Identification of Barriers to Sustainable Manufacturing Implementation—The Perspective of Manufacturers of Parts and Components for Agricultural Transport

Abstract

1. Introduction

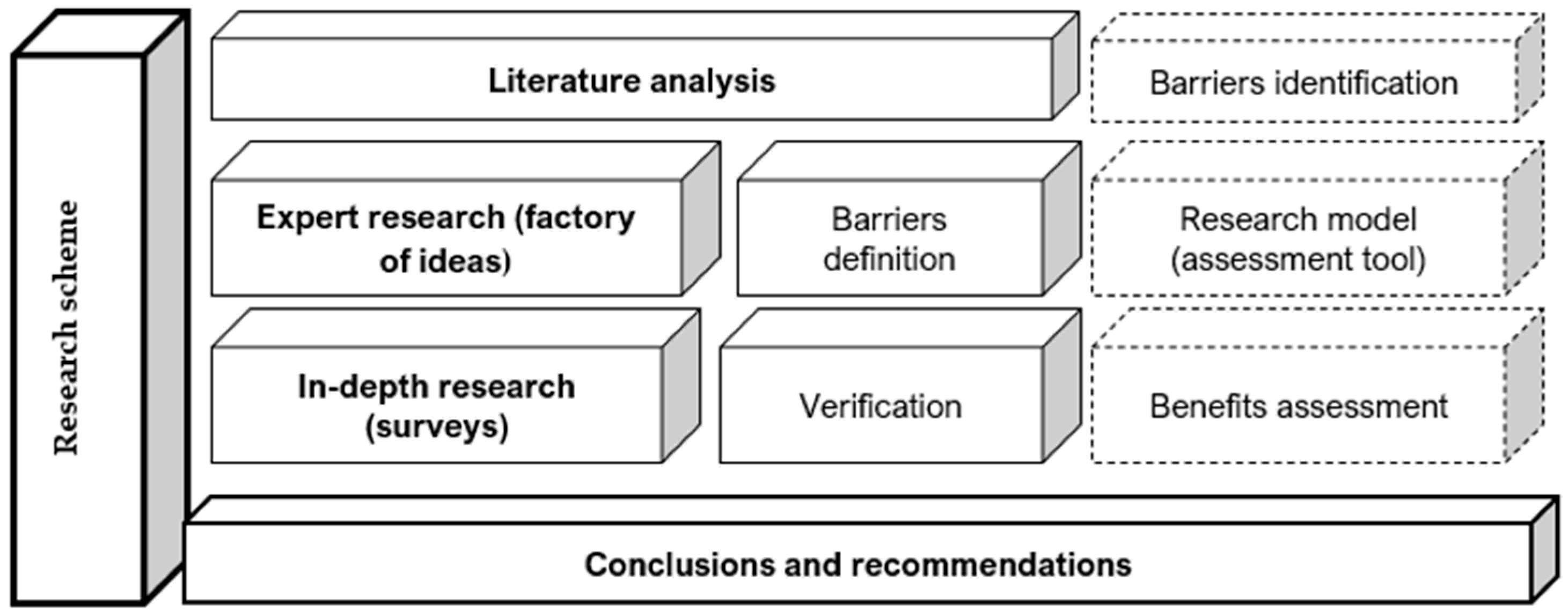

2. Research Framework

2.1. Research Problem Definition

2.2. Research Goal and Research Questions

3. Materials and Methods

4. Research Results

4.1. Literature Query

4.2. Factory of Ideas

4.3. In-Depth Research

5. Conclusions

- Anticipating and overcoming resistance in relation to selected SM postulates of the concept;

- Implementing visionary leadership;

- Questioning “constancy”;

- Implementing an intensive and extensive communication process;

- Choosing the right moment and waiting for implementation;

- Implementing of individual SM postulates;

- Legitimizing the implemented SM postulates.

- The concept of sustainable manufacturing has not been and is still not clearly defined; over the years, the concept has evolved from a complete lack of recognition of the need for its implementation to the emergence of interest in its various dimensions;

- In the literature on the subject, there are many definitions of sustainable manufacturing (although the extensive interpretative analysis of the proposals of various researchers carried out for research purposes is not presented in this study (publishing rigor)).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bradbury, H. Sustaining inner and outer worlds: A whole-systems approach to developing sustainable business practices in management. J. Manag. Educ. 2003, 27, 172–187. [Google Scholar] [CrossRef]

- Cappelli, P.; Keller, J. Classifying work in the new economy. Acad. Manag. Rev. 2013, 38, 596–675. [Google Scholar] [CrossRef]

