Impacts of COVID-19 and the Russian–Ukrainian Conflict on Food Supply Chain: A Case Study from Bread Supply Chain in Egypt

Abstract

1. Introduction

2. Literature Review

2.1. Disruptions in Food Supply Chain

2.2. Simulating Food Supply Chain Disruptions

3. Case Study

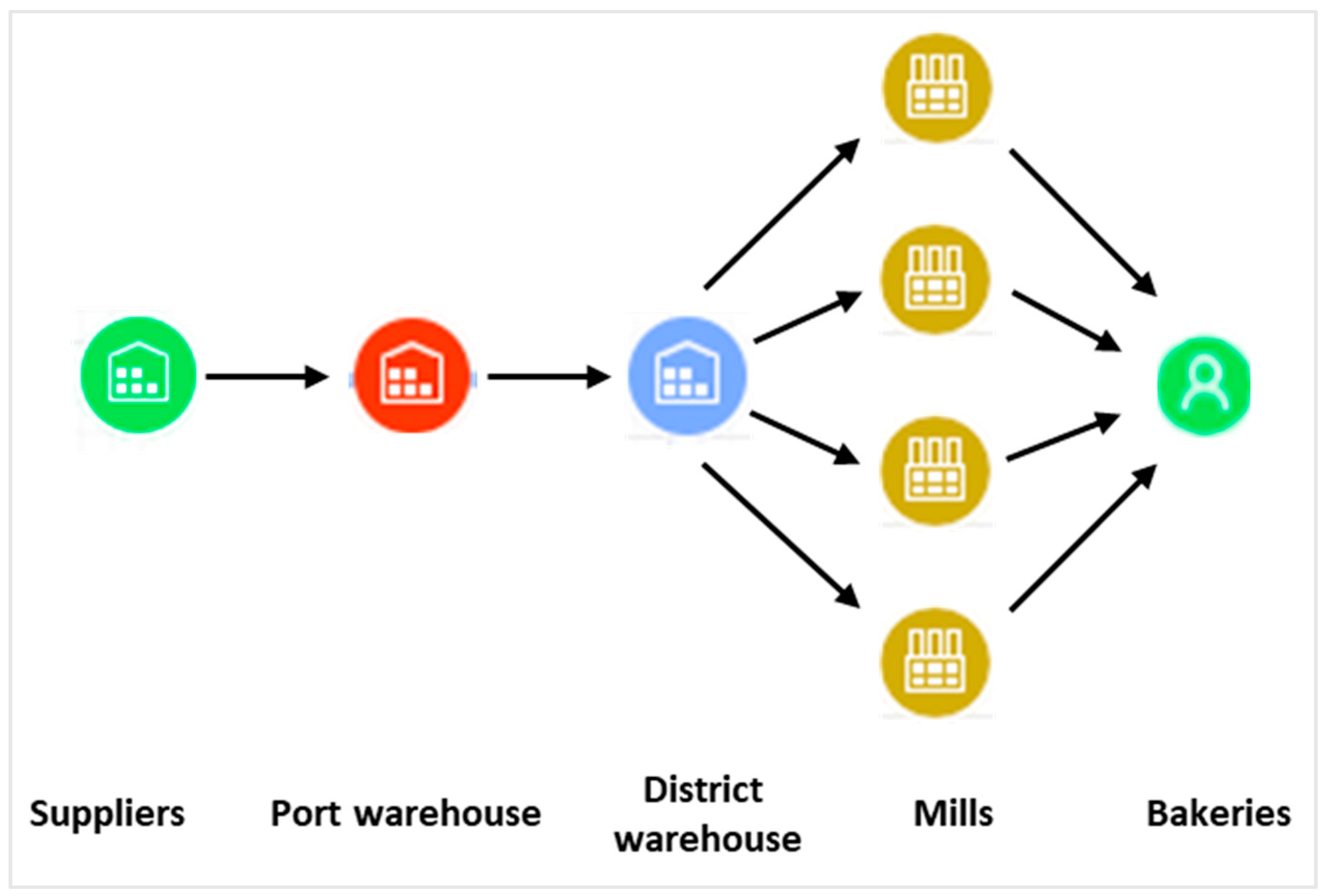

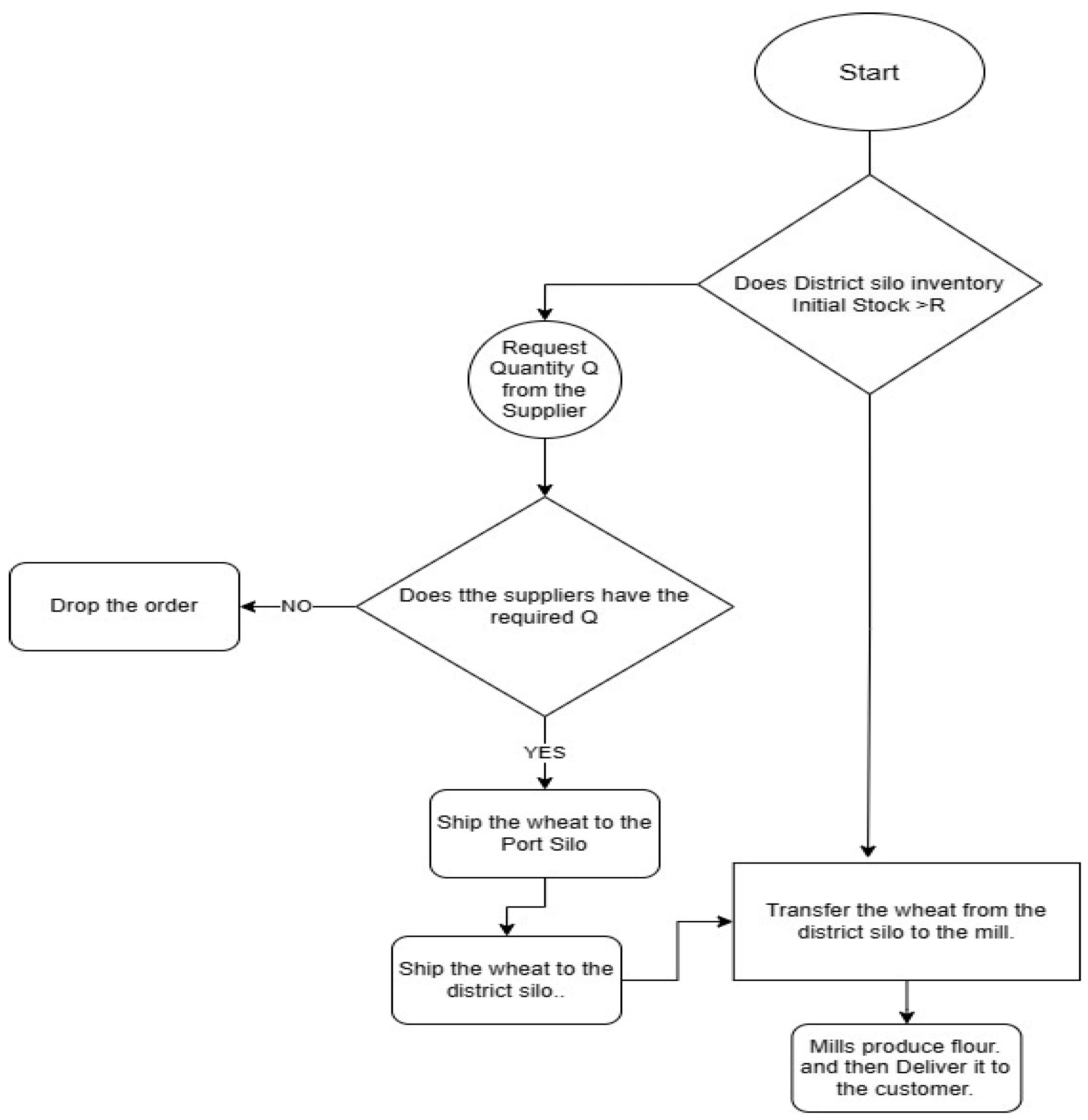

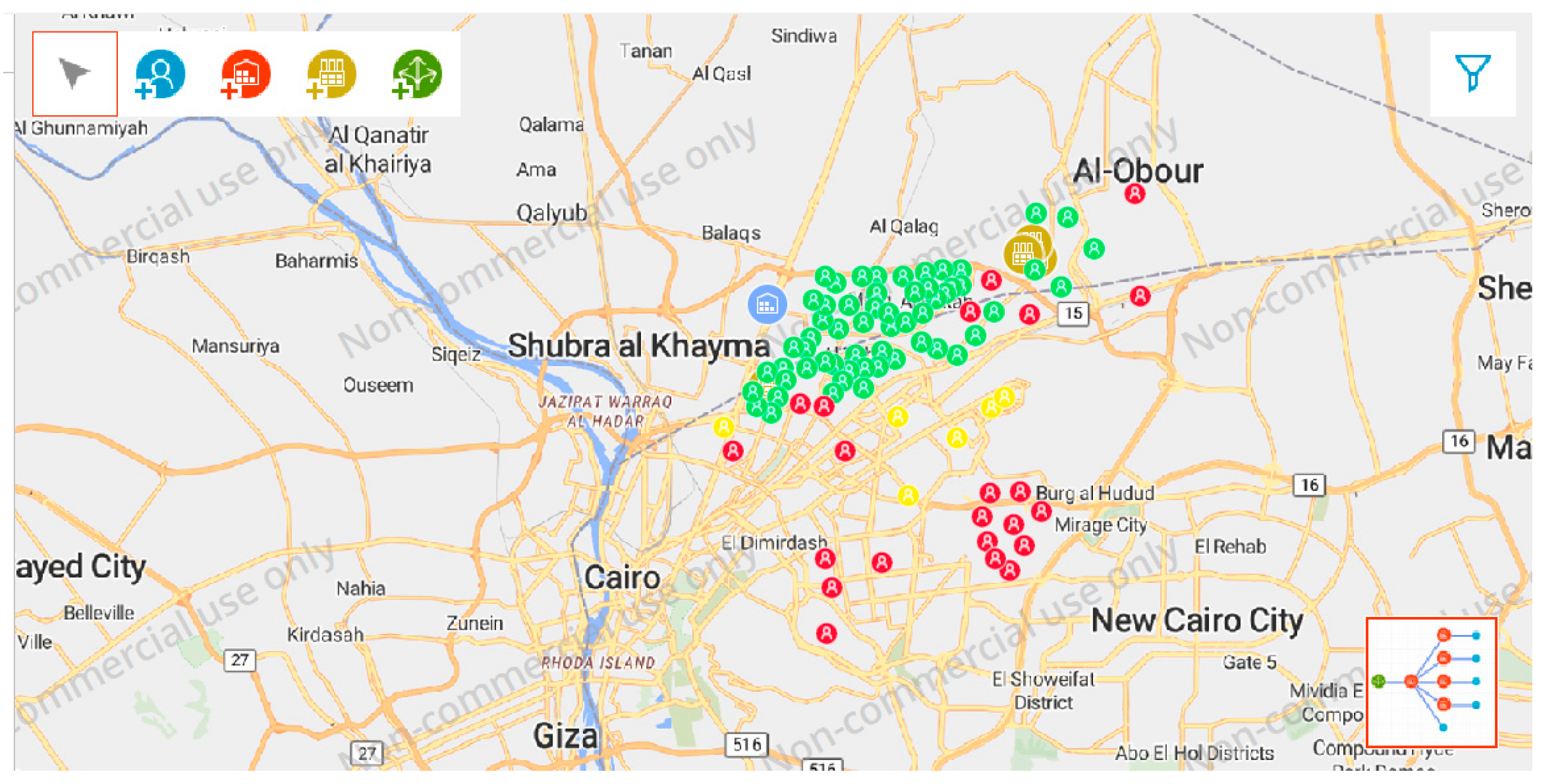

3.1. Problem Structure

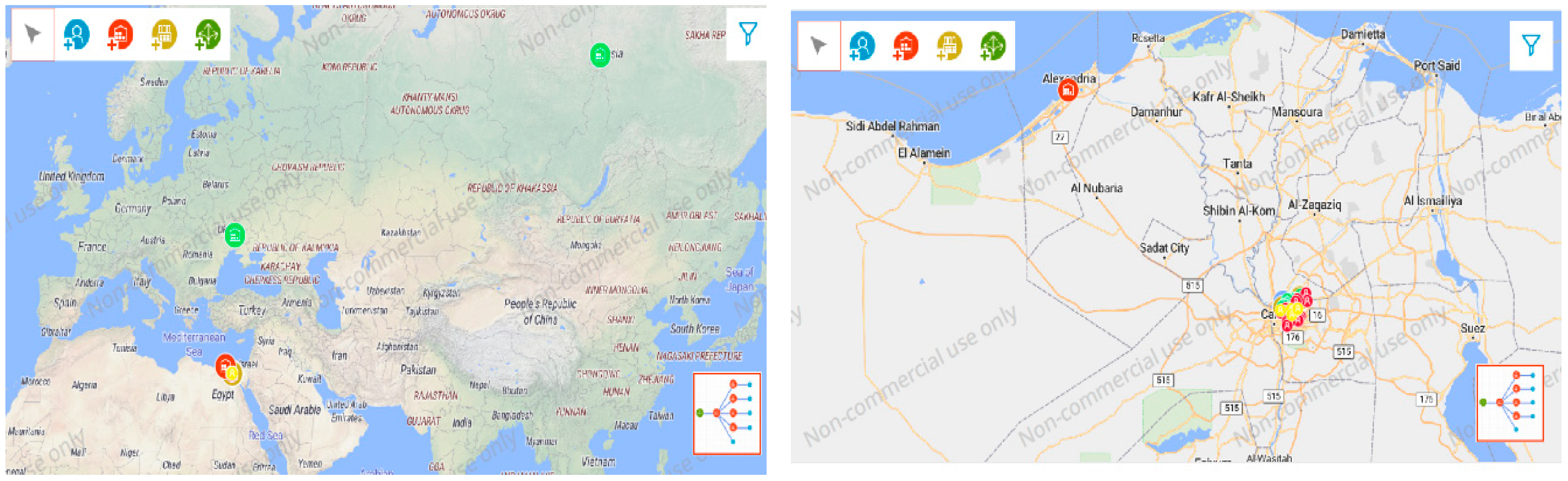

3.2. Simulation Model and Methodology

3.2.1. Scenario 1 (Initial State–Normal Conditions)

- Transportation time from source to port warehouse is 15 days.

- Transportation time from factories to customers is 15 min according to geographic location.

3.2.2. Scenario 2 (COVID-19)

- Transportation time from source to port warehouse increased by 40% [61].

- Transportation time from factories to their customers is 30 min according to geographic location. This was mainly due to the multiple health checkpoints on the roads as a prevention technique against the pandemic.

- Pandemic highest peaks occurred between May and the end of July 2020. During this time the country went into a state of lock down.

- The lockdown was lifted in August 2020, and the demand increased by 50% due to fear and panic buying.

