Research on the Mechanism of Coal-Wall Spalling and Flexible Reinforcement in Soft-Coal Seams Based on the Mogi–Coulomb Criterion

Abstract

1. Introduction

2. Materials and Methods

2.1. Project Overview of 91–105 Working Face of Lu’an Wangzhuang Coal Mine

2.2. Research Methods

3. Results and Analysis

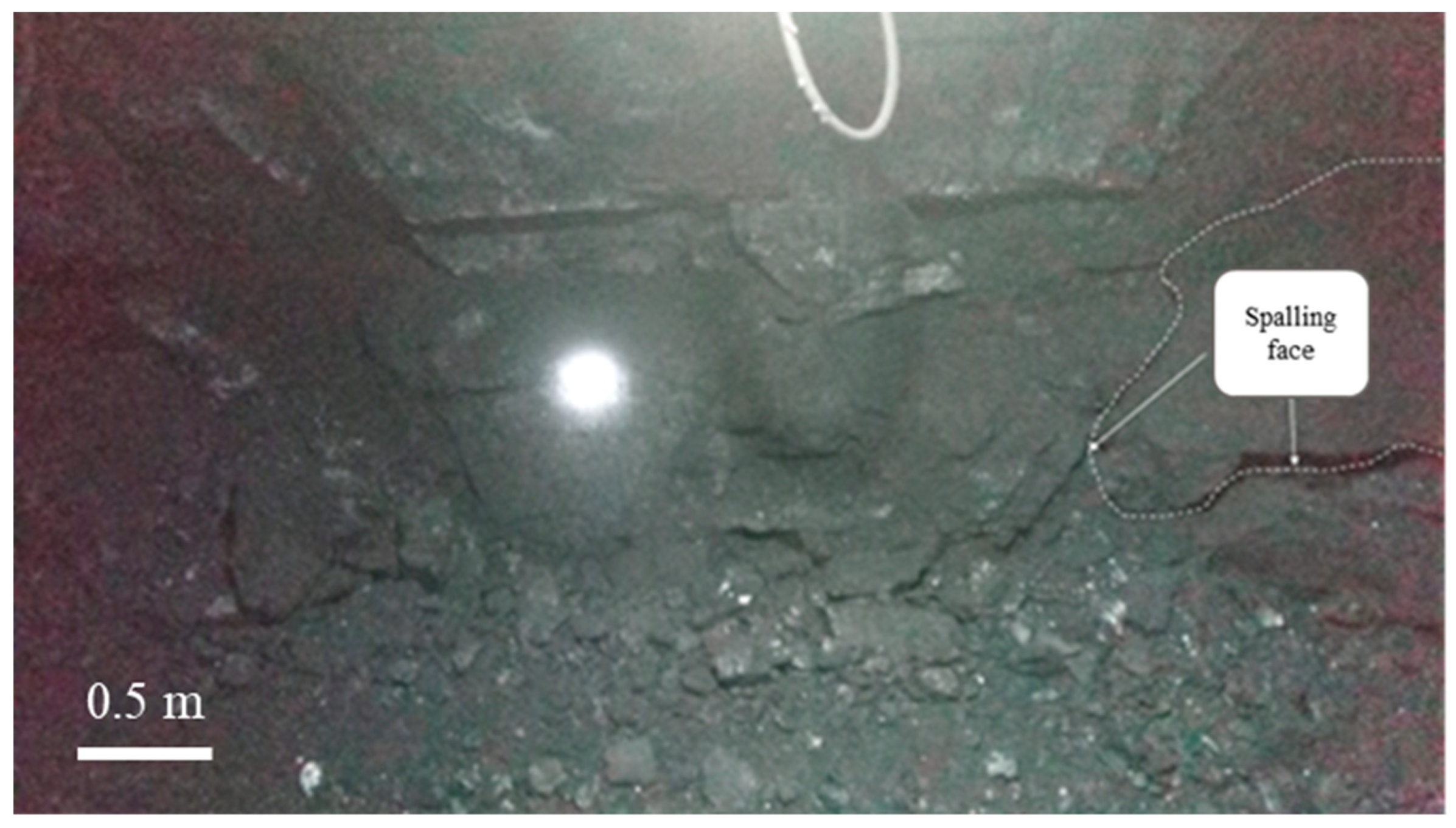

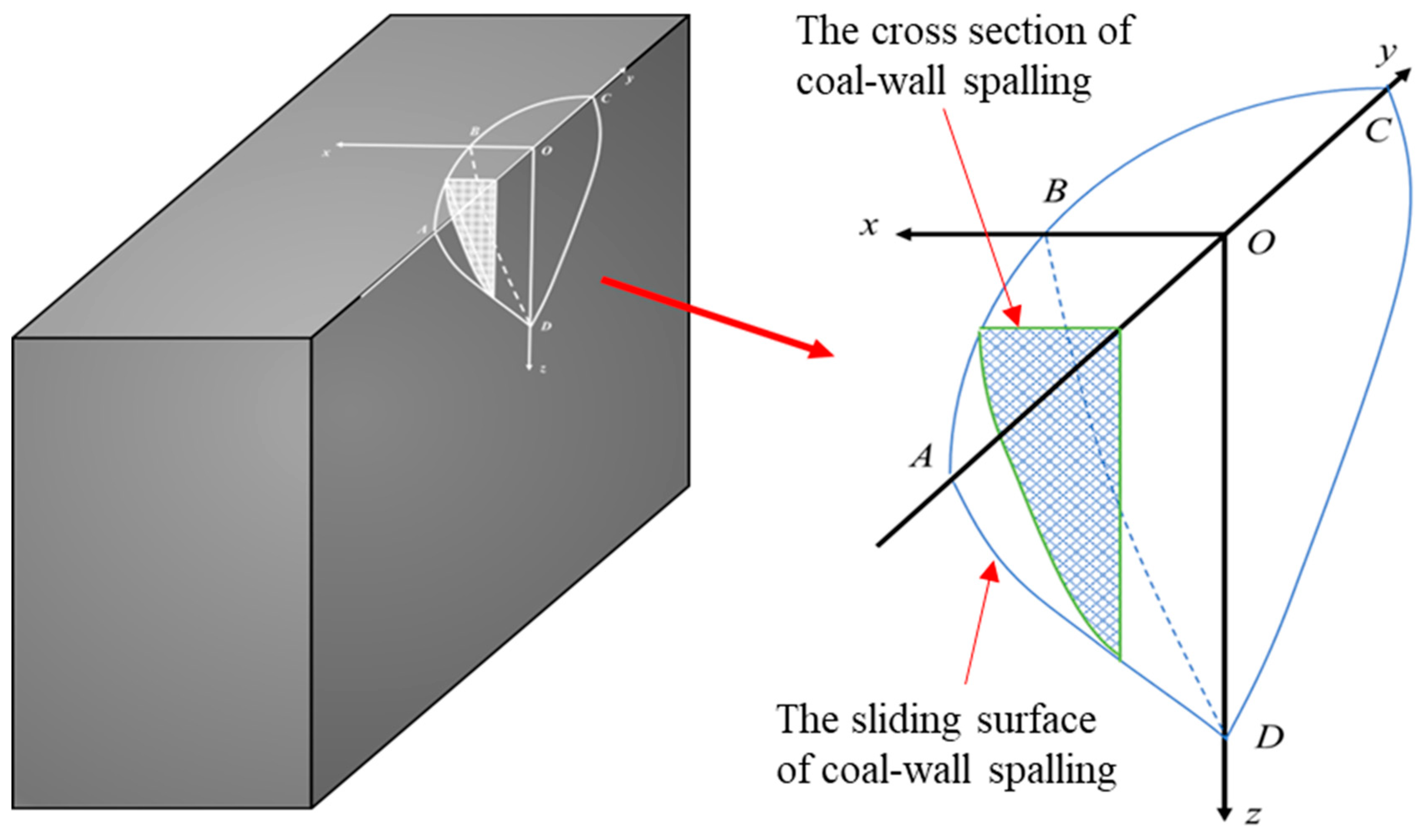

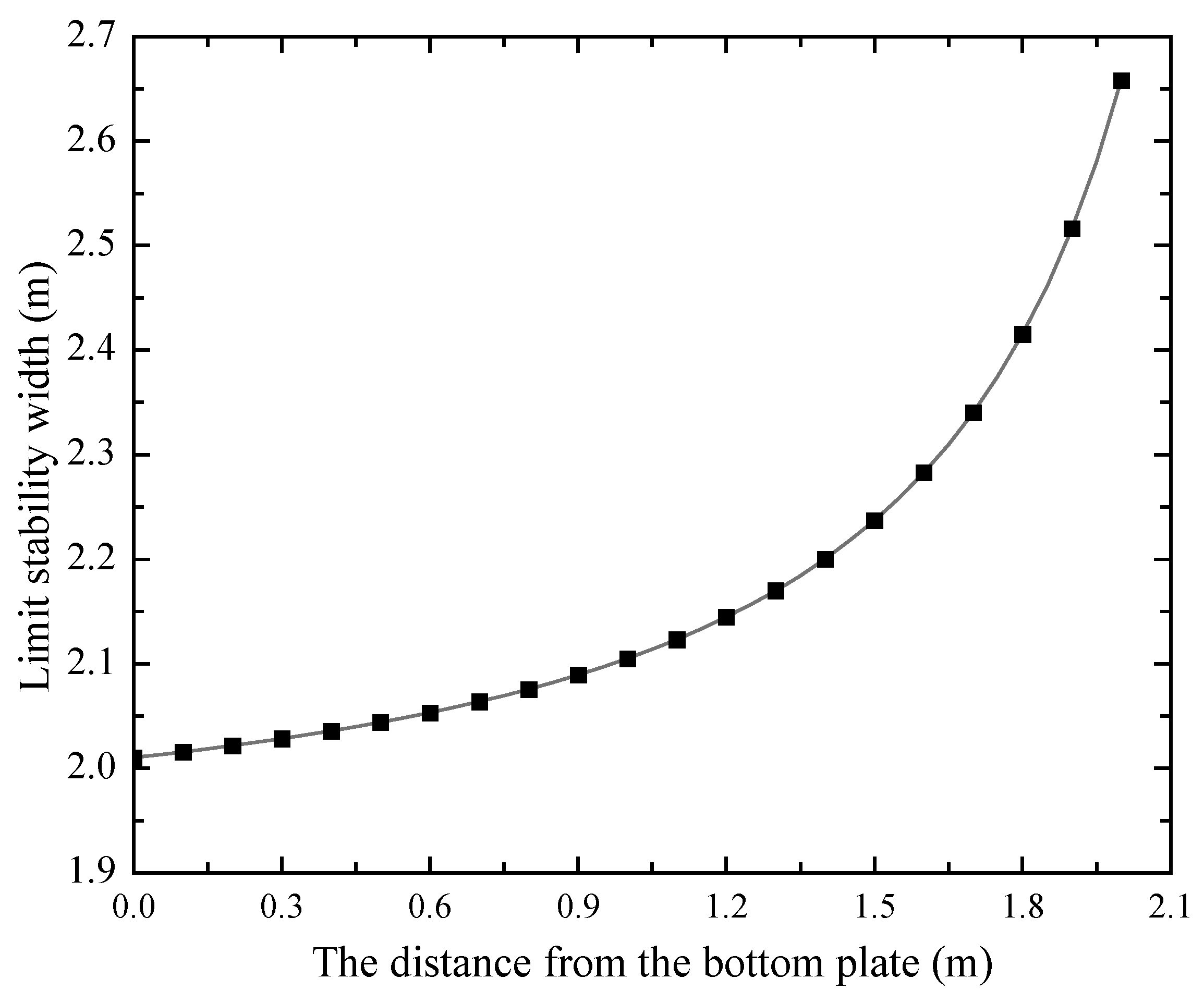

3.1. Determination of the Spalling Shape of the Soft-Coal Seam

