Energy Efficiency Policies for Small and Medium-Sized Enterprises: A Review

Abstract

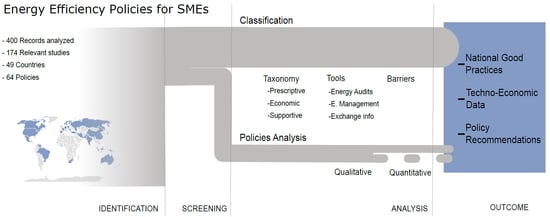

1. Introduction

- RQ1—What are the energy efficiency policies for small- and medium-sized enterprises reported in the open literature?

- RQ2—What is the quantitative and qualitative information available in terms of policy analysis?

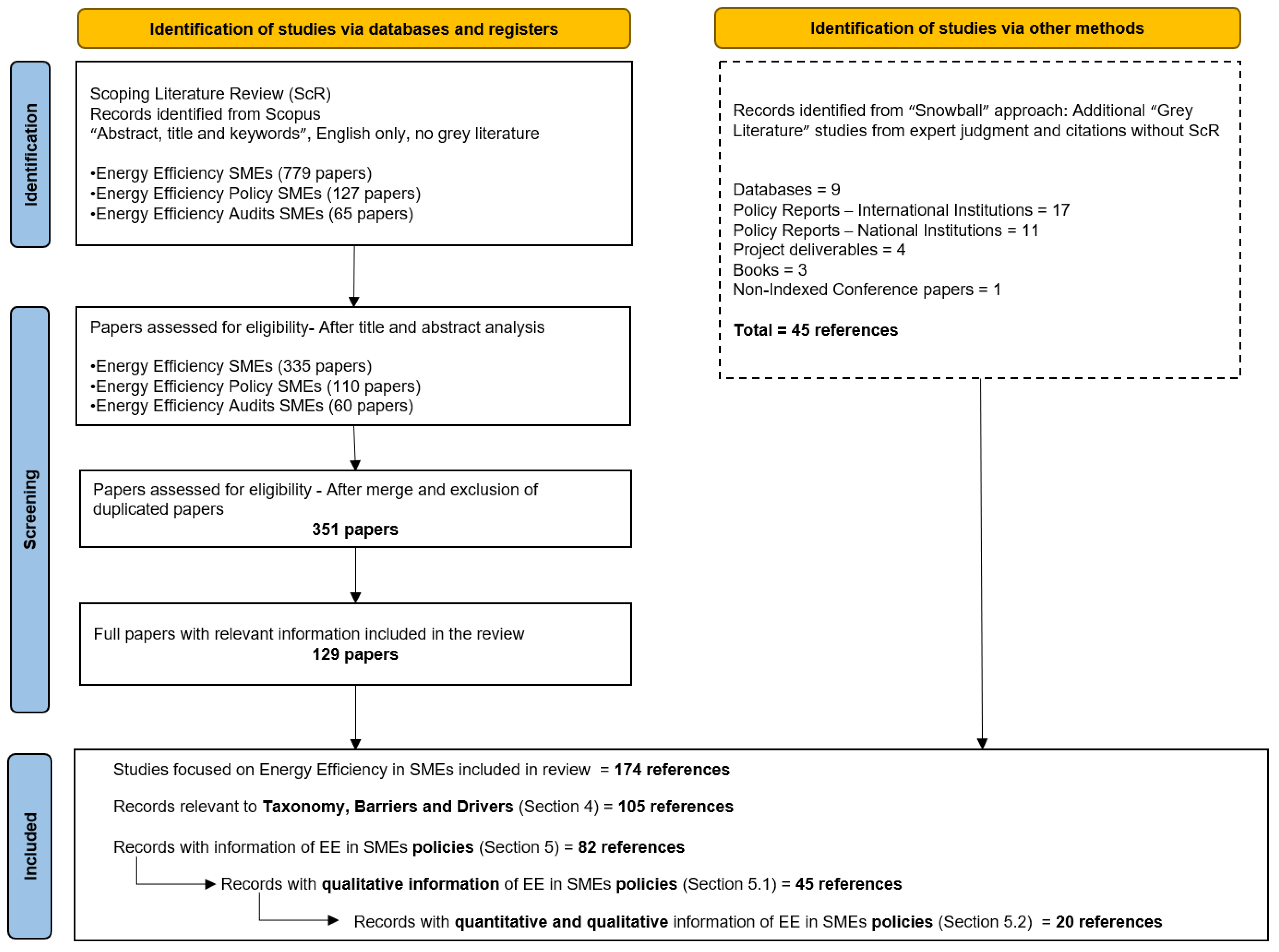

2. Materials and Methodology

- “Energy Efficiency SMEs”: “energy” AND “efficiency” AND (“smes” OR “sme”);

- “Energy Efficiency Policy SMEs”: “energy” AND “efficiency” AND (“smes” OR “sme”) AND (“policy” OR “policies”);

- “Energy Efficiency Audit SMEs”: “energy” AND “efficiency” AND (“smes” OR “sme”) AND “audits”.

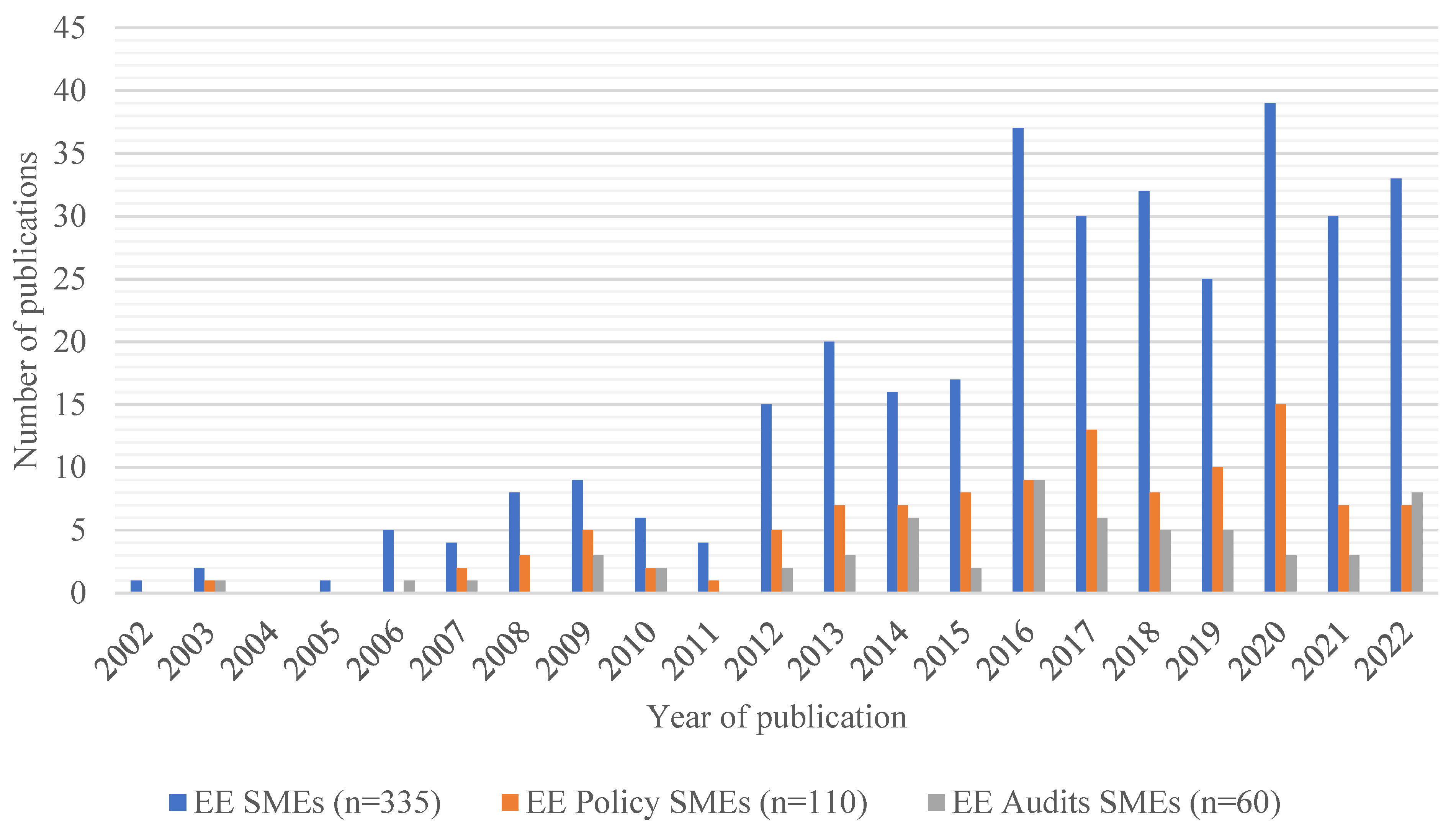

3. Bibliometric Analysis

4. Energy Efficiency Taxonomy

4.1. Framework for the Classification of Energy Efficiency Policies of Enterprises

- Prescriptive policies, orienting the behavior of companies with different modulations and stringencies; this category includes regulations, mandates and agreements.

- Economic policies, adjusting price signals and influencing cost effectiveness of energy efficiency actions; they are represented by tax reliefs, direct financial support, cap and-trade systems, and incentivized energy prices.

- Supportive policies, reinforcing the information basis for decision making and improving competences; these are tools for identifying energy efficiency opportunities, cooperation programs, capacity building, and information and technical assistance.