- Pandey, S.; Rishi, P. Sustainable Development Goals through public sector social responsibility of Indian energy firms—A qualitative analysis. Int. J. Intell. Enterp. 2023, 10, 221–241. [Google Scholar] [CrossRef]

- Kolyasnikov, M.S.; Kelchevskaya, N.R. Knowledge management strategies in companies: Trends and the impact of Industry 4.0. Upravlenec 2020, 11, 82–96. [Google Scholar] [CrossRef]

- Niewiadomski, P. Determinanty Elastyczności Funkcjonowania Przedsiębiorstwa Produkcyjnego Sektora Maszyn Rolniczych; Wydawnictwo Politechniki Poznańskiej: Poznań, Poland, 2016. [Google Scholar]

- Gołda-Jacyna, I.; Izdebski, M.; Szczepański, E.; Gołda, P. The assessment of supply chain effectiveness. Arch. Transp. 2018, 45, 43. [Google Scholar] [CrossRef]

- Zwolińska, B.; Michlowicz, E. Impact of change in the structure of distribution system on incurred cost. Arch. Transp. 2016, 39, 192–202. [Google Scholar] [CrossRef]

- Michlowicz, E. Logistics engineering and Industry 4.0 and digital factory. Arch. Transp. 2021, 57, 59–72. [Google Scholar]

- Merkisz-Guranowska, A. Issues related to the optimization of location of vehicle recycling network entities. Arch. Transp. 2010, 22, 303–318. [Google Scholar] [CrossRef]

- Merkisz-Guranowska, A. Multicriteria optimization model for end-of-life vehicles’ recycling network. Int. J. Sustain. Dev. Plan. 2013, 8, 88–99. [Google Scholar] [CrossRef][Green Version]

- Merkisz-Guranowska, A. A comparative study on end-of-life vehicles network design. Arch. Transp. 2020, 54, 107–123. [Google Scholar] [CrossRef]

- Jacyna, M.; Merkisz, J. Proecological approach to modelling traffic organization in national transport system. Arch. Transp. 2014, 30, 31–41. [Google Scholar] [CrossRef]

- Mariappanadar, S.; Kramar, R. Sustainable HRM: The synthesis effect of high performance work systems on organisational performance and employee harm. Asia-Pac. J. Bus. Adm. 2014, 6, 206–224. [Google Scholar]

- Lee, H.W. Sustainable leadership: An empirical investigation of its effect on organizational effectiveness. Int. J. Organ. Theory Behav. 2017, 20, 419–453. [Google Scholar] [CrossRef]

- Aragão, C.G.; Jabbour, C.J.C. Green training for sustainable procurement? Insights from the Brazilian public sector. Ind. Commer. Train. 2017, 49, 48–54. [Google Scholar] [CrossRef]

- Bansal, P.; Song, H.-C. Similar but not the same: Differentiating corporate sustainability from corporate responsibility. Acad. Manag. Ann. 2017, 11, 105–114. [Google Scholar] [CrossRef]

- Almarzooqi, A.H.; Khan, M.; Khalid, K. The role of sustainable HRM in sustaining positive organizational outcomes: An interactional framework. Int. J. Product. Perform. Manag. 2019, 68, 1272–1292. [Google Scholar] [CrossRef]

- Ybema, J.F.; van Vuuren, T.; van Dam, K. HR practices for enhancing sustainable employability: Implementation, use, and outcomes. Int. J. Hum. Resour. Manag. 2020, 31, 886–907. [Google Scholar] [CrossRef]

- Wikhamn, W. Innovation, sustainable HRM and customer satisfaction. Int. J. Hosp. Manag. 2019, 76, 102–110. [Google Scholar] [CrossRef]

- Iqbal, Q.; Piwowar-Sulej, K. Sustainable leadership in higher education institutions: Social innovation as a mechanism. Int. J. Sustain. High. Educ. 2022, 23, 1–20. [Google Scholar] [CrossRef]

- Iqbal, Q.; Ahmad, N.H. Sustainable development: The colors of sustainable leadership in learning organization. Sustain. Dev. 2021, 29, 108–119. [Google Scholar] [CrossRef]

- Hariyani, D.; Mishra, S. Organizational enablers for sustainable manufacturing and industrial ecology. Clean. Eng. Technol. 2022, 6, 100375. [Google Scholar] [CrossRef]

- Mittal, V.K.; Sangwan, K.S. Prioritizing barriers to green manufacturing: Environmental, social and economic perspectives. Procedia CIRP 2014, 17, 559–564. [Google Scholar] [CrossRef]

