Analysis of the Efficiency of Landfill Gas Treatment for Power Generation in a Cogeneration System in Terms of the European Green Deal

Abstract

1. Introduction

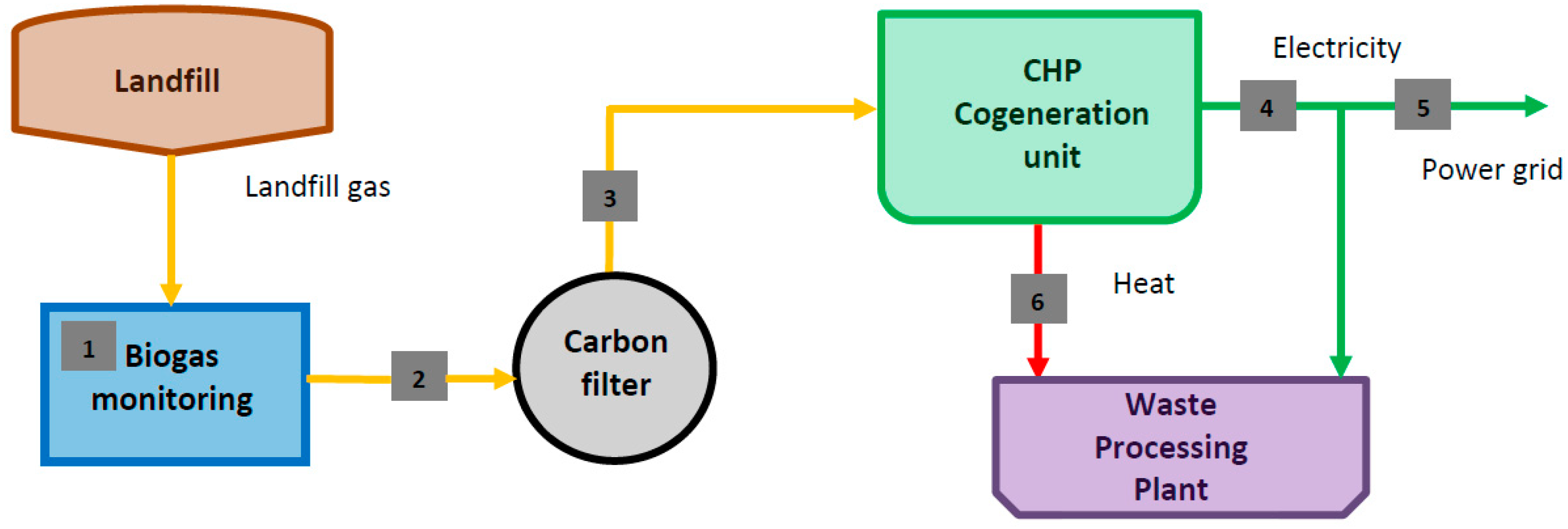

