Grill and Chill: A Comprehensive Analysis of the Environmental Impacts of Private Household Barbecuing in Germany

Abstract

1. Introduction

2. Materials and Methods

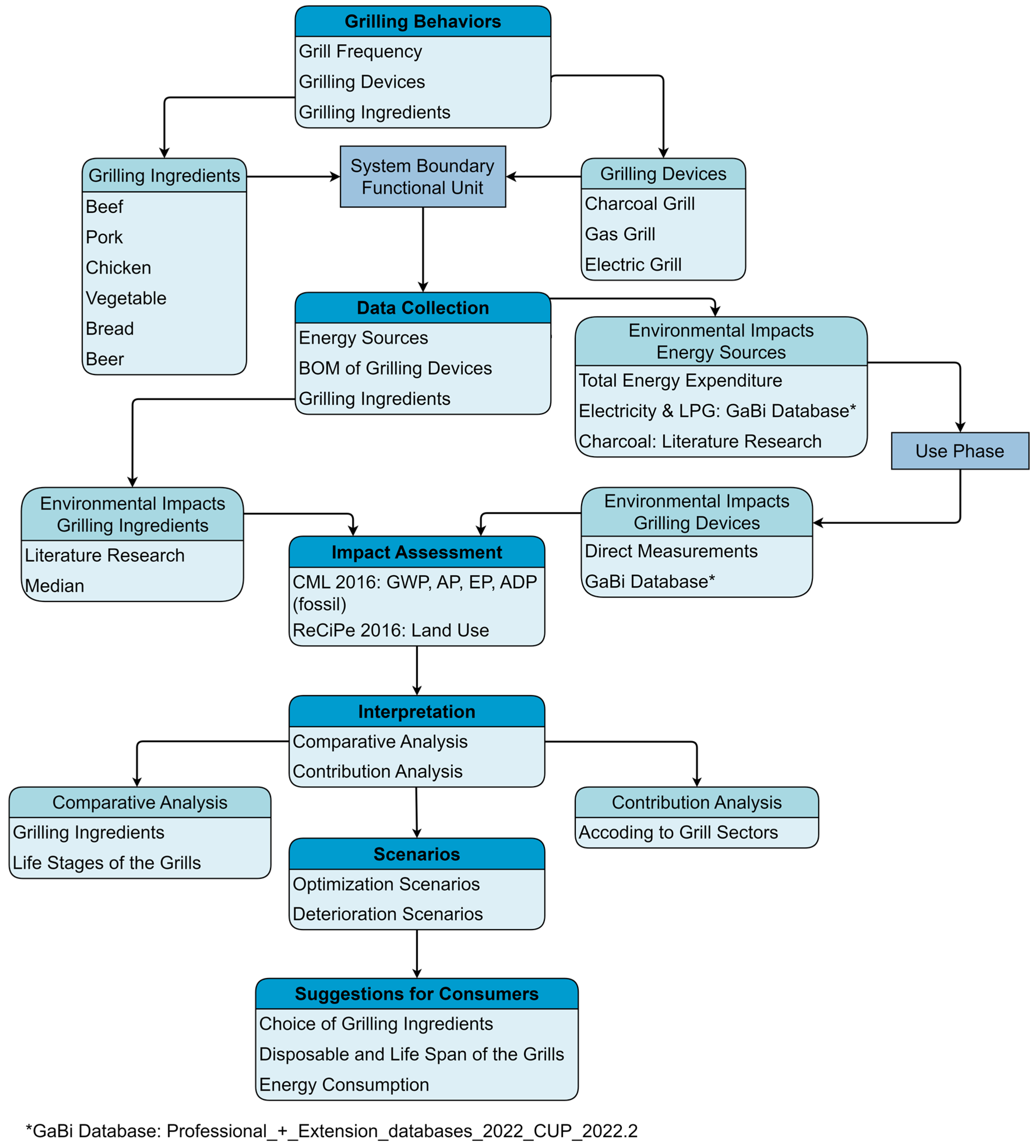

2.1. Research Framework

2.2. LCA

2.2.1. Goal and Scope

Functional Unit

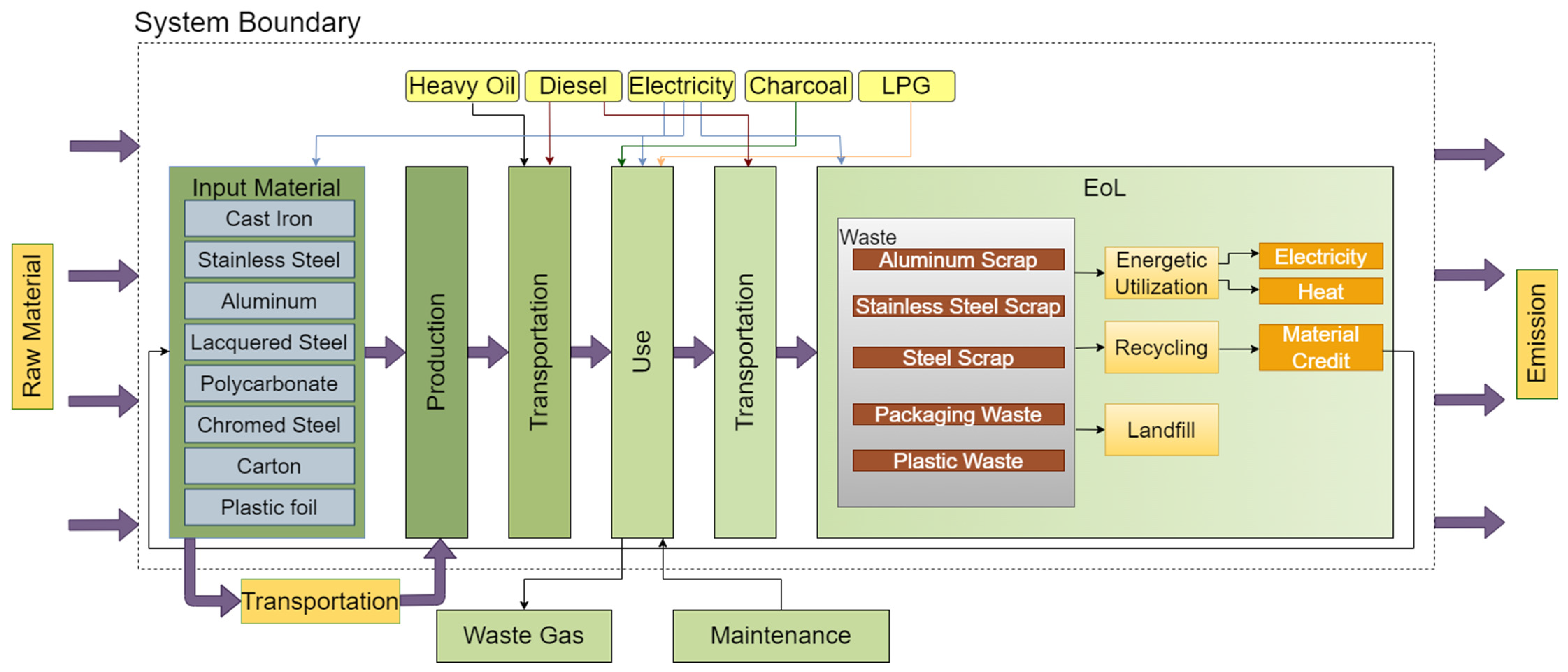

System Boundaries

