Application of Hydraulic Energy-Saving Technology in the Teaching, Research, and Practice of Mechanical Engineering

Abstract

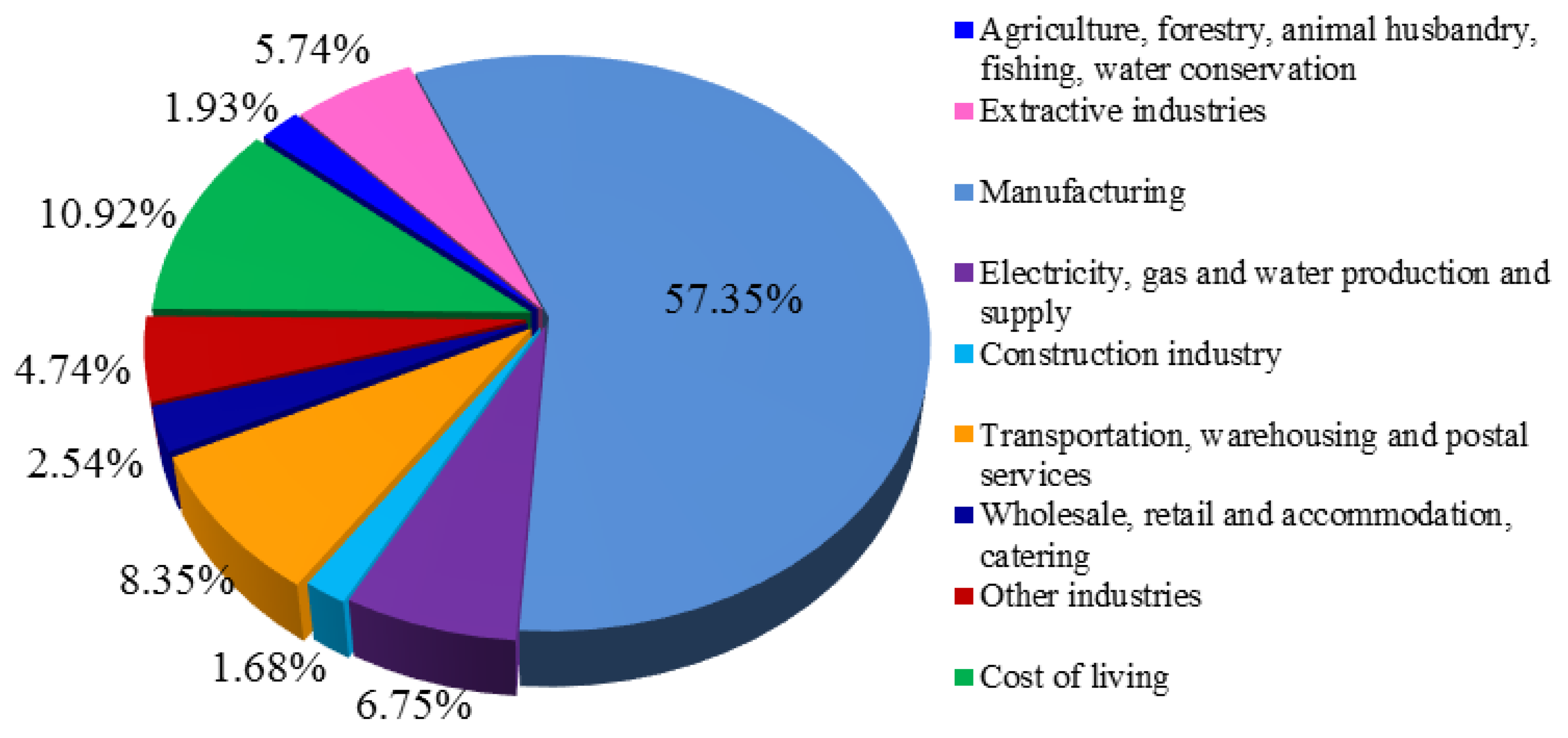

1. Introduction

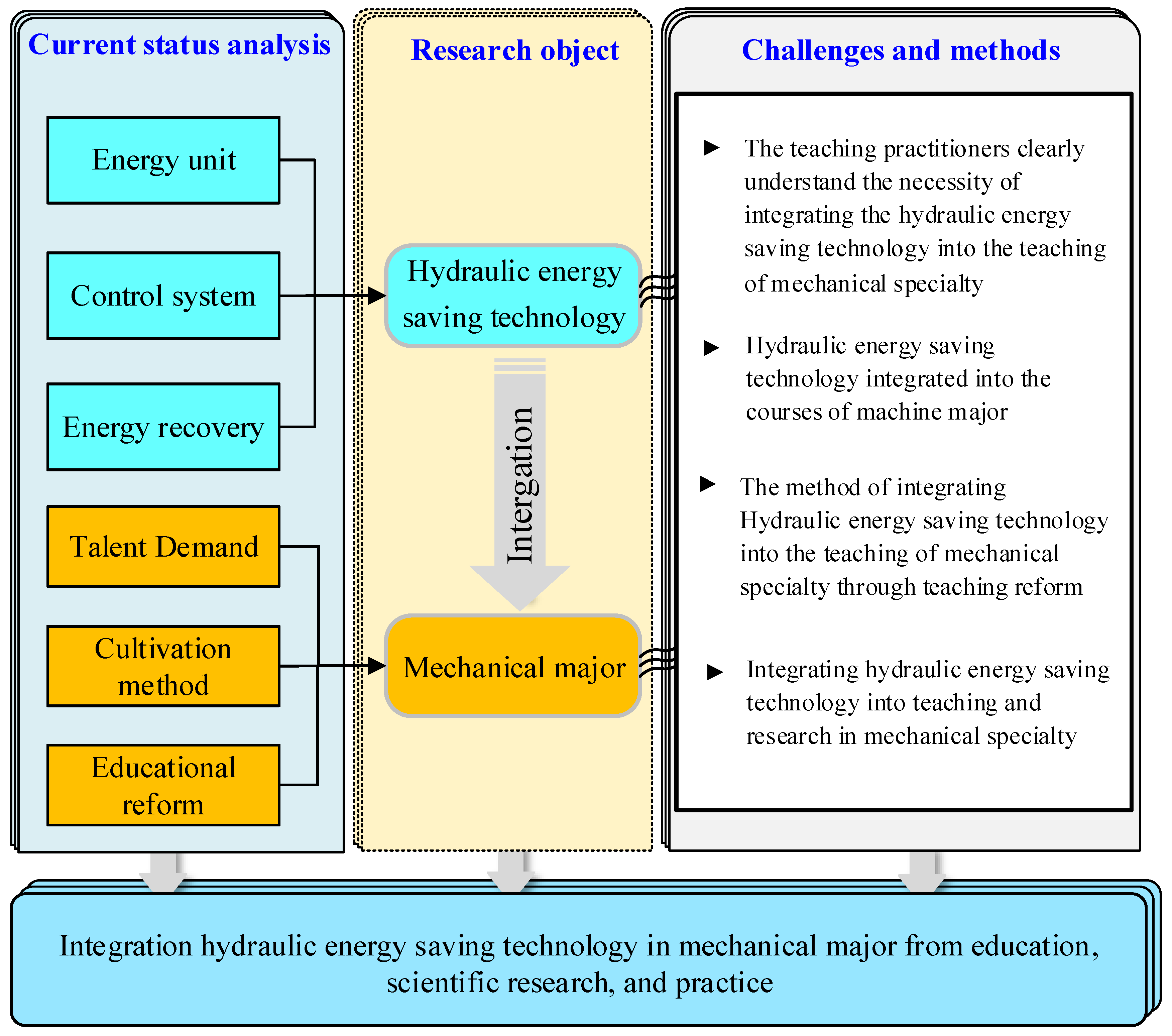

2. Methods: Objects and Framework

3. Hydraulic Energy-Saving Technology

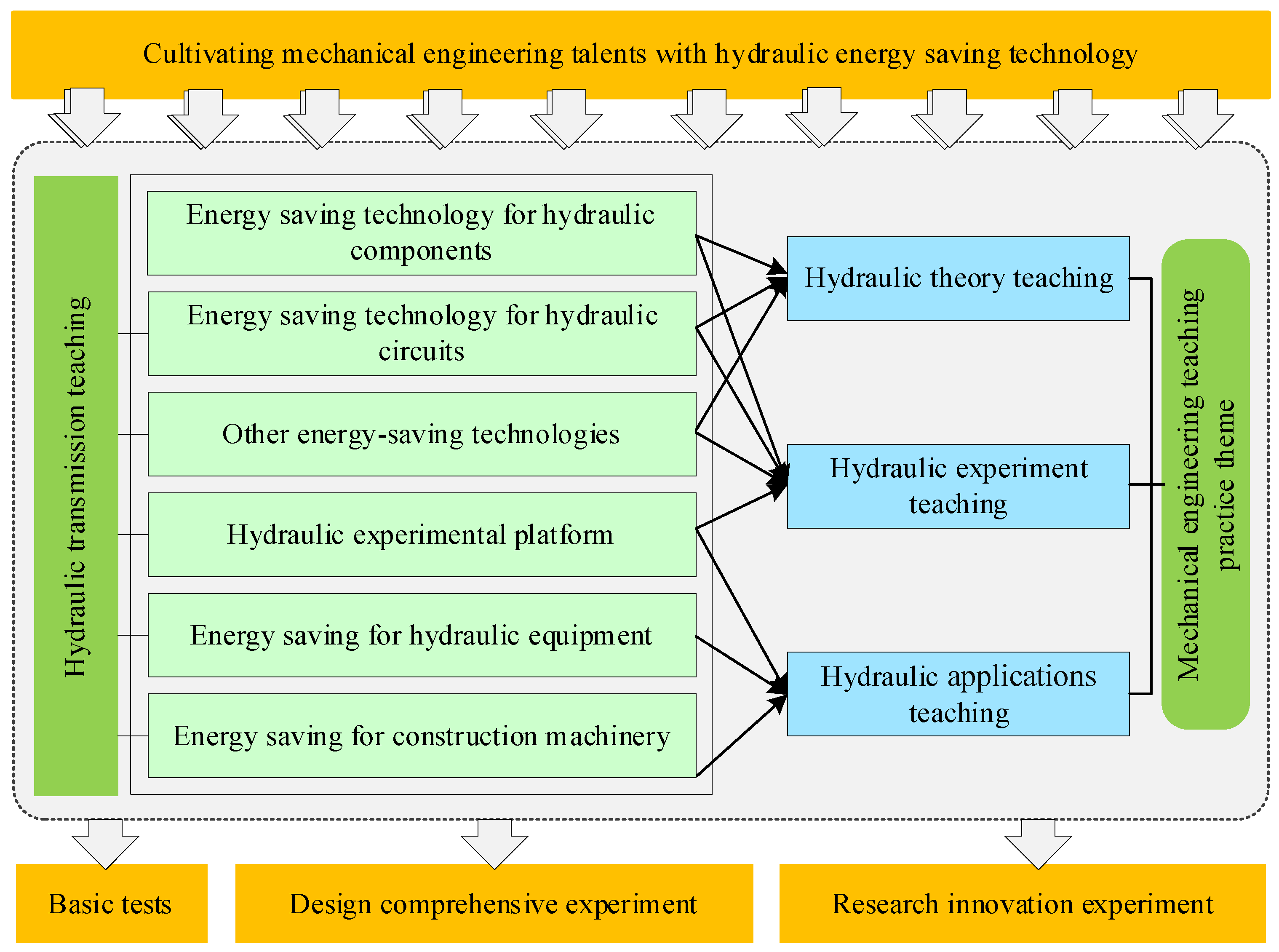

4. Integration of Hydraulic Energy-Saving Technology into Mechanical Engineering Education and Research

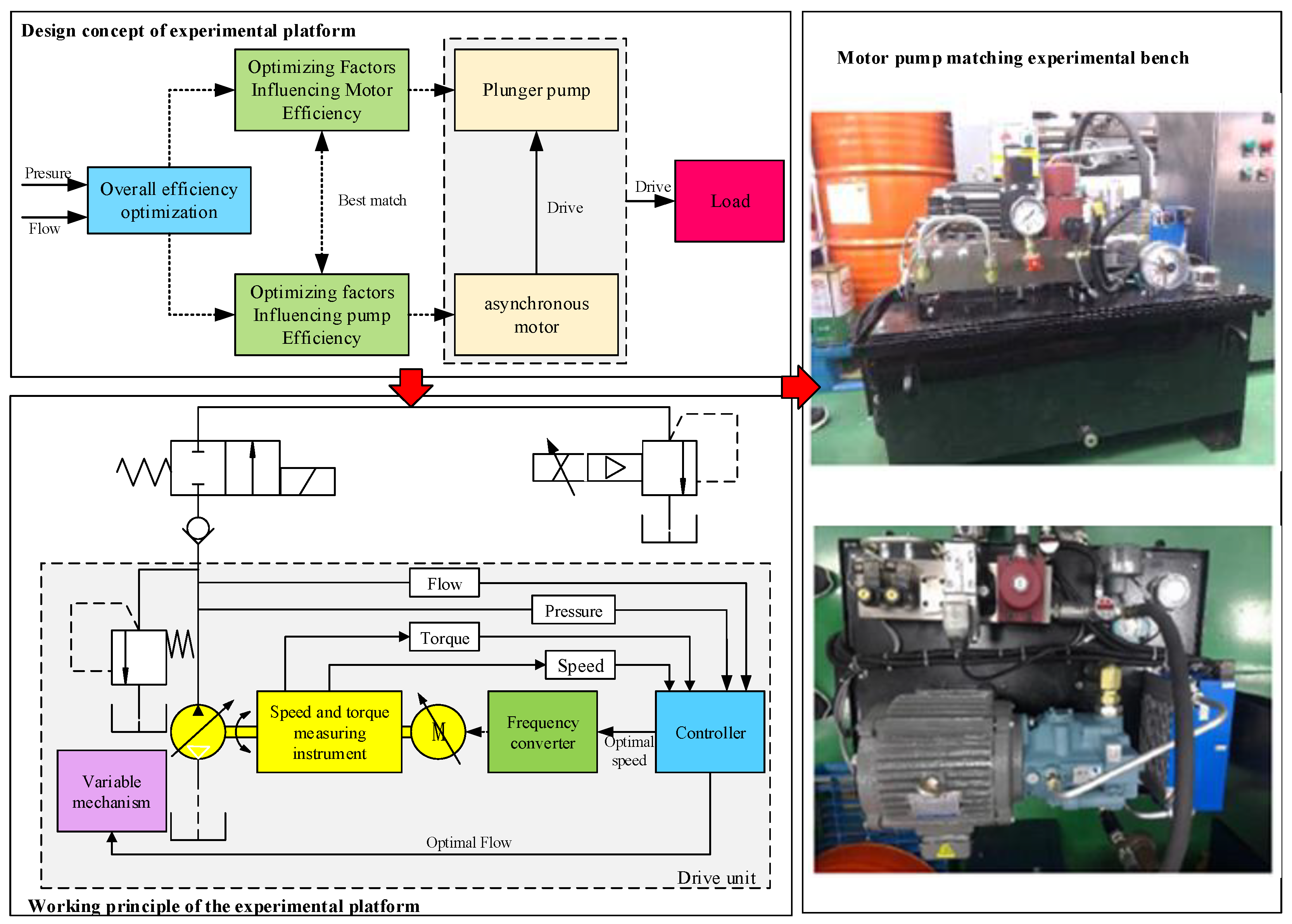

- Integrating hydraulic energy-saving technology into hydraulic theory and practice courses.Here, students first need to clarify the energy loss characteristics of each energy unit in a hydraulic system and integrate hydraulic energy-saving technology from a component selection perspective. They are then required to master the design of various energy-saving hydraulic circuits, including