2.1. Demand-Side Management Barriers, Drivers, and Applications in the Industry

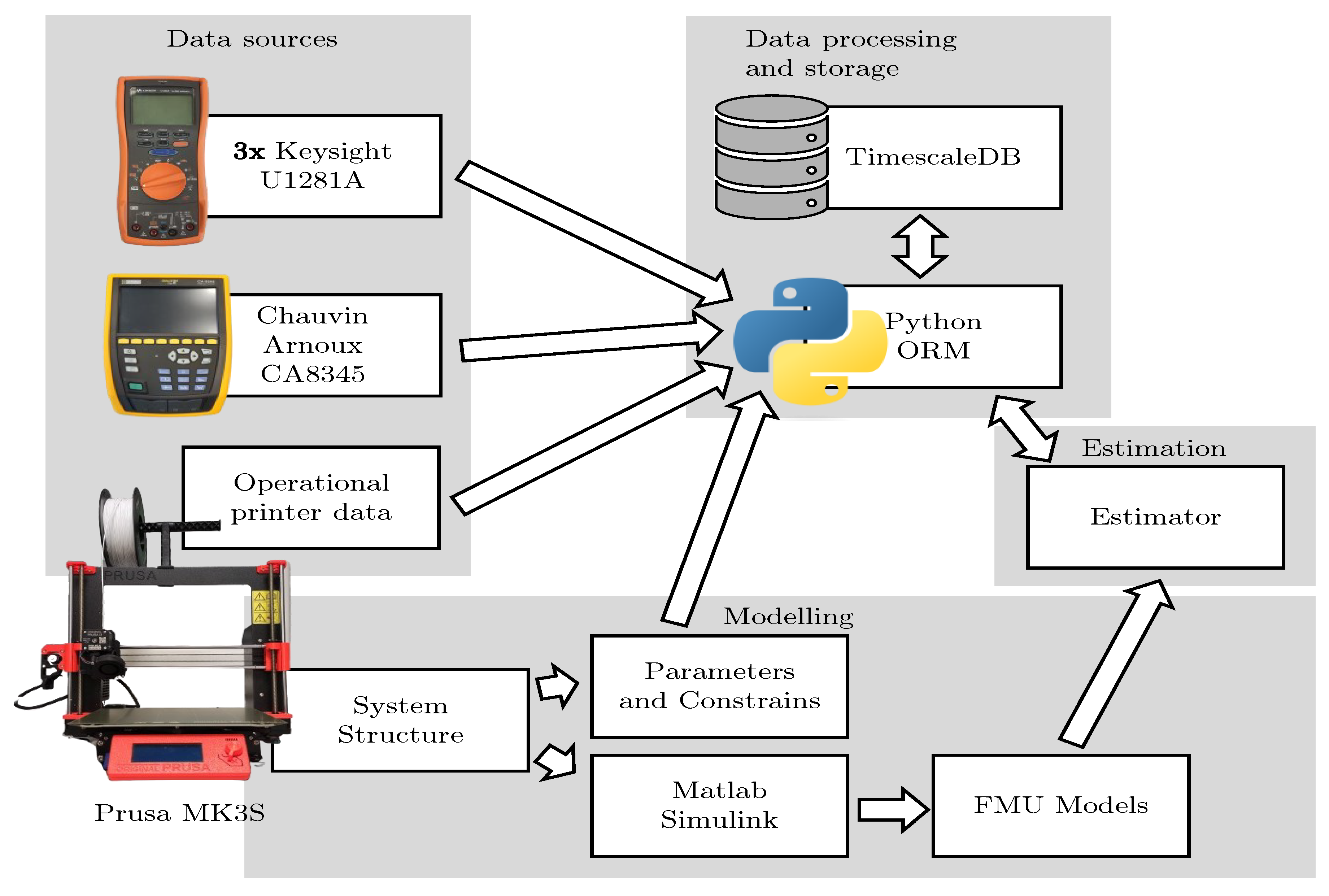

Due to its long history, DSM in the industrial sector has already been the subject of a number of studies considering the possible benefits. Multiple reviews point out the arising potentials to integrate the DSM objectives into industrial applications, by introducing operational data management. In order to operate an industrial demand-side managed plant, integrated communication systems and sensors, automated metering, and intelligent devices are necessary [

7]. In 2021, Siddiquee et al. [

11] identified information sharing as a key barrier for applied demand-response, which should be tackled by big data and data analytics to enable DR applications. Menghi et al. [

12] analyzed energy efficiency barriers of manufacturing systems in 2019 and pointed out the opportunities introduced by Industry 4.0 and data management systems. In detail, most EE barriers are related to transparent data acquisition and structured data evaluation. In a review of energy-intense industries, Golmohamadi [

13] also points out the availability of technical and market data as a key challenge to address to enable DSM applications.