- Muduli, K.; Govindan, K.; Barve, A.; Geng, Y. Barriers to green supply chain management in Indian mining industries: A graph theoretic approach. J. Clean. Prod. 2013, 47, 335–344. [Google Scholar] [CrossRef]

- Ghose, M.K. Indian small-scale mining with special emphasis on environmental management. J. Clean. Prod. 2003, 11, 159–165. [Google Scholar] [CrossRef]

- Abdullah, M.; Zailani, S.; Iranmanesh, M.; Jayaraman, K. Barriers to green innovation initiatives among manufacturers: The Malaysian case. Rev. Manag. Sci. 2016, 10, 683–709. [Google Scholar] [CrossRef]

- Sharma, Y.C.; Aggarwal, P.; Singh, T.N. Economic liabilities of environmental pollution by coal mining: Indian scenario. Environ. Dev. Sustain. 2009, 11, 589–599. [Google Scholar] [CrossRef]

- Bhanot, N.; Rao, P.V.; Deshmukh, S.G. An integrated approach for analysing the enablers and barriers of sustainable manufacturing. J. Clean. Prod. 2016, 142, 4412–4439. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Govindan, K.; NoorulHaq, A.; Geng, Y. An ISM approach for the barrier analysis in implementing green supply chain management. J. Clean. Prod. 2013, 47, 283–297. [Google Scholar] [CrossRef]

- Russo, M.V.; Harrison, N.S. Organizational design and environmental performance: Clues from the electronics industry. Acad. Manag. J. 2005, 48, 582–593. [Google Scholar] [CrossRef]

- Ghazilla, R.A.R.; Sakundarini, N.; Abdul-Rashid, S.H.; Ayub, N.S.; Olugu, E.U.; Musa, S.N. Drivers and barriers analysis for green manufacturing practices in Malaysian SMEs: A preliminary findings. Procedia CIRP 2015, 26, 658–663. [Google Scholar] [CrossRef]

- Barve, A.; Muduli, K. Modelling the challenges of green supply chain management practices in Indian mining industries. J. Manuf. Technol. Manag. 2013, 24, 1102–1122. [Google Scholar] [CrossRef]

- Luthra, S.; Kumar, S.; Garg, D.; Haleem, A. Barriers to renewable/sustainable energy technologies adoption: Indian perspective. Renew. Sustain. Energy Rev. 2015, 41, 762–776. [Google Scholar] [CrossRef]

- Govindan, K.; Kaliyan, M.; Kannan, D.; Haq, A.N. Barriers analysis for green sup-ply chain management implementation in Indian industries using analytic hierarchy process. Int. J. Prod. Econ. 2014, 147, 555–568. [Google Scholar] [CrossRef]

- Jawahir, I.S.; Bradley, R. Technological elements of circular economy and the principles of 6R-based closed-loop material flow in sustainable manufacturing. Procedia CIRP 2016, 40, 103–108. [Google Scholar] [CrossRef]

- Dhull, S.; Narwal, M.S. Drivers and barriers in green supply chain management adaptation: A state-of-art review. Uncertain Supply Chain Manag. 2016, 4, 61–76. [Google Scholar] [CrossRef]

- Shankar, K.M.; Kannan, D.; Kumar, P.U. Analyzing sustainable manufacturing practices—A case study in Indian context. J. Clean. Prod. 2017, 164, 1332–1343. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, H.; Wu, C.; Huang, Z. An economic model of integration framework of lean production and green manufacturing based on sustainability balanced scorecard. Bol. Tec./Tech. Bull. 2017, 55, 263–269. [Google Scholar]

- Fargani, H.; Cheung, W.M.; Hasan, R. An empirical analysis of the factors that support the drivers of sustainable manufacturing. Procedia CIRP 2016, 56, 491–495. [Google Scholar] [CrossRef]

- Koho, M.; Torvinen, S.; Romiguer, A.T. Objectives, enablers and challenges of sustainable development and sustainable manufacturing. In Proceedings of the 2011 IEEE International Symposium on Assembly and Manufacturing (ISAM), Tampere, Finland, 25–27 May 2011; pp. 1–6. [Google Scholar]

- Kumar, S.; Kumar, N.; Haleem, A. Conceptualisation of Sustainable Green Lean Six Sigma: An empirical analysis. Int. J. Bus. Excell. 2015, 8, 210. [Google Scholar] [CrossRef]

- Chiou, T.Y.; Chan, H.K.; Lettice, F.; Chung, S.H. The influence of greening the suppliers and green innovation on environmental performance and competitive advantage in Taiwan. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 822–836. [Google Scholar] [CrossRef]