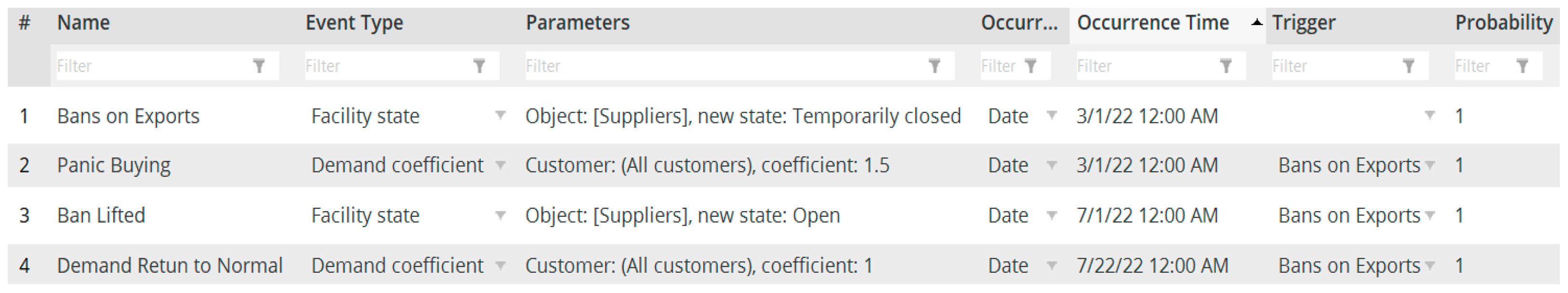

3.2.3. Scenario 3 (The Russian–Ukrainian War)

4. Results and Analysis

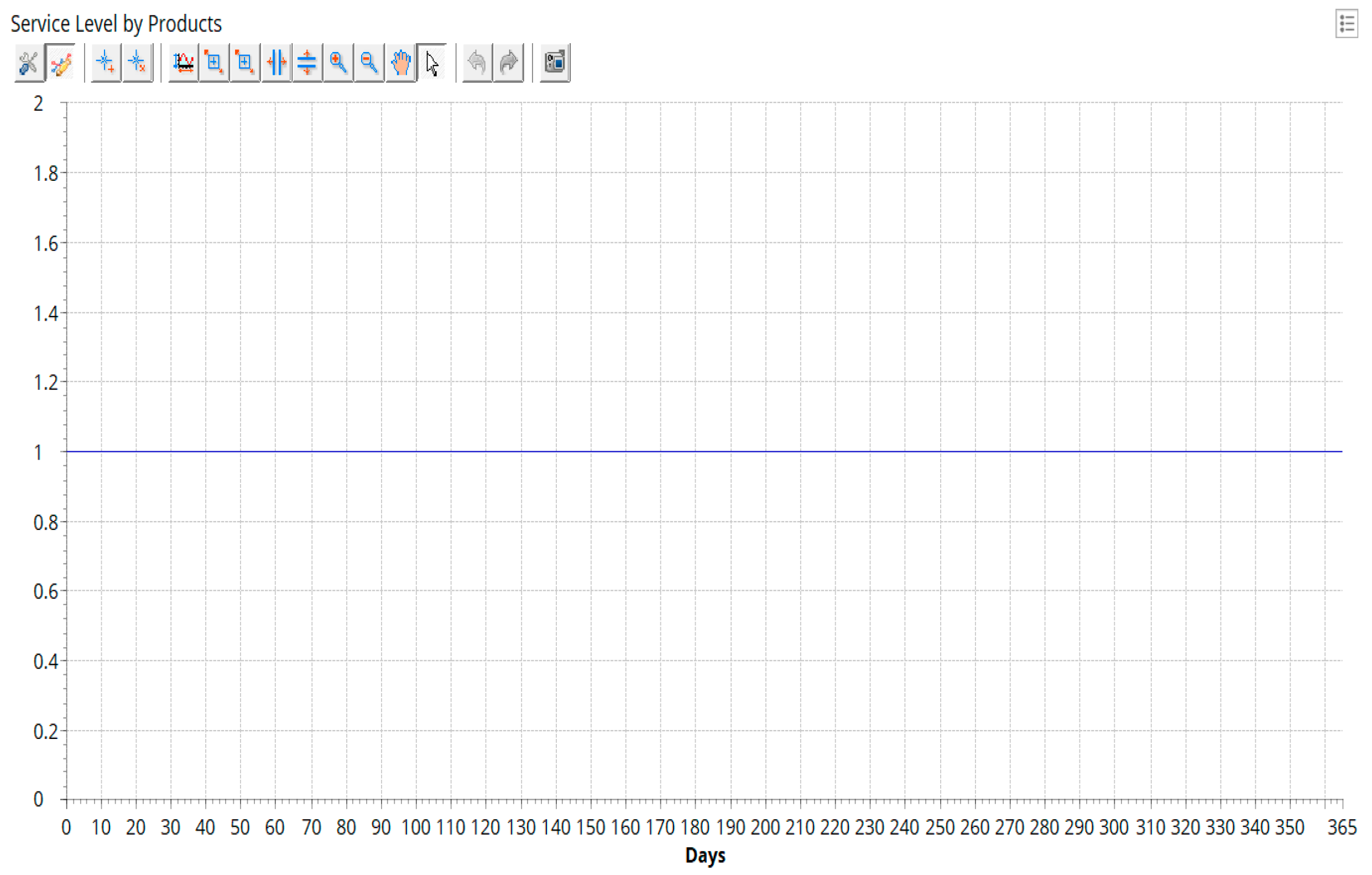

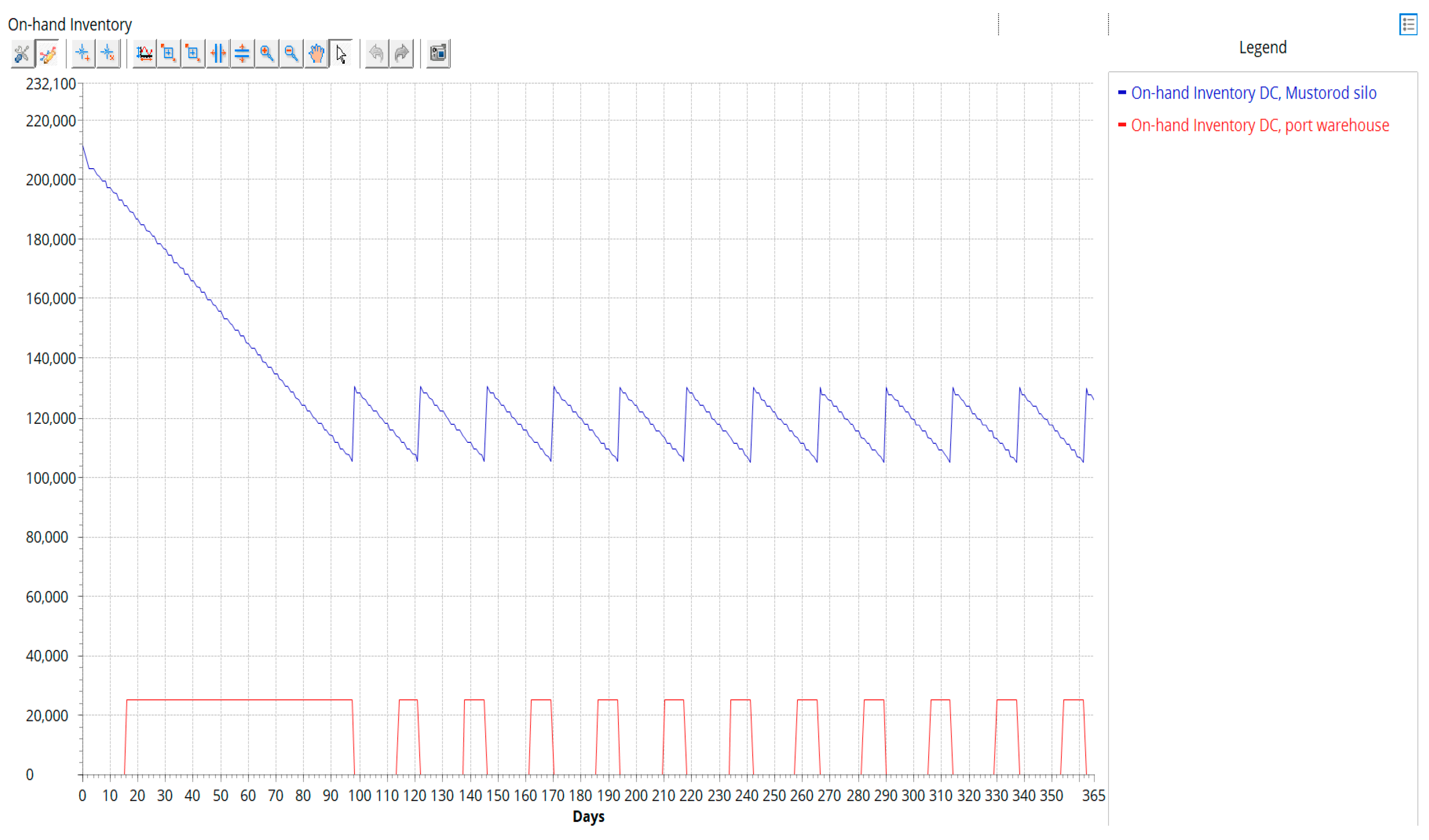

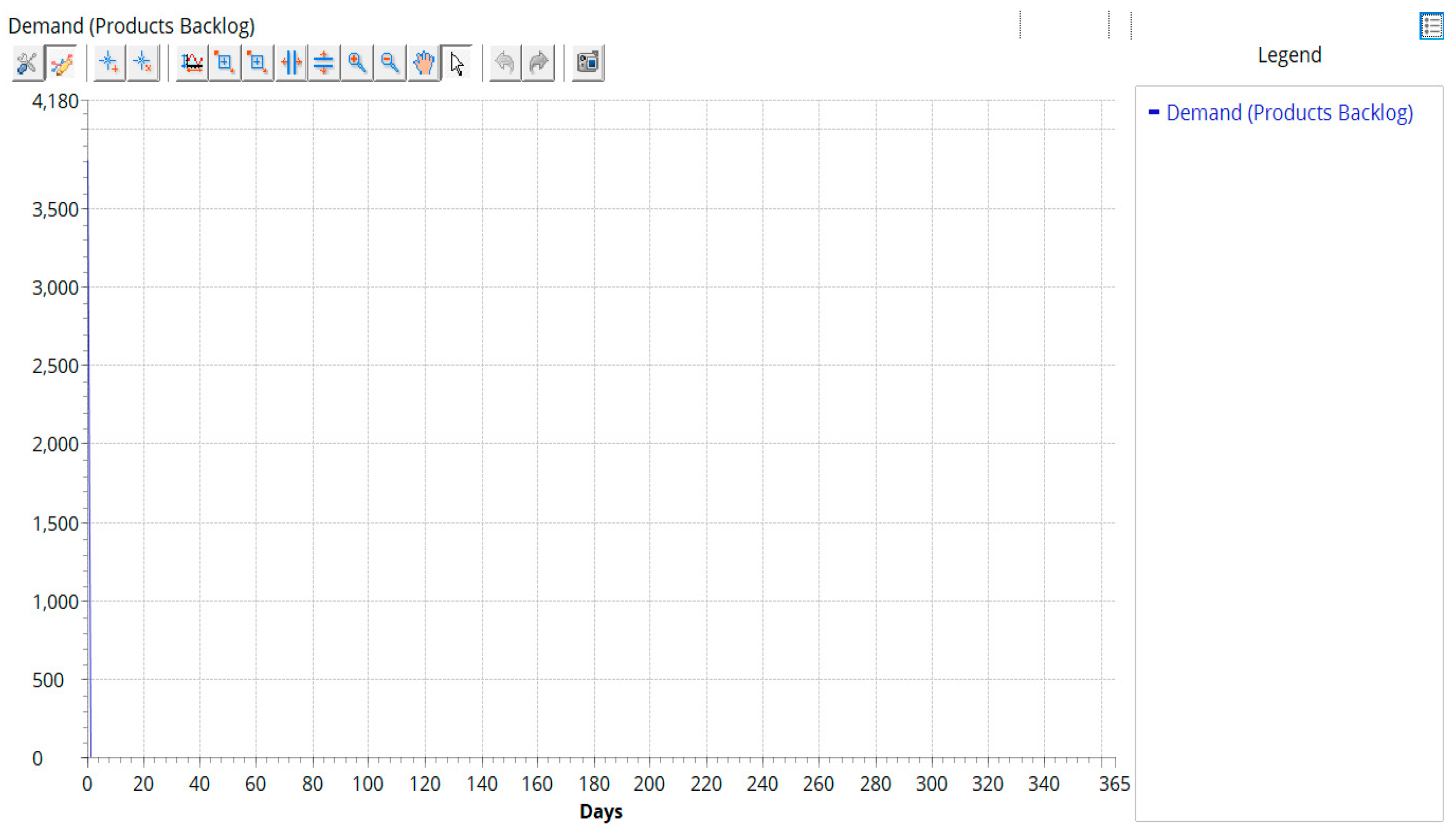

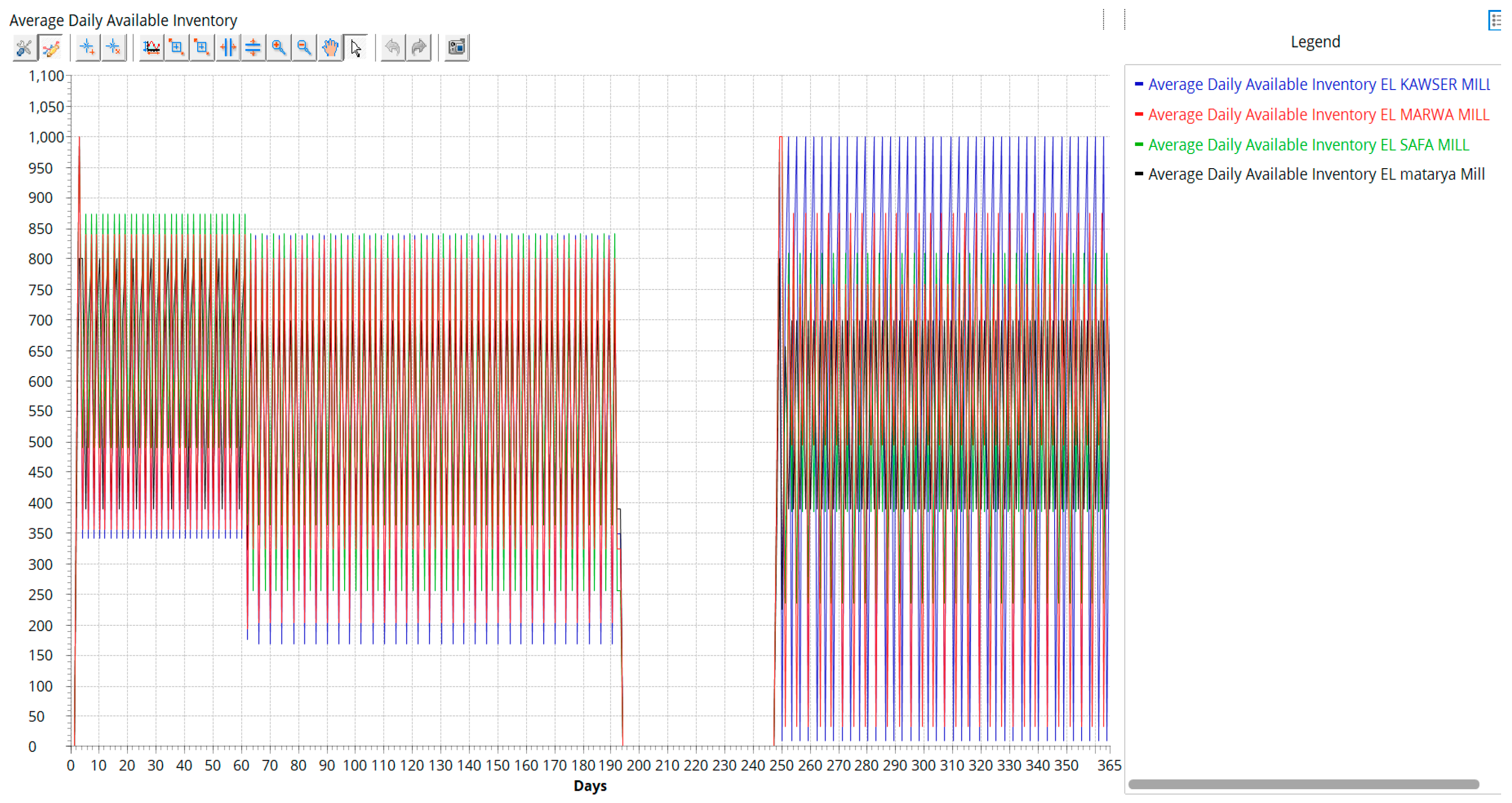

4.1. Scenario 1 (Initial State–Normal Conditions)

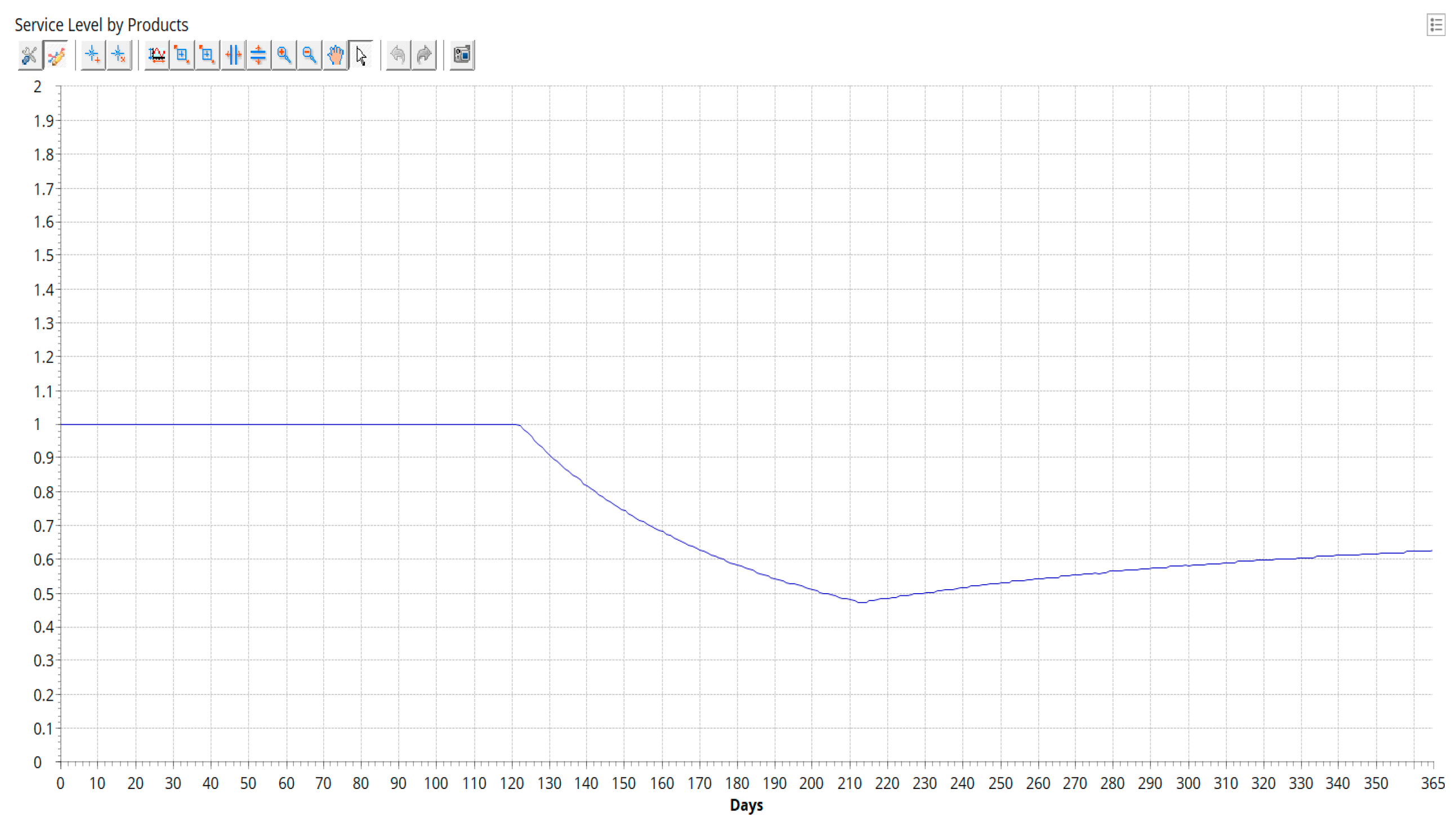

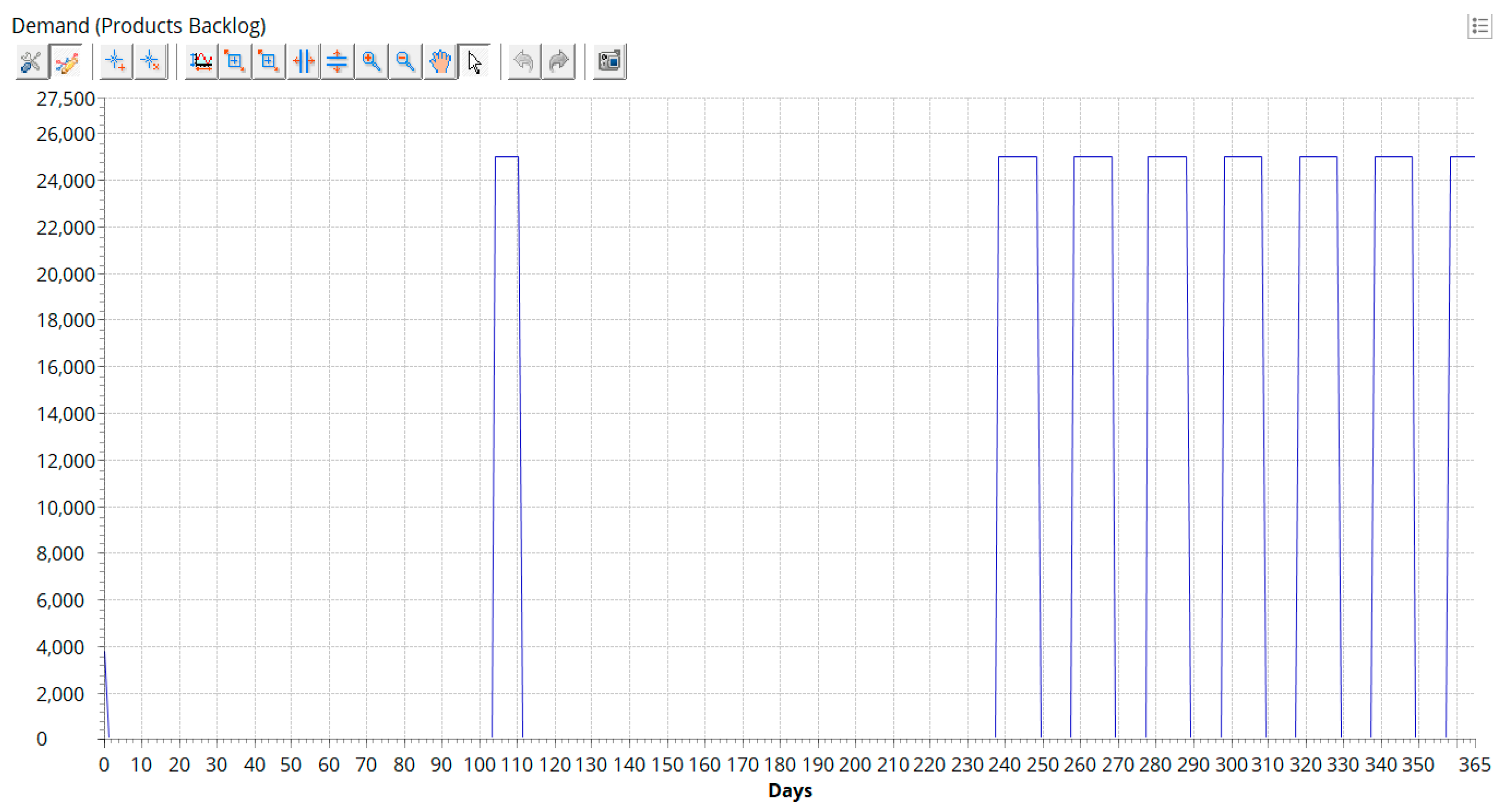

4.2. Scenario 2 (COVID-19)

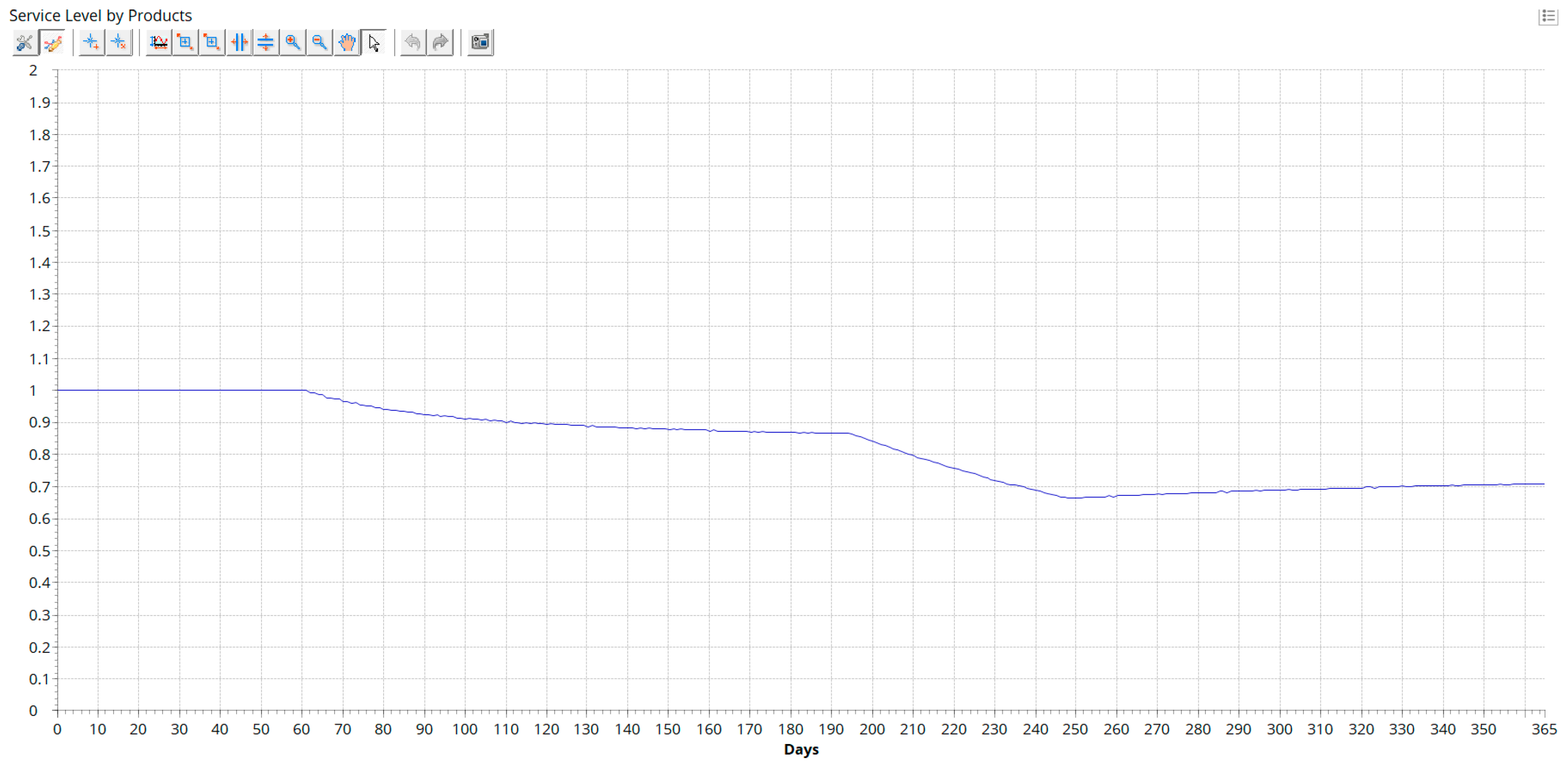

4.3. Scenario 3 (The Russian–Ukrainian War)

5. Discussion and Implications

6. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mari, S.I.; Lee, Y.H.; Memon, M.S. Sustainable and Resilient Supply Chain Network Design under Disruption Risks. Sustainability 2014, 6, 6666–6686. [Google Scholar] [CrossRef]

- Elkington, J. Partnerships from cannibals with forks: The triple bottom line of 21st-century business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- Mostafa, N.; Negm, A. Promoting organizational sustainability and innovation: An exploratory case study from the Egyptian chemical industry. Procedia Manuf. 