In December 2019, Europe’s Green Deal—the European Union (EU)’s commitment to become the first climate-neutral continent by 2050—was launched for the first time. Buildings are responsible for over one-third of the greenhouse gas emissions in the EU. Reducing these emissions—either through greater energy efficiency or reduced energy consumption—is crucial to achieve climate neutrality by 2050 [

5]. Buildings in the EU, as in Lithuania, account for about 40% of the total energy use [

6] and 36% of energy-related greenhouse gas emissions, which is why the 2023 update of Directive (EU) 2023/1791 of the European Parliament and of the Council of 13 September 2023 provides wider energy efficiency standards [

7]. Similarly, Directive (EU) 2024/1275 of the European Parliament and of the Council of 24 April 2024 on the energy performance of buildings states that by 2030 all new buildings, and by 2050 all buildings in the EU as a whole, should be zero-emission. The average primary energy consumption of all residential buildings should be reduced by 16% by 2030, and by 20–22% by 2035, and the renovation of the worst-performing buildings is foreseen to achieve a reduction in energy consumption of 55%. Almost 75% of existing buildings are energy-inefficient, which is why Lithuania’s long-term renovation strategy involves large-scale renovation to improve their energy performance across Europe [

8,

9]. In line with the National Energy Independence Strategy [

10], Lithuania has set targets for renewable energy sources to account for 45% of final energy consumption by 2030.

Alongside the rapid growth of the renewable energy sector, the reduction in energy consumption, including for the operation of buildings, needs equal attention. In addition to the energy needed to heat the building, the energy needed to cool the building must also be taken into account in order to make buildings sustainable. To create sustainable buildings, even today, in new and renovated houses, including Passive House (PH) projects, we need to include solutions that can absorb the scenarios mentioned in climate change projections. To model future scenarios with climate variability, we need to know that we are designing and building correctly in today’s climate and that our design parameters are within the performance limits set by monitoring. We need to understand the limits of the tools we have today and improve them, and the best way to conduct this is through long-term monitoring and the analysis of the data.