4.2. Policies for Energy Efficiency of SMEs

| Prescriptive Policies | Economic Policies | Supportive Policies | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Regulation on Equipment Process | Regulation on Energy Management | Negotiated Agreements | Energy Taxes | Energy Tax Reductions | Financial Incentives—Loans | Financial Incentives—Subsidies | Cap and Trade Scheme | Identification Opportunity | Cooperative Measures | Capacity Building | Publicity | Additional References | |

| Australia | X | e | x | e | p | x | x | x | x | [67,68,69,70,71] | |||

| Austria | X | x | x | x | x | x | x | [30,31,72] | |||||

| Belgium | X | x | x | x | x | x | x | x | x | [30,31,41,73,74,75,76] | |||

| Brazil | x | x | x | x | x | x | |||||||

| Canada | x | x | x | x | x | x | p | x | x | x | x | [50,77] | |

| Chile | x | x | x | x | x | ||||||||

| China | x | x | x | x | x | x | [45,50,55,78,79,80] | ||||||

| Czech Republic | x | x | x | x | x | x | x | e | [30,31] | ||||

| Denmark | x | x | x | x | x | x | x | [30,31,41,76,81] | |||||

| Finland | x | x | e | x | x | x | x | x | x | x | [30,31,44,81] | ||

| France | x | e | x | x | x | x | x | x | x | x | x | [30,31,56] | |

| Germany | x | x | x | x | x | x | x | x | x | x | x | [18,30,31,47,70,82,83,84,85,86] | |

| Greece | x | x | x | x | x | x | x | x | [30,31] | ||||

| Hungary | x | x | x | x | x | x | x | x | [30,31] | ||||

| India | x | x | x | x | x | e | x | x | |||||

| Indonesia | x | x | x | x | |||||||||

| Ireland | x | x | x | x | x | x | x | x | x | x | [30,31,41,53,87] | ||

| Italy | x | x | x | x | x | x | x | x | x | x | x | [30,31,52,58,62,88,89,90,91,92,93,94,95,96,97] | |

| Japan | x | x | x | x | x | x | x | x | x | [39,42,45,75,76,98] | |||

| Latvia | x | x | x | x | x | x | [30,31,43] | ||||||

| Lithuania | e | x | e | x | x | [30,31,99,100] | |||||||

| Luxembourg | x | x | x | x | x | x | [30,31] | ||||||

| Mexico | x | x | x | x | x | [101] | |||||||

| Netherlands | x | x | x | x | x | x | x | x | x | x | [30,31,38,41,64] | ||

| New Zealand | x | x | x | x | x | [50] | |||||||

| Norway | x | x | e | x | x | x | x | e | |||||

| Poland | x | x | x | x | x | x | [30,31,81] | ||||||

| Portugal | x | x | x | x | x | x | x | x | [30,31,102,103] | ||||

| Republic of Korea | x | x | x | x | p | x | x | [40,50,65] | |||||

| Russia | x | x | x | x | |||||||||

| Slovak Republic | x | x | x | x | x | x | x | x | x | [30,31] | |||

| South Africa | x | x | x | x | x | x | x | ||||||

| Spain | x | x | x | x | x | x | x | x | x | x | [30,31,41,75] | ||

| Sweden | x | x | x | x | x | e | x | x | x | x | [31,54,76,104,105,106,107,108,109,110] | ||

| Switzerland | x | x | x | x | x | x | e | [50] | |||||

| Turkey | x | x | x | x | x | x | x | ||||||

| UK | x | x | x | x | x | x | x | x | x | x | [30,31,37,88,111,112,113] | ||

| USA | x | x | x | x | p | x | x | x | x | [50,57,70,114,115,116,117,118] | |||

- Energy audits (EAs) focus on energy-intensive companies; development of support schemes for the implementation of EE measures included in EAs; availability of low-interest capital for investments in EPIAs; creation of one-stop shops also with the cooperation of key institutions.

- Energy management systems (EnMSs) involve step-by-step implementation support; advice and first certification support; specific sectoral guidance.

- Exchange of information involves the creation of regular structures for common exchange and follow-up for SMEs; increasing institutional support; using a mix of approaches to cover a broad range of SMEs.

4.3. Barriers to and Drivers of Energy Efficiency in SMEs

5. Review of Qualitative and Quantitative Studies on Energy Efficiency Policies for SMEs

5.1. Qualitative Studies on Energy Efficiency Policies for SMEs

| Country | Policy/Program | Type | Evaluation Period | Ref | Topic | #SMEs | Savings | Sector | Public CE | Barriers/ Drivers |

|---|---|---|---|---|---|---|---|---|---|---|

| Australia | Queensland Climate Smart Business Cluster Program | S | 2009–2011 | [67] | PE | Y | N | All sectors | N | Y |

| EEAP—Enterprise Energy Audit Program | E | 1991–1997 | [70] | PR | Y | N | Industry | N | Y | |

| EEAP—Enterprise Energy Audit Program | E | 1991–1997 | [71] | PE | N | N | Industry | N | Y | |

| No specific policy | O | 2012 | [68] | CS | Y | N a | Mainly services | N a | Y | |

| Austria | Klimaaktiv | S | 2008–2017 | [72] | PR | Y | Y | All sectors | N | N |

| Belgium | Different SME policies | V | 2008–2015 | [75] | PE | N | Y | All sectors | N | N |

| Policies to stimulate ESCO market | V | 2001–2015 | [76] | PR | N | N | Industry | N | N | |

| Various voluntary agreements | P | 2002–2020 | [41] | PR | N | Y | Industry | N | Y | |

| Bulgaria | OPIC—SME support scheme in Bulgaria | E | 2014–2020 | [157] | PE | Y | Y | All sectors | Y | Y |

| Denmark | Policies to stimulate ESCO market | V | 2001–2015 | [76] | PR | N | N | Industry | N | N |

| Several policies | V | 2010–2014 | [81] | PR | N | Y | All sectors | N | Y | |

| Agreement on industrial energy efficiency | P | 1993–2019 | [41] | PR | N | Y | EII | N | Y | |

| Finland | Several policies | V | 1992–2011 | [81] | PR | N | Y | All sectors | N | Y |

| Germany | LEEN and energy audit program for SMEs | S | 2009–2014 | [82] | PR | Y | N | Manufacturing | N | Y |

| LEEN—Learning Energy Efficiency Networks | S | 2009–2014 | [83] | PR | Y | Y | Manufacturing | N | Y | |

| Energy audit program for SMEs | E | 2008–2016 | [84] | CS | Y | N | All sectors | N | Y | |

| Energy audit program for SMEs | E | 2008–2017 | [70] | PR | Y | Y | All sectors | Y | Y | |

| Energy audit program for SMEs | E | 2008–2012 | [18] | PE | Y | Y | All sectors | Y | Y | |

| Energy audit program for SMEs | E | 2008–2011 | [85] | PE | Y | Y | All sectors | Y | N | |

| Energy audit program for SMEs | E | 2008–2012 | [86] | PE | Y | Y | All sectors | Y | N | |

| Ireland | Energy Agreements Program | P | 2006–2019 | [41] | PR | N | Y | EII | N | Y |

| Italy | National energy efficiency action plan 2017 | V | 2014–2020 | [88] | PR | N | Y | Mainly industry | Y | N |

| EED Art 8 Mandatory EAs | P | 2019 | [89] | PE | Y | Y | All sectors | N | N | |

| Different SMEs policies | V | 2005–2021 | [90] | PR | N | N | All sectors | N | Y | |

| National energy efficiency campaign “Italy in Class A” | S | 2015–2021 | [91] | PE | N | N | All sectors | N | N | |

| White Certificates | E | 2006–2015 | [92] | PE | N | N | All sectors | N | N | |

| Japan | Policies to stimulate ESCO market | V | 2001–2015 | [76] | PR | N | N | Industry | N | N |

| Voluntary Agreement Program Climate | P | 2001–2003 | [98] | PR | Y | N | Industry | N | N | |

| VAP 114 Business associations | P | 1997–2012 | [39] | PR | Y | N | All sectors | N | N | |

| Several policies | V | 1990–2014 | [42] | PR | N | Y | Mainly industry | Y | N | |

| Different SME policies | V | 2005–2015 | [75] | PE | N | N | All sectors | Y | N | |

| EnMS regulation under the Energy Conservation Law (ECL) | P | 2009–2010 | [182] | PE | Y | N | Mainly industry | N | Y | |

| Latvia | Latvian Energy Efficiency Obligation Scheme (EEOS) | E | 2017–2020 | [43] | PE | N | N | All sectors | Y | N |

| Lithuania | Auditas pramonei LT | E | 2015–2018 | [99] | CS | Y | Y | Manufacturing | N | N |

| Mexico | MSSP—Mexican Sustainable Supply Program | E + S | 2005–2013 | [101] | PE | Y | Y | All sectors | Y | N |

| Netherlands | Dutch voluntary agreements on energy efficiency | P | 2009–2012 | [38] | PR | Y | N | All sectors | N | N |

| MJAs—Dutch negotiated agreements on energy saving in industry | P | 2002–2012 | [64] | PR | N | N | All sectors | Y | Y | |

| Various voluntary agreements | P | 1991–2020 | [41] | PR | N | Y | All sectors | N | Y | |

| Norway | Several policies | V | 2012 | [81] | PR | N | Y | All sectors | N | Y |

| Portugal | EFINERG Project—EE in SMEs (250–500 toe) | O | 2012 | [102] | PE | Y | N | Manufacturing | N | Y |

| South Korea | Voluntary agreements | P | 1999–2010 | [40] | PR | N | N | Industry | N | N |

| Target management scheme | V | 2008–2013 | [65] | PR | Y | N | Energy Intensive | N | N | |

| Spain | Different SMEs policies | V | 2008–2015 | [75] | PE | N | Y | All sectors | Y | N |

| Policies to stimulate ESCO market | V | 2001–2015 | [41] | PR | N | N | Industry | N | N | |