quantitative pumps and variable frequency speed control motor electro-hydraulic systems, load sensitive control systems, and secondary regulation hydrostatic transmission systems. Finally, students are required to understand the application of other energy-saving technologies, such as installing energy recovery devices, adopting new power systems, and using advanced computer technology to improve control systems.Consequently, practical coursework is an effective means through which students and teachers can better understand and master hydraulic energy-saving technology, ensuring better integration of hydraulic energy-saving technology into the mechanical engineering teaching and research process, over and above the integration of hydraulic energy-saving technology into the classroom. By designing experimental courses related to hydraulic energy-saving technology and building corresponding experimental platforms, students can further consolidate their theoretical knowledge. Additionally, teachers can better integrate hydraulic energy-saving technology research results into the teaching process, and students can be encouraged to apply their knowledge during enterprise training to solve the current energy-saving and emission-reduction problems that enterprises may be facing, as shown in Figure 5.

- Building a platform for school–enterprise cooperation, achieving course integration, and building a new cooperative talent cultivation model.Utilization efficiency can be improved by integrating the educational resources of colleges and universities with the industrial resources of enterprises. In the teaching process, the school sets the hydraulic transmission class for the enterprise, or the enterprise provides practical skills guidance for students so that they can experience the business environment and gain operational experience before graduation. Enterprises regard students as their own employees, and unified enterprise management and assessment processes are conducted with them—that is, the training of high-quality, skilled talent to meet the needs of the enterprise can be considered to be the educational goal. Accordingly, reaching a consensus with the school to create an appropriate teaching mode for their joint training requirements is essential. Through the construction of a school–enterprise cooperative platform, the application of hydraulic energy-saving technology in teaching, research, and engineering practice can be further promoted by the organic combination of classroom teaching and practical training operations, cultivating a comprehensive teaching mode suitable for different industries and enterprises.