2. Object of Research

3. Materials and Methods

3.1. Landfill Gas

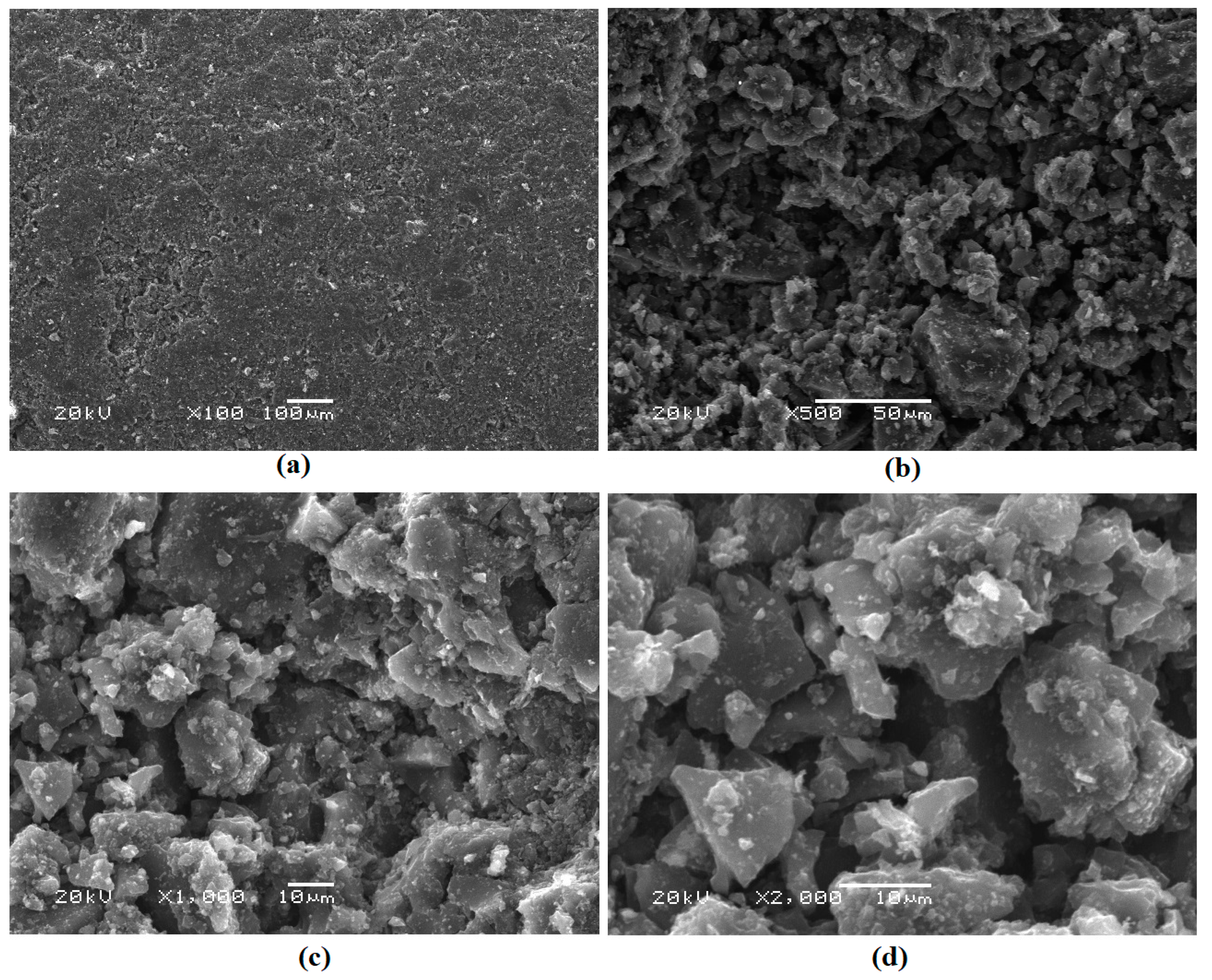

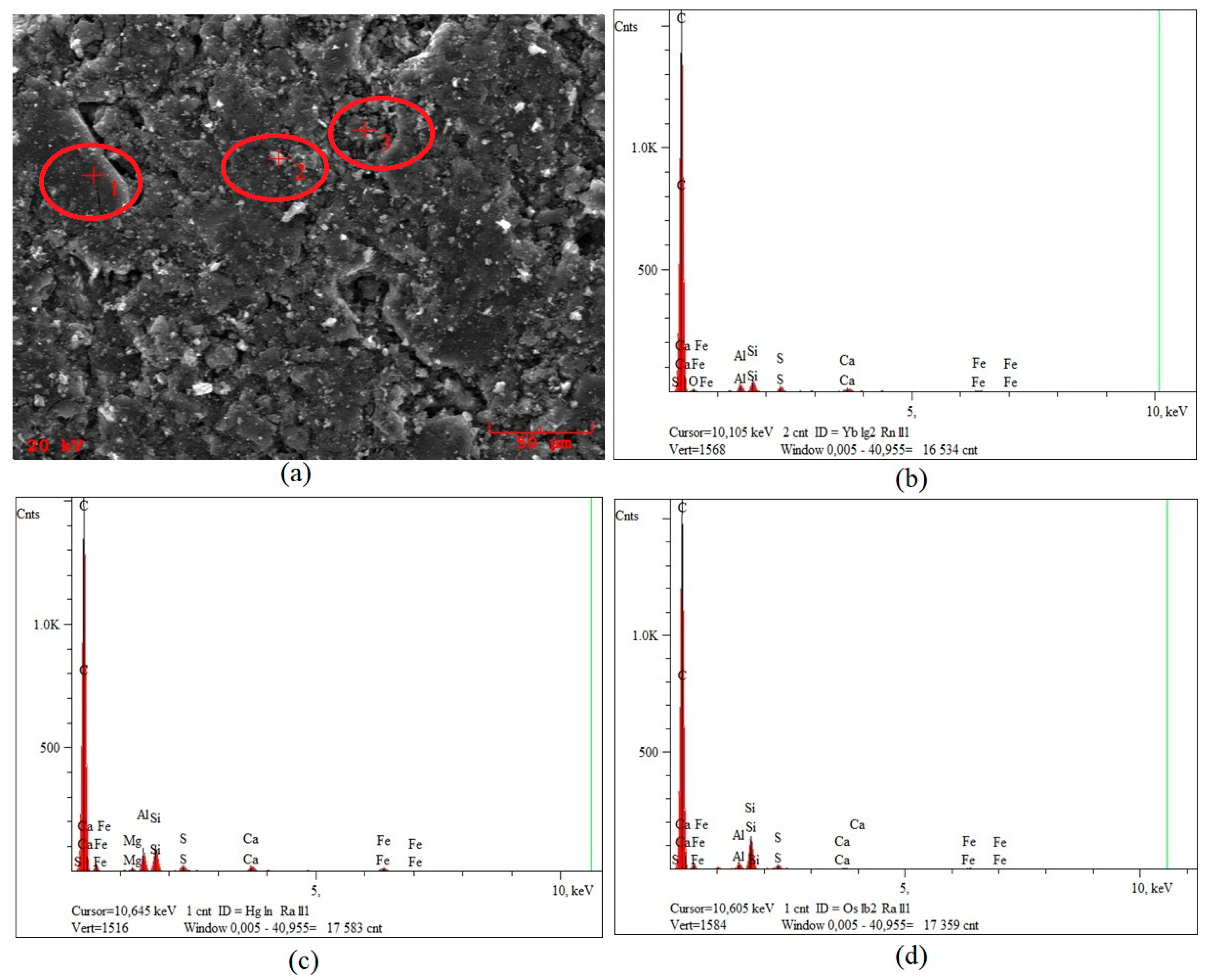

3.2. Activated Carbon

4. Results and Discussion