2.2.2. Life Cycle Inventory

2.2.3. Impact Assessment

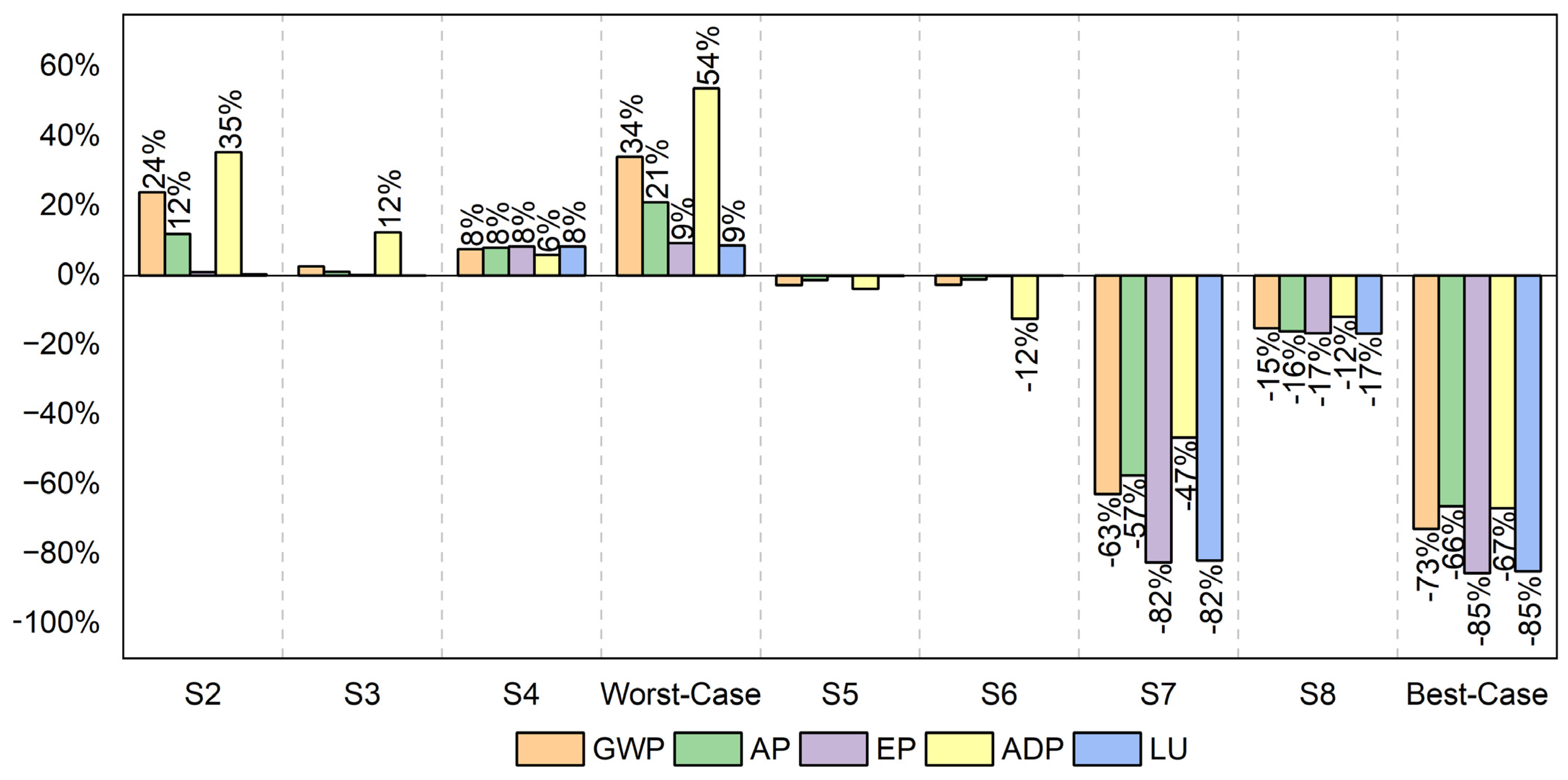

2.3. Scenarios

2.3.1. Reference Scenario

2.3.2. Future Scenarios

3. Results

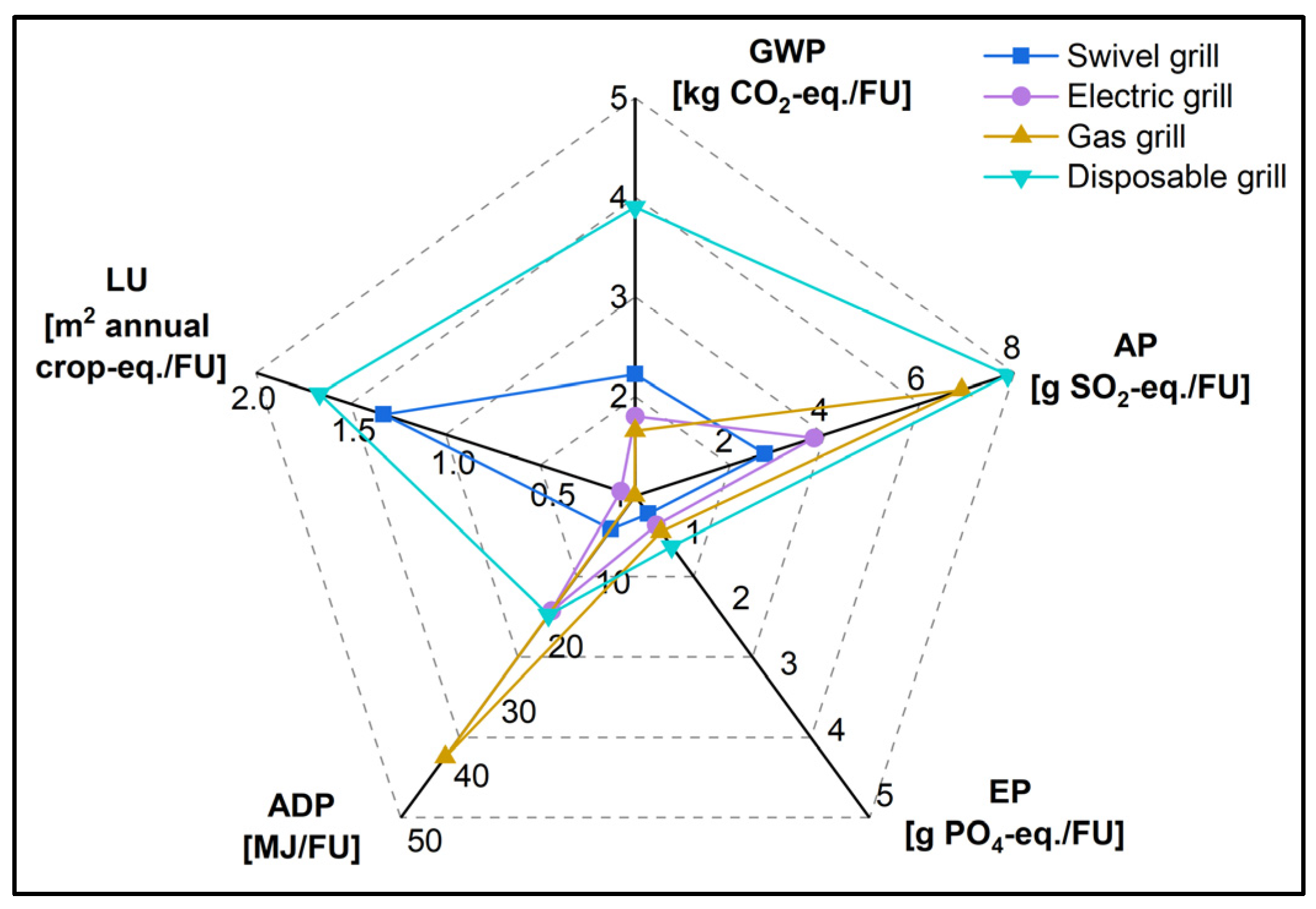

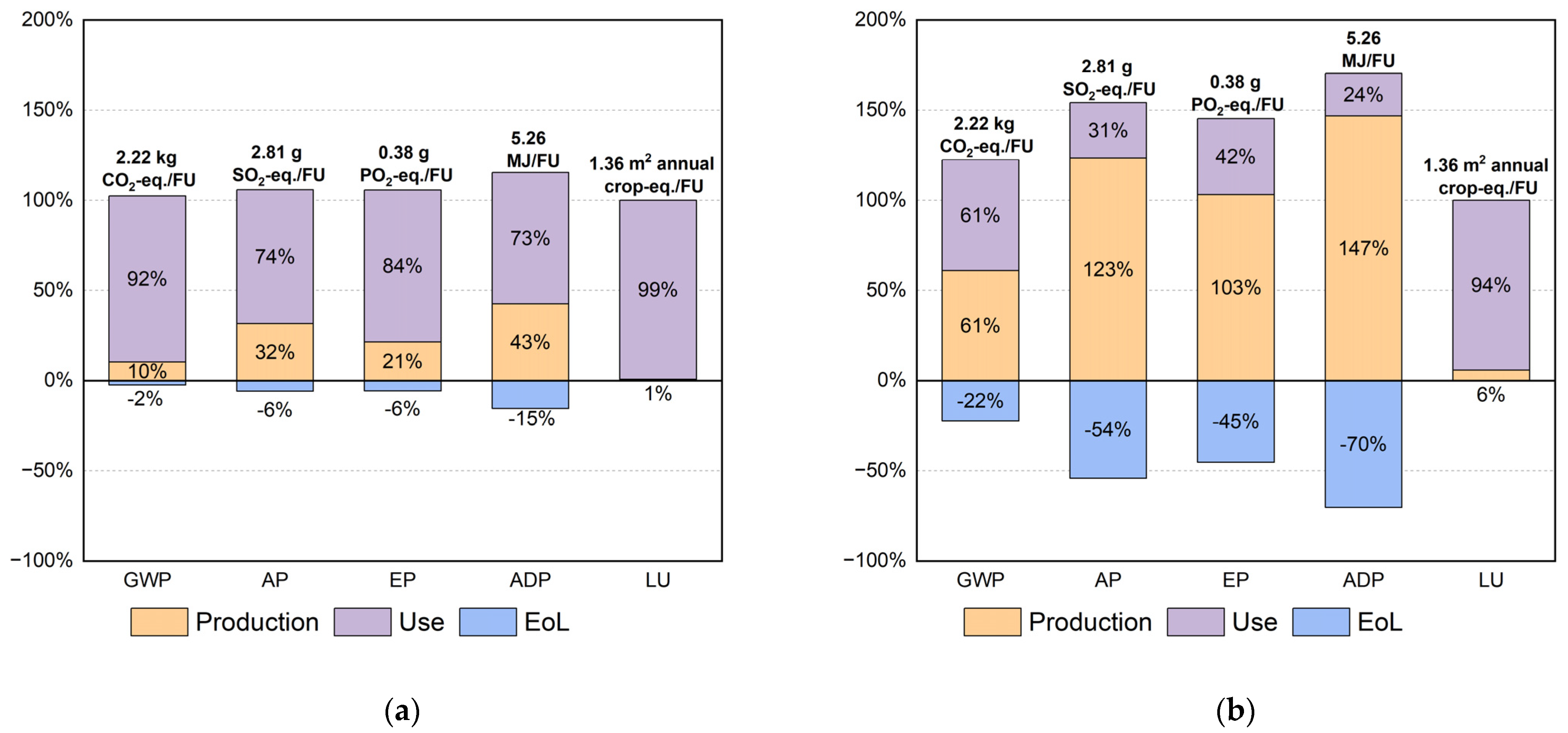

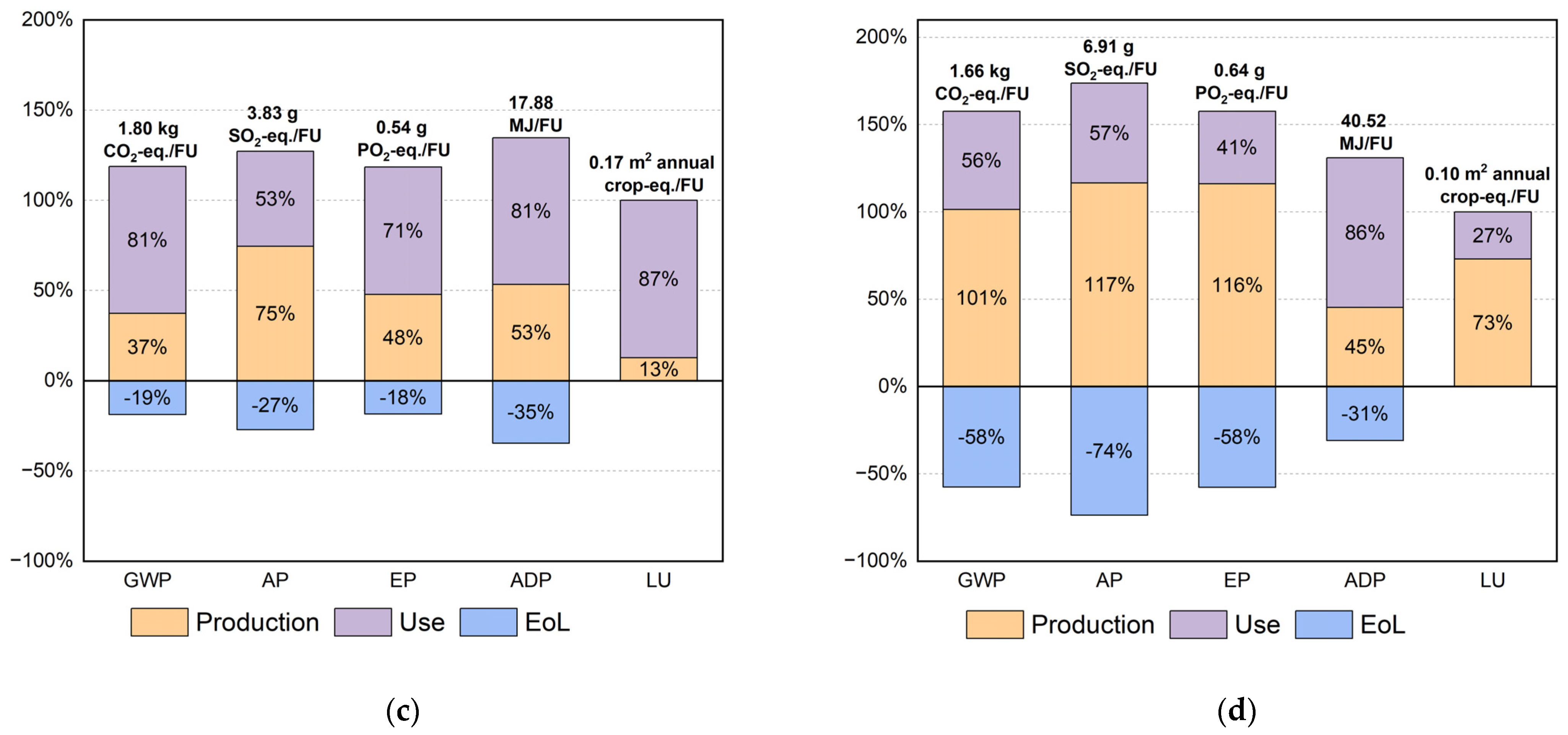

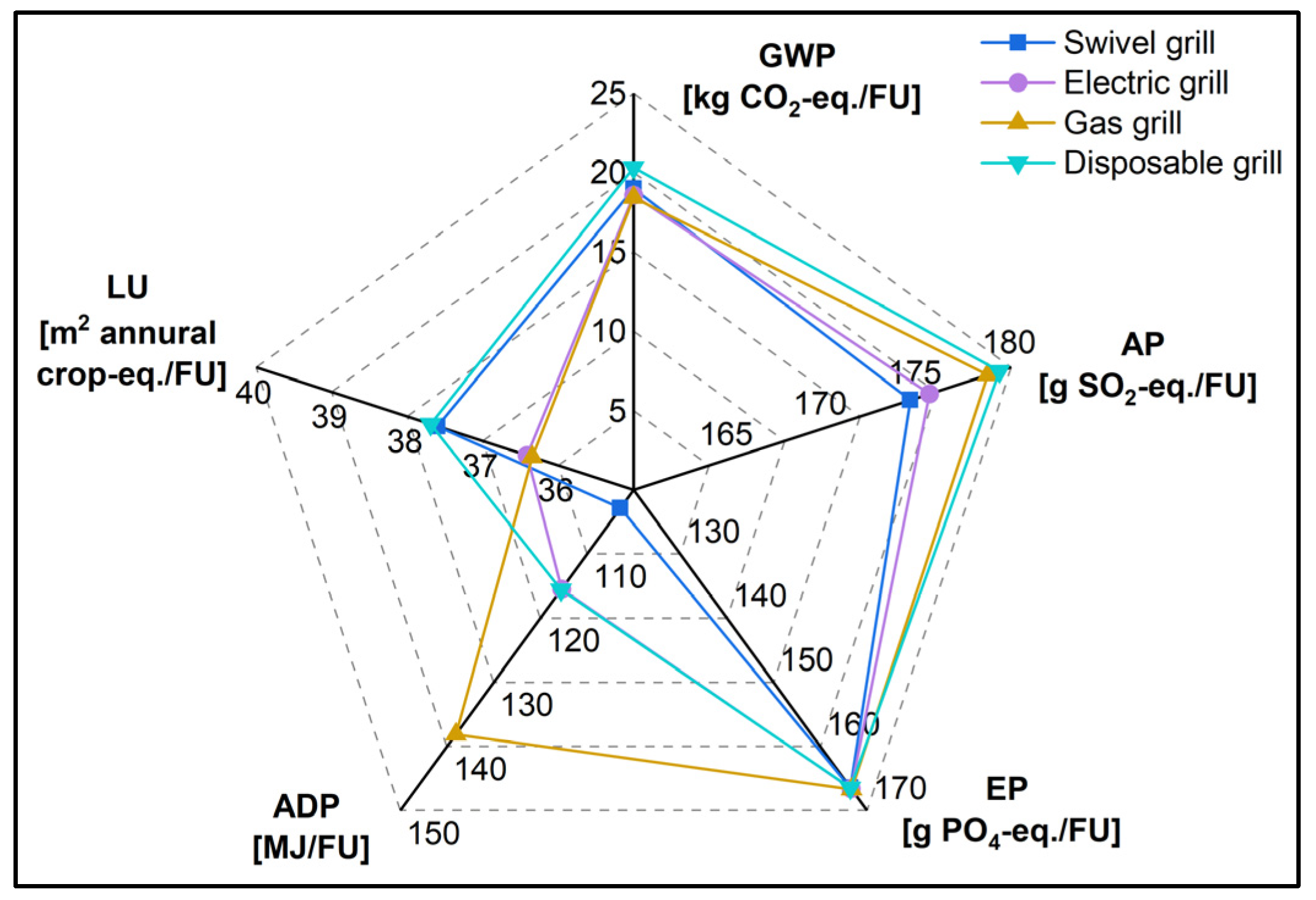