- Jovane, F.; Westkämper, E.; Williams, D. The Manufuture Road: Towards Compet-itive and Sustainable High-Adding-Value Manufacturing; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Govindan, K.; Madan Shankar, K.; Kannan, D. Application of fuzzy analytic net-work process for barrier evaluation in automotive parts remanufacturing towards cleaner production—A study in an Indian scenario. J. Clean. Prod. 2016, 114, 199–213. [Google Scholar] [CrossRef]

- Rahimifard, S.; Coates, G.; Staikos, T.; Edwards, C.; Abu-Bakar, M. Barriers, drivers and challenges for sustainable product recovery and recycling. Int. J. Sustain. Eng. 2009, 2, 80–90. [Google Scholar] [CrossRef]

- Bey, N.; Hauschild, M.Z.; McAloone, T.C. Drivers and barriers for implementation of environmental strategies in manufacturing companies. CIRP Ann. Manuf. Technol. 2013, 62, 43–46. [Google Scholar] [CrossRef]

- Luken, R.; Van Rompaey, F. Drivers for and barriers to environmentally sound tech-nology adoption by manufacturing plants in nine developing countries. J. Clean. Prod. 2008, 16, S67–S77. [Google Scholar] [CrossRef]

- Nambiar, A. Challenges in sustainable manufacturing. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Dhaka, Bangladesh, 26–28 December 2022; pp. 10–15. [Google Scholar]

- Chen, C.C.; Shih, H.S.; Shyur, H.J.; Wu, K.S. A business strategy selection of green supply chain management via an analytic network process. Comput. Math. Appl. 2012, 64, 2544–2557. [Google Scholar] [CrossRef]

- Aboelmaged, M.G. Reconstructing Six Sigma barriers in manufacturing and service organizations: The effects of organizational parameters. Int. J. Qual. Reliab. Manag. 2011, 28, 519–541. [Google Scholar] [CrossRef]

- Kumar, S.; Luthra, S.; Govindan, K.; Kumar, N.; Haleem, A. Barriers in green lean six sigma product development process: An ISM approach. Prod. Plan. Control 2016, 27, 604–620. [Google Scholar] [CrossRef]

- Hahn, R. ISO 26000 and the standardization of strategic management processes for sustainability and corporate social responsibility. Bus. Strateg. Environ. 2013, 22, 442–455. [Google Scholar] [CrossRef]

- ISO 26000; ISO 26000: Guidance on Social Responsibility. 1st ed. International Organization for Standardization: Geneva, Switzerland, 2010.

- Nunes, B.; Bennett, D. Green operations initiatives in the automotive industry: An environmental reports analysis and benchmarking study. Benchmarking Int. J. 2010, 17, 396–420. [Google Scholar] [CrossRef]

- Alefari, M.; Salonitis, K.; Xu, Y. The role of leadership in implementing lean manufacturing. Procedia CIRP 2017, 63, 756–761. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; de Sousa Jabbour, A.B.L.; Govindan, K.; de Freitas, T.P.; Soubihia, D.F.; Kannan, D.; Latan, H. Barriers to the adoption of green operational practices at Brazilian companies: Effects on green and operational performance. Int. J. Prod. Res. 2016, 54, 3042–3058. [Google Scholar] [CrossRef]

- Hariyani, D.; Mishra, S.; Sharma, M.K. A descriptive statistical analysis of barriers to the adoption of integrated sustainable-green-lean-six sigma-agile manufacturing system (ISGLSAMS) in Indian manufacturing industries. Benchmarking 2022, 30, 2705–2733. [Google Scholar] [CrossRef]

- Berger, S.L.T.; Tortorella, G.L.; Rodriguez, C.M.T. Lean Supply Chain Management: A Systematic Literature Review of Practices, Barriers and Contextual Factors Inherent to Its Implementation; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; pp. 39–68. [Google Scholar]

- Cherrafi, A.; Elfezazi, S.; Chiarini, A.; Mokhlis, A.; Benhida, K. The integration of lean manufacturing, Six Sigma and sustainability: A literature review and future research directions for developing a specific model. J. Clean. Prod. 2016, 139, 828–846. [Google Scholar] [CrossRef]

- Giunipero, L.C.; Hooker, R.E.; Denslow, D. Purchasing and supply management sustainability: Drivers and barriers. J. Purch. Supply Manag. 2012, 18, 258–269. [Google Scholar] [CrossRef]

- Kulatunga, A.K.; Jayatilaka, P.R.; Jayawickrama, M. Drivers and barriers to im-plement sustainable manufacturing concepts in Sri Lankan manufacturing sector. In Proceedings of the 11th Global Conference on Sustainable Manufacturing, Berlin, Germany, 23–25 September 2013; pp. 171–176. [Google Scholar]