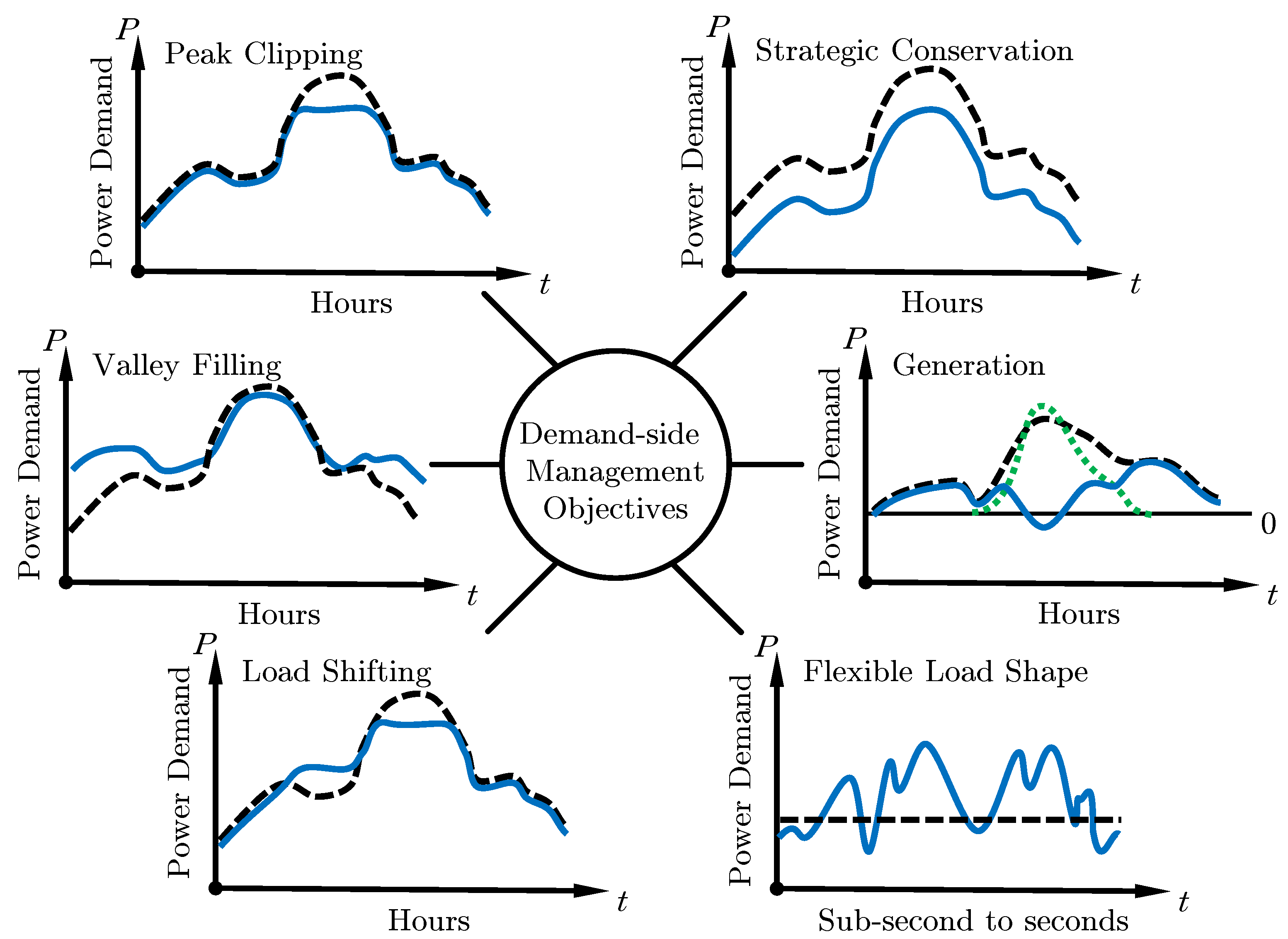

A driver to overcome the data-related barriers are savings through various incentive programs. As VRES, e.g., wind power or photovoltaic power, feature the lowest levelized cost of energy, direct savings can be achieved by utilizing these sources, with the DSM objective of generation. There is a strong correlation between electricity prices and the availability of renewables [

14]. Thus, with the rising share of VRES, a rising volatility of prices in the energy exchange markets is anticipated. The rising financial and greenhouse gas emission saving potentials are seen as the key driver towards industrial DSM. There are further saving potentials enabled by flattening the load curve with valley filling or peak shaving, as the charge for the electricity connection of industrial consumers is usually dependent on the quarter-hourly maximum load. In several scientific publications, the topics of DR and EE are considered without interdependencies. Contrary, more recent publications emphasize in particular the investment in energy efficiency measures, as this can result in the reduction of peak loads and demand-response synergies [

15,

16,

17].

