Abstract

Using transnational panel data from 61 nations and regions from 2000 to 2019, this article empirically examines both the influence of artificial intelligence on the Global Value Chain as it pertains to the manufacturing industry and its mechanism of action. According to the report, AI significantly improves the industrial sector’s GVC position; this finding still holds after multiple robustness and endogeneity tests of the model. The findings of the heterogeneity test at the national level demonstrate that, in developing nations as opposed to developed countries, AI has a stronger impact on advancing the GVC position of the manufacturing industry. Heterogeneity tests at the industry level show that AI has a significant role in promoting the GVC of high, medium and low technology manufacturing industries. The mechanism test demonstrates three primary ways by which AI contributes to improving the GVC position of the manufacturing industry: by improving both production efficiency and technological innovation capacity, and by reducing trade costs. This study provides policy implications for the promotion of AI with respect to China’s manufacturing industry GVC position.

1. Introduction

With the development of economic globalization, the global value chain division of labor systems led by multinational corporations in developed countries is constantly deepening, and the global value chain (GVC) has become a paradigm for international production [1]. Different countries and regions occupy different positions in the global value chain division of labor systems based on their respective factor advantages. Developed countries occupy high-value links such as research and marketing in the value chain system with their technological and capital advantages, while developing countries occupy low value links such as assembly with cheap labor. If this division of pattern is maintained continuously, it will widen the development gap between developed and developing countries, which is not conducive to the sustainable development of the global economy [2]. The development of artificial intelligence provides new ideas for solving this problem and reshaping the competitive international landscape. As a representative technology of the Fourth Industrial Revolution, artificial intelligence plays an important role in improving production efficiency and liberating labor, freeing developing countries from the low position of GVC and moving towards mid to high positions such as research and marketing [3]. It promotes the rationalization of the GVC division of labor system and also promotes the healthy development of the global competitive landscape.

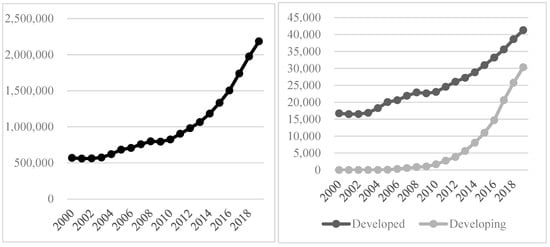

The promotion of a new round of industrial revolution on a global scale has led to a rapid increase in the use of manufacturing industrial robots in various countries and regions. This article uses the stock data of manufacturing industrial robots provided by the International Federation of Robotics (IFR) in various countries and regions for presentation. Figure 1 (left) shows the usage of manufacturing industrial robots in 61 sample countries and regions worldwide. The usage of industrial robots in the manufacturing industry in sample countries and regions is showing an upward trend. The total number of industrial robots used in the manufacturing industry was 569,187 units in 2000, and reached 2,184,694 units in 2019, with an average annual growth rate of 7.34%. In order to better demonstrate the usage of industrial robots in manufacturing industries in countries and regions with different levels of development, this article shows the usage of industrial robots in developed and developing countries in Figure 1 (right). The usage of industrial robots in manufacturing industries in developed countries shows a high starting point and low growth, while in developing countries it shows a low starting point and high growth. Meanwhile, developed countries have always been ahead of developing countries, but the gap between the two is gradually narrowing.

Figure 1.

Usage of industrial robots in the manufacturing industry (data source from IFR).

With the development of intelligent manufacturing, artificial intelligence will run through various links in the value chain, such as product research and development design, production manufacturing, and marketing services, to achieve the intelligence of the entire manufacturing value chain, and ultimately promote the competitive advantage of the industry and the improvement of the GVC position. Therefore, it is necessary to study the relationship between artificial intelligence and the GVC position of the manufacturing industry, and to explain the mechanism by which artificial intelligence affects the improvement of the GVC position of the manufacturing industry through quantitative analysis. This will verify the differences in the impact of artificial intelligence on the improvement of the GVC position of the manufacturing industry in countries with different development levels, and promote sustainable development of the global economy.

2. Literature Review

Presently, there are few studies on the impact of AI on the GVC position of the manufacturing industry. This paper reviews two aspects: the influencing factors on GVC position and the related studies on AI and manufacturing industry development.

The first is the study of the factors influencing GVC position. Some scholars believe that technological innovation capacity (Durand and Milberg, 2020 [4]; Wang et al., 2021 [5]), the level of human capital (Pananond et al., 2020 [6]), the level of physical capital (Adarov and Stehrer, 2021 [7]; Yang et al., 2022 [8]) and other factors internal to a country or region play an important role in GVC position. Other scholars argue that external factors such as foreign direct investment (Fernandes et al., 2022 [9]), trade costs (Yao et al., 2021 [10]), and institutional environment (Carril-Caccia et al., 2020 [11]) affect a country or region’s GVC position. Still other scholars have focused on the impact of digitization and ICT on GVC position. Based on an empirical study using micro data from Indian manufacturing firms, Karishma (2019) found that digital technology is conducive to the advancement of the manufacturing industry in terms of GVC position [12]. Oliveira et al. (2021) argue that digital enterprises have greater autonomy and flexibility in their pursuit of value chain upgrades [13]. Cieślik (2021) found that ICT helped to improve the GVC position of Central European countries [14].

Second, we explore research related to artificial intelligence and manufacturing development. Eder et al. (2023) used the sample data of manufacturing SMEs from 2008 to 2015 to study the relationship between industrial robotics and labor productivity [15]. The results of the study showed that robot-based SMEs had twice the sales of non-robot-based SMEs and that the use of robots by SMEs increased labor productivity by 5%. In addition, artificial intelligence can have a significant impact on technological innovation. AI, like other general-purpose technologies, can generate complementary innovations as technologies continue to proliferate, leading to a multiplier effect (Brynjolfsson et al., 2017 [16]). Using panel data from 14 manufacturing industries in China from 2008 to 2017, Liu et al. (2020) empirically investigated the impact of AI on technological innovation and found both that technological innovation is facilitated by AI and that AI has a bigger influence on low-tech sector technological innovation [17].