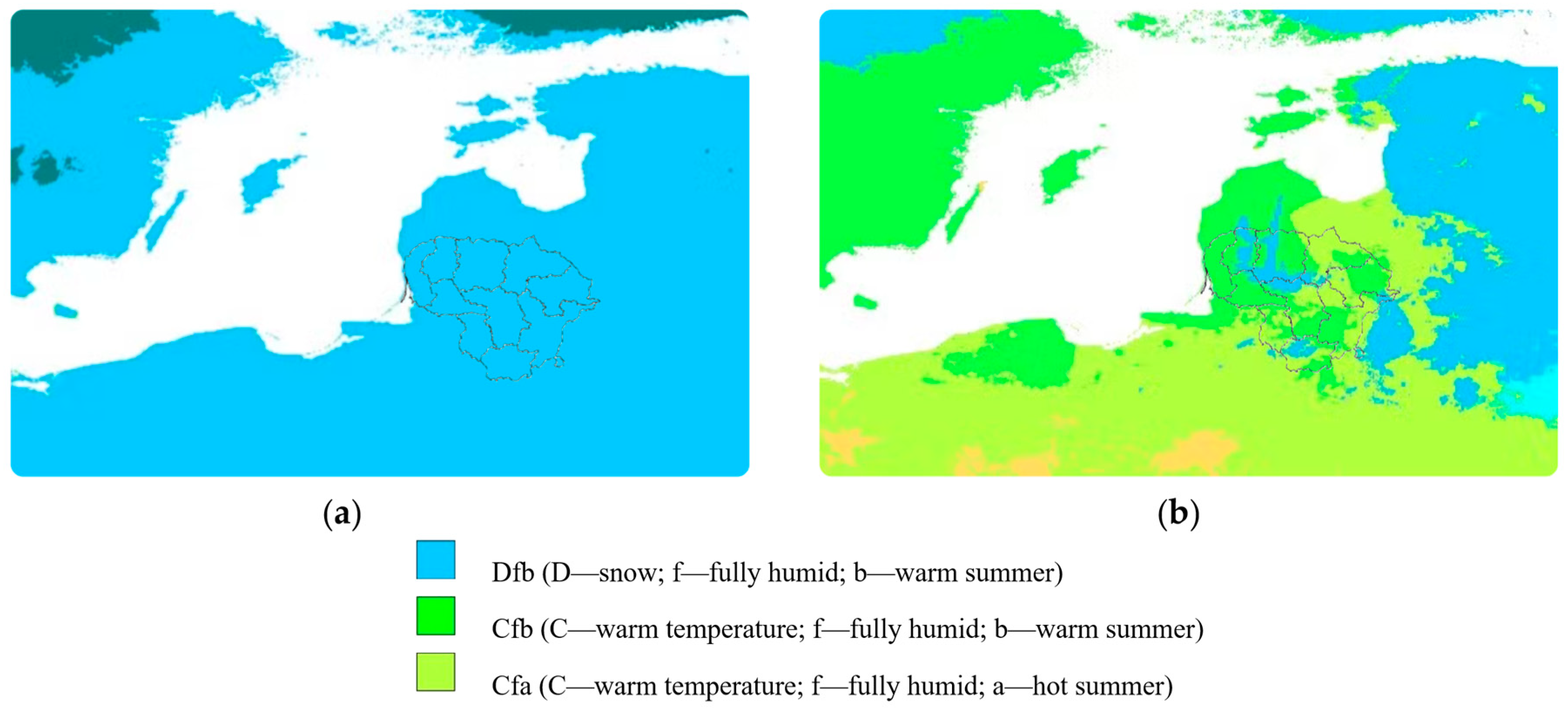

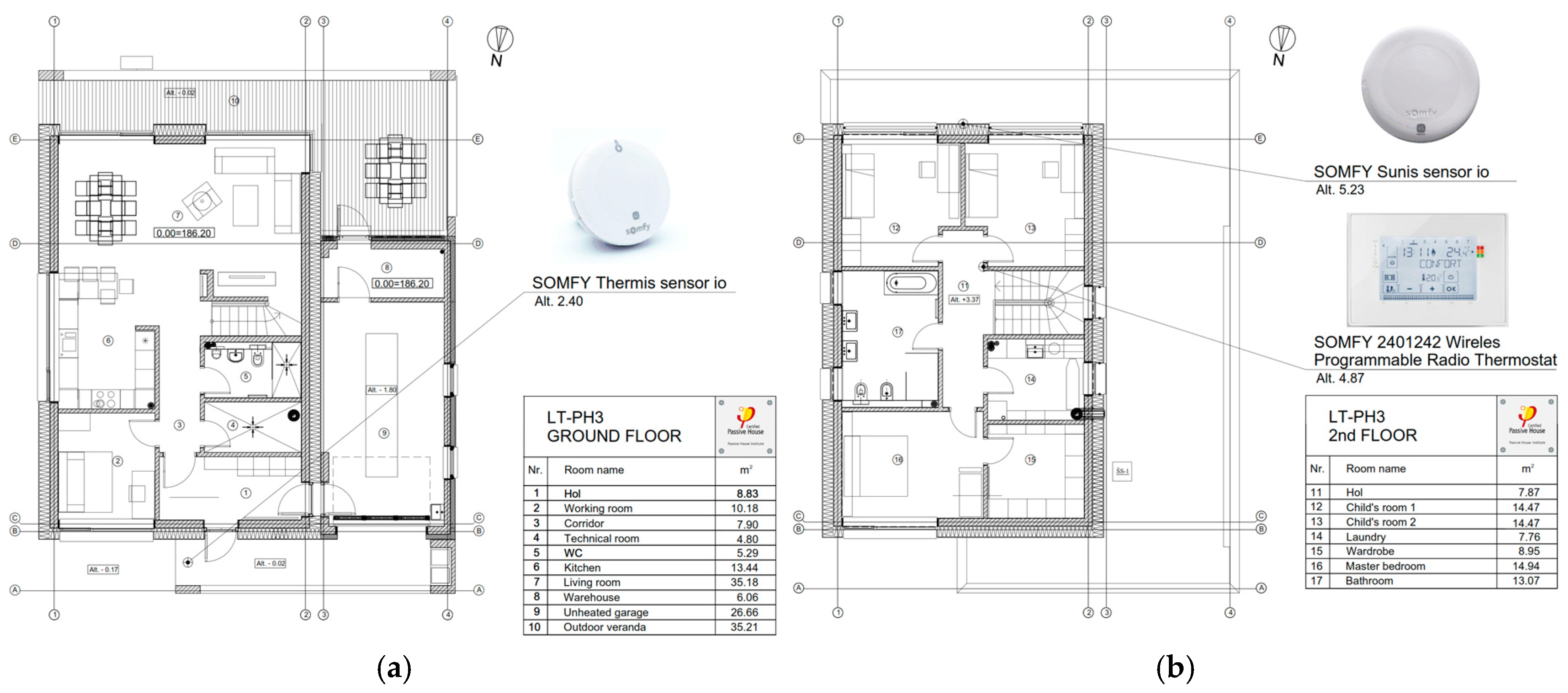

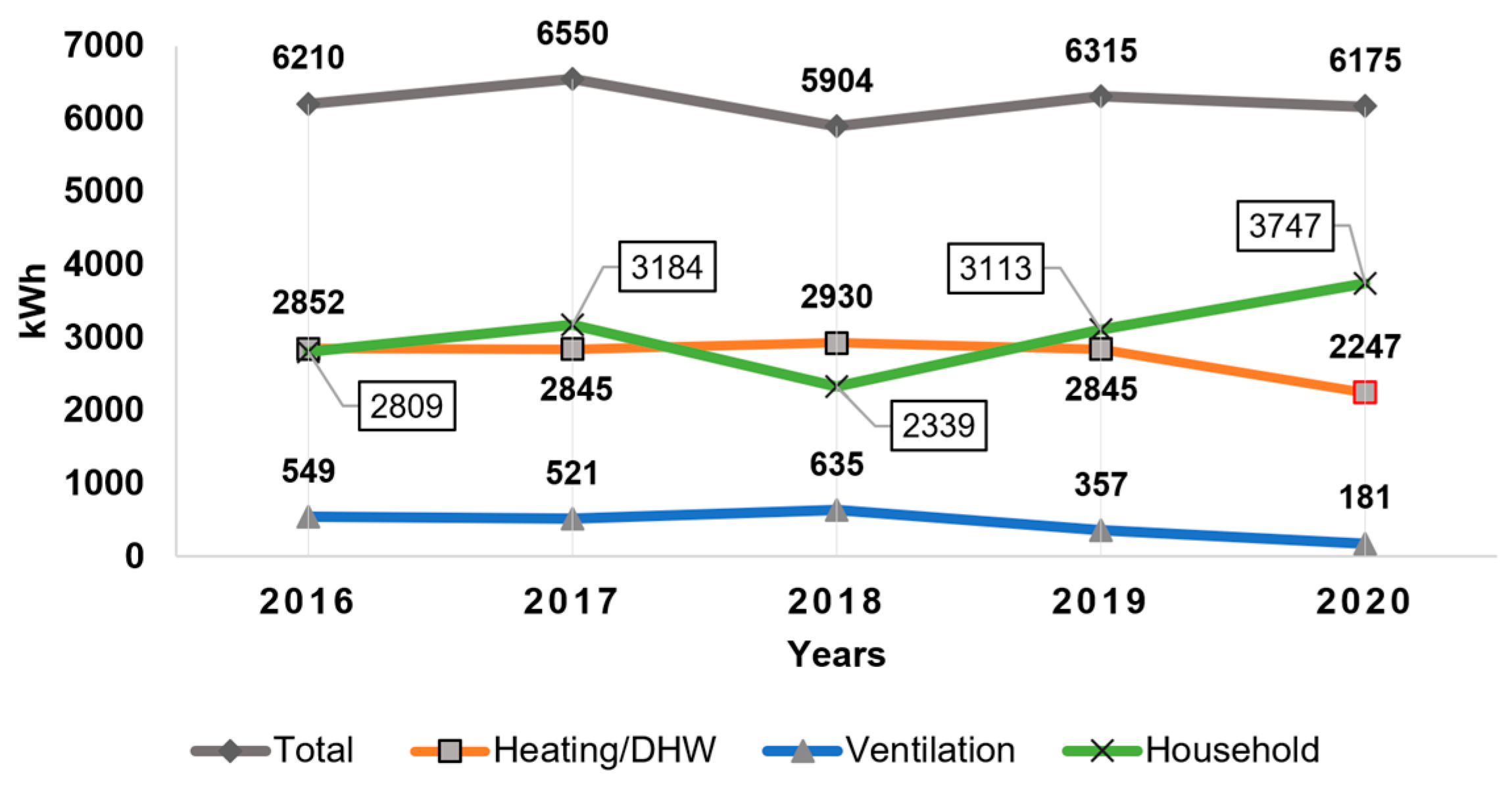

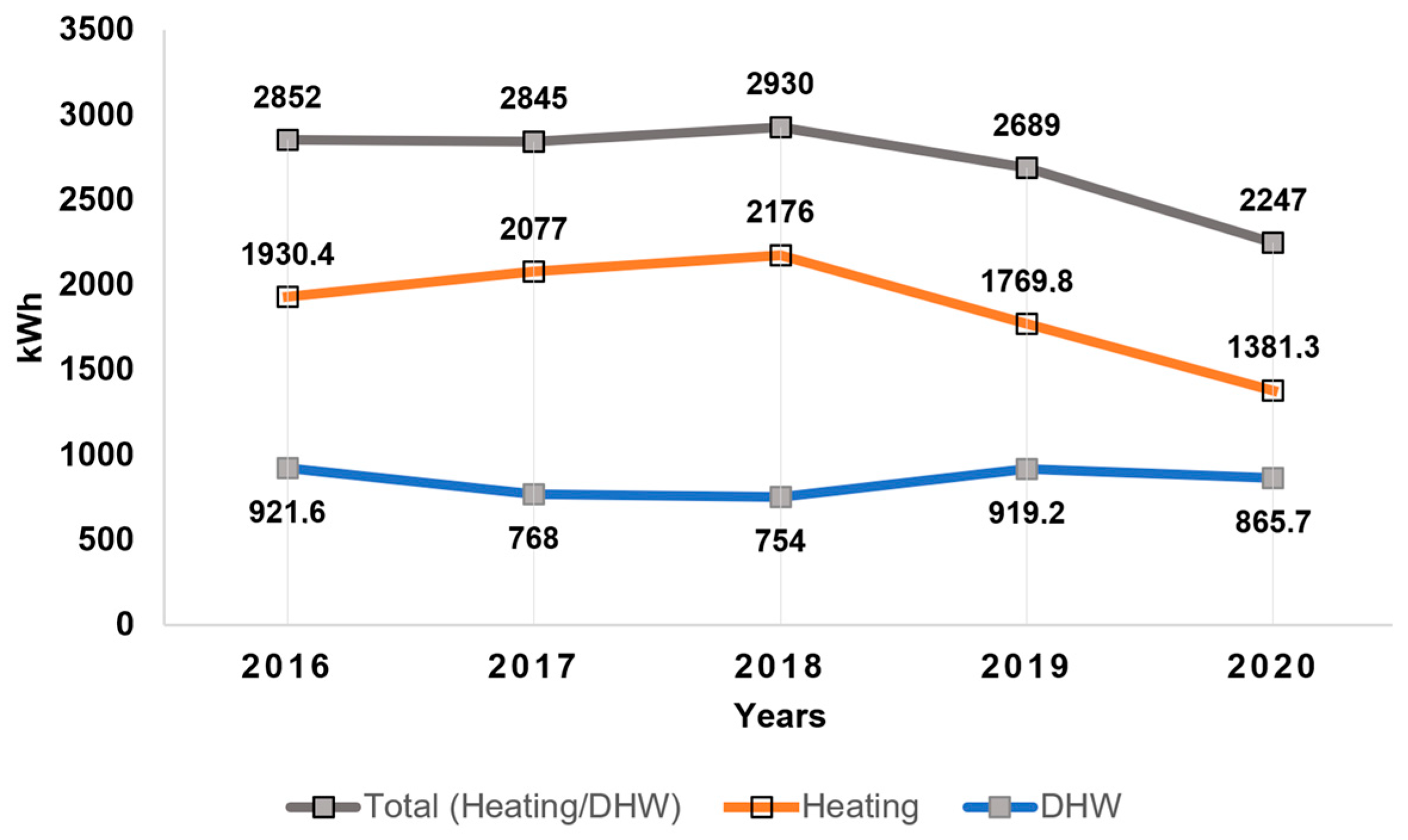

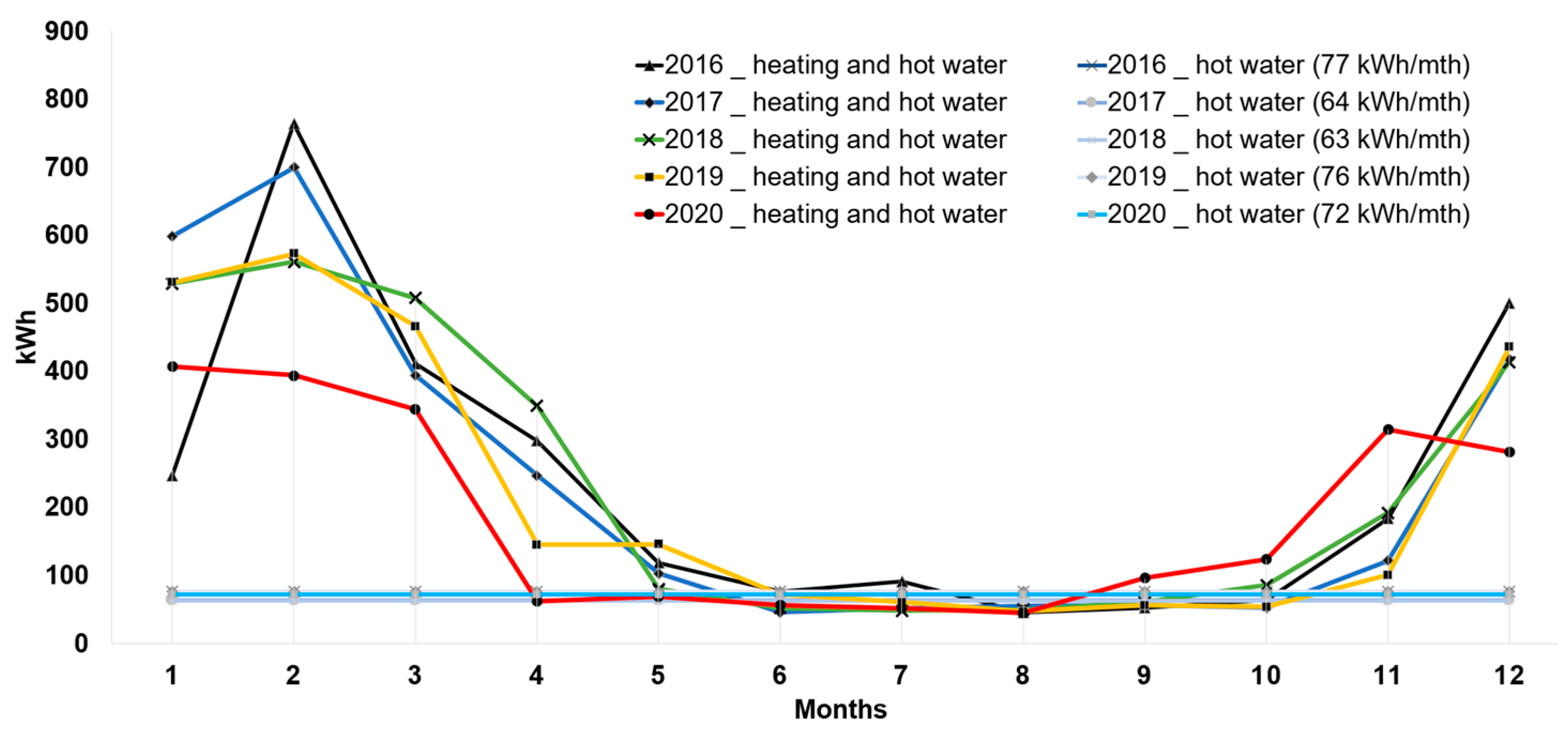

This study found that single-family dwellings occupy a significant share of the residential building stock in Lithuania and thus have a significant impact on the overall energy consumption of buildings nationwide. The analysis revealed that Lithuanian architects designing single-family dwellings do not use the BPS national tool NRGpro and are not legally obliged to carry out such modelling, which results in blind designing in terms of the energy efficiency of buildings. One of the reasons for this is the lack of trust in NRGpro. The aim of this paper is to increase the confidence of architects designing single-family dwellings in building performance simulation (BPS) software. For this purpose, the five-year monitoring data of the first single-family house LT-PH3, built in Lithuania and certified by the German Passive House Institute, were used and analysed. This paper also analyses the Lithuanian construction sector and the algorithm for the development of single-family residential projects. This paper shows that for the design of a compact single-family dwelling, the energy performance and comfort parameters modelled by BPS are close to the performance