The actual possibilities are largely dependent on the flexibility of loads, i.e., not all energy consumers can be switched off or controlled. Loads can be distinguished as non-interruptible, schedulable, controllable, transferable, and energy storing [

18], and possible measures are chosen appropriately. It is also possible to extend the scope of industrial consumers to the building services. Dababneh et al. [

19] and Jin et al. [

20] used the average, respectively rated power of machines as heating sources in the HVAC planning to reduce peak power demand. For the automotive manufacturing industry, Emec et al. [

21] researched the load shift and process optimization potential, and concluded a 20% energy consumption and cost savings potential. Tristán et al. [

22] researched the introduction of an energy management system for three industrial systems in combination with combined heat and power, as well as a photovoltaic array for energy flexible applications. The scientific SotA thus indicates the application potential for cross-cutting and complex application scenarios.

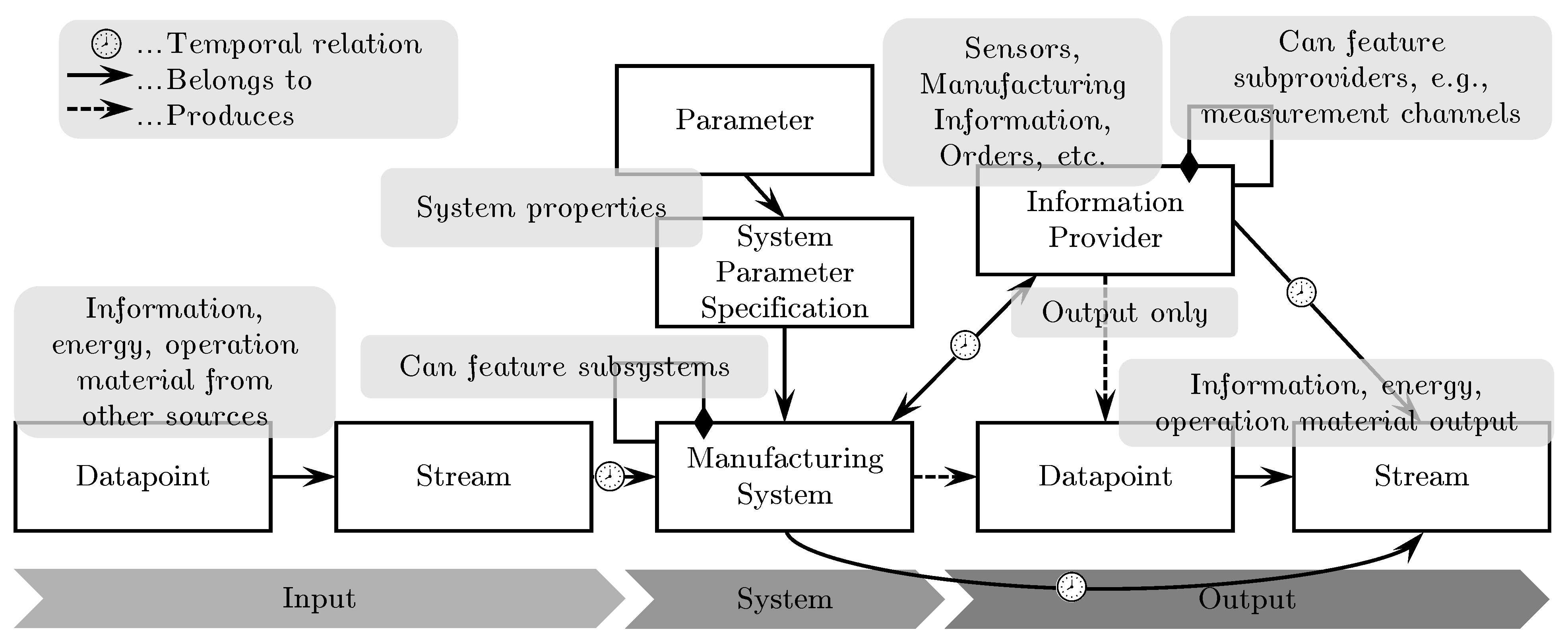

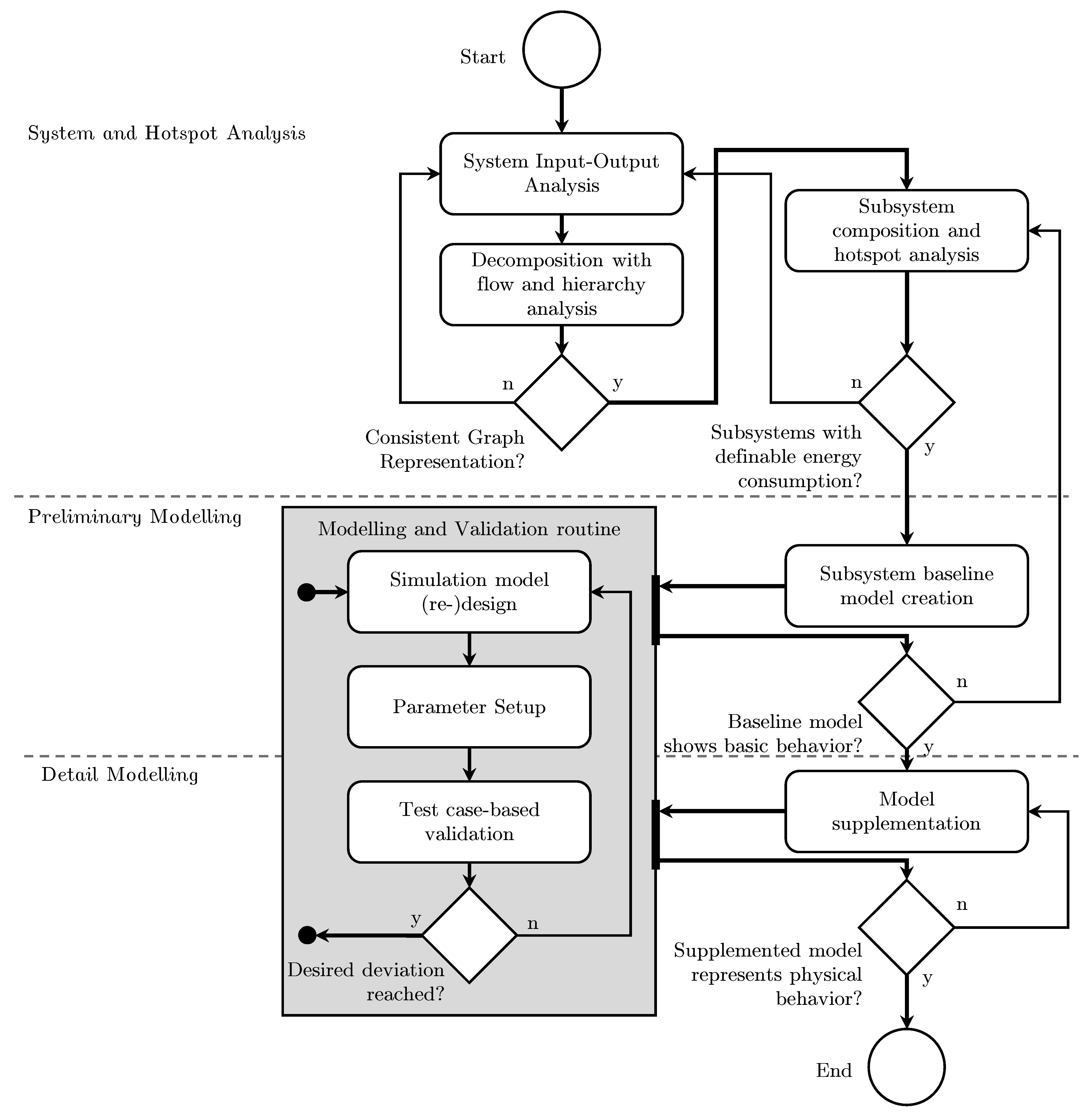

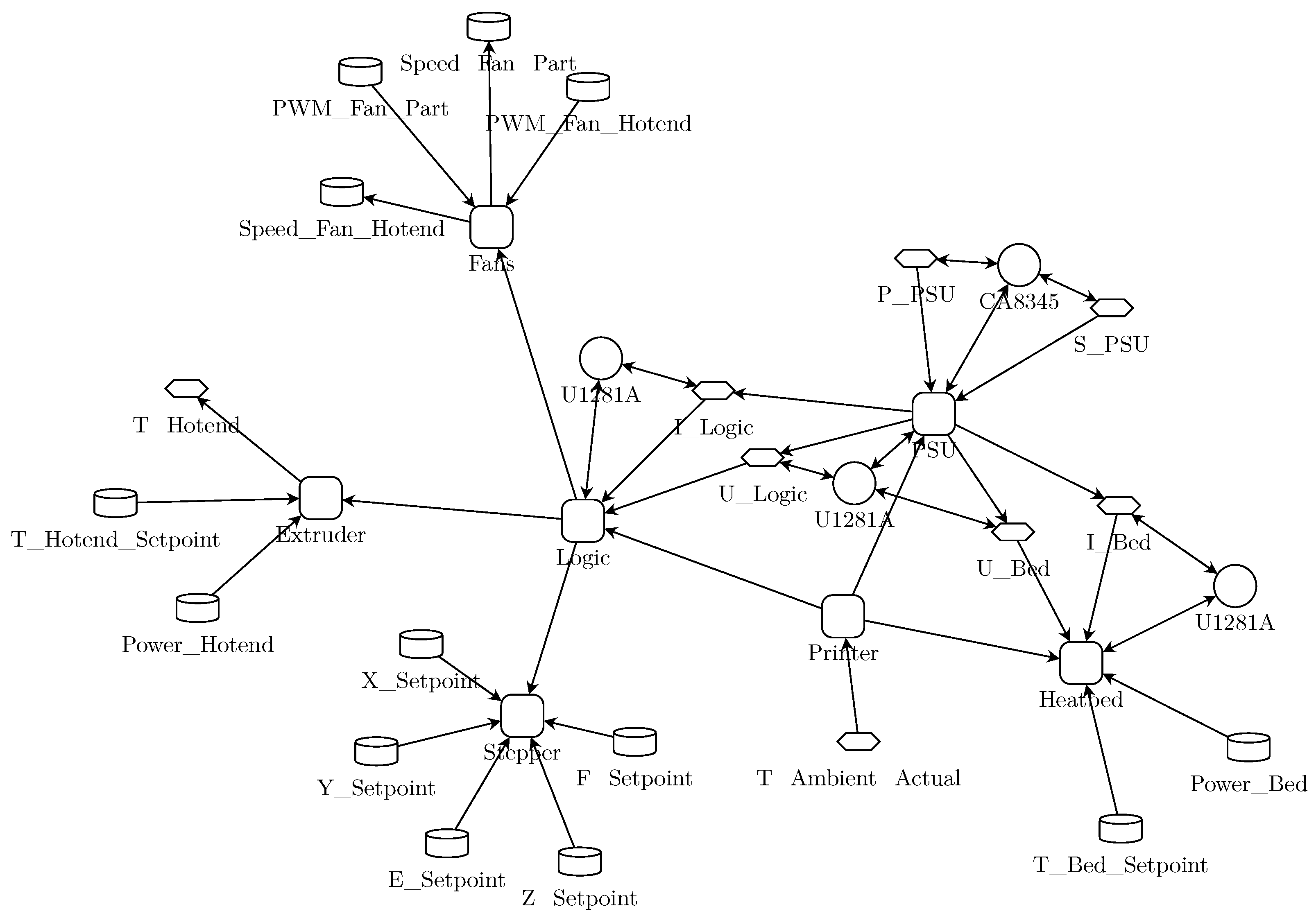

2.2. Formal Representation of Manufacturing Systems

In their review of energy efficiency barriers Mengi et al. [

12] pointed out the possibilities of data acquisition and furthermore stressed the complexity of production environments for data analysis. Thus, a structured procedure is necessary to map a physical manufacturing system formally. While conventional methods organized the data flow over several levels, namely field level, control level, supervisory level, planning, and management level, modern methods, e.g., the Industry 4.0 paradigm, use a node-based structure. While a node-based structure is able to depict complex flows, it may become congested and not able to visualize a system’s hierarchy properly. Thus, within a modern industrial environment, a system’s hierarchy and data flow have to be separated.