In conclusion, several researchers have looked at how ICT and digitalization have affected the GVC position of the industrial sector; however, few researchers have looked at how AI has affected this position. At the same time, the existing studies focus more on the impact of intelligence on manufacturing productivity and innovation capacity, while ignoring the impact of intelligence on the trade environment and other external environments that affect the position of manufacturing global value chain. It is vital to investigate the influence of artificial intelligence on the current GVC position of the manufacturing industry since the fast development of artificial intelligence technology is driving the reconstruction of Global Value Chains. Because of this, this study investigates the mechanism of how AI affects the GVC position of the manufacturing industry and undertakes empirical research to reach reasonably certain findings. This study may be used as a reference to strengthen the manufacturing sector’s GVC position as the field of global intelligence advances.

3. Theoretical Basis

3.1. Artificial Intelligence

The perspective of studying artificial intelligence in this article is based on the manufacturing industry, so the definition of artificial intelligence in this article mainly starts from the perspective of the manufacturing industry. Wright and Bourne (1988) first proposed the concept of artificial intelligence in manufacturing, defining it as intelligent machines that achieve small-scale production without human intervention, and optimizing the production process through computational modeling [18]. Kusiak (1990) believe that artificial intelligence in manufacturing refers to the simulation of the thinking and processing methods of the human brain through advanced and powerful computers during the production process, in order to complete a series of important tasks such as analysis and decision-making. At the same time, intelligent devices are used to replace mechanical and cumbersome physical activities, or to add bricks and tiles to human intellectual activities [19]. Wang et al. (2021) explained the meaning of artificial intelligence in manufacturing from a technological perspective, pointing out that artificial intelligence in manufacturing is supported by technologies such as artificial intelligence and big data, and completes a series of tasks such as product research and development, production, and management through human-computer interaction [20].

Regarding the measurement of artificial intelligence in manufacturing, scholars often measure it by constructing indicator systems. However, there is currently no widely recognized evaluation system, and for the research object of this article, relevant data cannot be obtained. Therefore, this article draws on the practices of domestic and foreign scholars such as Acemoglu and Restrepo (2018) [21], Prentice et al. (2020) [22], and uses the inventory data of industrial robots in the manufacturing industry provided by the World Robotics Association (IFR) as a measurement indicator for the level of artificial intelligence in manufacturing. Industrial robots are intelligent machines that are capable of automatic control, repetitive programming, and are multi-purpose. They are an important application field and typical representative of intelligent technology. Therefore, the usage of industrial robots can to some extent reflect the level of artificial intelligence in manufacturing industry.

3.2. GVC

The concept of the Global Value Chain (GVC) is an extension of concepts such as value chain and global commodity chain. The concept of GVC, which is currently widely used and highly recognized internationally, was proposed by the United Nations Industrial Development Organization (UNIDO). GVC refers to a large cross-enterprise network organizational system built in the international market to realize the value of goods or services, covering various links such as raw materials, production, marketing, recycling, etc.

Under the global production network system, a country’s position in the global value chain is reflected in the level of technological complexity of its production and export products. Generally speaking, developed countries specialize in high technical-complexity processes such as research and development design and key component production in the production value chain, while developing countries focus on low technical-complexity processes such as raw material supply, assembly and processing, and simple component production. According to the logic that trade structure reflects production structure, the export complexity of a country or region can reflect its position in the global value chain.

4. Mechanistic Analysis

This research primarily examines the effects of AI on the industrial sector GVC position from three perspectives.

4.1. Improve Production Efficiency

Artificial intelligence improves production efficiency by supplying new factors of production and optimizing the allocation of production factors, which in turn enhances the GVC position of manufacturing industries.

First, AI is an intelligent new factor of production; it can accelerate the renewal of the original machines and equipment, improve the intelligent level of machines and equipment, reduce the production error rate, and enhance the production efficiency and production capacity. In addition, as a capital- and technology-intensive production factor, intelligent equipment represented by industrial robots is widely used to replace routine and procedural labor work, thus saving labor inputs and reducing labor costs. Compared with the human labor force, not only can intelligent manufacturing equipment and systems work in all weather, but the accuracy and speed of the work are also greatly improved. This further improves production efficiency, making the added value of the manufacturing link continuously increase in the value chain, which, ultimately, is conducive to the enhancing of the GVC position of manufacturing.

Second, AI promotes the optimal allocation of production factors and improves production efficiency, thereby enhancing the GVC position of the manufacturing industry. On the one hand, AI can analyze and identify market data, excavate its hidden value, push enterprises to adjust their production plans in a timely manner, achieve personalized and customized production, and improve the flexibility and production efficiency of the production line, so as to enhance the added value of the link in which the manufacturing enterprises themselves are located, and realize the upgrading of the value chain. On the other hand, intelligent devices transfer production factors from low added value to high added value. By transferring factors of production from sectors with low added value to sectors with high added value, it improves the efficiency of resource utilization and allocation and maximizes the role of existing factors of production. This enables the existing factors of production, such as equipment, resources, and labor, to be adjusted and optimized according to the actual production situation.

4.2. Improve Technological Innovation Capability

AI can enhance the knowledge acquisition and absorption capacity of enterprises, promote knowledge and technology spillover, thereby improving technological innovation capacity and promoting the manufacturing industry GVC position.

First, AI can enhance the knowledge acquisition and absorption capacity of enterprises. The development of AI prompts enterprises to achieve interactive learning of internal cognition and the external environment, accelerates the creative restructuring of new and old knowledge [23], promotes the mining of external knowledge and the creation of internal knowledge, stimulates innovation vitality and improves technological innovation capacity, which is conducive to enhancing the value creation capacity of each link of the value chain, thereby enhancing the manufacturing industry GVC position.