4.1. Landfill Gas Research

4.2. Research on Activated Carbon

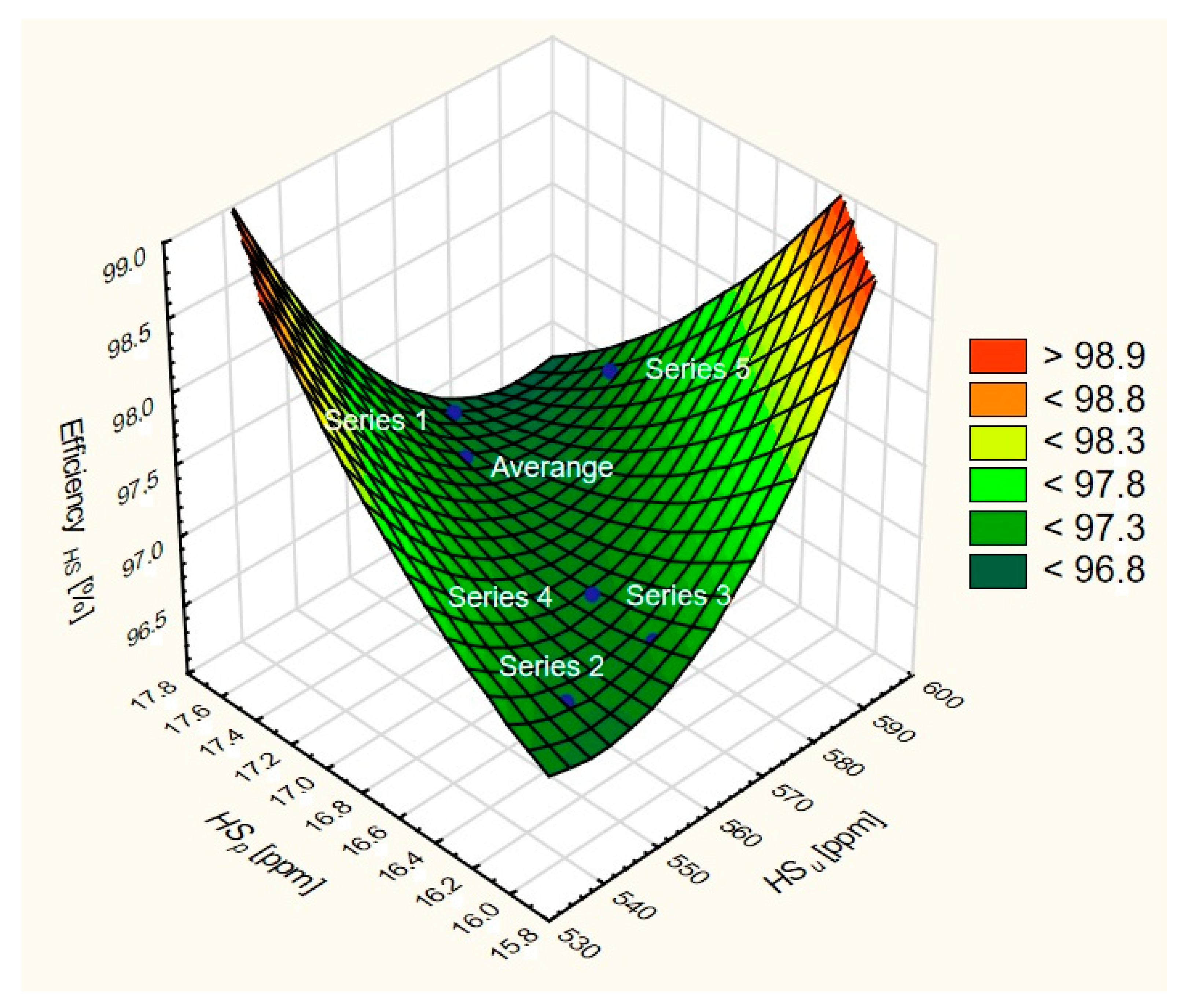

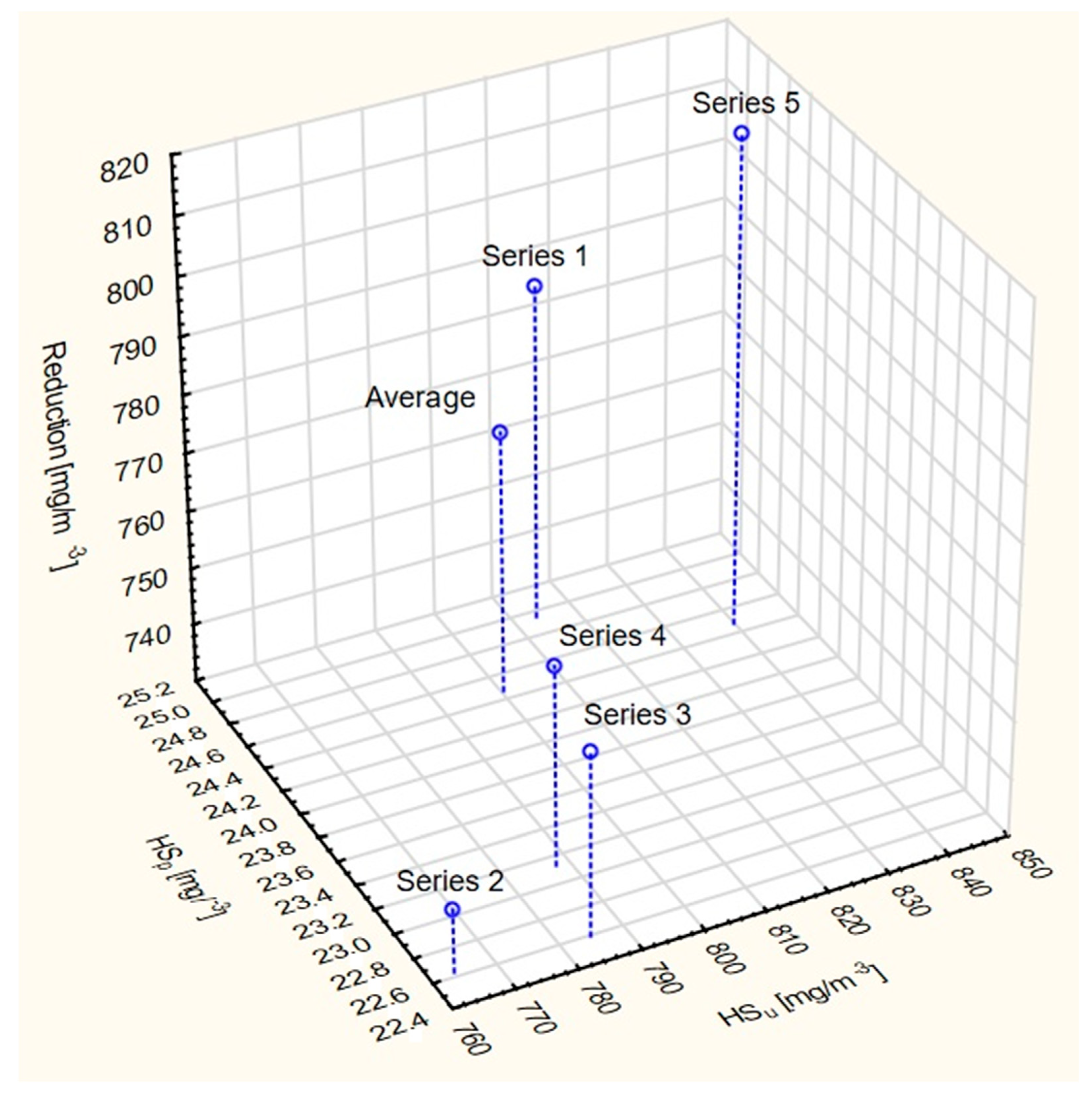

4.3. Hydrogen Sulfide Removal Efficiency

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- EC—European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions. 11.12.2019 COM (2019) 640 Final. In The European Green Deal; EC: Brussels, Belgium, 2019. [Google Scholar]