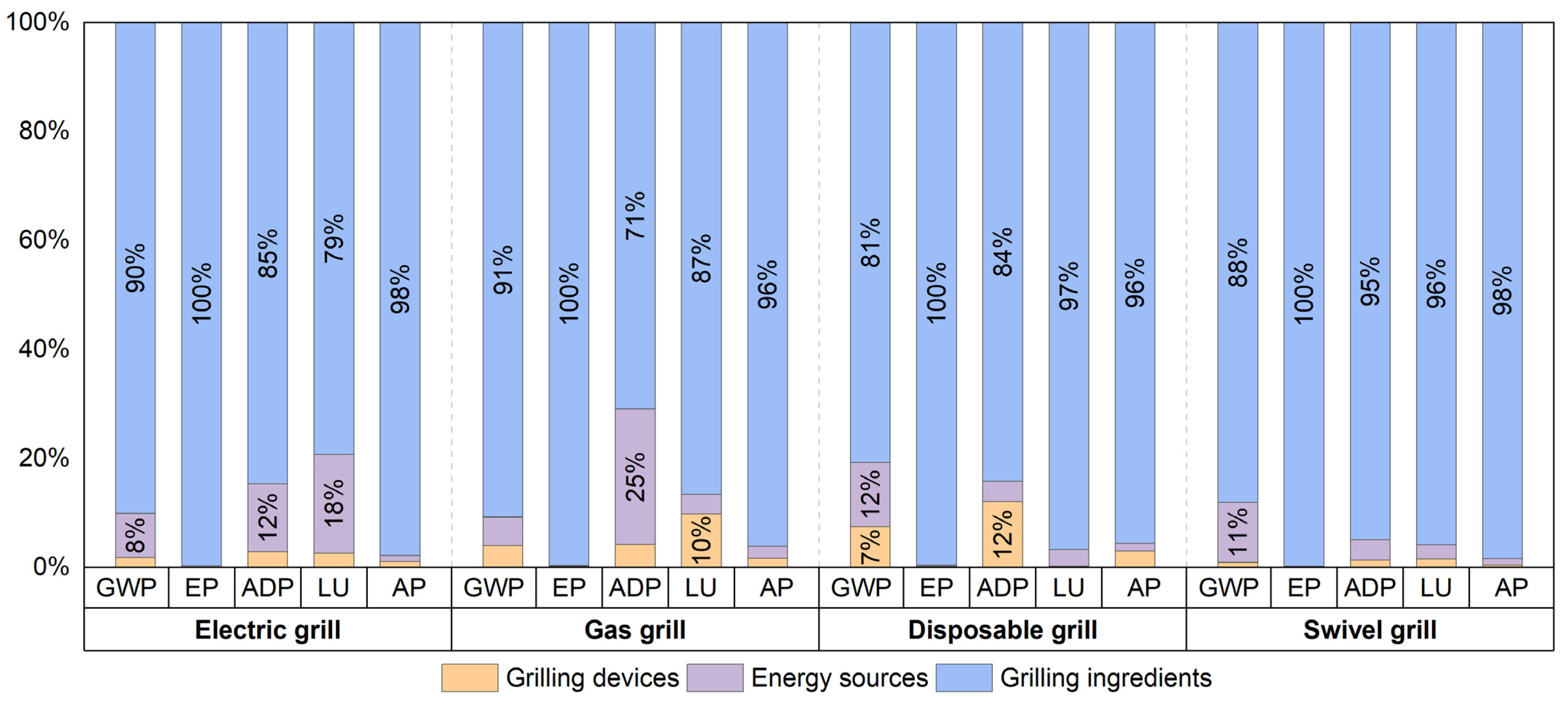

3.1. Emviromental Impacts of Grilling Devices

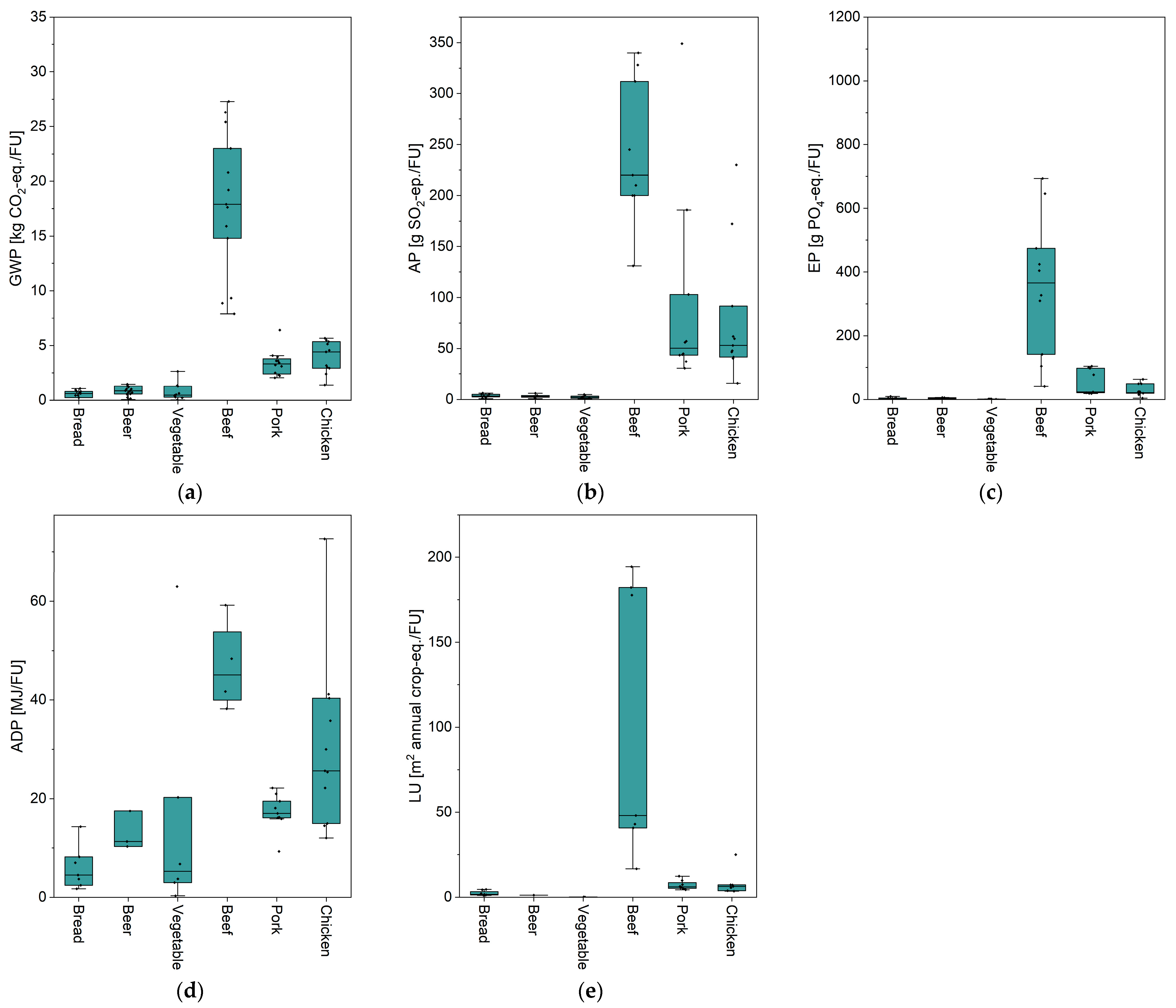

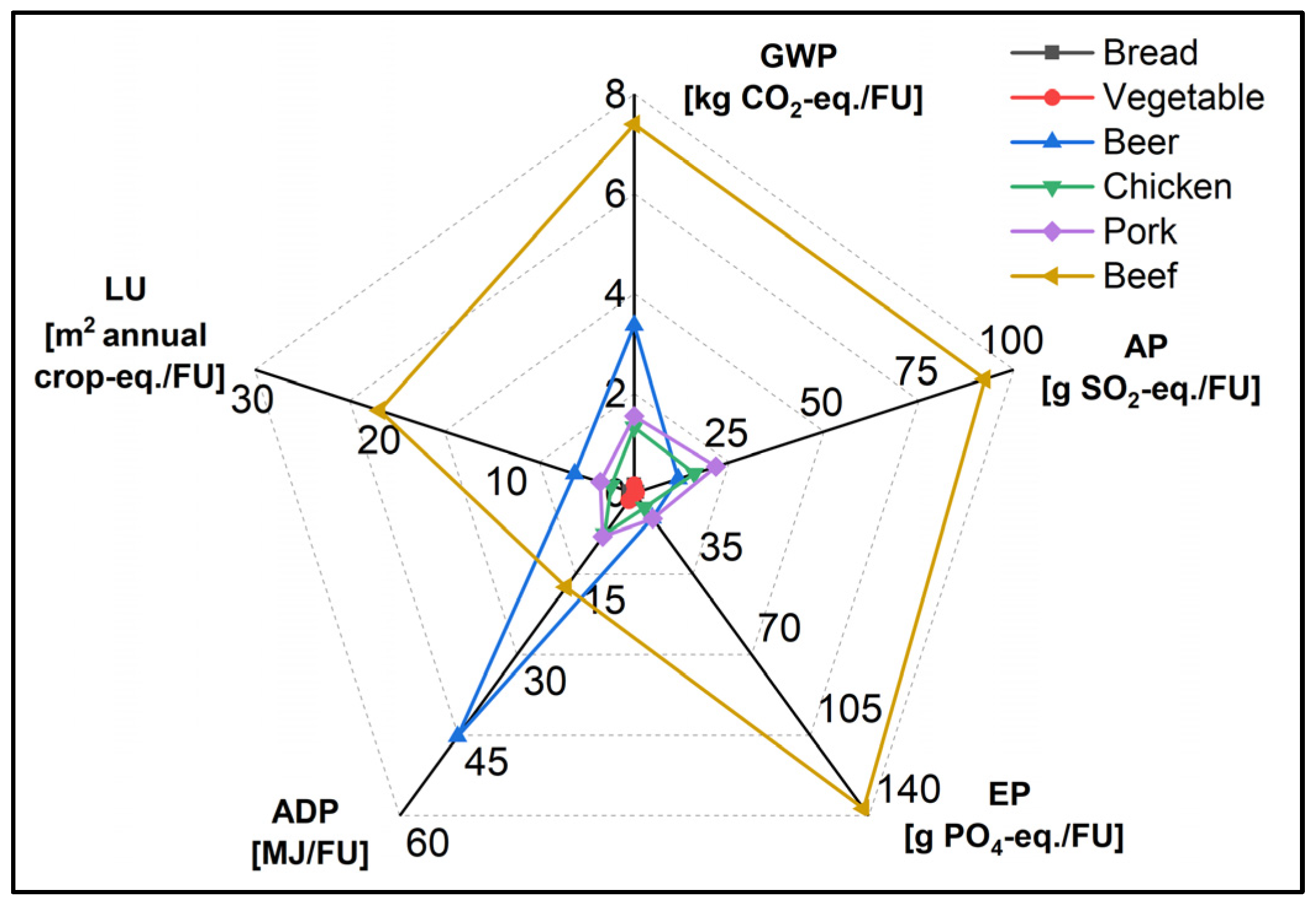

3.2. Emviromental Impacts of Grilling Ingredients

4. Discussion

4.1. Comparison of the Environmental Impacts of Grilling Ingredients

4.2. Comparison of the Environmental Impacts of Grilling Devices

4.3. Comparison of the Environmental Impacts of Different Barbecuing Types and Sectors

4.4. Comparison of the Environmental Impacts of Different Scenarios

4.5. Recommended Actions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Bill of Materials (BoM) for the Investigated Grilling Devices