Second, AI promotes knowledge and technology spillover. AI can accelerate the rapid development and application of technology among enterprises, accelerating the technology spillover effect and cumulative circular effect between manufacturing R&D and application sectors [24]. In addition, intelligent enterprises will increase the use of high-quality intermediate goods that match their own production technology and process level, which will upgrade the overall quality of intermediate goods input by enterprises. The quality upgrade of intermediate goods inputs helps enterprises integrate resources and complement their strengths, i.e., by gathering and integrating global innovation elements and reinventing them on the basis of digestion and absorption, a process that is also a manifestation of technology spillover. This helps improve technological innovation capacity. It stimulates the greater production advantages and vitality of manufacturing enterprises, improves the technical added value of products and enhances the GVC position of the manufacturing industry.

4.3. Reduce Trade Costs

Trade cost in a broad sense refers to the various costs of the whole trade process, except for the cost of producing the goods. Transportation costs and information search costs are important components [25]. AI can help reduce the information search costs of enterprises and reduce the transportation costs in the trade process to obtain higher trade added value and thus promote the GVC position of the manufacturing industry.

AI reduces the cost of information searches. With the development of artificial intelligence technologies such as big data and IOT, enterprises can quickly collect information about the production, consumption, transportation, and other aspects of exported products, changing the traditional mode of waiting for time nodes for feedback. For example, manufacturing enterprises can use big data technology to analyze consumer behavior, adjust the structure of production in a timely manner, and supply chain enterprises can use artificial intelligence technology to monitor and make decisions, which can monitor products in transit and supply information, assisting decision-making in selecting the most suitable upstream and downstream partners. The above changes ultimately affect the production chain, promoting the chain value appreciation of the entire export product movement process, increasing the added value of manufacturing export products, and thus promoting its GVC position.

AI reduces transportation costs. The intelligent logistics system intelligence can perceive, analyze, and process logistics information, adjust logistics transportation routes in a timely manner, reduce transportation costs of goods, and improve transportation efficiency [26]. Therefore, enterprises can rely on efficient transportation networks and low transportation costs to achieve rapid flow of production factors on a global scale, quickly matching the advantageous production factors of different countries, and enable more countries to participate in commodity production [27]. By expanding production and bringing economies of scale, enterprises can obtain higher profits in global production, and achieve an increase in the GVC position of the manufacturing industry.

Based on this, the following hypotheses are proposed.

Hypothesis 1:

AI contributes to the promotion of the manufacturing industry’s GVC position.

Hypothesis 2:

There are three ways AI promotes the manufacturing industry’s GVC position: by improving both production efficiency and technological innovation capacity and by reducing trade costs.

5. Empirical Analysis

5.1. Econometric Model Construction

In order to explore the impact of AI on the manufacturing industry’s GVC position and to establish the following econometric model, this paper draws on the study of Zhang (2023) [28].

where denotes the dependent variable, manufacturing industry GVC; denotes the core independent variable AI; the control variables include: human capital level (), physical capital level (), trade openness (), industrial structure (), and government public service level (); subscripts and denote country and year, respectively, denotes country and region fixed effects, denotes time fixed effects, and is random disturbance terms. In addition, to eliminate possible heteroskedasticity, all variables are logarithmically treated. In Model (1), is the coefficient of interest in this paper; if it is statistically significant and positive, it indicates that intelligence helps promote the manufacturing industry GVC position.

5.2. Variable Description

Dependent variable: the manufacturing industry GVC position (). Szymczak et al. (2022) argue that the technological characteristics of a country or a region’s export goods can reflect its position in the GVC division of labor [29], the higher the technological complexity of a country or a region’s export goods, the higher its GVC position.

In this paper, drawing on Dai et al. (2022) [30], the technical complexity of exports is used to measure the GVC position of a country or a region’s manufacturing industry. First, export technological complexity at the product level is measured by

where represents the country, represents the product, is the export value of product in country, is the total export value of the country, is the share of product in the country’s exports in the total level of sample countries and regions, and is the GDP per capita of the country.

Second, using the export complexity at each product level, the technical complexity of exports at the country level is calculated by weighting the average with the ratio of the country’s exports of each product to the country’s total exports as the weight.

Core independent variable: AI (). This paper uses the stock of industrial robots in manufacturing in each country and region as a measure of AI.

Control variables: human capital level (). The level of human capital is generally measured by years of education, which can reflect the overall quality of labor in different countries or regions and is closely related to the level of manufacturing production technology. However, a higher level of education does not necessarily mean a higher quality of labor. Therefore, this article uses the human capital index (average hourly wage) calculated by years of education and education return rate to measure the level of human capital [31].

The level of physical capital (). The manufacturing industry’s ascent to a higher GVC position is supported by the effective physical capital accumulation that results from a quick rise in the level of physical capital. However, weak market effects may cause an increase in physical capital to result in a significant number of non-performing assets, which might hinder the manufacturing industry’s attainment of a higher GVC position. In this study, the amount of physical capital is determined by the gross fixed capital creation to GDP ratio of a nation or area.

Degree of openness to external trade (). The degree of trade openness reflects the level of institutional development of a country, i.e., the higher the degree of trade openness of a country, the easier its institutional operating environment, which in turn is conducive to creating a favorable export environment, reducing trade costs and helping to promote the manufacturing industry’s GVC position. Trade openness also helps strengthen the effect of technology diffusion and improve the technological innovation capability of domestic manufacturing enterprises, similarly enhancing the manufacturing industry Global Value Chain position. This paper measures the degree of trade openness using the share of total exports and imports of goods and services to the GDP of each country and region.

Industrial structure (). Industrial structure is one of the important factors affecting the industry’s Global Value Chain position. The essence of industrial structure optimization is to optimize factor endowment structure; the gradual transformation of industrial development from labor-intensive to technology-intensive, the optimization of manufacturing export commodity structure and the enhancement of manufacturing value-added acquisition capacity. In this paper, industrial structure is measured using the share of industrial value added to the GDP of a country or region.

The level of government public services (). As resource allocation is important, improvements in government public service levels can help improve the management effectiveness and efficiency of government, promote the optimal allocation of factor resources and contribute to the upgrading of manufacturing industry GVC position. In this paper, we use the share of general government public consumption expenditure to GDP of a country or region to measure the level of government public services.