2018, 22, 1007–1014. [Google Scholar] [CrossRef]

- Kumar, S.; Managi, S. Does Stringency of Lockdown Affect Air Quality? Evidence from Indian Cities. Econ. Disasters Clim. Change 2020, 4, 481–502. [Google Scholar] [CrossRef]

- Huremović, D. Psychiatry of Pandemics; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Food and Agriculture Organization of the United Nations. Adjusting Business Models to Sustain Agri-Food Enterprises during COVID-19; FAO: Rome, Italy, 2020. Available online: https://www.fao.org/documents/card/en/c/ca8996en (accessed on 20 March 2023). [CrossRef]

- Domenico, L.D.; Pullano, G.; Sabbatini, C.E.; Boëlle, P.-Y.; Colizza, V. Impact of lockdown on COVID-19 epidemic in Île-de-France and possible exit strategies. BMC Med. 2020, 18, 240. [Google Scholar] [CrossRef] [PubMed]

- Ren, X. Pandemic and lockdown: A territorial approach to COVID-19 in China, Italy and the United States. Eurasian Geogr. Econ. 2020, 61, 423–434. [Google Scholar] [CrossRef]

- Hassan, M.K.; Rabbani, M.R.; Abdullah, Y. Socioeconomic Impact of COVID-19 in MENA Region and The Role of Islamic Finance. Int. J. Islam. Econ. Financ. 2021, 4, 51–78. [Google Scholar] [CrossRef]

- Dun & Bradstreet. 2020. Available online: https://dnb.ru/media/entry/72/DNB_Business_Impact_of_the_Coronavirus_US.pdf (accessed on 22 March 2023).

- Hoek, R.V. Research opportunities for a more resilient post-COVID-19 supply chain–closing the gap between research findings and industry practice. Int. J. Oper. Prod. Manag. 2020, 40, 341–355. [Google Scholar] [CrossRef]

- Iacovacci, C.; Caratù, M.; Addamo, G.; Grasso, V. Analyzing the Impact of COVID-19 on Business Performance through the Case-Study of a Green Italian Start-Up. Sustainability 2023, 15, 12949. [Google Scholar] [CrossRef]