- Promoting teaching through research.Hydraulic energy-saving technology research can be introduced into the teaching content and course design, such that classroom teaching and practical content can be improved. Teachers can actively apply for research projects related to hydraulic energy-saving technology and allow students to participate in the completion of research content derived from relevant research projects, improving their cognitive abilities with respect to hydraulic energy-saving technology, and further promoting such research progress.

- Teacher cultivation.The teachers of hydraulic transmission courses should visit hydraulic-related enterprises to conduct in-depth research, master the latest hydraulic energy-saving technologies, engage in related research, and achieve specific research outcomes. Moreover, experts in the field can be invited to conduct academic lectures to improve the quality of teaching.

- Competition to promote learning.Various hydraulic transmission technology innovation competitions at all levels can be conducted to improve the cognitive abilities of students related to hydraulic energy-saving technologies. Students can be encouraged to participate actively in various energy-saving and emission-reduction competitions and to strengthen their understanding of green manufacturing and related energy-saving concepts.

5. Case Study

5.1. Practical Teaching Reform Cases

5.1.1. Experimental Methods

5.1.2. Experimental Results and Analysis

5.2. Discussion

5.2.1. Discussion of the Experimental Results

5.2.2. Discussion of Practical Teaching Reform

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Energy Department of the National Bureau of Statistics China Energy Statistical Yearbook 2017; China Statistical Publishing House: Beijing, China, 2017.

- Liu, C.; Cai, W.; Jia, S.; Zhang, M.; Guo, H.; Hu, L.; Jiang, Z. Emergy-based evaluation and improvement for sustainable manufacturing systems considering resource efficiency and environment performance. Energy Convers. Manag. 2018, 177, 176–189. [Google Scholar] [CrossRef]

- Cao, H.; Li, H.; Zeng, D.; Ge, W. The state-of-art and future development strategies of green manufacturing. China Mech. Eng. 2020, 31, 135–144. [Google Scholar]

- Wang, A.; Zhang, X. Green Manufacturing Technology of Manufacturing Industry Sustainable Development. In Proceedings of the 3rd International Conference on Advanced Engineering Materials and Technology, Zhangjiajie, China, 11–12 May 2013; p. 1343. [Google Scholar]

- Zhao, P.-Y.; Chen, Y.-L.; Zhou, H. Overview of hydraulic hybrid engineering machinery system and control strategy. J. Zhejiang Uni. Eng. Sci. 2016, 50, 449–459. [Google Scholar]

- Gao, M.; He, K.; Li, L.; Wang, Q.; Liu, C. A review on energy consumption, energy efficiency and energy saving of metal forming processes from different hierarchies. Processes 2019, 7, 357. [Google Scholar] [CrossRef]

- Zhao, K.; Liu, Z.; Yu, S.; Li, X.; Huang, H.; Li, B. Analytical energy dissipation in large and medium-sized hydraulic press. J. Clean. Prod. 2015, 103, 908–915. [Google Scholar] [CrossRef]

- Li, L.; Huang, H.; Zhao, F.; Liu, Z. Operation scheduling of multi-hydraulic press system for energy consumption reduction. J. Clean. Prod. 2017, 165, 1407–1419. [Google Scholar] [CrossRef]

- Ettema, R.; Thornton, C.; Julien, P.; Hogan, T. Applied research can enhance hydraulic engineering education. J. Hydraul. Eng. 2020, 146, 04020031. [Google Scholar] [CrossRef]

- Vukasinovic, V.; Gordic, D.; Sustersic, V.; Josijevic, M.; Nikolic, J. The implementation of 3D printing in engineering education in the field of hydraulic and pneumatic components. 3D Print. Addit. Manuf. 2023. online ahead of print. [Google Scholar] [CrossRef]

- Hu, A.K.; Mao, X.H.; Fu, C.H.; Wu, M.K.; Zhou, S. Engineering curriculum reform based on outcome-based education and five-color psychology theory. Sustainability 2023, 15, 8915. [Google Scholar] [CrossRef]