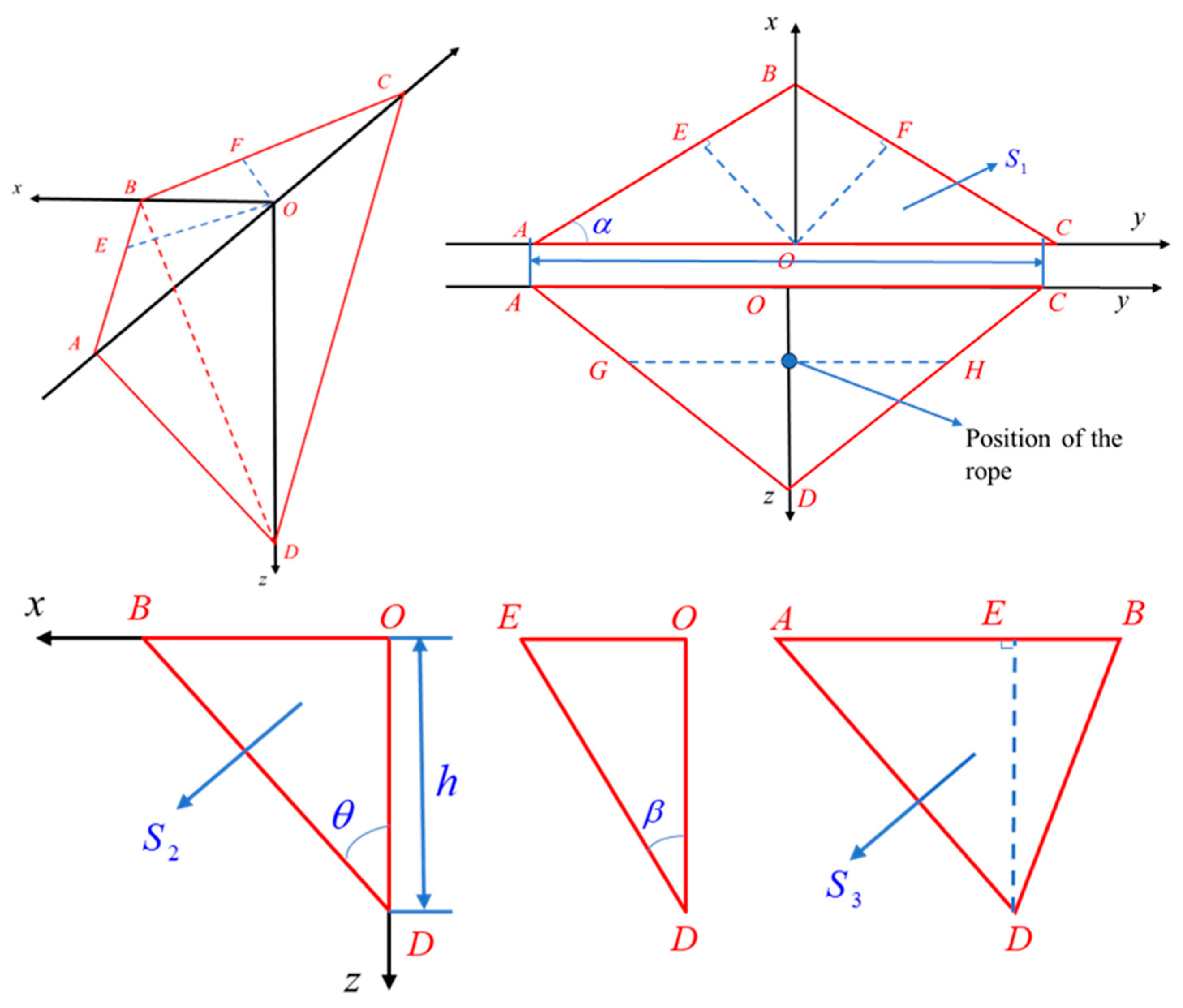

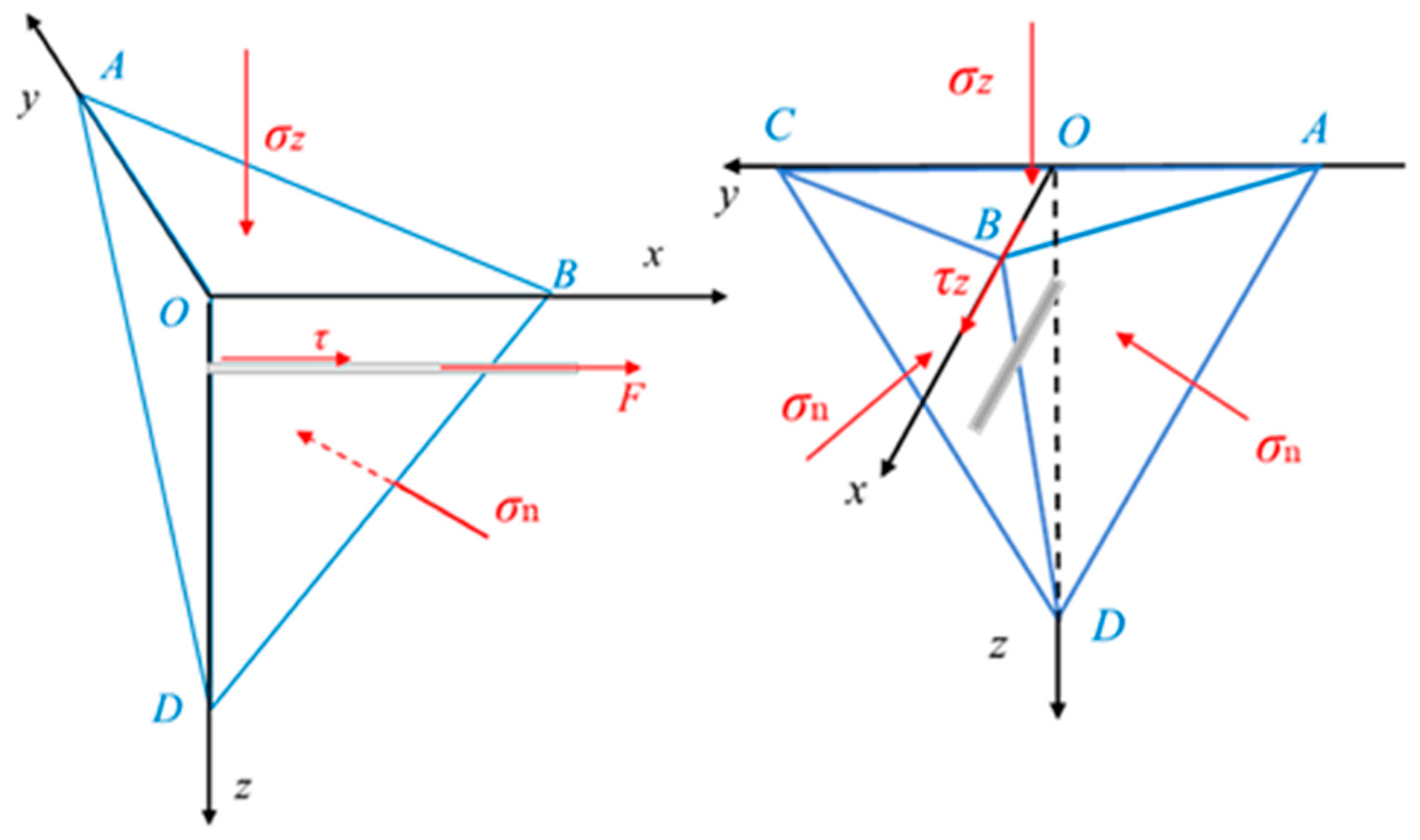

3.2. Determination of the Safety-Stability Coefficient of the Coal-Wall Sliding Face

3.3. Analysis of Mechanism of Grouting–Flexible Rope Reinforcement