- Romagnoli, G.; Gallo, M.; Liccardo, A.; Riedel, R. Guest editorial: Opportunities and threats in providing remote access to manufacturing-related environments. J. Manuf. Technol. Manag. 2023, 34, 497–506. [Google Scholar] [CrossRef]

- Xenophon, K.; Guanyi, L. Food Supply Chain Safety and Security: A Concern of Global Importance. J. Mark. Channels 2017, 24, 111–114. [Google Scholar] [CrossRef]

- Aday, S.; Aday, M.S. Impacts of COVID-19 on Food Supply Chain. Food Qual. Saf. 2020, 4, 167–180. [Google Scholar] [CrossRef]

- Sers, C.F.; Mughal, M. COVID-19 outbreak and the need for rice self-sufficiency in West Africa. World Dev. 2020, 135, 105071. [Google Scholar] [CrossRef] [PubMed]

- FAO. COVID-19 and the Impact on Food Security in the Near East and North Africa: How to Respond? FAO: Rome, Italy, 2020. [CrossRef]

- IMF. Egypt: Overcoming the COVID Shock and Maintaining Growth 2021. Available online: https://www.imf.org/en/News/Articles/2021/07/14/na070621-egypt-overcoming-the-covid-shock-and-maintaining-growth (accessed on 2 May 2023).