5.3. Data Sources

The data used in this paper come from several sources. Firstly, the United Nations Comtrade statistical database. The first is the three-digit code classification standard of the Standard International Trade Classification (SITC Rev. 3) which uses the corresponding product codes to find the export data of manufacturing products of corresponding countries and regions in the UN Comtrade database; this is then used to measure the manufacturing industry GVC position of each country. The second data source is the World Robot Database published by the International Federation of Robotics (IFR), which includes the number of industrial robots installed and stocked in 75 countries and regions from 1993 to 2019, as well as the number of industrial robots by industry worldwide. The third is the World Development Indicators Database (WDI), from which the level of physical capital, the degree of openness to the outside world, the industrial structure and the levels of government public service are derived. The fourth is the Payne World Table (PWT 10.0), from which the human capital level index is derived. By matching the year and country (region) names, the final unbalanced panel data of 61 countries and regions from 2000 to 2019 were selected. The descriptive statistics of each variable are shown in Table 1.

Table 1.

Descriptive statistics of variables.

5.4. Empirical Results and Discussions

5.4.1. Benchmark Regression Results

In this paper, a two-way fixed effects model is used for empirical testing. The general fixed effects model only fixes the individual effects, and the two-way fixed effects model fixes the time effects and individual effects separately to control for other factors that may affect the dependent variable as well as the time trend, thus making the empirical results more reliable (Wooldridge, 2016) [32]. The analysis software is Stata 15.0 and the benchmark regression results are shown in Table 2.

Table 2.

Benchmark regression results.

Model (1) only included the core independent variables, and the results showed that the artificial intelligence coefficient was significantly positive. After incorporating individual fixed effects and time fixed effects in Model (2), artificial intelligence still significantly promotes the global value chain position of the manufacturing industry to climb. Model (3) added control variables on top of Model (1), and the results showed a positive correlation between artificial intelligence and global value chain position. The artificial intelligence variable was significant at the 1% level, with an estimated coefficient of 0.0371. In Model (4), fixed effects of country and region, fixed effects of time, and control variables were added simultaneously. According to the econometric model set in this article, the regression results showed that the coefficient of the artificial intelligence variable was 0.0107, which was significantly positive at the 1% level. This indicates that artificial intelligence has a significant promoting effect on the global value chain position of the manufacturing industry. The development of artificial intelligence has significantly increased the global value chain position of the manufacturing industry by 1.07%, which verifies Hypothesis 1 of this study. In addition, the level of physical capital, degree of openness to external trade, and industrial structure are significantly positive at the 10% level, indicating that these three variables have a promoting effect on the global value chain status of the manufacturing industry.

5.4.2. Robustness Test

This paper conducted the following robustness tests, with results shown in Table 3.

Table 3.

Robustness Test.

➀ Substituting core independent variables. The baseline regression uses data on the stock of industrial robots in manufacturing industries in each country and region to measure AI. Here, the number of industrial robots installed in manufacturing (indrob2) is selected as a proxy variable for robustness estimation, with the estimation method still chosen as a two-way fixed effect method. The regression results are reported in Column 1 of Table 3; it shows that the estimated coefficient of the proxy variable is 0.0053 and that it passes the significance test at the 10% level. This indicates that AI still makes a significant contribution to improvements in the manufacturing industry’s GVC position after replacing the core independent variables.

➁ Winsorizing. To further alleviate the problem of heteroskedasticity due to the variable measurements, this paper performs tailing below the 1% quantile and above the 99% quantile for the GVC position of manufacturing industry index. It removes the estimation results that are not robust due to the sample outliers. Regression results are reported in Column 2 of Table 3. They show that the regression results are also consistent with the baseline regression results after removing the outlier sample points, which proves that the estimation results are not pseudo-causal arising from outliers.

➂ Replacement of the measurement model. Due to the potential for persistent features in changes to the manufacturing industry GVC position, the level in the present period may be influenced by the level in the previous period. Therefore, we incorporate the dynamic effect of the manufacturing industry’s GVC position on the basis of Model (1) and establish the following dynamic panel model:

where is a one-period lag of manufacturing industry GVC position, and denotes the regression coefficient of the first-order lag of gvc, which reflects the influence of the relevant factors in the previous period on the current period. In this paper, Model (4–2) is estimated using the systematic GMM regression method. The systematic GMM model has the characteristics of a strong instrumental variable, which can mitigate the possible endogeneity problem to some extent. The regression results are presented in Column 3 of Table 3, where the AI coefficient is 0.0084 and significant at the 1% level, again proving that AI helps promote manufacturing industry GVC position. Furthermore, the model setting is reliable and the selection of instrumental variables in the model is reasonable according to both the p-values of AR(2) and the Sargan test.

5.4.3. Endogenous Test

The model may also suffer from endogeneity problems due to omitted variables and reverse causality. Specifically, there may be unobservable factors that affect both AI and the manufacturing industry’s GVC position. There may also be reverse causality between AI and the manufacturing industry’s GVC position, i.e., regions or countries with a higher GVC position tend to have higher levels of AI development as well. These two problems may lead to biased coefficient estimates of intelligence variables; therefore, this paper uses the instrumental variables approach to mitigate the endogeneity problems involved.

This paper draws on the ideas and methods of Cui et al. (2020), and uses the average value of the stock of industrial robots in manufacturing in other countries and regions to remove their own country (region) as the instrumental variable. Due to the increasing level of competition among manufacturing industries in each country and the introduction of new production equipment and technologies [33], there is a correlation between the level of industrial robot use in manufacturing industries in other countries and regions and the use of industrial robots in their own countries, which satisfies the hypothesis of correlation of instrumental variables. However, the increase in the level of industrial robot use in other countries and regions does not have an impact on the national manufacturing industry GVC position, which meets the requirement of exogeneity of the instrumental variable. This indicates that the instrumental variable has some rationality. Table 4 shows the results of the estimation of the model using 2SLS. The regression results indicate that the AI variable is significantly negatively correlated with the instrumental variable selected in this paper, satisfying the hypothesis of correlation. There is a negative correlation between the level of industrial robot use in manufacturing in other countries and the level of use of industrial robots in manufacturing in their own countries. This is primarily because there is some competition among countries and regions for the use of industrial robots once there is a certain total number of industrial robots in the global manufacturing industry. The results of the two-stage regression demonstrate that the effect of AI on the manufacturing industry’s GVC position is significantly positive at the 1% level, which is consistent with the findings of the benchmark regression and suggests that the positive effect of AI on the GVC position is still robust even after potential endogeneity issues have been taken into account.