- Tutak, M.; Brodny, J.; Bindzár, P. Assessing the Level of Energy and Climate Sustainability in the European Union Countries in the Context of the European Green Deal Strategy and Agenda 2030. Energies 2021, 14, 1767. [Google Scholar] [CrossRef]

- Graz, K.; Gronba-Chyla, A.; Chyla, K. Microplastics found in compost as a barrier to the circular economy (CE). Przemysł Chem. 2023, 102, 381–383. [Google Scholar] [CrossRef]

- Generowicz, A.; Gronba-Chyła, A.; Kulczycka, J.; Harazin, P.; Gaska, K.; Ciuła, J.; Ocłoń, P. Life Cycle Assessment for the environmental impact assessment of a city’ cleaning system. The case of Cracow (Poland). J. Clean. Prod. 2023, 382, 135184. [Google Scholar] [CrossRef]

- Ravani, M.; Georgiou, K.; Tselempi, S.; Monokrousos, N.; Ntinas, G.K. Carbon Footprint of Greenhouse Production in EU—How Close Are We to Green Deal Goals? Sustainability 2024, 16, 191. [Google Scholar] [CrossRef]

- Przydatek, G.; Basta, E. Systemic Efficiency Assessment of Municipal Solid Waste Management in the Suburban Municipality. E3S Web Conf. 2020, 154, 03001. [Google Scholar] [CrossRef]

- Directive (EU) 2018/850 of the European Parliament and of the Council of 30 May 2018 Amending Directive 1999/31/EC on the Landfill of Waste. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32018L0850 (accessed on 10 November 2023).

- Husgafvel, R. Company Perspectives on Circular Economy Management, Assessment and Reporting in the Kymenlaakso Region in Finland. Sustainability 2024, 16, 20. [Google Scholar] [CrossRef]

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives, L 312/3. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32008L0098 (accessed on 14 November 2023).

- Vakalis, S.; Moustakas, K. Applications of the 3T Method and the R1 Formula as Efficiency Assessment Tools for Comparing Waste-to-Energy and Landfilling. Energies 2019, 12, 1066. [Google Scholar] [CrossRef]

- Wysowska, E.; Kicińska, A. Assessment of health risks with water consumption in terms of content of selected organic xenobiotics. Desalination Water Treat. 2021, 234, 1–14. [Google Scholar] [CrossRef]

- Wysowska, E.; Wiewiórska, I.; Kicińska, A. Minerals in tap water and bottled waters and their impact on human health. Desalination Water Treat. 2022, 259, 133–151. [Google Scholar] [CrossRef]

- Makara, A.; Kowalski, Z.; Radomski, P.; Olczak, P. Treatment of wastewater from the production of meat and bone meal by the Fenton process and coagulation. Pol. J. Chem. Technol. 2022, 24, 51–60. [Google Scholar] [CrossRef]

- Shitophyta, L.M.; Padya, S.A.; Zufar, A.F.; Rahmawati, N. The Impact of Alkali Pretreatment and Organic Solvent Pretreatment on Biogas Production from Anaerobic Digestion of Food Waste. J. Ecol. Eng. 2022, 23, 179–188. [Google Scholar] [CrossRef]

- Barzegaravval, H.; Hosseini, S.E.; Wahid, M.A.; Saat, A. Effects of fuel composition on the economic performance of biogas-based power generation systems. Appl. Therm. Eng. 2018, 128, 1543–1554. [Google Scholar] [CrossRef]

- Hwang, H.; Kweon, T.; Kang, H.; Hwang, Y. Resource and Greenhouse Gas Reduction Effects through Recycling of Platinum-Containing Waste. Sustainability 2024, 16, 80. [Google Scholar] [CrossRef]

- Adamcová, D.; Vaverková, M.; Břoušková, E. Emission assessment at the Štěpánovice municipal solid waste landfill focusing on CH4 emissions. J. Ecol. Eng. 2016, 17, 9–17. [Google Scholar] [CrossRef]

- Labianca, M.; Faccilongo, N.; Monarca, U.; Lombardi, M. A Location Model for the Agro-Biomethane Plants in Supporting the REPowerEU Energy Policy Program. Sustainability 2024, 16, 215. [Google Scholar] [CrossRef]

- Ciuła, J.; Kowalski, S.; Generowicz, A.; Barbusiński, K.; Matuszak, Z.; Gaska, K. Analysis of Energy Generation Efficiency and Reliability of a Cogeneration Unit Powered by Biogas. Energies 2023, 16, 2180. [Google Scholar] [CrossRef]

- Tsompanoglou, K.; Koutsou, O.P.; Stasinakis, A.S. Evaluating the Operation of a Full-Scale Sequencing Batch Reactor–Reverse Os-mosis–Evaporation System Used to Treat Landfill Leachates: Removal of Pollutants, Energy Consumption and Greenhouse Gas Emissions. Energies 2023, 16, 6872. [Google Scholar] [CrossRef]