parameters, and the basic comparative data provided increase the applicability of the results and conclusions of this study for the design of energy-efficient buildings not only in Lithuania but also in other Dfb climate zones around the world. This study also showed that in order to assess the performance of a single-family residential building in operation and to maintain the designed comfort criteria under changing conditions of use and climate change, each building needs a basic monitoring system for its main systems and elements, which should be installed during the construction of the building. If intelligently designed, it would not only record the performance of the systems but could also contribute to their management, including in combination with artificial intelligence. The monitoring results analysed in this paper contribute to the increased relevance of the topic of building sustainability and provide practical insights for architects, engineers, and researchers in the field.

1.1. Lithuanian Building Sector

Lithuania’s National Energy Independence Strategy also sets ambitious targets for energy efficiency, reducing primary and final energy intensity by a factor of 1.5 by 2030 and 2.4 by 2050 [

10]. The question is as follows: what is the right way to carry out this work so that 100 years from now homes renovated and newly built in 2024 will still be energy-efficient, comfortable, and sustainable? When designing houses, only multi-year climate data are considered, so we must include solutions in the design of new and renovated houses that can buffer the scenarios mentioned in the climate change projections and reflect today’s climate reality. Unfortunately, building renovation in Lithuania is largely limited to multi-family dwellings and only to reducing their heating costs, focusing on improving the heat transfer coefficient (U-value) of the building’s thermal envelope and modernising the heating system. Controlling overheating, reducing energy consumption for cooling, and ensuring hygienic air quality are rarely included in the design of renovation and new building projects.

In line with the obligations of the EU Directive, Lithuania has adopted a system of energy performance requirements, and energy performance design and the certification of buildings has been regulated by STR 2.01.02:2016 [

11]. The NRGsert programme has been in operation since 1 January 2007 for the certification of constructed houses. Until 2016, there was no national tool for the design and energy performance modelling of buildings, so there was neither the possibility nor the obligation to check the energy performance of projects during the design process. The transition from one energy performance class to a higher one has been challenging for a significant part of the Lithuanian building sector, and the process has been met with widespread resistance, which has led to a softening of conditions. Insufficient communication, a lack of informed judgement, and a lack of understanding by a critical section of the public of the benefits of the higher energy class requirements for buildings have shaped the public’s, including the architectural community’s, negative attitudes towards improving the energy efficiency of buildings and distrust of the system itself. Today, all new buildings in Lithuania are designed for energy performance class A++, but there are still no monitoring studies in Lithuania to confirm the compliance of the designed energy performance indicators with the performance ones. In 2016, the national energy efficiency modelling software NRGpro 4 for building design and modelling was launched [

12]. In 2023, it had up to 120 active users, but there are no statistics on how many of the 1379 certified architects in Lithuania use it. Energy performance modelling for building design, including single- and two-family dwellings, is not popular among architects. In the case of multi-family dwellings, energy performance assessment is carried out by certified engineers, but there are no such requirements for the preparation of single- and two-family dwellings.