- Lodgaard, E.; Ingvaldsen, J.A.; Gamme, I.; Aschehoug, S. Barriers to lean implemen-tation: Perceptions of top managers, middle managers and workers. Procedia CIRP 2016, 57, 595–600. [Google Scholar] [CrossRef]

- Veiga, G.L.; Lima, E.P.; Angelis, J.J.; Costa, S.E.G. The strategic role of lean a dis-cussion. Braz. J. Oper. Prod. Manag. 2011, 8, 9–30. [Google Scholar] [CrossRef]

- Hines, P.; Found, P.; Griffiths, G.; Harrison, R. Staying lean; thriving, not just surviving. Cardiff. Hsu, C.W., Hu, A.H., 2008. Green supply chain management in the electronic industry. Int. J. Environ. Sci. Technol. 2008, 5, 205–216. [Google Scholar]

- Mittal, V.K.; Sangwan, K.S. Development of a model of barriers to environmentally conscious manufacturing implementation. Int. J. Prod. Res. 2014, 52, 584–594. [Google Scholar] [CrossRef]

- Govindan, K.; Hasanagic, M. A systematic review on drivers, barriers, and practices towards circular economy: A supply chain perspective. Int. J. Prod. Res. 2018, 56, 278–311. [Google Scholar] [CrossRef]

- Sarkis, J.; Helms, M.M.; Hervani, A.A. Reverse logistics and social sustainability. Corp. Soc. Responsib. Environ. Manag. 2010, 17, 337–354. [Google Scholar] [CrossRef]

- Brammer, S.; Hoejmose, S.; Marchant, K. Environmental management in SMEs in the UK: Practices, pressures and perceived benefits. Bus. Strateg. Environ. 2012, 21, 423–434. [Google Scholar] [CrossRef]

- Bhanot, N.; Rao, P.V.; Deshmukh, S.G. Enablers and barriers of sustainable manufacturing: Results from a survey of researchers and industry professionals. Procedia CIRP 2015, 29, 562–567. [Google Scholar] [CrossRef]

- Xia, X.; Govindan, K.; Zhu, Q. Analyzing internal barriers for automotive parts remanufacturers in China using grey-DEMATEL approach. J. Clean. Prod. 2015, 87, 811–825. [Google Scholar] [CrossRef]

- Kumar, R. Barriers in implementation of lean manufacturing system in Indian in-dustry: A survey. Int. J. Latest Trends Eng. Technol. 2014, 4, 243–251. [Google Scholar]

- Cherrafi, A.; Elfezazi, S.; Garza-Reyes, J.A.; Benhida, K.; Mokhlis, A. Barriers in Green Lean implementation: A combined systematic literature review and interpretive structural modelling approach. Prod. Plan. Control 2017, 28, 829–842. [Google Scholar] [CrossRef]

- Kaur, J.; Sidhu, R.; Awasthi, A.; Chauhan, S.; Goyal, S. A DEMATEL based approach for investigating barriers in green supply chain management in Canadian manufac-turing firms. Int. J. Prod. Res. 2018, 56, 312–332. [Google Scholar] [CrossRef]

- Singh, A.; Singh, B.; Dhingra, A.K. Practices: Drivers and barriers of green manufacturing practices a survey of indian industries. Int. J. Eng. 2012, 1, 5–19. [Google Scholar]

- Wiedmann, K.-P.; Hennigs, N.; Pankalla, L.; Kassubek, M.; Seegebarth, B. Adoption barriers and resistance to sustainable solutions in the automotive sector. J. Bus. Res. 2011, 64, 1201–1206. [Google Scholar] [CrossRef]

- del González, P.R. Analysing the factors influencing clean technology adoption: A study of the Spanish pulp and paper industry. Bus. Strateg. Environ. 2005, 14, 20–37. [Google Scholar] [CrossRef]

- Mittal, V.K.; Sangwan, K.S.; Herrmann, C.; Egede, P.; Wulbusch, C. Drivers and barriers of environmentally conscious manufacturing: A comparative study of Indian and German organizations. In Proceedings of the 19th CIRP Conference on Life Cycle Engineering, Berkeley, CA, USA, 23–25 May 2012; pp. 97–102. [Google Scholar]

- Petrini, M.; Pozzebon, M. Managing sustainability with the support of business intelligence: Integrating socio-environmental indicators and organisational context. J. Strateg. Inf. Syst. 2009, 18, 178–191. [Google Scholar] [CrossRef]