Table 4.

Endogenous test.

In addition, this paper performs the unidentifiable test for instrumental variables. The results reject the original hypothesis. Following this, the weak instrumental variables test is conducted, with results showing that the Kleibergen-Paap rk Wald F and Cragg-Donald Wald F statistics are greater than 10, which rejects the hypothesis of weak instrumental variables. Based on the value of the robust weakly identified Anderson-Rubin Wald statistic, there is a strong correlation between the instrumental variables selected in this paper and the endogenous variables.

5.4.4. Heterogeneity Test

➀ Country-level heterogeneity

To further explore the country-level differences of the impact of AI on GVC position, this paper divides the sample into two parts: developed and developing countries. Based on the baseline regression model, dummy variables for developed countries (developed) are introduced with developing countries as the reference group. The developed country dummy variables are then cross-multiplied with the AI variables (developed lnindrob); regression results are reported in Table 5.

Table 5.

Heterogeneity test.

They show that the coefficient of the effect of AI on the manufacturing industry’s GVC position for developing countries as a reference group is 0.0153, which is significant at the 1% level. The coefficient of the effect of AI on GVC position in developed countries is 0.0018 (the coefficient is the sum of the coefficient of developing countries as the reference group and the coefficient of the dummy variable for developed countries), and passes the 1% significance test, demonstrating that AI has a greater effect on promoting the GVC position of manufacturing industries in developing countries. This may be due to the lower level of development of manufacturing industries in developing countries, and the vigorous development of AI makes manufacturing industries in developing countries significantly more intelligent and technologically advanced, which helps to improve their GVC position. As a result, the promotion effect of AI on the upgrading of the GVC position of manufacturing industries in developed countries is less pronounced. This may be because developed countries are at the forefront of manufacturing technology, have abundant human capital and have a strong capacity to transform innovation.

➁ Industry-level heterogeneity

This study continues to examine the industrial heterogeneity of the influence of AI on the GVC position of manufacturing industries, taking into account that there may be variances in the effect of AI on GVC positions with different technology levels. According to Mancini et al. (2023) [34], in order to examine the industry-level variations of AI on the GVC position, the sample was separated into three categories of industries based on the intensity of R&D: high technology, medium technology, and low technology.

Table 4 and Table 5 display the results of the regression. With an estimated coefficient of 0.0102, the influence of AI on the GVC rank of low-tech manufacturing industries is considerable at the 1% level. The coefficient of the effect of AI on GVC position of medium-tech manufacturing industries is significantly positive at the 1% level with an estimated coefficient of 0.0070. The results in Column (4) show that the estimated coefficient of AI is likewise noticeably positive. The above results indicate that AI makes a significant contribution to improvement in the GVC position of manufacturing industries at high, medium and low technology levels. This finding of this paper also implies that advancing AI in manufacturing industries of different technology levels will help to promote the GVC position of manufacturing industries.

5.4.5. Mechanism Test

The theoretical analysis above shows that AI enhances the manufacturing industry’s GVC position in three ways: improving both production efficiency and technological innovation capacity and reducing trade costs. Therefore, this paper will test the above impact mechanisms by constructing a mediating effect model. Drawing on the study of Pahl and Timmer (2020) [35], a stepwise regression of Models (5)–(7) is conducted to test whether the above influence mechanisms exist:

where is the mediating variable, including production efficiency (), technological innovation capability (), and trade cost (). Current studies on the measurement of production efficiency usually include total factor productivity and labor productivity. Limited by the availability of data, this paper draws on the study of Collalti et al. (2020) [36] which uses manufacturing labor productivity as a proxy variable for production efficiency, the ratio of manufacturing value added to employment in each country and region. The level of technological innovation () is measured using the number of patent applications in a country or region, with data coming from the World Development Indicators database. ‘Cost’ denotes trade costs and trade costs include both fixed trade costs and variable trade costs. This paper draws on the study of Stornelli et al. to measure fixed trade costs using a country or region’s GDP [37]. GDP can reflect a country’s market size in response, and the larger the market size the smaller the trade cost apportioned to each sales unit. Variable trade costs are derived from a country or region’s tariff level (weighted average), with data from the World Development Indicators database.

Table 6 report the regression results of the mediating mechanism test. Columns 1–3 show the estimated results with production efficiency as the mediating variable. The results in Column 1 indicate that the estimated coefficient of the AI variable is 0.0107 and that it is significantly positive at the 1% level. This implies that there is a mediating effect of the effect of AI on the manufacturing industry’s GVC position (the test of whether there is a mediating effect is the same below and will not be repeated). In Columns 2 and 3, the coefficient of the effect of AI on production efficiency is 0.0273, which is significant at the 5% level, but the coefficient of the effect of production efficiency on the manufacturing industry’s GVC position; does not pass the significance test. In this paper, we test whether the indirect effect is significant by employing the Bootstrap method and sampling 1000 times. The results show that the indirect effect is significant. Meanwhile, the results of Column 3 show the estimated coefficient of intelligence is significantly positive, and that the coefficients of and both have the same sign and are significant, indicating that there is a partial mediating effect of the mediating variable. The proportion of the mediating effect to the total effect is 6.05%. This implies that AI can significantly improve production efficiency and promote the manufacturing industry’s GVC position by improving production efficiency, which partially verifies Hypothesis 2.

Table 6.

Mechanism test.