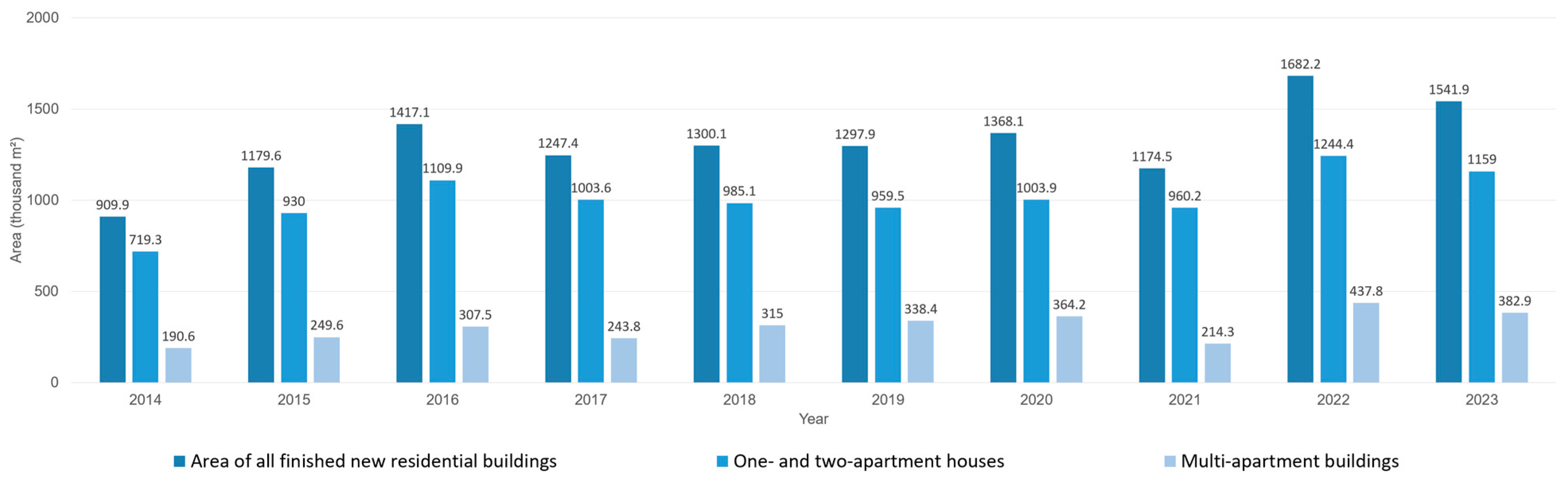

Currently, residential buildings account for 64% of the total building stock in Lithuania, while apartment buildings account for 29% and detached houses for 34% of the total area of the building stock. According to the estimates of the Lithuanian Centre of Registers, during 2021–2022, about 23,000 new houses—single- and two-family residential buildings—were registered in Lithuania, almost 1000 per month [

13]. According to the Official Statistics Portal of Lithuania, from 2014 to 2024, out of the total 13 million m

2 of living space built, 10 million m

2 was single- and two-family dwellings, which is 77% of the total built residential space in the decade (

Figure 2). Thus, the single-dwelling house is an important unit of the city and the country, with a significant impact on the overall energy efficiency performance of buildings in the whole country.

The design technology for residential buildings differs for different uses. When designing sustainable buildings, the design process itself must be sustainable. In Lithuania, when designing single-family or semi-detached dwellings, the architect—the project manager—is in most cases the only specialist who, from the beginning of the project preparation to the obtaining of the building permit (SLD), guides the design and determines all the main comfort criteria of the future house [

15] including its energy efficiency and operating costs for heating and domestic hot water (DHW). In the design of single- and two-family dwellings, there is no energy efficiency and comfort modelling part of the design, and in the absence of the possibility to check the rationality of the solutions for the specific architecture of the building to be designed in the specific environment from the energy efficiency and comfort point of view, the designs are developed blind. This problem is compounded by the fact that the specialists preparing the spatial planning documents also lack competence and, in the formulation of plots, development zones, access roads, and other decisions, often create conditions that prevent the construction of an energy-efficient house on the plot. Heating, ventilation, and air conditioning (HVAC) and building energy performance certification (PENS) engineers, who could influence the architect’s decisions and lead to a higher level of comfort in time for the design phase, are involved in the construction of single-family houses. After the SLD has been obtained and/or after the building has been constructed, modifications become costly, or there is no time left.

1.2. Building Design Process and Passive House Concept

Architecture is an art. Building design is a complex interdisciplinary process [

16]. It involves professionals with different professions and competencies, with the architect striving for the uniqueness of the building each time [

17]. The design of a building is influenced by many individual and interrelated external environmental and internal factors, and a slight change in one of them can change the final result beyond recognition. Therefore, when designing a building, it is difficult for an architect to use research that, by selecting only a few criteria, produces theoretical template solutions [

15]. It is necessary to be familiar with the template and the boundary conditions of the study and to trust the findings of the study, so the likelihood of an architect designing a house in this way is low. They need an inexpensive, easy-to-use BPS tool that they can operate independently. The use of such a tool would be most effective at an early stage in the analysis of the design environment and concept development.

Many BPS programmes have been developed. These include the national building energy performance modelling programme NRGpro, developed in Lithuania based on the current building technical regulations [

12], and the Passive House Planning Package (PHPP) [

18], EnergyPlus™ [

19], TRNSYS [

20], COMFIE [

21], IDA ICE [

22], and others. Managing these applications is complex and requires competencies that architects lack. To involve architects more in the BPS process, the German Passive House Institute has developed a simplified version of the PHPP, EasyPH, for the modelling of single-family houses, which should facilitate the BPS process. The use of these tools could be accelerated by monitoring-based evidence showing that the comfort and energy efficiency design criteria of the building modelled in the BPS programme meet the performance criteria.

Some of the key aspects of assessing a building’s sustainability are its comfort and human well-being, its energy efficiency, the durability of the solutions adopted in its design and construction, and its resilience to the challenges of economic and climate change.