4. Discussion

4.1. The Effect of Parameters Affecting Stability of Coal Wall

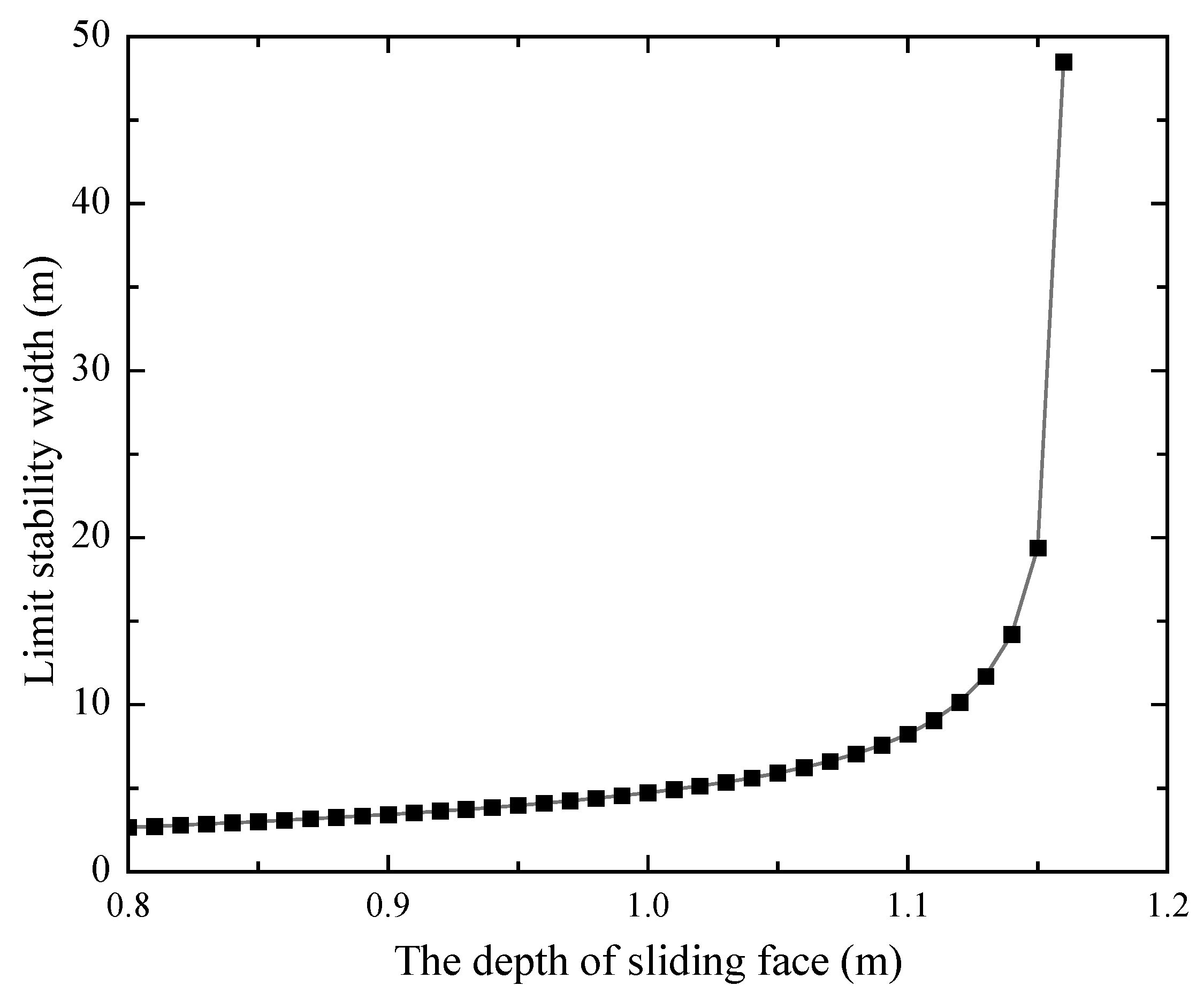

- (1)

- Safety-stability coefficient at different sliding face positions

- (2)