For the energy focus within DSM applications, an alternative representation can also be based on the energy flow. Fundamental works are based on the energetic input–output analysis by Bullard and Herendeen [

23] and the embodied energy paradigm formalized by Costanza [

24]. The embodied energy paradigm was adapted for a general industrial context by Rahimifard [

25] and traces the energy consumption of processes to the manufacturing of goods and services. While the concept has a long history, it is still used in research and practical applications [

26]. The embodied energy flow shows a structured possibility to trace energy flows over various hierarchical levels and allocate the consumption in products.

The actual process levels’ common modeling paradigm utilizes exergy principles [

27] or systems engineering paradigms. Individual processes are then concisely identified by their singular inputs in the form of material and energy, and, conversely, their outputs as waste heat and products [

27]. Anchored around the unit processes, Duflou et al. [

28] propose a concept that aims to increase the efficiency of both energy utilization and resource management within manufacturing through the implementation of a five-level hierarchy. This hierarchy includes the device/unit process, the line/cell/multi-machine system, the plant, the multi-plant system, and the enterprise/supply chain. The unit process interfaces distinguish between inputs and outputs for various materials, energy types, and emissions.

For DR applications, dos Santos et al. [

18] differentiated industrial applications on the levels’ unit process, multi-machine, and factory level. Wiendahl et al. [

29] acknowledges differentiating views for changeable manufacturing, highlighting the process level as common ground for all activities. For the integration of simulation models of cyber-physical production systems from various engineering domains into meta-models, Merschak et al. [

30] suggest the levels’ components, modules, systems, factories, and cyber-physical production systems.