Even the most energy-efficient house can be uncomfortable [

23]. The understanding of building comfort as the combined, synchronised performance of all parts of a building, exterior and interior, structure and engineering systems, use and sustainability of the functional scheme, and others, is only just beginning to develop in Lithuania. Lacking interdisciplinary knowledge and experience, comfort criteria are still understood in a very narrow way and are either not taken into account at all, or they are not assessed and designed as a whole but individually. In each different climate zone, with different sizes, orientations, shading situations, U-values of the thermal envelope, thermal capacities of buildings, numbers of inhabitants, and, most importantly, comfort perceptions of the inhabitants, amongst other indicators, the composition of the elements of a Passive House and their meanings will vary. In each different country and family, the economically sound solution will be different [

24]. Therefore, step one in the development of a comfortable building of any purpose and size is the Design Task. The energy performance of a building is only one of more than twenty criteria for building comfort, and the comfort of a building is one of many aspects of its sustainability. All of them need to be designed, modelled, coordinated, and implemented without errors. A wide variety of factors determine the comfort of a house, including the deposition of particulate matter on the building walls [

25], wind [

26,

27,

28], the materiality of the façade [

29], etc.

The climate, house-building best practices and experience, building usage patterns, and many other important factors that determine the design of a comfortable house can vary significantly even within the same country. It is therefore very important to study and monitor the use, comfort, and engineering systems of Passive Houses and energy-efficient houses. Since 2011, Lithuania has also started designing and building the Passive House standard developed by the German Passive House Institute [

30]—Passive House (PH).

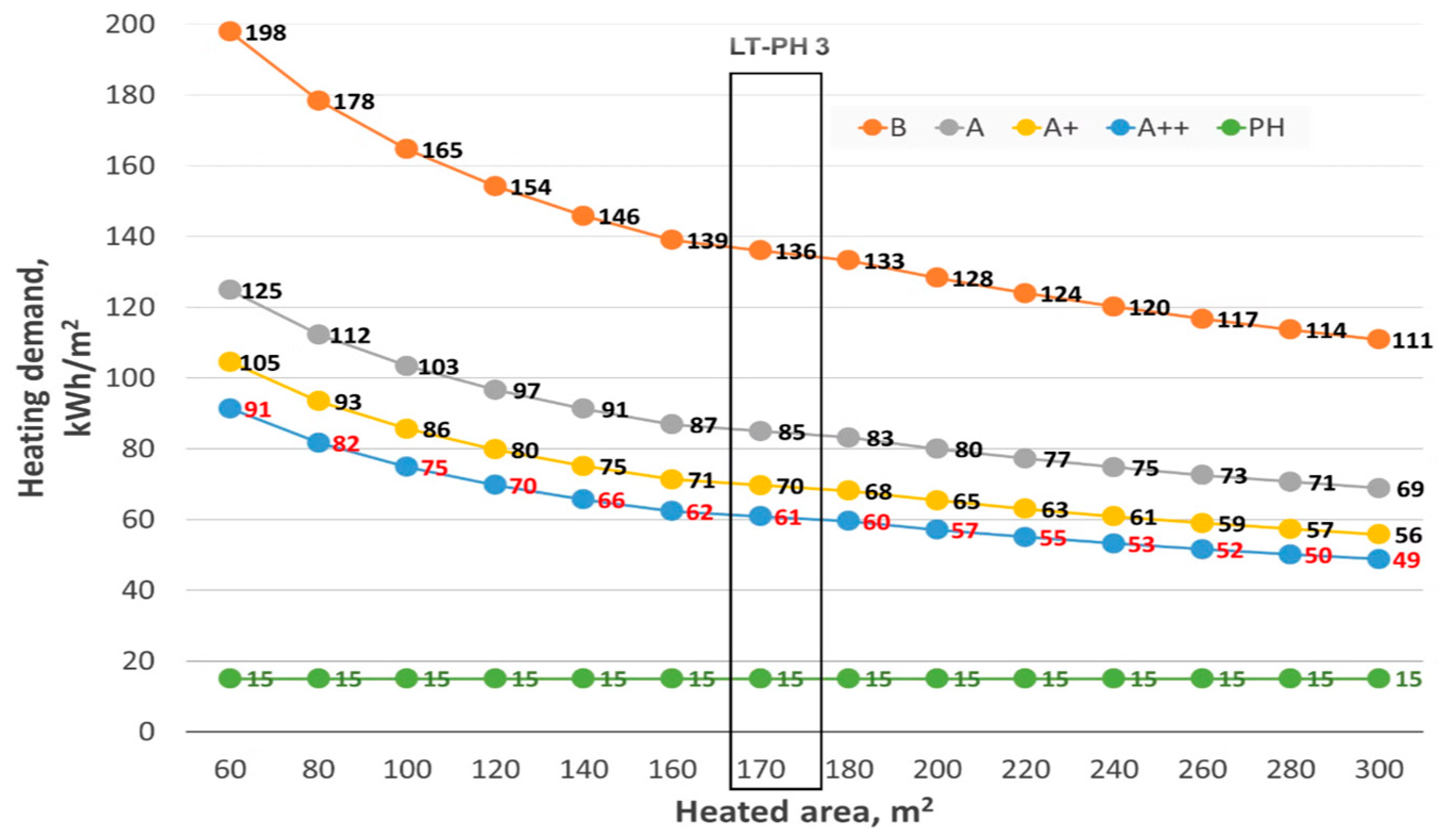

Figure 3 shows the maximum permissible thermal demand requirements for a Passive House and the energy performance classes of Lithuanian buildings and their evolution [

11].

