; Zhang, W.; Wang, D. Systematic assessment of dredged sludge dewaterability improvement with different organic polymers based on analytic hierarchy process. J. Environ. Sci. 2021, 103, 311–321. [Google Scholar] [CrossRef]

- Li, S.; Wang, B. Research on Evaluating Algorithms for the Service Quality of Wireless Sensor Networks Based on Interval-Valued Intuitionistic Fuzzy EDAS and CRITIC Methods. Math. Probl. Eng. 2020, 2020, 5391940. [Google Scholar] [CrossRef]

- He, Z.; Li, M.; Cai, Z.; Zhao, R.; Hong, T.; Yang, Z.; Zhang, Z. Optimal irrigation and fertilizer amounts based on multi-level fuzzy comprehensive evaluation of yield, growth and fruit quality on cherry tomato. Agric. Water Manag. 2021, 243, 106360. [Google Scholar] [CrossRef]

- Eliche-Quesada, D.; Corpas-Iglesias, F.A.; Perez-Villarejo, L.; Iglesias-Godino, F.J. Recycling of sawdust, spent earth from oil filtration, compost and marble residues for brick manufacturing. Constr. Build. Mater. 2012, 34, 275–284. [Google Scholar] [CrossRef]

- Singh, A.P.; Chakrabarti, S.; Kumar, S.; Singh, A. Assessment of air quality in Haora River basin using fuzzy multiple-attribute decision making techniques. Environ. Monit. Assess. 2017, 189, 373. [Google Scholar] [CrossRef]

- Chang, Y.; Wu, X.; Chen, G.; Ye, J.; Chen, B.; Xu, L.; Zhou, J.; Yin, Z.; Ren, K. Comprehensive risk assessment of deepwater drilling riser using fuzzy Petri net model. Process Saf. Environ. Prot. 2018, 117, 483–497. [Google Scholar] [CrossRef]

- Fu, S.; Gu, S.; Zhang, Y.; Zhang, M.; Weng, J. Towards system-theoretic risk management for maritime transportation systems: A case study of the yangtze river estuary. Ocean Eng. 2023, 286, 115637. [Google Scholar] [CrossRef]

- Saha, S.; Gayen, A.; Pourghasemi, H.R.; Tiefenbacher, J.P. Identification of soil erosion-susceptible areas using fuzzy logic and analytical hierarchy process modeling in an agricultural watershed of Burdwan district, India. Environ. Earth Sci. 2019, 78, 649. [Google Scholar] [CrossRef]

- Zhou, M.; Zheng, Y.-Q.; Chen, Y.-W.; Cheng, B.-Y.; Herrera-Viedma, E.; Wu, J. A large-scale group consensus reaching approach considering self-confidence with two-tuple linguistic trust/distrust relationship and its application in life cycle sustainability assessment. Inf. Fusion 2023, 94, 181–199. [Google Scholar] [CrossRef]

- Zhang, B.; Li, C.-C.; Dong, Y.; Pedrycz, W. A Comparative Study Between Analytic Hierarchy Process and Its Fuzzy Variants: A Perspective Based on Two Linguistic Models. Ieee Trans. Fuzzy Syst. 2021, 29, 3270–3279. [Google Scholar] [CrossRef]

- Samonto, S.; Kar, S.; Pal, S.; Sekh, A.A.; Castillo, O.; Park, G.-K. Best fit membership function for designing fuzzy logic controller aided intelligent overcurrent fault protection scheme. Int. Trans. Electr. Energy Syst. 2021, 31, e12875. [Google Scholar] [CrossRef]

- Hasuike, T.; Katagiri, H. An objective formulation of membership function based on fuzzy entropy and pairwise comparison. J. Intell. Fuzzy Syst. 2017, 32, 4443–4452. [Google Scholar] [CrossRef]

- Zheng, G.; Zhu, N.; Tian, Z.; Chen, Y.; Sun, B. Application of a trapezoidal fuzzy AHP method for work safety evaluation and early warning rating of hot and humid environments. Saf. Sci. 2012, 50, 228–239. [Google Scholar] [CrossRef]

- Ashraf, S.; Abdullah, S.; Mahmood, T.; Aslam, M. Cleaner Production Evaluation in Gold Mines Using Novel Distance Measure Method with Cubic Picture Fuzzy Numbers. Int. J. Fuzzy Syst. 2019, 21, 2448–2461. [Google Scholar] [CrossRef]

- Yu, X.; Zheng, H.; Sun, L.; Shan, Y. An emissions accounting framework for industrial parks in China. J. Clean. Prod. 2020, 244, 118712. [Google Scholar] [CrossRef]

- Lyu, Y.; Gao, H.; Yan, K.; Liu, Y.; Tian, J.; Chen, L.; Wan, M. Carbon peaking strategies for industrial parks: Model development and applications in China. Appl. Energy 2022, 322, 119442. [Google Scholar] [CrossRef]

- Kim, H.-W.; Ohnishi, S.; Fujii, M.; Fujita, T.; Park, H.-S. Evaluation and Allocation of Greenhouse Gas Reductions in Industrial Symbiosis. J. Ind. Ecol. 2018, 22, 275–287. [Google Scholar] [CrossRef]

- Ranson, M.; Stavins, R.N. Linkage of greenhouse gas emissions trading systems: Learning from experience. Clim. Policy 2016, 16, 284–300. [Google Scholar] [CrossRef]

- Guan, D.; Meng, J.; Reiner, D.M.; Zhang, N.; Shan, Y.; Mi, Z.; Shao, S.; Liu, Z.; Zhang, Q.; Davis, S.J. Structural decline in China’s CO2 emissions through transitions in industry and energy systems. Nat. Geosci. 2018, 11, 551–555. [Google Scholar] [CrossRef]

- Giannetti, B.F.; Agostinho, F.; Eras, J.J.C.; Yang, Z.; Almeida, C.M.V.B. Cleaner production for achieving the sustainable development goals. J. Clean. Prod. 2020, 271, 122127. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).