| Sweden | Several policies | V | 1990–2014 | [42] | PE | Y | Y | Mainly industry | Y | N |

| Different SMEs policies | V | 1990–2011 | [75] | PE | N | N | EII | N | N | |

| Several policies | V | 2004–2014 | [81] | PR | N | Y | All sectors | Y | Y | |

| Highland + PFE | E | 2003–2008 | [104] | PE | Y | Y | Industry | Y | Y | |

| SEAP—Swedish Energy Audit Program | E | 2010–2014 | [123] | PE | Y | Y | All sectors | Y | Y | |

| Several policies | V | 1990–2020 | [108] | PE | N | Y | Industry | Y | N | |

| PFE—Program for Energy Efficiency in Energy-Intensive Industries | P | 2005–2014 | [54] | PE | N | Y | All sectors | N | N | |

| Regional EEN policy program—ENERGIG | S | 2014–2019 | [109] | PR | Y | N | Industry | N | Y | |

| Regional EEN policy program—ENERGIG | S | 2015–2018 | [110] | PR | Y | Y | Industry | Y | Y | |

| Regional EEN policy program—ENERGIG | S | 2011–2016 | [184] | PE | Y | N a | Industry | N | Y | |

| Long-term agreements for SMEs | P | - | [107] | PE | Y | Y | EII | Y | N | |

| Policies to stimulate ESCO market | V | 2001–2015 | [76] | PR | N | N | Industry | N | N | |

| SEAP—Swedish Energy Audit Program | E | 2010–2014 | [185] | PE | Y | Y | All sectors | Y | N | |

| Highland + SEAP | E | 2006–2014 | [70] | PR | Y | Y | Manufacturing | Y | Y | |

| United Kingdom | National energy efficiency action plan 2017 | V | 2014–2020 | [88] | PR | N | N | Mainly industry | N | N |

| Climate change agreements (CCAs) and climate change levy (CCL) | E + P | 1999–2010 b | [37] | PE | N | Y | All sectors | N | N | |

| United States | IAC—Industrial Assessment Centers | E + S | 1981–2000 | [70] | PR | Y | Y | Industry | N | N |

| IAC + 30 U.S. State and Regional Climate Policy actions of EPA | E + S | 1984–2011 | [114] | PE | Y | N | Industry | N | Y | |

| Information program and support scheme | E + S | 1976–2004 | [117] | CS | Y | Y | All sectors | N | Y | |

| IAC—Industrial Assessment Centers | E + S | 1981–2009 | [118] | PE | Y | Y | Industry | Y | N | |

| IAC—Industrial Assessment Centers | E + S | 1981–2009 | [186] | PE | Y | Y | Industry | Y | Y |

5.2. Quantitative Studies on Energy Efficiency Policies for SMEs

- Six stand-alone programs from five countries (two from Sweden).

- Four programs include energy audits as part of more general schemes for energy efficiency in SMEs.

- Two policies are focused on tax levies for energy-intensive industries (including both SMEs and large companies). Access to these programs requires the completion of energy audits.

- Finally, two energy efficiency networks are presented as examples of good practices for the implementation of energy efficiency policies in SMEs. In these cases, the EAs are not mandatory (or at least not certified).

| Type of Policy | Country | Policy | Reference Years | #SMEs d | Impl. EPIAs per EA | Impl. Rate (%) | Prog. Cost [M EUR] | Cost Energy Audit [EUR] | Savings [GWh/y] | Pot. Savings [GWh/y] | Public CE [EUR/MWh] | CE EPIAs [EUR/MWh] | PP j [y] | Ref |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Energy Audits for SMEs | AU | EEAP | 1991–1997 | 1200 (100) | 4.7 | 81% | 4166 | 1.3 | [18,70,123] | |||||

| DE | German energy audit program for SMEs c | 2008–2010 | 542 | 1.4 | 40% | 225–625 | [84] | |||||||

| 2008–2010 | 9292 | 1.6 | 43% | 17.7 | 953 | 1653 | 1–1.3 | 6.1 | [18,70,123] | |||||

| 2008–2010 | 10,400 (542) | 2.8 | 53% | 18.9 | 900–4000 | 1921 | 38,000 | 0.5–0.7 | 5–23 | 6.1 | [85] | |||

| 2008–2013 | 24,300 (1471) | 1200–4800 | 10–20% i | 6 | [86] | |||||||||

| JP | ECCJ audit program | 2004–2007 | 2409 | 7.7 | 2380 | 3.2 | [42] | |||||||

| SE | Highland Project | 2003–2008 | 139 (47) | 1.0 | 22% | 7 | 16 | [18,70,123] | ||||||

| 2003–2008 | 340 | 3.0 | 50% | 0.6 | 2000 | 40 | 75 | 5–10 | [104] | |||||

| SEAP | Ex-ante | 900 | 3.5 | 700–1400 | 2.5–5.0 | [107] | ||||||||

| 2010–2013 | 241 | 9.2 | 53% | 1.5 | 9160 | 110–160 | 207–306 | 0.7–1.3 | 125–265 | [185] | ||||

| 2010–2014 | 713 | 4.5 | 53% | 3.5 | 4540 | 340 | 589 | 7 | 7.6 | [123] | ||||

| US | IAC | 1981–2009 | 14,800 | 3.8 | 50% e | 7–10/y f | 7000 | 18,833 | 1.1 | [18,70,117,123] | ||||

| Energy Efficiency for SMEs a | BE | Flanders–Audit Covenant | 2005–2013 | 229 | 1166 | [75] | ||||||||

| BG | OPIC | 2014–2020 | 426 | 1.0 | 154 g | 356 | 434 | 5.9 | [157] | |||||

| MX | MSSP | 2005–2012 | 972 | 2 | 156 g | 0.8 | [101] | |||||||

| ES | PAE4+ | 2008–2012 | 260 | 2.85 | 14,600 | 2360 | 1.2 | 115 | [75] | |||||

| Energy Intensive Industries a,b | IT | EII “Energivori” | 2014–2018 | 2546 | 1186 | 119 | [88,90] | |||||||

| SE | PFE | 2005–2007 | 98 | 70 h | [104] | |||||||||

| 2005–2012 | 101 | 12.5 | 43% | 88 h | 1450 | 6.5 | 9.3–16 | 1.5 | [54] | |||||

| EE Networks a | DE | LEEN | 2009–2014 | 948 | 3.7 | 6208 | [82,83] | |||||||

| SE | ENERGIG | 2015–2018 | 44 (15) | 14.0 | 50% | 5,5 | 5.8 | [110] |

6. Concluding Discussion

- To allow for a better understanding of policy performance and to compare different policy mechanisms, a harmonized approach for the evaluation of EE policies for SMEs is needed, including specific methodologies and indicators.

- Quantitative studies on the topic are still scarce in terms of the policies and countries analyzed as well as the number of SMEs covered; moreover, their effective comparison has been limited due to the high heterogeneity of the adopted approaches and/or the lack of information about them.

- All evaluation studies reporting quantitative information (Table 3) have focused on policies including the adoption of EA. In this sense, EA seems to be a pre-condition for performing quantitative evaluations of the savings and cost effectiveness of a program.

- According to some policy schemes, EA certification is mandatory. However, due to the complexity of the implementation of certified energy audits and energy management systems in non-energy-intensive SMEs, the implementation of simplified forms should be taken into consideration by policymakers.

- Targeted policies and tools, tailored as function of the size, sector and energy intensity of the company, appear to be a successful approach to overcome barriers for EE in SMEs.

- A more integrated approach combining different economic and supportive instruments may help SMEs with improving the EPIA implementation rate, starting from no-cost EE and low-risk interventions.

- The most successful strategies include the engagement of local or regional associations instead of national governments, due to the more common territorial context of SME activities.

- Capacity-building programs and learning networks (which are well received by SMEs), as part of a broader range of support, can help ensure the longevity of the policy, as SMEs develop their own skills that help them undertake energy audits and implement EPIAs.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEA. Policy Pathway—Accelerating Energy Efficiency in Small and Medium-Sized Enterprises; International Energy Agency: Paris, France, 2015. [Google Scholar]

- OECD. No Net Zero without SMEs: Exploring the Key Issues for Greening SMEs and Green Entrepreneurship; ECD SME and Entrepreneurship Papers, No. 30; OECD Publishing: Paris, France, 2021. [Google Scholar]

- European Commission. An SME Strategy for a Sustainable and Digital Europe (COM/2020/103 Final); European Commission: Brussels, Belgium, 2020.

- European Commission. Flash Eurobarometer 498. SMEs, Resource Efficiency and Green Markets; Publications Office of the European Union: Luxembourg, 2022.