Columns 4 and 5 of Table 6 show the estimation results with technological innovation capability as the mediating variable. The results in Column 4 indicate that the coefficient of the effect of AI on technological innovation capability is significantly positive, which implies that AI significantly improves technological innovation capability. The results in Column 5 indicate that the estimated coefficient of technological innovation is not significant and, in this paper, the same Bootstrap method is used to sample 1000 times. The results show that the indirect effect is significant, while the estimated coefficient of AI is significantly positive, indicating that, with a mediating effect of 0.54%, there is a partial mediating effect of the mediating variable. This implies that AI promotes the manufacturing industry’s GVC position through improvements in technological innovation capability, which partially verifies Hypothesis 2.

Columns 6 to 9 of Table 6 report the tests of mediating mechanisms for reducing trade costs. Among them, Columns 6 and 7 show the estimation results with fixed trade costs as the mediating variable. The results in Column 6 indicate that AI significantly reduces fixed trade costs. In Column 7, AI and fixed trade cost are included in the model simultaneously. The estimated coefficient of fixed trade cost is 0.0861, which passes the significance test at the 5% level, indicating that the indirect effect is significant. The estimated coefficient of AI is significantly positive, indicating that there is a partial mediating effect of the mediating variable; the mediating effect accounts for 49.09%. The results in Columns 8 and 9 are the estimated results with variable trade costs as the mediating variable, and the results in Column 8 also show that AI significantly reduces variable trade costs. The results in Column 9 show significant indirect effects and partial mediating effects for the mediating variables, with the mediating effect accounting for 11.29% of the total effect. This indicates that AI can indeed promote the manufacturing industry’s GVC position by reducing trade costs; research Hypothesis 2 of this paper has been verified.

6. Conclusions and Policy Recommendations

6.1. Conclusions

This study analyses both the heterogeneity across various nations and locations, as well as industries with various degrees of technology, and empirically investigates the influence of AI on GVC in the manufacturing industry. The findings demonstrate that: (1) The manufacturing industry’s GVC position may be considerably enhanced by the development of AI. According to industry heterogeneity analysis results, the advancement of AI has a significant impact on the GVC position of the manufacturing sector at various levels of technology. The results of country heterogeneity analysis demonstrate that AI has a stronger impact on improving the GVC position of the manufacturing sector in developing countries than in developed countries. (2) The promotion effect of AI on the global value chain status of the manufacturing industry can be realized both through enhancing the core competitiveness of the manufacturing industry such as improving production efficiency and technological innovation capability, and also through reducing trade costs and improving the external trade environment of the manufacturing industry.

The findings of this paper are similar to those of Karishma, but the Karishma study focused on Indian companies while this paper is more global and focuses on manufacturing industries in 61 different countries and regions. This helps us compare the heterogeneous impact of AI development on manufacturing industries in different countries and regions. Karishma argues that the higher the level of digitization, the higher the GVC position of the firm, but this ignores the equally positive contribution of AI to low- and medium-technology industries, which this paper points to. Similar to the studies of Graetz and Michaels (2018) [38], this paper argues that AI significantly improves both the productivity and technological innovation of manufacturing industries, thus enhancing the GVC position of the manufacturing industry. However, at the same time, current studies have ignored the role played by AI in reducing trade costs [39]. The innovation of this paper is that it not only analyzes the impact of AI on the internal characteristics of the manufacturing industry such as productivity and innovation capability, but also investigates the impact of AI on external factors that can affect the global value chain position of the manufacturing industry such as the trade environment, all of which provide some reference for further clarifying the future development direction of AI.

At the same time, this article also discovered several interesting research directions for readers and future exploration. With the development and application of artificial intelligence, when we switch from human labor-intensive manufacturing methods to AI-based ones, should our pricing standards for different products be changed, and what factors should be used as benchmarks for product pricing? In the research perspective of this article, starting from the positive aspects of artificial intelligence, will artificial intelligence impact countries with labor resource advantages, and will it have a negative impact on their industrial and economic development? These questions are all directions worth exploring in the future. Similarly, this article also has some shortcomings. Artificial intelligence not only includes industrial robots, but also digital twins and other technologies. Due to the availability of data, this article uses industrial robots to measure the level of artificial intelligence, which may have an impact on research and whether better indicators can be found for measurement in the future. These are all areas that this article should optimize in the future.

6.2. Policy Recommendations

(1) Enhancing the level of manufacturing intelligence and promoting enterprise productivity. This paper finds that AI can facilitate the climb up the global value chain of manufacturing industry by improving production efficiency. First, AI ought to both perfect the construction of new infrastructure such as intelligent computing centers and the industrial Internet, consolidating the underlying architecture for intelligent development so as to promote the intelligent transformation and upgrading of manufacturing industry in an efficient and stable manner [40]. Secondly, it is necessary to make full use of industrial robots, artificial intelligence and other intelligent equipment and technologies to promote new modes of R&D and design intelligence. Other recommendations are to personalize customization and flexible manufacturing in the manufacturing industry and to enhance the ability to capture additional value in the manufacturing value chain. This will promote the upgrading of manufacturing industry GVC. Finally, to assist the intelligent development of the manufacturing industry, the government should increase financial investment and relevant policy support for the development of artificial intelligence technology.

(2) Improving technological innovation capability and promoting the GVC position of the manufacturing industry. The findings of this study indicate that raising the manufacturing sector’s GVC position through technical innovation is a successful strategy. However, because it only plays a small part, it is essential to fully leverage the potential of technological innovation to support improvements to the manufacturing sector’s GVC position [41]. First, as human capital is an important factor affecting technological innovation capability, it is necessary to ensure the creation of both sufficient skilled talent and investment in human capital at multiple levels; these might include the government, enterprises and universities. It is also necessary to expand the supply of high-skilled labor, promote the mutual matching of high-skilled labor and intelligence, bring into play the synergistic innovation effect of high-end factors and realize the transformation of the manufacturing industry from a traditional factor-driven one to an “innovation-driven” one [42], by injecting strong vitality into manufacturing technology innovation, it will promote its GVC. Second, the government should create a good innovation atmosphere and actively build an innovation service platform to better promote the industrialization and application of scientific and technological achievements. In order to increase a firm’s passion for technical research and development and enhance its capacity for independent innovation, intellectual property protection mechanisms have to be improved and market order preserved.