In a systems-based formalization, energy consumers such as machines are typically represented as individual systems. Within this representation, systems are represented as a block with internal properties, containing material, energy, and information as inputs and outputs [

31]. Each system can feature subsystems, which also feature the respective in- and outputs. The representation is primarily focused towards the design of mechatronic systems and thus features a static hierarchy. For operational purposes, the formal model needs to constitute also dynamic information, material, and energy transfers. For example, a measurement device may be connected to different machines, a situation that cannot be represented with static flows.

The scientific SotA thus does not agree on a standardized representation of industrial systems. While there are multiple variants to visualize an industrial system, the actual depiction depends on the use case. Modern manufacturing systems require a graph-based depiction to be represented properly.

2.3. Process Load Modeling and Estimation

In the field of energy-related process load modeling and estimation techniques for manufacturing systems, various scientific efforts have been made to identify and improve prediction approaches. Schmidt et al. [

32] delved into the predictive methods related to assets in the manufacturing industry, specifically highlighting the limitations of Gutowski’s approach, noting that, although it was applied to various manufacturing processes, the lack of coefficients hindered its direct use in predicting energy consumption for specific machine tools. In addition, Schmidt et al. [

32] categorized machine types by complexity as simple, adjustable, single-purpose, and multi-purpose complex, and advocated the use of semi-empirical equations to model complex machines. The energy consumption monitoring patterns can be classified as constant consumption, controlled constant consumption, and variable consumption [

33].