| ID | Component | Count | Weight [g] | Material Matching in LCA Software |

|---|---|---|---|---|

| 1 | Lid | 1 | 1548 | Cast aluminum |

| 2.1 | Ceramic spacer | 2 | 16 | Ceramic |

| 2.2 | Plastic spacer | 2 | 14 | Polycarbonate |

| 3 | Handle | 1 | 73 | Polycarbonate |

| 4 | Cooking grate | 2 | 3478 | Cast iron |

| 5 | Heat element assembly | 1 | 456 | Stainless steel |

| 6 | Heat element support | 1 | 25 | Stainless steel |

| 7 | Controller bracket sleeve | 1 | 114 | Stainless steel |

| 8 | Temperature controller | 1 | 571 | Polycarbonate |

| 9 | Cook box | 1 | 1744 | Cast aluminum |

| 10 | Carrying handle | 2 | 256 | Polycarbonate |

| 11 | Rear cradle | 1 | 498 | Polycarbonate |

| 12 | Cradle logo | 1 | 19 | Polycarbonate |

| 13 | Front cradle | 1 | 476 | Polycarbonate |

| 14 | Disposable drip pan | 1 | 50 | Aluminum |

| 15 | Wire hanger | 1 | 57 | Stainless steel |

| 16 | Catch pan | 1 | 156 | Stainless steel |

| 17 | Plastic plate | 2 | 328 | Polycarbonate |

| 18 | Screw | 1 | 109 | Stainless steel |

| 19 | Steel foot | 4 | 1248 | Painted steel |

| 20 | Plastic frame | 1 | 1484 | Polycarbonate |

| 21 | Packaging | 1 | 2035 | Carton (83%) and plastic (17%) |

| Total | 29 | 14,755 |

| ID | Component | Count | Weight [g] | Material Matching in LCA Software |

|---|---|---|---|---|

| 1 | Upper support | 1 | 200 | Steel |

| 2 | Drive wheel | 1 | 35 | Steel |

| 3 | Leg holder | 1 | 166 | Steel |

| 4 | Upper leg | 1 | 152 | Painted steel |

| 5 | Middle leg | 5 | 740 | Painted steel |

| 6 | Bottom leg | 3 | 453 | Painted steel |

| 7 | Iron chain | 1 | 331 | Galvanized chain |

| 8 | Fire bowl | 1 | 1113 | Painted steel |

| 9 | Grill grate | 1 | 622 | Stainless steel |

| 10 | Thermal insulation board | 1 | 490 | Steel |

| 11 | Fire bowl legs | 3 | 206 | Steel |

| 12 | Screw | 24 | 57 | Stainless steel |

| 13 | Packaging | 1 | 735 | Carton (83%) and plastic (17%) |

| Total | 44 | 5300 |

| ID | Component | Count | Weight [g] | Material Matching in LCA Software |

|---|---|---|---|---|

| 1 | Flame cover TURBO ZONE | 0 | 0 | - |

| 2 | Flame cover | 2 | 602 | Stainless steel |

| 3 | Upper part (lid) | 1 | 6850 | Stainless steel |

| 4 | Grill grate | 3 | 2013 | Enameled cast iron |

| 5 | Side shelf suspension | 2 | 110 | Stainless steel |

| 6 | Side shelf | 2 | 3616 | Stainless steel |

| 7 | Side shelf suspension | 2 | 110 | Stainless steel |

| 8 | Control knob | 3 | 72 | Polycarbonate |

| 9 | Fat drawer | 1 | 200 | Stainless steel |

| 10 | Side part underframe left | 1 | 12,188 | Painted steel |

| 11–13 | Wheel axle, wheel, hub cap | 0 | 0 | - |

| 14 | Suspension grease drip tray | 1 | 20 | Stainless steel |

| 15 | Fat collection tray | 1 | 360 | Stainless steel |

| 16 | Front cross brace | 1 | Included in ID 10 | Painted steel |

| 17 | Door | 1 | Included in ID 10 | Painted steel |

| 18 | Lang gas bottle holder | 1 | Included in ID 10 | Painted steel |

| 19 | Gas bottle holder | 1 | Included in ID 10 | Painted steel |

| 20 | Door stoper | 1 | Included in ID 10 | Painted steel |

| 21 | Base plate | 1 | Included in ID 10 | Painted steel |

| 22 | Side part underframe right | 1 | Included in ID 10 | Painted steel |

| 23 | Roller with brake | 4 | 200 | Polycarbonate |

| 24 | Gas pressure regulator with hose | 1 | 145 | Stainless steel |

| 25 | Back wall base frame | 1 | Included in ID 10 | Painted steel |

| 26 | Heat shield with burner | 1 | Included in ID 10 | Painted steel |

| 27 | Side stove | 0 | 0 | - |

| 28 | Heat shield | 1 | Included in ID 10 | Painted steel |

| 29 | Side stove | 0 | 0 | - |

| 30 | Pot grate | 0 | 0 | - |

| 31 | Thermometer | 1 | 78 | Stainless steel |

| 32 | Hot grid | 1 | 744 | Stainless steel |

| 33 | Adjusting knob | 0 | 0 | - |

| Other components | ||||

| 1 | Back top layer | 1 | 1440 | Painted steel |

| 2 | Upper side wall frame left | 1 | 500 | Painted steel |

| 3 | Upper side wall frame right | 1 | 500 | Painted steel |

| 4 | Front upper frame | 1 | 1199 | Painted steel |

| 5 | Cover for lighter | 1 | 1326 | Painted steel |

| 6 | Lighter | 1 | 176 | Stainless steel |

| 7 | Burner | 1 | 689 | Stainless steel |

| 8 | Packaging | 1 | 5302 | Carton (83%) and plastic (17%) |

| Total | 44 | 38,440 | ||

| ID | Component | Count | Weight [g] | Material Matching in LCA Software |

|---|---|---|---|---|

| 1 | Grill grate | 1 | 230 | Chrome-plated steel |

| 2 | Back wall base frame | 2 | 110 | Stainless steel |

| 3 | Screw, 10 mm | 9 | 1 | Stainless steel |

| 4 | Screw, 20 mm | 3 | 2 | Stainless steel |

| 5 | Wingnut | 12 | 2 | Stainless steel |

| 6 | Plastic foot | 3 | 1 | Polycarbonate |

| 7 | Reinforcement | 1 | 63 | Painted steel |

| 8 | Holder | 3 | 69 | Painted steel |

| 9 | Sticker with warnings | 1 | n/a | Papier |

| 10 | Grill tray | 1 | 503 | Painted steel |

| 11 | Packaging | 1 | 157 | Carton (83%) and plastic (17%) |

| Total | 37 | 1138 |

| ID | Component | Count | Weight [g] | Material Matching in LCA Software |

|---|---|---|---|---|

| 1 | Top handle | 1 | 24 | Polycarbonate |

| 2 | Ventilation slider | 4 | 11 | Steel sheet |

| 4 | Lid | 1 | 1614 | Painted steel |

| 5 | Grill grate | 1 | 850 | Chrome-plated steel |

| 6 | Charcoal holder | 2 | 125 | Steel |

| 7 | Charcoal grate | 1 | 737 | Steel |

| 9 | Kettle | 1 | 3550 | Painted steel |

| 10 | Bottom handle | 1 | 24 | Polycarbonate |

| 11 | Ash tray | 1 | 149 | Aluminum |

| 12–13 | Support leg | 3 | 350 | Chrome-plated steel |

| 14 | Support leg cap | 1 | 2 | Polycarbonate |

| 15 | Mounting bracket | 3 | 5 | Steel |

| 16 | Wheel | 2 | 25 | Polycarbonate |

| 18 | Floor grid | 1 | 400 | Chrome-plated steel |

| Other components | ||||

| 1 | Washer | 3 | 2 | Galvanized steel |

| 2 | Screw | 3 | 6 | Steel |

| 3 | Screw stainless, thick | 2 | 7 | Stainless steel |

| 4 | Screw stainless, thin | 1 | 1 | Stainless steel |

| 5 | Nut | 2 | 1 | Aluminum |

| 6 | Washer upper handle | 1 | 112 | Chrome-plated steel |

| 7 | Packaging | 1 | 1275 | Carton (83%) and plastic (17%) |

| Total | 28 | 9246 | ||

| ID | Component | Count | Weight [g] | Material Matching in LCA Software |

|---|---|---|---|---|

| 1 | Steel grid | 1 | 44 | Stainless steel |

| 2 | Aluminum bowl | 1 | 91 | Aluminum |

| 3 | Plastic packaging | 1 | 4 | Polyethylene |

| 4 | Paper packaging | 1 | 81 | Paper |

| 5 | Charcoal | 1 | 430 | Charcoal |

| Total | 5 | 650 |

Appendix A.1. Disclaimer

Appendix B. Environmental Impacts of Grilling Ingredients

| Data Source | Method as Stated by the Authors | Production Scale | Cultivation | GWP [g CO2-eq./FU] | AP [g SO2-eq./FU] | EP [g PO4-eq./FU] | ADP/PED [MJ/FU] | LU [m2 Annual crop-eq./FU] |

|---|---|---|---|---|---|---|---|---|

| [56] | ReCiPe | Industrial bakery | - | 937 | 6.27 | (0.49) * | - | 2.1 |

| [57] | CML 2 baseline 2000 | Private household | Conv. | −501 | 5.14 | 4.22 | - | - |

| Industrial bakery | Conv. | −560 | 4.98 | 4.21 | - | - | ||

| [58] | Not specified | Private household | Conv. | 650 | 2.55 | 0.39 | 8.2 | 1.1 |

| Industrial bakery | Conv. | 450 | 2.50 | 0.39 | 4.5 | 1.1 | ||

| Private household | Org. | 440 | 1.00 | 0.09 | 7.0 | 1.7 | ||

| Industrial bakery | Org. | 230 | 0.80 | 0.09 | 3.7 | 1.7 | ||

| [59] | Not specified | Private household | Org. | 610 | - | - | 14.3 | 4.58 |

| [60] | PAS 2050 | Industrial bakery | Conv. | 1056 | - | - | - | - |

| [61] | Not specified | Industrial bakery | Conv. | 804 | 3.2 | 3.1 | 2.46 | 1.4 |

| Industrial bakery | Org. | 786 | 3.4 | 9.3 | 1.74 | 4.4 |

| Data Source | Method as Stated by the Authors | Production Scale | Plant Species | GWP [kg CO2-eq./FU] | AP [g SO2-eq./FU] | EP [g PO4-eq./FU] | ADP/PED [MJ/FU] | LU [m2 Annual crop-eq./FU] |

|---|---|---|---|---|---|---|---|---|

| [62] | PAS | Open land | Mixed | 0.3 | 0.9 | 1.0 | - | - |

| [63] | ReCiPe midpoint | Greenhouse | Lettuce | 0.43 | 1.75 | (0.3) ** | 6.75 | 0.1 |

| [64] | CML | Greenhouse | Lettuce | 0.5 | 2.5 | 1.1 | - | - |

| [65] | CML 2001 | Greenhouse | Lettuce | 2.64 | 4 | 0.75 | 63 | - |

| Open land | Lettuce | 0.27 | 2.5 | 0.875 | 3 | - | ||

| [66] | IPCC | Greenhouse | Lettuce | 1.28 | - | - | - | - |

| Open land | Lettuce | 0.63 | - | - | - | - | ||

| [67] | Not specified | Open land | Lettuce | 0.03 | 0.2 | 0.08 | 0.32 | - |

| Greenhouse | Lettuce | 0.21 | 1.35 | 0.28 | 3.74 | - |

| Data Source | Method as Stated by the Authors | Production Scale | Package | GWP [kg CO2-eq./FU] | AP [g SO2-eq./FU] | EP [g PO4-eq./FU] | ADP/PED [MJ/FU] | LU [m2 Annual crop-eq./FU] |

|---|---|---|---|---|---|---|---|---|

| [68] | Not specified | Large factory | - | 1.2 | 6.0 | 3.0 | - | 1.2 |

| [69] | PAS 2050 | Large factory | - | 1.27 | - | - | - | - |

| Small factory | - | 1.92 | - | - | - | - | ||

| [70] | CML 2001 | - | Glass (330 mL) | 0.842 | 3.85 | 2.72 | 17.5 | - |

| - | Aluminum (440 mL) | 0.575 | 2.92 | 2.42 | 11.3 | - | ||

| - | Steel (440 mL) | 0.510 | 2.13 | 2.39 | 10.3 | - | ||

| [71] | PAS 2050 | - | Glass (330 mL) | 0.74 | - | - | - | - |

| - | Glass (660 mL) | 0.57 | - | - | - | - | ||

| - | Aluminum (330 mL) | 0.69 | - | - | - | - | ||

| - | Steel (30 L) | 0.25 | - | - | - | - | ||

| [72] | GWP: IPCC 2013 GWP 100a AP, EP: ILCD 2011 Midpoint ADP: CML-IA baseline | Large factory | Glass | 0.87 | - | - | - | - |

| Small factory | Glass | 1.3 | - | - | - | - | ||

| [73] | PAS 2050 | Large factory | Glass (660 mL) | 1.032 | - | - | - | - |

| Large factory | PET (660 mL) | 1.015 | - | - | - | - | ||

| Small factory | Glass (660 mL) | 1.471 | - | - | - | - | ||

| Small factory | PET (660 mL) | 1.423 | - | - | - | - | ||

| [74] | CML 1992 | - | Returnable glass bottles (330 mL) | 0.05 | 0.78 | 6.06 | - | - |