(3) Improve the role of artificial intelligence in reducing trade costs and promoting manufacturing GVC positions. Manufacturing enterprises should strengthen the effective use of new technologies such as the Internet, big data and artificial intelligence, so that they can quickly obtain the various kinds of information they need and reduce information search costs. In this way, they will improve the efficiency of information matching and information communication among enterprises and alleviate the information asymmetry problem that constrains all links in the value chain. This will increase both economic profit levels and the added value of final products. Companies should also promote further integration in the traditional logistics industry chain with artificial intelligence, strengthen the use of logistics robots in various logistics links such as assembly, transportation, warehousing, loading and unloading, handling and distribution of production lines, accelerate the transformation of traditional logistics to intelligent, integrated, flexible and visualized intelligent logistics, improve the efficiency of the whole process of logistics and transportation, reduce transportation costs, and improve the ability to obtain added value for manufacturing exports [43]. These measures will improve the GVC positions of manufacturing industries.

Author Contributions

Conceptualization, J.L. and X.J.; methodology, X.J.; software, M.S.; validation, X.J., M.S. and Y.Y.; formal analysis, X.J.; investigation, Y.Y.; resources, J.L.; data curation, M.S.; writing—original draft preparation, X.J.; writing—review and editing, X.J.; visualization, M.S.; supervision, Y.Y.; project administration, X.J.; funding acquisition, J.L. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the Humanities and Social Sciences Research Planning Foundation of China’s Ministry of Education (Grant No. 19YJA790055).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

Author Mengxue Shi was employed by the company Bank of Suzhou Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Dwivedi, Y.K.; Hughes, L.; Ismagilova, E.; Aarts, G.; Coombs, C.; Crick, T.; Duan, Y.; Dwivedi, R.; Edwards, J.; Eirug, A.; et al. Artificial Intelligence (AI): Multidisciplinary perspectives on emerging challenges, opportunities, and agenda for research, practice and policy. Int. J. Inf. Manag. 2021, 57, 101994. [Google Scholar] [CrossRef]

- Lee, K.; Malerba, F.; Primi, A. The fourth industrial revolution, changing global value chains and industrial upgrading in emerging economies. J. Econ. Policy Reform 2020, 23, 359–370. [Google Scholar] [CrossRef]

- Dilyard, J.; Zhao, S.; You, J.J. Digital innovation and Industry 4.0 for global value chain resilience: Lessons learned and ways forward. Thunderbird Int. Bus. Rev. 2021, 63, 577–584. [Google Scholar] [CrossRef]

- Durand, C.; Milberg, W. Intellectual monopoly in global value chains. Rev. Int. Political Econ. 2020, 27, 404–429. [Google Scholar] [CrossRef]

- Wang, S.; He, Y.; Song, M. Global value chains, technological progress, and environmental pollution: Inequality towards developing countries. J. Environ. Manag. 2021, 277, 110999. [Google Scholar] [CrossRef]

- Pananond, P.; Gereffi, G.; Pedersen, T. An integrative typology of global strategy and global value chains: The management and organization of cross-border activities. Glob. Strategy J. 2020, 10, 421–443. [Google Scholar] [CrossRef]

- Adarov, A.; Stehrer, R. Implications of foreign direct investment, capital formation and its structure for global value chains. World Econ. 2021, 44, 3246–3299. [Google Scholar] [CrossRef]

- Yang, B.; Liu, B.; Peng, J.; Liu, X. The impact of the embedded global value chain position on energy-biased technology progress: Evidence from chinas manufacturing. Technol. Soc. 2022, 71, 102065. [Google Scholar] [CrossRef]

- Fernandes, A.M.; Kee, H.L.; Winkler, D. Determinants of global value chain participation: Cross-country evidence. World Bank Econ. Rev. 2022, 36, 329–360. [Google Scholar] [CrossRef]

- Yao, X.; Shah, W.U.H.; Yasmeen, R.; Zhang, Y.; Kamal, M.A.; Khan, A. The impact of trade on energy efficiency in the global value chain: A simultaneous equation approach. Sci. Total Environ. 2021, 765, 142759. [Google Scholar] [CrossRef]

- Carril-Caccia, F.; Pavlova, E. Mergers and acquisitions & trade: A global value chain analysis. World Econ. 2020, 43, 586–614. [Google Scholar]

- Karishma, B. Digital Technologies and “Value” Capture in Global Value Chains: Empirical Evidence from Indian Manufacturing Firms; Wider Working Paper; The United Nations University World Institute for Development Economics Research (UNU-WIDER): Helsinki, Finland, 2019. [Google Scholar]

- Oliveira, L.; Fleury, A.; Fleury, M.T. Digital power: Value chain upgrading in an age of digitization. Int. Bus. Rev. 2021, 30, 101850. [Google Scholar] [CrossRef]

- Cieślik, E. Towards the industry 4.0: Have ICT services improved the position of Central and Eastern Europe in global production linkages? Manuf. Lett. 2021, 28, 11–16. [Google Scholar] [CrossRef]

- Eder, A.; Koller, W.; Mahlberg, B. The contribution of industrial robots to labor productivity growth and economic convergence: A production frontier approach. J. Product. Anal. 2023, 1–25. [Google Scholar] [CrossRef]

- Brynjolfsson, E.; Rcck, D.; Syverson, C. Artificial Intelligence and the Modern Productivity Paradox: A Clash of Expectations and Statistics. NBER Working Paper. In The Economics of Artificial Intelligence: An Agenda; University of Chicago Press: Chicago, IL, USA, 2017. [Google Scholar]

- Liu, J.; Chang, H.; Forrest, J.Y.L.; Yang, B. Influence of artificial intelligence on technological innovation: Evidence from the panel data of china’s manufacturing sectors. Technol. Forecast. Soc. Chang. 2020, 158, 120142. [Google Scholar] [CrossRef]