- Díaz, I.; Ramos, I.; Fdz-Polanco, M. Economic analysis of microaerobic removal of H2S from biogas in full-scale sludge digesters. Bioresour. Technol. 2015, 192, 280–286. [Google Scholar] [CrossRef] [PubMed]

- Kowalski, Z.; Kulczycka, J.; Verhé, R.; Desender, L.; De Clercq, G.; Makara, A.; Generowicz, N.; Harazin, P. Second-generation biofuel production from the organic fraction of municipal solid waste. Front. Energy Res. 2022, 10, 919415. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, R.; Zheng, Y.; Zhang, B.; Jiang, Y.; An, Z.; Bai, J. Carbon emission reduction analysis of CHP system driven by biogas based on emission factors. Energy Build. Environ. 2022, 9, 576–588. [Google Scholar] [CrossRef]

- Un, C. A Sustainable Approach to the Conversion of Waste into Energy: Landfill Gas-to-Fuel Technology. Sustainability 2023, 15, 14782. [Google Scholar] [CrossRef]

- Dyachok, V.; Venhe, L.; Huhlych, S. The Biomethanization Gas Purification of Using Chlorophyll-Synthesizing Microalgae. J. Ecol. Eng. 2022, 23, 259–264. [Google Scholar] [CrossRef]

- Nocete, E.S.; Rodríguez, J.P. A Simple Methodology for Estimating the Potential Biomethane Production in a Region: Application in a Case Study. Sustainability 2022, 14, 15978. [Google Scholar] [CrossRef]

- Amaraibi, R.J.; Joseph, B.; Kuhn, J. Techno-economic and sustainability analysis of siloxane removal from landfill gas used for electricity generation. J. Environ. Manag. 2022, 314, 115070. [Google Scholar] [CrossRef] [PubMed]

- Ciuła, J.; Kowalski, S.; Wiewiórska, I. Pollution Indicator of a Megawatt Hour Produced in Cogeneration—The Efficiency of Biogas Purification Process as an Energy Source for Wastewater Treatment Plants. J. Ecol. Eng. 2023, 24, 232–245. [Google Scholar] [CrossRef] [PubMed]

- Salah, W.A.; Atatri, M.; Zaid, A.; Abuhafeza, R.; Abuhelwa, M.; Bashir, M.J.K.; Abu Zneid, B. Analysis of Energy Recovery from Municipal Solid Waste and Its Environmental and Economic Impact in Tulkarm, Palestine. Energies 2023, 16, 5590. [Google Scholar] [CrossRef]

- Marcoberardino, G.D.; Vitali, D.; Spinelli, F.; Binotti, M.; Manzolini, G. Green Hydrogen Production from Raw Biogas: A Techno-Economic Investigation of Conventional Processes Using Pressure Swing Adsorption Unit. Processes 2018, 6, 19. [Google Scholar] [CrossRef]

- Xu, J.; Tian, O.; Li, Y. Toward the truth of condensing-water membrane for efficient biogas purification: Experimental and modeling analyses. J. Membr. Sci. 2022, 662, 120967. [Google Scholar] [CrossRef]

- Liu, D.; Sun, W.; Kong, Y.; Zhang, S. Effect of Dry and Wet Cycles on the Strength Characteristics of Biochar–Clay Mixture. Processes 2023, 11, 970. [Google Scholar] [CrossRef]

- Dimitriu, M. Considerations Over a Biogas Plant Components. Sci. Pap. Ser. Manag. Econ. Eng. Agric. Rural. Dev. 2014, 14, 121–126. Available online: http://managementjournal.usamv.ro/pdf/vol4_1/Art19.pdf (accessed on 12 December 2023).

- Batista, M.; Pinto, M.L.; Antunes, F.; Pires, J.; Carvalho, S. Chitosan Biocomposites for the Adsorption and Release of H2S. Materials 2021, 14, 6701. [Google Scholar] [CrossRef] [PubMed]

- Lee, U.; Han, J.; Wang, M. Evaluation of landfill gas emissions from municipal solid waste landfills for the life-cycle analysis of waste-to-energy pathways. J. Clean. Prod. 2017, 166, 335–342. [Google Scholar] [CrossRef]

- González, R.; Cabeza, I.O.; Casallas-Ojeda, M.; Gómez, X. Biological Hydrogen Methanation with Carbon Dioxide Utilization: Methanation Acting as Mediator in the Hydrogen Economy. Environments 2023, 10, 82. [Google Scholar] [CrossRef]