- Hrovatin, N.; Cagno, E.; Dolšak, J.; Zorić, J. How Important Are Perceived Barriers and Drivers versus Other Contextual Factors for the Adoption of Energy Efficiency Measures: An Empirical Investigation in Manufacturing SMEs. J. Clean. Prod. 2021, 323, 129123. [Google Scholar] [CrossRef]

- Ensign, P.C. Business Models and Sustainable Development Goals. Sustainability 2022, 14, 2558. [Google Scholar] [CrossRef]

- Chomać-Pierzecka, E. Pharmaceutical Companies in the Light of the Idea of Sustainable Development—An Analysis of Selected Aspects of Sustainable Management. Sustainability 2023, 15, 8889. [Google Scholar]

- Backlund, S.; Thollander, P.; Palm, J.; Ottosson, M. Extending the Energy Efficiency Gap. Energy Policy 2012, 51, 392–396. [Google Scholar] [CrossRef]

- Leoni, L.; Cantini, A.; De Carlo, F.; Salvio, M.; Martini, C.; Toro, C.; Martini, F. Energy-Saving Technology Opportunities and Investments of the Italian Foundry Industry. Energies 2021, 14, 8470. [Google Scholar] [CrossRef]

- Cagno, E.; Accordini, D.; Trianni, A.; Katic, M.; Ferrari, N.; Gambaro, F. Understanding the Impacts of Energy Efficiency Measures on a Company’s Operational Performance: A New Framework. Appl. Energy 2022, 328, 120118. [Google Scholar] [CrossRef]

- Zhou, B.; Yi, Q. An Energy-Oriented Maintenance Policy under Energy and Quality Constraints for a Multielement-Dependent Degradation Batch Production System. J. Manuf. Syst. 2021, 59, 631–645. [Google Scholar] [CrossRef]

- Do, P.; Hoang, A.; Iung, B.; Vu, H.-C. Energy Efficiency for Condition-Based Maintenance Decision-Making: Application to a Manufacturing Platform. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2018, 232, 379–388. [Google Scholar] [CrossRef]

- Flues, F.; Rübbelke, D.; Vögele, S. An Analysis of the Economic Determinants of Energy Efficiency in the European Iron and Steel Industry. J. Clean. Prod. 2015, 104, 250–263. [Google Scholar] [CrossRef]

- Munn, Z.; Peters, M.D.J.; Stern, C.; Tufanaru, C.; McArthur, A.; Aromataris, E. Systematic Review or Scoping Review? Guidance for Authors When Choosing between a Systematic or Scoping Review Approach. BMC Med. Res. Methodol. 2018, 18, 143. [Google Scholar] [CrossRef]

- Lu, H.; Price, L. Industrial Energy Auditing and Assessments: A Survey of Programs around the World. In Proceedings of the ECEEE 2011 Summer Study, Belambra Presquile de Giens, France, 6–11 June 2011. [Google Scholar]

- Thollander, P.; Rohde, C.; Kimura, O.; Helgerud, H.-E.; Realini, A.; Maggiore, S.; Cosgrove, J.; Johansson, I. A Review of Energy Efficiency Policies for Small and Medium-Sized Manufacturing Enterprises from around the World. In Proceedings of the ACEEE, Portland, OR, USA, 12–14 August 2019; pp. 3–135. [Google Scholar]

- Johansson, I.; Mardan, N.; Cornelis, E.; Kimura, O.; Thollander, P. Designing Policies and Programmes for Improved Energy Efficiency in Industrial SMEs. Energies 2019, 12, 1338. [Google Scholar] [CrossRef]

- Fleiter, T.; Gruber, E.; Eichhammer, W.; Worrell, E. The German Energy Audit Program for Firms—A Cost-Effective Way to Improve Energy Efficiency? Energy Effic. 2012, 5, 447–469. [Google Scholar] [CrossRef]

- Tanaka, K. Review of Policies and Measures for Energy Efficiency in Industry Sector. Energy Policy 2011, 39, 6532–6550. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. Syst. Rev. 2021, 10, 89. [Google Scholar] [CrossRef]

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG Emissions of Buildings—The Hidden Challenge for Effective Climate Change Mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar] [CrossRef]

- ODYSSEE-MURE Energy Efficiency Policy Mapper. Available online: https://www.measures.odyssee-mure.eu/policy-mapper-efficiency-tool.html#/ (accessed on 22 January 2024).

- IEA. Policy Database—Energy Efficiency. Available online: https://www.iea.org/policies?topic%5B0%5D=Energy%20Efficiency (accessed on 22 January 2024).

- IEA; IRENA. Join IEA/IRENA Policy and Measures Database. Available online: https://www.iea.org/policies?source%5B0%5D=IEA%2FIRENA%20Renewables%20Policies%20Database&source%5B1%5D=JOIN%20IEA%2FIRENA%20Policy%20and%20Measures%20Database (accessed on 22 January 2024).

- OECD. Taxing Energy Use 2019; OECD: Paris, France, 2019. [Google Scholar]

- OECD. Taxing Energy Use 2011; OECD: Paris, France, 2011. [Google Scholar]

- OECD. Taxing Energy Use 2015; OECD: Paris, France, 2015. [Google Scholar]

- Eurostat Energy Efficiency Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Energy_efficiency_statistics (accessed on 22 January 2024).

- van Eck, N.; Waltman, L. Software Survey: VOSviewer, a Computer Program for Bibliometric Mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed]

- European Commission. 2019 assessment of the Progress Made by Member States towards the National Energy Efficiency Targets for 2020 and towards the Implementation of the Energy Efficiency Directive as Required by Article 24(3) of the Energy Efficiency Directive 2012/27/EU (COM/2020/326 Final); European Commission: Brussels, Belgium, 2020.

- Bertoldi, P.; Economidou, M. EU Member States Energy Efficiency Policies for the Industrial Sector Based on the NEEAPs Analysis. In Proceedings of the ECEEE 2018 Industrial Summer Study, Berlin, Germany, 11–13 June 2018. [Google Scholar]

- European Investment Bank. Going Green. Who Is Investing in Energy Efficiency, and Why It Matters; EIB Investment Surveys; European Investment Bank: Luxembourg, 2020. [Google Scholar]

- Menghi, R.; Papetti, A.; Germani, M.; Marconi, M. Energy Efficiency of Manufacturing Systems: A Review of Energy Assessment Methods and Tools. J. Clean. Prod. 2019, 240, 118276. [Google Scholar] [CrossRef]

- Schulze, M.; Nehler, H.; Ottosson, M.; Thollander, P. Energy Management in Industry—A Systematic Review of Previous Findings and an Integrative Conceptual Framework. J. Clean. Prod. 2016, 112, 3692–3708. [Google Scholar] [CrossRef]

- ISO 50001; Energy Management Systems—Requirements with Guidance for Use. ISO Central Secretariat: Geneva, Switzerland, 2011.

- EEFIG. Energy Efficiency—The First Fuel for the EU Economy How to Drive New Finance for Energy Efficiency Investment; Energy Efficiency Financial Institutions Group, United Nations Environment Programme-Finance Initiative: Brussels, Belgium, 2015. [Google Scholar]

- Ekins, P.; Etheridge, B. The Environmental and Economic Impacts of the UK Climate Change Agreements. Energy Policy 2006, 34, 2071–2086. [Google Scholar] [CrossRef]

- Abeelen, C.; Harmsen, R.; Worrell, E. Planning versus Implementation of Energy-Saving Projects by Industrial Companies. Insights from the Dutch Long-Term Agreements. Energy Effic. 2016, 9, 153–169. [Google Scholar] [CrossRef]

- Wakabayashi, M.; Arimura, T.H. Voluntary Agreements to Encourage Proactive Firm Action against Climate Change: An Empirical Study of Industry Associations’ Voluntary Action Plans in Japan. J. Clean. Prod. 2016, 112, 2885–2895. [Google Scholar] [CrossRef]

- Seok, J.; Kim, J.; Park, H.S. Regulatory and Social Dynamics of Voluntary Agreement Adoption: The Case of Voluntary Energy Efficiency and GHG Reduction Agreement in South Korea. Energy Policy 2021, 148, 111903. [Google Scholar] [CrossRef]

- Cornelis, E. History and Prospect of Voluntary Agreements on Industrial Energy Efficiency in Europe. Energy Policy 2019, 132, 567–582. [Google Scholar] [CrossRef]

- Thollander, P.; Kimura, O.; Wakabayashi, M.; Rohdin, P. A Review of Industrial Energy and Climate Policies in Japan and Sweden with Emphasis towards SMEs. Renew. Sustain. Energy Rev. 2015, 50, 504–512. [Google Scholar] [CrossRef]

- Blumberga, A.; Āzis, R.; Reinbergs, D.; Pakere, I.; Blumberga, D. The Bright and Dark Sides of Energy Efficiency Obligation Scheme: The Case of Latvia. Energies 2021, 14, 4467. [Google Scholar] [CrossRef]

- Rezessy, S.; Bertoldi, P. Voluntary Agreements in the Field of Energy Efficiency and Emission Reduction: Review and Analysis of Experiences in the European Union. Energy Policy 2011, 39, 7121–7129. [Google Scholar] [CrossRef]

- Kim, J.W.; Liu, Y. Review of Voluntary Agreements on Energy Efficiency: Promoting Energy Efficiency Financing in ASEAN Countries; ADBI Working Paper 1170; Asian Development Bank Institute: Tokyo, Japan, 2021. [Google Scholar]

- Safarzadeh, S.; Rasti-Barzoki, M.; Hejazi, S.R. A Review of Optimal Energy Policy Instruments on Industrial Energy Efficiency Programs, Rebound Effects, and Government Policies. Energy Policy 2020, 139, 111342. [Google Scholar] [CrossRef]

- Töller, A.E. The Rise and Fall of Voluntary Agreements in German Environmental Policy. Ger. Policy Stud. 2013, 9, 49–92. [Google Scholar]

- Ottosson, C.; Peterson, K. First Results from the Swedish LTA Programme for Energy Efficiency in Industry. In Proceedings of the 2007 ECEEE Summer Study, La Colle sur Loup, France, 4–9 June 2007; Volume 7, pp. 1517–1525. [Google Scholar]

- Davidsdottir, B.; Ruth, M. Capital Vintage and Climate Change Policies: The Case of US Pulp and Paper. Environ. Sci. Policy 2004, 7, 221–233. [Google Scholar] [CrossRef]

- Narassimhan, E.; Gallagher, K.S.; Koester, S.; Alejo, J.R. Carbon Pricing in Practice: A Review of Existing Emissions Trading Systems. Clim. Policy 2018, 18, 967–991. [Google Scholar] [CrossRef]

- Goulder, L.H.; Schein, A.R. Carbon Taxes versus Cap and Trade: A Critical Review. Clim. Chang. Econ. 2013, 4, 1350010. [Google Scholar] [CrossRef]