- Abdalla, A.; Stellmacher, T.; Becker, M. Trends and Prospects of Change in Wheat Self-Sufficiency in Egypt. Agriculture 2023, 13, 7. [Google Scholar] [CrossRef]

- Ahram Online. Egypt Increases Local Wheat Procurement Price by 20% for New Harvest Season. Available online: https://english.ahram.org.eg/NewsContent/1/2/495688/Egypt/Society/Egypt-increases-local-wheat-procurement-price-by--.aspx (accessed on 10 July 2023).

- FAO. The State of Food Security and Nutrition in the World. 2022. Available online: https://www.fao.org/publications/sofi/2022/en/ (accessed on 14 July 2023).

- World Bank. The Impact of the War in Ukraine on Global Trade and Investment. Open Knowledge Repository. 2022. Available online: https://openknowledge.worldbank.org/handle/10986/37359 (accessed on 14 July 2023).

- Mandour, D.A. COVID-19 and Food Security Challenges in the MENA Region, Working Papers 1506. Econ. Res. Forum 2021. Available online: https://ideas.repec.org/p/erg/wpaper/1506.html (accessed on 20 March 2023).

- Grigg, D. Food Consumption in the Mediterranean Region. J. Econ. Hum. Geogr. 1999, 90, 391–409. [Google Scholar] [CrossRef]

- CIHEAM/FAO. Mediterranean Food Consumption Patterns: Diet, Environment, Society, Economy and Health. a White Paper Priority 5 of Feeding Knowledge Programme, Expo Milan 2015, CIHEAM-IAMB; Bari/FAO: Rome, Italy, 2015.

- Karunarathna, N.; Siriwardhane, D.; Jayarathne, A. Exploring the measurements of COVID-19-induced supply chain disruptions and their implications on the economic vulnerability of small-scale farmers. Int. J. Ind. Eng. Oper. Manag. 2023. ahead-of-print. [Google Scholar] [CrossRef]

- Liu, M.; Tang, H.; Wang, Y.; Li, R.; Liu, Y.; Liu, X.; Wang, Y.; Wu, Y.; Wu, Y.; Sun, Z. Enhancing Food Supply Chain in Green Logistics with Multi-Level Processing Strategy under Disruptions. Sustainability 2023, 15, 917. [Google Scholar] [CrossRef]

- Ardekani, Z.F.; Sobhani, S.M.J.; Barbosa, M.W.; De Sousa, P.R. Transition to a sustainable food supply chain during disruptions: A study on the Brazilian food companies in the COVID-19 era. Int. J. Prod. Econ. 2023, 257, 108782. [Google Scholar] [CrossRef] [PubMed]

- Le, T.T. How do food supply chain performance measures contribute to sustainable corporate performance during disruptions from the COVID-19 pandemic emergency? Int. J. Qual. Reliab. Manag. 2023, 40, 1233–1258. [Google Scholar] [CrossRef]

- Nava, N.J.; Ridley, W.; Dall’erba, S. A model of the U.S. food system: What are the determinants of the state vulnerabilities to production shocks and supply chain disruptions? Agric. Econ. 2022, 54, 95–109. [Google Scholar] [CrossRef]

- The Guardian. Fruit and Veg ‘Will Run Out’ unless Britain Charters Planes to Fly in Farm Workers from Eastern Europe. Available online: https://www.theguardian.com/environment/2020/mar/28/fruit-and-veg-will-run-out-unless-britain-charters-planes-to-fly-in-farm-workers-from-eastern-europe (accessed on 13 April 2023).

- IOM UN Migration. COVID-19 Analytical Snapshot #18: Migrants & Global Food Supply. 2020. Available online: https://www.iom.int/covid-19-analytical-snapshots (accessed on 13 April 2023).

- Ilinova, A.; Dmitrieva, D.; Kraslawski, A. Influence of COVID-19 pandemic on fertilizer companies: The role of competitive advantages. Resour. Policy 2021, 71, 0301–4207. [Google Scholar] [CrossRef] [PubMed]

- Nicola, M.; Alsafi, Z.; Sohrabi, C.; Kerwan, A.; Al-Jabir, A.; Iosifidis, C.; Agha, M.; Agha, R. The socio-economic implications of the coronavirus pandemic (COVID-19): A review. Int. J. Surg. 2020, 78, 185–193. [Google Scholar] [CrossRef] [PubMed]

- Luckstead, J.; Nayga, R.M., Jr.; Snell, H.A. Labor Issues in the Food Supply Chain Amid the COVID-19 Pandemic. Appl. Econ. Perspect. Policy 2020, 43, 382–400. [Google Scholar] [CrossRef] [PubMed]

- USDA. Food Supply Chain. Available online: https://www.usda.gov/coronavirus/food-supply-chain (accessed on 10 May 2023).

- Hobbs, J.E. Food supply chains during the COVID-19 pandemic. Can. J. Agric. Econ./Rev. Can. D’agroeconomie 2020, 68, 171–176. [Google Scholar] [CrossRef]

- The Guardian. US Producers ‘in Tears’ at Having to Cull Livestock on Their Farms. Available online: https://www.theguardian.com/environment/2020/jun/10/us-producers-in-tears-at-having-to-cull-livestock-on-their-farms (accessed on 10 May 2023).

- USA Today. Costco to Temporarily Limit Meat Purchases to 3 Items per Person. Available online: https://www.usatoday.com/story/money/2020/05/04/costco-limits-meat-purchases-3-items-per-person/3078198001/ (accessed on 10 May 2023).

- Garnett, P.; Doherty, B.; Heron, T. Vulnerability of the United Kingdom’s food supply chains exposed by COVID-19. Nat. Food 2020, 1, 315–318. [Google Scholar] [CrossRef] [PubMed]

- FAO eBooks. Legal Mechanisms to Contribute to Safe and Secured Food Supply Chains in Times of COVID-19; FAO eBooks: Rome, Italy, 2020. [Google Scholar] [CrossRef]

- Esteso, A.; Alemany, M.M.E.; Ottati, F.; Ortiz, Á. System dynamics model for improving the robustness of a fresh agri-food supply chain to disruptions. Oper. Res. Int. J. 2023, 23, 28. [Google Scholar] [CrossRef]

- Tonnang, H.E.Z.; Sokame, B.M.; Wamalwa, M.; Niassy, S.; Muriithi, B. System dynamics modeling for assessing the impact of COVID-19 on food supply chains: A case study of Kenya and Rwanda. Sustainability 2023, 15, 4717. [Google Scholar] [CrossRef]

- Huang, Y.; Li, J.; Qi, Y.; Shi, V. Predicting the Impacts of the COVID-19 Pandemic on Food Supply Chains and Their Sustainability: A Simulation Study. Discret. Dyn. Nat. Soc. 2021, 2021, 7109432. [Google Scholar] [CrossRef]

- Burgos, D.; Ivanov, D. Food retail supply chain resilience and the COVID-19 pandemic: A digital twin-based impact analysis and improvement directions. Transp. Res. Part E Logist. Transp. Rev. 2021, 152, 102412. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, R.; Panchal, R.; Tiwari, M.K. Impact of COVID-19 on logistics systems and disruptions in food supply chain. Int. J. Prod. Res. 2020, 59, 1993–2008. [Google Scholar] [CrossRef]

- Al Mal News. Available online: https://rb.gy/011mc9 (accessed on 12 May 2023).

- Kamal, O. Half-Baked, the other Side of Egypt’s “baladi” Bread Subsidy: A Study of the Market Intermediaries and Middlemen in the System; CIDOB: Barcelona, Spain, 2015. [Google Scholar]

- FAO. Data, Food Balances. Available online: https://www.fao.org/faostat/en/#data/FBS (accessed on 20 July 2022).

- World Trade Institute. Wheat Imports by Egypt. Available online: https://www.wti.org/media/filer_public/a4/56/a456d31b-b55c-427c-a79d-210161e8574a/wheat_imports_by_egypt.pdf (accessed on 3 May 2022).