- Swain, R.B.; Karimu, A.; Gråd, E. Sustainable development, renewable energy transformation and employment impact in the EU. Int. J. Sustain. Dev. Word Ecol. 2022, 29, 695–708. [Google Scholar] [CrossRef]

- Achinas, S.; Euverink, G.J.W. Effect of Temperature and Organic Load on the Performance of Anaerobic Bioreactors Treating Grasses. Environments 2020, 7, 82. [Google Scholar] [CrossRef]

- Kwon, Y.; Lee, S.; Bae, J.; Park, S.; Moon, H.; Lee, T.; Kim, K.; Kang, J.; Jeon, T. Evaluation of Incinerator Performance and Policy Framework for Effective Waste Management and Energy Recovery: A Case Study of South Korea. Sustainability 2024, 16, 448. [Google Scholar] [CrossRef]

- Kowalski, S.; Opoka, K.; Ciuła, J. Analysis of the end-of-life the front suspension beam of a vehicle. Eksploat. I Niezawodn.-Maint. Reliab. 2022, 24, 446–454. [Google Scholar] [CrossRef]

- Kwaśnicki, P.; Jarzebski, M.; Kardasz, P.; Inglotf, M. Characterization techniques of sandwich-type TiO2/QD composites for low-cost quantum dots’ solar cel. Opto-Electron. Rev. 2019, 27, 105–112. [Google Scholar] [CrossRef]

- Sikora, A. European Green Deal—Legal and financial challenges of the climate change. ERA Forum 2021, 21, 681–697. [Google Scholar] [CrossRef]

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Source 2018. Available online: https://eur-lex.europa.eu (accessed on 8 December 2023).

- Augustowski, D.; Kwaśnicki, P.; Dziedzic, J.; Rysz, J. Magnetron Sputtered Electron Blocking Layer as an Efficient Method to Improve Dye-Sensitized Solar Cell Performance. Energies 2020, 13, 2690. [Google Scholar] [CrossRef]

- Skjærseth, J.B. Towards a European Green Deal: The evolution of EU climate and energy policy mixes. Int. Environ. Agreem. 2021, 21, 25–41. [Google Scholar] [CrossRef]

- Statistica, version 14.1.0.4; TIBCOI Software Inc.: Palo Alto, CA, USA, 2023.

- Kajolinna, T.; Aakko-Saksa, P.; Roine, J.; Kåll, L. Efficiency testing of three biogas siloxane removal systems in the presence of D5, D6, limonene and toluene. Fuel Process. Technol. 2015, 138, 242–247. [Google Scholar] [CrossRef]

- Coppola, G.; Papurello, D. Biogas Cleaning: Activated Carbon Regeneration for H2S Removal. Clean. Technol. 2019, 1, 40–57. [Google Scholar] [CrossRef]

- Cabrera-Codony, A.; Montes-Morán, M.A.; Sánchez-Polo, M.; Martín, M.J.; Gonzalez-Olmos, R. Biogas Upgrading: Optimal Activated Carbon Properties for Siloxane Removal. Environ. Sci. Technol. 2014, 48, 7187–7195. [Google Scholar] [CrossRef] [PubMed]

- Ledesma, B.; Sabio, E.; González-García, C.M.; Román, S.; Fernandez, M.E.; Bonelli, P.; Cukierman, A.L. Batch and Continuous Column Adsorption of p-Nitrophenol onto Activated Carbons with Different Particle Sizes. Processes 2023, 11, 2045. [Google Scholar] [CrossRef]

- Papurello, D.; Tomasi, L.; Silvestri, S.; Santarelli, M. Evaluation of the Wheeler-Jonas parameters for biogas trace compounds removal with activated carbons. Fuel Process. Technol. 2016, 152, 93–101. [Google Scholar] [CrossRef]

- Yao, Z.; Zhang, W.; Yu, X. Fabricating Porous Carbon Materials by One-Step Hydrothermal Carbonization of Glucose. Processes 2023, 11, 1923. [Google Scholar] [CrossRef]

- Cinar, S.; Cinar, S.O.; Wieczorek, N.; Sohoo, I.; Kuchta, K. Integration of Artificial Intelligence into Biogas Plant Operation. Processes 2021, 9, 85. [Google Scholar] [CrossRef]

- Wang, P.; Lai, J.; Lin, X.; Li, X.; Xu, S. A Study on the Influence and Mechanism of Temperature and Dosage on PCDD/Fs Adsorption via Coal-Based Activated Carbon. Recycling 2023, 8, 98. [Google Scholar] [CrossRef]

- Niu, J.; Zhang, H.; Xu, W.; Guo, Y.; Li, L.; Cheng, F. Utilization of inherent minerals in coal for high-performance activated carbon production: The mechanism of deSO2 and/or deNOx enhanced by in situ transformed calcium sulfide (CaS). Energy 2024, 289, 129902. [Google Scholar] [CrossRef]