Garwood [

34] highlighted different modeling methods for energy simulation tools in the manufacturing sector. Notable distinctions were made between time-driven, event-driven, continuous flow, numerical techniques, agent-driven, and co-simulation models.

Correlating with the detail of the model, the amount of data-driven varies, i.e., while most multi-machine applications, e.g., scheduling of jobs, use recorded values, unit level applications in the contrary, tend to be explainable. In fact, aside from state-based scheduling models, as introduced by Shrouf et al. [

35], it is common to use the rated power or a measured average for multi-machine applications. Gong et al. [

36] proposed a state-based model to elucidate the energy consumption at a machine level, specifically focusing on the power consumption of a grinding machine. Beier et al. [

37] demonstrated real-time control using state-based models that rely on renewable energy sources and represent processes as discrete entities capable of switching between idle, production, and off states.

To compare the efficiencies of processes, energy key performance indicators (EnPIs) are needed. Yoon et al. [

38] conducted an analysis of the specific energy consumption (SEC) as an EnPI in different manufacturing processes, and found interesting differences. The SEC is defined as energy consumption per production of one material unit, thus enabling comparisons between different manufacturing technologies. In particular, the specific energy consumption of additive processes was found to be about 100 times higher than that of bulk-forming processes. A key difference between a digital twin and a virtual testbed is the fully virtualized control [

39]. Li et al. [

40] introduced the concept of an energy digital twin based on a data-driven hybrid Petri net (DDPHN), and demonstrated its superiority over multiple data-driven models in simulating the energy consumption behavior of die casting. The DDPHPN reached a coefficient of determination up to 0.9662 for the needed power consumption of the casting process, demonstrating the feasibility of the data-driven methods.

In the machining domain, several publications have focused on estimating energy consumption. Liu et al. [

41] proposed a model for the energy consumption of the machining process, featuring a validation error of 7.773% evaluating individual machine states, while Kara et al. [

42] performed an estimation of machining energy consumption on turning and milling machines, reaching over 90% prediction accuracy. The work of Salonitis et al. [

43] proposed machine disaggregation to explore energy efficiency potentials at the machine tool level by decomposing energy consumption into individual subsystems. Taken together, these efforts contribute to advancing the understanding and modeling of energy consumption in manufacturing processes.