- Machado, S.D.V.C. Exploring barriers in lean implementation. Int. J. Lean Six Sigma 2014, 5, 122–148. [Google Scholar]

- Zhang, L.; Narkhede, B.E.; Chaple, A.P. Evaluating lean manufacturing barriers: An interpretive process. J. Manuf. Technol. Manag. 2017, 28, 1086–1111. [Google Scholar] [CrossRef]

- Raut, R.; Narkhede, B.E.; Gardas, B.B.; Luong, H.T. An ISM approach for the barrier analysis in implementing sustainable practices. Benchmarking Int. J. 2018, 25, 1245–1271. [Google Scholar] [CrossRef]

- Ravi, V.; Shankar, R. Analysis of interactions among the barriers of reverse logistics. Technol. Forecast. Soc. Chang. 2005, 72, 1011–1029. [Google Scholar] [CrossRef]

- Weerakkody, V.; Janssen, M.; Dwivedi, Y.K. Transformational change and business process reengineering (BPR): Lessons from the British and Dutch public sector. Gov. Inf. Q. 2011, 28, 320–328. [Google Scholar] [CrossRef]

- Mittal, V.K.; Sindhwani, R.; Kapur, P.K. Two-way assessment of barriers to Lean– Green Manufacturing System: Insights from India. Int. J. Syst. Assur. Eng. Manag. 2016, 7, 400–407. [Google Scholar] [CrossRef]

- Baumgartner, R.J.; Ebner, D. Corporate sustainability strategies: Sustainability profiles and maturity levels. Sustain. Dev. 2010, 18, 76–89. [Google Scholar] [CrossRef]

- Wyrwicka, M.K.; Mrugalska, B. Mirages of Lean Manufacturing in Practice. Procedia Eng. 2017, 182, 780–785. [Google Scholar] [CrossRef]

- Berner, B.; Hantz, K.; Chojnacki, J.; Grieger, A. Środki transportowe do przewozu płodów rolnych. Autobusy Technol. Eksploat. Syst. Transp. 2015, 5, 33–36. [Google Scholar]

- Crute, V.; Ward, Y.; Brown, S.; Graves, A. Implementing Lean in aerospace challenging the assumptions and understanding the challenges. Technovation 2003, 23, 917–928. [Google Scholar] [CrossRef]

- Halling, B.; Wijk, K. Experienced barriers to lean in Swedish manufacturing and health care. Int. J. Lean Think. 2013, 4, 43–63. [Google Scholar]

- Pandey, H.; Garg, D.; Luthra, S. Identification and ranking of enablers of green lean Six Sigma implementation using AHP. Int. J. Product. Qual. Manag. 2018, 23, 187. [Google Scholar] [CrossRef]

- Gupta, H.; Kusi-Sarpong, S.; Rezaei, J. Barriers and overcoming strategies to supply chain sustainability innovation. Resour. Conserv. Recycl. 2020, 161, 104819. [Google Scholar] [CrossRef]

- Worley, J.M.; Doolen, T.L. The role of communication and management support in a lean manufacturing implementation. Manag. Decis. 2006, 44, 228–245. [Google Scholar] [CrossRef]

- Simons, T.L.; Peterson, R.S. Task conflict snd relationship conflict in top management teams: The pivotal role of intragroup trust. J. Appl. Psychol. 2000, 85, 102–111. [Google Scholar] [CrossRef] [PubMed]

- McLean, B.L.; Boren, T. Barriers to implementing sustainability locally: A case study of policy immobilities. Local Environ. 2015, 20, 1489–1506. [Google Scholar] [CrossRef]

- Kopitov, R. Enhancing Business Sustainability: Improving Business Policy’s Methodology by Managerial Principles’ Development. Procedia-Soc. Behav. Sci. 2013, 99, 133–142. [Google Scholar] [CrossRef]

- Lam, P.K.; Chin, K.S.; Pun, K.F. Managing conflict in collaborative new product development: A supplier perspective. Int. J. Qual. Reliab. Manag. 2007, 24, 891–907. [Google Scholar]

- Kwon, I.W.G.; Suh, T. Trust, commitment and relationships in supply chain management: A path analysis. Supply Chain Manag. 2005, 10, 26–33. [Google Scholar] [CrossRef]

- Kadambi, B. IT-Enabled Supply Chain Management—A Preliminary Study of Few Manufacturing Companies in India [WWW Document]. 2000. Available online: http://www.xlri.ac.in/cltm/LogistiX-2-2000.HTM (accessed on 7 January 2024).