- Ruslan, M.S.H.; Bilad, M.R.; Noh, M.H.; Sufian, S. Integrated project-based learning (IPBL) implementation for first year chemical engineering student: DIY hydraulic jack project. Educ. Chem. Eng. 2021, 35, 54–62. [Google Scholar] [CrossRef]

- Crookston, B.M.; Smith, V.B.; Welker, A.; Campbell, D.B. Teaching hydraulic design: Innovative learning in the classroom and the workplace. J. Hydraul. Eng. 2020, 146, 04020006. [Google Scholar] [CrossRef]

- Chanson, H.; Leng, X.Q.; Wang, H. Challenging hydraulic structures of the twenty-first century–from bubbles, transient turbulence to fish passage. J. Hydraul. Res. 2021, 59, 21–35. [Google Scholar] [CrossRef]

- Heybroek, K. Saving Energy in Construction Machinery Using Displacement Control Hydraulics: Concept Realization and Validation; Linköping University Electronic Press: Linköping, Sweden, 2008. [Google Scholar]

- Gao, M.; Huang, H.; Li, X.; Liu, Z. A novel method to quickly acquire the energy efficiency for piston pumps. J. Dyn. Syst. Meas. Control 2016, 138, 101004. [Google Scholar] [CrossRef]

- Gao, M.; Liu, Z.; Wang, Y. A novel method to quick acquire efficiency characteristics for three phase induction motor. China Mech. Eng. 2016, 27, 1755–1759. [Google Scholar]

- Cheng, H.; Liu, Z.; Xie, P.; Zhan, Y.; Yuan, H. Calculation method of minimum length retained in cylinder for swash-plate plunger pump based on energy loss. Trans. Chin. Soc. Agric. Mach. 2014, 45, 333–339. [Google Scholar]

- Li, L.; Huang, H.; Liu, Z.; Li, X.; Triebe, M.J.; Zhao, F. An energy-saving method to solve the mismatch between installed and demanded power in hydraulic press. J. Clean. Prod. 2016, 139, 636–645. [Google Scholar] [CrossRef]

- Bin, Y.; DeBoer, C. Energy-saving adaptive robust motion control of single-rod hydraulic cylinders with programmable valves. In Proceedings of the 2002 American Control Conference, Anchorage, AK, USA, 8–10 May 2002; pp. 4819–4824. [Google Scholar]

- Liu, S.; Yao, B. Coordinate control of energy saving programmable valves. IEEE Trans. Control Syst. Technol. 2008, 16, 34–45. [Google Scholar] [CrossRef]

- Lovrec, D.; Kastrevc, M.; Ulaga, S. Electro-hydraulic load sensing with a speed-controlled hydraulic supply system on forming-machines. Int. J. Adv. Manuf. Technol. 2009, 41, 1066–1075. [Google Scholar] [CrossRef]

- Halevi, Y.; Carpanzano, E.; Montalbano, G.; Koren, Y. Minimum energy control of redundant actuation machine tools. CIRP Ann. Manuf. Technol. 2011, 60, 433–436. [Google Scholar] [CrossRef]

- Peng, Y.; Wei, W. Application and control strategy of servo motor driven constant pump hydraulic system in precision injection molding. J. Mech. Eng. 2011, 47, 173–179. [Google Scholar] [CrossRef]

- Hongbo, Z.; Yousong, S. Research on pump-controlled servo hydraulic press and its energy consumption experiments. Adv. Mater. Res. 2014, 988, 590–596. [Google Scholar]

- Huang, H.; Jin, R.; Li, L.; Liu, Z. Improving the energy efficiency of a hydraulic press via variable-speed variable-displacement pump. J. Dyn. Syst. Meas. Control Trans. ASME 2018, 140, 111006. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, Y.; Hua, L.; Zhao, X.; Guo, W. Energy analysis and optimization of main hydraulic system in 10,000 kN fine blanking press with simulation and experimental methods. Energy Convers. Manag. 2019, 181, 143–158. [Google Scholar] [CrossRef]

- Heitzig, S.; Sgro, S.; Theissen, H. Energy efficiency of hydraulic systems with shared digital pumps. Int. J. Fluid Power 2014, 13, 49–57. [Google Scholar] [CrossRef]

- Huova, M.; Laamanen, A.; Linjama, M. Energy efficiency of three-chamber cylinder with digital valve system. Int. J. Fluid Power 2010, 12, 15–22. [Google Scholar] [CrossRef]