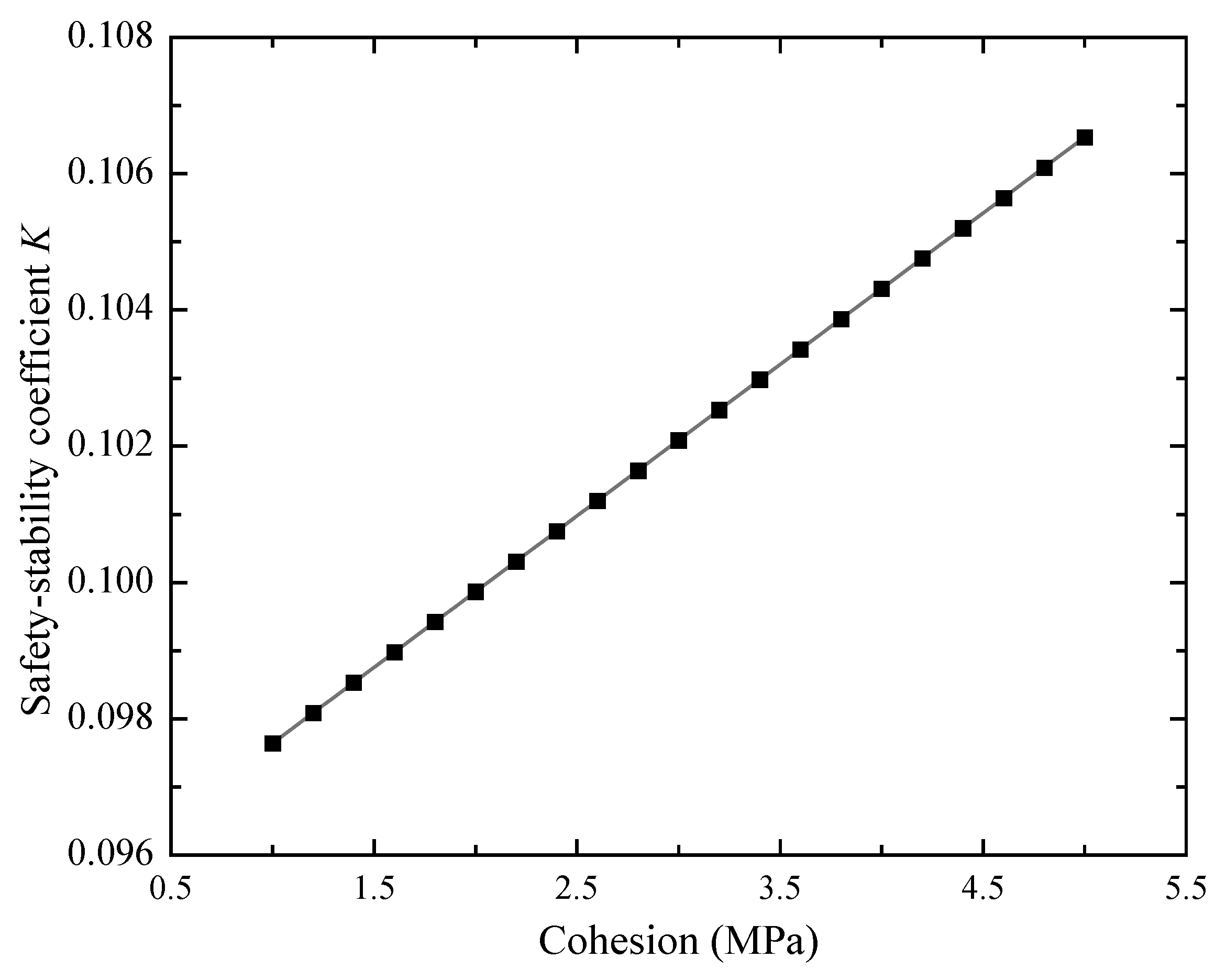

- Influence of cohesion and internal friction angle on safety-stability coefficient

- (3)

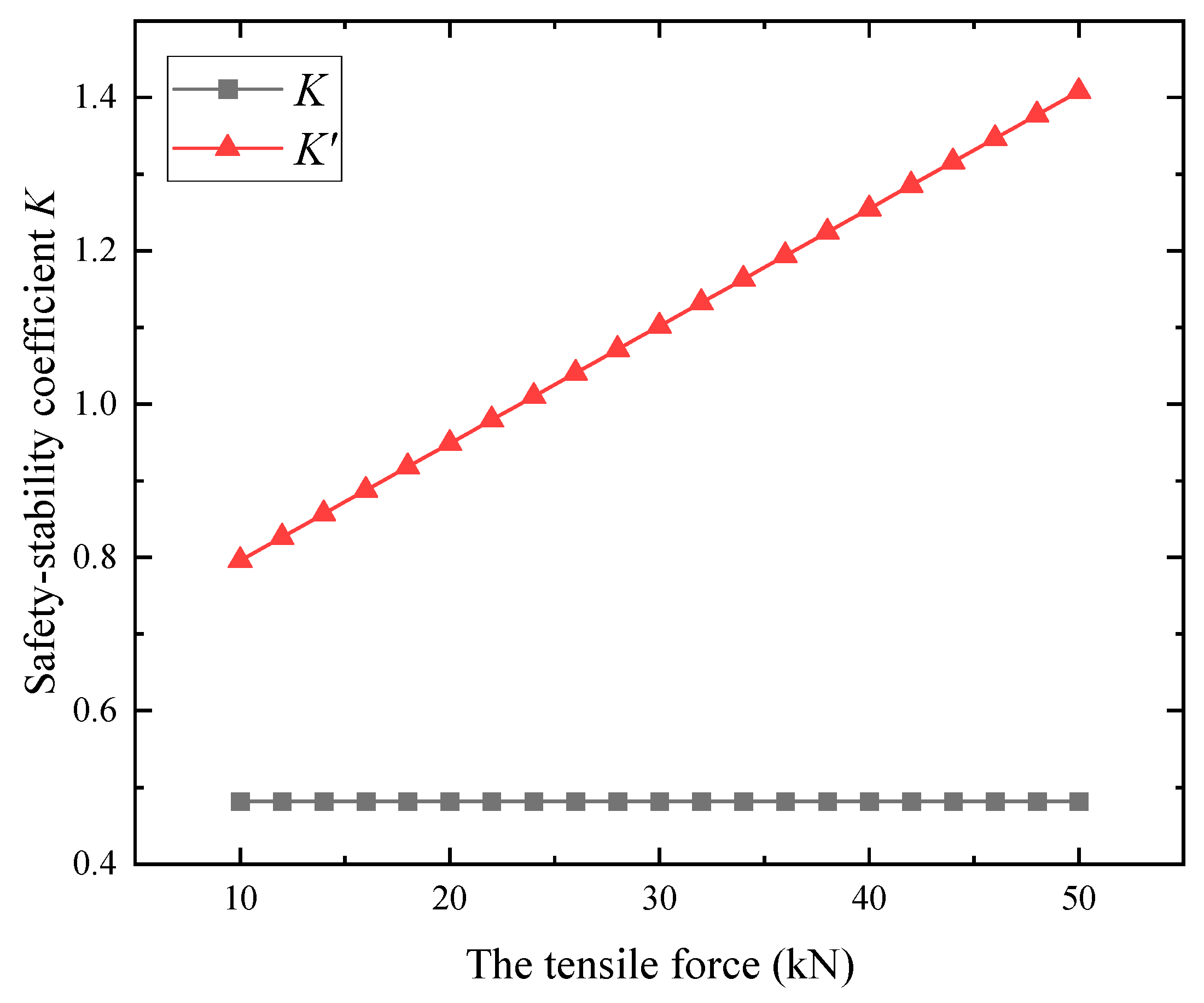

- Influence of the maximum tension of the flexible rope on the safety-stability coefficient