- Di Santo, D.; Biele, E.; De Chicchis, L. White Certificates as a Tool to Promote Energy Efficiency in Industry. In Proceedings of the ECEEE 2018 Industrial Summer Study, Berlin, Germany, 11–13 June 2018; pp. 43–53. [Google Scholar]

- SEAI. Review and Cost Benefit Analysis of the Accelerated Capital Allowances Scheme for Energy Efficient Equipment; Irish Government—Energy and Natural Resources & Sustainable Energy Authority of Ireland: Dublin, Ireland, 2014. [Google Scholar]

- Stenqvist, C.; Nilsson, L.J. Energy Efficiency in Energy-Intensive Industries-an Evaluation of the Swedish Voluntary Agreement PFE. Energy Effic. 2012, 5, 225–241. [Google Scholar] [CrossRef]

- Zhang, D.; Tong, Z.; Zheng, W. Does Designed Financial Regulation Policy Work Efficiently in Pollution Control? Evidence from Manufacturing Sector in China. J. Clean. Prod. 2021, 289, 125611. [Google Scholar] [CrossRef]

- Ballu, M.; Di Stefano, P.; Scheuer, S. Étude Comparative Sur L’efficacité Des Soutiens Publics Aux Investissements de Maîtrise de L’énergie Dans L’Union Européenne; ADEME: Angers, France, 2012. (In French) [Google Scholar]

- Worrell, E.; Blinde, P.; Neelis, M.; Blomen, E.; Masanet, E. Energy Efficiency Improvement and Cost Saving Opportunities for the US Iron and Steel Industry. An ENERGY STAR (R) Guide for Energy and Plant Managers; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2011. [Google Scholar]

- Santino, D.; Biele, E.; Salvio, M. Guidelines for Energy Audits Under Article 8 of the EED: Italy ’s Implementation Practices and Tools; ENEA: Roma, Italy, 2019; Available online: https://www.efficienzaenergetica.enea.it/component/jdownloads/?task=download.send&id=377&catid=40&Itemid=101 (accessed on 22 January 2024).

- Santino, D.; Ferrari, S.; Salvio, M. Valutazioni Preliminari Sugli Indici Di Prestazione Energetica Nel Settore Della Produzione Del Vetro. ENEA-UTEE. 2016. Available online: https://www.efficienzaenergetica.enea.it/component/jdownloads/?task=download.send&id=287&catid=42&Itemid=101 (accessed on 22 January 2024). (In Italian).

- Atzori, D.; Calabrese, A.; Catoni, P.; Falconi, P.; Federici, A.; Ferrari, S.; Iorio, G.; Martini, C.; Moneta, R.; Ranieri, D.; et al. Dalla Diagnosi Alla Caratterizzazione Energetica Di Processi Industriali: Metodi per La Valutazione e La Promozione Degli Interventi Di Riqualificazione Energetica; Report RdS/PAR2015/066; Ricerca di Sistema elettrico-ENEA: 2016. Available online: https://www.efficienzaenergetica.enea.it/pubblicazioni/dalla-diagnosi-alla-caratterizzazione-energetica-di-processi-industriali-metodi-per-la-valutazione-e-la-promozione-degli-interventi-di-riqualificazione-energetica.html (accessed on 22 January 2024). (In Italian).

- DUEE-SPS-ESE Publications and Proceedings-Energy Audits. Available online: https://www.efficienzaenergetica.enea.it/servizi-per/imprese/diagnosi-energetiche/pubblicazioni-e-atti.html (accessed on 22 January 2024). (In Italian).

- ENEA. Energy Efficiency Annual Report 2020. Analysis and Results from Energy Efficiency Policies in Italy; ENEA: Rome, Italy, 2020. [Google Scholar]

- Nehler, T.; Rasmussen, J. How Do Firms Consider Non-Energy Benefits? Empirical Findings on Energy-Efficiency Investments in Swedish Industry. J. Clean. Prod. 2016, 113, 472–482. [Google Scholar] [CrossRef]

- Bressers, H.; de Bruijn, T.; Dinica, V. Integration and Communication as Central Issues in Dutch Negotiated Agreements on Industrial Energy Efficiency. Eur. Environ. 2007, 17, 215–230. [Google Scholar] [CrossRef]

- Suk, S.; Liu, X.; Sudo, K. A Survey Study of Energy Saving Activities of Industrial Companies in the Republic of Korea. J. Clean. Prod. 2013, 41, 301–311. [Google Scholar] [CrossRef]

- MiSE. Annual Report on Energy Efficiency. Results Achieved and Targets for 2020; Ministy of Economic Development: Rome, Italy, 2020. [Google Scholar]

- Meath, C.; Linnenluecke, M.; Griffiths, A. Barriers and Motivators to the Adoption of Energy Savings Measures for Small- and Medium-Sized Enterprises (SMEs): The Case of the ClimateSmart Business Cluster Program. J. Clean. Prod. 2016, 112, 3597–3604. [Google Scholar] [CrossRef]

- Redmond, J.; Walker, B. The Value of Energy Audits for SMEs: An Australian Example. Energy Effic. 2016, 9, 1053–1063. [Google Scholar] [CrossRef]

- Australian Government Energy Efficiency Improvement Scheme (EEIS). Available online: https://www.environment.act.gov.au/energy/smarter-use-of-energy/energy-efficiency-improvement-scheme (accessed on 22 January 2024).

- Andersson, E.; Arfwidsson, O.; Bergstrand, V.; Thollander, P. A Study of the Comparability of Energy Audit Program Evaluations. J. Clean. Prod. 2017, 142, 2133–2139. [Google Scholar] [CrossRef]

- Harris, J.; Anderson, J.; Shafron, W. Investment in Energy Efficiency: A Survey of Australian Firms. Energy Policy 2000, 28, 867–876. [Google Scholar] [CrossRef]

- Lackner, P.; Kulterer, K. Energy-Efficient Business Programme Klimaaktiv Supports Austrian Industrial SMEs. In Proceedings of the ECEEE 2018 Industrial Summer Study, Berlin, Germany, 11–13 June 2018; pp. 293–300. [Google Scholar]

- Thollander, P.; Paramonova, S.; Cornelis, E.; Kimura, O.; Trianni, A.; Karlsson, M.; Cagno, E.; Morales, I.; Jiménez Navarro, J.P. International Study on Energy End-Use Data among Industrial SMEs (Small and Medium-Sized Enterprises) and Energy End-Use Efficiency Improvement Opportunities. J. Clean. Prod. 2015, 104, 282–296. [Google Scholar] [CrossRef]

- Venmans, F. Triggers and Barriers to Energy Efficiency Measures in the Ceramic, Cement and Lime Sectors. J. Clean. Prod. 2014, 69, 133–142. [Google Scholar] [CrossRef]

- Thollander, P.; Zubizarreta-Jiménez, R.; Morales, I.; Kimura, O.; Cornelis, E.; Karlsson, M.; Söderström, M.; Backlund, S. Energy End-Use Policies and Programs towards Industrial SMEs—The Case of Japan, Belgium, Spain and Sweden-IEA IETS Annex XVI Energy Efficiency in SMEs Task I; IETS TCP. International Energy Agency: Paris, France, 2014. [Google Scholar]

- Cornelis, E.; Kimura, O.; Karlsson, M.; Paramonova, S.; Thollander, P.; Jiménez-Navarro, J.P.; Morales, I.; Bertelsen, C.W. IEA IETS Annex XVI. Energy Efficiency in SMEs. Task IV: Energy Services and Business Models for Industrial SMEs; IETS TCP. International Energy Agency: Paris, France, 2015. [Google Scholar]

- Côté, R.; Booth, A.; Louis, B. Eco-Efficiency and SMEs in Nova Scotia, Canada. J. Clean. Prod. 2006, 14, 542–550. [Google Scholar] [CrossRef]

- Kostka, G.; Moslener, U.; Andreas, J. Barriers to Increasing Energy Efficiency: Evidence from Small-and Medium-Sized Enterprises in China. J. Clean. Prod. 2013, 57, 59–68. [Google Scholar] [CrossRef]

- Zhang, S.; Worrell, E.; Crijns-Graus, W. Mapping and Modeling Multiple Benefits of Energy Efficiency and Emission Mitigation in China’s Cement Industry at the Provincial Level. Appl. Energy 2015, 155, 35–58. [Google Scholar] [CrossRef]

- Lo, K.; Li, H.; Wang, M. Energy Conservation in China’s Energy-Intensive Enterprises: An Empirical Study of the Ten-Thousand Enterprises Program. Energy Sustain. Dev. 2015, 27, 105–111. [Google Scholar] [CrossRef]

- Bröckl, M.; Illman, J.; Oja, L.; Vehviläinen, I. Energy Efficiency in Small and Medium Enterprises; Nordic Council of Ministers: Copenhagen, Denmark, 2014. [Google Scholar]

- Wohlfarth, K.; Schlomann, B.; Eichhammer, W.; Worrell, E. Chances for Changes—Tailoring Energy-Efficiency Measures to Target Groups. In Proceedings of the 2016 ECEEE Industrial Summer Study, Karlsruhe, Germany, 12–14 September 2016; pp. 137–149. [Google Scholar]

- Rohde, C.; Durand, A.; Neusel, L.; Barckhausen, A.; Jensterle, M. Energy Efficiency Networks: Latest Developments in Germany and in the World. In Proceedings of the ECEEE Industrial Summer Study, Online, 14–17 September 2020; pp. 23–33. [Google Scholar]