A Passive House is an energy-efficient house that meets the builder’s expectations and offers the highest level of comfort building [

31]. Its quality is based on the combination of several carefully coordinated building elements (envelope and engineering systems and equipment). It is created by the Passive House Planning Package (PHPP) [

18] examining the digital building model, the economic feasibility of architectural, structural, and engineering solutions, and their impact on the energy efficiency of the building [

32]. The Passive House design algorithm is based on a two-stage modelling process, the design proposal and the Technical Working Design, which produces a house with some significant benefits [

33]. According to the Passive House Institute database, a total of six Passive Houses had been certified in Lithuania by 2024 [

34].

The Passive House concept was developed by Prof. Dr. W. Feist. Passive House monitoring, which began in 1991 with the construction of the world’s first Passive House in Darmstadt-Kranichstein, Germany, today covers thousands of Passive Houses on different continents [

35] and in every climate zone on the planet [

15,

36,

37]. The data collected through monitoring are evaluated [

38,

39,

40], and their results are used to improve the Passive House design algorithm and the digital modelling and certification tool PHPP. This research also aims to determine the accuracy of the Passive House design process by comparing the results modelled by the PHPP 8.5 with those measured during operation [

41,

42]. This will be conducted using existing and new methodologies and modelling tools [

43], including in Lithuania [

44]. The Passive House system does not constrain the architect’s decisions, the architectural expression, style, and materiality of the house. These houses can also be built of straw [

45]. The PH algorithm only adds to the evaluation of the architectural solutions’ important criteria such as building comfort, energy efficiency, and affordability. The renovation of both multi-family and single-family dwellings according to the EnerPHit standard has been shown to perform as designed in different countries and climates [

46,

47]. In Passive House modelling, small inaccuracies in the sensitive parameters can significantly affect the results [

48], so it is important to be aware of the conditions under which the data were collected and the study was carried out. Also, due to the influence of the use of the building on its energy performance results, it is not possible to compare and evaluate buildings of the same size but with different uses.

The design of passive and low-energy buildings is based on a climate zone analysis, a carefully considered functional layout, a detailed assessment of the building orientation and the environmental impact on the building, a balance of the building’s thermal envelope losses and solar and internal heat gains, the optimisation of the thermal envelope’s U-values to reduce the heating demand, the use of high-efficiency engineering equipment, and the use of renewable energy sources. The cooling demand is reduced by using external solar control systems, increasing the thermal capacity and inertness of the building, using night ventilation, and selecting the correct values for glazing parameters [

49]. This careful, precise Passive House design algorithm automatically solves many aspects of building sustainability.

The increase in confidence in the design system is driven by the availability and easy accessibility of monitoring-based evidence of the performance of the designed parameters, as well as the openness of data. Research in the energy-efficient buildings sector is extensive, but its applicability in practice is difficult. When looking at the research evaluating Passive Houses, it is difficult to find buildings that are 100% complete and 100% PH-compliant, with construction, engineering, and other equipment and their use throughout the study as designed, and most of all with design parameters that are consistent with the performance parameters as modelled by monitoring. Studies have compared Passive Buildings of different sizes, with an unspecified building use algorithm, located in different climatic zones, at different stages of construction completion and operating conditions [

37], monitored in PHs, whose occupants complain of overheating due to the lack of blinds [

23], assessing PHs with a 50% deviation of heating costs from the design [

42]. It is therefore difficult to understand the conditions under which the results presented in these studies are obtained and what the results would be in the absence of these defects or errors.

To make research more applicable in practice, it would be useful to systematise and unify the basic comparative data to enable the researcher to identify buildings suitable for analysis more quickly. In this way, at an early stage of project development, the energy efficiency and comfort perspectives of a newly designed building could be quickly assessed using comparative analysis, Embodied Carbon in Construction, and Life Cycle Assessment [

15]. When researching Passive House projects, there are many relevant factors, such as the climate, building size, etc., which would be useful to be able to sort through in an advanced search of the PHI database [

34], and, once several datasets have been selected, the different houses generated by the basic comparative data template could be collated and compared.

The impact of building use on performance is controversial [

50] and differs for different energy efficiency levels [

51]. Studies show that if the house has very good insulation, the parameters ranked by the biggest impact are the (1) occupation mode, (2) thermostat, and (3) heated area. Also, the actual occupancy algorithm of a building, or its mismatch with the designed one, can influence the performance in the context of energy efficiency by up to 50% [

42] or determine the prospects of the study [

52].

Studies and research on energy-efficient homes have also been carried out in Lithuania: studies have been conducted to determine the heating load of low-energy buildings [

53,

54], the Passive House model has been developed [

44], and studies on building energy consumption have been carried out, which have been limited to the application of calculation methods without analysing the actual energy consumption in the building [

53]. In 2009, a study was carried out on the first single-family dwelling house in Lithuania that complies with the Passive House concept. Unfortunately, there is no comparison of the real operating costs of this building with the planned ones. This shows the need to know and analyse the performance of energy-efficient buildings in appropriate climatic conditions using long-term data.