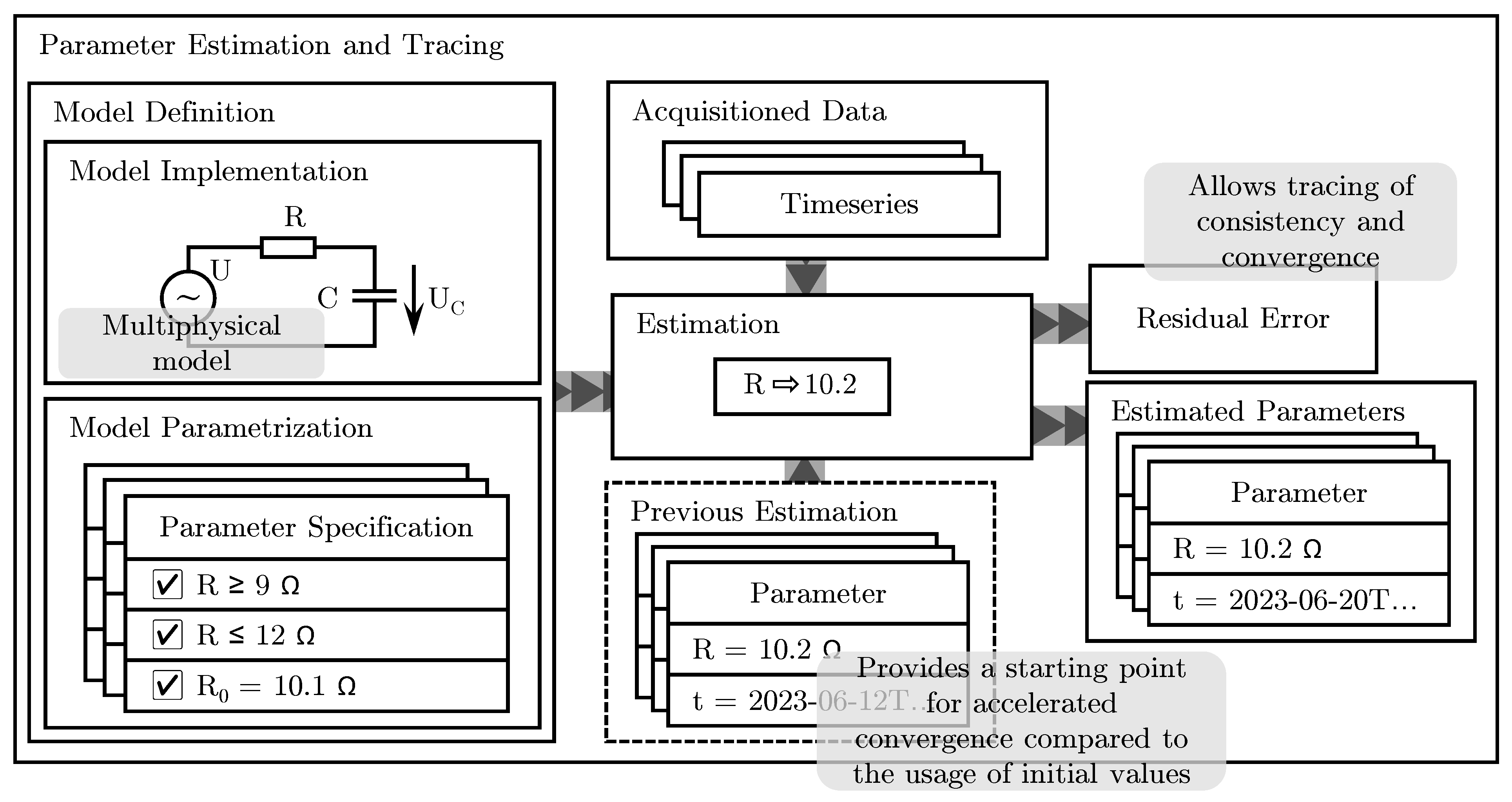

Within the conducted literature survey, mostly white-box models, i.e., where all parameters for the calculation of the energy consumption are known, and black-box models, i.e., where the energy consumption of a system is calculated by purely data-driven methods, were applied. Grey-box models, on the contrary, which combine the existing knowledge of a system and apply data-driven methods, were not intensely studied on a process level for energy consumption estimation in industrial applications.

For other applications with grey-box models, multiple solutions exist. Fleschutz et al. [

44] propose an energy optimization software framework for industrial applications on a system level, including multiple energy sources, energy storage systems and data-driven load analysis. Within the framework, multiple DR aspects can be optimized, including the peak load. Vanfretti et al. [

45] introduced the RaPId toolbox to estimate FMI models for power and electric systems. ModestPy, an FMI-based python package, is a gray-box estimator, mainly applied in building services and HVAC systems [

46]. For the model-predictive control of buildings, Drgona et al. [

47] provide a thorough review and a unified framework, acknowledging the existing solutions and tools. Grosch et al. [

48] propose an OpenAI-based framework to optimize factory operations energetically. A recent application of the parameter estimation method as an adaptive energy model was proposed by Bermeo-Ayerbe [

49], and it outperformed artificial neural nets and autoregressive models with a maximum fit rate of approximately 82%, where other models had a rate less than 66%.