- Liu, N.; Jiang, J. Effects of activated carbon on the in-situ control of odorous gases emitted from anaerobic digestion of food waste and the microbial community response. Environ. Technol. Innov. 2021, 21, 101170. [Google Scholar] [CrossRef]

| Test Series Number | Parameters of Untreated Landfill Gas | ||||

|---|---|---|---|---|---|

| CH4 [%] | CO2 [%] | O2 [%] | H2S [%] | H2S [ppm] | |

| Series 1 | 57.3 | 30.4 | 0.6 | 0.62 | 618.6 |

| Series 2 | 59.6 | 31.1 | 0.5 | 0.67 | 667.1 |

| Series 3 | 55.7 | 30.1 | 0.5 | 0.62 | 615.7 |

| Series 4 | 59.3 | 30.9 | 0.4 | 0.53 | 531.4 |

| Series 5 | 58.7 | 34.0 | 0.1 | 0.58 | 577.9 |

| Series 6 | 57.6 | 33.7 | 0.4 | 0.55 | 552.0 |

| Average | 58.2 | 31.7 | 0.4 | 0.59 | 593.8 |

| Test Series Number | LFG Parameters before the Carbon Filter | LFG Parameters after the Carbon Filter | ||||||

|---|---|---|---|---|---|---|---|---|

| CH4 | CO2 | O2 | H2S [ppm] | CH4 | CO2 | O2 | H2S [ppm] | |

| [%] | [%] | [%] | [%] | [%] | [%] | |||

| Series 1 | 58.4 | 34.1 | 0.4 | 577.0 | 58.8 | 33.8 | 0.3 | 17.7 |

| Series 2 | 58.6 | 33.3 | 0.3 | 541.6 | 57.9 | 32.5 | 0.3 | 16.0 |

| Series 3 | 59.9 | 32.7 | 0.3 | 556.4 | 59.1 | 32.1 | 0.4 | 16.0 |

| Series 4 | 59.6 | 33.6 | 0.3 | 558.7 | 58.8 | 32.9 | 0.3 | 16.4 |

| Series 5 | 57.7 | 35.3 | 0.1 | 595.6 | 58.1 | 35.8 | 0.2 | 17.3 |

| Series 6 | 56.1 | 32.7 | 0.2 | 567.6 | 57.2 | 33.1 | 0.2 | 17.3 |

| Average | 58.4 | 33.6 | 0.3 | 566.1 | 58.3 | 33.4 | 0.3 | 16.8 |

| Number Series Badań | Hydrogen Sulfide Content in Untreated Gas HSu [ppm] | Hydrogen Sulfide Content in Treated Gas HSp [ppm] | Efficiency of Hydrogen Sulfide Removal [%] |

|---|---|---|---|

| Series 1 | 577.0 | 17.7 | 96.92 |

| Series 2 | 541.6 | 16.0 | 97.03 |

| Series 3 | 556.4 | 16.0 | 97.12 |

| Series 4 | 558.7 | 16.4 | 97.07 |

| Series 5 | 595.6 | 17.3 | 97.08 |

| Series 6 | 567.6 | 17.3 | 97.07 |

| Average | 566.1 | 16.8 | 97.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciuła, J.; Generowicz, A.; Gronba-Chyła, A.; Wiewiórska, I.; Kwaśnicki, P.; Cygnar, M. Analysis of the Efficiency of Landfill Gas Treatment for Power Generation in a Cogeneration System in Terms of the European Green Deal. Sustainability 2024, 16, 1479. https://doi.org/10.3390/su16041479

Ciuła J, Generowicz A, Gronba-Chyła A, Wiewiórska I, Kwaśnicki P, Cygnar M. Analysis of the Efficiency of Landfill Gas Treatment for Power Generation in a Cogeneration System in Terms of the European Green Deal. Sustainability. 2024; 16(4):1479. https://doi.org/10.3390/su16041479

Chicago/Turabian StyleCiuła, Józef, Agnieszka Generowicz, Anna Gronba-Chyła, Iwona Wiewiórska, Paweł Kwaśnicki, and Mariusz Cygnar. 2024. "Analysis of the Efficiency of Landfill Gas Treatment for Power Generation in a Cogeneration System in Terms of the European Green Deal" Sustainability 16, no. 4: 1479. https://doi.org/10.3390/su16041479

APA StyleCiuła, J., Generowicz, A., Gronba-Chyła, A., Wiewiórska, I., Kwaśnicki, P., & Cygnar, M. (2024). Analysis of the Efficiency of Landfill Gas Treatment for Power Generation in a Cogeneration System in Terms of the European Green Deal. Sustainability, 16(4), 1479. https://doi.org/10.3390/su16041479