| - | Disposable glass bottles (330 mL) | 0.14 | 3.03 | 5.15 | - | - |

| Data Source | Method as Stated by the Authors | Origin Calves | Production System * | Diet | GWP [kg CO2-eq./FU] | AP [g SO2-eq./FU] | EP [g PO4-eq./FU] | ADP/PED [MJ/FU] | LU [m2 Annual crop-eq./FU] |

|---|---|---|---|---|---|---|---|---|---|

| [75] | ReCiPe | Suckler | C/I | Concentrate | 23 | 328 | 40.9 | - | - |

| [76] | CML 2001 | Suckler | C/I | Concentrate | 14.8 | - | 104 | 38.2 | - |

| Suckler | C/I | Roughage | 19.2 | - | 142 | 48.4 | - | ||

| [46] | EP: EDIP LCA Food; all others: ReCiPe Midpoint | Suckler | O/E | Roughage | 25.41 | 220 | (1009.71) ** | - | 194.43 |

| Suckler | O/E | Roughage | 26.3 | 200 | (861.71) ** | - | 177.71 | ||

| Suckler | C/I | Concentrate | 17.62 | 200 | (779.27) ** | - | 40.67 | ||

| [48] | Not specified | Suckler | O/E | Roughage | 27.3 | 210 | (1651) ** | 59.2 | 42.9 |

| Dairy | C/I | Roughage | 17.9 | 131 | (737) ** | 41.7 | 16.7 | ||

| [77] | Not specified | Dairy | N.A. | Concentrate | 7.9 | - | - | - | - |

| Dairy | N.A. | Roughage | 15.9 | - | - | - | - | ||

| [78] *** | Not specified | Dairy | C/I | N.A. | 20.81 | 312 | - | - | - |

| [79] *** | ReCiPe midpoint | Dairy | O/E | N.A. | 9.34 | 340 | (490) **** | - | 118 |

| - | C/I | N.A. | 8.86 | 245 | (360) **** | - | 48 | ||

| [61] | Not specified | Dairy | O/E | N.A. | 18.2 | 711 | 326 | 18.1 | - |

| Data Source | Method as Stated by the Authors | Country of Origin | GWP [kg CO2-eq./FU] | AP [g SO2-eq./FU] | EP [g PO4-eq./FU] | ADP/PED [MJ/FU] | LU [m2 Annual crop-eq./FU] |

|---|---|---|---|---|---|---|---|

| [80] | IPCC | - | 3.6 | - | - | - | - |

| [81] | EDIP | DK | 3.6 | 45 | (147) * | - | - |

| [82] | Not specified | SE | 4.08 | 52 | - | 16.1 | 12.34 |

| [83] | Not specified | FR | 2.3 | 43.5 | 20.8 | 15.9 | 5.43 |

| 3.97 | 37.2 | 21.6 | 22.2 | 9.87 | |||

| [61] | Not specified | UK | 6.4 | 349 | 100 | 17 | 7.4 |

| [84] | ReCiPe Midpoint | ES | 3.42 | 186 | (19.5) ** | - | 4.96 |

| [85] | CML 2 Baseline 2000 | DE | 3.22 | 57.1 | 23.3 | 19.5 | - |

| [86] | CML 2001 | EU | 2.25 | 44 | 19.0 | 16.2 | - |

| [87] | Not specified | NL | 2.5 | - | - | 18.1 | 4.4 |

| Data Source | Method | Country of Origin | Comment | GWP [kg CO2-eq./FU] | AP [g SO2-eq./FU] | EP [g PO4-eq./FU] | ADP/PED [MJ/FU] | LU [m2 Annual crop-eq./FU] |

|---|---|---|---|---|---|---|---|---|

| [61] | Not specified | UK | Conv. | 4.57 | 172 | 49 | 12 | 6.4 |

| Free-range | 5.48 | 230 | 63 | 14.5 | 7.3 | |||

| [88] | CML | UK | Conv. | 4.41 | 46.75 | 20.31 | 25.37 | 5.6 |

| Free-range | 5.13 | 59.73 | 24.26 | 25.65 | 7.2 | |||

| Org. | 5.66 | 91.55 | 48.82 | 40.34 | 25 | |||

| [89] | CML 2 Baseline 2000 | IR | Summer | 2.93 | 41.75 | 14.69 | 41.16 | - |

| Winter | 5.35 | 61.9 | 19.34 | 72.63 | - | |||

| [90] | CML 2 Baseline 2000 | US | Conv. | 1.40 | 15.8 | 3.9 | 14.96 | - |

| [91] | CML 2001 | PT | Conv. | 3.0 | 53.1 | 24.6 | 22.2 | - |

| [92] | CML 2 Baseline 2000 | FR | Conv. | 3.17 | 40.5 | 21.0 | 30.0 | 3.82 |

| BR | Conv. | 2.40 | 47.9 | 20.7 | 35.8 | 3.56 |

References

- brandlogistics.net. GFK-Studie: Der Grillmarkt in 2020. Available online: https://www.brandlogistics.net/gfk-studie-der-grillmarkt-in-2020 (accessed on 31 July 2023).

- Reale, F.; Castellani, V.; Hischier, R.; Corrado, S.; Sala, S. Consumer Footprint: Basket of Products Indicator on Household Appliances; European Commission, Joint Research Centre, Publication Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Favi, C.; Germani, M.; Landi, D.; Mengarelli, M.; Rossi, M. Comparative life cycle assessment of cooking appliances in Italian kitchens. J. Clean. Prod. 2018, 186, 430–449. [Google Scholar] [CrossRef]

- Landi, D.; Consolini, A.; Germani, M.; Favi, C. Comparative life cycle assessment of electric and gas ovens in the Italian context: An environmental and technical evaluation. J. Clean. Prod. 2019, 221, 189–201. [Google Scholar] [CrossRef]

- Hischier, R.; Reale, F.; Castellani, V.; Sala, S. Environmental impacts of household appliances in Europe and scenarios for their impact reduction. J. Clean. Prod. 2020, 267, 121952. [Google Scholar] [CrossRef] [PubMed]

- Grignon-Masse, L.; Riviere, P.; Adnot, J. Strategies for reducing the environmental impacts of room air conditioners in Europe. Energy Policy 2011, 39, 2152–2164. [Google Scholar] [CrossRef]

- Ma, J.; Yin, F.; Liu, Z.; Zhou, X. The eco-design and green manufacturing of a refrigerator. Procedia Environ. Sci. 2012, 16, 522–529. [Google Scholar] [CrossRef]

- Spiegel. Verkaufszahlen von Fernsehern Gehen Deutlich Zurück. Available online: https://www.spiegel.de/netzwelt/gadgets/fernseher-verkaeufe-nach-coronaboom-sinkt-die-nachfrage-a-ee09c398-a9c7-45ed-b0e4-9156acc1e108 (accessed on 31 July 2023).

- Johnson, E. Charcoal versus LPG grilling: A carbon-footprint comparison. Environ. Impact Assess. Rev. 2009, 29, 370–378. [Google Scholar] [CrossRef]

- Johnson, E.; Gafford, A. USA Carbon Footprints of Grills, by Fuel & Grill Type. Fuels 2022, 3, 475–485. [Google Scholar] [CrossRef]

- TÜV Rheinland. Klimaoptimiertes Grillen Entlastet die Umwelt. Available online: https://kritisches-netzwerk.de/forum/oekobilanz-von-tuev-rheinland-klimaoptimiertes-grillen-entlastet-die-umwelt (accessed on 2 June 2023).

- Statista. Was Trinken Sie in der Regel zum Grillen? Available online: https://de.statista.com/statistik/daten/studie/719644/umfrage/beliebteste-getraenke-beim-grillen-in-deutschland/ (accessed on 16 August 2023).

- Sphera. Managed LCA Content (Formerly Known As GaBi Data): CUP2023.1; Sphera: Salt Lake City, UT, USA, 2023. [Google Scholar]

- Sphera. LCA for Experts, Version 10.6.1.35; Sphera: Leinfelden-Echterdingen, Germany, 2023. [Google Scholar]

- Afrane, G.; Ntiamoah, A. Comparative life cycle assessment of charcoal, biogas, and liquefied petroleum gas as cooking fuels in Ghana. J. Ind. Ecol. 2011, 15, 539–549. [Google Scholar] [CrossRef]

- SimaPro. Meet the Developer: PRé Sustainability. Available online: https://simapro.com/about/about-pre/ (accessed on 4 June 2023).

- Sphera. GaBi Databases & Modeling Principles 2021. Available online: https://sphera.com/wp-content/uploads/2020/04/Modeling-Principles-GaBi-Databases-2021.pdf (accessed on 5 June 2023).

- ISO 14040:1997; Environmental Management-Life Cycle Assessment-Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 1997.

- ISO 14040:2006/Amd 1:2020; Environmental Management: Life Cycle Assessment-Principles and Framework-Amendment 1. International Organization for Standardization: Geneva, Switzerland, 2020.

- Davis, S.J.; Caldeira, K. Consumption-based accounting of CO2 emissions. Proc. Natl. Acad. Sci. USA 2010, 107, 5687–5692. [Google Scholar] [CrossRef]

- Hoekstra, A.Y.; Mekonnen, M.M. The water footprint of humanity. Proc. Natl. Acad. Sci. USA 2012, 109, 3232–3237. [Google Scholar] [CrossRef]

- Wiedmann, T.O.; Schandl, H.; Lenzen, M.; Moran, D.; Suh, S.; West, J.; Kanemoto, K. The material footprint of nations. Proc. Natl. Acad. Sci. USA 2015, 112, 6271–6276. [Google Scholar] [CrossRef] [PubMed]

- Stadler, K.; Wood, R.; Bulavskaya, T.; Södersten, C.-J.; Simas, M.; Schmidt, S.; Usubiaga, A.; Acosta-Fernández, J.; Kuenen, J.; Bruckner, M. EXIOBASE 3: Developing a time series of detailed environmentally extended multi-regional input-output tables. J. Ind. Ecol. 2018, 22, 502–515. [Google Scholar] [CrossRef]

- Sala, S.; Castellani, V. The consumer footprint: Monitoring sustainable development goal 12 with process-based life cycle assessment. J. Clean. Prod. 2019, 240, 118050. [Google Scholar] [CrossRef]

- gfu. Welchen Grilltyp Ziehen Sie vor? Available online: https://de.statista.com/statistik/daten/studie/1244014/umfrage/umfrage-zur-bevorzugten-grillart-deutschland-grossbritannien/ (accessed on 12 June 2023).