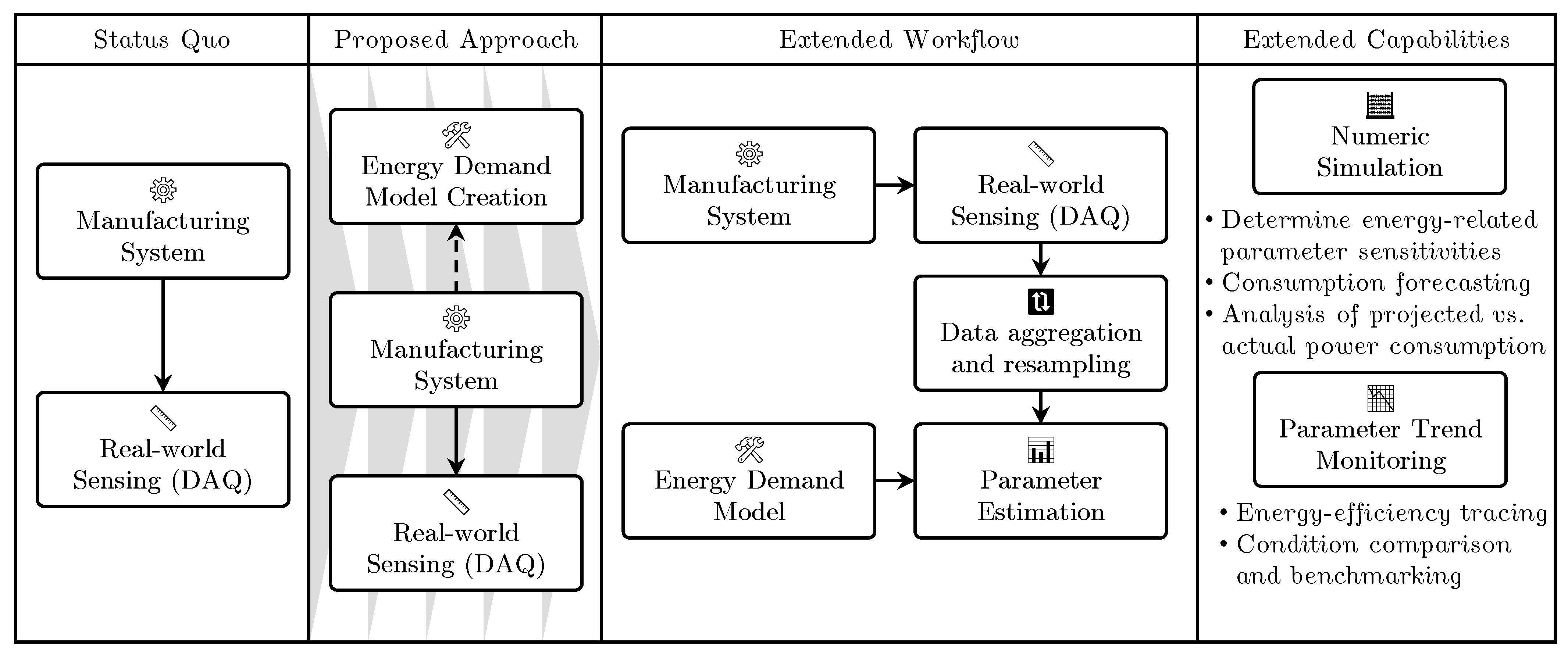

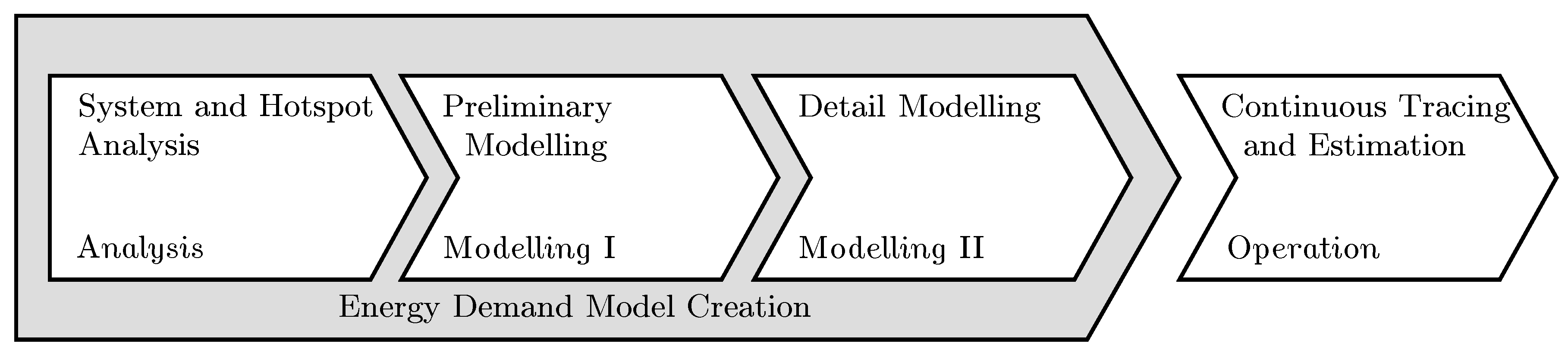

Table 1 contains a selection of existing tools for parameter estimation of programmable objective functions, as well as simulation and data-driven models. To the best knowledge of the authors, none of the existing parameter estimation solutions evaluated contain the necessary data preparation for energy simulations on a process/unit level, suitable for the mutable nature of industrial applications.

2.4. Knowledge Gaps

The addressed scientific problem is the missing knowledge of applicability and potential of a consistent parameter estimation method for energy consumption considerations. Contrary to buildings, manufacturing entities, e.g., machines, can exhibit a significantly more complex system architecture and mostly include multiphysical phenomena. In detail, manufacturing entities feature a variety of information, energy, and material in- and outputs, which are subject to temporal changes of relations and can be comprised of subsystems, where the same characteristics apply.

The trends and developments in industrial ICT result in widespread data acquisition, while a key issue of industrial DSM is data availability. To counter the complexity of industrial systems, a holistic analysis is needed to retrieve meaningful insights from data processing [

12]. In order to interpret the collected data, data-driven black-box applications, e.g., machine learning, become significantly more prevalent. Although the performance of these applications enables detailed predictions and insights, they come with the downside that they lack explainability and are often computationally expensive. White-box models, on the contrary, are poorly suited for most retrofitting applications, caused by the requirement to gather all the necessary detail information and parameters. Moreover, the considerable modeling effort to incorporate minor physical effects mostly exceeds the possible benefits for industrial applications in the operational phase. Thus, the gap in knowledge is identified as follows

The scientific SotA indicates no known approach to deal with the complexity and mutability of industrial systems for DSM applications, including consistent system modeling.

Although a variety of parameter estimation tools are known, there is no demonstrated use for the objectives of DSM. Furthermore, the potentials of identified parameters have not been evaluated within the context of industrial DSM.

By closing the gap between the missing data and appropriate evaluation, a variety of benefits are anticipated. In detail, the common energy sustainable goals would be assisted by provision of a tool to define, quantify, measure, and monitor EnPIs. Furthermore, with forecastable demands, VRES can be utilized to a higher degree to increase self-sufficiency and lower the carbon footprint. Details on the contribution to DSM are discussed in the next section.