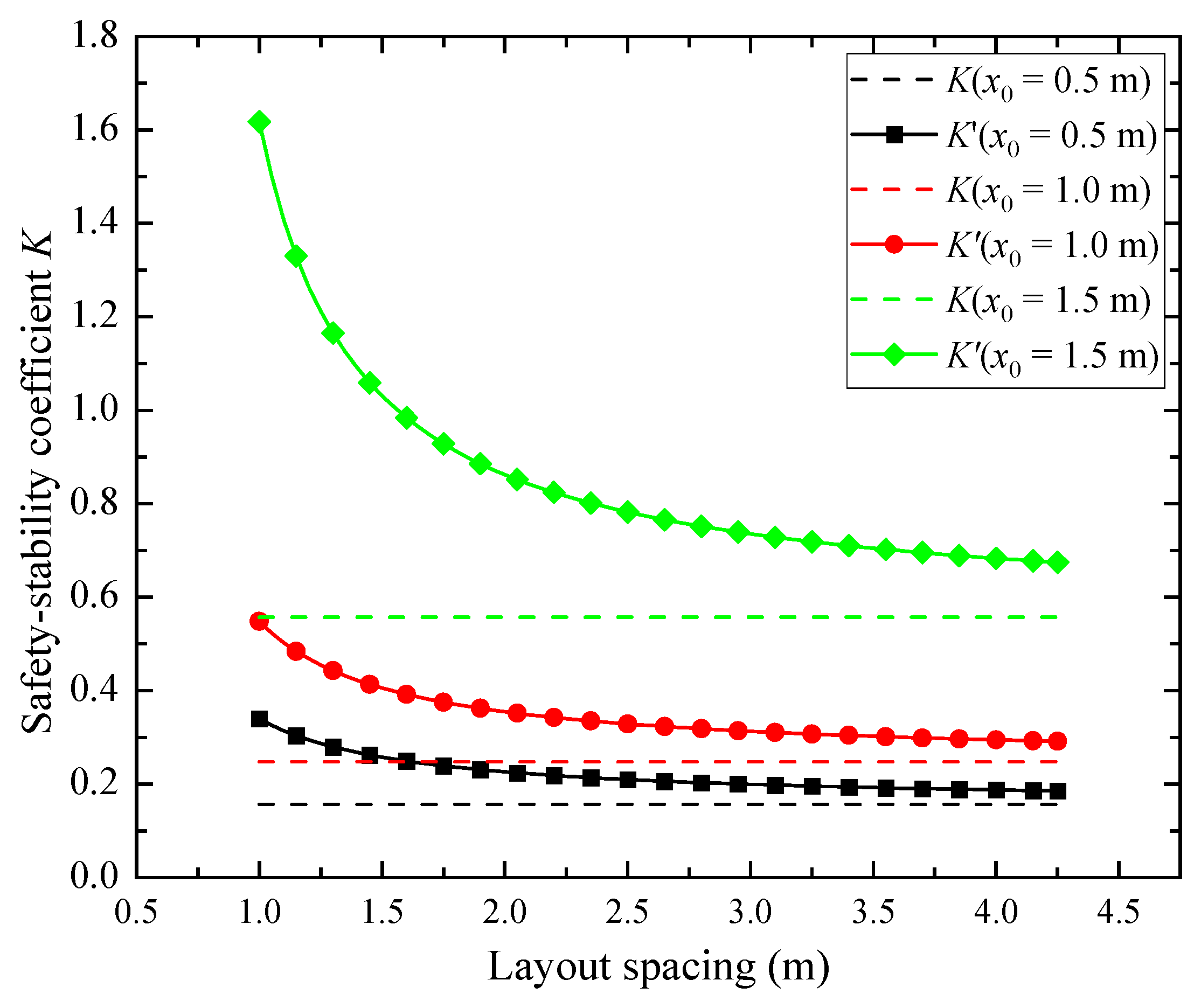

4.2. The Effect of Parameters on the Normal Stress of the Flexible Reinforcement System

4.3. Methods and Measures for Preventing Spalling

4.4. Application Examples

4.5. Model Applicability and Scalability

5. Conclusions

- (1)

- Based on the Mogi–Coulomb criterion and the ultimate equilibrium condition of the mechanical model, the differential equation of the coal-wall slip surface is formulated. The functional relationship of the slip surface is obtained, and the soft coal-wall slip surface can be approximated as a straight line. Therefore, traces of coal-wall spalling can be approximated as linear.

- (2)

- Based on the Mogi–Coulomb criterion, combined with the limit-equilibrium analysis method, the mechanical model of the coal wall is created. The calculation formula of the safety-stability coefficient of the coal wall is obtained. It is found that the stability of the coal wall is related to the properties of the coal body (cohesion and internal friction angle). The higher the cohesion and internal friction angle of the coal body, the better the safety and stability of the coal wall. The larger cohesion of coal can effectively stop coal-wall spalling. Therefore, the cohesion of the coal can be improved through flexible reinforcement so as to improve the stability of the coal body. It was determined that the most dangerous sliding surface of the 91–105 working face of the Lu’an Wangzhuang coal mine was located at 0.6 times the mining height.

- (3)

- The influencing mechanism of the safety -factor, the ultimate stability width, and the key reinforcement parameters of the sliding surface of the coal wall after flexible reinforcement were analyzed. After flexible reinforcement, the occurrence of spalling can be effectively prevented through the action of the flexible reinforcement system. The reinforcement effect is mainly related to the strength of the flexible rope, the aperture ratio, the laying spacing, and the selection of the reinforcement materials. Flexible ropes with strong load-bearing capacity can enhance the reinforcement effect. The flexible reinforcement effect is mainly affected by the tensile force generated by the flexible rope and the friction between the slurry and coal and between the flexible rope and coal. The opposite trend between the two friction forces makes it necessary to select a certain value of the aperture ratio to ensure the reinforcement effect. Smaller laying spacing can quickly enhance reinforcement, but it can also increase costs. It is necessary to reasonably select the reinforcement material and determine the reinforcement parameters, such as aperture ratio and layout spacing. This paper proposes an alternative method for determining the layout spacing. With a layout spacing of 1.5 m, the safety-stability factor at 0.6 times the mining height increases from 0.09 to 1.03.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, G.; Li, Z.; Du, F.; Cao, Z. Study on the failure characteristics of coal wall spalling in thick coal seam with gangue. Adv. Civ. Eng. 2020, 2020, 6668458. [Google Scholar] [CrossRef]

- Hongwei, W.; Li, F.; Zhouyan, Z.; Yanjun, L.; Peipei, C.; Jianqiang, J.; Baolin, J.; Yong, L. Coal-wall spalling prevention mechanism using advance-grooving pressure relief in the large-mining-height working face of a shallow coal seam. Energy Sci. Eng. 2024, 12, 5105–5118. [Google Scholar] [CrossRef]

- Jing, G. Drainage-weathering damage rule of thick coal seam and micro-blasting control technology of coal wall rib spalling. Min. Saf. Environ. Prot. 2023, 50, 109–113. [Google Scholar]

- Liu, H.; Chen, Y.; Han, Z.; Liu, Q.; Luo, Z.; Cheng, W.; Zhang, H.; Qiu, S.; Wang, H. Coal wall spalling mechanism and grouting reinforcement technology of large mining height working face. Sensors 2022, 22, 8675. [Google Scholar] [CrossRef] [PubMed]