- POSpulse. Welche Lebensmittel Dürfen Beim Grillen Nicht Fehlen? Available online: https://de.statista.com/statistik/daten/studie/1055922/umfrage/bevorzugte-lebensmittel-beim-grillen/ (accessed on 28 May 2023).

- VuMA. Bevölkerung in Deutschland nach Häufigkeit von Grillen bzw. Barbecue in der Freizeit von 2017 bis 2021. Available online: https://de.statista.com/statistik/daten/studie/247175/umfrage/haeufigkeit-des-wanderns-in-der-freizeit/ (accessed on 5 June 2023).

- Stephan, L.; Ute, S.; Sabine, B. Analyse der Datenerhebungen nach ElektroG und UStatG über das Berichtsjahr 2018 zur Vorbereitung der EU-Berichtspflichten 2020; Umweltbundesamt: Berlin, Germany, 2020. [Google Scholar]

- Aufgetischt.net. Grill & BBQ Studie 2019/20. Available online: https://www.aufgetischt.net/grillstudie/ (accessed on 5 June 2023).

- Boeser-Wolf. Wozu Kann Man Baguette Essen. Available online: https://www.boeser-wolf.schule.de/frankreich-fuer-kinder/restaurant/reportage/brot.html (accessed on 7 June 2023).

- Keramikgrill. Grillen für Viele Personen: Tipps für Die Entspannte Grillparty. Available online: https://www.keramikgrills.com/ratgeber/grillen-fuer-viele-personen/ (accessed on 7 June 2023).

- Statista. Grillen & Outdoor Cooking 2017. Available online: https://de.statista.com/statistik/studie/id/47908/dokument/tabellenband-grillen-und-outdoor-cooking-2017/ (accessed on 5 June 2023).

- Swissmilk. Grillparty: Welche Mengen pro Person? Available online: https://www.swissmilk.ch/de/rezepte-kochideen/tipps-tricks/grillparty-welche-mengen-pro-person/ (accessed on 7 June 2023).

- Abdel-Shafy, H.I.; Mansour, M.S.M. A review on polycyclic aromatic hydrocarbons: Source, environmental impact, effect on human health and remediation. Egypt. J. Pet. 2016, 25, 107–123. [Google Scholar] [CrossRef]

- Liesegang, C.; Aleysa, M.; Mathias, B.; Pillhofer, T.; Alfred, T. Charakterisierung von Emissionen aus Holzkohlegrills und ihr Einfluss auf die Luftqualität. UMID Umw. Mensch Inf. 2021, 2, 27–38. [Google Scholar]

- Nguyen, T.L.; Hermansen, J.E.; Mogensen, L. Environmental Assessment of Danish Pork; Aarhus University: Aarhus, Denmark, 2011. [Google Scholar]

- Juha-Matti, K. Experiences and improvement possibilities: LCA case study of broiler chicken production. In Proceedings of the 3rd International Conference on Life Cycle Management, Zurich, Germany, 27–29 August 2007. [Google Scholar]

- Cimini, A.; Moresi, M. Environmental impact of the main household cooking systems: A survey. Ital. J. Food Sci. 2022, 34, 86–113. [Google Scholar] [CrossRef]

- Guinée, J.B. Handbook on life cycle assessment: Operational guide to the ISO standards. Int. J. Life Cycle Assess. 2001, 6, 255. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Britta, B.; Corinna, E.; Harald, E.; Sören, H.; Marius, K.; Carlolin, K. Deutschland Rohstoffsituationsbericht 2021; Bundesanstalt für Geowissenschaften und Rohstoffe: Hannover, Germany, 2022. [Google Scholar]

- Yellishetty, M.; Mudd, G.M.; Ranjith, P.G.; Tharumarajah, A. Environmental life-cycle comparisons of steel production and recycling: Sustainability issues, problems and prospects. Environ. Sci. Policy 2011, 14, 650–663. [Google Scholar] [CrossRef]

- Johnson, J.; Reck, B.K.; Wang, T.; Graedel, T.E. The energy benefit of stainless steel recycling. Energy Policy 2008, 36, 181–192. [Google Scholar] [CrossRef]

- Noleppa, S.; Cartsburg, M. Nahrungsmittelverbrauch und Fußabdrücke des Konsums in Deutschland; WWF: Berlin, Germany, 2015. [Google Scholar]

- Scherhaufer, S.; Schuller, H.; Leverenz, D. Ermittlung der Weggeworfenen Lebensmittelmengen und Vorschläge zur Verminderung der Wegwerfrate bei Lebensmitteln in Deutschland; Bundesministerium für Ernährung und Landwirtschaft (BMEL): Stuttgart, Germany, 2012. [Google Scholar]

- Bragaglio, A.; Napolitano, F.; Pacelli, C.; Pirlo, G.; Sabia, E.; Serrapica, F.; Serrapica, M.; Braghieri, A. Environmental impacts of Italian beef production: A comparison between different systems. J. Clean. Prod. 2018, 172, 4033–4043. [Google Scholar] [CrossRef]

- de Vries, M.; de Boer, I.J.M. Comparing environmental impacts for livestock products: A review of life cycle assessments. Livest. Sci. 2010, 128, 1–11. [Google Scholar] [CrossRef]

- Nguyen, T.L.T.; Hermansen, J.E.; Mogensen, L. Environmental consequences of different beef production systems in the EU. J. Clean. Prod. 2010, 18, 756–766. [Google Scholar] [CrossRef]

- Andreas, G.; Viola, I.; Miretti, S.; Macchi, E.; Perona, G.; Battaglini, L.M.; Baratta, M. A New Approach to LCA Evaluation of Lamb Meat Production in Two Different Breeding Systems in Northern Italy. Front. Vet. Sci. 2020, 7, 651. [Google Scholar]

- Geß, A.; Hazar Kalonya, D. Sustainable Husbandry?—A Comparative LCA of Three Lamb Breeding Systems in Turkey. Circ. Econ. Sustain. 2023, 3, 1769–1791. [Google Scholar] [CrossRef] [PubMed]

- Geß, A.; Tolsdorf, A.; Ko, N. A life cycle perspective of lamb meat production systems from Turkey and the EU. Small Rumin. Res. 2022, 208, 106637. [Google Scholar] [CrossRef]

- Koroneos, C.; Roumbas, G.; Gabari, Z.; Papagiannidou, E.; Moussiopoulos, N. Life cycle assessment of beer production in Greece. J. Clean. Prod. 2005, 13, 433–439. [Google Scholar] [CrossRef]

- Rasines, L.; Morera, S.; San Miguel, G.; Artés-Hernández, F.; Aguayo, E. Environmental and economic sustainability of fresh-cut and pre-cooked vegetables. Sci. Total Environ. 2023, 872, 162169. [Google Scholar] [CrossRef]

- UNECE. Life Cycle Assessment of Electricity Generation Options; UNECE: New York, NY, USA, 2021. [Google Scholar]

- McDonald, J.D.; Zielinska, B.; Fujita, E.M.; Sagebiel, J.C.; Chow, J.C.; Watson, J.G. Emissions from charbroiling and grilling of chicken and beef. J. Air Waste Manag. Assoc. 2003, 53, 185–194. [Google Scholar] [CrossRef]

- Korsaeth, A.; Jacobsen, A.Z.; Roer, A.-G.; Henriksen, T.M.; Sonesson, U.; Bonesmo, H.; Skjelvåg, A.O.; Strømman, A.H. Environmental life cycle assessment of cereal and bread production in Norway. Acta Agric. Scand. Sect. A–Anim. Sci. 2012, 62, 242–253. [Google Scholar] [CrossRef]

- Bimpeh, M.; Djokoto, E.; Doe, H.; Jequier, R. Life Cycle Assessment (LCA) of the Production of Homemade and Industrial Bread in Sweden; Life Cycle Assessment Course (1N1800); KTH: Stockholm, Sweden, 2006. [Google Scholar]

- Braschkat, J., Patyk, A., Quirin, M., Reinhardt, G.A., Eds.; Life cycle assessment of bread production: A comparison of eight different scenarios. In Proceedings of the 4th International Conference on “Life Cycle Assessment in the Agrifood Sector”, Horsens, Denmark, 6–8 October 2004. [Google Scholar]

- Michal, K.; Thomas, N.; Emmanuel, F.; Gerard, G. (Eds.) Ecodesign opportunities for a farmer’s bread: Two case studies from north-western France. In Proceedings of the 8th Conference on LCA in the Agri-Food Sector, Saint-Malo, France, 1–4 October 2012. [Google Scholar]

- Jensen, J.K.; Arlbjørn, J.S. Product carbon footprint of rye bread. J. Clean. Prod. 2014, 82, 45–57. [Google Scholar] [CrossRef]

- Williams, A.; Audsley, E.; Sandars, D. Determining the Environmental Burdens and Resource Use in the Production of Agricultural and Horticultural Commodities: Defra Project Report IS0205; Cranfield University and Defra: Bedford, UK, 2006. [Google Scholar]

- Kashyap, D.; de Vries, M.; Pronk, A.; Adiyoga, W. Environmental impact assessment of vegetable production in West Java, Indonesia. Sci. Total Environ. 2023, 864, 160999. [Google Scholar] [CrossRef]

- Frankowska, A.; Jeswani, H.K.; Azapagic, A. Environmental impacts of vegetables consumption in the UK. Sci. Total Environ. 2019, 682, 80–105. [Google Scholar] [CrossRef] [PubMed]

- Perrin, A.; Basset-Mens, C.; Gabrielle, B. Life cycle assessment of vegetable products: A review focusing on cropping systems diversity and the estimation of field emissions. Int. J. Life Cycle Assess. 2014, 19, 1247–1263. [Google Scholar] [CrossRef]

- i Canals, L.M.; Muñoz, I.; Hospido, A.; Plassmann, K.; McLaren, S.; Edwards-Jones, G.; Hounsome, B. Life Cycle Assessment (LCA) of Domestic vs. Imported Vegetables: Case Studies on Broccoli, Salad Crops and Green Beans; University of Surrey: Guildford, UK, 2008. [Google Scholar]

- Foteinis, S.; Chatzisymeon, E. Life cycle assessment of organic versus conventional agriculture: A case study of lettuce cultivation in Greece. J. Clean. Prod. 2016, 112, 2462–2471. [Google Scholar] [CrossRef]