- Fleiter, T.; Schleich, J.; Ravivanpong, P. Adoption of Energy-Efficiency Measures in SMEs-An Empirical Analysis Based on Energy Audit Data from Germany. Energy Policy 2012, 51, 863–875. [Google Scholar] [CrossRef]

- Gruber, E.; Fleiter, T.; Mai, M.; Frahm, B.J. Efficiency of an Energy Audit Program for SMEs in Germany—Results of an Evaluation Study. In Proceedings of the ECEEE 2011 Summer Study, Belambra Presquile de Giens, France, 6–11 June 2011; pp. 663–673. [Google Scholar]

- Schleich, J.; Fleiter, T. Effectiveness of Energy Audits in Small Business Organizations. Resour. Energy Econ. 2019, 56, 59–70. [Google Scholar] [CrossRef]

- Sorrell, S.; O’Malley, E. Production Must Go on: Barriers to Energy Efficiency in the Irish Mechanical Engineering Industry. In The Economics of Energy Efficiency; Sorrell, S., O’Malley, E., Schleich, J., Scott, S., Eds.; Edward Elgar Publishing: Dublin, Ireland, 2004. [Google Scholar]

- Malinauskaite, J.; Jouhara, H.; Ahmad, L.; Milani, M.; Montorsi, L.; Venturelli, M. Energy Efficiency in Industry: EU and National Policies in Italy and the UK. Energy 2019, 172, 255–269. [Google Scholar] [CrossRef]

- Herce, C.; Biele, E.; Martini, C.; Salvio, M.; Toro, C. Impact of Energy Monitoring and Management Systems on the Implementation and Planning of Energy Performance Improved Actions: An Empirical Analysis Based on Energy Audits in Italy. Energies 2021, 14, 4723. [Google Scholar] [CrossRef]

- Toro, C.; Biele, E.; Herce, C.; Martini, C.; Salvio, M.; Threpsiadi, A.; Wilkinson-Dix, J. Overview of Energy Efficiency Policies and Programmes for SMEs in Italy. In Proceedings of the Energy Evaluation Europe 2022, Paris, France, 28–30 September 2022. [Google Scholar]

- Preziosi, M.; Federici, A.; Merli, R. Evaluating the Impact of Public Information and Training Campaigns to Improve Energy Efficiency: Findings from the Italian Industry. Energies 2022, 15, 1931. [Google Scholar] [CrossRef]

- Stede, J. Bridging the Industrial Energy Efficiency Gap—Assessing the Evidence from the Italian White Certificate Scheme. Energy Policy 2017, 104, 112–123. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A. Exploring Drivers for Energy Efficiency within Small- and Medium-Sized Enterprises: First Evidences from Italian Manufacturing Enterprises. Appl. Energy 2013, 104, 276–285. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Worrell, E. Innovation and Adoption of Energy Efficient Technologies: An Exploratory Analysis of Italian Primary Metal Manufacturing SMEs. Energy Policy 2013, 61, 430–440. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A. Analysis of the Most Effective Energy Efficiency Opportunities in Manufacturing Primary Metals, Plastics, and Textiles Small- and Medium-Sized Enterprises. J. Energy Resour. Technol. 2012, 134, 021005. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Farnè, S. An Empirical Investigation of Barriers, Drivers and Practices for Energy Efficiency in Primary Metals Manufacturing SMEs. Energy Procedia 2014, 61, 1252–1255. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Worrell, E.; Pugliese, G. Empirical Investigation of Energy Efficiency Barriers in Italian Manufacturing SMEs. Energy 2013, 49, 444–458. [Google Scholar] [CrossRef]

- Wakabayashi, M. Voluntary Business Activities to Mitigate Climate Change: Case Studies in Japan. Energy Policy 2013, 63, 1086–1090. [Google Scholar] [CrossRef]

- Lisauskas, A.; Kveselis, V.; Dzenajavičienė, E.F.; Masaitis, S.; Perednis, E. Analysis of Energy Audits Results and Impacts: Case of Small and Medium Enterprises in Lithuania. Energy Effic. 2022, 15, 48. [Google Scholar] [CrossRef]

- Streimikiene, D.; Ciegis, R.; Grundey, D. Promotion of Energy Efficiency in Lithuania. Renew. Sustain. Energy Rev. 2008, 12, 772–789. [Google Scholar] [CrossRef]

- van Hoof, B.; Lyon, T.P. Cleaner Production in Small Firms Taking Part in Mexico’s Sustainable Supplier Program. J. Clean. Prod. 2013, 41, 270–282. [Google Scholar] [CrossRef]

- Catarino, J.; Henriques, J.; Egreja, F. Portuguese SME toward Energy Efficiency Improvement. Energy Effic. 2015, 8, 995–1013. [Google Scholar] [CrossRef]

- Ruivo, L.; Russo, M.; Lourenço, R.; Pio, D. Energy Management in the Portuguese Ceramic Industry: Analysis of Real-World Factories. Energy 2021, 237, 121628. [Google Scholar] [CrossRef]

- Thollander, P.; Danestig, M.; Rohdin, P. Energy Policies for Increased Industrial Energy Efficiency: Evaluation of a Local Energy Programme for Manufacturing SMEs. Energy Policy 2007, 35, 5774–5783. [Google Scholar] [CrossRef]

- Thollander, P.; Ottosson, M. An Energy Efficient Swedish Pulp and Paper Industry—Exploring Barriers to and Driving Forces for Cost-Effective Energy Efficiency Investments. Energy Effic. 2008, 1, 21–34. [Google Scholar] [CrossRef]

- Rohdin, P.; Thollander, P.; Solding, P. Barriers to and Drivers for Energy Efficiency in the Swedish Foundry Industry. Energy Policy 2007, 35, 672–677. [Google Scholar] [CrossRef]

- Thollander, P.; Dotzauer, E. An Energy Efficiency Program for Swedish Industrial Small- and Medium-Sized Enterprises. J. Clean. Prod. 2010, 18, 1339–1346. [Google Scholar] [CrossRef]

- Thollander, P.; Rohdin, P.; Moshfegh, B.; Karlsson, M.; Söderström, M.; Trygg, L. Energy in Swedish Industry 2020-Current Status, Policy Instruments, and Policy Implications. J. Clean. Prod. 2013, 51, 109–117. [Google Scholar] [CrossRef]

- Jalo, N.; Johansson, I.; Kanchiralla, F.M.; Thollander, P. Do Energy Efficiency Networks Help Reduce Barriers to Energy Efficiency?—A Case Study of a Regional Swedish Policy Program for Industrial SMEs. Renew. Sustain. Energy Rev. 2021, 151, 111579. [Google Scholar] [CrossRef]

- Johansson, I.; Johnsson, S.; Thollander, P. Impact Evaluation of an Energy Efficiency Network Policy Programme for Industrial SMEs in Sweden. Resour. Environ. Sustain. 2022, 9, 100065. [Google Scholar] [CrossRef]

- Revell, A.; Stokes, D.; Chen, H. Small Businesses and the Environment: Turning over a New Leaf? Bus. Strateg. Environ. 2010, 19, 273–288. [Google Scholar] [CrossRef]

- Chowdhury, J.I.; Hu, Y.; Haltas, I.; Balta-Ozkan, N.; Matthew, G.J.; Varga, L. Reducing Industrial Energy Demand in the UK: A Review of Energy Efficiency Technologies and Energy Saving Potential in Selected Sectors. Renew. Sustain. Energy Rev. 2018, 94, 1153–1178. [Google Scholar] [CrossRef]

- UK Government. CRC Energy Efficiency Scheme. Available online: https://www.gov.uk/government/collections/crc-energy-efficiency-scheme (accessed on 22 January 2024).

- Abadie, L.M.; Ortiz, R.A.; Galarraga, I.; Markandya, A. Energy Efficiency Policy in the USA: The Impact of the Industrial Assessment Centres (IAC) Programme and State and Regional Climate Policy Actions. In The Dynamics of Environmental and Economic Systems: Innovation, Environmental Policy and Competitiveness; Springer: Dordrecht, The Netherlands, 2012; pp. 61–82. [Google Scholar]

- Blass, V.; Corbett, C.J.; Delmas, M.A.; Muthulingam, S. Top Management and the Adoption of Energy Efficiency Practices: Evidence from Small and Medium-Sized Manufacturing Firms in the US. Energy 2014, 65, 560–571. [Google Scholar] [CrossRef]

- Newell, R.G.; Pizer, W.A.; Raimi, D.U.S. Federal Government Subsidies for Clean Energy: Design Choices and Implications. Energy Econ. 2019, 80, 831–841. [Google Scholar] [CrossRef]

- Anderson, S.T.; Newell, R.G. Information Programs for Technology Adoption: The Case of Energy-Efficiency Audits. Resour. Energy Econ. 2004, 26, 27–50. [Google Scholar] [CrossRef]

- DOE. IMPACT: Industrial Technologies Program, Summary of Program Results for CY 2009; U.S. Department of Energy: Washington, DC, USA, 2013. [Google Scholar]

- Hirzel, S.; Nabitz, L.; Wohlfarth, K.; Rohde, C.; Behling, I.; Clarke, D.; Perera, N.; Turner, R. A Study on Energy Efficiency in Enterprises: Energy Audits and Energy Management Systems; European Commission. Publications Office of the European Union: Luxembourg, 2016. [Google Scholar]

- Kalantzis, F.; Revoltella, D. How Energy Audits Promote SMEs’ Energy Efficiency Investment; EIB Working Papers; European Investment Bank: Luxembourg, 2019. [Google Scholar]

- Väisänen, H.; Christensen, W.; Despretz, H.; Espegren, K.A.; Gaspar, C.; Lytras, K.; Meyer, B.; Reinikainen, E.; Sattler, M.; Starzer, O. Guidebook for Energy Audit Programme Developers; SAVE-Project AUDIT II; 2002. Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=6674849b901d84015b59469e25561646d72751a6 (accessed on 22 January 2024).