- Xue, B.; Wang, C.; Wang, Y.; Zhang, W.; Yang, S. An investigation of the coal wall zoning failure patterns resulting from the changes in support parameters of large mining height. Mech. Time-Depend. Mater. 2023, 28, 2599–2618. [Google Scholar] [CrossRef]

- Li, F.; Wang, C.; Li, Z.; Duan, B.; Xia, B.; Liang, D. Study on the evolution characteristics of coal mass spalling during coal and gas outbursts. Phys. Scr. 2024, 99, 105052. [Google Scholar] [CrossRef]

- Li, S.; Wang, L.; Zhu, C.; Ren, Q. Research on mechanism and control technology of rib spalling in soft coal seam of deep coal mine. Adv. Mater. Sci. Eng. 2021, 2021, 2833210. [Google Scholar] [CrossRef]

- Liu, X.; Cai, D.; Gu, Z.; Zhang, S.; Zhou, X.; Gao, A. Analysis of progressive damage and energy consumption characteristics of gas-bearing coal under cyclic dynamic loads. Energy 2024, 306, 132419. [Google Scholar] [CrossRef]

- Zang, Z.; Li, Z.; Gu, Z.; Niu, Y.; Yin, S.; Kong, X.; Zhang, X. The multi-dimensional joint response of the electric potential time–frequency-field in the fracture process of flawed coal under dynamic load. Theor. Appl. Fract. Mec. 2024, 131, 104415. [Google Scholar] [CrossRef]

- Guo, W.; Wang, G.; Li, Y.; Chen, D. Research on coal wall failure and stability control technology of large coal seams with a soft and thick seam. Energy Sci. Eng. 2024, 12, 3599–3613. [Google Scholar] [CrossRef]

- Li, G.; Wang, X.; Bai, J.; Zhang, Y.; Zhang, F.; Li, M. Weighting Failure Mechanisms of Pre-Driven Recovery Rooms and Evaluation of Hydraulic Fracturing Applications: A Case Study. Appl. Sci. 2023, 13, 5116. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Q.; Zhang, J.; Liu, H.; Zhu, G.; Wang, Y. Study on the controller factors associated with roof falling and ribs spalling in deep mine with great mining height and compound roof. Eng. Fail. Anal. 2021, 129, 105723. [Google Scholar] [CrossRef]

- Chen, B.; Liu, C.; Wu, F. A deep-hole microblasting technique for controlling coal wall spalling during mining of a vertically jointed seam. Energy Sci. Eng. 2022, 10, 2253–2267. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J.; Zhou, N.; Sun, Q.; Li, M.; Cui, Z. Experimental investigation into the bedding plane slip effect on the overlying strata behavior in longwall top coal caving of soft coal seam. Adv. Civ. Eng. 2019, 2019, 1718751. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, J.; Lin, H.; Liu, H.; Gao, S.; He, Y. The catastrophic failure mechanisms and the prevention of dynamic pressure-related hazards during mining under an interval goaf through an isolated coal pillar in shallow and closely spaced coal seams. Appl. Sci. 2024, 14, 10554. [Google Scholar] [CrossRef]

- Cui, F.; Zhang, T.; Cheng, X. Research on control of rib spalling disaster in the three-soft coal seam. Shock Vib. 2021, 2021, 2404218. [Google Scholar] [CrossRef]

- Tian, M.; Han, L.; Xiao, H.; Meng, Q. Experimental study of deformations and failures of the coal wall in a longwall working face. Eng. Fail. Anal. 2021, 125, 105428. [Google Scholar] [CrossRef]

- Li, G.; Li, Z.; Du, F.; Cao, Z. Mechanical mechanism of rib spalling and sensitivity analysis of gangue parameters to rib spalling in gangue-bearing coal seams. Environ. Sci. Pollut. Res. 2023, 30, 38713–38727. [Google Scholar] [CrossRef]

- Jiao, H.; Yang, W.; Chen, X.; Yang, L.; Li, Z. High mining face flexible reinforcement to prevent coal wall spalling by cuttable aluminum–plastic pipe pre-grouting. Energies 2022, 15, 3233. [Google Scholar] [CrossRef]

- An, Y.; Zhang, N.; Zhao, Y.; Xie, Z. Field and numerical investigation on roof failure and fracture control of thick coal seam roadway. Eng. Fail. Anal. 2021, 128, 105594. [Google Scholar] [CrossRef]

- Liu, X.; Wang, W.; Liu, Q.; Yuan, C. The mechanism of reinforced backfill body with flexible mesh. Adv. Civ. Eng. 2021, 2021, 5569708. [Google Scholar] [CrossRef]

- Xie, S.; Pan, H.; Chen, D.; Zeng, J.; Song, H.; Cheng, Q.; Xiao, H.; Yan, Z.; Li, Y. Stability analysis of integral load-bearing structure of surrounding rock of gob-side entry retention with flexible concrete formwork. Tunn. Undergr. Sp. Tech. 2020, 103, 103492. [Google Scholar] [CrossRef]

- Chao, Z.; Li, Z.; Dong, Y.; Shi, D.; Zheng, J. Estimating compressive strength of coral sand aggregate concrete in marine environment by combining physical experiments and machine learning-based techniques. Ocean Eng. 2024, 308, 118320. [Google Scholar] [CrossRef]

- Chao, Z.; Fowmes, G.; Mousa, A.; Zhou, J.; Zhao, Z.; Zheng, J.; Shi, D. A new large-scale shear apparatus for testing geosynthetics-soil interfaces incorporating thermal condition. Geotext. Geomembr. 2024, 52, 999–1010. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, E.; Li, M.; Song, Z.; Zhang, L.; Zhao, D. Mechanical response and gas flow characteristics of pre-drilled coal subjected to true triaxial stresses. Gas Sci. Eng. 2023, 111, 204927. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, E.; Jiang, C.; Zhang, D.; Li, M.; Yu, B.; Zhao, D. True triaxial experimental study of anisotropic mechanical behavior and permeability evolution of initially fractured coal. Nat. Resour. Res. 2023, 32, 567–585. [Google Scholar] [CrossRef]

- You, M. True-triaxial strength criteria for rock. Int. J. Rock Mech. Min. Sci. 2009, 46, 115–127. [Google Scholar] [CrossRef]

- Xie, H.; Lu, J.; Li, C.; Li, M.; Gao, M. Experimental study on the mechanical and failure behaviors of deep rock subjected to true triaxial stress: A review. Int. J. Min. Sci. Technol. 2022, 32, 915–950. [Google Scholar] [CrossRef]