- Locateli, C.C.; Teixeira, P.L.; Pieri, E.R.D.; Krus, P.; Negri, V.J.D. Digital Hydraulic System Using Pumps and On/Off Valves Controlling the Actuator. In Proceedings of the 8th FPNI Ph.D Symposium on Fluid Power, Lappeenranta, Finland, 11–13 June 2014; p. V001T01A009. [Google Scholar]

- Li, L.; Huang, H.H.; Zhao, F.; Liu, Z.F. A coordinate method applied to partitioned energy-saving control for grouped hydraulic presses. J. Manuf. Syst. 2016, 41, 102–110. [Google Scholar] [CrossRef]

- Minav, T.; Immonen, P.; Laurila, L.; Vtorov, V. Electric energy recovery system for a hydraulic forklift–theoretical and experimental evaluation. IET Electr. Power Appl. 2011, 5, 377–385. [Google Scholar] [CrossRef]

- Song, H.; Wang, Z.J. Grain refinement by means of phase transformation and recrystallization induced by electropulsing. Trans. Nonferr. Metal Soc. China 2011, 21, s353–s357. [Google Scholar] [CrossRef]

- Yao, J.; Li, B.; Kong, X.; Zhou, F. Displacement and dual-pressure compound control for fast forging hydraulic system. J. Mech. Sci. Technol. 2016, 30, 353–363. [Google Scholar] [CrossRef]

- Yan, X.; Chen, B.; Zhang, D.; Wu, C.; Luo, W. An energy-saving method to reduce the installed power of hydraulic press machines. J. Clean Prod. 2019, 233, 538–545. [Google Scholar] [CrossRef]

- Li, L.; Huang, H.; Zhao, F.; Sutherland, J.W.; Liu, Z. An energy-saving method by balancing the load of operations for hydraulic press. IEEE/ASME Trans. Mechatron. 2017, 22, 2673–2683. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, Y.; Hua, L.; Zhao, X.; Wang, X. Energy improvement of fineblanking press by valve-pump combined controlled hydraulic system with multiple accumulators. J. Clean. Prod. 2020, 257, 120505. [Google Scholar] [CrossRef]

| Motor Speed (r/min) | Overall Energy Efficiency of the Drive Unit (%) | ||||

|---|---|---|---|---|---|

| Load Power 1.0 kW | Load Power 2.0 kW | Load Power 3.0 kW | Load Power 4.0 kW | Load Power 5.0 kW | |

| 600 | 66.23 | 78.12 | - | - | - |

| 700 | 68.49 | 83.23 | 81.07 | 74.49 | 72.86 |

| 800 | 68.97 | 86.00 | 83.06 | 76.63 | 75.33 |

| 900 | 70.21 | 86.84 | 86.51 | 84.57 | 82.72 |

| 1000 | 69.32 | 87.90 | 88.65 | 90.50 | 91.05 |

| 1100 | 67.57 | 86.77 | 88.97 | 92.81 | 93.48 |

| 1200 | 64.94 | 84.89 | 87.41 | 92.38 | 94.46 |

| 1300 | 62.89 | 83.22 | 86.81 | 92.17 | 95.20 |

| 1400 | 61.35 | 76.74 | 85.03 | 92.59 | 94.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, M.; Wang, Q.; Shan, X.; Li, Q.; Zhang, L. Application of Hydraulic Energy-Saving Technology in the Teaching, Research, and Practice of Mechanical Engineering. Sustainability 2024, 16, 1315. https://doi.org/10.3390/su16031315

Gao M, Wang Q, Shan X, Li Q, Zhang L. Application of Hydraulic Energy-Saving Technology in the Teaching, Research, and Practice of Mechanical Engineering. Sustainability. 2024; 16(3):1315. https://doi.org/10.3390/su16031315

Chicago/Turabian StyleGao, Mengdi, Qingyang Wang, Xiuyang Shan, Qiang Li, and Lifeng Zhang. 2024. "Application of Hydraulic Energy-Saving Technology in the Teaching, Research, and Practice of Mechanical Engineering" Sustainability 16, no. 3: 1315. https://doi.org/10.3390/su16031315

APA StyleGao, M., Wang, Q., Shan, X., Li, Q., & Zhang, L. (2024). Application of Hydraulic Energy-Saving Technology in the Teaching, Research, and Practice of Mechanical Engineering. Sustainability, 16(3), 1315. https://doi.org/10.3390/su16031315