- Cooremans, C.; Schönenberger, A. Energy Management: A Key Driver of Energy-Efficiency Investment? J. Clean. Prod. 2019, 230, 264–275. [Google Scholar] [CrossRef]

- Paramonova, S.; Thollander, P. Ex-Post Impact and Process Evaluation of the Swedish Energy Audit Policy Programme for Small and Medium-Sized Enterprises. J. Clean. Prod. 2016, 135, 932–949. [Google Scholar] [CrossRef]

- Viesi, D.; Pozzar, F.; Federici, A.; Crema, L.; Mahbub, M.S. Energy Efficiency and Sustainability Assessment of about 500 Small and Medium-Sized Enterprises in Central Europe Region. Energy Policy 2017, 105, 363–374. [Google Scholar] [CrossRef]

- Fresner, J.; Morea, F.; Krenn, C.; Aranda Uson, J.; Tomasi, F. Energy Efficiency in Small and Medium Enterprises: Lessons Learned from 280 Energy Audits across Europe. J. Clean. Prod. 2017, 142, 1650–1660. [Google Scholar] [CrossRef]

- Cagno, E.; Trucco, P.; Trianni, A.; Sala, G. Quick-E-Scan: A Methodology for the Energy Scan of SMEs. Energy 2010, 35, 1916–1926. [Google Scholar] [CrossRef]

- Lamoureux, S.M.; Movassaghi, H.; Kasiri, N. The Role of Government Support in SMEs’ Adoption of Sustainability. IEEE Eng. Manag. Rev. 2019, 47, 110–114. [Google Scholar] [CrossRef]

- Morvaj, Z.; Bukaric, V. Energy Efficiency Policy. In Energy Efficiency; Palm, J., Ed.; IntechOpen: London, UK, 2010; pp. 1–28. [Google Scholar]

- Sousa Lira, J.M.; Salgado, E.G.; Beijo, L.A. Which Factors Does the Diffusion of ISO 50001 in Different Regions of the World Is Influenced? J. Clean. Prod. 2019, 226, 759–767. [Google Scholar] [CrossRef]

- Jalo, N.; Johansson, I.; Andrei, M.; Nehler, T.; Thollander, P. Barriers to and Drivers of Energy Management in Swedish SMEs. Energies 2021, 14, 6925. [Google Scholar] [CrossRef]

- Johansson, M.T.; Thollander, P. A Review of Barriers to and Driving Forces for Improved Energy Efficiency in Swedish Industry– Recommendations for Successful in-House Energy Management. Renew. Sustain. Energy Rev. 2018, 82, 618–628. [Google Scholar] [CrossRef]

- Prashar, A. Adopting PDCA (Plan-Do-Check-Act) Cycle for Energy Optimization in Energy-Intensive SMEs. J. Clean. Prod. 2017, 145, 277–293. [Google Scholar] [CrossRef]

- Grigoraș, G.; Neagu, B.-C. An Advanced Decision Support Platform in Energy Management to Increase Energy Efficiency for Small and Medium Enterprises. Appl. Sci. 2020, 10, 3505. [Google Scholar] [CrossRef]

- Hampton, S. Making Sense of Energy Management Practice: Reflections on Providing Low Carbon Support to Three SMEs in the UK. Energy Effic. 2019, 12, 1473–1490. [Google Scholar] [CrossRef]

- IEA. Capturing the Multiple Benefits of Energy Efficiency; IEA: Paris, France, 2015. [Google Scholar]

- IEA. Multiple Benefits of Energy Efficiency; IEA: Paris, France, 2019. [Google Scholar]

- Johansson, I.; Thollander, P. Non-Energy Benefits in Energy Audit and Energy Efficiency Network Policy Programs for Industrial SMEs. In Proceedings of the ECEEE 2019 Summer Study Proceedings, Hyères, France, 3–8 June 2019; pp. 225–233. [Google Scholar]

- Skumatz, L.A. Efficiency Programs’ Non-Energy Benefits: How States Are Finally Making Progress in Reducing Bias in Cost-Effectiveness Tests. Electr. J. 2015, 28, 96–109. [Google Scholar] [CrossRef]

- Cagno, E.; Moschetta, D.; Trianni, A. Only Non-Energy Benefits from the Adoption of Energy Efficiency Measures? A Novel Framework. J. Clean. Prod. 2019, 212, 1319–1333. [Google Scholar] [CrossRef]

- Nehler, T. A Systematic Literature Review of Methods for Improved Utilisation of the Non-Energy Benefits of Industrial Energy Efficiency. Energies 2018, 11, 3241. [Google Scholar] [CrossRef]

- Nehler, T. Linking Energy Efficiency Measures in Industrial Compressed Air Systems with Non-Energy Benefits—A Review. Renew. Sustain. Energy Rev. 2018, 89, 72–87. [Google Scholar] [CrossRef]

- Nehler, T.; Parra, R.; Thollander, P. Implementation of Energy Efficiency Measures in Compressed Air Systems: Barriers, Drivers and Non-Energy Benefits. Energy Effic. 2018, 11, 1281–1302. [Google Scholar] [CrossRef]

- Thollander, P.; Karlsson, M.; Rohdin, P.; Wollin, J.; Rosenqvist, J. 7-Investments, Nonenergy Benefits, and Conservation. In Introduction to Industrial Energy Efficiency. Energy Auditing, Energy Management, and Policy Issues; Thollander, P., Karlsson, M., Rohdin, P., Wollin, J., Rosenqvist, J., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 147–158. ISBN 978-0-12-817247-6. [Google Scholar]

- UNIDO. Global Industrial Energy Efficiency Benchmarking. An Energy Policy Tool Working Paper; United Nations Industrial Development Organization: Vienna, Austria, 2010. [Google Scholar]

- Fleiter, T.; Eichhammer, W.; Wietschel, M.; Hagemann, M.; Hirzel, S. Costs and Potentials of Energy Savings in European Industry—A Critical Assessment of the Concept of Conservation Supply Curves. In Proceedings of the ECEEE 2009 Summer Study, La Colle sur Loup, France, 1–6 June 2009; pp. 1261–1272. [Google Scholar]

- Evans, L.; Kauffman, A.; Woods, D.; Kwon, H.; Haydock, H.; Morgan-Price, S.; Tweed, J. Assessment and Communication of Relevant EU-Funded Projects Supporting the Market Uptake of Energy Efficiency Measures in Industry and Services Final Report Study Contract Number EASME/2019/OP/0011; European Commission. Publications Office of the European Union: Luxembourg, 2021. [Google Scholar]

- DeCanio, S.J. Barriers within Firms to Energy-Efficient Investments. Energy Policy 1993, 21, 906–914. [Google Scholar] [CrossRef]

- Decanio, S.J. The Efficiency Paradox: Bureaucratic and Organizational Barriers to Profitable Energy-Saving Investments. Energy Policy 1998, 26, 441–454. [Google Scholar] [CrossRef]

- Sorrell, S.; Schleich, J.; Scott, S.; O’malley, E.; Trace, F.; Boede, U.; Koewener, D.; Mannsbart, W.; Ostertag, K.; Radgen, P. Reducing Barriers to Energy Efficiency in Private and Public Organisations. Final Report; European Commission-Non Nuclear Energy Programme: Joule III, JOS3CT970022; European Commission: Brussels, Belgium, 1998. [Google Scholar]

- Blumstein, C.; Krieg, B.; Schipper, L.; York, C. Overcoming Social and Institutional Barriers to Energy Conservation. Energy 1980, 5, 355–371. [Google Scholar] [CrossRef]

- Jaffe, A.B.; Stavins, R.N. The Energy-Efficiency Gap What Does It Mean? Energy Policy 1994, 22, 804–810. [Google Scholar] [CrossRef]

- O’Malley, E.; Scott, S.; Sorrell, S. The Economics of Energy Efficiency: Barriers to Cost-Effective Investment SONNET-Social Innovation in Energy Transitions View Project Environment Policy View Project; The Economic and Social Research Institute: Dublin, Ireland, 2003. [Google Scholar]

- Sorrell, S.; O’Malley, E.; Schleich, J.; Scott, S. The Economics of Energy Efficiency: Barriers to Cost-Effective Investment; Edward Elgar: Cheltenham, UK, 2004; ISBN 9781840648898. [Google Scholar]

- Jollands, N.; Waide, P.; Ellis, M.; Onoda, T.; Laustsen, J.; Tanaka, K.; de T’Serclaes, P.; Barnsley, I.; Bradley, R.; Meier, A. The 25 IEA Energy Efficiency Policy Recommendations to the G8 Gleneagles Plan of Action. Energy Policy 2010, 38, 6409–6418. [Google Scholar] [CrossRef]

- Cagno, E.; Worrell, E.; Trianni, A.; Pugliese, G. A Novel Approach for Barriers to Industrial Energy Efficiency. Renew. Sustain. Energy Rev. 2013, 19, 290–308. [Google Scholar] [CrossRef]

- Fleiter, T.; Hirzel, S.; Worrell, E. The Characteristics of Energy-Efficiency Measures—A Neglected Dimension. Energy Policy 2012, 51, 502–513. [Google Scholar] [CrossRef]

- Nigohosyan, D.; Vutsova, A.; Vassileva, I. Effectiveness and Efficiency of the EU-Supported Energy Efficiency Measures for SMEs in Bulgaria in the Period 2014–2020: Programme Design Implications. Energy Effic. 2021, 14, 24. [Google Scholar] [CrossRef]

- Rahbauer, S.; Menapace, L.; Menrad, K.; Decker, T. Adoption of Green Electricity by Small- and Medium-Sized Enterprises in Germany. Renew. Sustain. Energy Rev. 2016, 59, 1185–1194. [Google Scholar] [CrossRef]