- Groover, M.P. Automation, Production Systems, and Computer-Integrated Manufacturing; PHI: Englewood Cliffs, NJ, USA, 2002. [Google Scholar]

- Cudney, E.; Elrod, C. A comparative analysis of integrating lean concepts into supply chain management in manufacturing and service industries. Int. J. Lean Six Sigma 2011, 2, 5–22. [Google Scholar] [CrossRef]

- Kumaravel, S.; Chakraborty, A. Identifying Drivers of Sustainability Initiatives in Manufacturing Organizations—An Exploratory Study from the Indian Cement Industry; Springer: Berlin/Heidelberg, Germany, 2018; pp. 11–20. [Google Scholar]

- Deif, A.M. A system model for green manufacturing. J. Clean. Prod. 2011, 19, 1553–1559. [Google Scholar] [CrossRef]

- Antony, J.; Antony, F.J.; Kumar, M.; Cho, B.R. Six sigma in service organisations: Benefits, challenges and difficulties, common myths, empirical observations and success factors. Int. J. Qual. Reliab. Manag. 2007, 24, 294–311. [Google Scholar] [CrossRef]

- Schaper, M. The challenge of environmental responsibility and sustainable development: Implications for SME and entrepreneurship academics. In Radical Changes in the World: Will SMEs Soar or Crash; Springer: Berlin/Heidelberg, Germany, 2002; pp. 541–553. [Google Scholar]

- Nordin, N.; Deros, M.B.; Wahab, D.A. Change management issues in lean manufacturing: Literature analysis. In Proceedings of the Engineering Postgraduate Conference (EPC) Faculty of Engineering and Built Environment; UKM: Kuala Lumpur, Malaysia, 2008. [Google Scholar]

- Okoli, C.; Pawlowski, S. The Delphi Method as a Research Tool: An Example. Design Considerations and Applications. Inf. Manag. 2014, 42, 15–29. [Google Scholar] [CrossRef]

- Paliwoda, S.J. Predicting the Future Using Delphi. Manag. Decis. 1993, 21, 31–38. [Google Scholar] [CrossRef]

- Paulus, P.B.; Dzindolet, M.T.; Poletes, G.; Camacho, L.M. Perception of performance in group brainstorming: The illusion of group productivity. Personal. Soc. Psychol. Bull. 1993, 19, 78–89. [Google Scholar] [CrossRef]

- Suddaby, R. Editor’s Comments: Construct Clarity in Theories of Management and Organization. Acad. Manag. Rev. 2010, 35, 346–357. [Google Scholar]

- Peter, J.P. Construct validity: A Review of Basic Issues and Marketing Practices. J. Mark. Res. 1981, 18, 133–145. [Google Scholar] [CrossRef]

- Hoskisson, R.E.; Hitt, M.A.; Johnson, R.A.; Moesel, D.D. Construct Validity of an Objective (Entropy) Categorical Measure of Diversification Strategy. Strateg. Manag. J. 1993, 14, 215–235. [Google Scholar] [CrossRef]

| Scope and Range of Activity | 1 | 2 | 3 | 4 | 5 | AV. |

|---|---|---|---|---|---|---|

| % of Indications (Number of Indications) | ||||||

| Unfavorable legal and economic environment | - | 14.9 (11) | 17.6 (13) | 28.4 (21) | 39.2 (29) | 3.92 |

| Excessive focus on profit (manufacturing efficiency), not taking into account environmental aspects and interpersonal relationships (implementing the concept in a technical way); implementation of the concept only to obtain economic and financial benefits | 5.4 (4) | 4.1 (3) | 40.5 (30) | 28.4 (21) | 21.6 (16) | 3.57 |

| Excessive focus on current affairs (lack of vision for the future); preoccupation with current problems | 5.4 (4) | 9.5 (7) | 29.7 (22) | 35.1 (26) | 20.3 (15) | 3.55 |

| Traditional habits, patterns, behaviors; traditional organizational culture | 5.4 (4) | 12.2 (9) | 29.7 (22) | 35.1 (26) | 17.6 (13) | 3.47 |

| Cessation of implementation due to a change in priorities (short-term goals) | 6.8 (5) | 12.2 (9) | 33.8 (25) | 31.1 (23) | 16.2 (12) | 3.38 |

| Weak training system on sustainable manufacturing practices | 5.4 (4) | 10.8 (8) | 43.2 (32) | 28.4 (21) | 12.2 (9) | 3.31 |

| Using ready-made patterns and solutions without matching them to the conditions and context of the company | 4.1 (3) | 18.9 (14) | 36.5 (27) | 28.4 (21) | 12.2 (9) | 3.26 |