- Official Portal of Cairo Governorate. East Cairo Neighborhoods. Available online: http://www.cairo.gov.eg/en (accessed on 3 May 2022).

- Official Portal of Cairo Governorate. Bakeries in East Cairo Neighborhoods. Available online: http://www.cairodc.gov.eg/servicess/BakeriesM.aspx (accessed on 3 May 2022).

- Youm 7. Determining the Maximum Serving of Bakery Flour. Available online: https://rb.gy/lq9g7w (accessed on 5 May 2022).

- UNCTAD. Review of Maritime Transport 2023. Available online: https://unctad.org/publication/review-maritime-transport-2023 (accessed on 5 May 2022).

- Fernandes, G.; Teixeira, P.; Santos, T.A. The impact of the Ukraine conflict in internal and external grain transport costs. Transp. Res. Interdiscip. Perspect. 2023, 19, 100803. [Google Scholar] [CrossRef]

- Anylogistix Supply Chain Software. Available online: https://www.anylogistix.com/ (accessed on 6 December 2023).

- Hermogenes, L.R.D.S.; De Almeida, I.D.P.; Moreira, M.Â.L.; De Araújo Costa, I.P.; Gomes, C.F.S.; Santos, M.D.; De Oliveira Costa, D.; De Moura Pereira, D.A. E-commerce Supply Chain analysis using the ANYLOGISTIX computational tool. Procedia Comput. Sci. 2022, 214, 487–494. [Google Scholar] [CrossRef]

- Bai, S.-Z.; Wang, W.-L. The Impact of Transportation Disruption on Adaptive Supply Chain: A Hybrid Simulation Study. In Proceedings of the 2007 International Conference on Management Science and Engineering, Harbin, China, 20–22 August 2007; pp. 844–849. [Google Scholar] [CrossRef]

- Zegordi, S.H.; Davarzani, H. Developing a supply chain disruption analysis model: Application of colored Petri-nets. Expert Syst. Appl. 2012, 39, 2102–2111. [Google Scholar] [CrossRef]

- Melnyk, S.A.; Rodrigues, A.; Ragatz, G.L. Using simulation to investigate supply chain disruptions. In International Series in Management Science/Operations Research; Springer: Boston, MA, USA, 2009; pp. 103–122. [Google Scholar] [CrossRef]

- Beškovnik, B.; Zanne, M.; Golnar, M. Dynamic changes in port logistics caused by the COVID-19 pandemic. J. Mar. Sci. Eng. 2022, 10, 1473. [Google Scholar] [CrossRef]

- Ivanov, D. Supply Chain Simulation and Optimization with Anylogistix, 5th, ed.; Berlin School of Economics and Law: Berlin, Germany, 2021. [Google Scholar]

- WHO. Egypt: Who Coronavirus Disease (COVID-19) Dashboard with Vaccination Data; World Health Organization: Geneva, Switzerland, 2022. Available online: https://covid19.who.int/region/emro/country/eg (accessed on 17 May 2022).

- UNCTAD. COVID-19 and Food Security in Vulnerable Countries. Available online: https://unctad.org/news/covid-19-and-food-security-vulnerable-countries (accessed on 17 May 2022).

- European Council Council of the European Union. Infographic-Ukrainian Grain Exports Explained. Available online: https://www.consilium.europa.eu/en/infographics/ukrainian-grain-exports-explained/ (accessed on 13 January 2024).

- United Nations. Sustainable Development. Available online: https://sdgs.un.org/ (accessed on 15 January 2024).

- Leal Filho, W.; Viera Trevisan, L.; Paulino Piers Eustachio, J.H.; Dibbern, T.; Castillo Apraiz, J.; Rampasso, I.; Anholon, R.; Gornati, B.; Morello, M.; Lambrechts, E. Sustainable supply chain management and the UN sustainable development goals: Exploring synergies towards sustainable development. TQM J. 2023. ahead-of-print. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Yu, Z.; Farooq, K. Green capabilities, green purchasing, and triple bottom line performance: Leading toward environmental sustainability. Bus. Strategy Environ. 2022, 32, 2022–2034. [Google Scholar] [CrossRef]

- Grida, M.; Mostafa, N.A. Are smart contracts too smart for Supply Chain 4.0? A blockchain framework to mitigate challenges. J. Manuf. Technol. Manag. 2023, 34, 644–665. [Google Scholar] [CrossRef]

- Kwak, D.-W.; Seo, Y.-J.; Mason, R. Investigating the relationship between supply chain innovation, risk management capabilities and competitive advantage in global supply chains. Int. J. Oper. Prod. Manag. 2018, 38, 2–21. [Google Scholar] [CrossRef]

- Roh, S.; Tam, J.; Lee, S.-W.; Seo, Y.-J. Risk Assessment of Maritime Supply Chain Security in Ports and Waterways. Int. J. Supply Chain. Manag. 2018, 7, 300–307. [Google Scholar]

- The Guardian. More than 100 Container Ships Rerouted from Suez Canal to Avoid Houthi Attacks. Available online: https://www.theguardian.com/business/2023/dec/20/more-than-100-container-ships-rerouted-suez-canal-red-sea-houthi-attacks-yemen (accessed on 13 January 2024).

- State Information Service. Suez Canal. Available online: https://www.sis.gov.eg/Story/171459/Suez-Canal?lang=en-us (accessed on 13 January 2024).

- CNBC. Red Sea Crisis Could Jeopardize Inflation Fight as Shipping Costs Spike Globally. Available online: https://www.cnbc.com/2024/01/11/red-sea-crisis-could-jeopardize-inflation-fight-as-shipping-costs-spike-globally.html (accessed on 13 January 2024).

- Lee, K.H.; Abdollahian, M.; Schreider, S.; Taheri, S. Supply Chain Demand Forecasting and Price Optimisation Models with Substitution Effect. Mathematics 2023, 11, 2502. [Google Scholar] [CrossRef]

- Yang, Y.; Lin, J.; Liu, G.; Zhou, L. The behavioural causes of bullwhip effect in supply chains: A systematic literature review. Int. J. Prod. Econ. 2021, 236, 108120. [Google Scholar] [CrossRef]

- Gori, F.; Castellini, A. Alternative Food Networks and Short Food Supply Chains: A Systematic Literature Review Based on a Case Study Approach. Sustainability 2023, 15, 8140. [Google Scholar] [CrossRef]

| Inventory Control Policy | |

|---|---|

| Mill-1 (El-Safa) | Min-max policy (s = 500, S = 1000) |

| Mill-2 (El-Marwa) | Min-max policy (s = 500, S = 1000) |

| Mill-3 (El-Kawser) | Min-max policy (s = 500, S = 1000) |

| Mill-4 (El-Matrya) | Min-max policy (s = 400, S = 8000) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mostafa, N.A.; Hussein, A.A.; Elsheeta, M.; Romagnoli, G. Impacts of COVID-19 and the Russian–Ukrainian Conflict on Food Supply Chain: A Case Study from Bread Supply Chain in Egypt. Sustainability 2024, 16, 994. https://doi.org/10.3390/su16030994

Mostafa NA, Hussein AA, Elsheeta M, Romagnoli G. Impacts of COVID-19 and the Russian–Ukrainian Conflict on Food Supply Chain: A Case Study from Bread Supply Chain in Egypt. Sustainability. 2024; 16(3):994. https://doi.org/10.3390/su16030994

Chicago/Turabian StyleMostafa, Noha A., Abdelwahab A. Hussein, Mohab Elsheeta, and Giovanni Romagnoli. 2024. "Impacts of COVID-19 and the Russian–Ukrainian Conflict on Food Supply Chain: A Case Study from Bread Supply Chain in Egypt" Sustainability 16, no. 3: 994. https://doi.org/10.3390/su16030994

APA StyleMostafa, N. A., Hussein, A. A., Elsheeta, M., & Romagnoli, G. (2024). Impacts of COVID-19 and the Russian–Ukrainian Conflict on Food Supply Chain: A Case Study from Bread Supply Chain in Egypt. Sustainability, 16(3), 994. https://doi.org/10.3390/su16030994