- Romero-Gámez, M.; Audsley, E.; Suárez-Rey, E.M. Life cycle assessment of cultivating lettuce and escarole in Spain. J. Clean. Prod. 2014, 73, 193–203. [Google Scholar] [CrossRef]

- Poore, J.; Nemecek, T. Reducing food’s environmental impacts through producers and consumers. Science 2018, 360, 987–992. [Google Scholar] [CrossRef] [PubMed]

- Cimini, A.; Moresi, M. Mitigation measures to minimize the cradle-to-grave beer carbon footprint as related to the brewery size and primary packaging materials. J. Ind. Ecol. 2018, 236, 1–8. [Google Scholar] [CrossRef]

- Amienyo, D.; Azapagic, A. Life cycle environmental impacts and costs of beer production and consumption in the UK. Int. J. Life Cycle Assess. 2016, 21, 492–509. [Google Scholar] [CrossRef]

- Cimini, A.; Moresi, M. Carbon footprint of a pale lager packed in different formats: Assessment and sensitivity analysis based on transparent data. J. Clean. Prod. 2016, 112, 4196–4213. [Google Scholar] [CrossRef]

- Morgan, D.R.; Styles, D.; Lane, E.T. Thirsty work: Assessing the environmental footprint of craft beer. Sustain. Prod. Consum. 2021, 27, 242–253. [Google Scholar] [CrossRef]

- Cimini, A.; Moresi, M. Effect of brewery size on the main process parameters and cradle-to-grave carbon footprint of lager beer. J. Ind. Ecol. 2018, 22, 1139–1155. [Google Scholar] [CrossRef]

- Mata, T.M.; Costa, C.A.V. Life cycle assessment of different reuse percentages for glass beer bottles. Int. J. Life Cycle Assess. 2001, 6, 307–319. [Google Scholar] [CrossRef]

- Lupo, C.D.; Clay, D.E.; Benning, J.L.; Stone, J.J. Life-cycle assessment of the beef cattle production system for the northern great plains, USA. J. Environ. Qual. 2013, 42, 1386–1394. [Google Scholar] [CrossRef]

- Pelletier, N.; Pirog, R.; Rasmussen, R. Comparative life cycle environmental impacts of three beef production strategies in the Upper Midwestern United States. Agric. Syst. 2010, 103, 380–389. [Google Scholar] [CrossRef]

- McAuliffe, G.A.; Takahashi, T.; Lee, M.R.F. Framework for life cycle assessment of livestock production systems to account for the nutritional quality of final products. Food Energy Secur. 2018, 7, e00143. [Google Scholar] [CrossRef] [PubMed]

- Asem-Hiablie, S.; Battagliese, T.; Stackhouse-Lawson, K.R.; Alan Rotz, C. A life cycle assessment of the environmental impacts of a beef system in the USA. Int. J. Life Cycle Assess. 2019, 24, 441–455. [Google Scholar] [CrossRef]

- Huerta, A.R.; Güereca, L.P.; Lozano, M. Environmental impact of beef production in Mexico through life cycle assessment. Resour. Conserv. Recycl. 2016, 109, 44–53. [Google Scholar] [CrossRef]

- Reckmann, K.; Traulsen, I.; Krieter, J. Environmental Impact Assessment: Methodology with special emphasis on European pork production. J. Environ. Manag. 2012, 107, 102–109. [Google Scholar] [CrossRef] [PubMed]

- Dalgaard, R.; Halberg, N.; Hermansen, J.E. Danish Pork Production: An Environmental Assessment; University of Aarhus: Aarhus, Denmark, 2007. [Google Scholar]

- Cederberg, C. Environmental Assessment of Future Pig Farming Systems: Quantifications of Three Scenarios from the FOOD 21 Synthesis Work; SIK Institutet för Livsmedel och Bioteknik: Göteborg, Sweden, 2004. [Google Scholar]

- Basset-Mens, C.; van der Werf, H.M.G. Scenario-based environmental assessment of farming systems: The case of pig production in France. Agric. Ecosyst. Environ. 2005, 105, 127–144. [Google Scholar] [CrossRef]

- Noya, I.; Villanueva-Rey, P.; González-García, S.; Fernandez, M.D.; Rodriguez, M.R.; Moreira, M.T. Life Cycle Assessment of pig production: A case study in Galicia. J. Clean. Prod. 2017, 142, 4327–4338. [Google Scholar] [CrossRef]

- Reckmann, K.; Traulsen, I.; Krieter, J. Life Cycle Assessment of pork production: A data inventory for the case of Germany. Livest. Sci. 2013, 157, 586–596. [Google Scholar] [CrossRef]

- Dourmad, J.-Y.; Ryschawy, J.; Trousson, T.; Bonneau, M.; Gonzàlez, J.; Houwers, H.W.; Hviid, M.; Zimmer, C.; Nguyen, T.L.; Morgensen, L. Evaluating environmental impacts of contrasting pig farming systems with life cycle assessment. Animal 2014, 8, 2027–2037. [Google Scholar] [CrossRef] [PubMed]

- van Zanten, H.H.; Bikker, P.; Mollenhorst, H.; Meerburg, B.G.; de Boer, I.J. Environmental impact of replacing soybean meal with rapeseed meal in diets of finishing pigs. Animal 2015, 9, 1866–1874. [Google Scholar] [CrossRef] [PubMed]

- Leinonen, I.; Williams, A.G.; Wiseman, J.; Guy, J.; Kyriazakis, I. Predicting the environmental impacts of chicken systems in the United Kingdom through a life cycle assessment: Broiler production systems. Poult. Sci. 2012, 91, 8–25. [Google Scholar] [CrossRef] [PubMed]

- Kalhor, T.; Rajabipour, A.; Akram, A.; Sharifi, M. Environmental impact assessment of chicken meat production using life cycle assessment. Inf. Process. Agric. 2016, 3, 262–271. [Google Scholar] [CrossRef]

- Pelletier, N. Environmental performance in the US broiler poultry sector: Life cycle energy use and greenhouse gas, ozone depleting, acidifying and eutrophying emissions. Agric. Syst. 2008, 98, 67–73. [Google Scholar] [CrossRef]

- González-García, S.; Gomez-Fernández, Z.; Dias, A.C.; Feijoo, G.; Moreira, M.T.; Arroja, L. Life Cycle Assessment of broiler chicken production: A Portuguese case study. J. Clean. Prod. 2014, 74, 125–134. [Google Scholar] [CrossRef]

- Da Silva Junior, V.P.; Cherubini, E.; Soares, S.R. (Eds.) Comparison of Two Production Scenarios of Chickens Consumed in France. In Proceedings of the 8th Conference on LCA in the Agri-Food Sector, Saint-Malo, France, 1–4 October 2012. [Google Scholar]

| Grilling Ingredients | Quantity |

|---|---|

| Beef | 105 g |

| Pork | 120 g |

| Chicken | 75 g |

| Vegetables | 100 g |

| Bread | 70 g |

| Beer | 1 L |

| Impact Categories | Unit | Values |

|---|---|---|

| GWP | kg CO2-eq./kg | 2.71 |

| AP | g SO2-eq./kg | 2.66 |

| EP | g PO4-eq./kg | 0.384 |

| ADP | MJ/kg | 4.17 |

| LU | m2 annual crop-eq./kg | 1.84 |

| Scenarios | Grilling Device | Energy Consumption | Grilling Ingredient |

|---|---|---|---|

| Reference | Lifespan: 5 a Weight: 100% | Consumption quantity: 100% | Food waste: 20% 35% Beef 40% Pork 25% Chicken |

| S2—heavy grill, short lifespan | Lifespan: 2 a Weight: 120% | - | - |

| S3—high energy demand | - | Consumption quantity: 150% | - |

| S4—high food waste | - | - | Food waste: 30% |

| Worst-Case Scenario (=combination of S2 to S4) | Lifespan: 2 a Weight: 120% | Consumption quantity: 150% | Food waste: 30% |

| S5—lightweight grill, long lifespan | Lifespan: 10 a Weight: 80% | - | - |

| S6—low energy demand | - | Consumption quantity: 50% | - |

| S7—adapted diet | - | - | Without beef 60% Pork 40% Chicken |

| S8—no food waste | - | - | Food waste: 0% |

| Best-Case Scenario (=combination of S5 to S8) | Lifespan: 10 a Weight: 80% | Consumption quantity: 50% | Without beef 60% Pork 40% Chicken Food waste: 0% |

| Impact Categories | Unit | Swivel Grill | Round Grill | Kettle Grill | Disposable Charcoal Grill | Electric Grill | Gas Grill |

|---|---|---|---|---|---|---|---|

| GWP | kg CO2-eq./FU | 2.22 | 2.08 | 2.29 | 3.90 | 1.80 | 1.66 |

| AP | g SO2-eq./FU | 2.81 | 2.23 | 3.18 | 7.86 | 3.83 | 6.91 |

| EP | g PO4-eq./FU | 0.38 | 0.33 | 0.43 | 0.87 | 0.54 | 0.64 |

| ADP | MJ/FU | 5.26 | 4.05 | 6.13 | 18.53 | 17.88 | 40.52 |

| LU | m2 annual crop-eq./FU | 1.36 | 1.35 | 1.37 | 1.68 | 0.17 | 0.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, S.; Dorling, K.C.; Prenzel, T.M.; Albrecht, S. Grill and Chill: A Comprehensive Analysis of the Environmental Impacts of Private Household Barbecuing in Germany. Sustainability 2024, 16, 1041. https://doi.org/10.3390/su16031041

Geng S, Dorling KC, Prenzel TM, Albrecht S. Grill and Chill: A Comprehensive Analysis of the Environmental Impacts of Private Household Barbecuing in Germany. Sustainability. 2024; 16(3):1041. https://doi.org/10.3390/su16031041

Chicago/Turabian StyleGeng, Shaoran, Kevin Christopher Dorling, Tobias Manuel Prenzel, and Stefan Albrecht. 2024. "Grill and Chill: A Comprehensive Analysis of the Environmental Impacts of Private Household Barbecuing in Germany" Sustainability 16, no. 3: 1041. https://doi.org/10.3390/su16031041

APA StyleGeng, S., Dorling, K. C., Prenzel, T. M., & Albrecht, S. (2024). Grill and Chill: A Comprehensive Analysis of the Environmental Impacts of Private Household Barbecuing in Germany. Sustainability, 16(3), 1041. https://doi.org/10.3390/su16031041