| Inconsistency of goals. Misunderstanding needs. Lack of interest of companies in the implementation of projects whose benefits are considered in the long term. Little business potential. | 10.8 (8) | 18.9 (14) | 27.0 (20) | 20.3 (15) | 23.0 (17) | 3.26 |

| Implementation of the concept in a random, fragmentary way | 8.1 (6) | 16.2 (12) | 33.8 (25) | 27.0 (20) | 14.9 (11) | 3.24 |

| Insufficient communication about the goals and nature of the changes | 4.1 (3) | 16.2 (12) | 40.5 (30) | 32.4 (24) | 6.8 (5) | 3.22 |

| No support from third parties (advice, consultation) | 8.1 (6) | 18.9 (14) | 41.9 (31) | 18.9 (14) | 12.2 (9) | 3.08 |

| Resistance from employees | 6.8 (5) | 16.2 (12) | 45.9 (34) | 29.7 (22) | 1.4 (1) | 3.03 |

| Lack of motivation and commitment resulting from a lack of vision and resulting benefits | 8.1 (6) | 24.3 (18) | 39.2 (29) | 24.3 (18) | 4.1 (3) | 2.92 |

| Failure to take into account the real needs of enterprises | 16.2 (12) | 18.9 (14) | 35.1 (26) | 17.6 (13) | 12.2 (9) | 2.91 |

| Lack of modern technological solutions; mismatch with the requirements of the environment (lack of compatibility) | 14.9 (11) | 16.2 (12) | 40.5 (30) | 21.6 (16) | 6.8 (5) | 2.89 |

| Unsatisfactory effects of the previous implementation attempt for companies, consisting in insufficient applicability of the proposed solutions | 13.5 (10) | 23.0 (17) | 37.8 (28) | 12.2 (9) | 13.5 (10) | 2.89 |

| Staff rotation | 17.6 (13) | 21.6 (16) | 33.8 (25) | 14.9 (11) | 12.2 (9) | 2.82 |

| Low awareness of the need to implement the concept of sustainable manufacturing; little understanding of the essence, especially among executive employees | 14.9 (11) | 16.2 (12) | 41.9 (31) | 27.0 (20) | - | 2.81 |

| Low awareness of potential profits (reluctance from the perspective of long-term expectations) | 16.2 (12) | 23.0 (17) | 37.8 (28) | 10.8 (8) | 12.2 (9) | 2.80 |

| Improper style of implementation of individual solutions | 20.3 (15) | 18.9 (14) | 33.8 (25) | 17.6 (13) | 9.5 (7) | 2.77 |

| Imposing solutions, no possibility to participate in the transformation process (blocking employee initiatives) | 12.2 (9) | 28.4 (21) | 35.1 (26) | 20.3 (15) | 4.1 (3) | 2.76 |

| Excessive formalization | 17.6 (13) | 21.6 (16) | 39.2 (29) | 14.9 (11) | 6.8 (5) | 2.72 |

| Lack of commitment from management | 12.2 (9) | 32.4 (24) | 33.8 (25) | 20.3 (15) | 1.4 (1) | 2.66 |

| Low staff competences, lack of specialist knowledge | 20.3 (15) | 18.9 (14) | 41.9 (31) | 16.2 (12) | 2.7 (2) | 2.62 |

| No financial resources; identifying transformation with large outlays | 23.0 (17) | 39.2 (29) | 25.7 (19) | 9.5 (7) | 2.7 (2) | 2.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niewiadomski, P.; Stachowiak, A. Identification of Barriers to Sustainable Manufacturing Implementation—The Perspective of Manufacturers of Parts and Components for Agricultural Transport. Sustainability 2024, 16, 2244. https://doi.org/10.3390/su16062244

Niewiadomski P, Stachowiak A. Identification of Barriers to Sustainable Manufacturing Implementation—The Perspective of Manufacturers of Parts and Components for Agricultural Transport. Sustainability. 2024; 16(6):2244. https://doi.org/10.3390/su16062244

Chicago/Turabian StyleNiewiadomski, Przemysław, and Agnieszka Stachowiak. 2024. "Identification of Barriers to Sustainable Manufacturing Implementation—The Perspective of Manufacturers of Parts and Components for Agricultural Transport" Sustainability 16, no. 6: 2244. https://doi.org/10.3390/su16062244

APA StyleNiewiadomski, P., & Stachowiak, A. (2024). Identification of Barriers to Sustainable Manufacturing Implementation—The Perspective of Manufacturers of Parts and Components for Agricultural Transport. Sustainability, 16(6), 2244. https://doi.org/10.3390/su16062244