- Wright, P.K.; Bourne, D.A. Manufacturing Intelligence; Addison-Wesley Longman Publishing Co., Inc.: Reading, MA, USA, 1988. [Google Scholar]

- Kusiak, A. Intelligent Manufacturing; System; Prentice-Hall: Englewood Cliffs, NJ, USA, 1990. [Google Scholar]

- Wang, B.; Tao, F.; Fang, X.; Liu, C.; Liu, Y.; Freiheit, T. Smart manufacturing and intelligent manufacturing: A comparative review. Engineering 2021, 7, 738–757. [Google Scholar] [CrossRef]

- Acemoglu, D.; Restrepo, P. The race between man and machine: Implications of technology for growth, factor shares, and employment. Am. Econ. Rev. 2018, 108, 1488–1542. [Google Scholar] [CrossRef]

- Prentice, C.; Dominique Lopes, S.; Wang, X. The impact of artificial intelligence and employee service quality on customer satisfaction and loyalty. J. Hosp. Mark.Manag. 2020, 29, 739–756. [Google Scholar] [CrossRef]

- Lin, R. Analysis on the Application of Artificial Intelligence in the Global Value Chain Upgrade of Manufacturing Enterprises. In Proceedings of the 2021 3rd International Conference on Artificial Intelligence and Advanced Manufacture, Manchester, UK, 23–25 October 2021; pp. 1400–1404. [Google Scholar]

- Vlačić, E.; Dabić, M.; Daim, T.; Vlajčić, D. Exploring the impact of the level of absorptive capacity in technology development firms. Technol. Forecast. Soc. Chang. 2019, 138, 166–177. [Google Scholar] [CrossRef]

- Lyu, H.; Li, D.; Fang, H.; Huang, X.; Chen, H.; Huang, H. Impact of Artificial Intelligence on Global Value Chain Networks: An Evaluation Based on Fixed Effect Regression Models. In Proceedings of the 2nd International Conference on Mathematical Statistics and Economic Analysis, MSEA 2023, Nanjing, China, 26–28 May 2023. [Google Scholar]

- Benzidia, S.; Makaoui, N.; Bentahar, O. The impact of big data analytics and artificial intelligence on green supply chain process integration and hospital environmental performance. Technol. Forecast. Soc. Chang. 2021, 165, 120557. [Google Scholar] [CrossRef]

- Yang, T.; Yi, X.; Lu, S.; Cheng, S. Intelligent manufacturing for the process industry driven by industrial artificial intelligence. Engineering 2021, 7, 1224–1230. [Google Scholar] [CrossRef]

- Zhang, S. Impact of industrial robot applications on global value chain participation of China manufacturing industry: Mediation effect based on product upgrading. PLoS ONE 2023, 18, e0293399. [Google Scholar] [CrossRef]

- Szymczak, S.; Parteka, A.; Wolszczak-Derlacz, J. Position in global value chains and wages in Central and Eastern European countries. Eur. J. Ind. Relat. 2022, 28, 211–230. [Google Scholar] [CrossRef]

- Dai, F.; Liu, R.; Guo, H.; Du, X. How does intermediate consumption affect GVC positions?-A comparison between China and US. China Econ. Rev. 2020, 63, 101531. [Google Scholar] [CrossRef]

- Abraham, K.G.; Mallatt, J. Measuring human capital. J. Econ. Perspect. 2022, 36, 103–130. [Google Scholar] [CrossRef]

- Wooldridge, J.M. Introductory Econometrics: A Modern Approach; Nelson Education: Toronto, ON, Cananda, 2016. [Google Scholar]

- Cui, J.; Tam, O.K.; Wang, B.; Zhang, Y. The environmental effect of trade liberalization: Evidence from China’s manufacturing firms. World Econ. 2020, 43, 3357–3383. [Google Scholar] [CrossRef]

- Mancini, M.; Montalbano, P.; Nenci, S.; Vurchio, D. Positioning in Global Value Chains: World Map and Indicators. A New Dataset Available for GVC Analyses; DiSSE Working Paper 03/23; Sapienza, Univ. of Rome: Rome, Italy, 2023. [Google Scholar]

- Pahl, S.; Timmer, M.P. Do global value chains enhance economic upgrading? A long view. J. Dev. Stud. 2020, 56, 1683–1705. [Google Scholar] [CrossRef]

- Collalti, A.; Ibrom, A.; Stockmarr, A.; Cescatti, A.; Alkama, R.; Fernández-Martínez, M.; Matteucci, G.; Sitch, S.; Friedlingstein, P.; Ciais, P.; et al. Forest production efficiency increases with growth temperature. Nat. Commun. 2020, 11, 5322. [Google Scholar] [CrossRef] [PubMed]

- Stornelli, A.; Ozcan, S.; Simms, C. Advanced manufacturing technology adoption and innovation: A systematic literature review on barriers, enablers, and innovation types. Res. Policy 2021, 50, 104229. [Google Scholar] [CrossRef]

- Graetz, G.; Michaels, G. Robots at work. Rev. Econ. Stat. 2018, 100, 753–768. [Google Scholar] [CrossRef]

- Wu, K.; Tang, Z.; Zhang, L. Population Aging, Industrial Intelligence and Export Technology Complexity. Sustainability 2022, 14, 13600. [Google Scholar] [CrossRef]

- Jia, S. Capital account opening and economic growth—An empirical test based on systematic GMM. In Proceedings of the E3S Web of Conferences, Strasbourg, France, 5–7 May 2021; EDP Sciences: Lejulis, France, 2021; Volume 235, p. 01019. [Google Scholar]

- Antràs, P.; Chor, D. Global value chains. Handb. Int. Econ. 2022, 5, 297–376. [Google Scholar]

- Kano, L.; Tsang, E.W.K.; Yeung, H.W. Global value chains: A review of the multi-disciplinary literature. J. Int. Bus. Stud. 2020, 51, 577–622. [Google Scholar] [CrossRef]

- Acemoglu, D.; Restrepo, P. Robots and Jobs: Evidence from US Labor Markets. J. Political Econ. 2020, 128, 2188–2244. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).