- Al-Ajmi, A.M.; Zimmerman, R.W. Relation between the Mogi and the Coulomb failure criteria. Int. J. Rock Mech. Min. Sci. 2005, 42, 431–439. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, M.; Chen, Y.; Dong, Z.; Chen, H.; Chen, S.; Xue, J.; Konietzky, H. Coupled numerical simulation of coal failure caused by thermal impacting in Underground coal gasification zone. In Proceedings of the ARMA US Rock Mechanics/Geomechanics Symposium, Golden, CO, USA, 23 June 2024. [Google Scholar]

- Xue, B.; Zhang, W.; Wang, C. Determination of working resistance of support parameter variation of large mining height support: The case of Caojiatan coal mine. Geomech. Geophys. Geo-Resour. 2024, 10, 1. [Google Scholar] [CrossRef]

- Sun, J.; Li, B.; Zhang, R.; Huang, Z. Feasibility of water injection on the coal wall of loose thick coal seam to prevent rib spalling and its optimal moisture content. Geofluids 2022, 2022, 5733695. [Google Scholar] [CrossRef]

- Yao, Q.; Li, X.; Sun, B.; Ju, M.; Chen, T.; Zhou, J.; Liang, S.; Qu, Q. Numerical investigation of the effects of coal seam dip angle on coal wall stability. Int. J. Rock Mech. Min. Sci. 2017, 100, 298–309. [Google Scholar] [CrossRef]

- Guo, W.; Zhang, S.; Li, Y. The effect of joint damage on a coal wall and the influence of joints on the abutment pressure on a fully mechanised working face with large mining height. Shock Vib. 2021, 2021, 9963175. [Google Scholar] [CrossRef]

- Wang, J.; Yang, S.; Kong, D. Failure mechanism and control technology of longwall coalface in large-cutting-height mining method. Int. J. Min. Sci. Technol. 2016, 26, 111–118. [Google Scholar] [CrossRef]

- Lei, W.; Li, X.; Du, W.; Zhang, J.; Zhang, J.; Shang, F.; Xu, T. Research on mechanism and prevention technology of rib spalling in fully-mechanized coal mining face with soft and unstable seam. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Xi’an, China, 15–16 December 2018. [Google Scholar]

- Yu, X.; Wei, W.; Li, Z.; Li, M.; Wu, S. Stability analysis and failure control of a longwall panel with a large mining height considering fracture distribution. Bull. Eng. Geol. Environ. 2023, 82, 54. [Google Scholar]

- Wang, J.; Wang, Z. Systematic principles of surrounding rock control in longwall mining within thick coal seams. Int. J. Min. Sci. Technol. 2019, 29, 65–71. [Google Scholar] [CrossRef]

- Xu, Y.; Du, Y. Research and application of coal wall limit stability height based on wedge model. Yanshilixue Yu Gongcheng Xuebao 2022, 41, 3240–3249. [Google Scholar]

- Murmu, S.; Budi, G. Spalling hazard occurrence in longwall excavation: A case study. Min. Metall. Explor. 2023, 40, 1899–1919. [Google Scholar] [CrossRef]

- Murmu, S.; Budi, G. Study on the mechanism, prediction, and control of coal wall spalling in deep longwall panels utilizing advanced numerical simulation methodology. Geofluids 2022, 2022, 5622228. [Google Scholar] [CrossRef]

- Yang, S.; Kong, D. Flexible reinforcement mechanism and its application in the control of spalling at large mining height coal face. J. China Coal Soc. 2015, 40, 1361–1367. [Google Scholar]

- YANG, S.; YANG, Y. Experimental study on optimizing parameters of flexible reinforcement technology of coal wall. J. China Coal Soc. 2019, 44, 2622–2631. [Google Scholar]

- Guan, J. Study on instability mechanism and control technology for coal wall of large mining height fully-mechanized mining working face of coal seam 3# in Lu’an group. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2016. [Google Scholar]

- Song, J.; Wang, X. Numerical simulation study on flexible reinforcement of coal wall in working face. Coal Sci. Technol. Mag. 2020, 41, 44–47. [Google Scholar]

| The Surrounding Rock | The Lithology | Average Thickness/m |

|---|---|---|

| Main roof | Mudstone | 4.10 |

| Medium-grained sandstone | 5.60 | |

| Immediate roof | Mudstone | 7.08 |

| Immediate floor | Mudstone | 2.56 |

| Hard floor | Medium-grained sandstone | 3.35 |

| Weight kN/m3 | Elastic Modulus /GPa | Cohesion/MPa | Internal Friction Angle/° | Poisson’s Ratio | Tensile Strength/MPa | Compressive Strength /MPa | Cohesion of Direct Roof/MPa | Internal Friction Angle of Direct Roof/° |

|---|---|---|---|---|---|---|---|---|

| 14.11 | 2.87 | 1.32 | 27.38 | 0.36 | 0.88 | 13.56 | 3.46 | 23.77 |

| Drilling Diameter/mm | Depth of Drilling/m | Angle of Drilling/° | Diameter of Rope/mm | Layout Spacing/m | Aperture Ratio | Grouting Pressure/MPa | Installation Height/m |

|---|---|---|---|---|---|---|---|

| 40 | 4 | 5 | 24 | 1.5 | 1.67 | 2 | 2.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, W.; Zhao, H.; Gao, L.; Liu, Y. Research on the Mechanism of Coal-Wall Spalling and Flexible Reinforcement in Soft-Coal Seams Based on the Mogi–Coulomb Criterion. Sustainability 2024, 16, 10981. https://doi.org/10.3390/su162410981

Zhao W, Zhao H, Gao L, Liu Y. Research on the Mechanism of Coal-Wall Spalling and Flexible Reinforcement in Soft-Coal Seams Based on the Mogi–Coulomb Criterion. Sustainability. 2024; 16(24):10981. https://doi.org/10.3390/su162410981

Chicago/Turabian StyleZhao, Wenjie, Hongbao Zhao, Lu Gao, and Yubing Liu. 2024. "Research on the Mechanism of Coal-Wall Spalling and Flexible Reinforcement in Soft-Coal Seams Based on the Mogi–Coulomb Criterion" Sustainability 16, no. 24: 10981. https://doi.org/10.3390/su162410981

APA StyleZhao, W., Zhao, H., Gao, L., & Liu, Y. (2024). Research on the Mechanism of Coal-Wall Spalling and Flexible Reinforcement in Soft-Coal Seams Based on the Mogi–Coulomb Criterion. Sustainability, 16(24), 10981. https://doi.org/10.3390/su162410981