- Meijer, L.L.J.; Huijben, J.C.C.M.; van Boxstael, A.; Romme, A.G.L. Barriers and Drivers for Technology Commercialization by SMEs in the Dutch Sustainable Energy Sector. Renew. Sustain. Energy Rev. 2019, 112, 114–126. [Google Scholar] [CrossRef]

- Duc Luong, N. A Critical Review on Energy Efficiency and Conservation Policies and Programs in Vietnam. Renew. Sustain. Energy Rev. 2015, 52, 623–634. [Google Scholar] [CrossRef]

- Johansson, I.; Thollander, P.; Esteban, E.; Schalk, K.; Baurecht, D.; Janssen, M.; Scimemi, G.; Engers, C.; Marian, M. Review of Regional Energy Efficiency Policies towards Industrial SMEs from within Europe. In Proceedings of the ECEEE 2020 Industrial Summer Study, Online, 13–16 September 2020; pp. 15–22. [Google Scholar]

- Hrovatin, N.; Dolšak, N.; Zorić, J. Factors Impacting Investments in Energy Efficiency and Clean Technologies: Empirical Evidence from Slovenian Manufacturing Firms. J. Clean. Prod. 2016, 127, 475–486. [Google Scholar] [CrossRef]

- Önüt, S.; Soner, S. Analysis of Energy Use and Efficiency in Turkish Manufacturing Sector SMEs. Energy Convers. Manag. 2007, 48, 384–394. [Google Scholar] [CrossRef]

- Farkas, T.; Muresan, C.; Stet, D.; Czumbil, L.; Ceclan, A.; Micu, D.D. The Impact of an Energy Efficiency Action Plan for an Energy-Intensive SME in Romania—A Case Study. In Proceedings of the SyNERGY MED 2022-2nd International Conference on Energy Transition in the Mediterranean Area, Thessaloniki, Greece, 17–19 October 2022. [Google Scholar]

- Fernández-Viñé, M.B.; Gómez-Navarro, T.; Capuz-Rizo, S.F. Eco-Efficiency in the SMEs of Venezuela. Current Status and Future Perspectives. J. Clean. Prod. 2010, 18, 736–746. [Google Scholar] [CrossRef]

- Pathirana, S.; Yarime, M. Introducing Energy Efficient Technologies in Small- and Medium-Sized Enterprises in the Apparel Industry: A Case Study of Sri Lanka. J. Clean. Prod. 2018, 178, 247–257. [Google Scholar] [CrossRef]

- Al-Ghandoor, A.; ALSalaymeh, M.; Al-Abdallat, Y.; Al-Rawashdeh, M. Energy and Exergy Utilizations of the Jordanian SMEs Industries. Energy Convers. Manag. 2013, 65, 682–687. [Google Scholar] [CrossRef]

- Souhankar, A.; Mortezaee, A.; Hafezi, R. Potentials for Energy-Saving and Efficiency Capacities in Iran: An Interpretive Structural Model to Prioritize Future National Policies. Energy 2023, 262, 125500. [Google Scholar] [CrossRef]

- Hassan, M.T.; Burek, S.; Asif, M. Barriers to Industrial Energy Efficiency Improvement–Manufacturing SMEs of Pakistan. Energy Procedia 2017, 113, 135–142. [Google Scholar] [CrossRef]

- Fadly, D. Greening Industry in Vietnam: Environmental Management Standards and Resource Efficiency in SMEs. Sustainability 2020, 12, 7455. [Google Scholar] [CrossRef]

- Haselip, J.; Desgain, D.; Mackenzie, G. Financing Energy SMEs in Ghana and Senegal: Outcomes, Barriers and Prospects. Energy Policy 2014, 65, 369–376. [Google Scholar] [CrossRef]

- Rademaekers, K.; Smith, M.; Demurtas, A.; Torres-Vega, P.C.; Janzow, N.; Zibell, L.; Hoogland, O.; Pollier, K.; Crènes, M.; Radigois, G.; et al. Study on Energy Prices, Costs and Their Impact on Industry and Households (ENER/A4/2019-179); European Commission. DG Ener. Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Constantinos, C.; Sørensen, S.Y.; Larsen, P.B.; Alexopoulou, S. SMEs and the Environment in the European Union; Publications Office of the European Union: Luxembourg, 2010; Available online: https://op.europa.eu/en/publication-detail/-/publication/aa507ab8-1a2a-4bf1-86de-5a60d14a3977 (accessed on 22 January 2024).

- Hasanbeigi, A.; Price, L. A Review of Energy Use and Energy Efficiency Technologies for the Textile Industry. Renew. Sustain. Energy Rev. 2012, 16, 3648–3665. [Google Scholar] [CrossRef]

- Kannan, R.; Boie, W. Energy Management Practices in SME––Case Study of a Bakery in Germany. Energy Convers. Manag. 2003, 44, 945–959. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Thollander, P.; Backlund, S. Barriers to Industrial Energy Efficiency in Foundries: A European Comparison. J. Clean. Prod. 2013, 40, 161–176. [Google Scholar] [CrossRef]

- Jaroszewska, M.; Chaja, P.; Dziadkiewicz, A. Sustainable Energy Management: Are Tourism SMEs in Poland Ready for Circular Economy Solutions? Int. J. Sustain. Energy Plan. Manag. 2019, 24, 75–84. [Google Scholar] [CrossRef]

- Latini, A.; Viola, C.; Scoccianti, M.; Campiotti, C.A. An Energetic Outlook of the Italian Food and Drink Industry. Qual.-Access Success 2014, 15, 333–339. [Google Scholar]

- Andersson, E.; Karlsson, M.; Thollander, P.; Paramonova, S. Energy End-Use and Efficiency Potentials among Swedish Industrial Small and Medium-Sized Enterprises—A Dataset Analysis from the National Energy Audit Program. Renew. Sustain. Energy Rev. 2018, 93, 165–177. [Google Scholar] [CrossRef]

- Haavikko, H.; Kärhä, K.; Hourula, M.; Palander, T. Attitudes of Small and Medium-Sized Enterprises towards Energy Efficiency in Wood Procurement: A Case Study of Stora Enso in Finland. Croat. J. For. Eng. 2019, 40, 107–123. [Google Scholar]

- Hertel, M.; Menrad, K. Adoption of Energy-Efficient Technologies in German SMEs of the Horticultural Sector—The Moderating Role of Personal and Social Factors. Energy Effic. 2016, 9, 791–806. [Google Scholar] [CrossRef]

- Kimura, O.; Noda, F. Does Regulation of Energy Management Systems Work? A Case Study of the Energy Conservation Law in Japan. In Proceedings of the ECEEE 2014 Industrial Summer Study, Arnhem, The Netherlands, 2–5 June 2014; pp. 647–657. [Google Scholar]

- Trianni, A.; Cagno, E.; Farné, S. Barriers, Drivers and Decision-Making Process for Industrial Energy Efficiency: A Broad Study among Manufacturing Small and Medium-Sized Enterprises. Appl. Energy 2016, 162, 1537–1551. [Google Scholar] [CrossRef]

- Paramonova, S.; Thollander, P. Energy-Efficiency Networks for SMEs: Learning from the Swedish Experience. Renew. Sustain. Energy Rev. 2016, 65, 295–307. [Google Scholar] [CrossRef]

- Backlund, S.; Thollander, P. Impact after Three Years of the Swedish Energy Audit Program. Energy 2015, 82, 54–60. [Google Scholar] [CrossRef]

- Muthulingam, S.; Corbett, C.J.; Benartzi, S.; Oppenheim, B. Energy Efficiency in Small and Medium-Sized Manufacturing Firms: Order Effects and the Adoption of Process Improvement Recommendations. Manuf. Serv. Oper. Manag. 2013, 15, 596–615. [Google Scholar] [CrossRef]

- USDOE. Industrial Assessment Centers (IACs) IACs Database. Available online: https://iac.university/ (accessed on 22 January 2024).

- Biele, E.; Herce, C.; Martini, C.; Salvio, M.; Toro, C. LEAP4SME International Observatory on Energy Efficiency Policies for Enterprises and SMEs: Key Messages. In Proceedings of the 17th Conference on Sustainable Development of Energy, Water and Environment Systems (SDEWES), Paphos, Cyprus, 6–10 November 2022. [Google Scholar]

- Toro, C. Energy Audits and EnMS: Key Messages from the Project National Observatories, Programme Assessments and Policy Implementation. In Proceedings of the International Observatory on Energy Efficiency in SMEs-LEAP4SME Final Event, Brussels, Belgium, 4 July 2023. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herce, C.; Martini, C.; Toro, C.; Biele, E.; Salvio, M. Energy Efficiency Policies for Small and Medium-Sized Enterprises: A Review. Sustainability 2024, 16, 1023. https://doi.org/10.3390/su16031023

Herce C, Martini C, Toro C, Biele E, Salvio M. Energy Efficiency Policies for Small and Medium-Sized Enterprises: A Review. Sustainability. 2024; 16(3):1023. https://doi.org/10.3390/su16031023

Chicago/Turabian StyleHerce, Carlos, Chiara Martini, Claudia Toro, Enrico Biele, and Marcello Salvio. 2024. "Energy Efficiency Policies for Small and Medium-Sized Enterprises: A Review" Sustainability 16, no. 3: 1023. https://doi.org/10.3390/su16031023

APA StyleHerce, C., Martini, C., Toro, C., Biele, E., & Salvio, M. (2024). Energy Efficiency Policies for Small and Medium-Sized Enterprises: A Review. Sustainability, 16(3), 1023. https://doi.org/10.3390/su16031023